MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 291 of 1273

On-Vehicle Inspection of MFIFUEL SYSTEM

a Harness side

connector

--------

m

J-----k

N

qp

CI

F

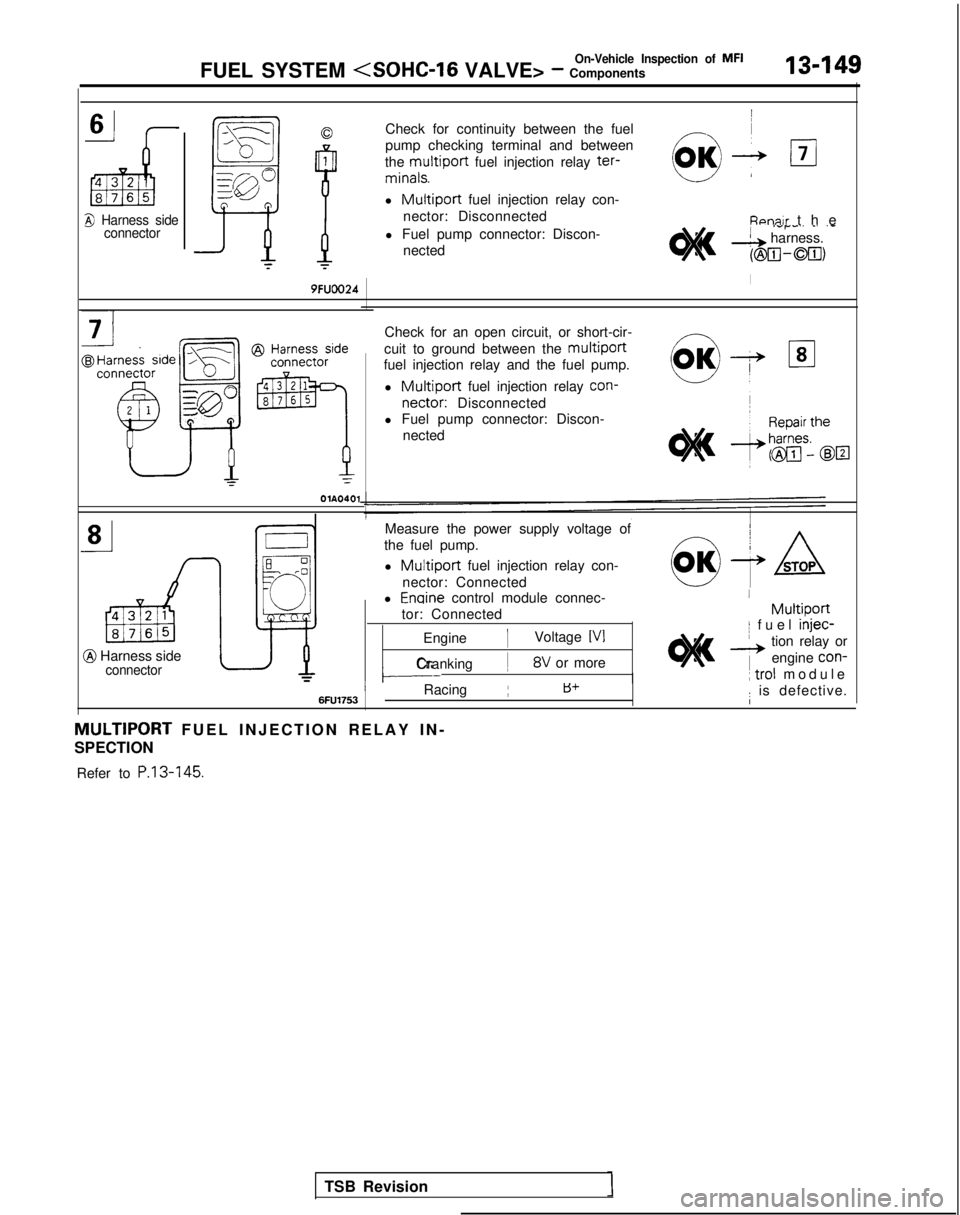

Check for continuity between the fuel

pump checking terminal and between

the

multiport fuel injection relay ter- minals.

l

Multiport fuel injection relay con-

nector: Disconnected Fipnn~r

the

l Fuel pump connector: Discon-

nected

.-P-” _’ ‘-& harness.

(@m-00,

I9FUOO24

OlA0401

Check for an open circuit, or short-cir-

cuit to ground between the

multiport

fuel injection relay and the fuel pump.

l

Multiport fuel injection relay con-

nectar:

Disconnected

l Fuel pump connector: Discon-

nected

@ Harness sideconnector

Measure the power supply voltage of

the fuel pump.

l

Multiport fuel injection relay con-

nector: Connected

l

Enoine control module connec-

tor: Connected

Engine

1Voltage IV1

cCranking ~8V or more-

I

MultiportI fuel injec-

__, tion relay or

1

engine con-

~

trol

module

TSB Revision

IRacing Iid+: is defective.6FU175.3I

MULTIPORT FUEL INJECTION RELAY IN

-

SPECTION

Refer to P.13-145.

Page 292 of 1273

On-Vehicle Inspection of MFI

13450FUEL SYSTEM

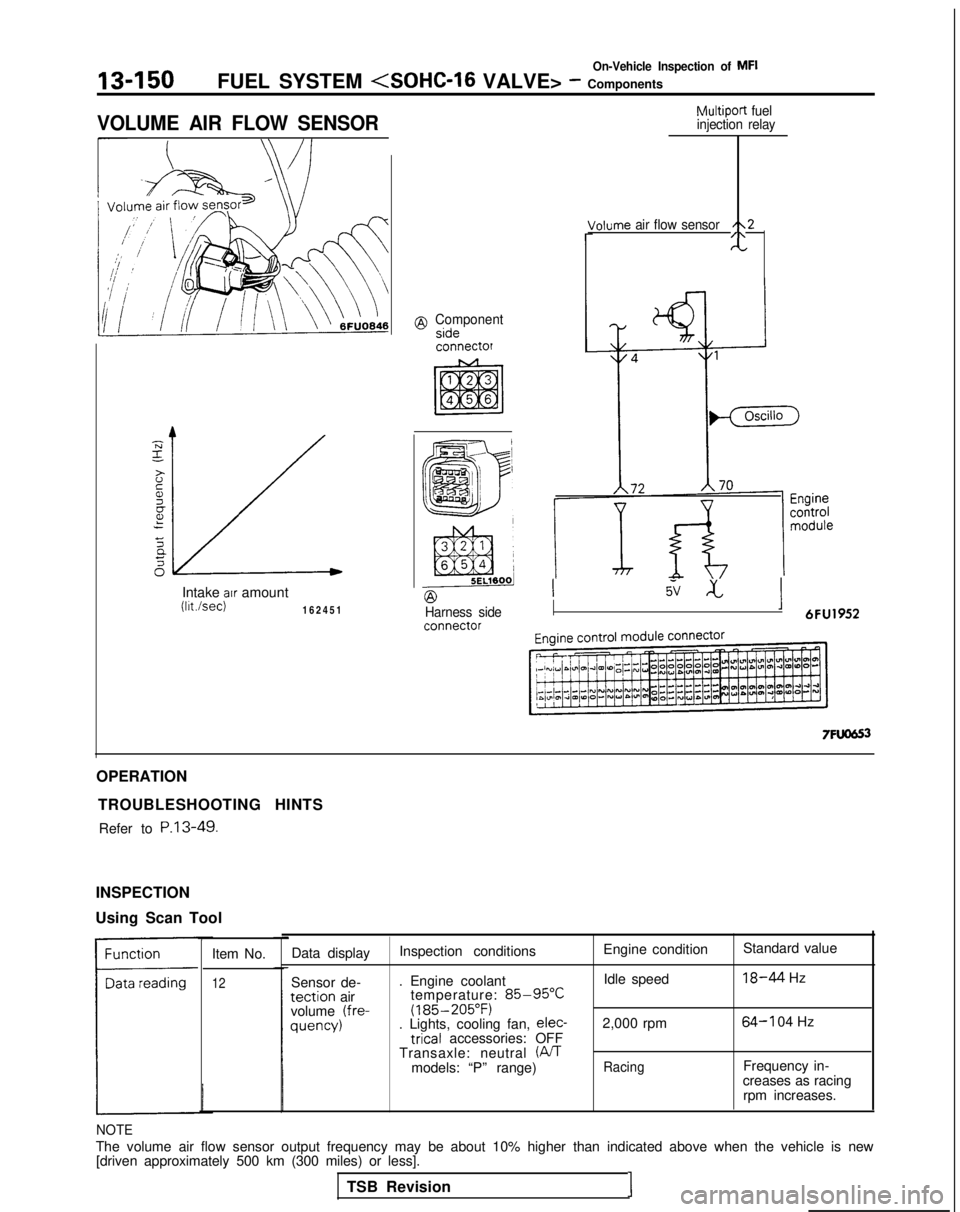

VOLUME AIR FLOW SENSOR

Intake air amountWsec)16245

1

@ Componentsideconnectof

Multiport

fuel

injection relay

/ohme air flow sensor/\2/\-

@Harness side

Isv xI 6FU1952

OPERATION TROUBLESHOOTING HINTSRefer to

P.13-49.

INSPECTION

Using Scan Tool

Item No.

12

Data displayInspection conditions Engine condition

Standard value

Sensor de- . Engine coolant Idle speed

18-44 Hz

tection airtemperature: 85-95°C

volume (fre- (185-205°F)

quency)

. Lights, cooling fan, elec-

2,000 rpm64-l 04 Hz tricaI

accessories: OFF

Transaxle: neutral

(PJTmodels: “P” range)RacingFrequency in-

creases as racing rpm increases.

NOTE

The volume air flow sensor output frequency may be about 10% higher than\

indicated above when the vehicle is new[driven approximately 500 km (300 miles) or less].

TSB Revision

1

Page 293 of 1273

On-Vehicle Inspection of MFIFUEL SYSTEM

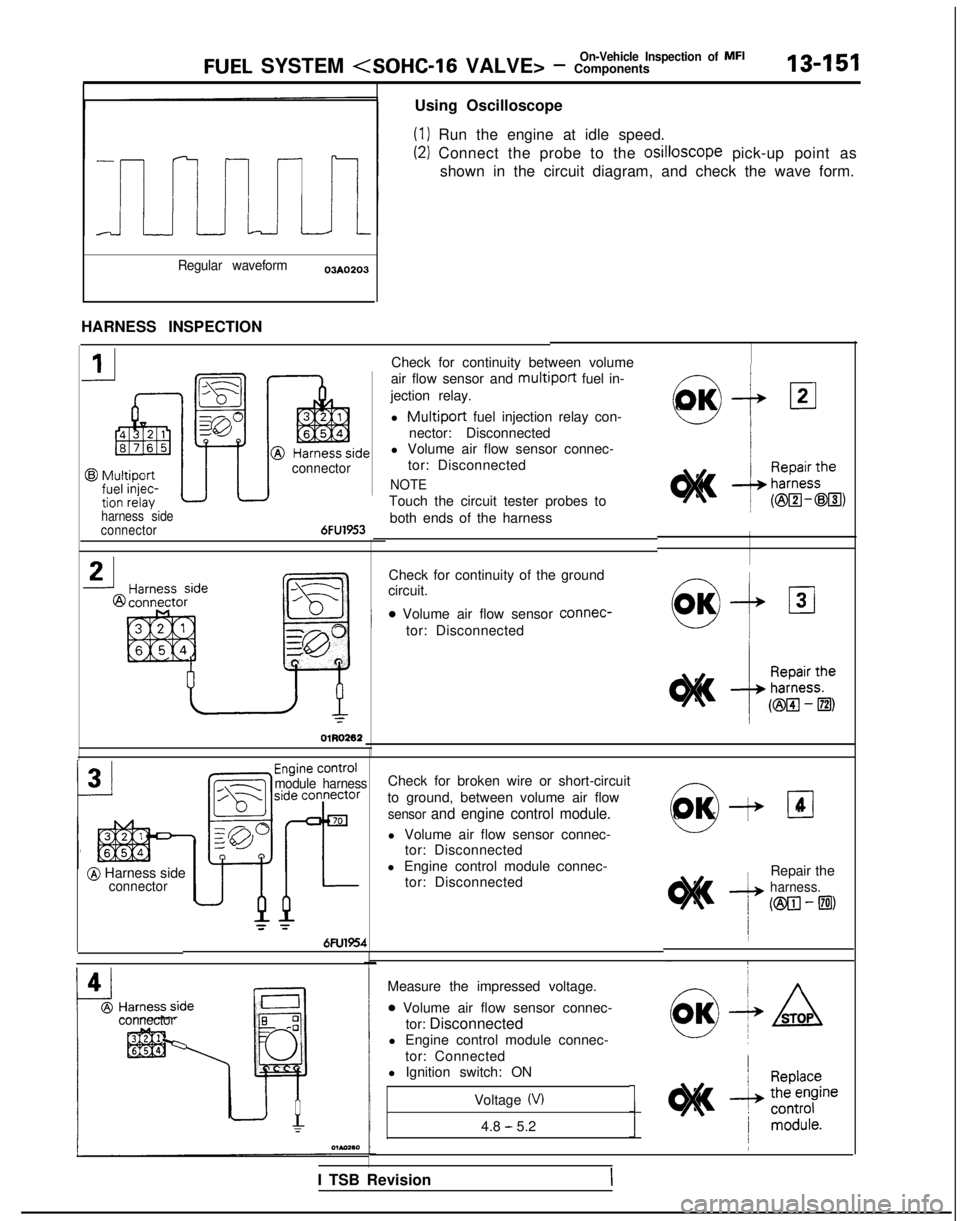

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the osilloscope

pick-up point as

shown in the circuit diagram, and check the wave form.

Regular waveform03AO203

HARNESS INSPECTION

Check for continuity between volume

air flow sensor and

multiport fuel in-

jection relay.

l

Multiport fuel injection relay con-

nector: Disconnected

l Volume air flow sensor connec-

tor: Disconnected

NOTE

Touch the circuit tester probes to

both ends of the harness

a+

OK 121

harness side

connector6FU1953

connector

Check for continuity of the ground-Icircuit.

0 Volume air flow sensor connec-WI+ 131tor: DisconnectedL-l I

OlR0262

/I

module harness

@ Harness sideconnector

= =

6FU1954

0O

K

-I+

Check for broken wire or short-circuit

to ground, between volume air flow

sensor and engine control module.

l Volume air flow sensor connec- tor: Disconnected

l Engine control module connec- tor: Disconnected

El4

Repair the

harness.

(ml-El)

Measure the impressed voltage.

0 Volume air flow sensor connec- tor: Disconnected

l Engine control module connec-

tor: Connected

l Ignition switch: ONconnector

Voltage (V)

4.8 - 5.2

I TSB Revision

Page 294 of 1273

13-152FUEL SYSTEM (SOHC-16 VALVE> - %i;:%~spection Of MF’

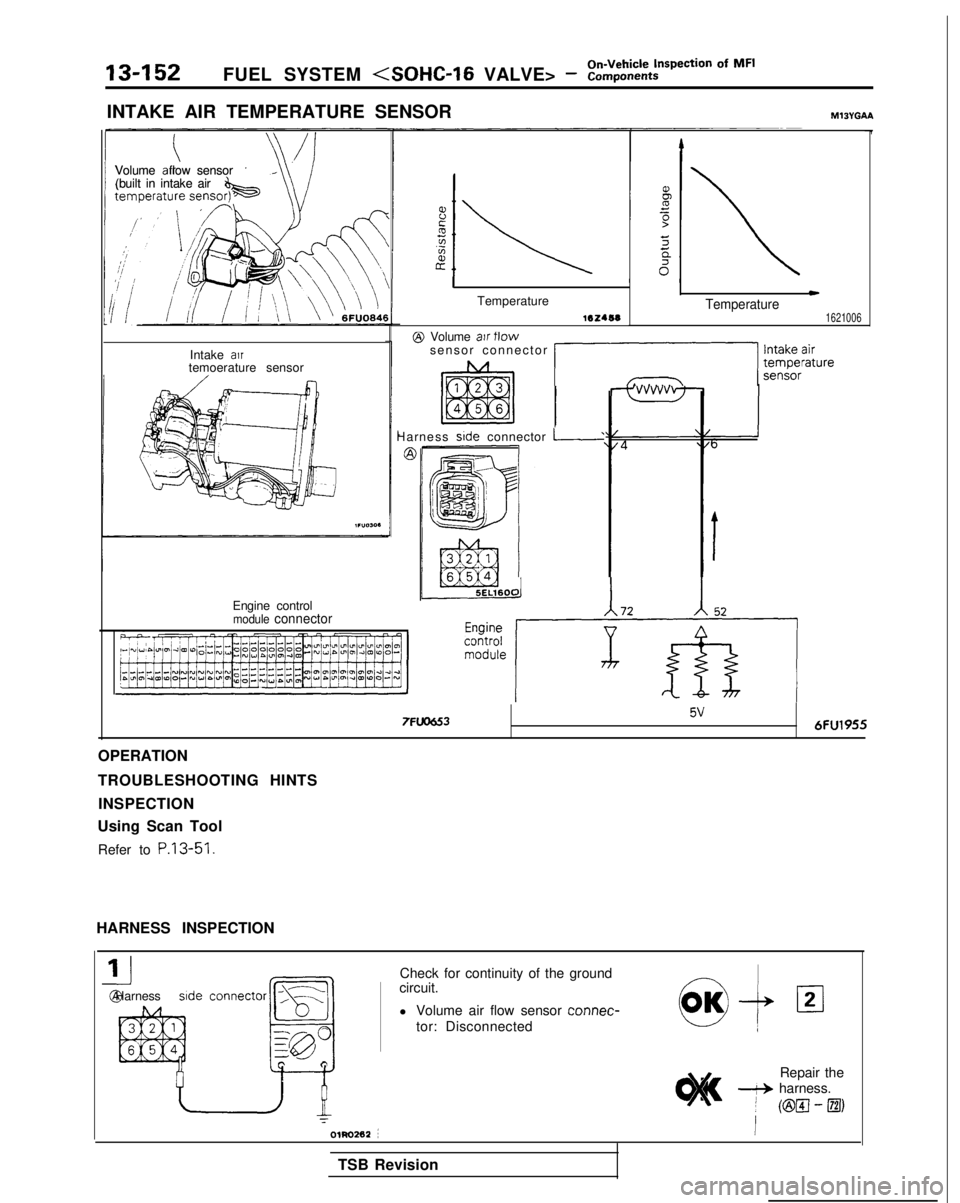

INTAKE AIR TEMPERATURE SENSORMl3YGAA

Volume air flow sensor

Volume air flow sensor

(built in intake air

(built in intake air

Intake

airtemoerature sensor

Engine control

module connector

I

TemperaturewTemperature1621006142468

@ Volume arr tlowsensor connector [-1 ~$%re

Harness side

connector k

A 72

~o~~~e p-$-J 5v

7FlD&53

6FU1955

OPERATION

TROUBLESHOOTING HINTS INSPECTION

Using Scan Tool

Refer to

P.13-51.

HARNESS INSPECTION @ Harness side

connector

-,T

[

a

1

g@-r.

Check for continuity of the ground

circuit.

l Volume air flow sensor connec-

tor: Disconnected

Repair the

+ harness.

/ (ml-El)

OlRo262 II

TSB Revision

Page 295 of 1273

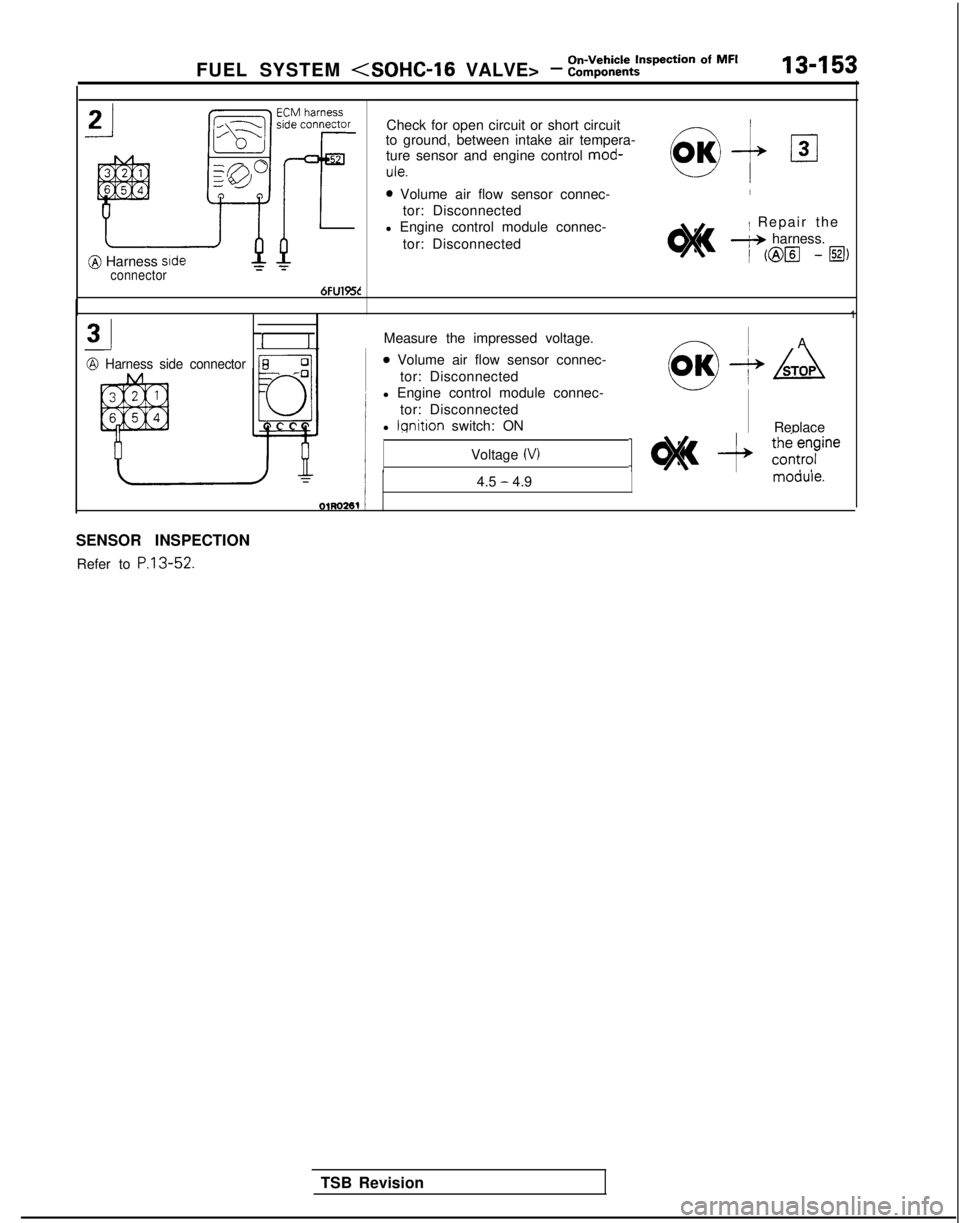

FUEL SYSTEM

@ Harness srdeconnector

Check for open circuit or short circuit

to ground, between intake air tempera-

ture sensor and engine control mod-

ule.

0 Volume air flow sensor connec-/

tor: Disconnected

l Engine control module connec-

tor: DisconnectedI Repair th

e

+ harness.

I @El -El)

@ Harness side connector

6FU195C

1

[IMeasure the impressed voltage.n

~

A

0 Volume air flow sensor connec-

tor: Disconnected

l Engine control module connec-

tor: Disconnected

l lqnition

switch: ON

-

Replace

Voltage

(VI1 c#?g -+ zl;;fne

4.5 - 4.9 moaule.

SENSOR INSPECTION Refer to P.13-52.

TSB Revision

Page 296 of 1273

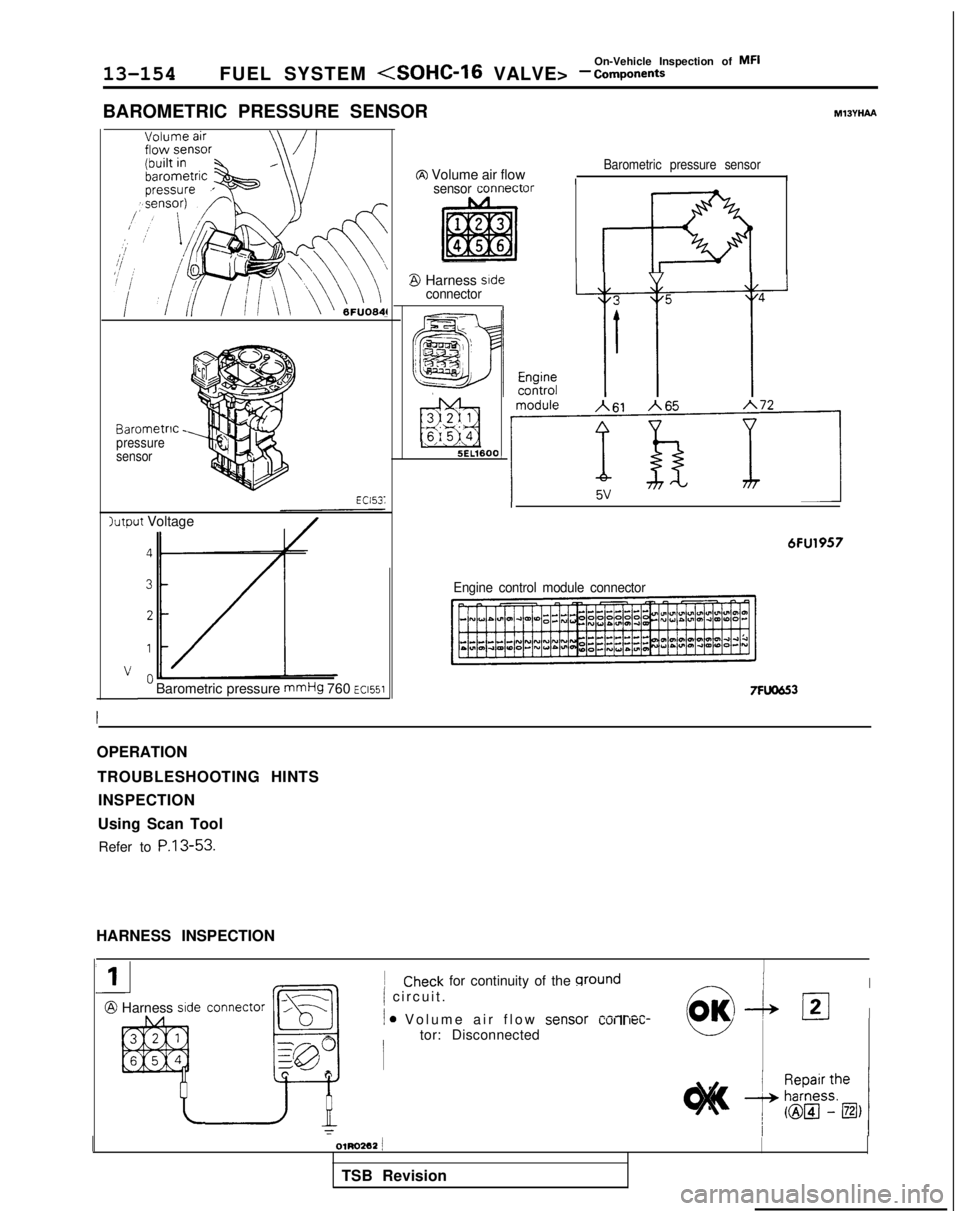

On-Vehicle Inspection of MFI13-154FUEL SYSTEM

BAROMETRIC PRESSURE SENSOR

MlJYHA4

Barometnc -pressure

sensor

htput Voltage

Barometric pressure

mmHg 760 ~~1551

CR Volume air flowBarometric pressure sensorI I

I-.____A__sensor conneclur

mB Harness sideconnector

,\ , , ,.k ,Im jfl5EL1600

6FU1957

Engine control module connector

7FlfO653

OPERATION TROUBLESHOOTING HINTSINSPECTION

Using Scan Tool Refer to

P.13-53.

HARNESS INSPECTION

@ Harness sideconnector I,?

la

1

gg

n

1Check for continuity of the ground-IIj circuit

.

/ 0 Volume air flo

w

----^- ^^^^^^ibd-b 121IsensorGUI II IGL-tor: Disconnectedw -

I

OlRO262 j

TSB Revision

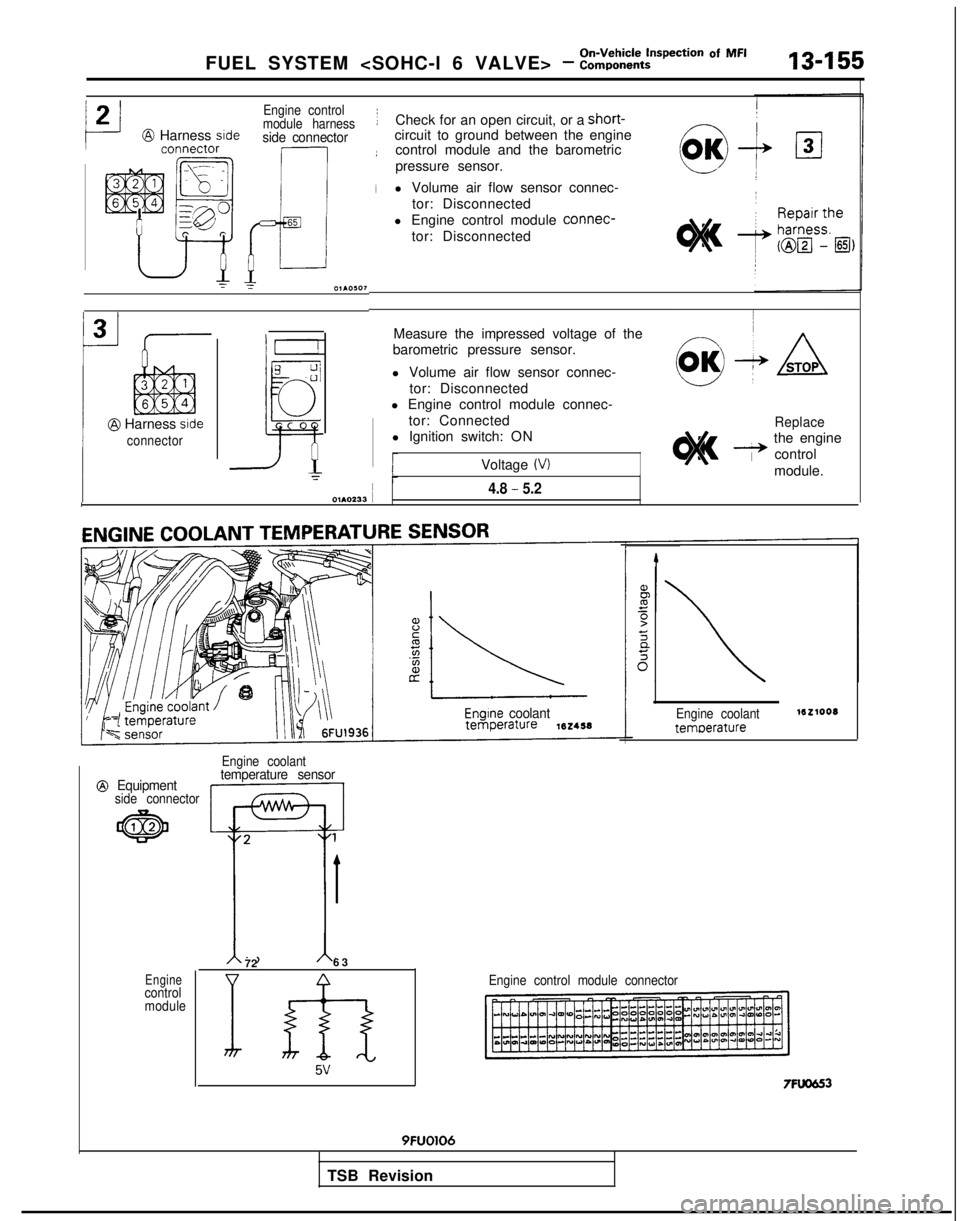

Page 297 of 1273

FUEL SYSTEM

L-J

2@ Harness side

@ Harness stde

connector Engine control

module harness

side connector

r----l65

mr01AO107

~Check for an open circuit, or a short-

circuit to ground between the engine

:control module and the barometric

pressure sensor.

il Volume air flow sensor connec-

tor: Disconnected

l Engine control module connec-

tor: Disconnected

Measure the impressed voltage of the

barometric pressure sensor.

l Volume air flow sensor connec- tor: Disconnected

l Engine control module connec-

tor: Connected

l Ignition switch: ON

Voltage

(VI

Replace

- the engine 1

control

module.

IOIAO233 I4.8 - 5.2I

Engrne coolant

Engine coolant

@ Equipment temperature sensorside connector

Enginecontrol

module

72

6

3

I fh5v

Engine coolanttemoerature

Engine control module connector

7FW6!53

9FUO106

TSB Revision

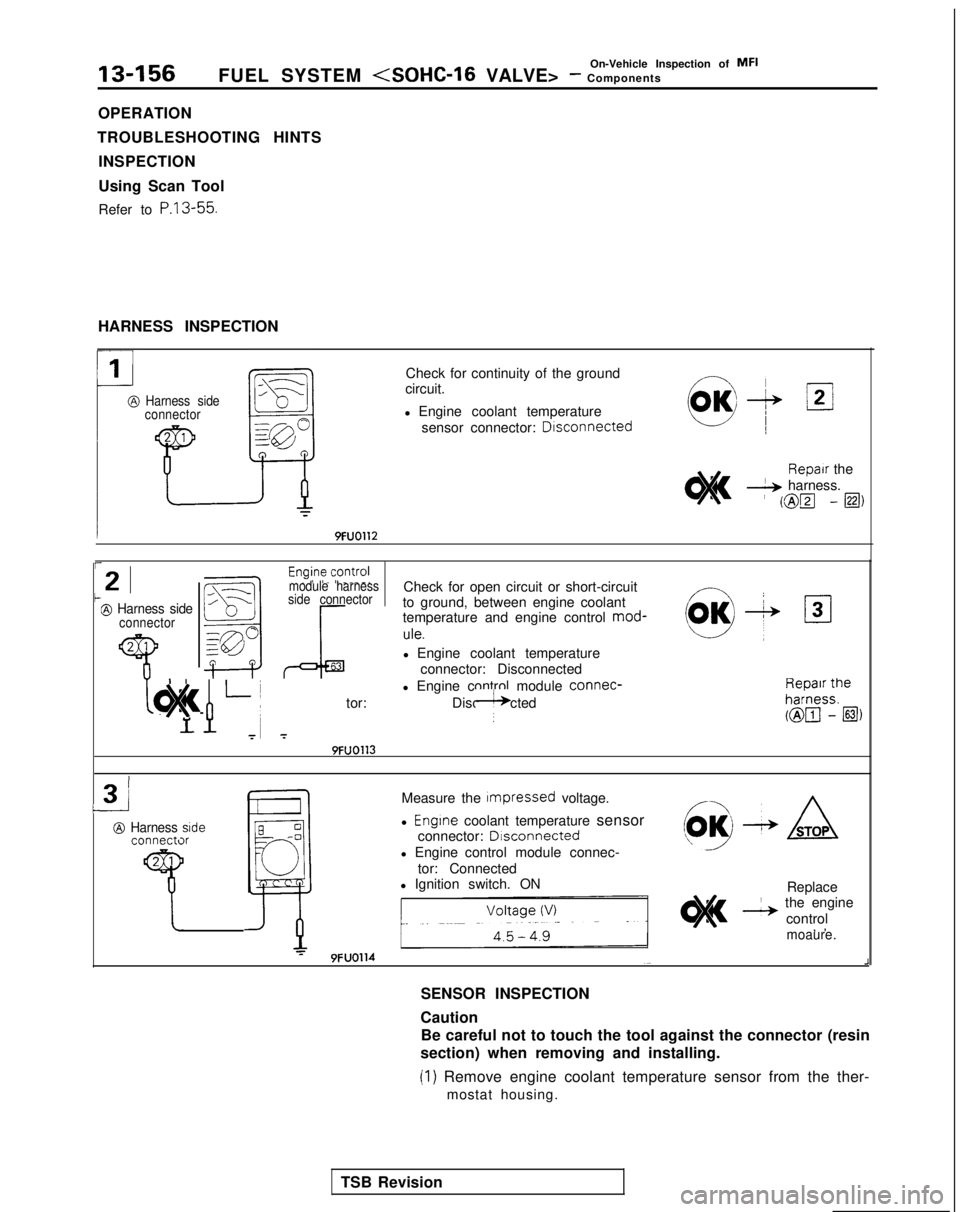

Page 298 of 1273

13-156On-Vehicle Inspection of MFI

FUEL SYSTEM (SOHC-16 VALVE> - Components

OPERATION

TROUBLESHOOTING HINTS INSPECTION

Using Scan Tool

Refer to

P.13-55.

HARNESS INSPECTION

Harness side

connector

Check for continuity of the ground

circuit.

l Engine coolant temperature sensor connector: Drsconnected

9FUO112

01

OK+ /2/

Repair the

& harness.

i @lz -@i,

r

21t@ Harness sideconnector

2 1

7

Check for open circuit or short-circuit

to ground, between engine coolant

temperature and engine control mod-

!:I->,

OK+ 131

ule.

l Engine coolant temperature

connector: Disconnected

l Engine control module connec-

~ 1 h h L

~

tor: Disconnected$)#!& ” g$jnii

7 7

c

module harness

side connector

9FUO113

3

@ Harness side connectx

Measure the Impressed

voltage.

l Engine coolant temperature sensor

connector: Dlsconnected

l Engine control module connec- tor: Connected

l Ignition switch. ON Replace

& the engine

control ,

I

9FUO114

moaure.

SENSOR INSPECTION

Caution

J

Be careful not to touch the tool against the connector (resin

section) when removing and installing.

(1) Remove engine coolant temperature sensor from the ther- mostat housing.

TSB Revision

Page 299 of 1273

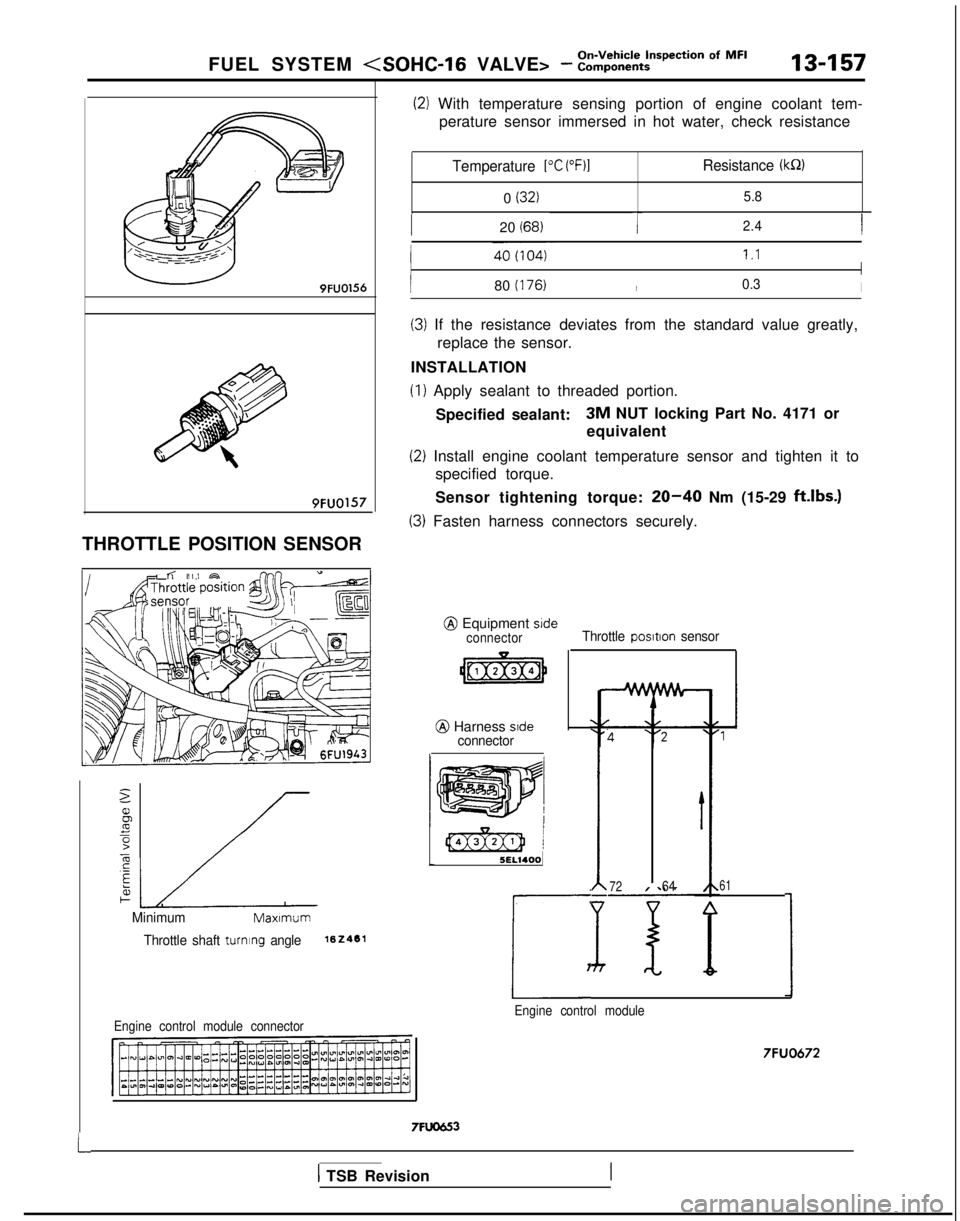

FUEL SYSTEM (SOHC-16 VALVE> - ::ii,,k%ti=pec*ion Of MF’13-157

9FUO156

9FUO157

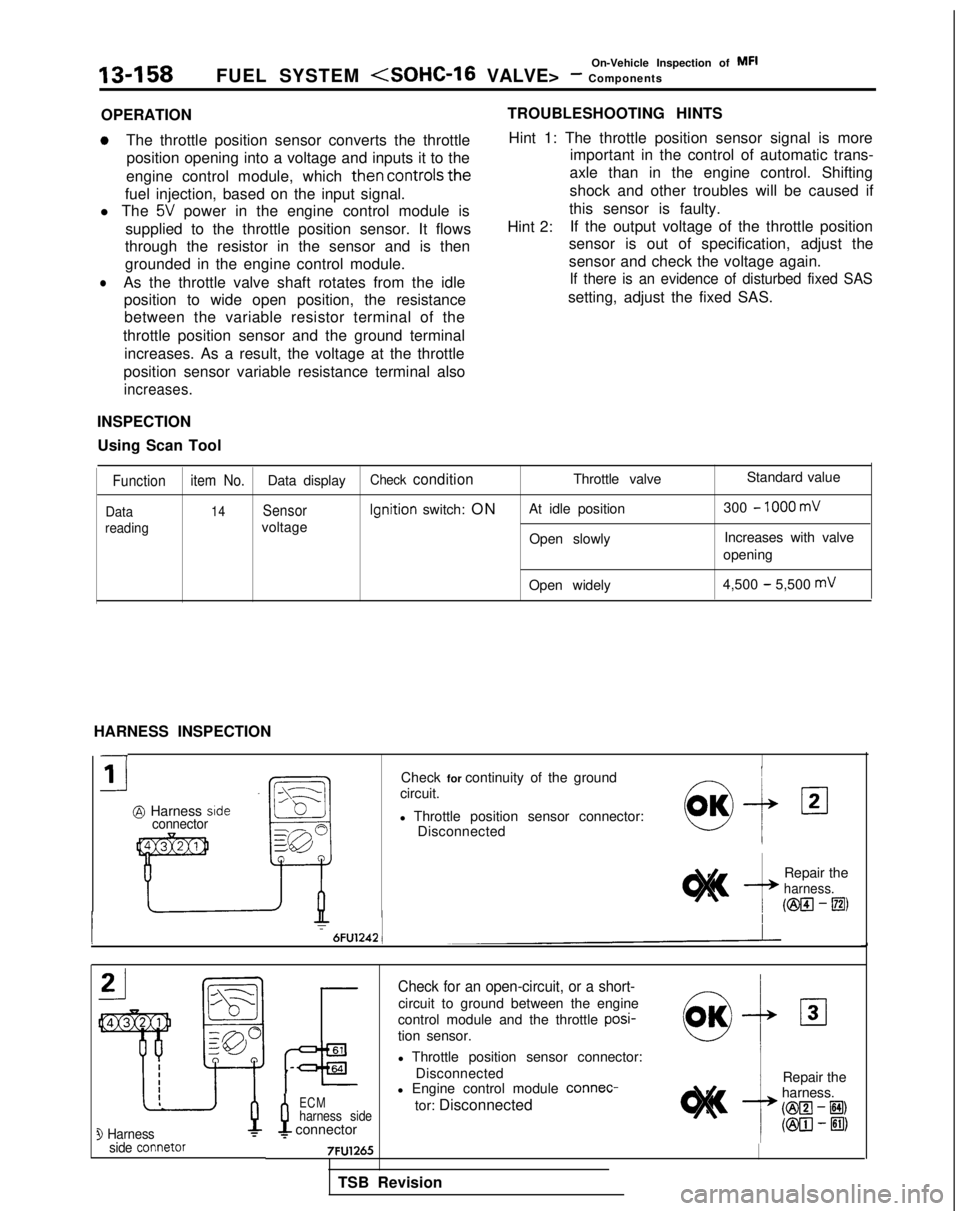

THROTTLE POSITION SENSOR

MinimumMaxlmum

Throttle shaft turning angle162461

(21 With temperature sensing portion of engine coolant tem-

perature sensor immersed in hot water, check resistance

Temperature PC (“F)lResistance (k!S)

0 (32)5.8

I20 (68)~12.4I

I80 (I 76)I0.3I

Engine control module connector

(3) If the resistance deviates from the standard value greatly,

replace the sensor.

INSTALLATION

(1) Apply sealant to threaded portion. Specified sealant:

3M NUT locking Part No. 4171 or

equivalent

(2) Install engine coolant temperature sensor and tighten it to specified torque.

Sensor tightening torque:

20-40 Nm (15-29 ft.lbs.)

(3) Fasten harness connectors securely.

@ Equipment sideconnectorThrottle posltlon sensor

@ Harness srdeconnector

pJ$q]

1

5EL1400

I72-

E

6461

r 1

Engine control module

7FUO672

L

7FUO653

1 TSB Revision

Page 300 of 1273

On-Vehicle Inspection of MFI

13-158FUEL SYSTEM (SOHC-16 VALVE> - Components

OPERATION

aThe throttle position sensor converts the throttle position opening into a voltage and inputs it to the

engine control module, which

then controls

the

fuel injection, based on the input signal.

l The

5V power in the engine control module is

supplied to the throttle position sensor. It flows

through the resistor in the sensor and is then

grounded in the engine control module.

lAs the throttle valve shaft rotates from the idle position to wide open position, the resistancebetween the variable resistor terminal of the

throttle position sensor and the ground terminal increases. As a result, the voltage at the throttle

position sensor variable resistance terminal also

increases.

INSPECTION

Using Scan Tool TROUBLESHOOTING HINTS

Hint 1: The throttle position sensor signal is more important in the control of automatic trans-

axle than in the engine control. Shifting

shock and other troubles will be caused if

this sensor is faulty.

Hint 2: If the output voltage of the throttle position

sensor is out of specification, adjust the

sensor and check the voltage again.

If there is an evidence of disturbed fixed SAS

setting, adjust the fixed SAS.

Function item No.Data displayCheck conditionThrottle valve Standard value

Data14Sensor Ignition

switch: ON At idle position 300 - 1000 mV

readingvoltage

Open slowlyIncreases with valve

opening

Open widely 4,500

- 5,500 mV

HARNESS INSPECTION

-

i1

@ Harness sideconnector

Check for continuity of the ground

circuit.

l Throttle position sensor connector: Disconnected

Repair the

harness.

(ml-m

3 Harnessside connetor

P

ECMharness sidef connector

Check for an open-circuit, or a short-

circuit to ground between the engine

control module and the throttle posi-

tion sensor.

l Throttle position sensor connector:

Disconnected

l Engine control module connec-

tor: Disconnected Repair the

harness. @El

- El)

(@III-ElII

TSB Revision