MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 301 of 1273

FUEL SYSTEM

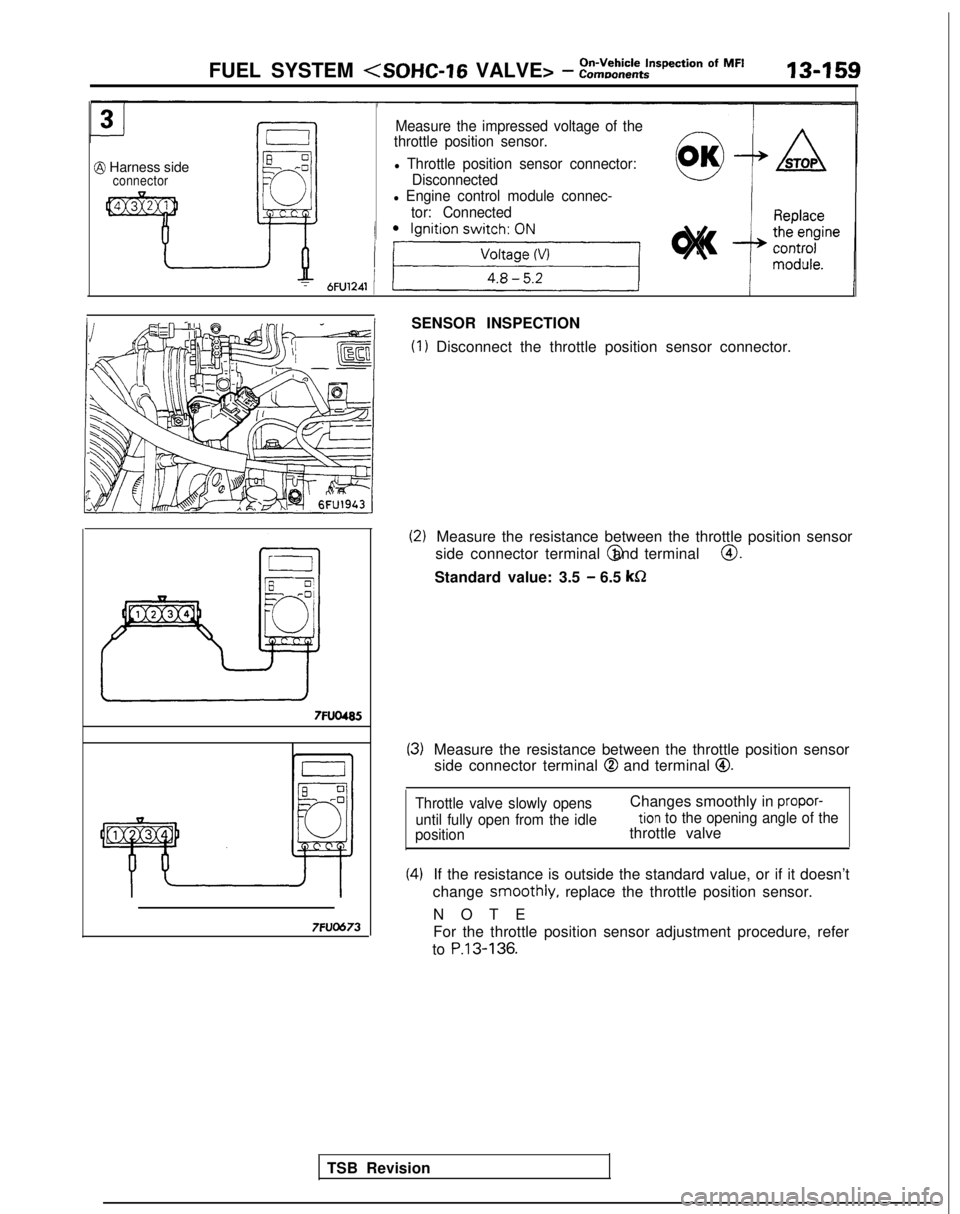

@ Harness sideconnector

Measure the impressed voltage of the

throttle position sensor.

l Throttle position sensor connector:

Disconnected

l Engine control module connec-

tor: Connected

76FU1241

7FlJO485

TSB Revision

7FUa673

SENSOR INSPECTION

(1) Disconnect the throttle position sensor connector.

(2)Measure the resistance between the throttle position sensor

side connector terminal @ and terminal @.

Standard value: 3.5

- 6.5 kQ

(3)Measure the resistance between the throttle position sensor side connector terminal

@ and terminal @.

Throttle valve slowly opensChanges smoothly in propor-

until fully open from the idletion to the opening angle of the

positionthrottle valve

(4)If the resistance is outside the standard value, or if it doesn’t

change smoothly,

replace the throttle position sensor.

NOTE

For the throttle position sensor adjustment procedure, refer

to

P.13-136.

Page 302 of 1273

On-Vehicle Inspection of MFI13-160FUEL SYSTEM (SOHC-16 VALVE> - Components

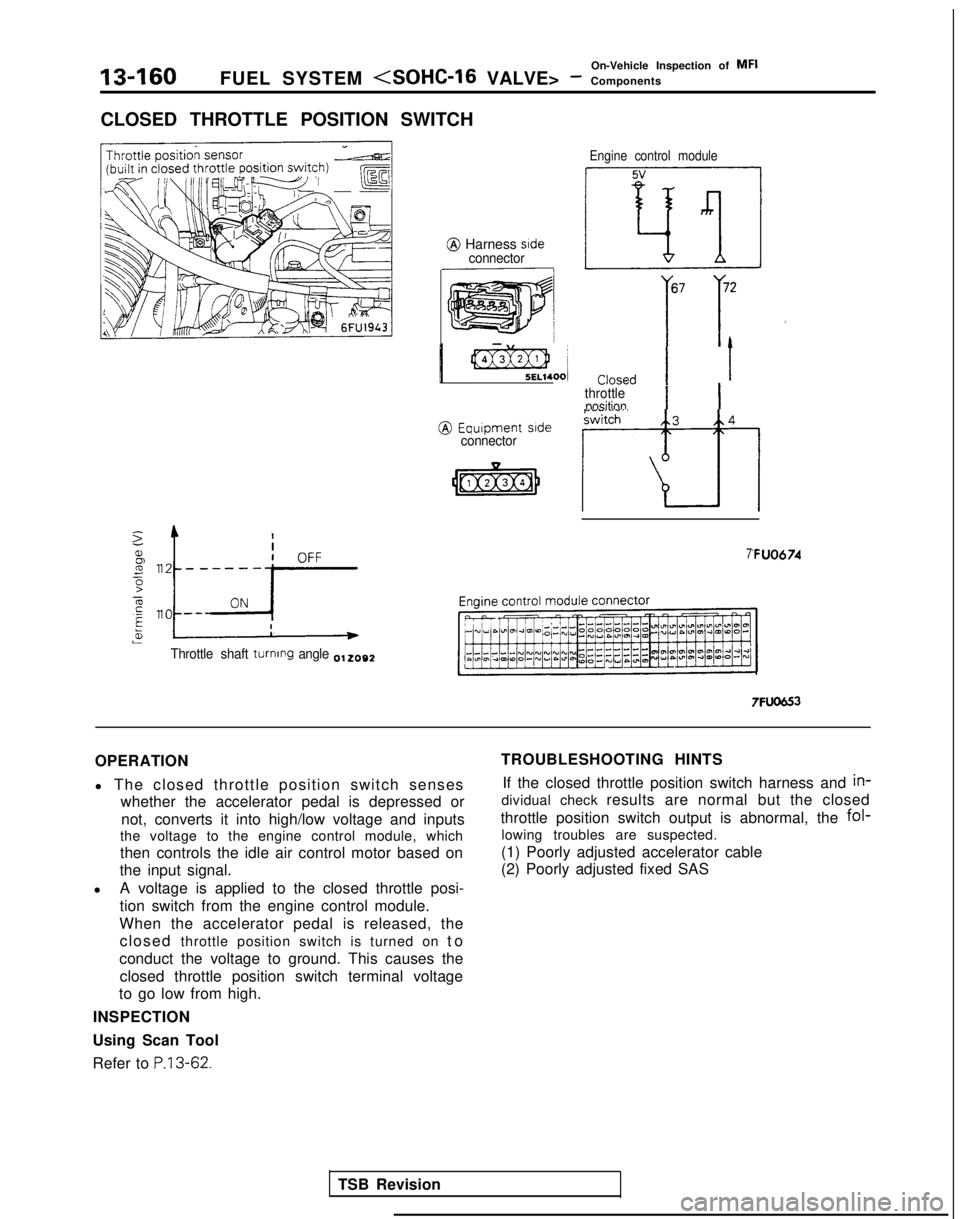

CLOSED THROTTLE POSITION SWITCH

za,

L

% ;; ----,-p

&

Throttle shaft turning angle 0,z092

@ Harness sideconnector

Engine control module

5v

‘il

67 72

II’1

1 -00, Closed

1/ 1

throttleposition

@ Equipment srdeswitch34

connector

ITT-l

7‘F:UO674

TSB Revision 7FUO653

OPERATION

l The closed throttle position switch senses whether the accelerator pedal is depressed or

not, converts it into high/low voltage and inputs

the voltage to the engine control module, which

then controls the idle air control motor based on

the input signal.

l A voltage is applied to the closed throttle posi-

tion switch from the engine control module.

When the accelerator pedal is released, the closed throttle position switch is turned on to

conduct the voltage to ground. This causes the closed throttle position switch terminal voltage

to go low from high.

INSPECTION

Using Scan Tool

Refer to

P.13-62.

TROUBLESHOOTING HINTS If the closed throttle position switch harness and in-

dividual check results are normal but the closed

throttle position switch output is abnormal, the fol-

lowing troubles are suspected.

(1) Poorly adjusted accelerator cable

(2) Poorly adjusted fixed SAS

Page 303 of 1273

FUEL SYSTEM

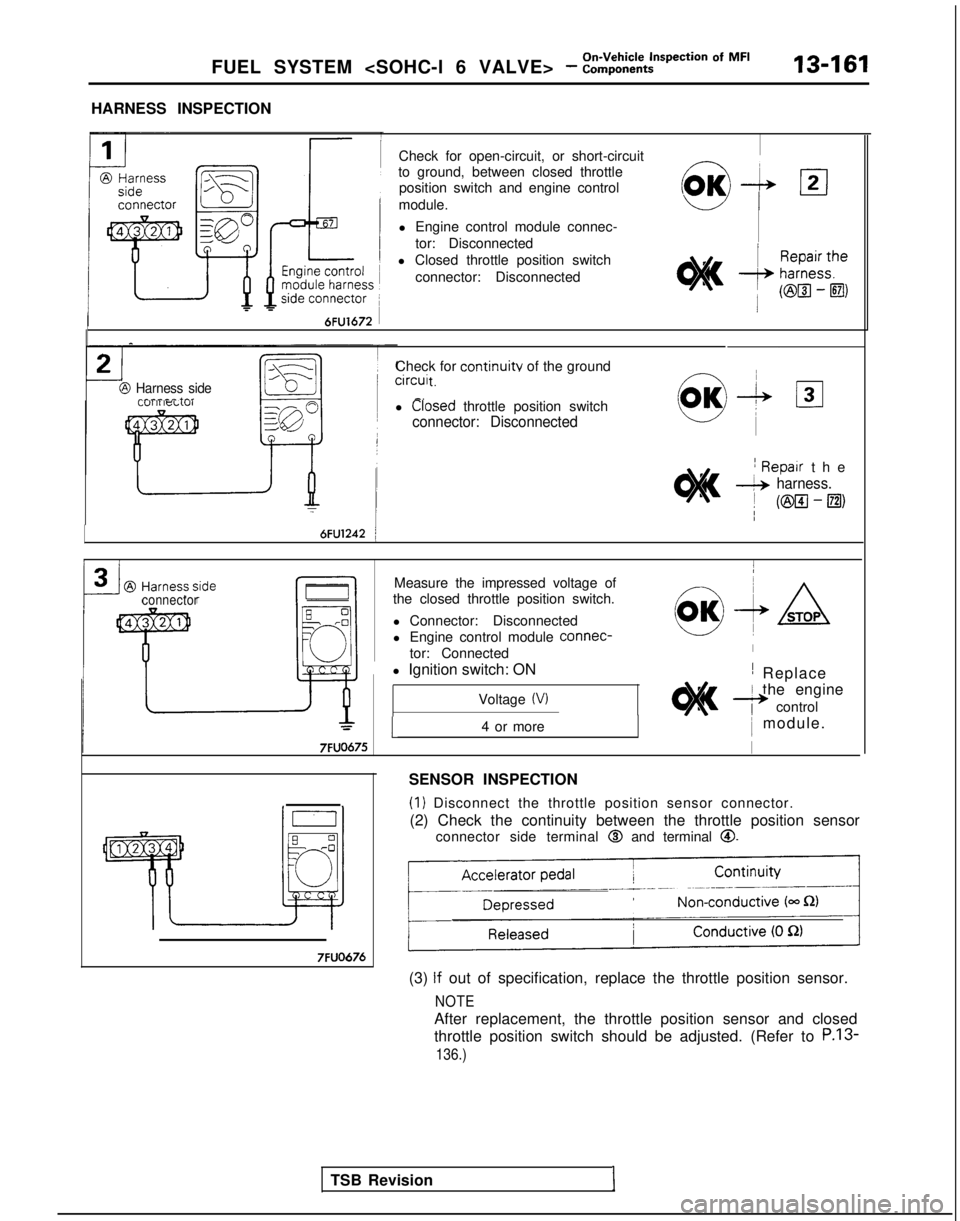

HARNESS INSPECTION

Check for open-circuit, or short-circuit

to ground, between closed throttle position switch and engine control

module.

l Engine control module connec- tor: Disconnected

l Closed throttle position switch

connector: Disconnected

@ Harness side^^^^^^ *^-

Check for continuitv of the groundt.

l Llosed

throttle position switch

connector: Disconnected

1

! Repair

the

4 harness.

6FU1242 /

connector

TSB Revision1

Measure the impressed voltage of

the closed throttle position switch.

l Connector: Disconnected

l Engine control module connec-

tor: Connected

l Ignition switch: ON

Voltage

(VI

I

I Replace

I the engine

7 control

14 or more1 module.

7FUO676

SENSOR INSPECTION

(I) Disconnect the throttle position sensor connector.

(2) Check the continuity between the throttle position sensor connector side terminal

@I and terminal @.

(3) If out of specification, replace the throttle position sensor.

NOTE

After replacement, the throttle position sensor and closed

throttle position switch should be adjusted. (Refer to

P.13-

136.)

Page 304 of 1273

On-Vehicle Inspection of MFI13-162FUEL SYSTEM (SOHC-16 VALVE> - Components

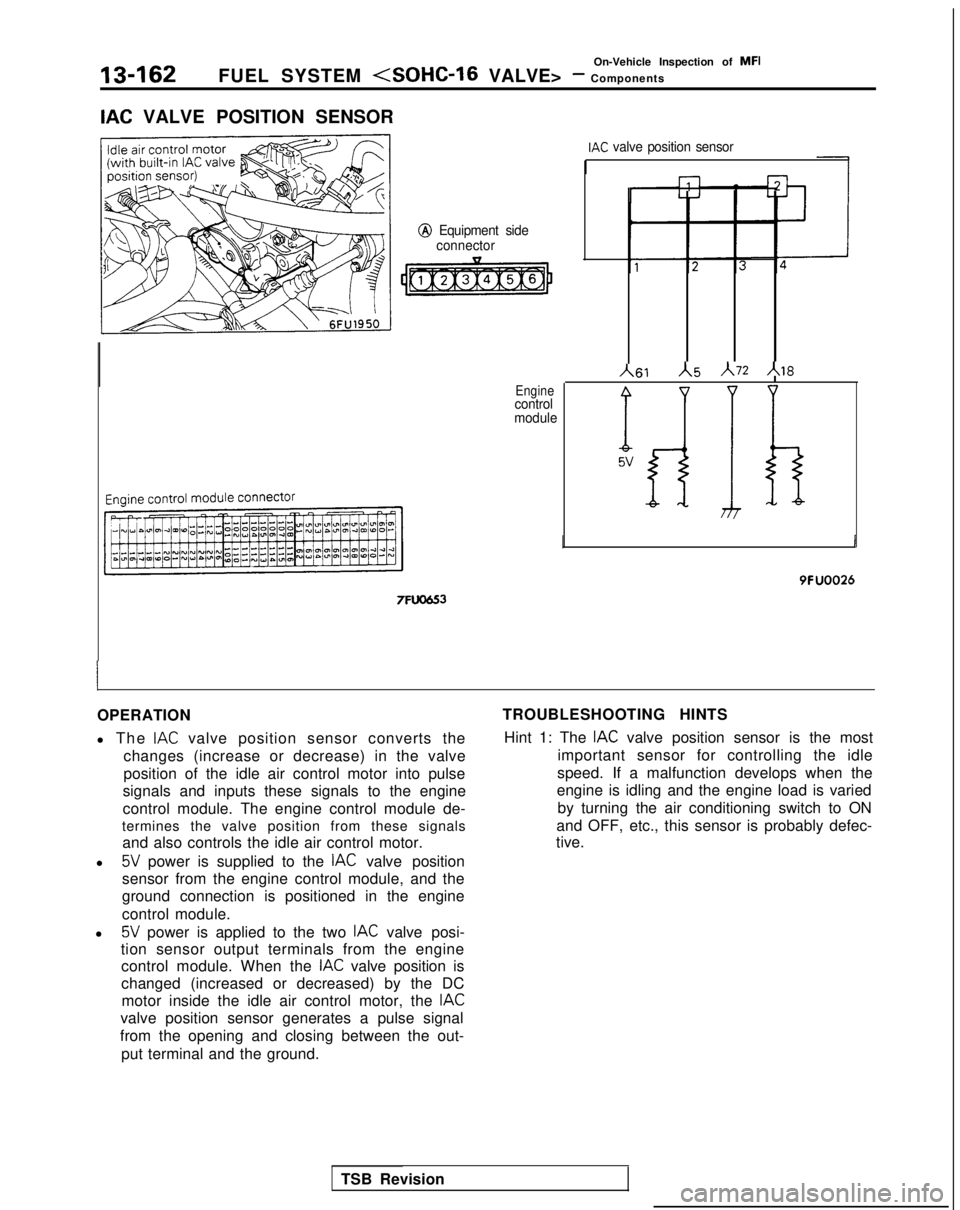

IAC VALVE POSITION SENSOR

@

Equipment side

connector 7FlJO653

Enginecontrol

module

IAC valve position sensor

h61 A\5

A72 Al8

% 5v

I

9FUOO26

OPERATION

l The

IAC valve position sensor converts the

changes (increase or decrease) in the valve

position of the idle air control motor into pulse

signals and inputs these signals to the engine

control module. The engine control module de-

termines the valve position from these signals and also controls the idle air control motor.

l

5V power is supplied to the IAC valve position

sensor from the engine control module, and the

ground connection is positioned in the engine

control module.

l

5V power is applied to the two IAC valve posi-

tion sensor output terminals from the engine control module. When the

IAC valve position is

changed (increased or decreased) by the DC motor inside the idle air control motor, the

IAC

valve position sensor generates a pulse signal

from the opening and closing between the out-

put terminal and the ground. TROUBLESHOOTING HINTS

Hint 1: The

IAC valve position sensor is the most

important sensor for controlling the idle

speed. If a malfunction develops when the

engine is idling and the engine load is varied

by turning the air conditioning switch to ON

and OFF, etc., this sensor is probably defec-

tive.

TSB Revision

Page 305 of 1273

FUEL SYSTEM

INSPECTION

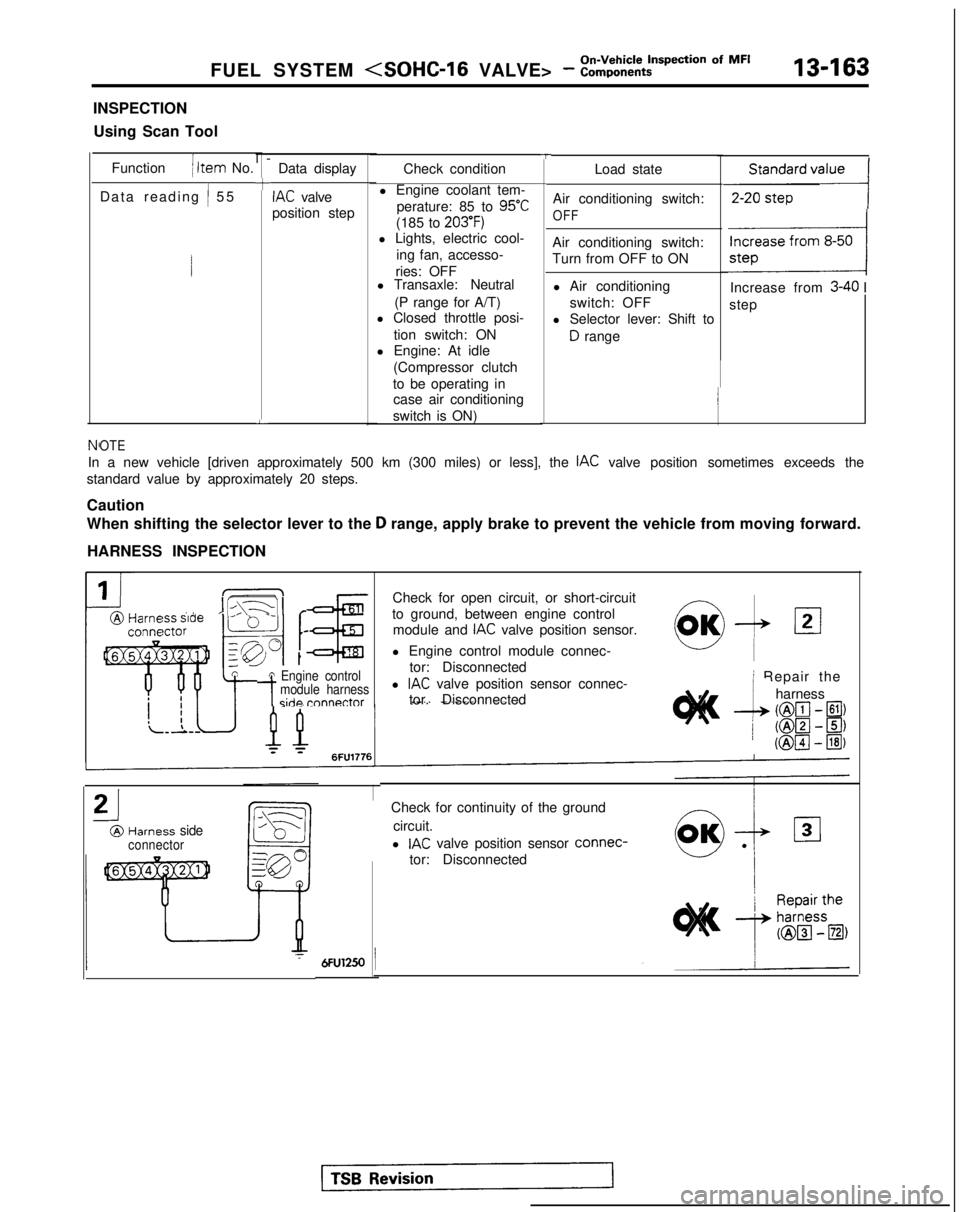

Using Scan Tool

Function

( Item No.

Data reading

/ 5

5

l-

+

L

Data display

IAC valve

position step

TCheck condition

l Engine coolant tem- perature: 85 to

95°C

(185 to 203’F)l Lights, electric cool- ing fan, accesso-

ries: OFF

l Transaxle: Neutral

(P range for A/T)

l Closed throttle posi-

tion switch: ON

l Engine: At idle

(Compressor clutch

to be operating in case air conditioning

switch is ON) Load state

Air conditioning switch:

OFF

Air conditioning switch:

Turn from OFF to ON l Air conditioning switch: OFF

l Selector lever: Shift to

D range

,,,,,,,,,I

Increase from 3-40 I

step

NfOTE

In a new vehicle [driven approximately 500 km (300 miles) or less], th\

e IAC valve position sometimes exceeds the

standard value by approximately 20 steps.

Caution

When shifting the selector lever to the

D range, apply brake to prevent the vehicle from moving forward.

HARNESS INSPECTION

IIL\-11 r@Harm ” ’ -conna

tA Engine control

-tmodule harnessside rnnnnctor

Check for open circuit, or short-circuit

to ground, between engine control module and

IAC valve position sensor.

l Engine control module connec- tor: Disconnected

l

IAC valve position sensor connec-

tor. Disconnected

21

@Harness sideconnector

0,OK-& 121

i Repair the

--L

harness

(@lcl- El)

/ ml-~) (@pJ

- @I)

Check for continuity of the ground

circuit.

l

IAC valve position sensor connec-

tor: Disconnected

Page 306 of 1273

13-164

On-Vehicle Inspection of MFI

FUEL SYSTEM

(SOHC-16 VALVE> - Components

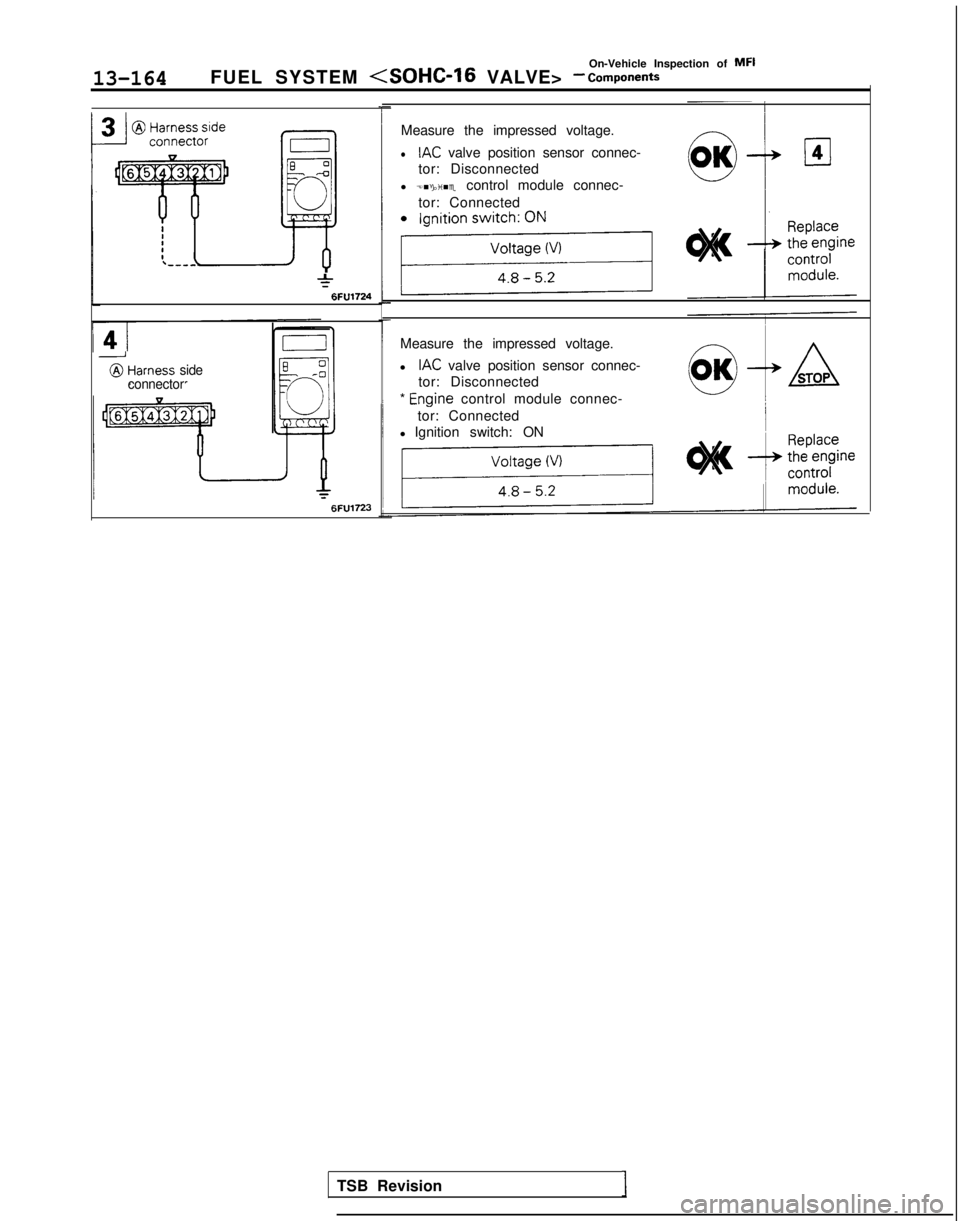

Measure the impressed voltage.

lIAC valve position sensor connec-

tor: Disconnected

l Engine control module connec-

tor: Connected

*6FU1724

$Harness side

connector

Measure the impressed voltage.

l

IAC valve position sensor connec-

tor: Disconnected

*

Engine control module connec-

tor: Connected

l Ignition switch: ON 6FU1723

TSB Revision

1

Page 307 of 1273

FUEL SYSTEM (SOHC-16 VALVE> - %$k%lnspectio” Of MF’13-165

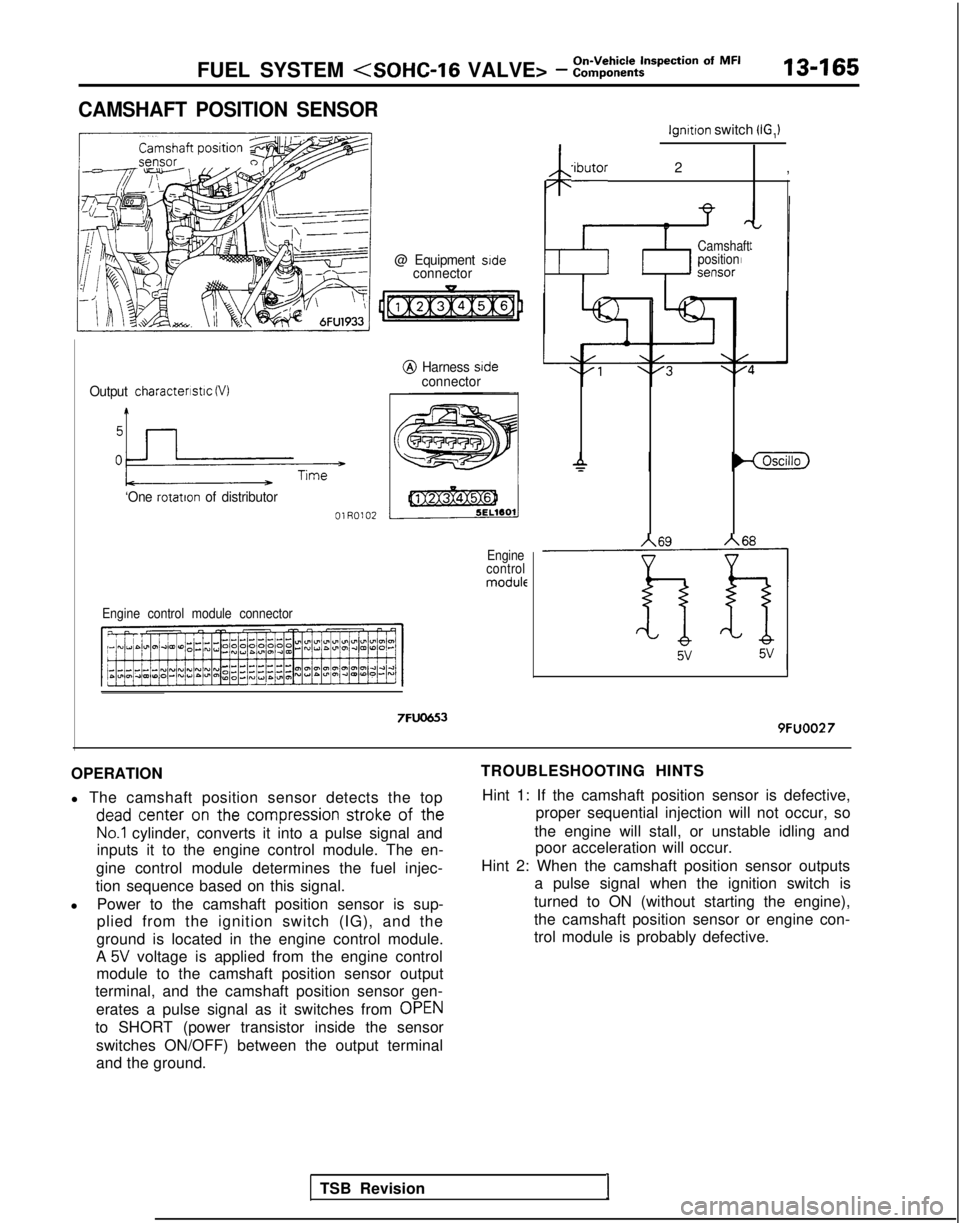

CAMSHAFT POSITION SENSOR

@ Equipment side

connector

Output

characteristic PJ)

‘One rotation of distributor

@ Harness stdeconnector

lgnltion switch (IG,)

Distributor pistributor& 2 ,

I

z

Camshaft

position

Engine

control

module

Engine control module connector

TSB RevisionI

7FUO6539FuOO27

OPERATION

l The camshaft position sensor detects the top dead

center

on the

compression

stroke

of

the

No.1 cylinder, converts it into a pulse signal and

inputs it to the engine control module. The en-

gine control module determines the fuel injec-

tion sequence based on this signal.

l Power to the camshaft position sensor is sup-

plied from the ignition switch (IG), and the

ground is located in the engine control module.

A

5V voltage is applied from the engine control

module to the camshaft position sensor output

terminal, and the camshaft position sensor gen-

erates a pulse signal as it switches from OPEN

to SHORT (power transistor inside the sensor

switches ON/OFF) between the output terminal

and the ground. TROUBLESHOOTING HINTS

Hint 1: If the camshaft position sensor is defective, proper sequential injection will not occur, so

the engine will stall, or unstable idling and poor acceleration will occur.

Hint 2: When the camshaft position sensor outputs a pulse signal when the ignition switch is

turned to ON (without starting the engine),

the camshaft position sensor or engine con-

trol module is probably defective.

Page 308 of 1273

13-166

On-Vehicle Inspection of MFI

FUEL SYSTEM

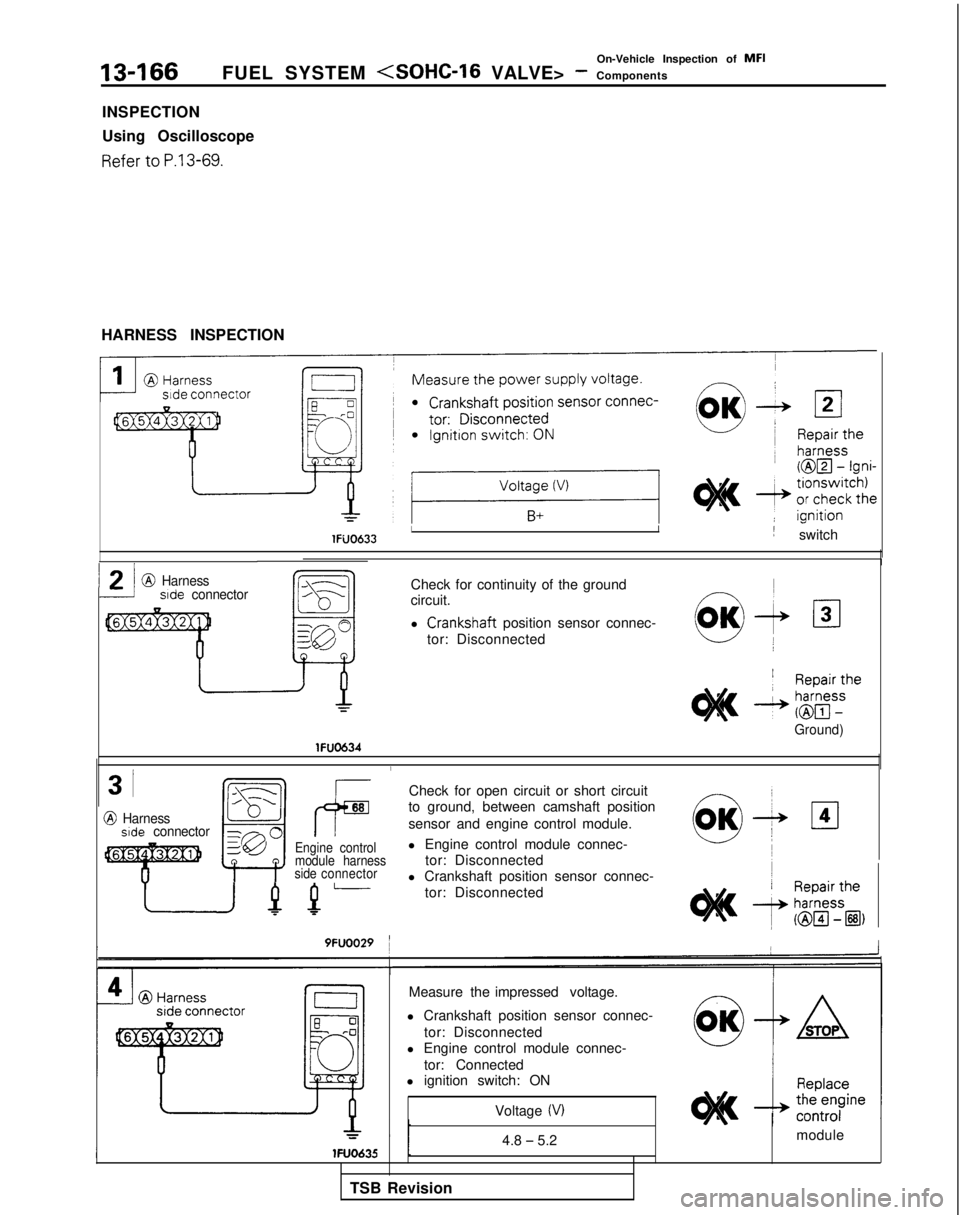

INSPECTION

Using Oscilloscope Refer

to P.13-69.

HARNESS INSPECTION

c

IIlFUO633j switch

1218 Harness -.-..-Aside

connectorCheck for continuity of the ground

circuit.

l Crankshaft

position sensor connec-

tor: Disconnected

Ground) lFUO634

I

3:

@ Harnessside connectorfF

68

Engine control

module harness

side connector

J 9P-

l Crankshaft position sensor connec-

tor: Disconnected

9FUOO29 II

Check for open circuit or short circuit

to ground, between camshaft position

sensor and engine control module.

l Engine control module connec- tor: Disconnected

Measure the impressed voltage.

l Crankshaft position sensor connec- tor: Disconnected

l Engine control module connec-

tor: Connected

l ignition switch: ON

Voltage

(V)

4.8 - 5.2 module

TSB Revision

Page 309 of 1273

FUEL SYSTEM

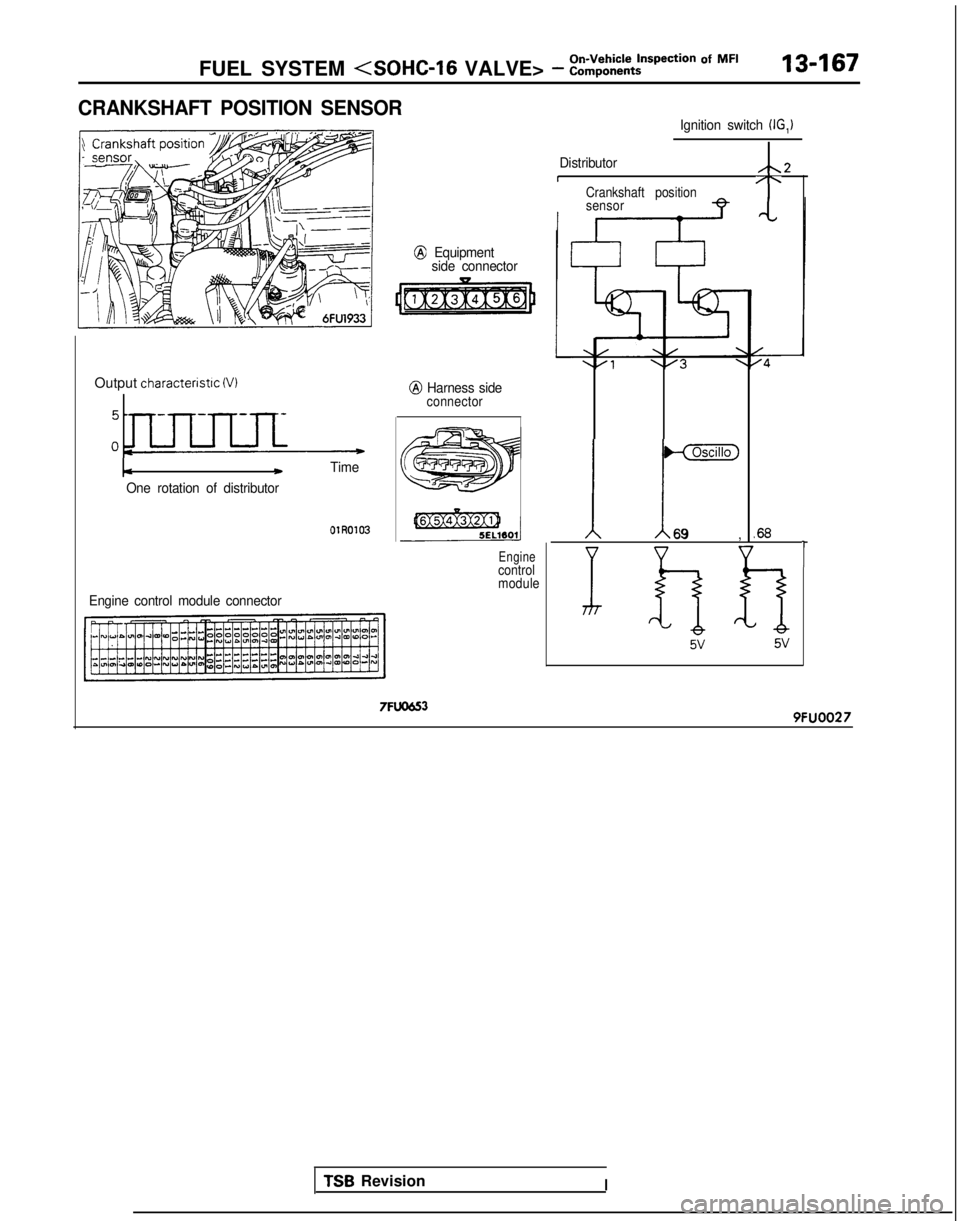

CRANKSHAFT POSITION SENSOR

@ Equipment

side connector

Output characteristic (V)

::

L*Time

One rotation of distributor

01R0103

Engine control module connector

@ Harness sideconnector

Enginecontrol

module

Ignition switch (IG,)

IDistributor

Crankshaft position

sensorI/\2

B

/\

TSB RevisionI

Oscillo

1 I”69 ,.68

I

IL hh5V5v 7FUO653

9FUOO27

Page 310 of 1273

13-168FUEL SYSTEM

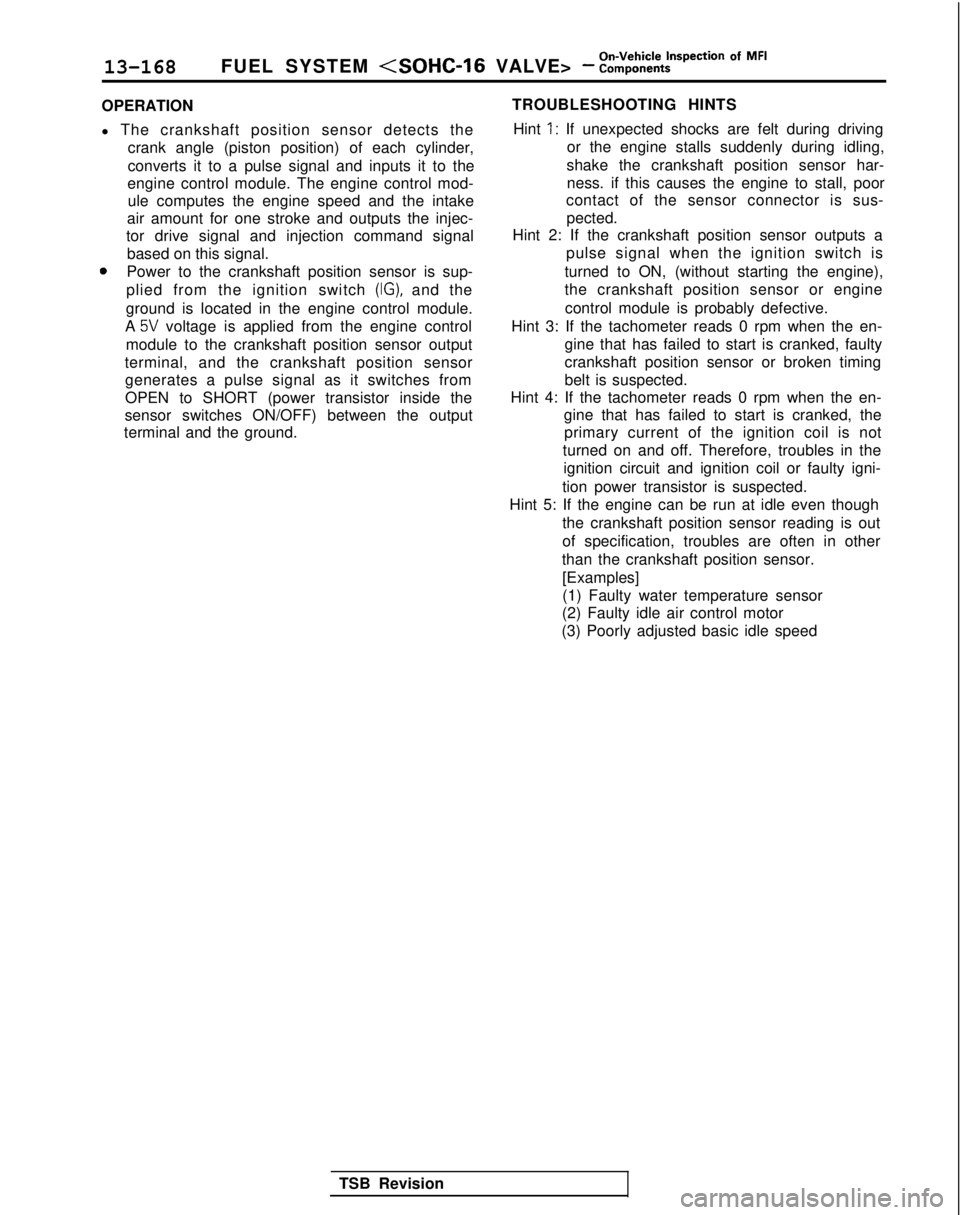

OPERATION

l The crankshaft position sensor detects thecrank angle (piston position) of each cylinder,

converts it to a pulse signal and inputs it to the

engine control module. The engine control mod- ule computes the engine speed and the intake

air amount for one stroke and outputs the injec-

tor drive signal and injection command signal

based on this signal.

0Power to the crankshaft position sensor is sup-

plied from the ignition switch

(IG), and the

ground is located in the engine control module.

A

5V voltage is applied from the engine control

module to the crankshaft position sensor output

terminal, and the crankshaft position sensor generates a pulse signal as it switches from

OPEN to SHORT (power transistor inside the

sensor switches ON/OFF) between the output

terminal and the ground. TROUBLESHOOTING HINTS

Hint

1: If unexpected shocks are felt during driving or the engine stalls suddenly during idling,

shake the crankshaft position sensor har- ness. if this causes the engine to stall, poor

contact of the sensor connector is sus-

pected.

Hint 2: If the crankshaft position sensor outputs a

pulse signal when the ignition switch is

turned to ON, (without starting the engine),

the crankshaft position sensor or engine control module is probably defective.

Hint 3: If the tachometer reads 0 rpm when the en- gine that has failed to start is cranked, faulty

crankshaft position sensor or broken timing

belt is suspected.

Hint 4: If the tachometer reads 0 rpm when the en- gine that has failed to start is cranked, theprimary current of the ignition coil is not

turned on and off. Therefore, troubles in the ignition circuit and ignition coil or faulty igni-

tion power transistor is suspected.

Hint 5: If the engine can be run at idle even though

the crankshaft position sensor reading is out

of specification, troubles are often in other

than the crankshaft position sensor. [Examples]

(1) Faulty water temperature sensor

(2) Faulty idle air control motor

(3) Poorly adjusted basic idle speed

TSB Revision