MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 731 of 1273

AUTOMATIC TRANSAXLE

- Troubleshooting23-25

r star

P =

<

zzGsEa

c”65

srBZzi;4

1

1

Y-

a

s

s-

7

ii-

s-

3-1

z-

3

1_:5s

5

f-

d

1i

‘I3

E*aOm5s;K

;$2zIrg:,8

EP2.2

$2-

If

E:

p2zz0om,c .Gis:75’‘5$5oz28-

-

-

7-

_/-

4

X

?I-

92L”$ElE0

-

zmz

“$

P::g=f,i?Ppzz?$5.- -CE$2

gsi

-

= 0

0752=o-+u$Z

52

gEEO-

- nsaxl’

-

;

4

i?

3

b

$

:

b

?

mk?

::

w

nalfu-

f3::2?gmyQr0.3-J$GbG

LF!‘,

SO” c-

f35eL?g_mc?PV,L 0

.FnEC+8r35-

x-

,hlft-r-

if5 -0

::2Bg

z

5

Pz=$5

3

4

- ck la

- fte

T

z2

B5t8s,-55

P$%88,3d-

x

-i1

Is,

c

5

‘0mc

gi?

DEEf

ge‘2

c”d

p$

“=‘

EiumTNm,ci )th(

l-

jhO#

X-

-

-

-

XX

X-X-

-

-

g,-

X

-.

I

-

5cIpcg;UCa, 22,$ ‘cG$68-

gz

?&SiEss

555m$g

IcE-

?5g

26a2

_’s

8fsz

gD$;i058-cw3

5zYE8g$nso’51b’F m

asz fis-$2x-uo

E(1

9

-z

N

E2

2m-

z-

r 0

35fc2 .ss:!0=3;Pg-

xx--x-X-X-

-

-

-

-

x-

-

-

-

-

-

-

-

6F-

X

X

xX-

-

-

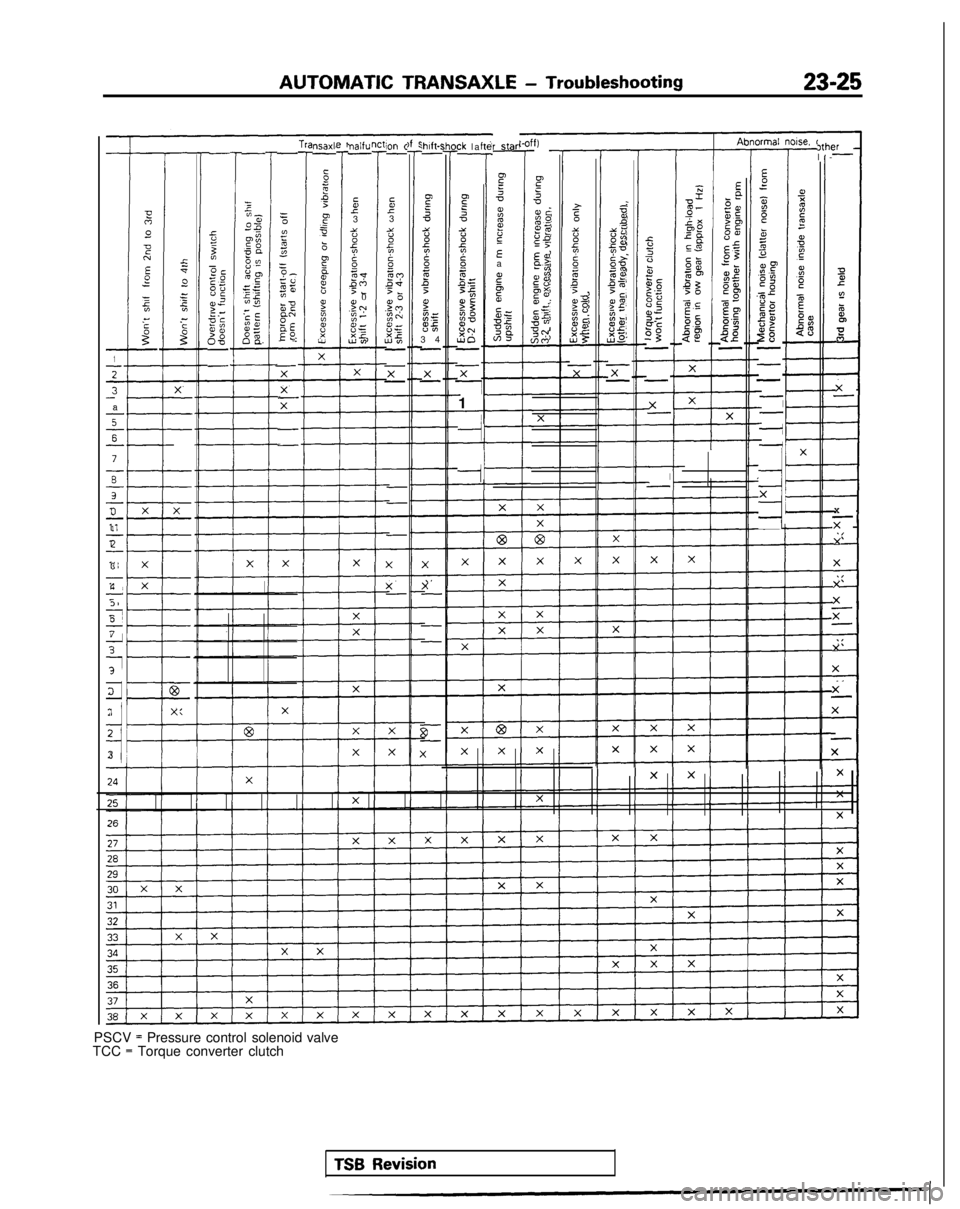

PSCV = Pressure control solenoid

TCC = Torque converter clutch

I-

X

TX

X

X

X

x- X

X

X-

X

-

X

valve

TSB Revision

Page 732 of 1273

23-26AUTOMATIC TRANSAXLE - Troubleshooting

HOT

TFA0715

AW

D

TFA0700

DATA LINK AND TEST

FLUID LEVEL AND CONDITION

1. Drive until the

fluid

temperature

reaches the

usual tem-

perature

[70-80°C (160- 18O”F)l.

2. Place

vehicle

on level floor.

3. Move

selector

lever sequentially

to

every

position

to fill

torque

converter

and hydraulic circuit

with fluid,

then

place

lever in “N” Neutral position.

This operation is necessary

t0

be sure that fluid

level check is accurate.

4. Before

removing

dipstick,

wipe all dirt from area around

dipstick.

Then take out

the

dipstick

and check the

condition

of the

fluid.

The

transaxle

should be overhauled under the following

conditions.

l If there

is a “burning” odor.

l If the

fluid

color

has become

noticeably

blacker.

lIf there

is a noticeably

great

amount

of metal particles in

the

fluid.

5.Check to

see if fluid

level is in “HOT” range on dipstick.

If

fluid

level is low, add automatic

transaxle

fluid

until level

reaches “HOT” range.

Low

fluid

level can cause a variety of

conditions

because it

allows

pump

to

take

in air along with fluid. Air trapped in

hydraulic circuit

forms

bubbles

which

make fluid

spongy.

Therefore,

pressures

will be erratic. Improper filling

can also raise fluid level too

high. When

transaxle

has too

much fluid,

gears churn up foam and

cause same

conditions

which occur with low fluid

level, resulting

in accelerated deterioration

of

automatic

transaxle

fluid.

In

either

case, air bubbles

can cause overheating,

fluid

oxidation,

which can interfere

with normal valve, clutch,

and

servo

operation.

Foaming can also result

in fluid

escaping

from

transaxle

vent where it

may be mistaken

for

a leak.

6. Be

sure to

examine

fluid

on dipstick

closely.

CONTROL CABLE

Whether control

cable is properly

adjusted

can be confirmed

by

checking

whether park/neutral

position

switch is perform-

ing

well.

1.

Apply

parking brakes and service

brakes securely.

2. Place

selector

lever

to

“R” range.

3. Set ignition

key to

“ST” position.

4.

Slowly

move

the

selector

lever

upward

until it

clicks as it

fits in

notch of “P” range. If starter

motor

operates

when

lever makes a click, “P”

position

is correct.

5.Then slowly

move

selector

lever to “N” range by

the

same

procedure as in foregoing

paragraph. If starter

motor

operates

when selector

lever

fits in ‘IN”, “N” position

is correct.

6.

Also check to be sure the

vehicle

doesn’t

begin to move

and

the

lever

doesn’t

stop

between

P-R-N-D.

7. The control

cable is properly

adjusted if, as described

above,the

starter

motor

starts

at both the

“P” range and the

“N” range.

TSB Revision

Page 733 of 1273

AUTOMATIC TRANSAXLE

- Troubleshootin

g

23-27

READ OUT OF FAULT CODES

(1)

Connect

the

voltmeter or scan tool

to the

connector

for data

link.

ItI ITi i i I_ . . c - 7 IIIL:‘!‘/‘!’ ‘j’:‘J

6666S@16R13388,: ELC-4PJT 12 modes1

@: Data link control

@: Ground

(2) Read

the

output fault

codes. Then

follow the remedy

procedures according to the

“Fault

Code Description”

on the following

page.

NOTE

l As many

as a maximum

of ten fault

codes, in the

sequence

of

occurrence,

can be stored

in the

Random Access

Memory (RAM) incorporated

within the

control

module.

l

The same

fault

code can be stored

as many

as three

times.

l

If the number

of stored

fault

codes or

fault

patterns

exceeds

ten,

already

stored

fault

codes

will be erased,

in

sequence

beginning

with the

oldest.

lDo

not

disconnect the

battery

until all fault

codes or

fault

patterns

have

been read out, because al! stored

fault

codes

or fault

patterns

will

be canceled when

the

battery is

disconnected.

~ ~~

(3)

If the

fail-safe

system is activated

and the

transaxle

is

locked in 3rd gear, the fault

code in the

Fail-Safe Code Description

will be stored

in the

RAM.

Three of these fault

codes can be stored.. ,.

Cigarette

lighter

socket

1

(4) The cancelation

will

occur if, with the

transaxle

locked rn 3rd

gear, the ignition

key is turned

to

the

OFF position,

but

Data link

connector the

fault code is stored

in the

RAM.

MB991 341

\

ROM back

16PO151

TSB Revision

Page 734 of 1273

23-28AUTOMATIC TRANSAXLE - Troubleshooting ’

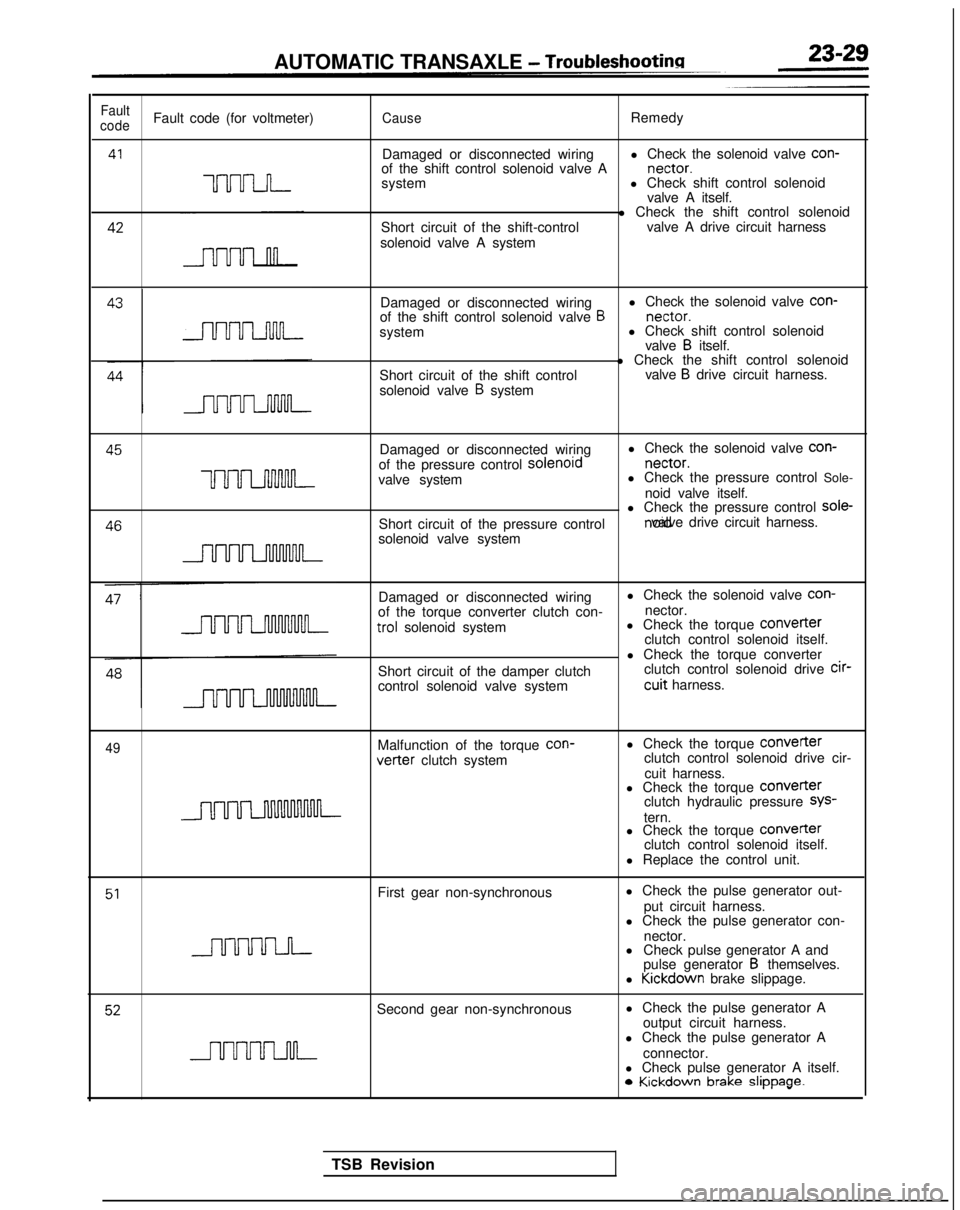

Fault Code Description for 1989 and 1990 model

FaultcodeFault code (for voltmeter)CauseRemedy

21Abnormal increase of TPS output

l Check the throttle position sen-

sor connector.

l Check the throttle position sen-

sor itself.

22

23

- l Adjust the throttle position sen-

Abnormal decrease of TPS outputsor.l Check the accelerator switch (No. 28: output or not).

l Check the throttle position sen- sor output circuit harness.

Incorrect adjustment of the

throttle-position sensor system

24Damaged or disconnected wiring

of the oil temperature sensor sys-

tern

l Check the oil temperature sen-

sor circuit harness.

l Check the oil temperature sen-

sor connector.

l Check the oil temperature sen-

sor itself.

25

26

Damaged or disconnected wiring l Check the kickdown

servo

of the kickdown

servo switch sys-

switch output circuit harness. tern.

or improper contact l Check the kickdown

servo

switch connector.

l Check the kickdown

servo

Short circuit of the kickdown

servo switch itself.

switch system

27Damaged or disconnected wiring

of the ignition pulse pick-up cable

system l Check the ignition pulse signal

line.

28Short circuit of the accelerator

switch system or improper adjust-

ment l Check the accelerator switch

output circuit harness.

l Check the accelerator switch

connector.

l Check the accelerator switch it-

self.

31

l Adjust the accelerator switch.

Malfunction of the microprocessor l Replace the control unit.

32First gear command during hrgh-speed drivingl Replace the control unit.

Damaged or disconnected wiring

of the pulse generator

B system l Check the pulse generator Boutput circuit harness.

l Check pulse generator B itself.

l Check the vehicle speed reed

switch (for chattering).

TSB Revision

Page 735 of 1273

AUTOMATIC TRANSAXLE - Troubleshootina

Fault

codeFault code (for voltmeter)CauseRemedy

41

UUU-LJ-I-

Damaged or disconnected wiring l Check the solenoid valve con-

of the shift control solenoid valve A nectar.

system l Check shift control solenoid

valve A itself. 42

Short circuit of the shift-control

solenoid valve A system l Check the shift control solenoid

valve A drive circuit harness

Damaged or disconnected wiring l Check the solenoid valve con-

of the shift control solenoid valve

B nectar.

system l Check shift control solenoid

valve

B itself.

Short circuit of the shift control

solenoid valve

B system l Check the shift control solenoid

valve

B drive circuit harness. 45

Damaged or disconnected wiringl Check the solenoid valve con-

of the pressure control solenord nectar.

uuuLnnnM-valve system

l Check the pressure control Sole-

noid valve itself. 46

l Check the pressure control sole-

Short circuit of the pressure control noid valve drive circuit harness.

solenoid valve system

Damaged or disconnected wiring

of the torque converter clutch con- trol

solenoid system

Short circuit of the damper clutch

control solenoid valve system l Check the solenoid valve con-

nector.

l Check the torque COnVeIter

clutch control solenoid itself.

l Check the torque converter clutch control solenoid drive cir-

cuit harness.

49Malfunction of the torque

con-vetter clutch system

l Check the torque

Converterclutch control solenoid drive cir-

cuit harness.

l Check the torque

COnVeITerclutch hydraulic pressure SYS-

tern.

l Check the torque COnVerter

clutch control solenoid itself.

l Replace the control unit.

51First gear non-synchronous l Check the pulse generator out-

put circuit harness.

l Check the pulse generator con-

nector.

l Check pulse generator A and

pulse generator

B themselves.

l Kickdown

brake slippage.

52Second gear non-synchronous l Check the pulse generator A

output circuit harness.

l Check the pulse generator A

connector.

l Check pulse generator A itself. 0

Kickdown brake slippage.

TSB Revision

Page 736 of 1273

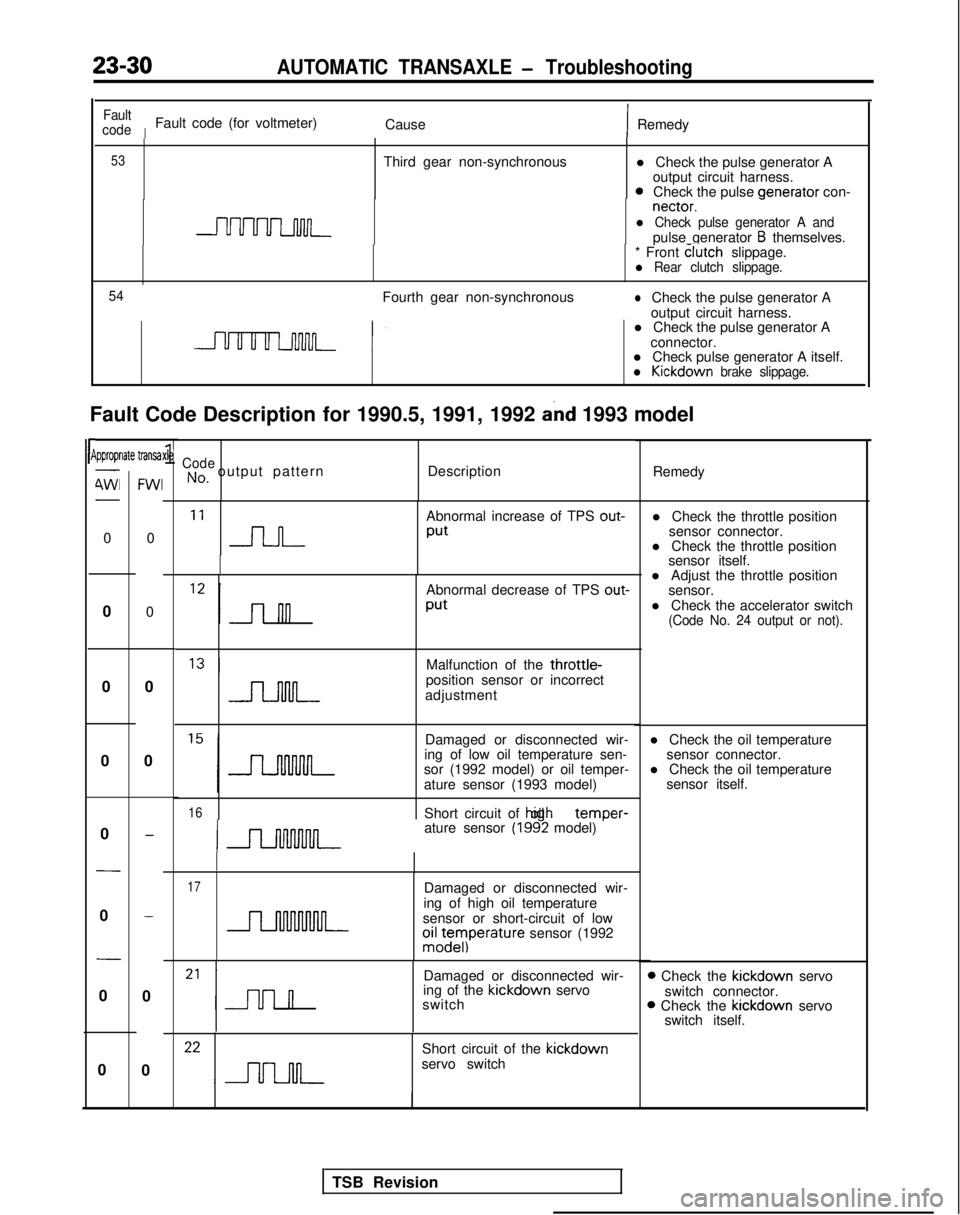

23-30AUTOMATIC TRANSAXLE - Troubleshooting

l Check the pulse generator Aoutput circuit harness.

0Check the pulse venerator

con- nectar.

-l Check pulse generator A andpulse generator B themselves.

Fault Code Description for 1990.5, 1991, 1992

and 1993 model

rP

Fault

code

IFault code (for voltmeter) CauseIRemedy

53Third gear non-synchronous

* Front clutch

slippage.

l Rear clutch slippage.

54

Fourth gear non-synchronouslCheck the pulse generator A

output circuit harness.

l Check the pulse generator A

connector.

l Check pulse generator A itself.

l Kickdown brake slippage.

ipproprlate transa-

4Wl-

0

0

0

0

0

-

0

-

0

0

FWI

0

0

0

0

-

-

0

0

xle1CodeNo, output pattern Description

Remedy

‘I n

Abnormal increase of TPS out-

Put

Abnormal decrease of TPS out-

Put

l Adjust the throttle position

sensor.

l Check the accelerator switch

(Code No. 24 output or not).

Malfunction of the throttle-position sensor or incorrect

adjustment

Damaged or disconnected wir-

ing of low oil temperature sen- l Check the oil temperature

sensor connector.

sor (1992 model) or oil temper- l Check the oil temperature

ature sensor (1993 model) sensor itself.

16Short circuit of hiah oil temDer-

ature sensor (1992 model) ’

17Damaged or disconnected wir-

ing of high oil temperature

sensor or short-circuit of low

oiz;eyIperature sensor (1992

Damaged or disconnected wir-

ing of the kickdown

servo

switch

Short circuit of the kickdown

servo switch l Check the throttle position

sensor connector.

l Check the throttle position sensor itself.

D Check the kickdown

servo

switch connector.

B Check the kickdown

servo

switch itself.

TSB Revision

Page 737 of 1273

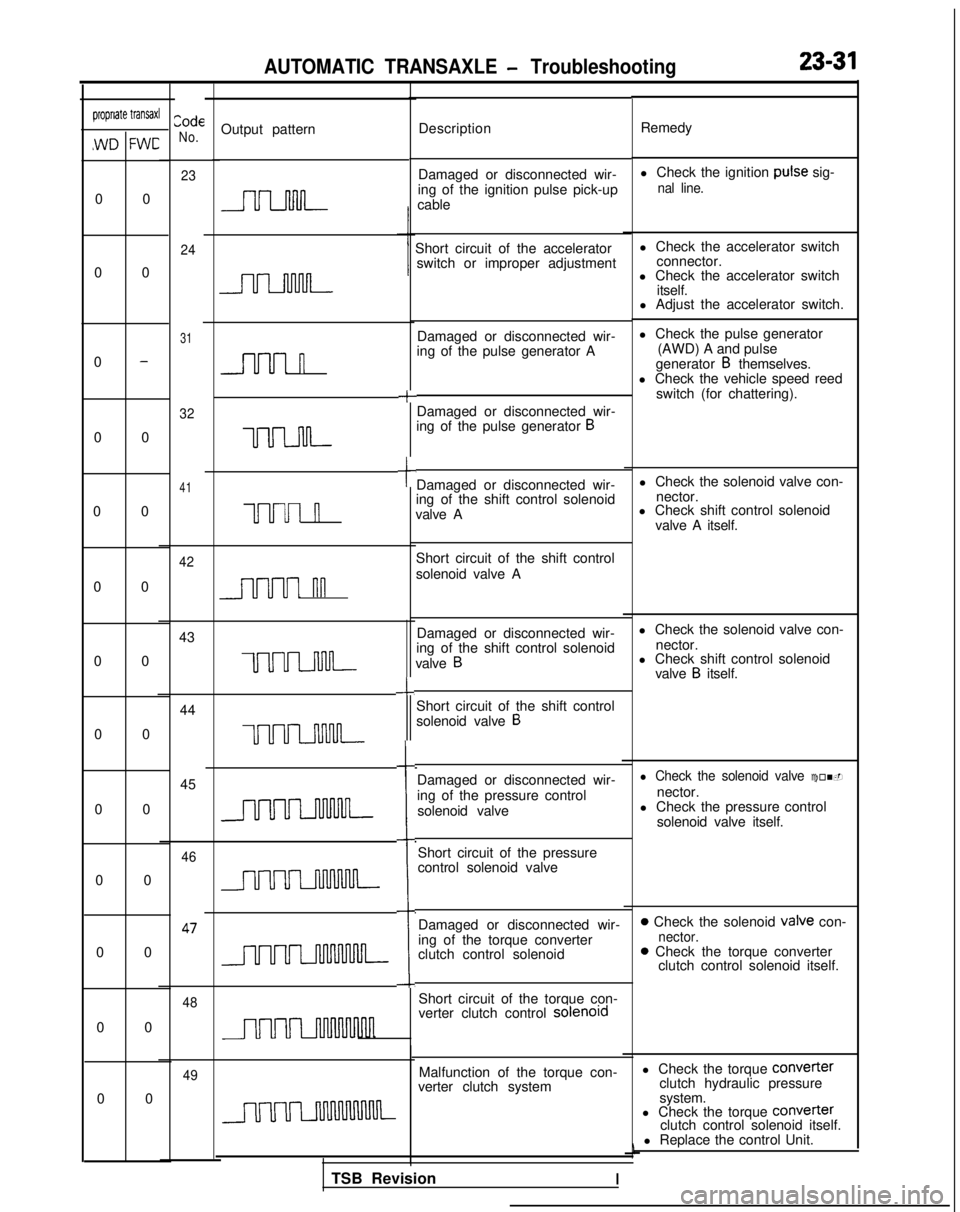

AUTOMATIC TRANSAXLE - Troubleshooting23-31

CodeNo.propriate transaxl

,WD FWC

Output pattern Description Remedy

Damaged or disconnected wir-

ing of the ignition pulse pick-up

cable l Check the ignition

puke sig-

nal line.

Short circuit of the accelerator

l Check the accelerator switch

switch or improper adjustment connector.

l Check the accelerator switch

itself.

l Adjust the accelerator switch.

Damaged or disconnected wir-

ing of the pulse generator A

+

l Check the pulse generator

(AWD) A and pulse

generator

B themselves.

l Check the vehicle speed reed

switch (for chattering).

Damaged or disconnected wir-

ing of the pulse generator

B

tDamaged or disconnected wir-

ing of the shift control solenoid

valve A l Check the solenoid valve con-

nector.

l Check shift control solenoid

valve A itself.

Short circuit of the shift control

solenoid valve A

Damaged or disconnected wir-

ing of the shift control solenoid

valve

B

l Check the solenoid valve con- nector.

-L

l Check shift control solenoidvalve B itself.

Short circuit of the shift control

solenoid valve

B

i

Damaged or disconnected wir-

ing of the pressure control solenoid valvel Check the solenoid valve con-

nector.

l Check the pressure control

solenoid valve itself.

Short circuit of the pressure

control solenoid valve

Damaged or disconnected wir-

ing of the torque converter

clutch control solenoid

0 Check the solenoid valve con-nector.0 Check the torque converter clutch control solenoid itself.

Short circuit of the torque con-

verter clutch control solenord

Malfunction of the torque con-

verter clutch system l Check the torque COnVefter

clutch hydraulic pressure

system.

0 0

0 0

0

-

0 0

0 0

0 00 00 0

0 0 0 0

0 0

0 00 0

23

24

31

32

41

n

uuuul

UUUI n

42

nn

43

uum

44 45

uum

46 47

48

TSB RevisionI

l Check the torque

Converter

clutch control solenoid itself.

l Replace the control Unit.

49

Page 738 of 1273

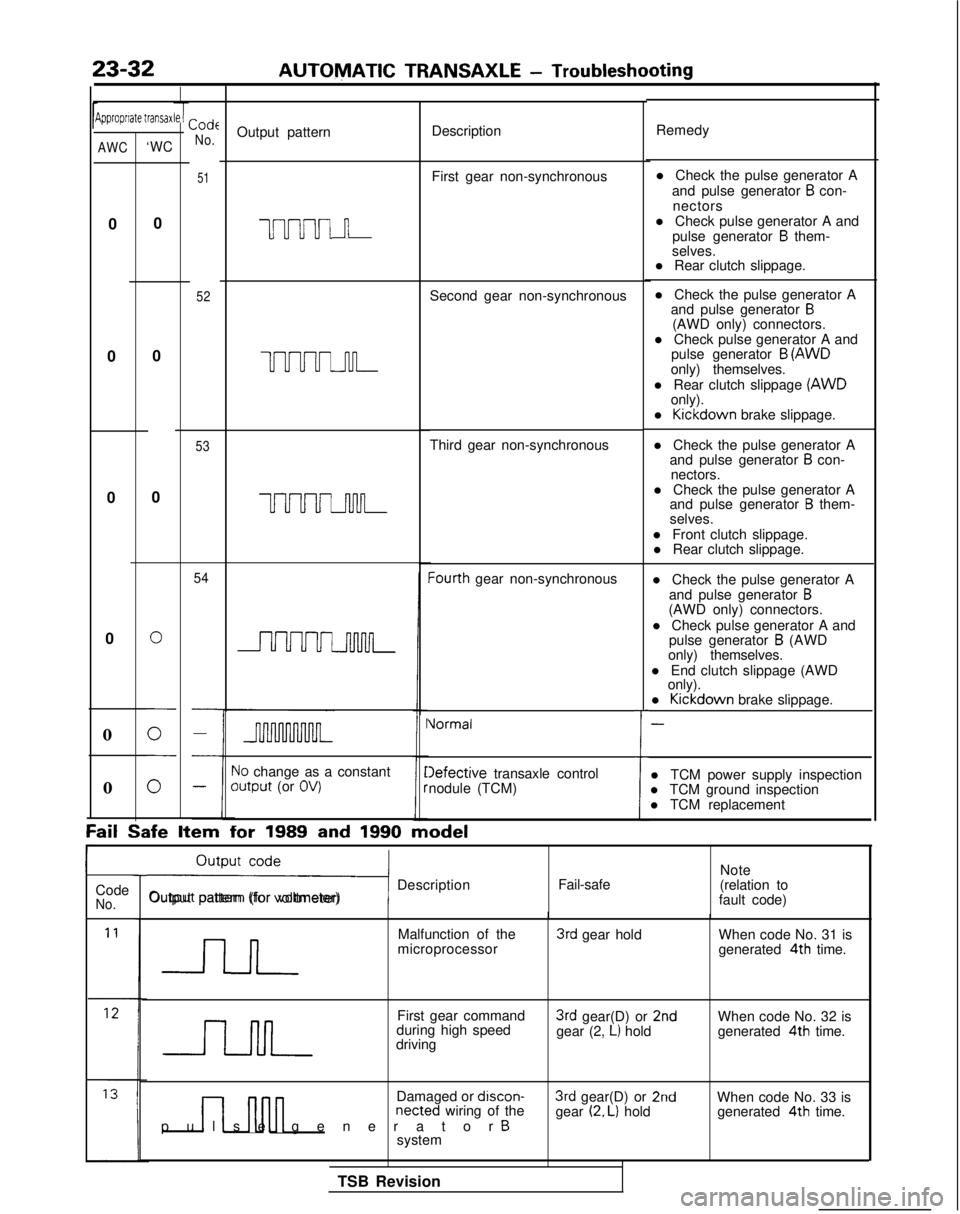

23-32AUTOMATIC TRANSAXLE

- Troubleshooting

Jipproprrate transaxCode

No.Output pattern Description

Remedy

51First gear non-synchronous

uuuul n

52Second gear non-synchronous l Check the pulse generator A

and pulse generator

B con-

nectors

l Check pulse generator A and pulse generator

B them-

selves.

l Rear clutch slippage.

l Check the pulse generator A and pulse generator

B(AWD only) connectors.

l Check pulse generator A and pulse generator

B (AWD

only) themselves.

l Rear clutch slippage (AWD

only).

l Kickdown

brake slippage.

l Check the pulse generator A and pulse generator

B con-

nectors.

l Check the pulse generator A and pulse generator

B them-

selves.

l Front clutch slippage. l Rear clutch slippage.

l Check the pulse generator A and pulse generator

B(AWD only) connectors.

l Check pulse generator A and pulse generator

B (AWD

only) themselves.

l End clutch slippage (AWD only).

l Kickdown

brake slippage.

-

l TCM power supply inspection

l TCM ground inspection

l TCM replacement

AWC‘WC

0

0 0

0

0

UUUUJ-u-l-

53Third gear non-synchronous

0

0

UUUUuwL

54Iourth gear non-synchronous

0

i

Vormal

10 change as a constantoutput (or OV)Iefective transaxle control

nodule (TCM)

0

Fail Safe

Item for

1989 and 1990 model

ri Description

Output pattern (for voltmeter) Fail-safeNote

(relation to

fault code)

Code

No.

Malfunction of the

microprocessor3rd gear hold When code No. 31 is

generated 4th

time.

First gear command

during high speed

driving

3rd gear(D) or 2ndgear (2, L) hold When code No. 32 is

generated 4th

time.

n nnn

Damaged or discon-netted wiring of the

pulse generator Bsystem

3rd gear(D) or 2ndgear (2. L) hold When code No. 33 is

generated 4th

time.

TSB Revision

Page 739 of 1273

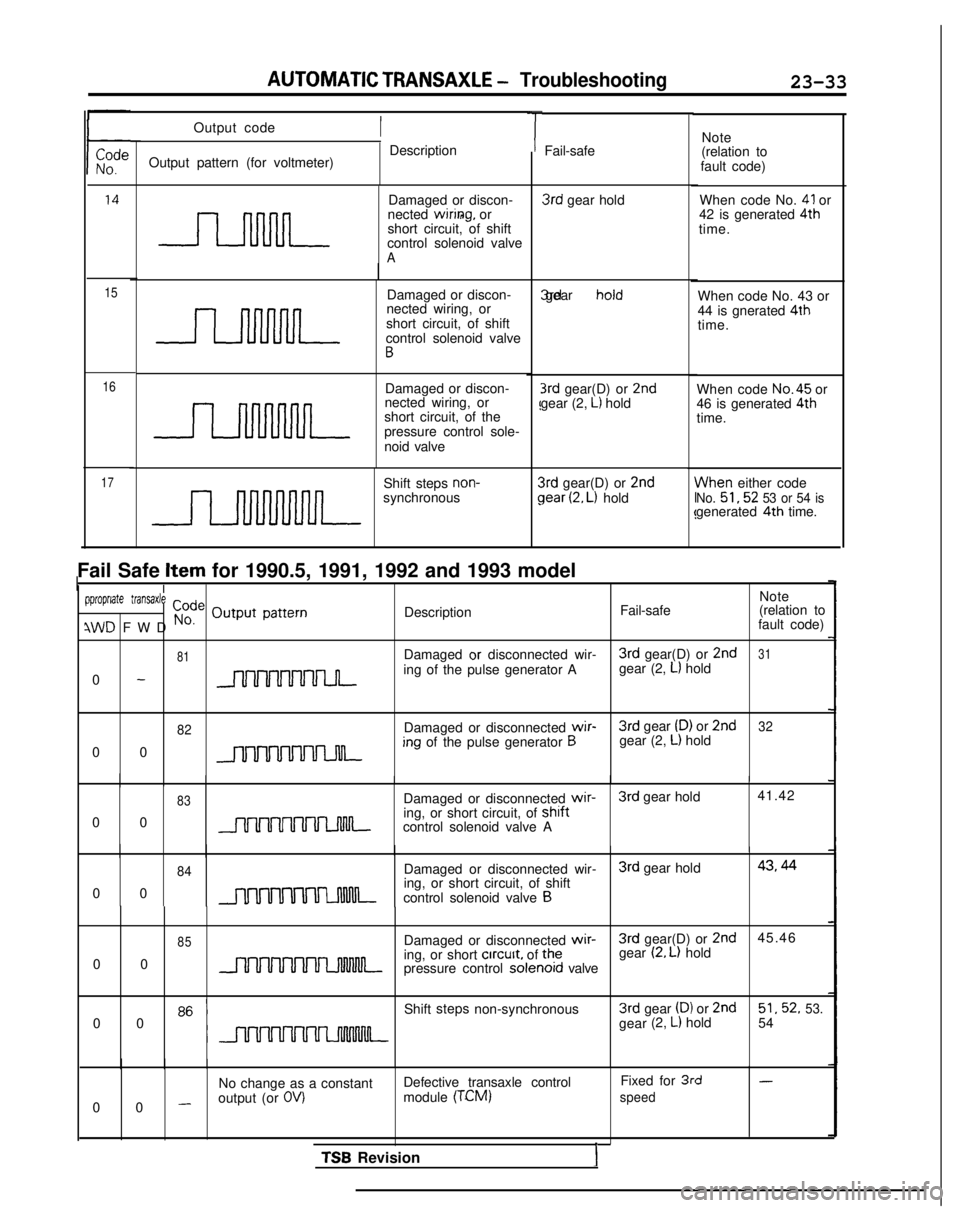

AUTOMATIC TRANSAXLE - Troubleshooting23-33

15

16

17

Output code

Output pattern (for voltmeter) Description

Damaged or discon-

nected

wiring, or

short circuit, of shift

control solenoid valve

A

Damaged or discon-

nected wiring, or

short circuit, of shift

control solenoid valve

B

Damaged or discon-

nected wiring, or

short circuit, of the

pressure control sole-

noid valve

Shift steps

non-synchronous

TFail-safe 3rd

gear hold 3rd gear hold

3rd gear(D) or 2ndgear (2, L) hold

3rd gear(D) or 2ndJear (2, L) hold

Note

(relation to

fault code)

When code No.

41 or

42 is generated 4th

time.

When code No. 43 or

44 is gnerated 4th

time.

When code No.45

or

46 is generated 4th

time.

flhen either codeNo. 51,52 53 or 54 isgenerated 4th

time.

Fail Safe

Item for 1990.5, 1991, 1992 and 1993 modelI

pproprlate transaxle Code Output patternNote

Description Fail-safe

(relation to

IWD FWD No.fault code)

81Damaged or disconnected wir- 3rd

gear(D) or 2nd31

0 -ing of the pulse generator A

gear (2, L) hold

82Damaged or disconnected wir- 3rd

gear (D) or 2nd32

0 0;ng of the pulse generator Bgear (2, L) hold

83Damaged or disconnected wir-

3rd

gear hold 41.42

0 0

ming, or short circuit, of shaftcontrol solenoid valve A

84Damaged or disconnected wir- 3rd

gear hold43,44

0 0m

ing, or short circuit, of shift

control solenoid valve B

85

Damaged or disconnected wir- 3rd

gear(D) or 2nd

45.46

0 0ming, or short crrcurt, of tne

gear (2. L) hold

pressure control solenord

valve

0 0 Shift

steps

non-synchronous 3rd

gear

(D) or 2nd51,52,53.gear (2, L) hold

54

No change as a constant Defective transaxle control Fixed for 3rd

-

0 0 -output (or OV)module (TCM)

speed

ITSB Revision

Page 740 of 1273

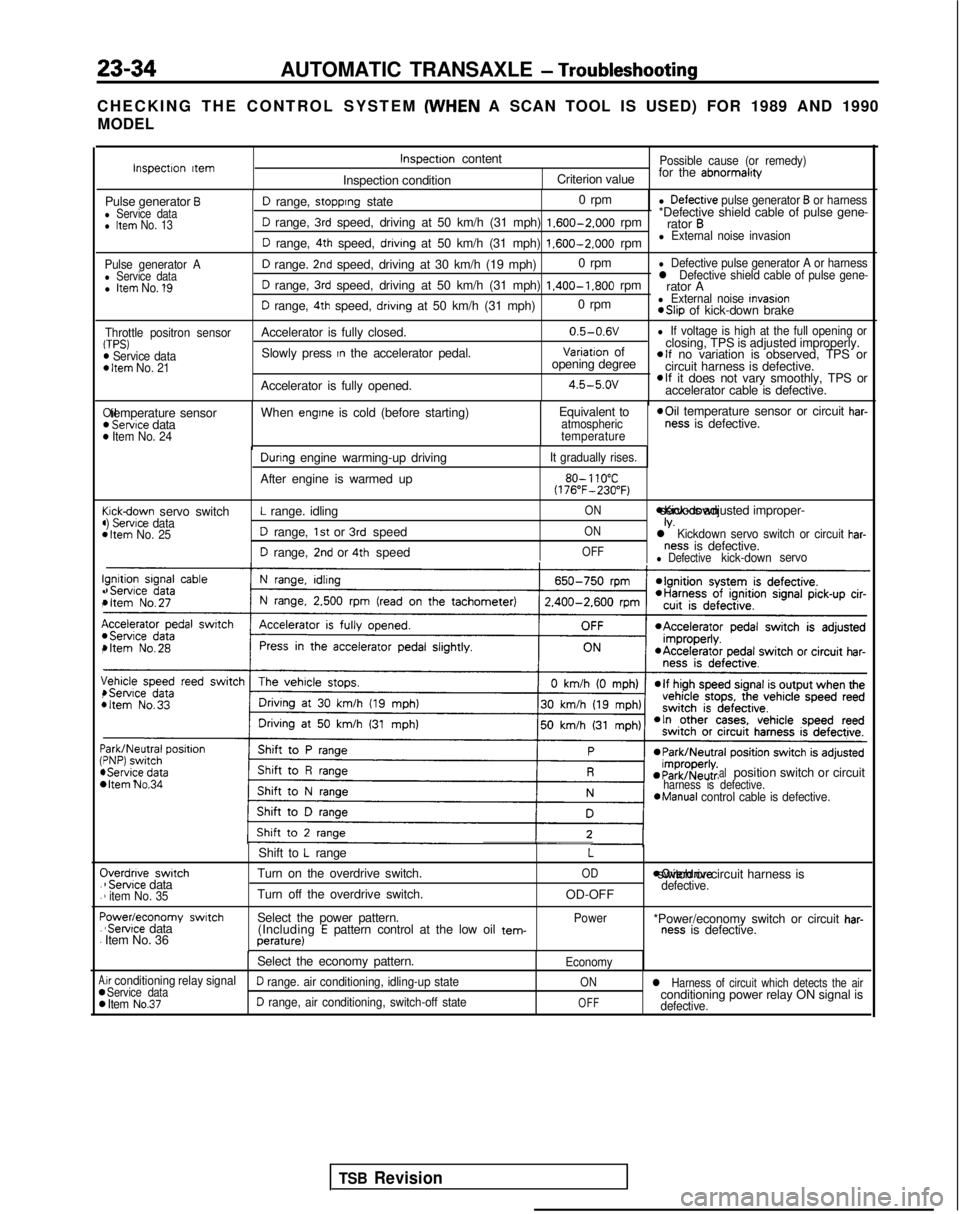

23-34AUTOMATIC TRANSAXLE - Troubleshooting

CHECKING THE CONTROL SYSTEM (WHEN

A SCAN TOOL IS USED) FOR 1989 AND 1990

MODEL

Pulse generator Al Service datal Item No. 1’9

Throttle positron sensorTPS)m Service dataD Item No. 21

I!(

(44

c44

I!.,

I(,

\,4

:44 C

.

.

F.

.

A00

D range, stopprng state 0 rpml Defectrve pulse generator B or harness

D range, 3rd speed, driving at 50 km/h (31 mph) 1.600-2.000

rpm*Defective shield cable of pulse gene-

rator B

D range, 4th speed, drivrng at 50 km/h (31 mph) 1.600-2.000

rpml External noise invasion

D range. 2nd speed, driving at 30 km/h (19 mph) 0 rpml Defective pulse generator A or harness

D range, 3rd speed, driving at 50 km/h (31 mph) 1.400-1.800

rpml Defective shield cable of pulse gene-rator A

D range, 4th speed, drivrng at 50 km/h (31 mph) 0 rpml External noise Invasion *Slip

of kick-down brake

Accelerator is fully closed. 0.5-0.6V

l If voltage is high at the full opening or

Slowly press In the accelerator pedal.Variatron of

closing, TPS is adjusted improperly.

opening degreeelf no variation is observed, TPS or

circuit harness is defective.

Accelerator is fully opened.

4.5-5.ovelf it does not vary smoothly, TPS or

accelerator cable is defective. Xl temperature sensor

) Servtce data) Item No. 24

When engtne is cold (before starting)

Equivalent toatmospheric

temperature *Oil

temperature sensor or circuit har-ness is defective.

cickdown servo switch) Servrce data1 Item No. 25

Durrng engine warming-up driving

After engine is warmed up

L range. idling

D range, 1st or 3rd speed

D range, 2nd or 4th speed

It gradually rises.

80- 110°C(176”F-230°F)

ON *Kick-down servo IS adjusted improper-

ONIV.l Kickdown servo switch or circuit har-

OFFness is defective.l Defectivekick-down

servo

bItem No.34 alposition switch or circuitharness is defective.*Manual

control cable is defective.

Iverdnve switch1 Servrce data1 item No. 35

‘owedeconomy swatch‘Servrce data

Item No. 36 Shift to

L range

Turn on the overdrive switch.

Turn off the overdrive switch.

Select the power pattern. (Including

E pattern control at the low oil tem-perature)

L

OD

OD-OFF

Power moverdrive switch or circuit harness is

defective.

*Power/economy switch or circuit har-ness is defective.

Select the economy pattern.

Economy

.ir conditioning relay signalService dataD range. air conditioning, idling-up stateONl Harness of circuit which detects the air

Item No.37D range, air conditioning, switch-off stateOFFconditioning power relay ON signal isdefective.

Inspectron ttemInspectron content

Inspection conditionPossible cause (or remedy)

Criterion value for the abnormalrty

Pulse generator Bl Service datal Item No. 13

TSB Revision