direction MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 198 of 788

Page 206 of 788

ON-VEHICLE SERVICE

REAR SUSPENSION34-6

If camber is not within the standard value, adjust by

following procedures.

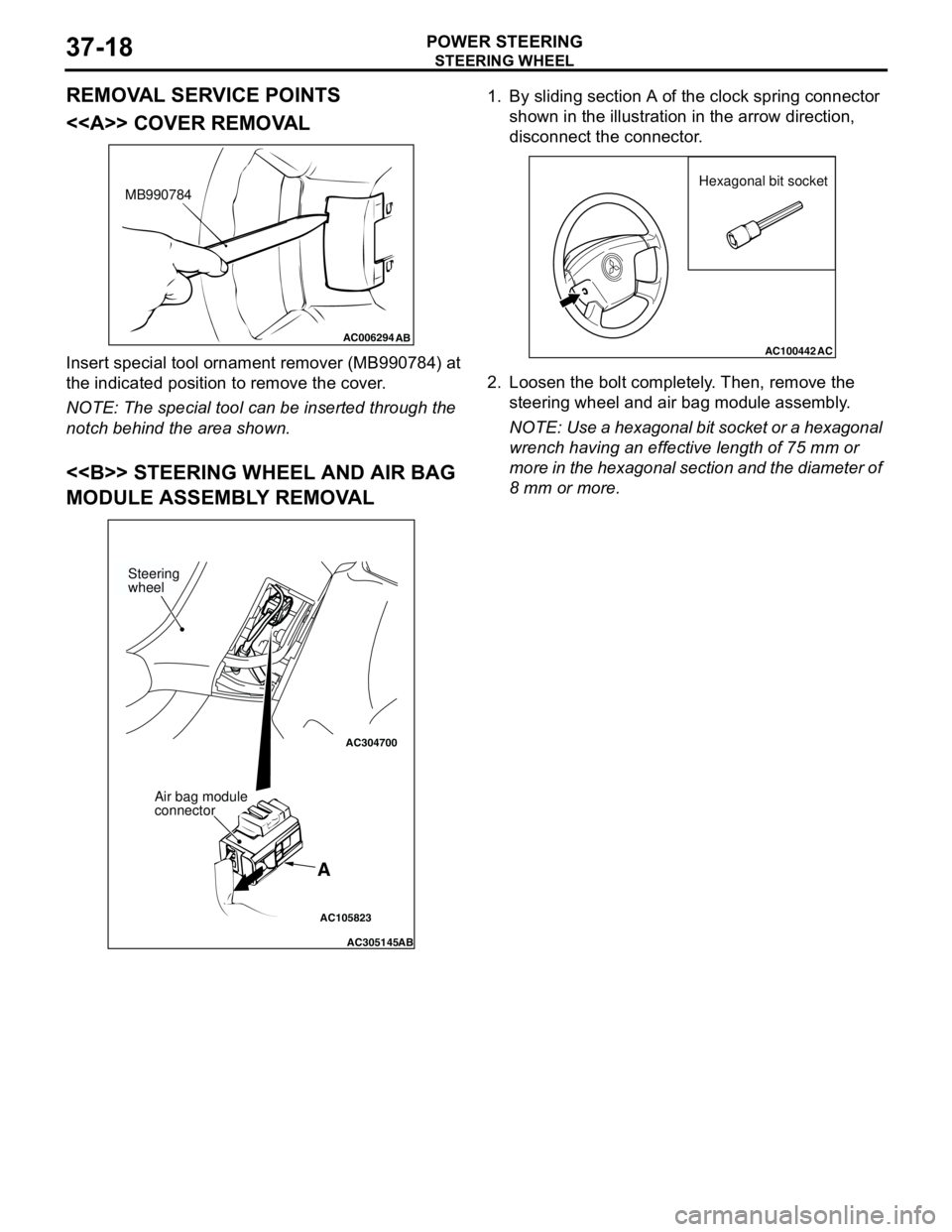

1. Disconnect the conjunction of the control link and

the trailing arm.

2. Carry out adjustment by turning the camber

adjusting bolt (lower arm assembly mounting bolt

which is located on the inner side of the body).

NOTE: .

•LH: Clockwise viewed from the front → (+)

camber

•RH: Clockwise viewed from the front → (-)

camber

•The scale has gradations of approximately 14'.

CAUTION

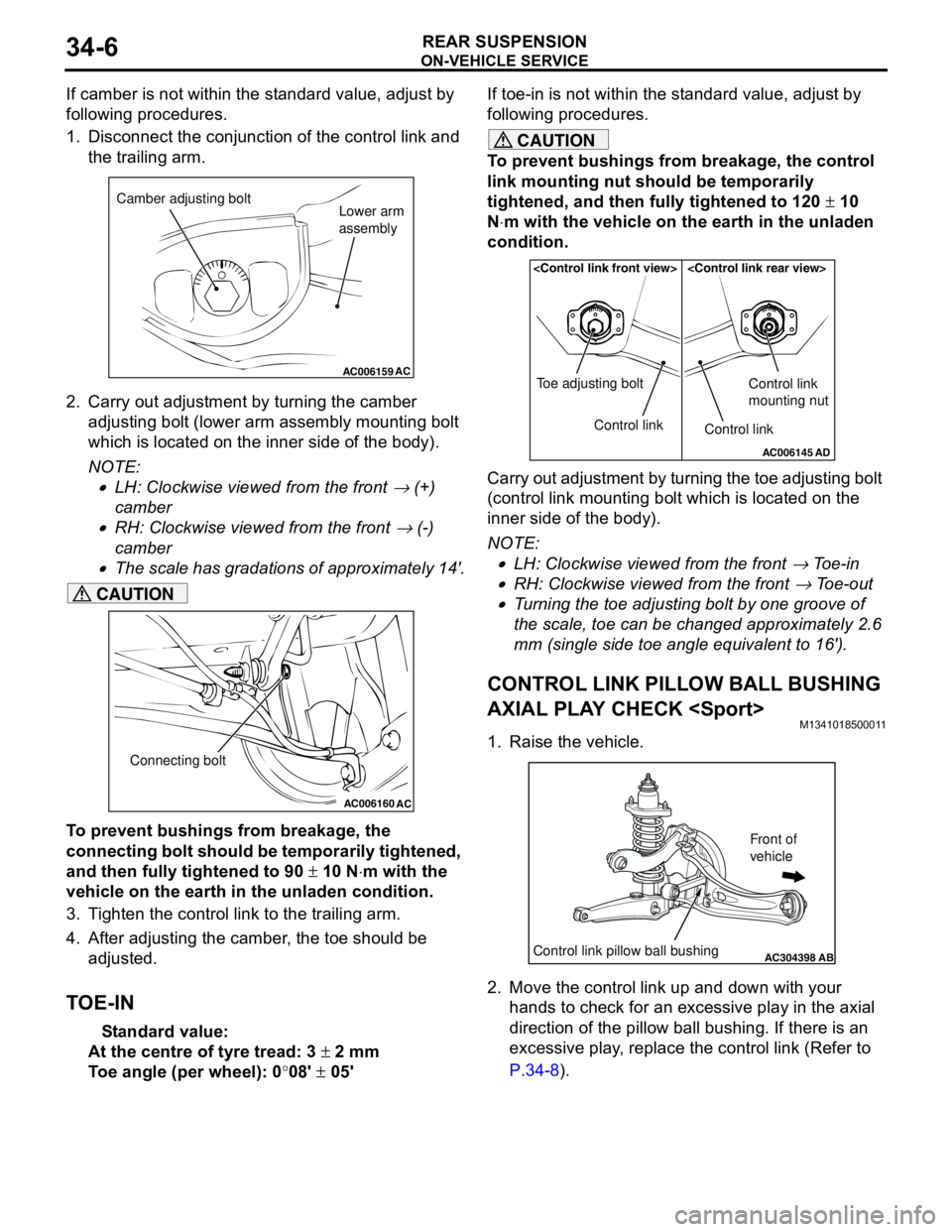

To prevent bushings from breakage, the

connecting bolt should be temporarily tightened,

and then fully tightened to 90 ± 10 N⋅m with the

vehicle on the earth in the unladen condition.

3. Tighten the control link to the trailing arm.

4. After adjusting the camber, the toe should be

adjusted.

TOE-IN

Standard value:

At the centre of tyre tread: 3 ± 2 mm

Toe angle (per wheel): 0°08' ± 05'If toe-in is not within the standard value, adjust by

following procedures.

CAUTION

To prevent bushings from breakage, the control

link mounting nut should be temporarily

tightened, and then fully tightened to 120 ± 10

N⋅m with the vehicle on the earth in the unladen

condition.

Carry out adjustment by turning the toe adjusting bolt

(control link mounting bolt which is located on the

inner side of the body).

NOTE: .

•LH: Clockwise viewed from the front → Toe-in

•RH: Clockwise viewed from the front → Toe-out

•Turning the toe adjusting bolt by one groove of

the scale, toe can be changed approximately 2.6

mm (single side toe angle equivalent to 16').

CONTROL LINK PILLOW BALL BUSHING

AXIAL PLAY CHECK

M1341018500011

1. Raise the vehicle.

2. Move the control link up and down with your

hands to check for an excessive play in the axial

direction of the pillow ball bushing. If there is an

excessive play, replace the control link (Refer to

P.34-8).

AC006159AC

Camber adjusting bolt

Lower arm

assembly

AC006160

AC

Connecting bolt

AC006145AD

Control link Toe adjusting boltControl link

Control link

mounting nut

AC304398ABControl link pillow ball bushing

Front of

vehicle

Page 207 of 788

ON-VEHICLE SERVICE

REAR SUSPENSION34-7

UPPER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

M1341018400014

1. Raise the vehicle.

2. Move the upper arm up and down with your hands

to check for an excessive play in the axial

direction of the pillow ball bushing. If there is an

excessive play, replace the upper arm (Refer to

P.34-8).

LOWER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

M1341016900057

1. Raise the vehicle.

2. Remove the stabilizer link and shock absorber

from the lower arm assembly.3. Move the lower arm up and down with your hands

to check for an excessive play in the axial

direction of the pillow ball bushing. If there is an

excessive play, replace the lower arm pillow ball

bushing (Refer to P.34-10).

4. After inspection, install the stabilizer link and

shock absorber to the lower arm assembly (Refer

to P.34-8).

STABILIZER LINK BALL JOINT DUST

COVER INSPECTION

M1341012800274

1. Check stabilizer link ball joint dust covers for

cracks or damage by pushing it with your finger.

2. If a dust cover is cracked or damaged, replace the

stabilizer link assembly.

NOTE: Cracks or damage to the dust cover may

cause damage to the ball joint.

AC304398AC

Upper arm pillow

ball bushing

Front of

vehicle

AC304398ADLower arm pillow ball bushing

Front of

vehicle

Page 210 of 788

CONTROL LINK, UPPER ARM AND LOWER ARM

REAR SUSPENSION34-10

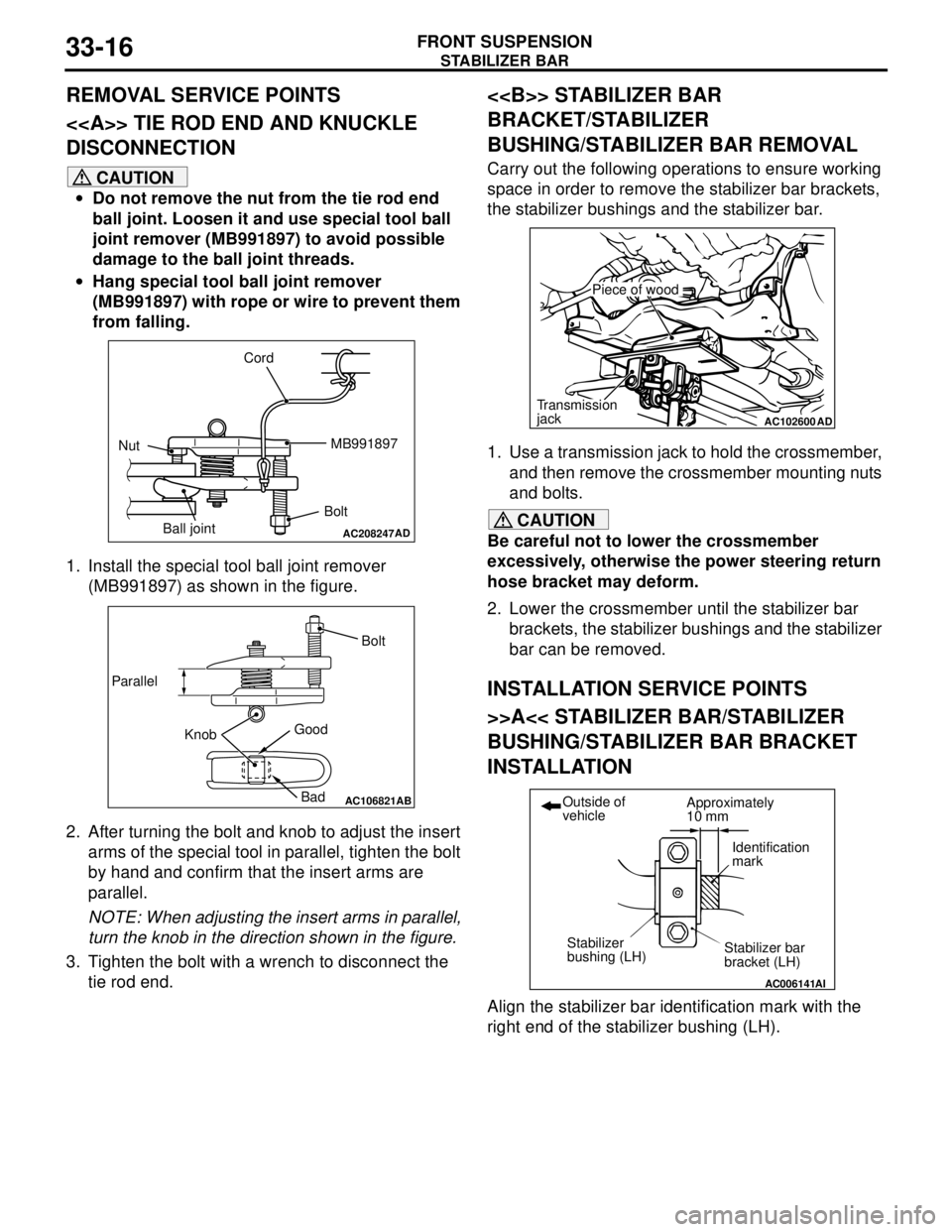

CONTROL LINK

BUSHING ROTATION STARTING TORQUE

CHECK

Check each pillow ball bushing as follows.

1. Insert the mounting bolt to the pillow ball bushing.

In the opposite direction, insert a washer, then

install the mounting nut.

2. After rotating the inner sleeve (contained washer)

several times, measure the rotation starting

torque of the pillow ball bushing using special tool

preload socket (MB990326).

Standard value: 0.5 − 3.0 N⋅m

3. If the measured value exceeds the standard

value, replace the control link, the upper arm, or

the lower arm pillow ball bushing.

4. If the measured value is lower than the standard

value, check that the pillow ball bushing turns

smoothly without excessive play. If there is no

excessive play and it turns smoothly, the pillow

ball bushing can be reused.

LOWER ARM BUSHING AND LOWER

ARM PILLOW BALL BUSHING

REPLACEMENT

M1341011800204

Replace the lower arm bushing and lower arm pillow

ball bushing as follows.

LOWER ARM BUSHING REPLACEMENT

CAUTION

Because the outside diameter of both edges of

the bushing are different, be careful not to

mistake the direction.

Use following special tools to drive out and press fit

the bushing.

•MB991447: Bushing Remover and Installer

•MB991448: Bushing Remover and Installer Base

•MB991449: Bushing Remover and Installer

Supporter

After press fitting, the space between the edges of

the bushing outer sleeve and of the lower arm should

be 1.5 mm.

AC107127AD

Lower arm pillow ball bushing Upper arm pillow ball bushing

AC102498

AC

MB990326

AC304399AB

Lower arm bushingLower arm pillow

ball bushing

Lower arm bushing

AC006168

AC

Driving Out

MB991447

Lower arm

MB991448MB991449

AC006169

AC

1.5 mm Press-Fitting

MB991447

Lower arm

MB991448MB991449

Page 214 of 788

TRAILING ARM ASSEMBLY

REAR SUSPENSION34-14

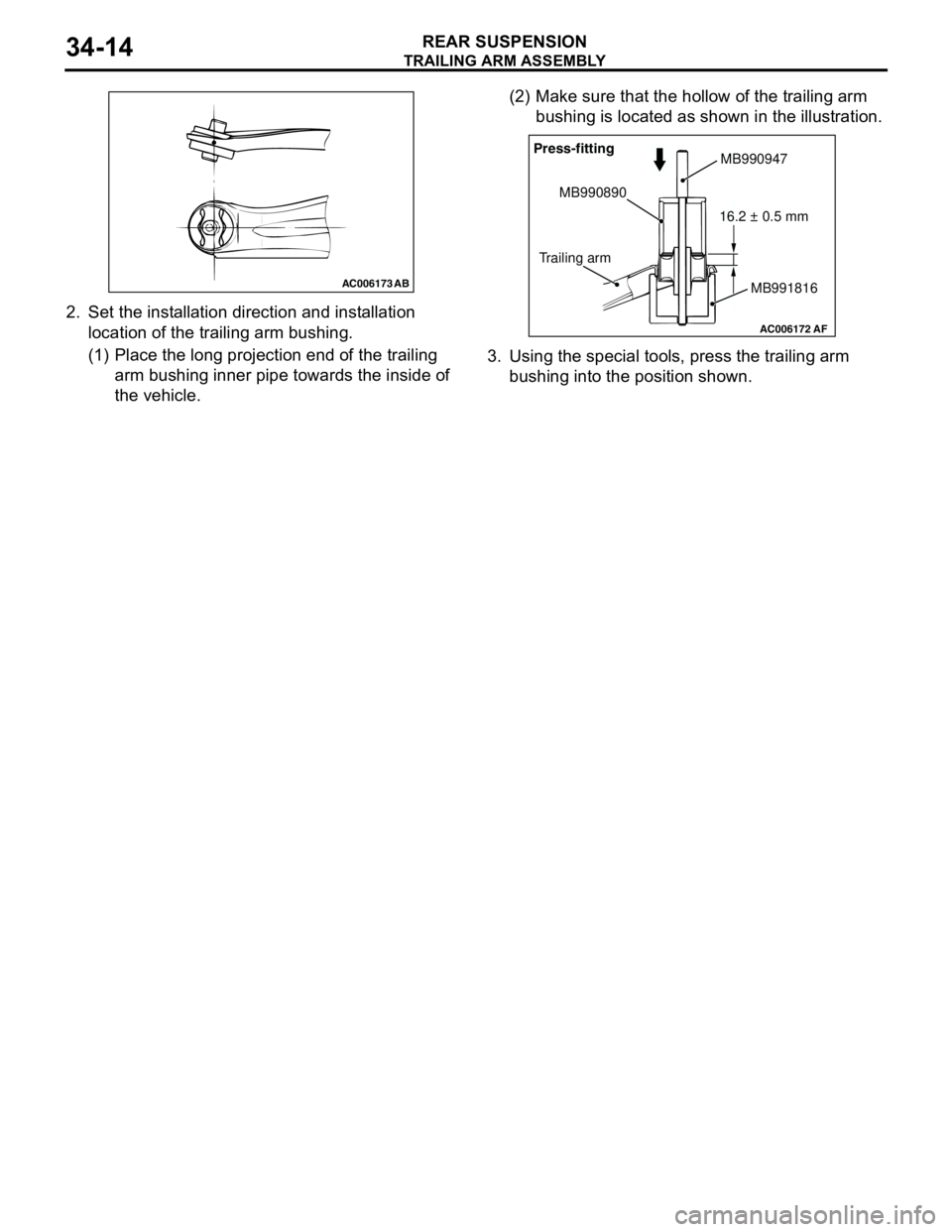

2. Set the installation direction and installation

location of the trailing arm bushing.

(1) Place the long projection end of the trailing

arm bushing inner pipe towards the inside of

the vehicle.(2) Make sure that the hollow of the trailing arm

bushing is located as shown in the illustration.

3. Using the special tools, press the trailing arm

bushing into the position shown.

AC006173 AB

AC006172AF

Press-fitting

MB990890

Trailing armMB990947

MB991816 16.2 ± 0.5 mm

Page 227 of 788

LUBRICANTS

PARKING BRAKES36-3

LUBRICANTS

M1361000400293

ON-VEHICLE SERVICE

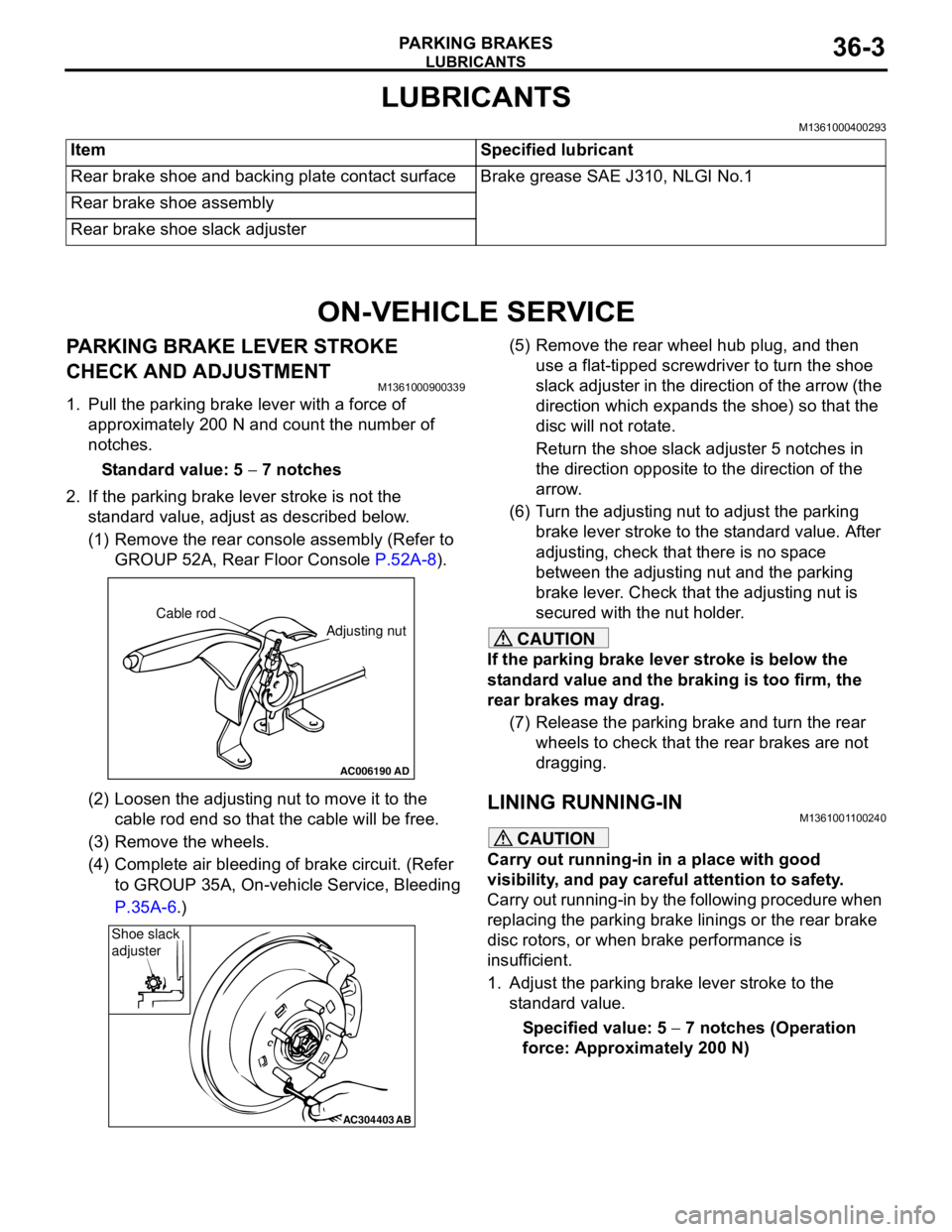

PARKING BRAKE LEVER STROKE

CHECK AND ADJUSTMENT

M1361000900339

1. Pull the parking brake lever with a force of

approximately 200 N and count the number of

notches.

Standard value: 5 − 7 notches

2. If the parking brake lever stroke is not the

standard value, adjust as described below.

(1) Remove the rear console assembly (Refer to

GROUP 52A, Rear Floor Console P.52A-8).

(2) Loosen the adjusting nut to move it to the

cable rod end so that the cable will be free.

(3) Remove the wheels.

(4) Complete air bleeding of brake circuit. (Refer

to GROUP 35A, On-vehicle Service, Bleeding

P.35A-6.)(5) Remove the rear wheel hub plug, and then

use a flat-tipped screwdriver to turn the shoe

slack adjuster in the direction of the arrow (the

direction which expands the shoe) so that the

disc will not rotate.

Return the shoe slack adjuster 5 notches in

the direction opposite to the direction of the

arrow.

(6) Turn the adjusting nut to adjust the parking

brake lever stroke to the standard value. After

adjusting, check that there is no space

between the adjusting nut and the parking

brake lever. Check that the adjusting nut is

secured with the nut holder.

CAUTION

If the parking brake lever stroke is below the

standard value and the braking is too firm, the

rear brakes may drag.

(7) Release the parking brake and turn the rear

wheels to check that the rear brakes are not

dragging.

LINING RUNNING-INM1361001100240

CAUTION

Carry out running-in in a place with good

visibility, and pay careful attention to safety.

Carry out running-in by the following procedure when

replacing the parking brake linings or the rear brake

disc rotors, or when brake performance is

insufficient.

1. Adjust the parking brake lever stroke to the

standard value.

Specified value: 5 − 7 notches (Operation

force: Approximately 200 N) Item Specified lubricant

Rear brake shoe and backing plate contact surface Brake grease SAE J310, NLGI No.1

Rear brake shoe assembly

Rear brake shoe slack adjuster

AC006190

Cable rod

Adjusting nut

AD

AC304403AB

Shoe slack

adjuster

Page 228 of 788

ON-VEHICLE SERVICE

PARKING BRAKES36-4

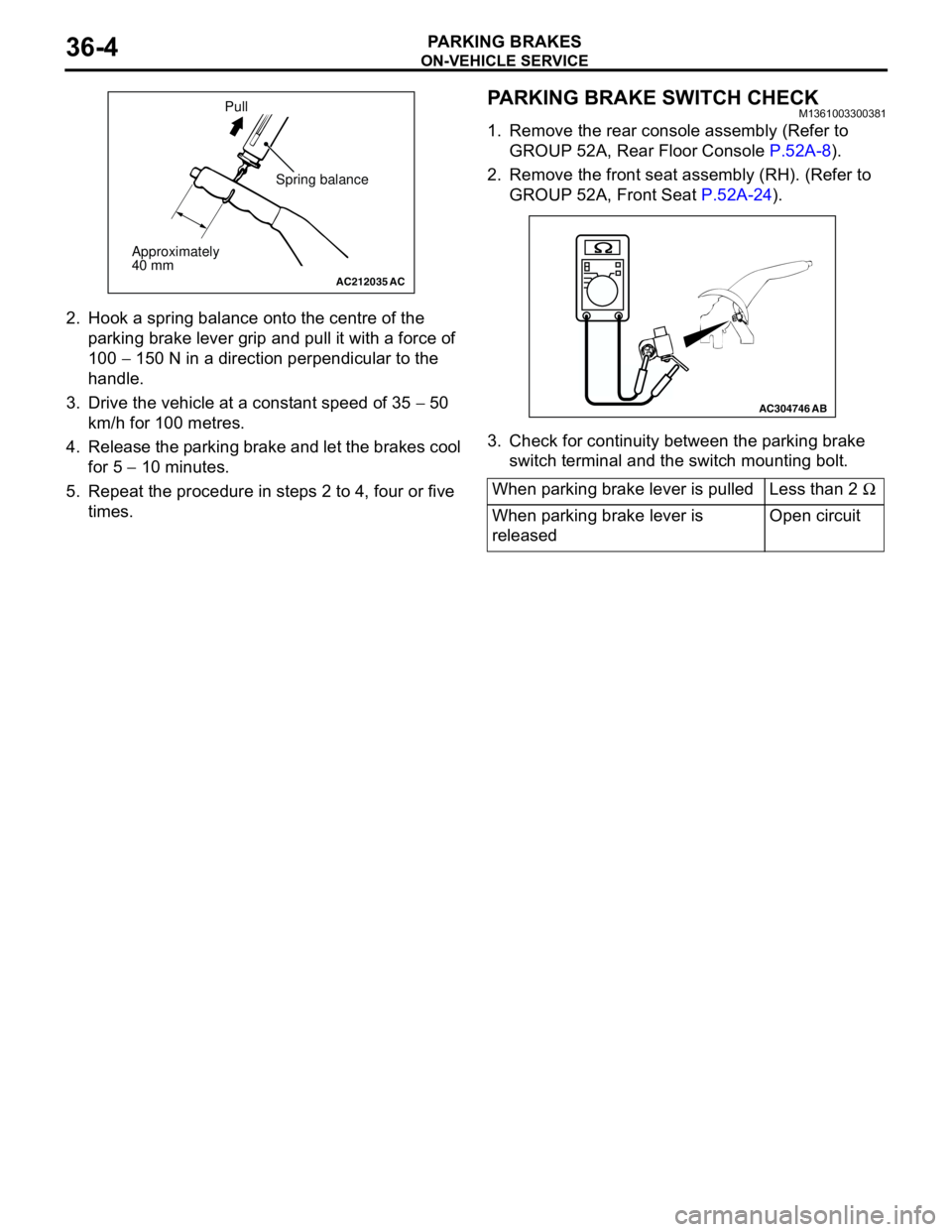

2. Hook a spring balance onto the centre of the

parking brake lever grip and pull it with a force of

100 − 150 N in a direction perpendicular to the

handle.

3. Drive the vehicle at a constant speed of 35 − 50

km/h for 100 metres.

4. Release the parking brake and let the brakes cool

for 5 − 10 minutes.

5. Repeat the procedure in steps 2 to 4, four or five

times.

PARKING BRAKE SWITCH CHECKM1361003300381

1. Remove the rear console assembly (Refer to

GROUP 52A, Rear Floor Console P.52A-8).

2. Remove the front seat assembly (RH). (Refer to

GROUP 52A, Front Seat P.52A-24).

3. Check for continuity between the parking brake

switch terminal and the switch mounting bolt.

AC212035AC

Spring balance

Approximately

40 mmPull

When parking brake lever is pulled Less than 2 Ω

When parking brake lever is

releasedOpen circuit

AC304746AB

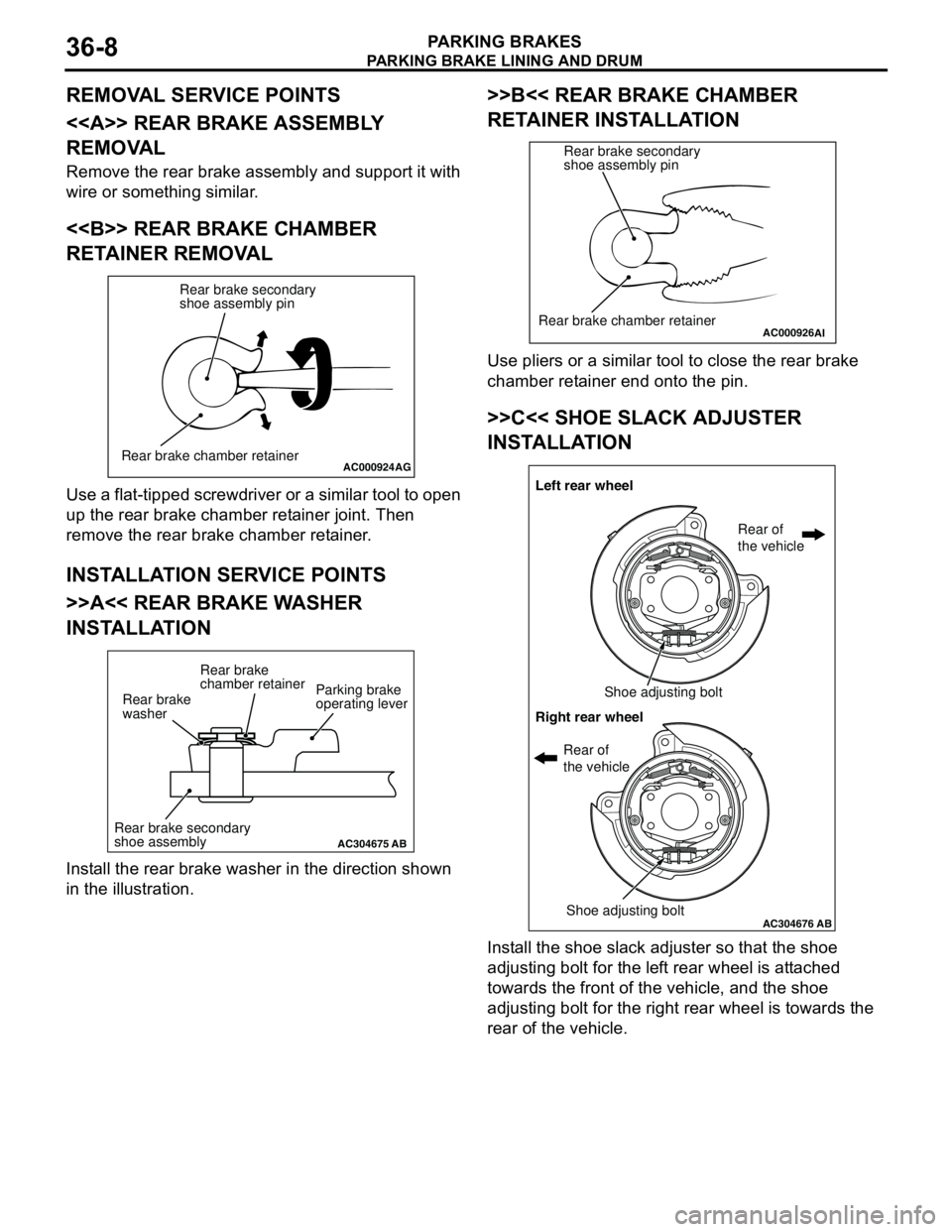

Page 232 of 788

Page 245 of 788

ON-VEHICLE SERVICE

POWER STEERING37-11

ON-VEHICLE SERVICE

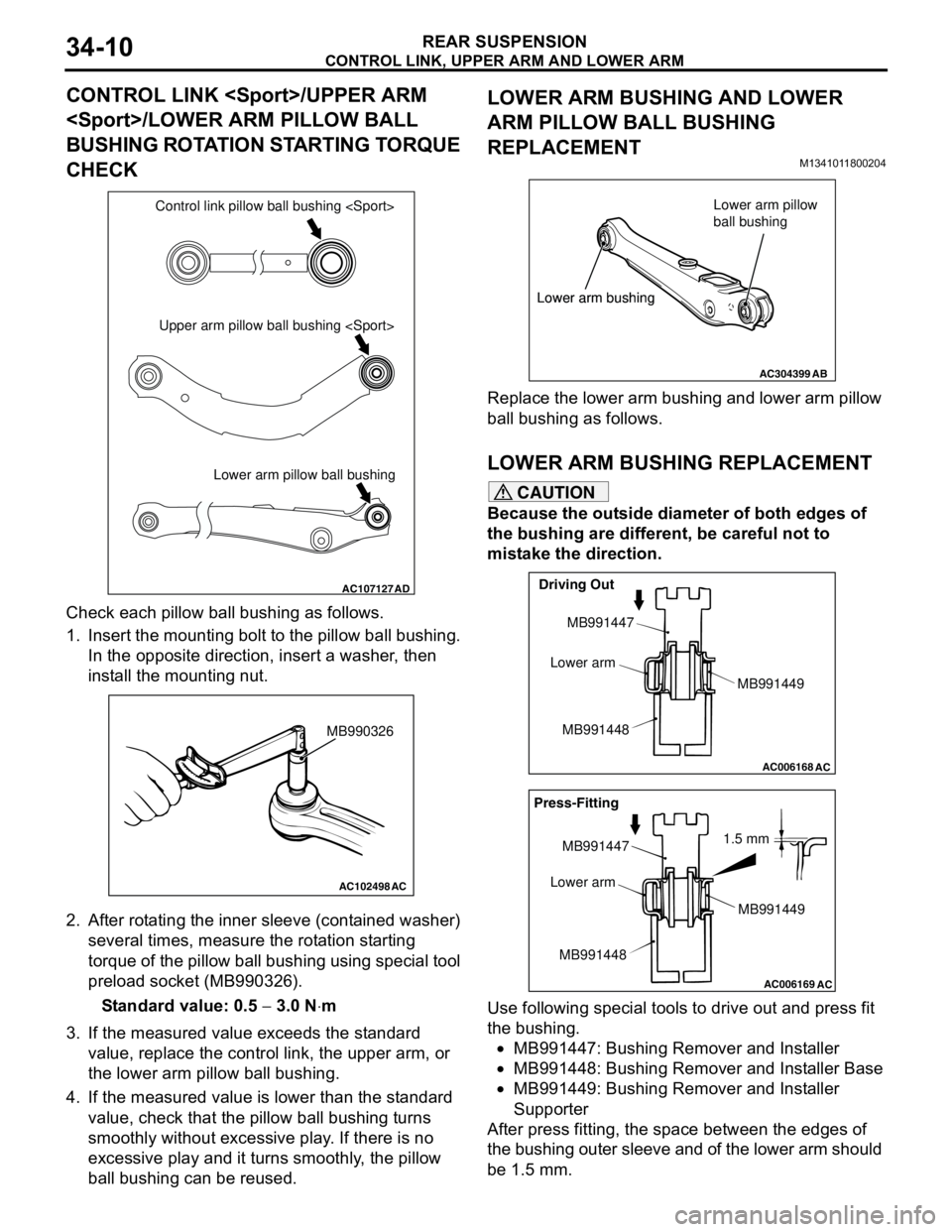

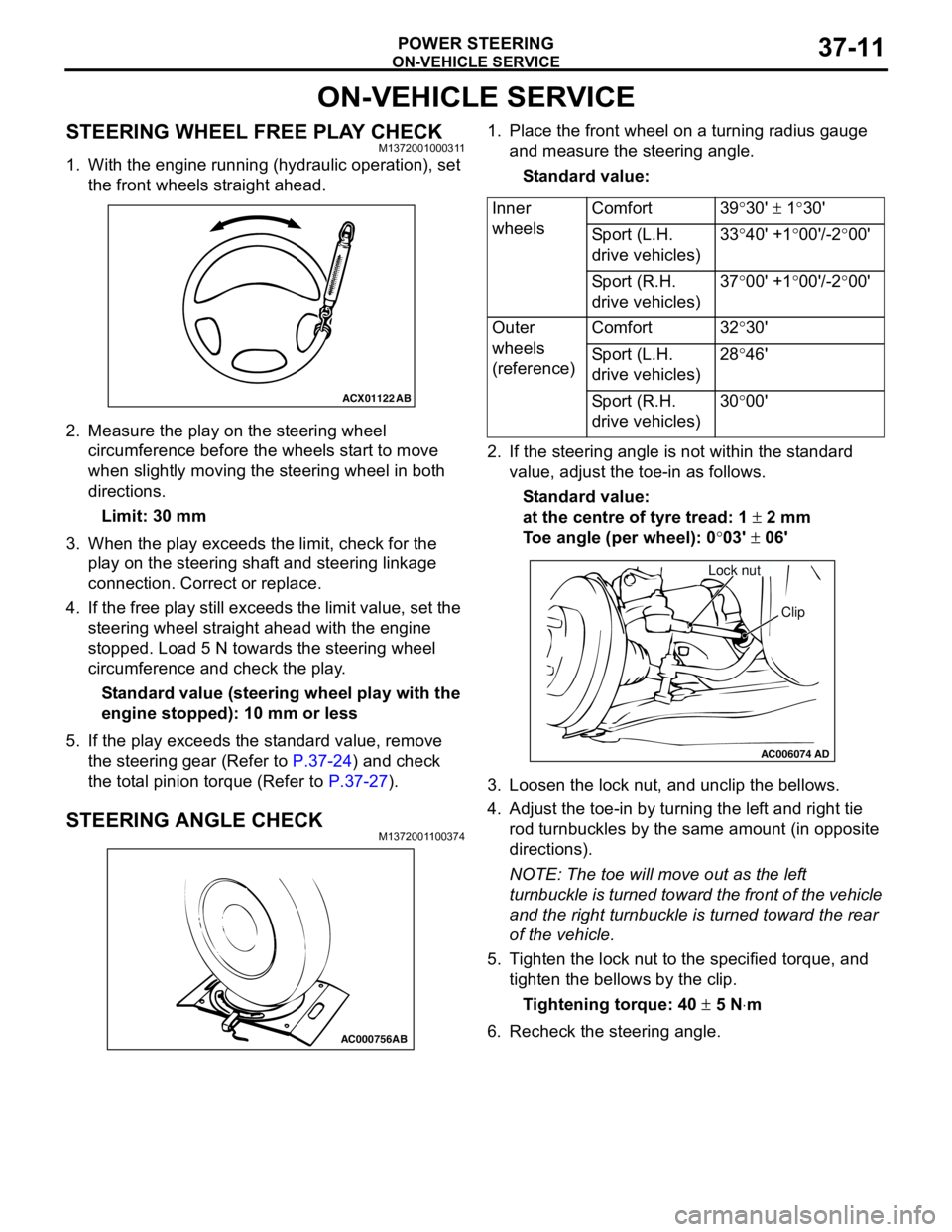

STEERING WHEEL FREE PLAY CHECKM1372001000311

1. With the engine running (hydraulic operation), set

the front wheels straight ahead.

2. Measure the play on the steering wheel

circumference before the wheels start to move

when slightly moving the steering wheel in both

directions.

Limit: 30 mm

3. When the play exceeds the limit, check for the

play on the steering shaft and steering linkage

connection. Correct or replace.

4. If the free play still exceeds the limit value, set the

steering wheel straight ahead with the engine

stopped. Load 5 N towards the steering wheel

circumference and check the play.

Standard value (steering wheel play with the

engine stopped): 10 mm or less

5. If the play exceeds the standard value, remove

the steering gear (Refer to P.37-24) and check

the total pinion torque (Refer to P.37-27).

STEERING ANGLE CHECKM1372001100374

1. Place the front wheel on a turning radius gauge

and measure the steering angle.

Standard value:

2. If the steering angle is not within the standard

value, adjust the toe-in as follows.

Standard value:

at the centre of tyre tread: 1 ± 2 mm

Toe angle (per wheel): 0°03' ± 06'

3. Loosen the lock nut, and unclip the bellows.

4. Adjust the toe-in by turning the left and right tie

rod turnbuckles by the same amount (in opposite

directions).

NOTE: The toe will move out as the left

turnbuckle is turned toward the front of the vehicle

and the right turnbuckle is turned toward the rear

of the vehicle.

5. Tighten the lock nut to the specified torque, and

tighten the bellows by the clip.

Tightening torque: 40 ± 5 N⋅m

6. Recheck the steering angle.

ACX01122

AB

AC000756AB

Inner

wheelsComfort 39°30' ± 1°30'

Sport (L.H.

drive vehicles)33°40' +1°00'/-2°00'

Sport (R.H.

drive vehicles)37°00' +1°00'/-2°00'

Outer

wheels

(reference)Comfort 32°30'

Sport (L.H.

drive vehicles)28°46'

Sport (R.H.

drive vehicles)30°00'

AC006074AD

Lock nut

Clip

Page 252 of 788