MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1131 of 1449

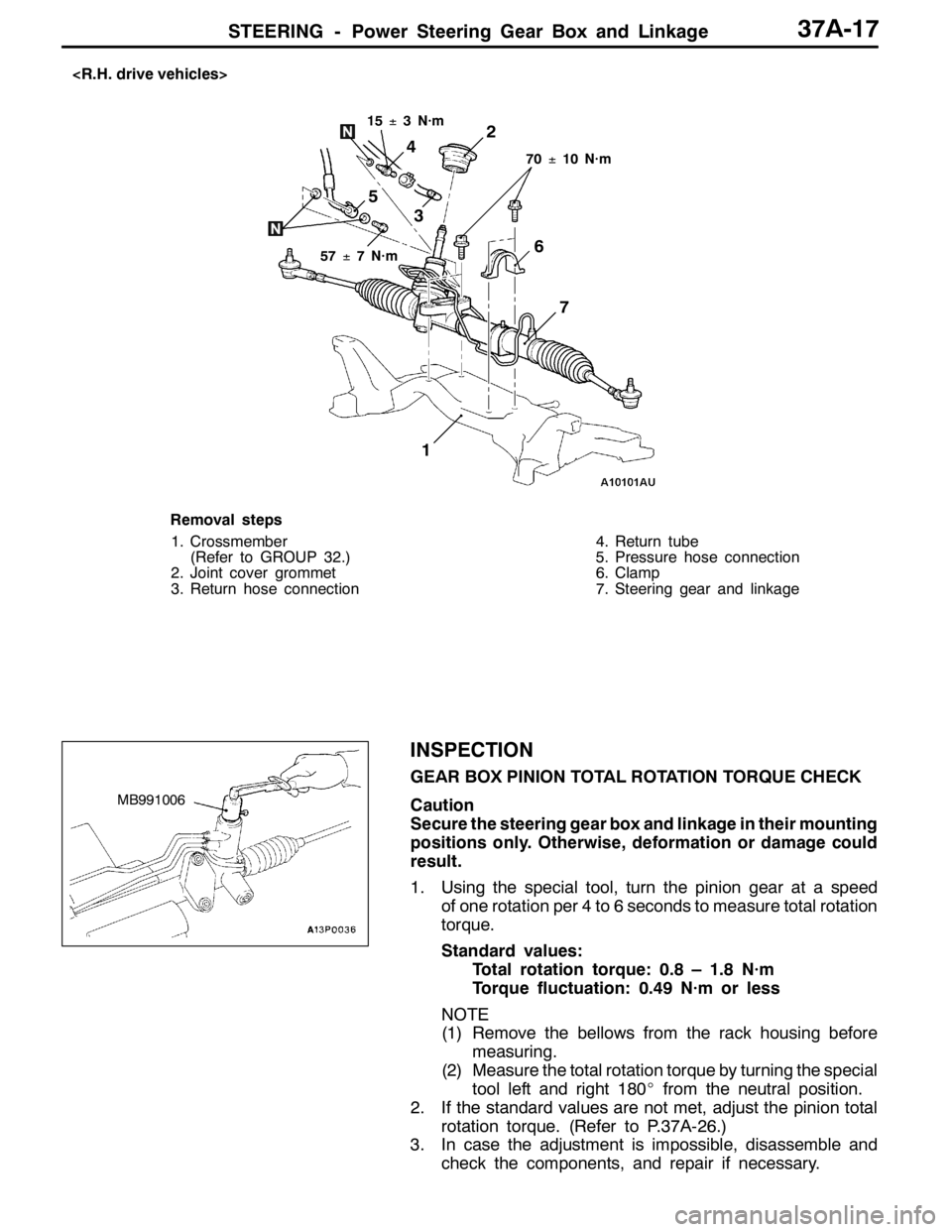

STEERING - Power Steering Gear Box and Linkage37A-17

17 6 2

3 4

15±3 N·m

57±7 N·m

5

70±10 N·m

Removal steps

1. Crossmember

(Refer to GROUP 32.)

2. Joint cover grommet

3. Return hose connection4. Return tube

5. Pressure hose connection

6. Clamp

7. Steering gear and linkage

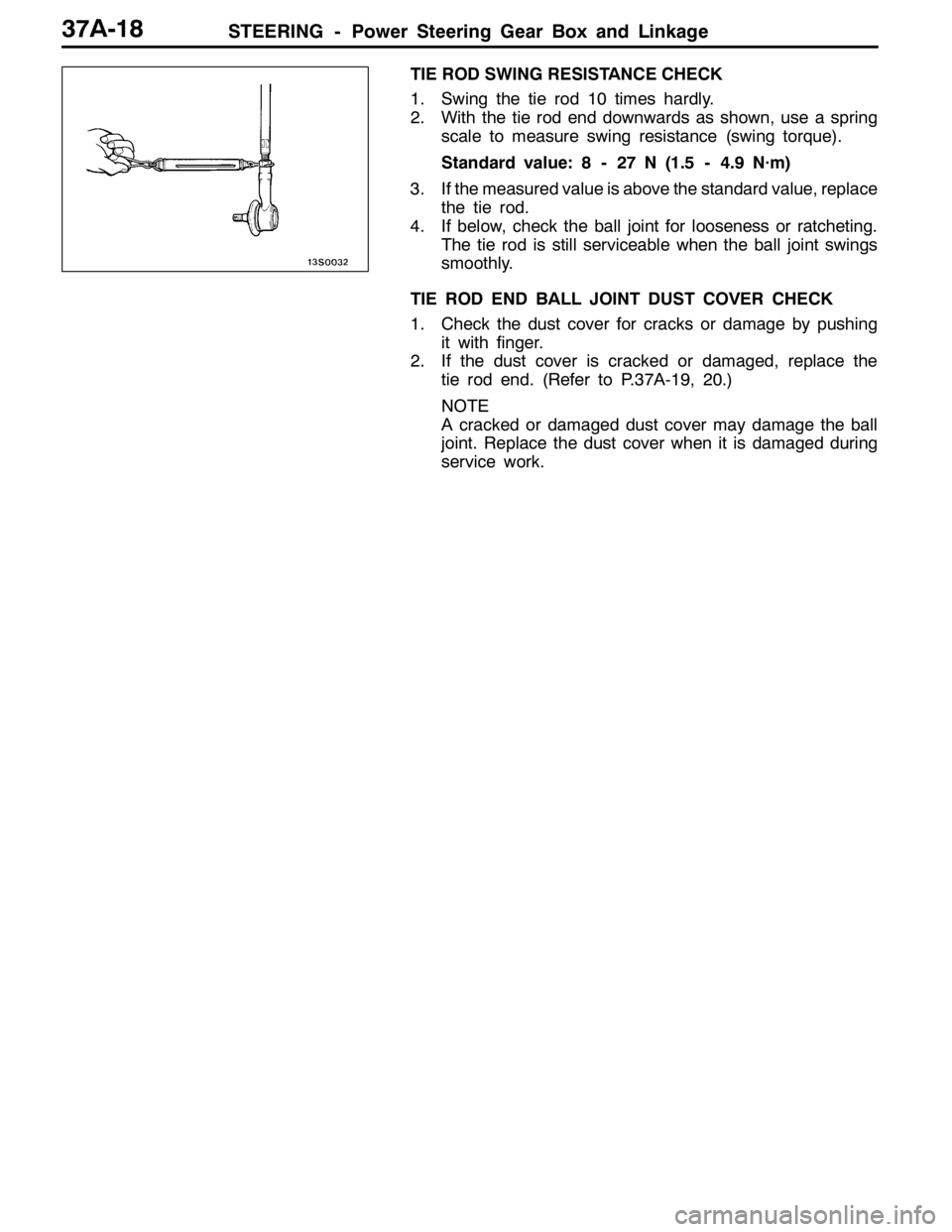

INSPECTION

GEAR BOX PINION TOTAL ROTATION TORQUE CHECK

Caution

Secure the steering gear box and linkage in their mounting

positions only. Otherwise, deformation or damage could

result.

1. Using the special tool, turn the pinion gear at a speed

of one rotation per 4 to 6 seconds to measure total rotation

torque.

Standard values:

Total rotation torque: 0.8 – 1.8 N·m

Torque fluctuation: 0.49 N·m or less

NOTE

(1) Remove the bellows from the rack housing before

measuring.

(2) Measure the total rotation torque by turning the special

tool left and right 180_from the neutral position.

2. If the standard values are not met, adjust the pinion total

rotation torque. (Refer to P.37A-26.)

3. In case the adjustment is impossible, disassemble and

check the components, and repair if necessary.

MB991006

Page 1132 of 1449

STEERING - Power Steering Gear Box and Linkage37A-18

TIE ROD SWING RESISTANCE CHECK

1. Swing the tie rod 10 times hardly.

2. With the tie rod end downwards as shown, use a spring

scale to measure swing resistance (swing torque).

Standard value: 8 - 27 N (1.5 - 4.9 N·m)

3. If the measured value is above the standard value, replace

the tie rod.

4. If below, check the ball joint for looseness or ratcheting.

The tie rod is still serviceable when the ball joint swings

smoothly.

TIE ROD END BALL JOINT DUST COVER CHECK

1. Check the dust cover for cracks or damage by pushing

it with finger.

2. If the dust cover is cracked or damaged, replace the

tie rod end. (Refer to P.37A-19, 20.)

NOTE

A cracked or damaged dust cover may damage the ball

joint. Replace the dust cover when it is damaged during

service work.

Page 1133 of 1449

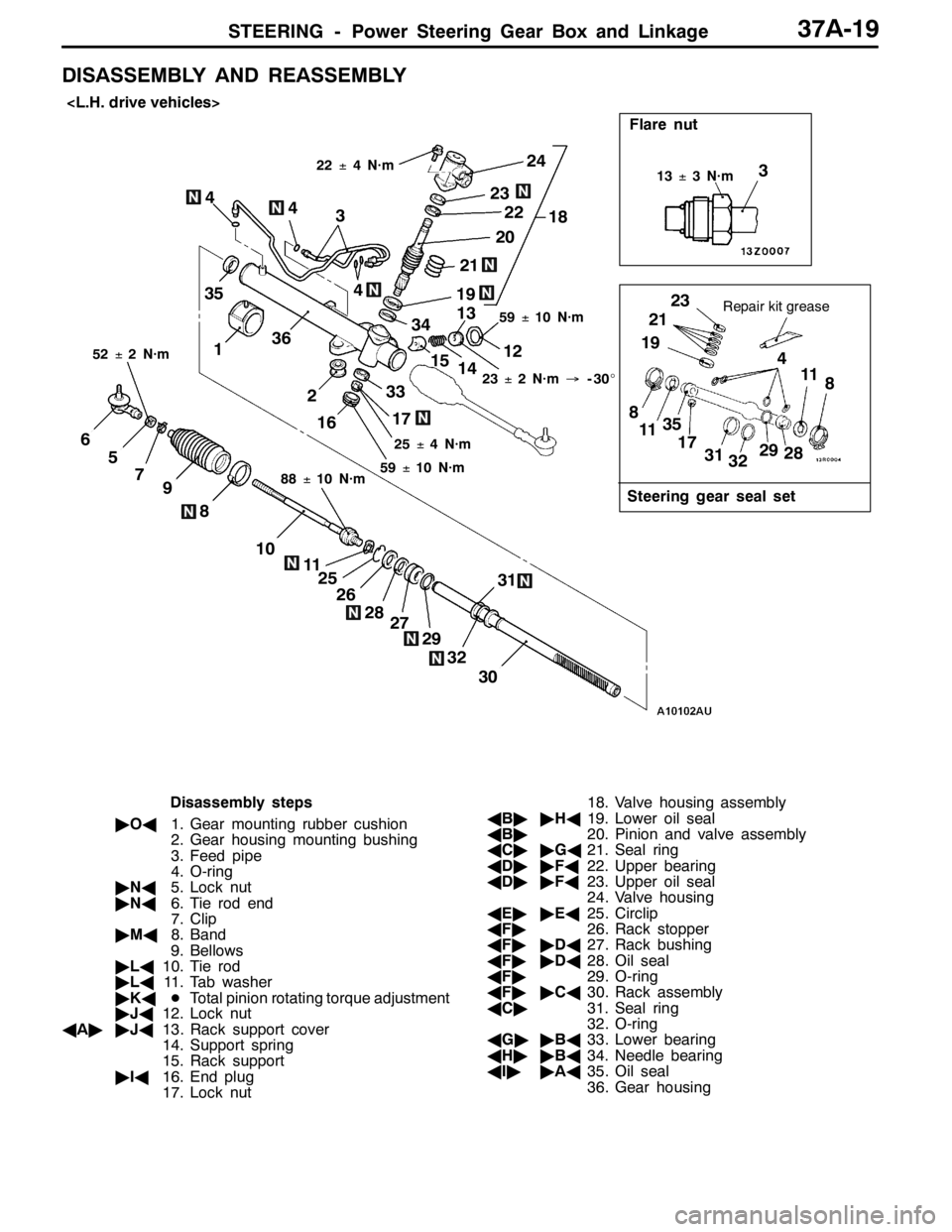

STEERING - Power Steering Gear Box and Linkage37A-19

DISASSEMBLY AND REASSEMBLY

31

30

28

11

10

8

97

5

6

29

2618

33

22

20

Flare nut

21

23

36

32 17

1615

14 13

12 3

19

Steering gear seal set

Repair kit grease35

23

21

19

8

1135

17

32 3129

2811

8 3

4 4

27 25

22±4 N·m

25±4 N·m59±10 N·m

88±10 N·m 52±2 N·m

13±3 N·m

1

2 4

23±2 N·m→-30_

59±10 N·m

34

24

4

Disassembly steps

"OA1. Gear mounting rubber cushion

2. Gear housing mounting bushing

3. Feed pipe

4. O-ring

"NA5. Lock nut

"NA6. Tie rod end

7. Clip

"MA8. Band

9. Bellows

"LA10. Tie rod

"LA11. Tab washer

"KADTotal pinion rotating torque adjustment

"JA12. Lock nut

AA""JA13. Rack support cover

14. Support spring

15. Rack support

"IA16. End plug

17. Lock nut18. Valve housing assembly

AB""HA19. Lower oil seal

AB"20. Pinion and valve assembly

AC""GA21. Seal ring

AD""FA22. Upper bearing

AD""FA23. Upper oil seal

24. Valve housing

AE""EA25. Circlip

AF"26. Rack stopper

AF""DA27. Rack bushing

AF""DA28. Oil seal

AF"29. O-ring

AF""CA30. Rack assembly

AC"31. Seal ring

32. O-ring

AG""BA33. Lower bearing

AH""BA34. Needle bearing

AI""AA35. Oil seal

36. Gear housing

Page 1134 of 1449

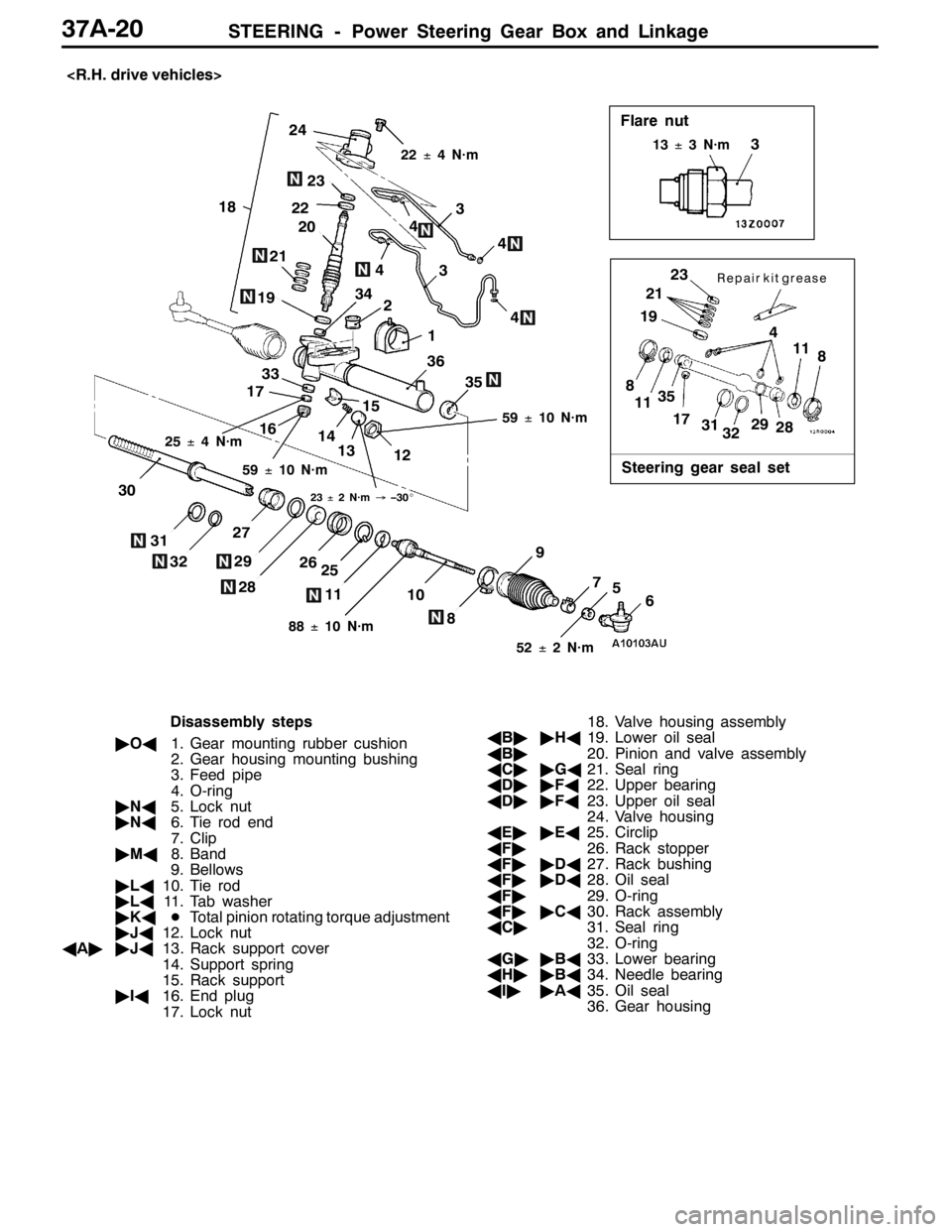

STEERING - Power Steering Gear Box and Linkage37A-20

18

24

23

22

21

20

34

36

33

17

1615

14

13

123

19

3523

21

19

8

1135

17

31

3229

2811

8

3

4 4

31

32

27

29

28

26

25

1110

8

9

756

304

22±4 N·m

25±4 N·m

59±10 N·m

59±10 N·m

88±10 N·m

52±2 N·m

23±2 N·m→–30_

13±3 N·m

1 2

4

Flare nut

Steering gear seal set

Repair kit grease3

4

Disassembly steps

"OA1. Gear mounting rubber cushion

2. Gear housing mounting bushing

3. Feed pipe

4. O-ring

"NA5. Lock nut

"NA6. Tie rod end

7. Clip

"MA8. Band

9. Bellows

"LA10. Tie rod

"LA11. Tab washer

"KADTotal pinion rotating torque adjustment

"JA12. Lock nut

AA""JA13. Rack support cover

14. Support spring

15. Rack support

"IA16. End plug

17. Lock nut18. Valve housing assembly

AB""HA19. Lower oil seal

AB"20. Pinion and valve assembly

AC""GA21. Seal ring

AD""FA22. Upper bearing

AD""FA23. Upper oil seal

24. Valve housing

AE""EA25. Circlip

AF"26. Rack stopper

AF""DA27. Rack bushing

AF""DA28. Oil seal

AF"29. O-ring

AF""CA30. Rack assembly

AC"31. Seal ring

32. O-ring

AG""BA33. Lower bearing

AH""BA34. Needle bearing

AI""AA35. Oil seal

36. Gear housing

Page 1135 of 1449

STEERING - Power Steering Gear Box and Linkage37A-21

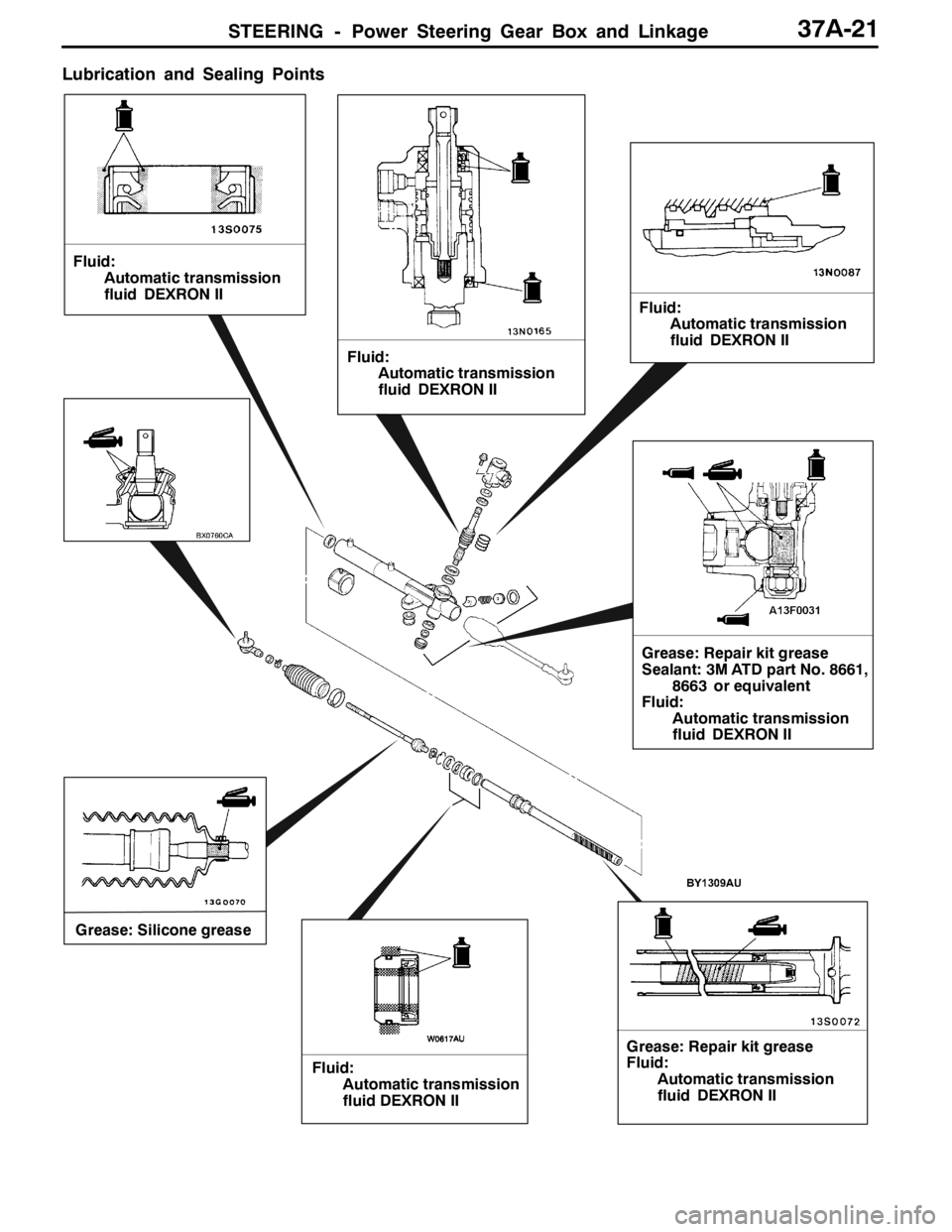

Lubrication and Sealing Points

Fluid:

Automatic transmission

fluid DEXRON II

Fluid:

Automatic transmission

fluid DEXRON II

Fluid:

Automatic transmission

fluid DEXRON II

Fluid:

Automatic transmission

fluid DEXRON II

Grease: Repair kit grease

Sealant: 3M ATD part No. 8661,

8663 or equivalent

Fluid:

Automatic transmission

fluid DEXRON II

Grease: Repair kit grease

Fluid:

Automatic transmission

fluid DEXRON II

Grease: Silicone grease

Page 1136 of 1449

STEERING - Power Steering Gear Box and Linkage37A-22

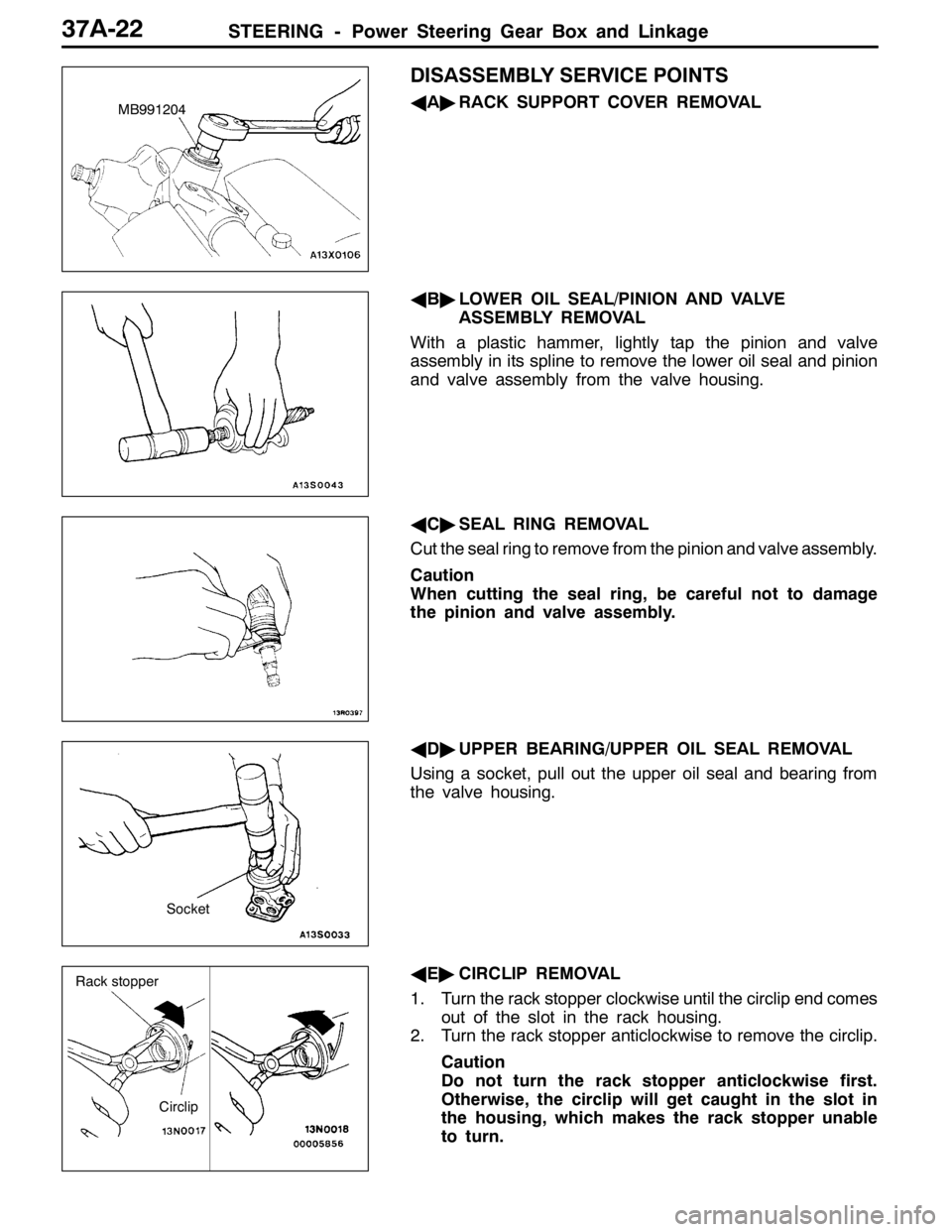

DISASSEMBLY SERVICE POINTS

AA"RACK SUPPORT COVER REMOVAL

AB"LOWER OIL SEAL/PINION AND VALVE

ASSEMBLY REMOVAL

With a plastic hammer, lightly tap the pinion and valve

assembly in its spline to remove the lower oil seal and pinion

and valve assembly from the valve housing.

AC"SEAL RING REMOVAL

Cut the seal ring to remove from the pinion and valve assembly.

Caution

When cutting the seal ring, be careful not to damage

the pinion and valve assembly.

AD"UPPER BEARING/UPPER OIL SEAL REMOVAL

Using a socket, pull out the upper oil seal and bearing from

the valve housing.

AE"CIRCLIP REMOVAL

1. Turn the rack stopper clockwise until the circlip end comes

out of the slot in the rack housing.

2. Turn the rack stopper anticlockwise to remove the circlip.

Caution

Do not turn the rack stopper anticlockwise first.

Otherwise, the circlip will get caught in the slot in

the housing, which makes the rack stopper unable

to turn.MB991204

Socket

Circlip

Rack stopper

Page 1137 of 1449

STEERING - Power Steering Gear Box and Linkage37A-23

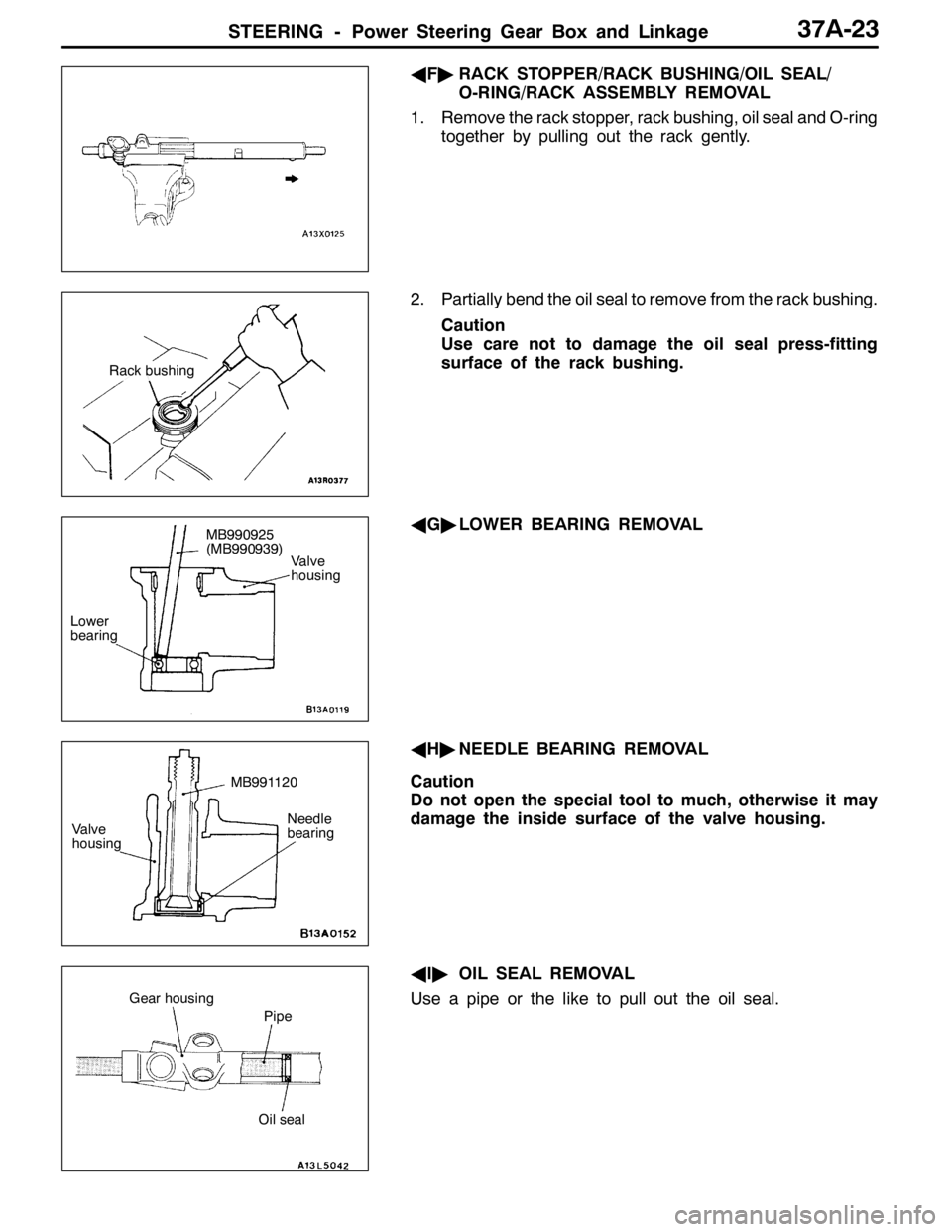

AF"RACK STOPPER/RACK BUSHING/OIL SEAL/

O-RING/RACK ASSEMBLY REMOVAL

1. Remove the rack stopper, rack bushing, oil seal and O-ring

together by pulling out the rack gently.

2. Partially bend the oil seal to remove from the rack bushing.

Caution

Use care not to damage the oil seal press-fitting

surface of the rack bushing.

AG"LOWER BEARING REMOVAL

AH"NEEDLE BEARING REMOVAL

Caution

Do not open the special tool to much, otherwise it may

damage the inside surface of the valve housing.

AI"OIL SEAL REMOVAL

Use a pipe or the like to pull out the oil seal.

Rack bushing

Valve

housing

MB990925

(MB990939)

Lower

bearing

MB991120

Needle

bearing Valve

housing

Oil seal

Gear housing

Pipe

Page 1138 of 1449

STEERING - Power Steering Gear Box and Linkage37A-24

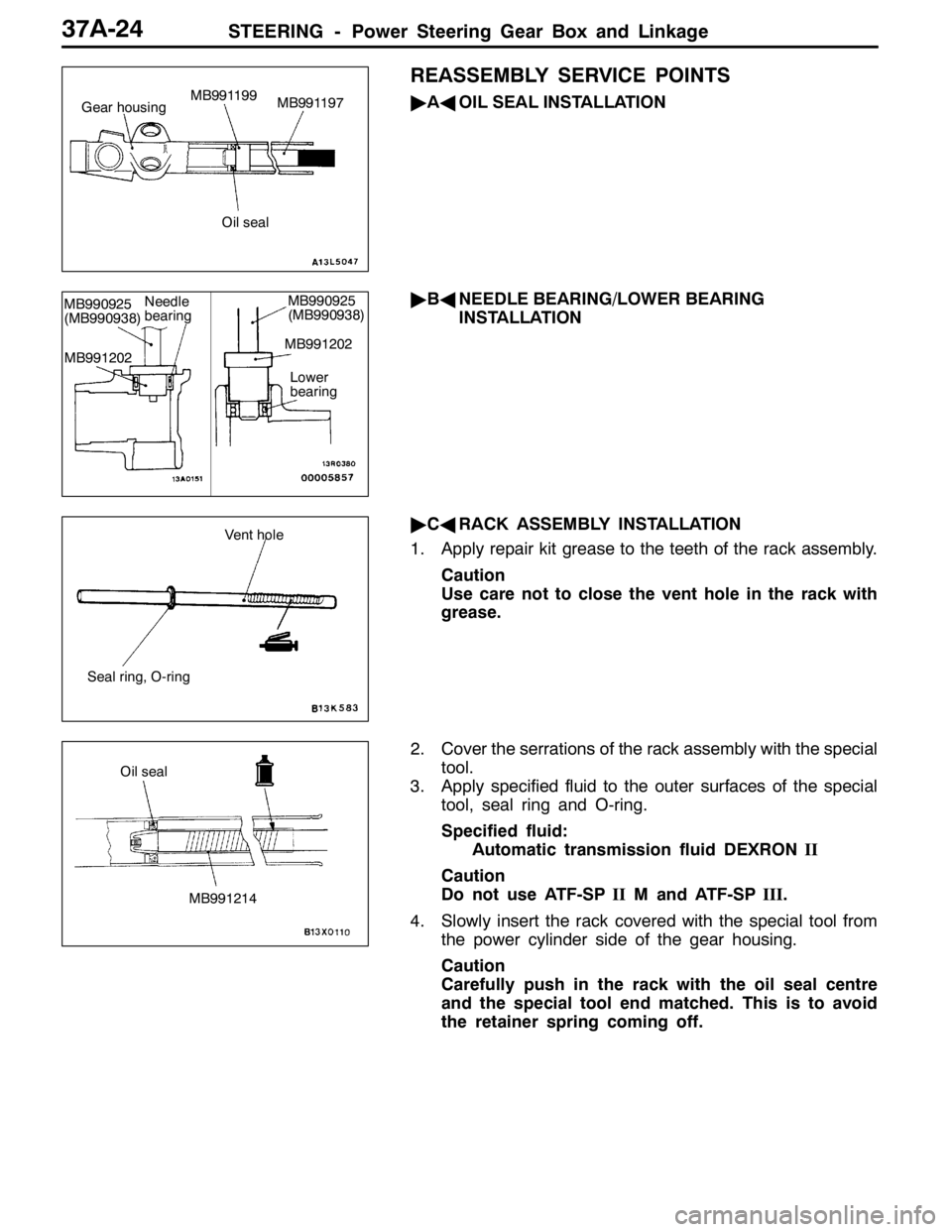

REASSEMBLY SERVICE POINTS

"AAOIL SEAL INSTALLATION

"BANEEDLE BEARING/LOWER BEARING

INSTALLATION

"CARACK ASSEMBLY INSTALLATION

1. Apply repair kit grease to the teeth of the rack assembly.

Caution

Use care not to close the vent hole in the rack with

grease.

2. Cover the serrations of the rack assembly with the special

tool.

3. Apply specified fluid to the outer surfaces of the special

tool, seal ring and O-ring.

Specified fluid:

Automatic transmission fluid DEXRONII

Caution

Do not use ATF-SPIIM and ATF-SPIII.

4. Slowly insert the rack covered with the special tool from

the power cylinder side of the gear housing.

Caution

Carefully push in the rack with the oil seal centre

and the special tool end matched. This is to avoid

the retainer spring coming off.MB991197

Gear housing

Oil seal MB991199

Needle

bearingMB990925

(MB990938)

MB991202

Lower

bearing MB990925

(MB990938)

MB991202

Vent hole

Seal ring, O-ring

MB991214 Oil seal

Page 1139 of 1449

STEERING - Power Steering Gear Box and Linkage37A-25

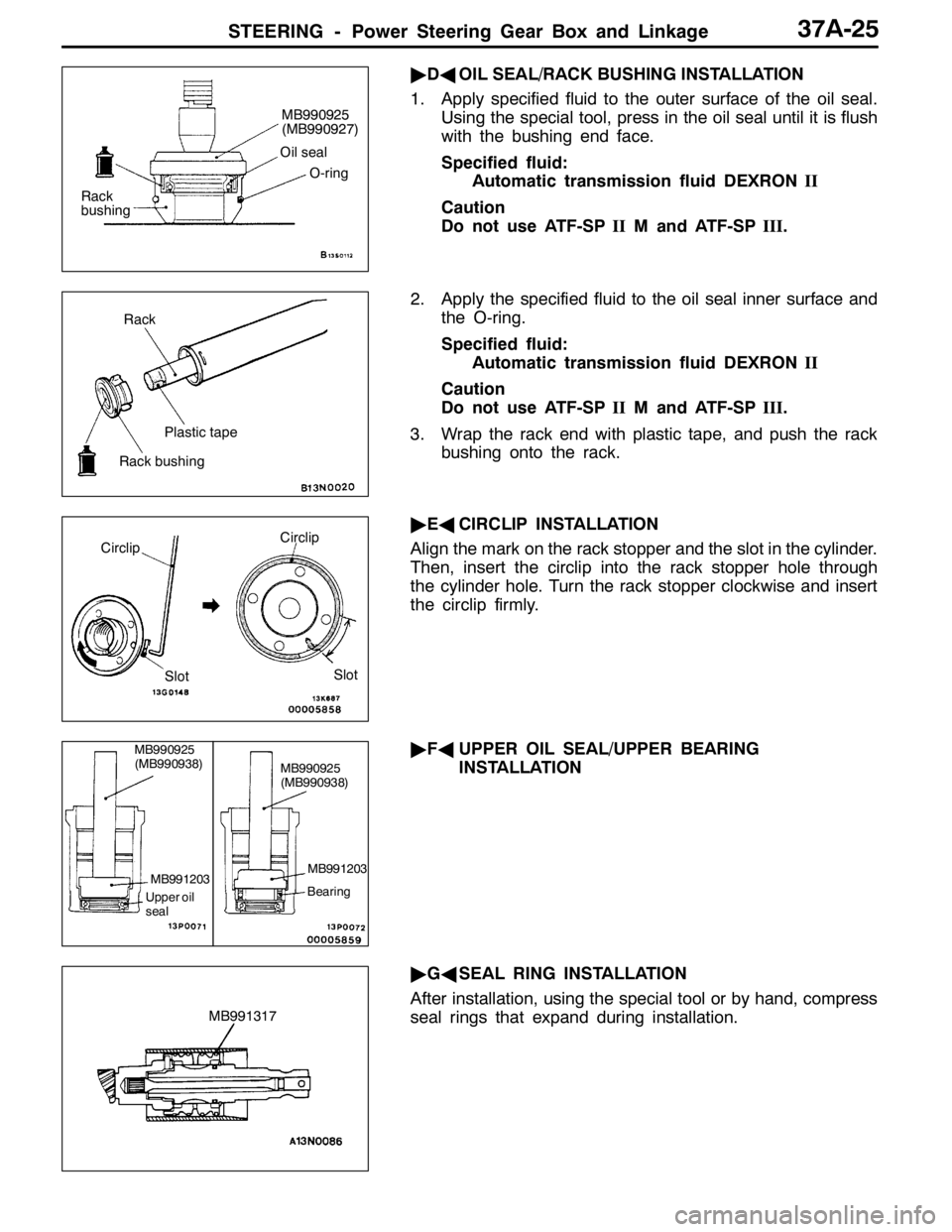

"DAOIL SEAL/RACK BUSHING INSTALLATION

1. Apply specified fluid to the outer surface of the oil seal.

Using the special tool, press in the oil seal until it is flush

with the bushing end face.

Specified fluid:

Automatic transmission fluid DEXRONII

Caution

Do not use ATF-SPIIM and ATF-SPIII.

2. Apply the specified fluid to the oil seal inner surface and

the O-ring.

Specified fluid:

Automatic transmission fluid DEXRONII

Caution

Do not use ATF-SPIIM and ATF-SPIII.

3. Wrap the rack end with plastic tape, and push the rack

bushing onto the rack.

"EACIRCLIP INSTALLATION

Align the mark on the rack stopper and the slot in the cylinder.

Then, insert the circlip into the rack stopper hole through

the cylinder hole. Turn the rack stopper clockwise and insert

the circlip firmly.

"FAUPPER OIL SEAL/UPPER BEARING

INSTALLATION

"GASEAL RING INSTALLATION

After installation, using the special tool or by hand, compress

seal rings that expand during installation.

MB990925

(MB990927)

Oil seal

O-ring

Rack

bushing

Rack bushingPlastic tape Rack

Slot

Circlip

SlotCirclip

MB991203MB991203 MB990925

(MB990938)

Upper oil

seal

MB990925

(MB990938)

Bearing

MB991317

Page 1140 of 1449

STEERING - Power Steering Gear Box and Linkage37A-26

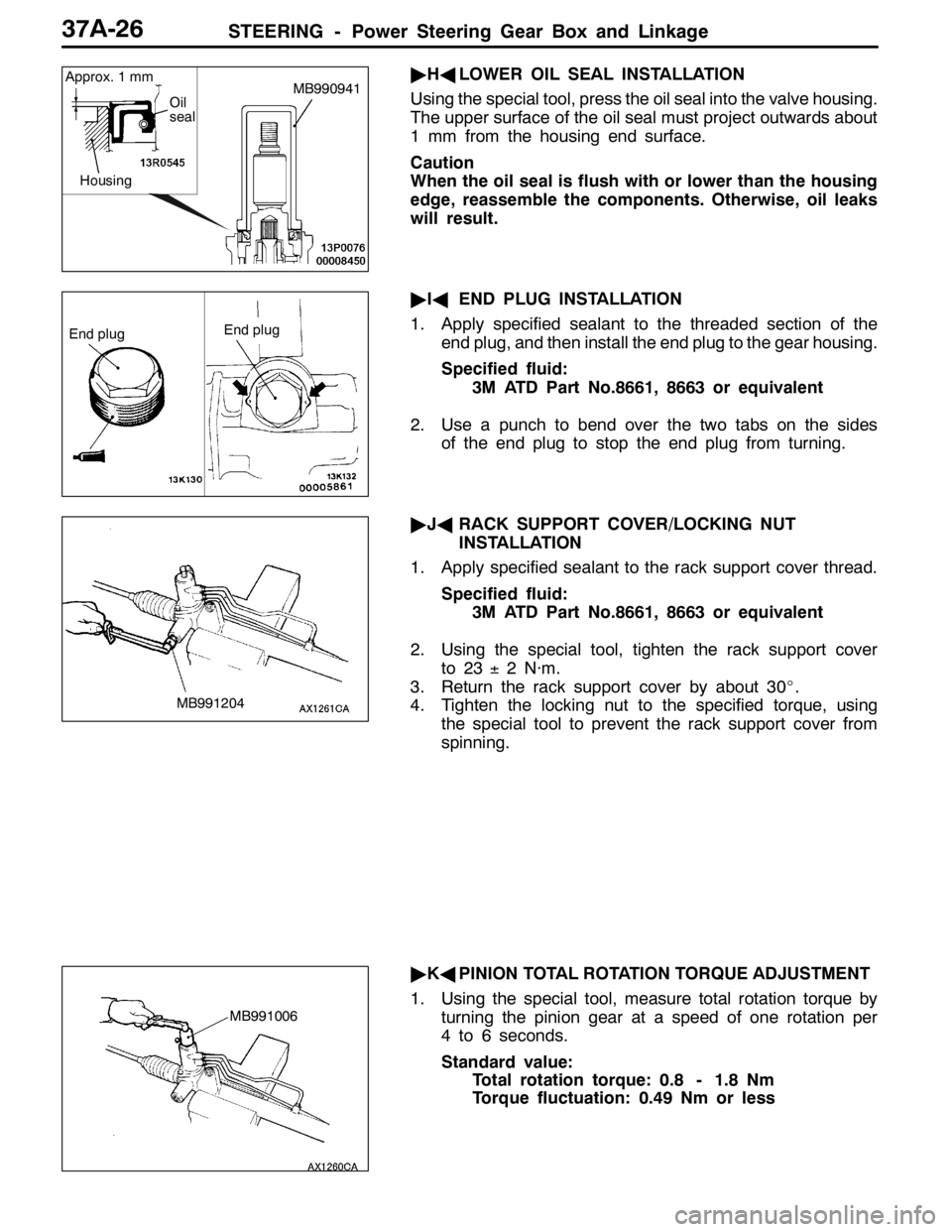

"HALOWER OIL SEAL INSTALLATION

Using the special tool, press the oil seal into the valve housing.

The upper surface of the oil seal must project outwards about

1 mm from the housing end surface.

Caution

When the oil seal is flush with or lower than the housing

edge, reassemble the components. Otherwise, oil leaks

will result.

"IAEND PLUG INSTALLATION

1. Apply specified sealant to the threaded section of the

end plug, and then install the end plug to the gear housing.

Specified fluid:

3M ATD Part No.8661, 8663 or equivalent

2. Use a punch to bend over the two tabs on the sides

of the end plug to stop the end plug from turning.

"JARACK SUPPORT COVER/LOCKING NUT

INSTALLATION

1. Apply specified sealant to the rack support cover thread.

Specified fluid:

3M ATD Part No.8661, 8663 or equivalent

2. Using the special tool, tighten the rack support cover

to 23±2 N·m.

3. Return the rack support cover by about 30_.

4. Tighten the locking nut to the specified torque, using

the special tool to prevent the rack support cover from

spinning.

"KAPINION TOTAL ROTATION TORQUE ADJUSTMENT

1. Using the special tool, measure total rotation torque by

turning the pinion gear at a speed of one rotation per

4 to 6 seconds.

Standard value:

Total rotation torque: 0.8-1.8 Nm

Torque fluctuation: 0.49 Nm or lessMB990941 Approx. 1 mmOil

seal

Housing

End plugEnd plug

MB991204

MB991006