MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1101 of 1449

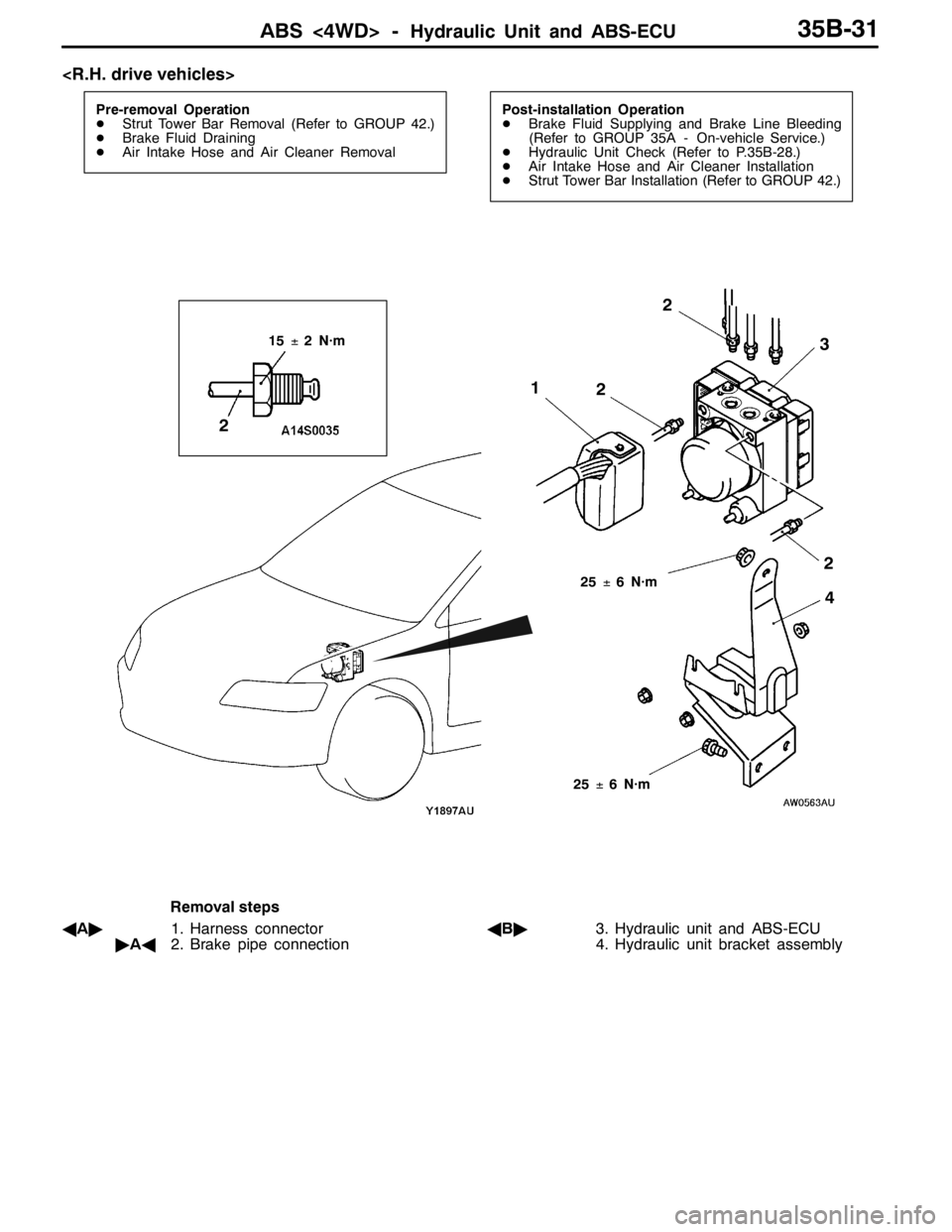

ABS <4WD> -Hydraulic Unit and ABS-ECU35B-31

Pre-removal Operation

DStrut Tower Bar Removal (Refer to GROUP 42.)

DBrake Fluid Draining

DAir Intake Hose and Air Cleaner RemovalPost-installation Operation

DBrake Fluid Supplying and Brake Line Bleeding

(Refer to GROUP 35A - On-vehicle Service.)

DHydraulic Unit Check (Refer to P.35B-28.)

DAir Intake Hose and Air Cleaner Installation

DStrut Tower Bar Installation (Refer to GROUP 42.)

213

4 2

2

2

15±2 N·m

25±6 N·m

25±6 N·m

Removal steps

AA"1. Harness connector

"AA2. Brake pipe connectionAB"3. Hydraulic unit and ABS-ECU

4. Hydraulic unit bracket assembly

Page 1102 of 1449

ABS <4WD> -Hydraulic Unit and ABS-ECU35B-32

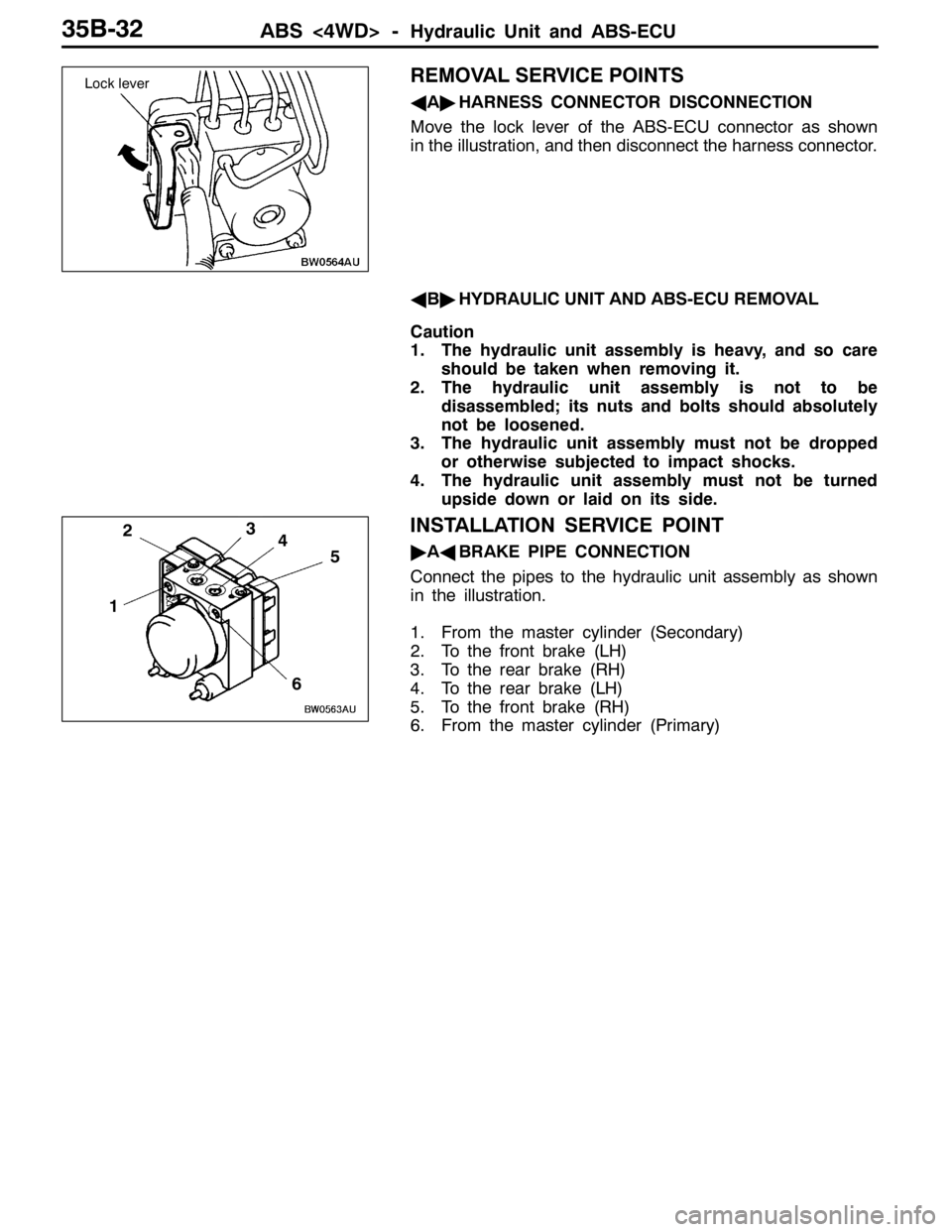

REMOVAL SERVICE POINTS

AA"HARNESS CONNECTOR DISCONNECTION

Move the lock lever of the ABS-ECU connector as shown

in the illustration, and then disconnect the harness connector.

AB"HYDRAULIC UNIT AND ABS-ECU REMOVAL

Caution

1. The hydraulic unit assembly is heavy, and so care

should be taken when removing it.

2. The hydraulic unit assembly is not to be

disassembled; its nuts and bolts should absolutely

not be loosened.

3. The hydraulic unit assembly must not be dropped

or otherwise subjected to impact shocks.

4. The hydraulic unit assembly must not be turned

upside down or laid on its side.

INSTALLATION SERVICE POINT

"AABRAKE PIPE CONNECTION

Connect the pipes to the hydraulic unit assembly as shown

in the illustration.

1. From the master cylinder (Secondary)

2. To the front brake (LH)

3. To the rear brake (RH)

4. To the rear brake (LH)

5. To the front brake (RH)

6. From the master cylinder (Primary)

Lock lever

1

234

5

6

Page 1103 of 1449

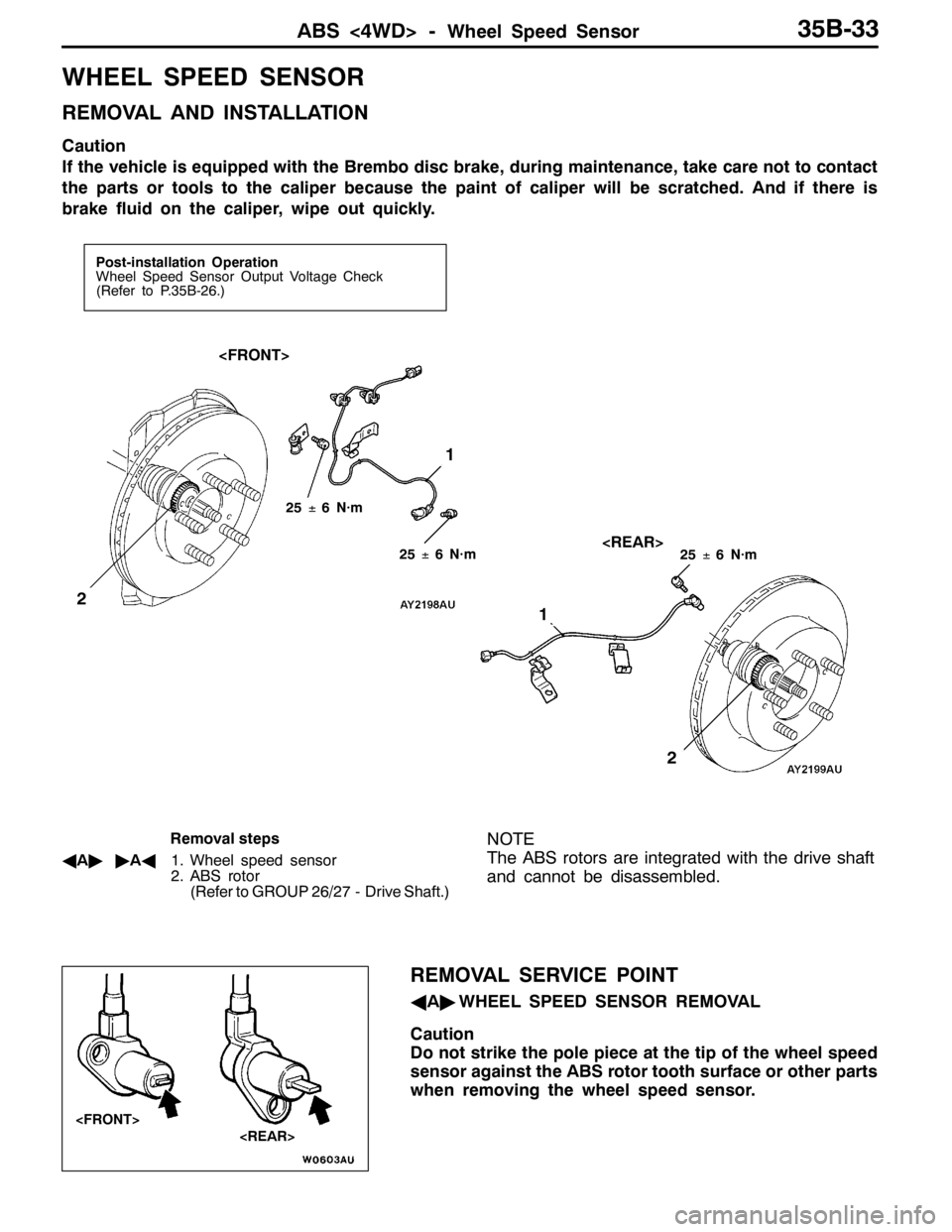

ABS <4WD> -Wheel Speed Sensor35B-33

WHEEL SPEED SENSOR

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched. And if there is

brake fluid on the caliper, wipe out quickly.

Post-installation Operation

Wheel Speed Sensor Output Voltage Check

(Refer to P.35B-26.)

1

2

1

2

25±6 N·m

25±6 N·m25±6 N·m

Removal steps

AA""AA1. Wheel speed sensor

2. ABS rotor

(Refer to GROUP 26/27 - Drive Shaft.)NOTE

The ABS rotors are integrated with the drive shaft

and cannot be disassembled.

REMOVAL SERVICE POINT

AA"WHEEL SPEED SENSOR REMOVAL

Caution

Do not strike the pole piece at the tip of the wheel speed

sensor against the ABS rotor tooth surface or other parts

when removing the wheel speed sensor.

Page 1104 of 1449

ABS <4WD> -Wheel Speed Sensor35B-34

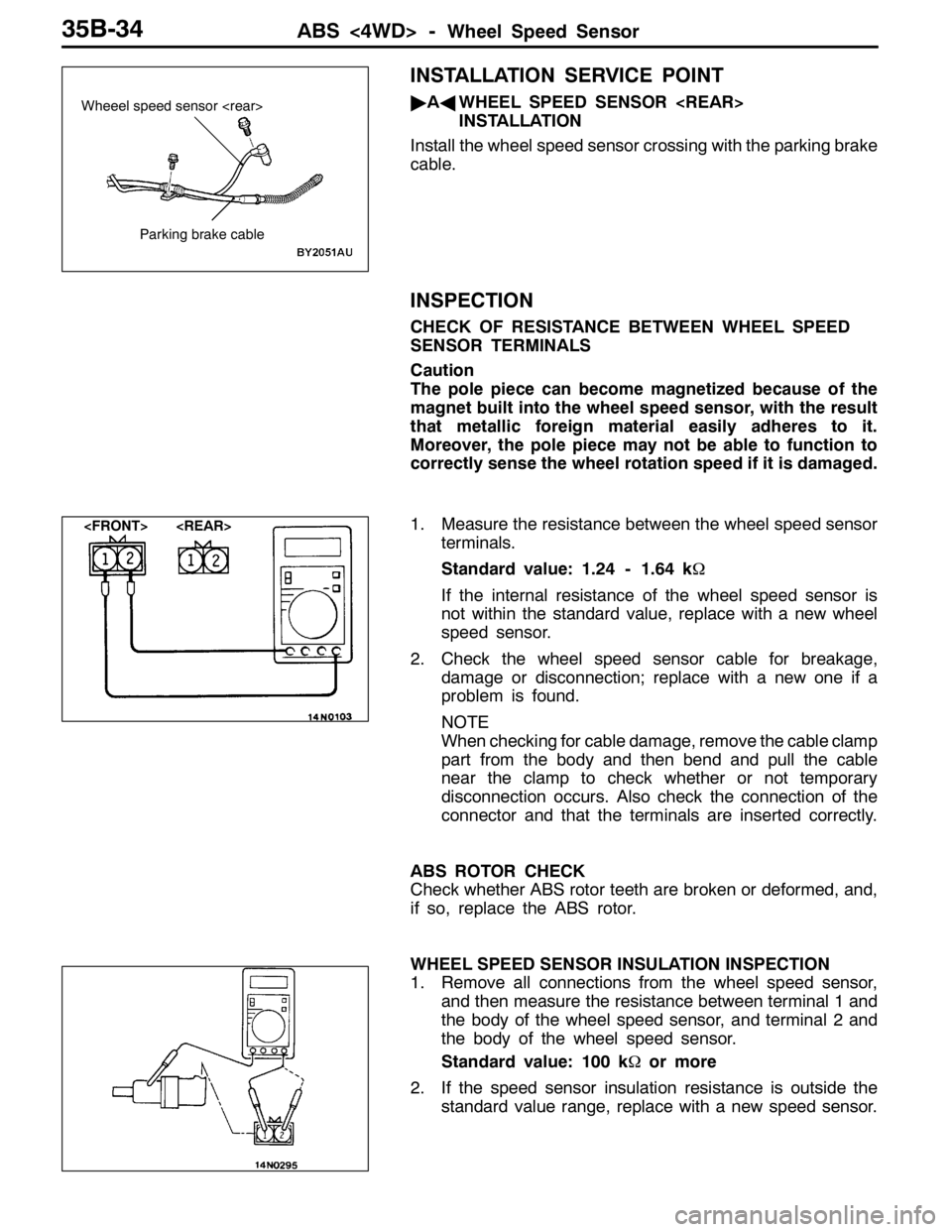

INSTALLATION SERVICE POINT

"AAWHEEL SPEED SENSOR

INSTALLATION

Install the wheel speed sensor crossing with the parking brake

cable.

INSPECTION

CHECK OF RESISTANCE BETWEEN WHEEL SPEED

SENSOR TERMINALS

Caution

The pole piece can become magnetized because of the

magnet built into the wheel speed sensor, with the result

that metallic foreign material easily adheres to it.

Moreover, the pole piece may not be able to function to

correctly sense the wheel rotation speed if it is damaged.

1. Measure the resistance between the wheel speed sensor

terminals.

Standard value: 1.24 - 1.64 kΩ

If the internal resistance of the wheel speed sensor is

not within the standard value, replace with a new wheel

speed sensor.

2. Check the wheel speed sensor cable for breakage,

damage or disconnection; replace with a new one if a

problem is found.

NOTE

When checking for cable damage, remove the cable clamp

part from the body and then bend and pull the cable

near the clamp to check whether or not temporary

disconnection occurs. Also check the connection of the

connector and that the terminals are inserted correctly.

ABS ROTOR CHECK

Check whether ABS rotor teeth are broken or deformed, and,

if so, replace the ABS rotor.

WHEEL SPEED SENSOR INSULATION INSPECTION

1. Remove all connections from the wheel speed sensor,

and then measure the resistance between terminal 1 and

the body of the wheel speed sensor, and terminal 2 and

the body of the wheel speed sensor.

Standard value: 100 kΩor more

2. If the speed sensor insulation resistance is outside the

standard value range, replace with a new speed sensor.

Wheeel speed sensor

Parking brake cable

Page 1105 of 1449

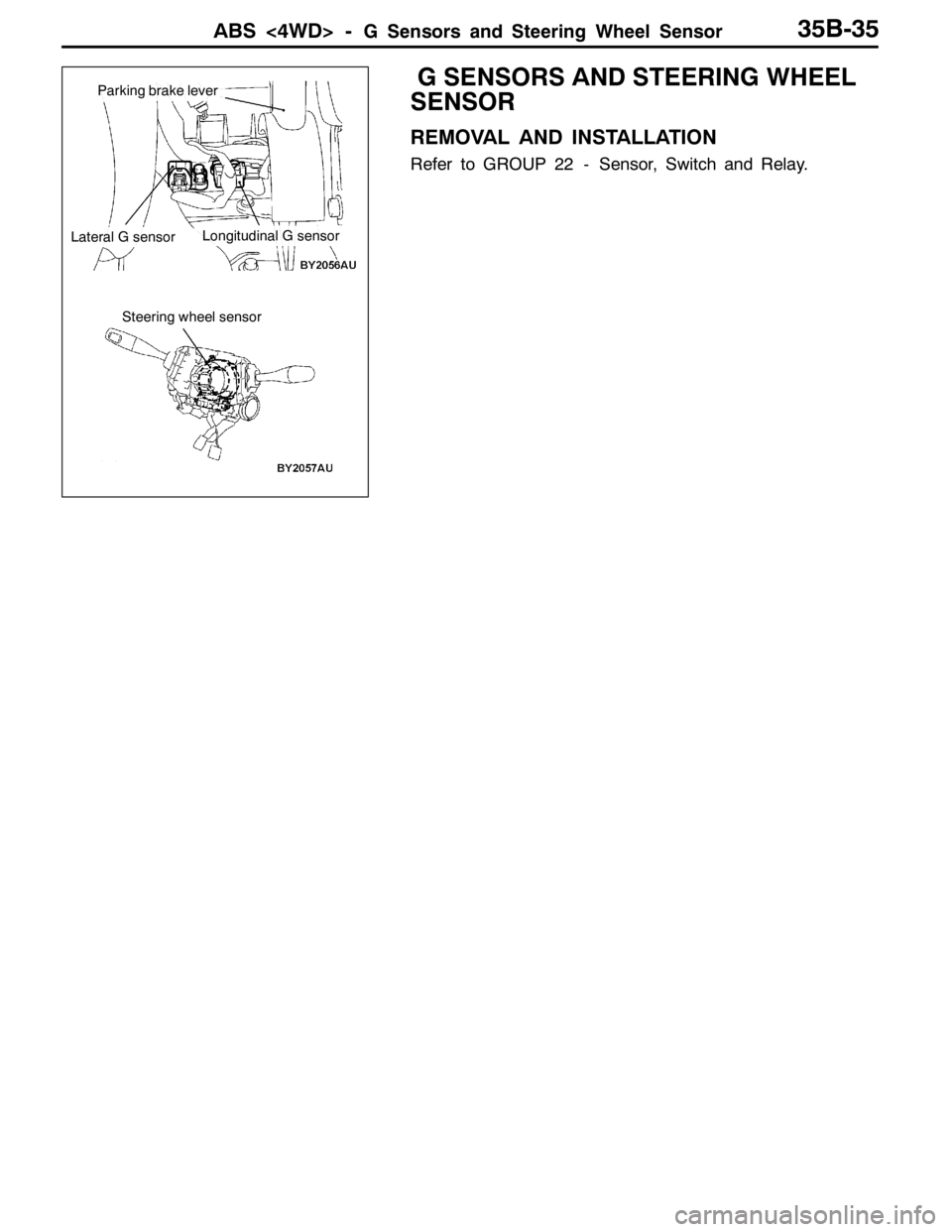

ABS <4WD> -G Sensors and Steering Wheel Sensor35B-35

G SENSORS AND STEERING WHEEL

SENSOR

REMOVAL AND INSTALLATION

Refer to GROUP 22 - Sensor, Switch and Relay.

Parking brake lever

Lateral G sensorLongitudinal G sensor

Steering wheel sensor

Page 1106 of 1449

NOTES

Page 1107 of 1449

36-1

PARKING BRAKES

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

LUBRICANTS 2..............................

ON-VEHICLE SERVICE 3.....................

Parking Brake Lever Stroke Check and

Adjustment 3..................................Parking Brake Switch Check 3..................

Lining Running-In 4............................

PARKING BRAKE LEVER 5..................

PARKING BRAKE CABLE 6..................

PARKING BRAKE DRUM 7...................

Page 1108 of 1449

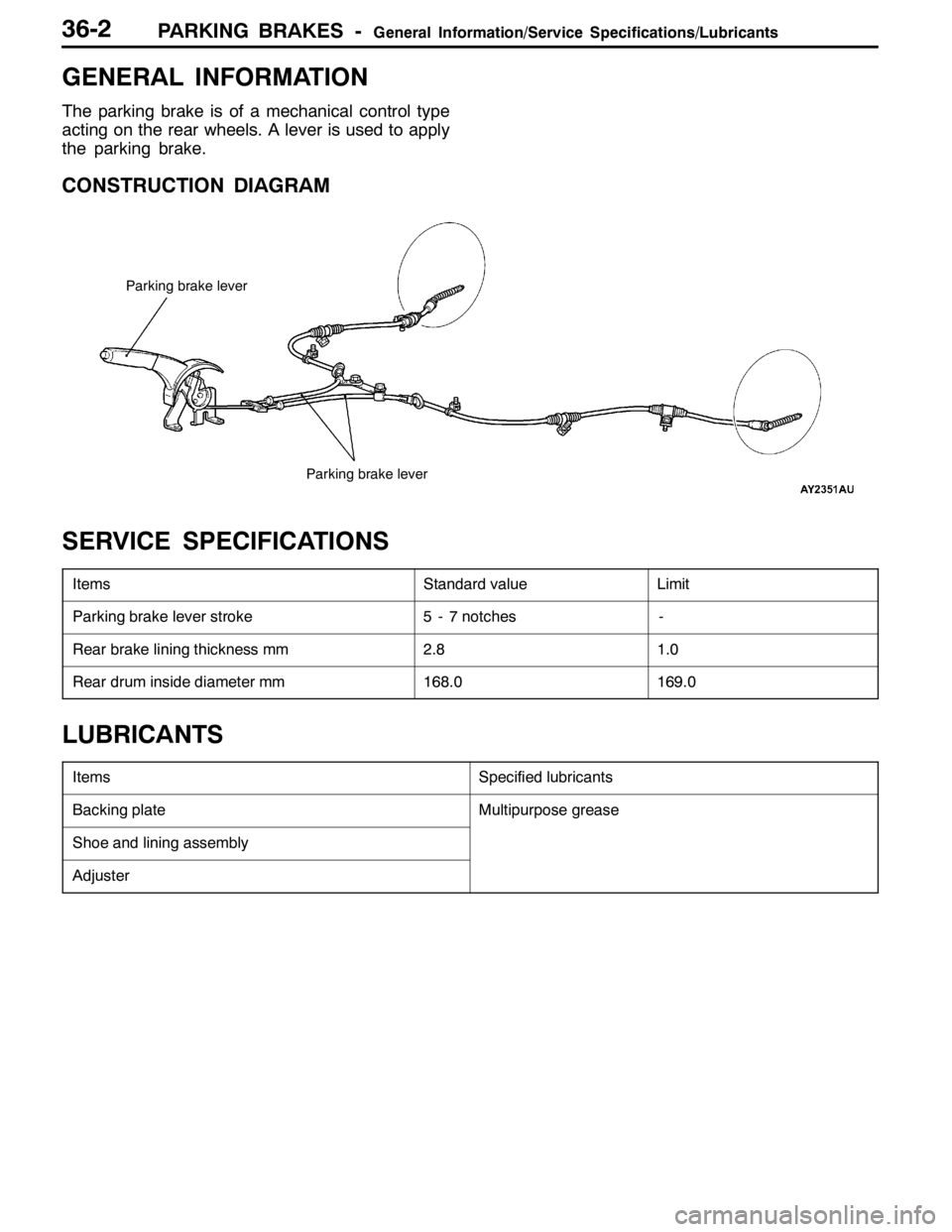

PARKING BRAKES -General Information/Service Specifications/Lubricants36-2

GENERAL INFORMATION

The parking brake is of a mechanical control type

acting on the rear wheels. A lever is used to apply

the parking brake.

CONSTRUCTION DIAGRAM

Parking brake lever

Parking brake lever

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Parking brake lever stroke5 - 7 notches-

Rear brake lining thickness mm2.81.0

Rear drum inside diameter mm168.0169.0

LUBRICANTS

ItemsSpecified lubricants

Backing plateMultipurpose grease

Shoe and lining assembly

Adjuster

Page 1109 of 1449

PARKING BRAKES -On-Vehicle Service36-3

ON-VEHICLE SERVICE

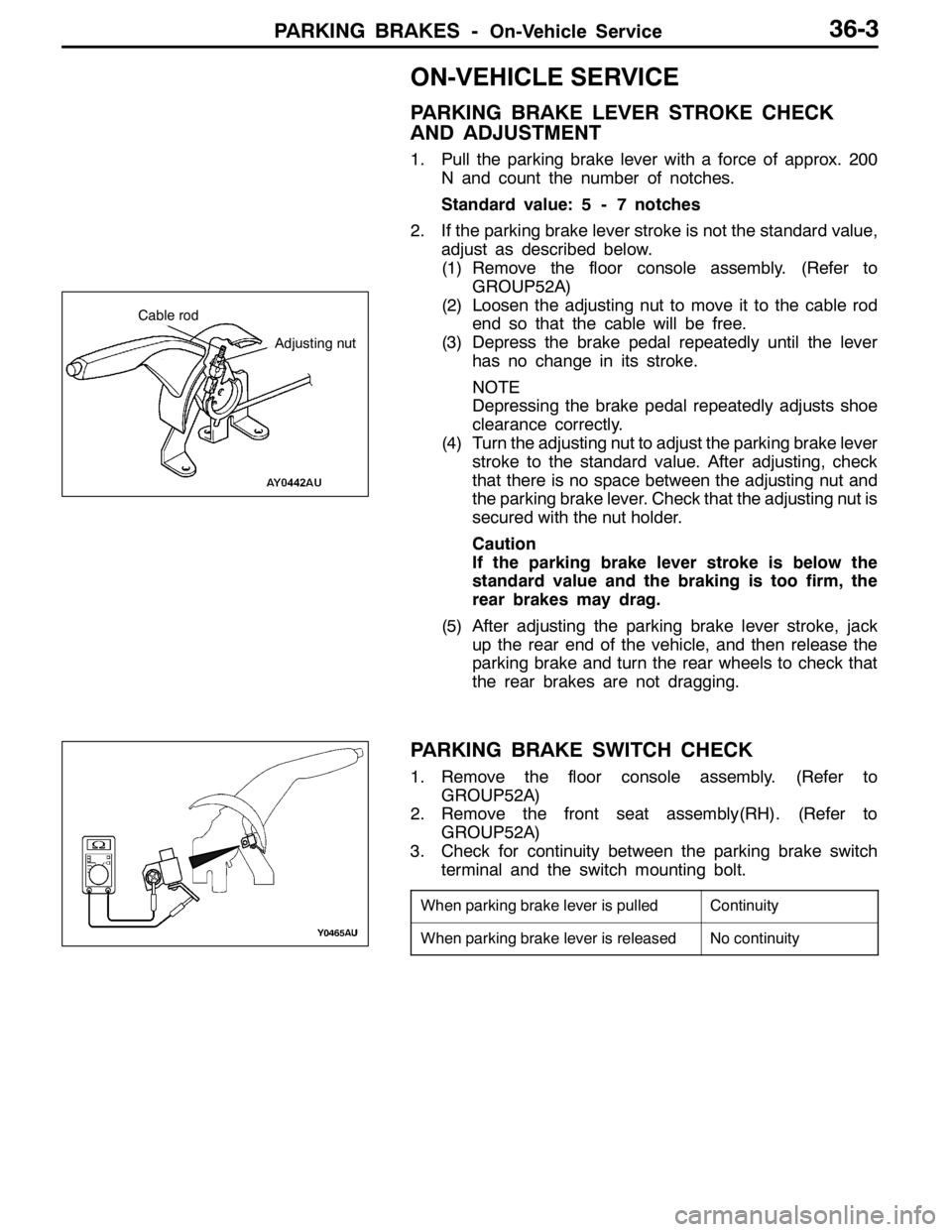

PARKING BRAKE LEVER STROKE CHECK

AND ADJUSTMENT

1. Pull the parking brake lever with a force of approx. 200

N and count the number of notches.

Standard value: 5 - 7 notches

2. If the parking brake lever stroke is not the standard value,

adjust as described below.

(1) Remove the floor console assembly. (Refer to

GROUP52A)

(2) Loosen the adjusting nut to move it to the cable rod

end so that the cable will be free.

(3) Depress the brake pedal repeatedly until the lever

has no change in its stroke.

NOTE

Depressing the brake pedal repeatedly adjusts shoe

clearance correctly.

(4) Turn the adjusting nut to adjust the parking brake lever

stroke to the standard value. After adjusting, check

that there is no space between the adjusting nut and

the parking brake lever. Check that the adjusting nut is

secured with the nut holder.

Caution

If the parking brake lever stroke is below the

standard value and the braking is too firm, the

rear brakes may drag.

(5) After adjusting the parking brake lever stroke, jack

up the rear end of the vehicle, and then release the

parking brake and turn the rear wheels to check that

the rear brakes are not dragging.

PARKING BRAKE SWITCH CHECK

1. Remove the floor console assembly. (Refer to

GROUP52A)

2. Remove the front seat assembly(RH). (Refer to

GROUP52A)

3. Check for continuity between the parking brake switch

terminal and the switch mounting bolt.

When parking brake lever is pulledContinuity

When parking brake lever is releasedNo continuity

Adjusting nut

Cable rod

Page 1110 of 1449

PARKING BRAKES -On-Vehicle Service36-4

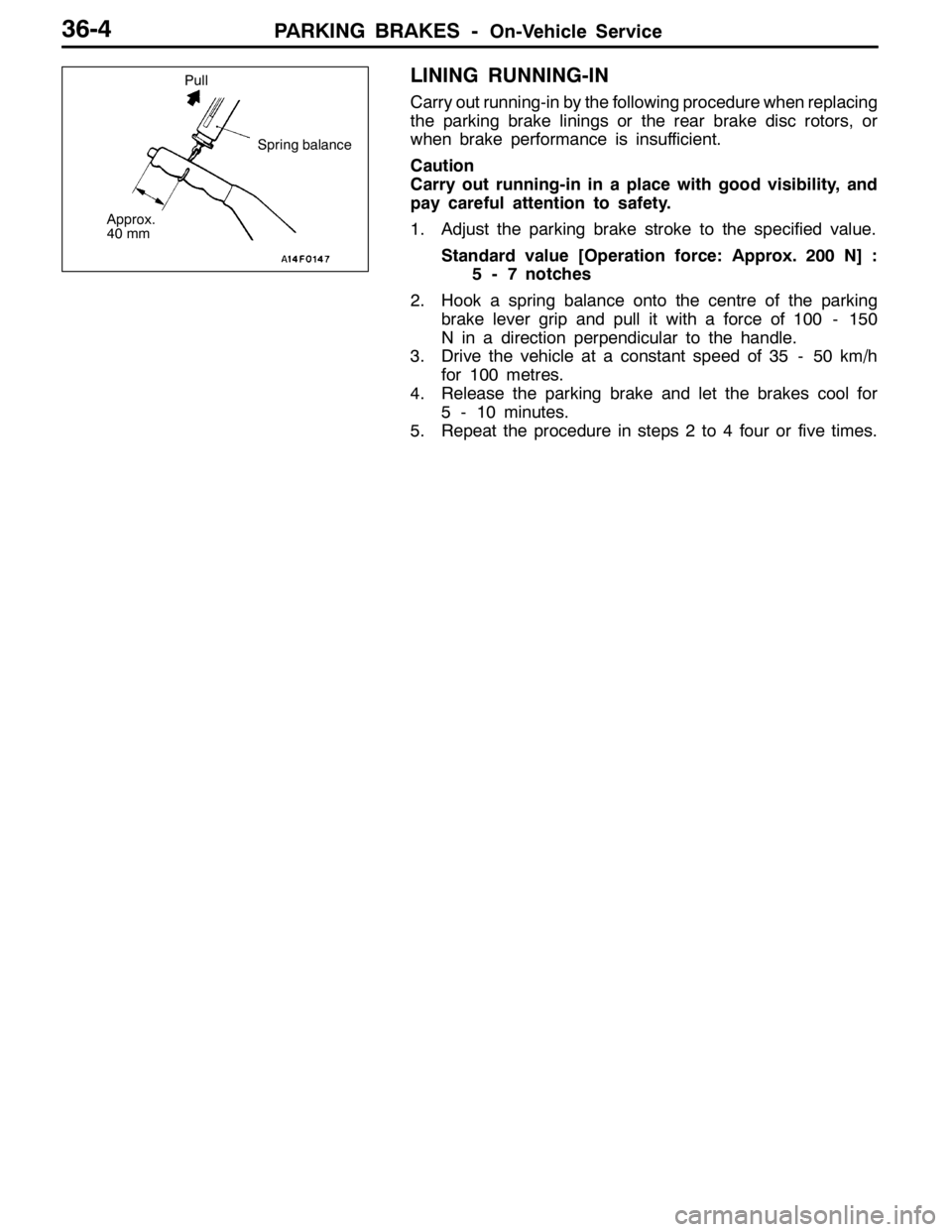

LINING RUNNING-IN

Carry out running-in by the following procedure when replacing

the parking brake linings or the rear brake disc rotors, or

when brake performance is insufficient.

Caution

Carry out running-in in a place with good visibility, and

pay careful attention to safety.

1. Adjust the parking brake stroke to the specified value.

Standard value [Operation force: Approx. 200 N] :

5 - 7 notches

2. Hook a spring balance onto the centre of the parking

brake lever grip and pull it with a force of 100 - 150

N in a direction perpendicular to the handle.

3. Drive the vehicle at a constant speed of 35 - 50 km/h

for 100 metres.

4. Release the parking brake and let the brakes cool for

5 - 10 minutes.

5. Repeat the procedure in steps 2 to 4 four or five times.

Pull

Spring balance

Approx.

40 mm