MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1181 of 1449

BODY -Doors42-33

REMOVAL SERVICE POINTS

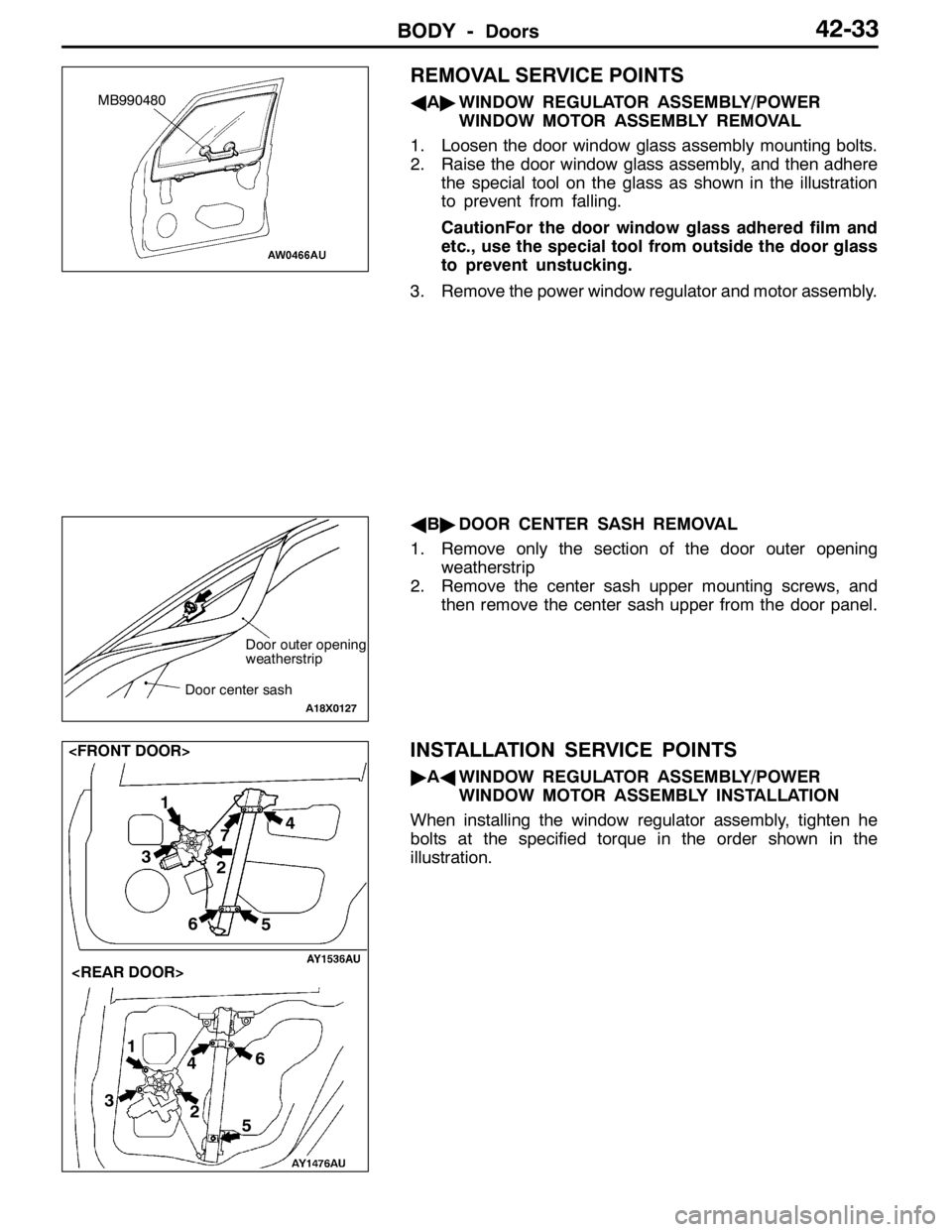

AA"WINDOW REGULATOR ASSEMBLY/POWER

WINDOW MOTOR ASSEMBLY REMOVAL

1. Loosen the door window glass assembly mounting bolts.

2. Raise the door window glass assembly, and then adhere

the special tool on the glass as shown in the illustration

to prevent from falling.

CautionFor the door window glass adhered film and

etc., use the special tool from outside the door glass

to prevent unstucking.

3. Remove the power window regulator and motor assembly.

AB"DOOR CENTER SASH REMOVAL

1. Remove only the section of the door outer opening

weatherstrip

2. Remove the center sash upper mounting screws, and

then remove the center sash upper from the door panel.

INSTALLATION SERVICE POINTS

"AAWINDOW REGULATOR ASSEMBLY/POWER

WINDOW MOTOR ASSEMBLY INSTALLATION

When installing the window regulator assembly, tighten he

bolts at the specified torque in the order shown in the

illustration.

MB990480

Door outer opening

weatherstrip

Door center sash

A18X0127

1

2 4

3

56

1

2

34

5 67

Page 1182 of 1449

BODY -DoorsBODY -Doors42-34

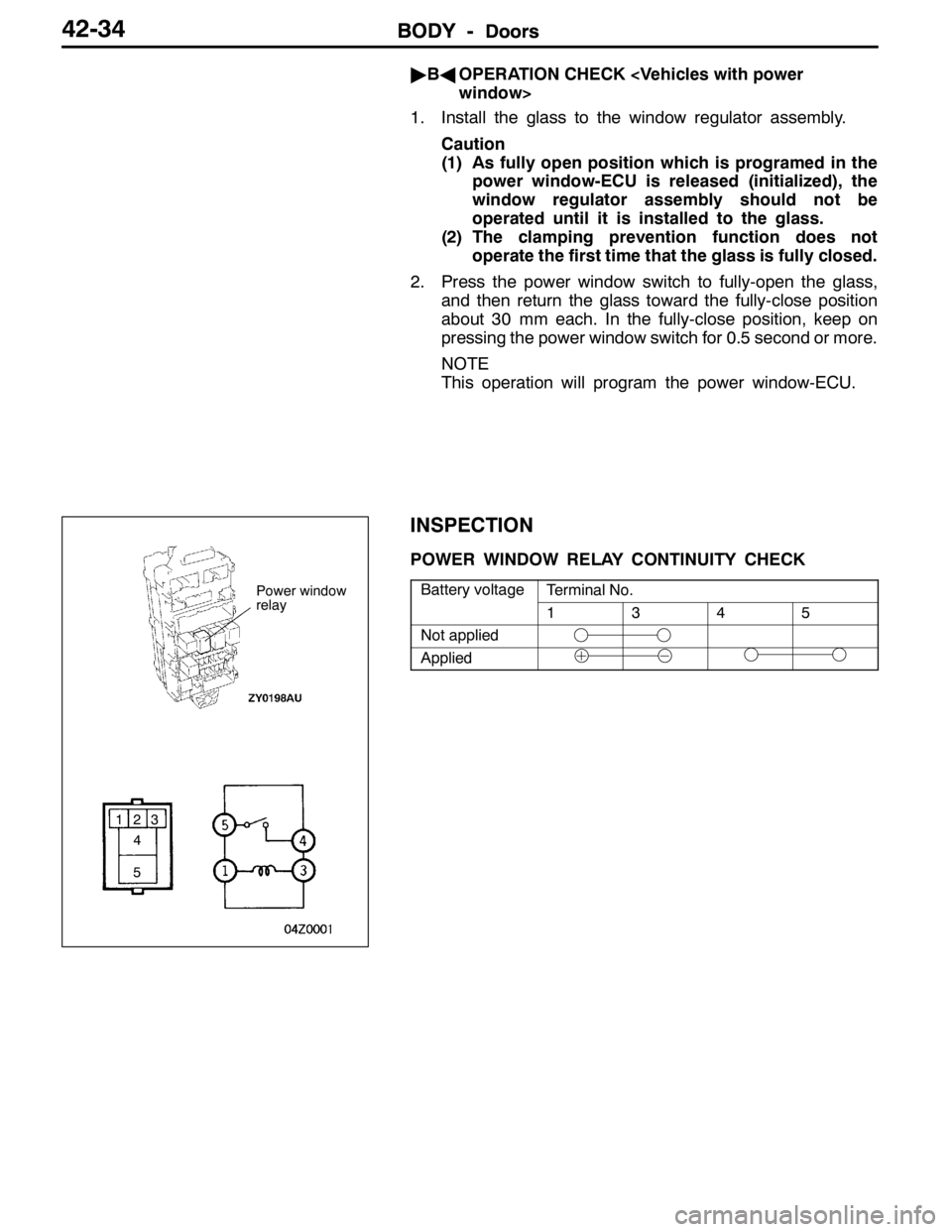

"BAOPERATION CHECK

1. Install the glass to the window regulator assembly.

Caution

(1) As fully open position which is programed in the

power window-ECU is released (initialized), the

window regulator assembly should not be

operated until it is installed to the glass.

(2) The clamping prevention function does not

operate the first time that the glass is fully closed.

2. Press the power window switch to fully-open the glass,

and then return the glass toward the fully-close position

about 30 mm each. In the fully-close position, keep on

pressing the power window switch for 0.5 second or more.

NOTE

This operation will program the power window-ECU.

INSPECTION

POWER WINDOW RELAY CONTINUITY CHECK

Battery voltageTerminal No.yg

1345

Not applied

Applied

Power window

relay

123

4

5

Page 1183 of 1449

BODY -Doors42-35

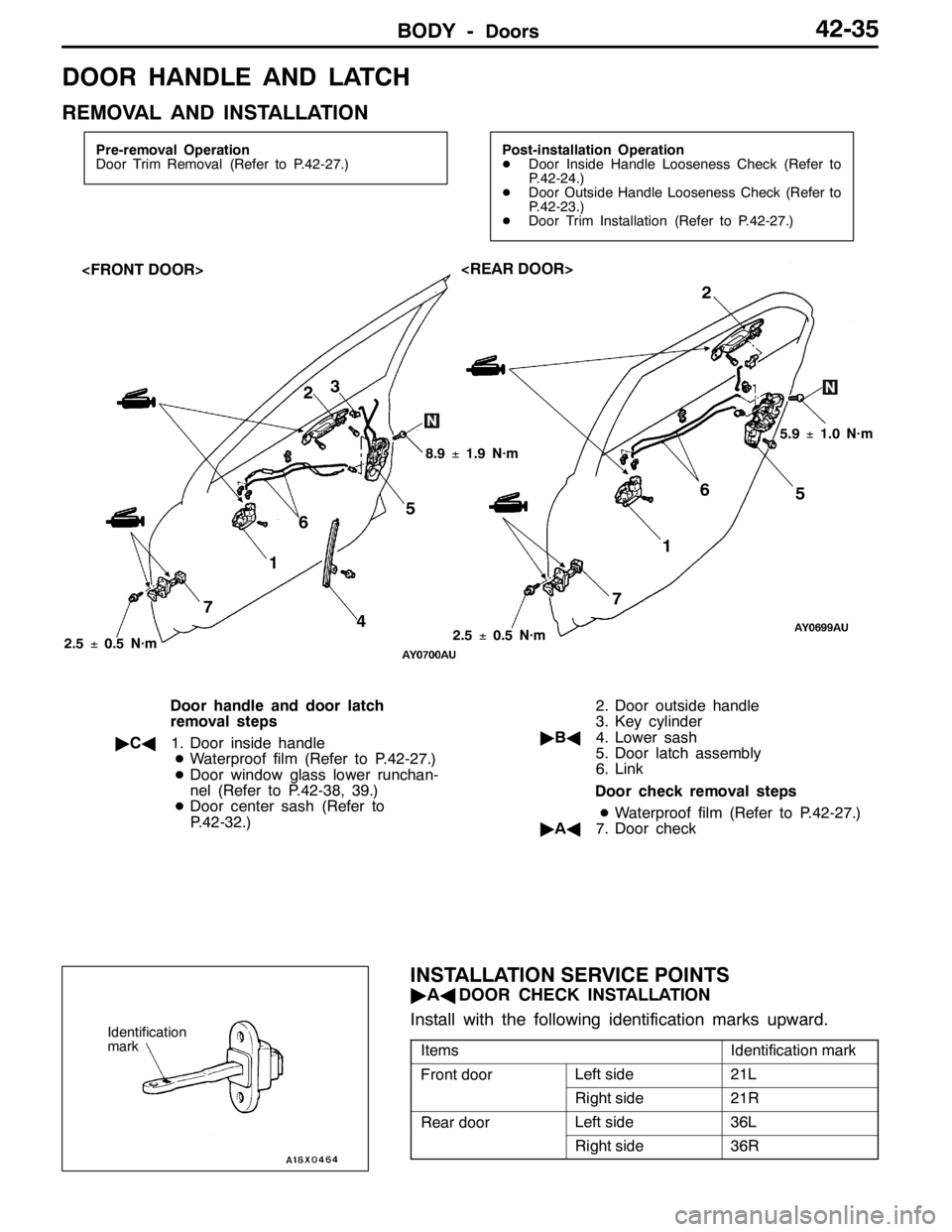

DOOR HANDLE AND LATCH

REMOVAL AND INSTALLATION

Pre-removal Operation

Door Trim Removal (Refer to P.42-27.)Post-installation Operation

DDoor Inside Handle Looseness Check (Refer to

P.42-24.)

DDoor Outside Handle Looseness Check (Refer to

P.42-23.)

DDoor Trim Installation (Refer to P.42-27.)

3

5

4 72

6

1

5.9±1.0 N·m

8.9±1.9 N·m

2

1

75 6

2.5±0.5 N·m

2.5±0.5 N·m

Door handle and door latch

removal steps

"CA1. Door inside handle

DWaterproof film (Refer to P.42-27.)

DDoor window glass lower runchan-

nel (Refer to P.42-38, 39.)

DDoor center sash (Refer to

P.42-32.)2. Door outside handle

3. Key cylinder

"BA4. Lower sash

5. Door latch assembly

6. Link

Door check removal steps

DWaterproof film (Refer to P.42-27.)

"AA7. Door check

INSTALLATION SERVICE POINTS

"AADOOR CHECK INSTALLATION

Install with the following identification marks upward.

ItemsIdentification mark

Front doorLeft side21L

Right side21R

Rear doorLeft side36L

Right side36R

Identification

mark

Page 1184 of 1449

BODY -DoorsBODY -Doors42-36

"BALOWER SASH INSTALLATION

Be sure to install the lower sash to the window rear sash

(at door) securely.

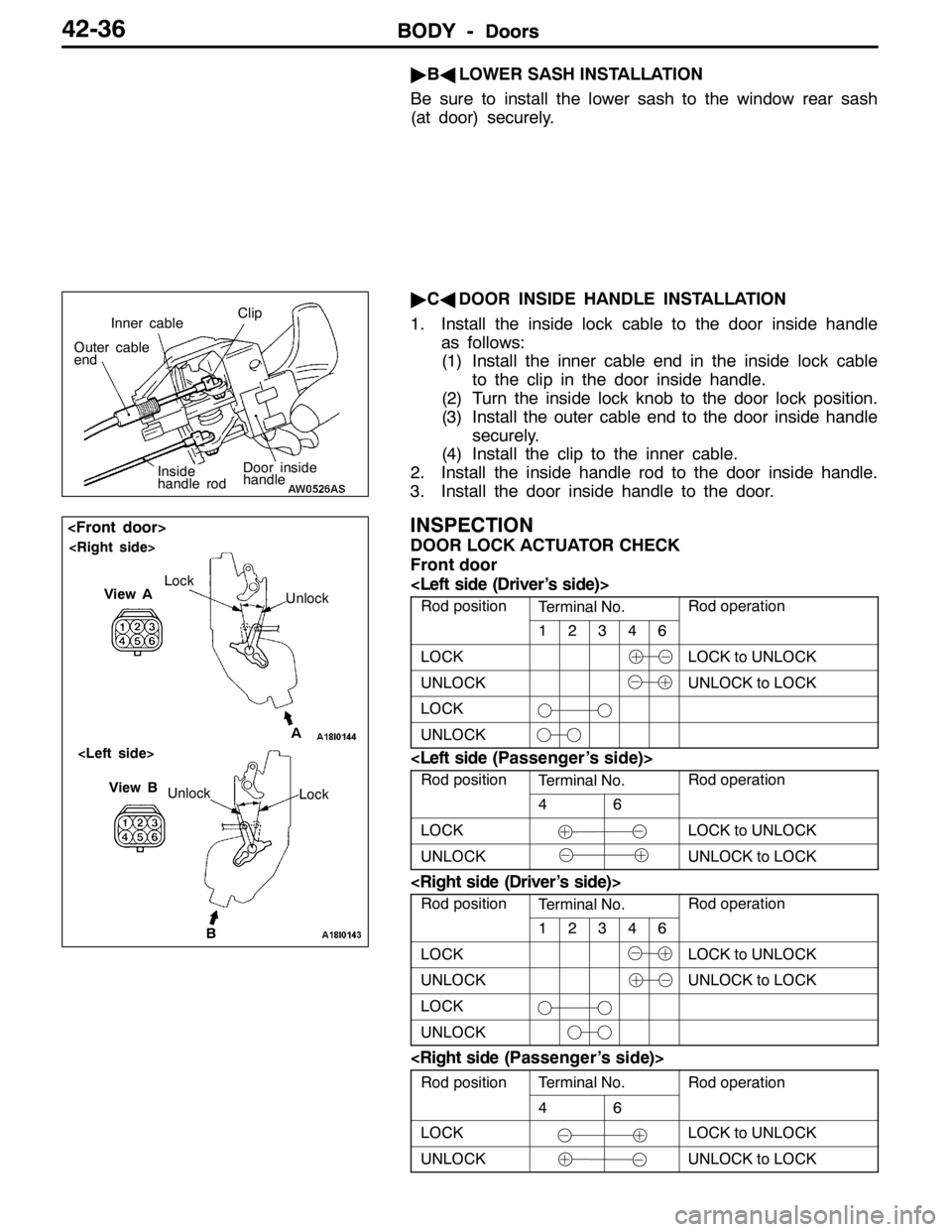

"CADOOR INSIDE HANDLE INSTALLATION

1. Install the inside lock cable to the door inside handle

as follows:

(1) Install the inner cable end in the inside lock cable

to the clip in the door inside handle.

(2) Turn the inside lock knob to the door lock position.

(3) Install the outer cable end to the door inside handle

securely.

(4) Install the clip to the inner cable.

2. Install the inside handle rod to the door inside handle.

3. Install the door inside handle to the door.

INSPECTION

DOOR LOCK ACTUATOR CHECK

Front door

Rod positionTerminal No.Rod operation

12346

LOCKLOCK to UNLOCK

UNLOCKUNLOCK to LOCK

LOCK

UNLOCK

Rod positionTerminal No.Rod operation

46

LOCKLOCK to UNLOCK

UNLOCKUNLOCK to LOCK

Rod positionTerminal No.Rod operation

12346

LOCKLOCK to UNLOCK

UNLOCKUNLOCK to LOCK

LOCK

UNLOCK

Rod positionTerminal No.Rod operationp

46

p

LOCKLOCK to UNLOCK

UNLOCKUNLOCK to LOCK

Door inside

handle

Inner cableClip

Outer cable

end

Inside

handle rod

B Unlock

View B

Lock

View A

Unlock Lock

A

Page 1185 of 1449

BODY -Doors42-37

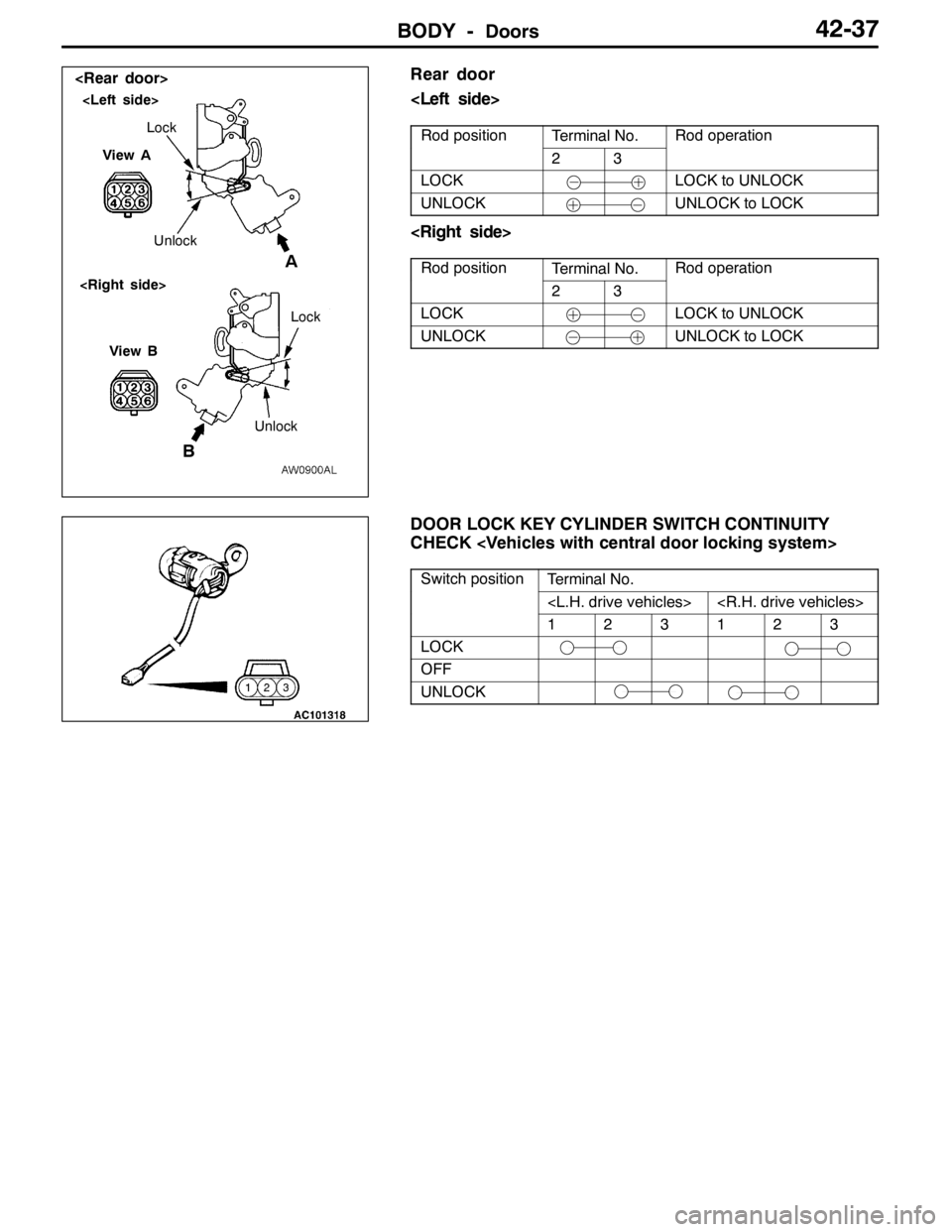

Rear door

Rod positionTerminal No.Rod operationp

23

p

LOCKLOCK to UNLOCK

UNLOCKUNLOCK to LOCK

Rod positionTerminal No.Rod operationp

23

p

LOCKLOCK to UNLOCK

UNLOCKUNLOCK to LOCK

DOOR LOCK KEY CYLINDER SWITCH CONTINUITY

CHECK

Switch positionTerminal No.p

123123

LOCK

OFF

UNLOCK

BA

View ALock

Unlock

View B

UnlockLock

Page 1186 of 1449

BODY -Doors42-38

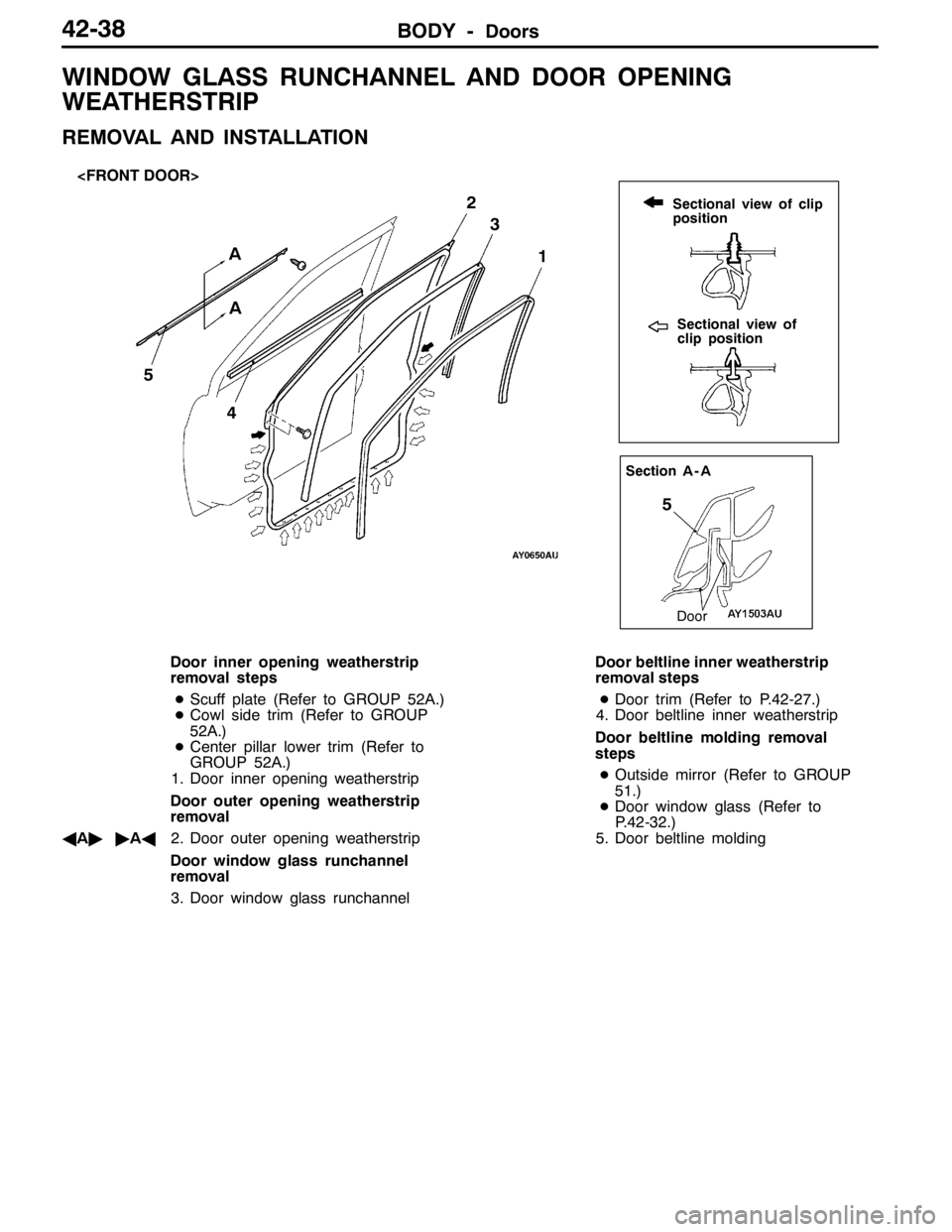

WINDOW GLASS RUNCHANNEL AND DOOR OPENING

WEATHERSTRIP

REMOVAL AND INSTALLATION

2

5

43

1

Sectional view of

clip position Sectional view of clip

position

Section A - A

Door

5

A

A

Door inner opening weatherstrip

removal steps

DScuff plate (Refer to GROUP 52A.)

DCowl side trim (Refer to GROUP

52A.)

DCenter pillar lower trim (Refer to

GROUP 52A.)

1. Door inner opening weatherstrip

Door outer opening weatherstrip

removal

AA""AA2. Door outer opening weatherstrip

Door window glass runchannel

removal

3. Door window glass runchannelDoor beltline inner weatherstrip

removal steps

DDoor trim (Refer to P.42-27.)

4. Door beltline inner weatherstrip

Door beltline molding removal

steps

DOutside mirror (Refer to GROUP

51.)

DDoor window glass (Refer to

P.42-32.)

5. Door beltline molding

Page 1187 of 1449

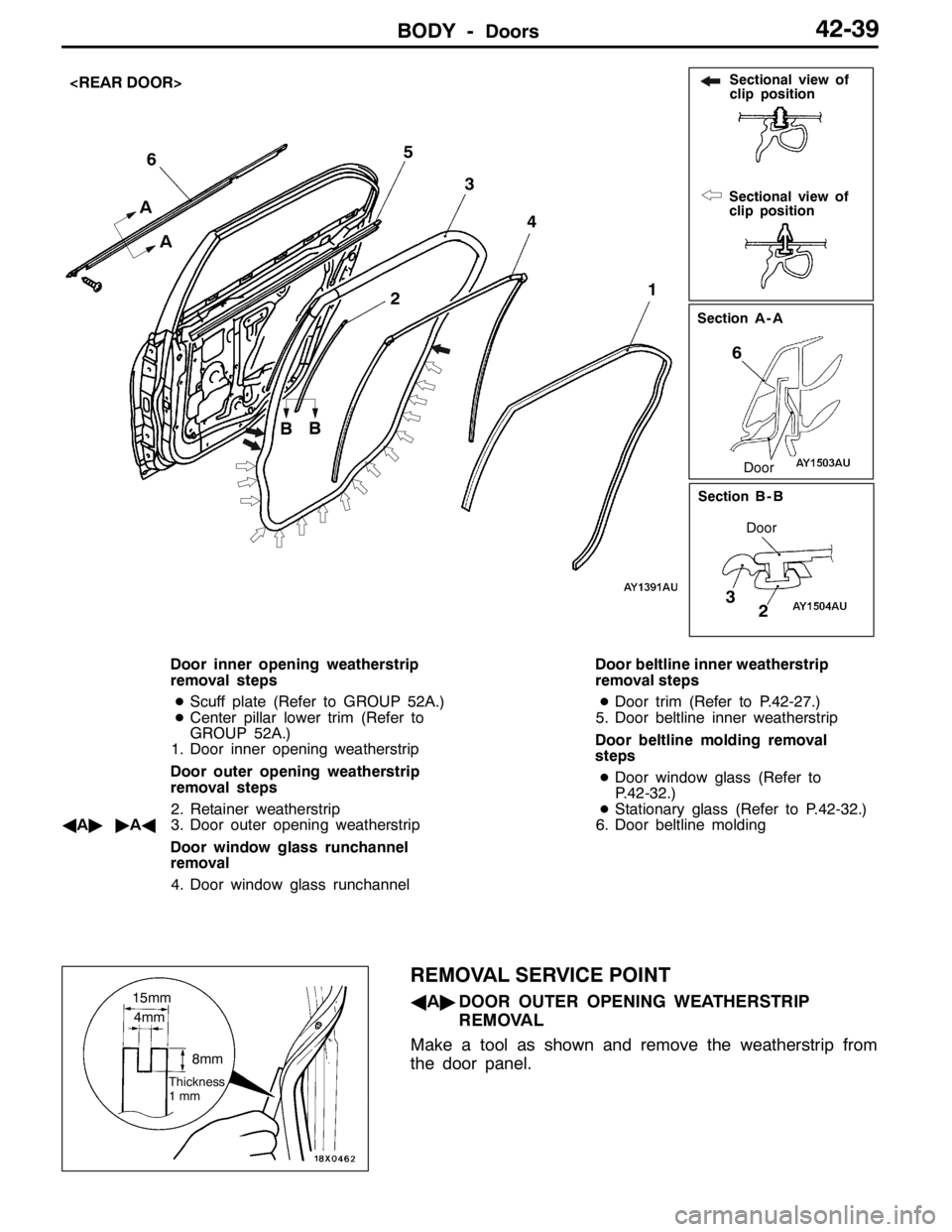

BODY -Doors42-39

Sectional view of

clip positionSectional view of

clip position

5

4 3

21

Section A - A

Door

6

A

A

6

BB

Section B - B

Door

23

Door inner opening weatherstrip

removal steps

DScuff plate (Refer to GROUP 52A.)

DCenter pillar lower trim (Refer to

GROUP 52A.)

1. Door inner opening weatherstrip

Door outer opening weatherstrip

removal steps

2. Retainer weatherstrip

AA""AA3. Door outer opening weatherstrip

Door window glass runchannel

removal

4. Door window glass runchannelDoor beltline inner weatherstrip

removal steps

DDoor trim (Refer to P.42-27.)

5. Door beltline inner weatherstrip

Door beltline molding removal

steps

DDoor window glass (Refer to

P.42-32.)

DStationary glass (Refer to P.42-32.)

6. Door beltline molding

REMOVAL SERVICE POINT

AA"DOOR OUTER OPENING WEATHERSTRIP

REMOVAL

Make a tool as shown and remove the weatherstrip from

the door panel.15mm

4mm

8mm

Thickness

1mm

Page 1188 of 1449

BODY -Doors42-40

INSTALLATION SERVICE POINTS

"AADOOR OUTER OPENING WATHERSTRIP

INSTALLATION

The clip colour identifies the left and right weatherstrips so

be sure to use the colours as install correctly.

Applicable sideIdentification colour

Right doorPink

Left doorNatural (White)

Page 1189 of 1449

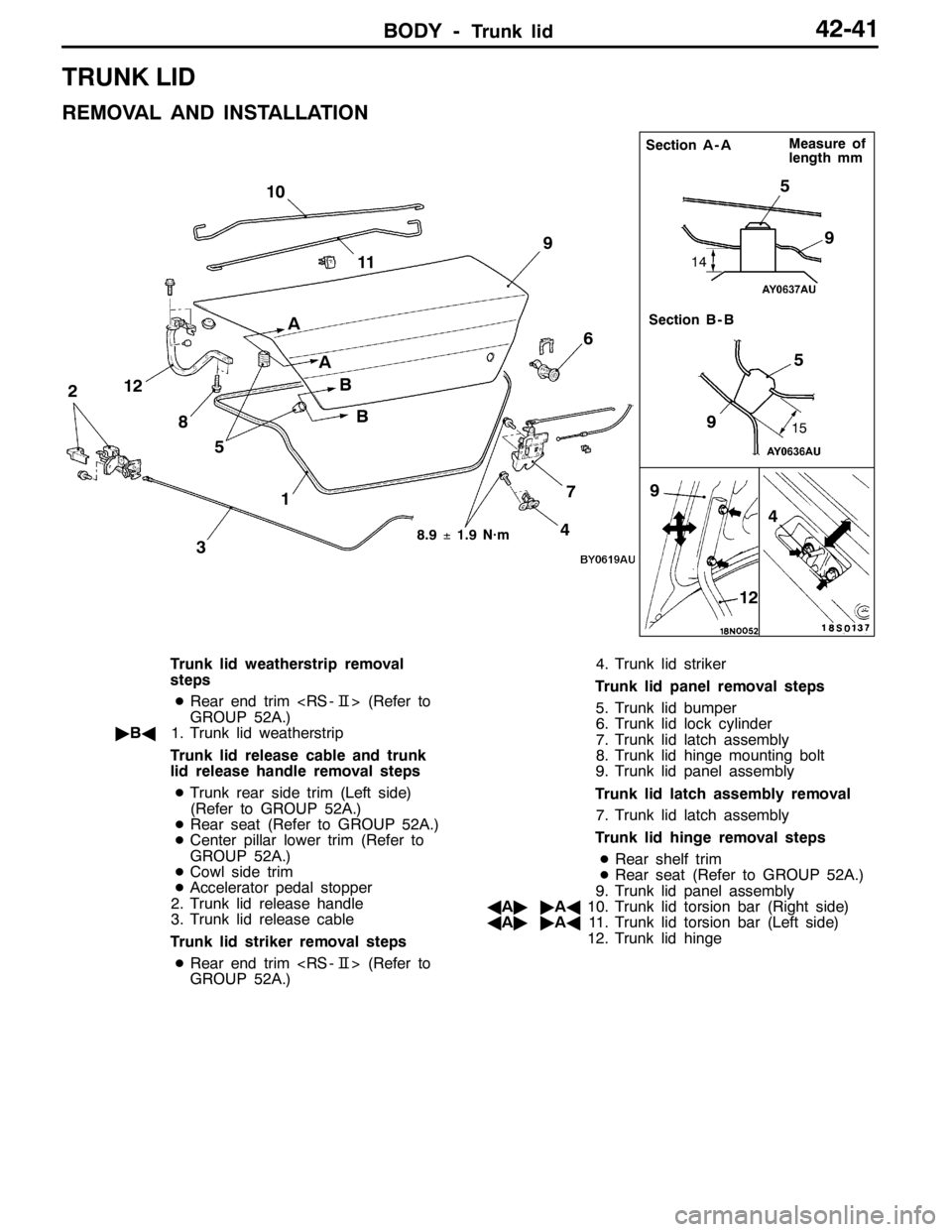

BODY -Trunk lid42-41

TRUNK LID

REMOVAL AND INSTALLATION

2

34 56

7 89 10

111

12A

A

B

B5 5

99

14Measure of

length mm

15

4 9

12

8.9±1.9 N·m

Section A - A

Section B - B

Trunk lid weatherstrip removal

steps

DRear end trim

GROUP 52A.)

"BA1. Trunk lid weatherstrip

Trunk lid release cable and trunk

lid release handle removal steps

DTrunk rear side trim (Left side)

(Refer to GROUP 52A.)

DRear seat (Refer to GROUP 52A.)

DCenter pillar lower trim (Refer to

GROUP 52A.)

DCowl side trim

DAccelerator pedal stopper

2. Trunk lid release handle

3. Trunk lid release cable

Trunk lid striker removal steps

DRear end trim

GROUP 52A.)4. Trunk lid striker

Trunk lid panel removal steps

5. Trunk lid bumper

6. Trunk lid lock cylinder

7. Trunk lid latch assembly

8. Trunk lid hinge mounting bolt

9. Trunk lid panel assembly

Trunk lid latch assembly removal

7. Trunk lid latch assembly

Trunk lid hinge removal steps

DRear shelf trim

DRear seat (Refer to GROUP 52A.)

9. Trunk lid panel assembly

AA""AA10. Trunk lid torsion bar (Right side)

AA""AA11. Trunk lid torsion bar (Left side)

12. Trunk lid hinge

Page 1190 of 1449

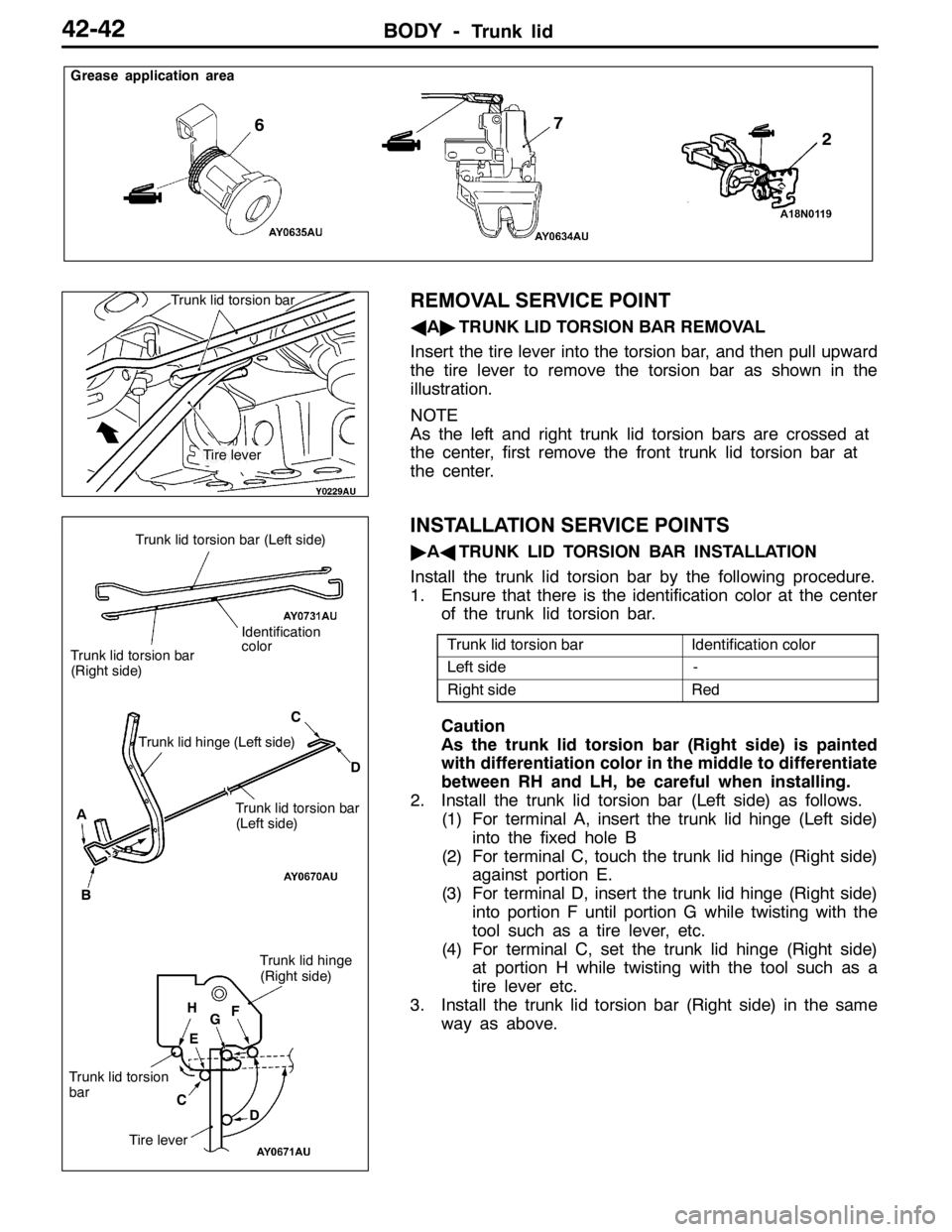

BODY -Trunk lid42-42

Grease application area

67

2

REMOVAL SERVICE POINT

AA"TRUNK LID TORSION BAR REMOVAL

Insert the tire lever into the torsion bar, and then pull upward

the tire lever to remove the torsion bar as shown in the

illustration.

NOTE

As the left and right trunk lid torsion bars are crossed at

the center, first remove the front trunk lid torsion bar at

the center.

INSTALLATION SERVICE POINTS

"AATRUNK LID TORSION BAR INSTALLATION

Install the trunk lid torsion bar by the following procedure.

1. Ensure that there is the identification color at the center

of the trunk lid torsion bar.

Trunk lid torsion barIdentification color

Left side-

Right sideRed

Caution

As the trunk lid torsion bar (Right side) is painted

with differentiation color in the middle to differentiate

between RH and LH, be careful when installing.

2. Install the trunk lid torsion bar (Left side) as follows.

(1) For terminal A, insert the trunk lid hinge (Left side)

into the fixed hole B

(2) For terminal C, touch the trunk lid hinge (Right side)

against portion E.

(3) For terminal D, insert the trunk lid hinge (Right side)

into portion F until portion G while twisting with the

tool such as a tire lever, etc.

(4) For terminal C, set the trunk lid hinge (Right side)

at portion H while twisting with the tool such as a

tire lever etc.

3. Install the trunk lid torsion bar (Right side) in the same

way as above.

Trunk lid torsion bar

Tire lever

Tire lever

D

Trunk lid torsion

bar

H

Identification

color

Trunk lid torsion bar

(Right side)

Trunk lid torsion bar

(Left side) Trunk lid hinge (Left side)

A

BC

D

Trunk lid hinge

(Right side)

C

F

G

E

Trunk lid torsion bar (Left side)