service MITSUBISHI MONTERO 1987 1.G Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 150 of 284

8430 METERS AND GAUGES - Service Adjustment Procedures.

SERVICE BJUSTMENT. PROCEDURES

SPEEDOMETER INSPECTION NOSHIAA

I. Adjust tire inflation pressure to the standard value. (Refer

to’GROUP 22 WHEELS AND TIRES-General Specifications)

2. Use speedometer tester to make sure that the speedome-

ter indication error is within the standard value.

Standard value :

Meter with “km/h” indication km/h

20 km/h +4

-1

40 km/h +4

0

80 km/h +5

0

120 km/h + 5.5

+0.5

Meter with “mph” indication

mph

10 mph

25 mph

50 mph

75 mph +I.5

21.5

+I.5

&I.5

Caution

1 When using a speedometer tester to inspect the

speedometer, be sure to chock the non-drive wheels

to prevent the vehicle from moving. Also be sure to

set the transfer shift lever to “2H”.

2 If there is a special regulation for speedometer

indication error in the area where the ‘vehicle is

operated, be sure to meet the requirement of the

regulation.

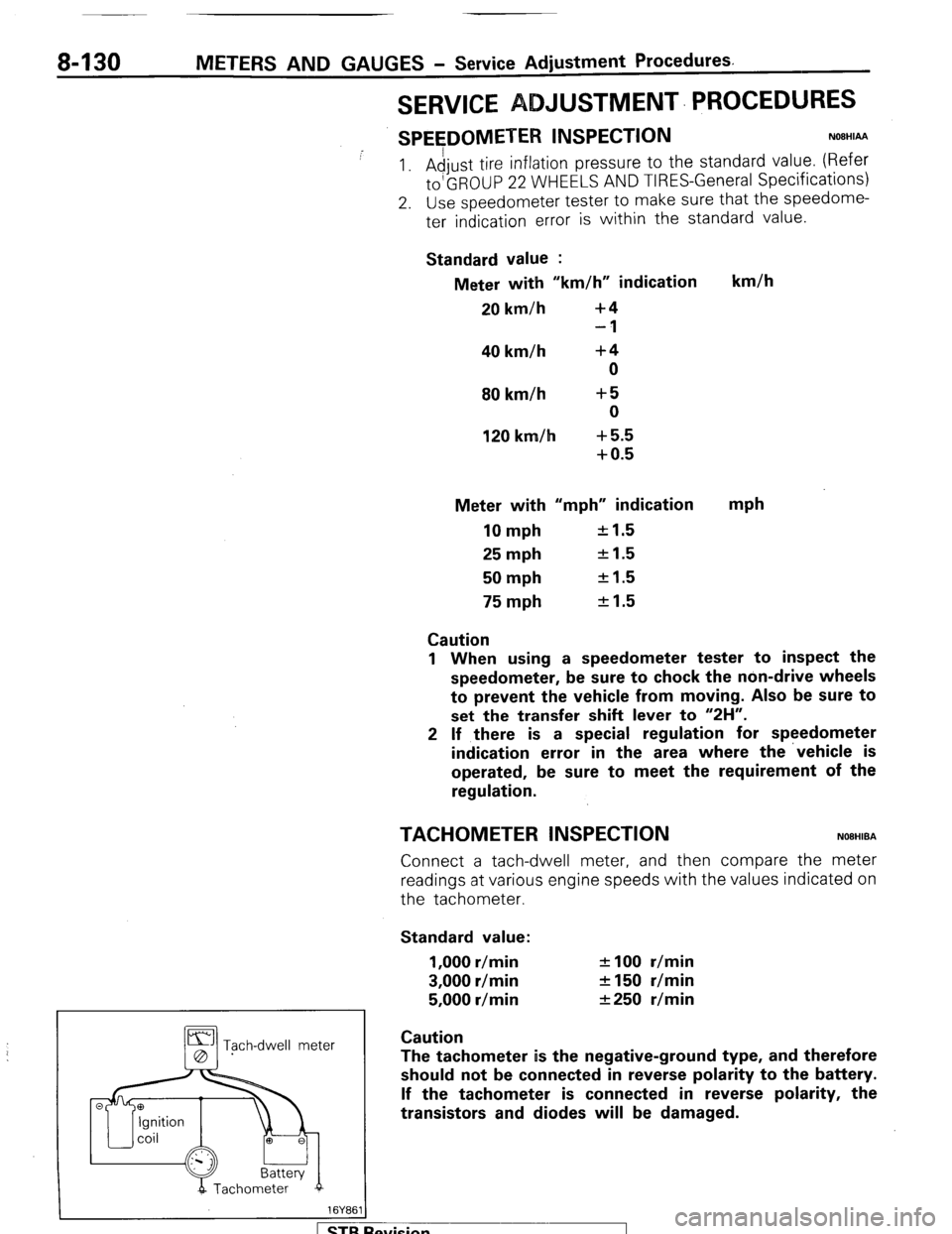

TACHOMETER INSPECTION NOBHIBA

Connect a tach-dwell meter, and then compare the meter

readings at various engine speeds with the values indicated on

the tachometer.

Standard value:

1,000 r/min

3,000 r/min

5,000 r/min f 100 r/min

2150 r/min

&250 r/min

Tgch-dwell meter Caution

The tachometer is the negative-ground type, and therefore

should not be connected in reverse polarity to the battery.

If the tachometer is connected in reverse polarity, the

transistors and diodes will be damaged.

evision

Page 151 of 284

METERS AND GAUGES - Service Adiustment Procedures 8-131

r

(harness side) 16W834

Stopper (upper)

FUEL GAUGE SIMPLE TEST NOEHICE

(1) Disconnect, from below the vehicle, the wiring connector

from the fuel gauge unit.

(2) Ground the connector at the harness through a test light.

(3) Turn the ignition key to the ON position.

(4) Check to be

sure that the test light flashes and the fuel

gauge indicator moves.

(5) If both the test light and gauge operate, the circuit to the

gauge unit is normal and the gauge unit itself is faulty.

If the test light flashes but the gauge does not operate, the

gauge is faulty.

If neither the test light nor the gauge operates, the fuel

gauge circuit is faulty.

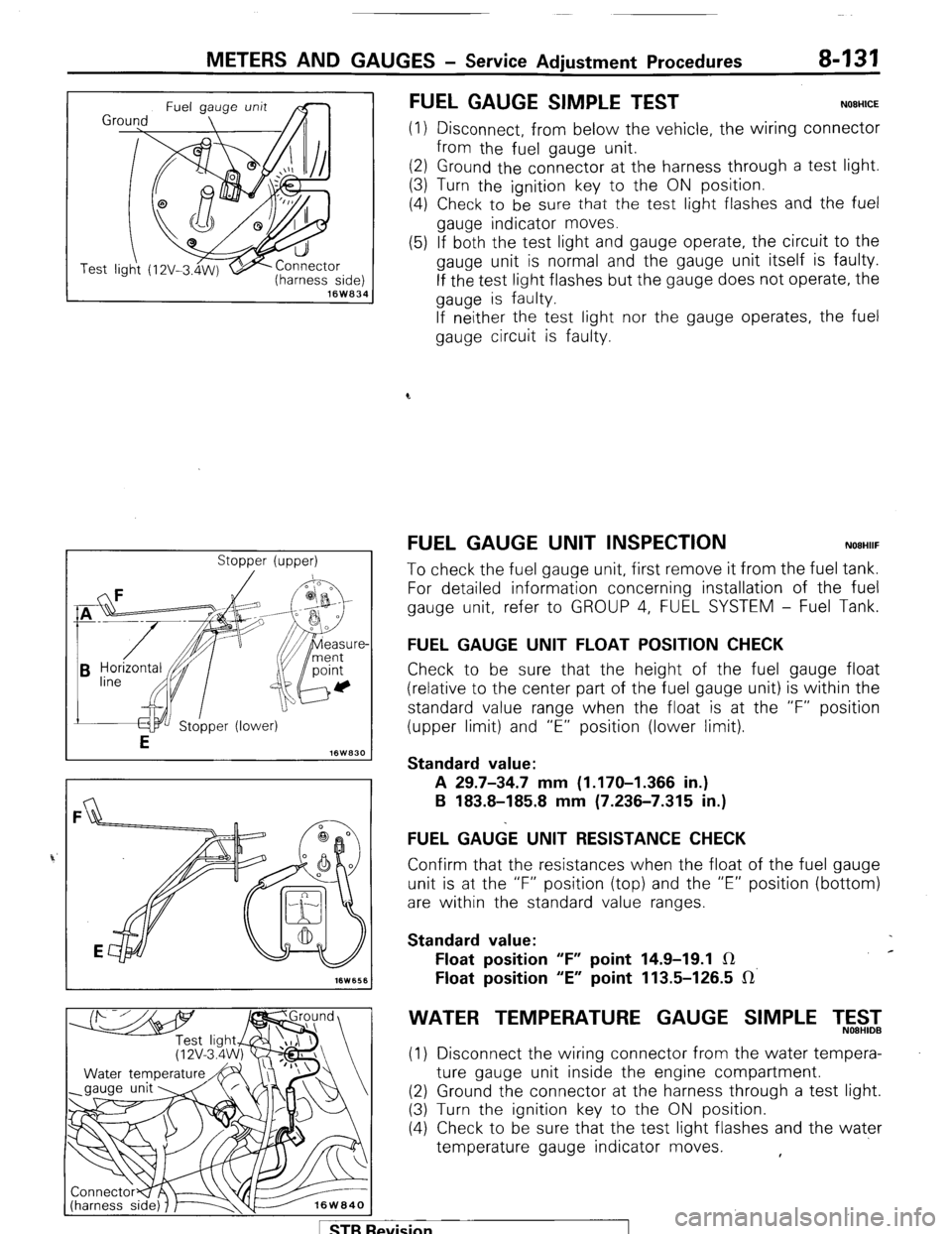

FUEL GAUGE UNIT INSPECTION NOEHIIF

To check the fuel gauge unit, first remove it from the fuel tank.

For detailed information concerning installation of the fuel

gauge unit, refer to GROUP 4, FUEL SYSTEM - Fuel Tank.

FUEL GAUGE UNIT FLOAT POSITION CHECK

Check to be sure that the height of the fuel gauge float

(relative to the center part of the fuel gauge unit) is within the

standard value range when the float is at the “F” position

(upper limit) and “E” position (lower limit).

Standard value:

A 29.7-34.7 mm (1.170-I .366 in.)

B 183.8-185.8 mm (7.236-7.315 in.)

FUEL GA&E UNIT RESISTANCE CHECK

Confirm that the resistances when the float of the fuel gauge

unit is at the “F” position (top) and the “E” position (bottom)

are within the standard value ranges.

Standard value:

Float position “F” point 14.9-19.1 IR c

Float position “E” point 113.5-126.5 IR’

WATER TEMPERATURE GAUGE SIMPLE T,5$2

(1) Disconnect the wiring connector from the water tempera-

ture gauge unit inside the engine compartment.

(2) Ground the connector at the harness through a test light.

(3) Turn the ignition key to the ON position.

(4) Check to be sure that the test light flashes and the water

temperature gauge indicator moves. ,

1 STB Revision

Page 152 of 284

8-132 METERS AND GAUGES - Service Adjustment Procedures

(5) If both the test light and gauge operate, the circuit to the

gauge unit is normal and the gauge unit itself is faulty.

If the test light flashes but the gauge does not operate, the

gauge is faulty.

If 1 neither the test light nor the gauge operates, the water

temperature gauge circuit is faulty.

Se

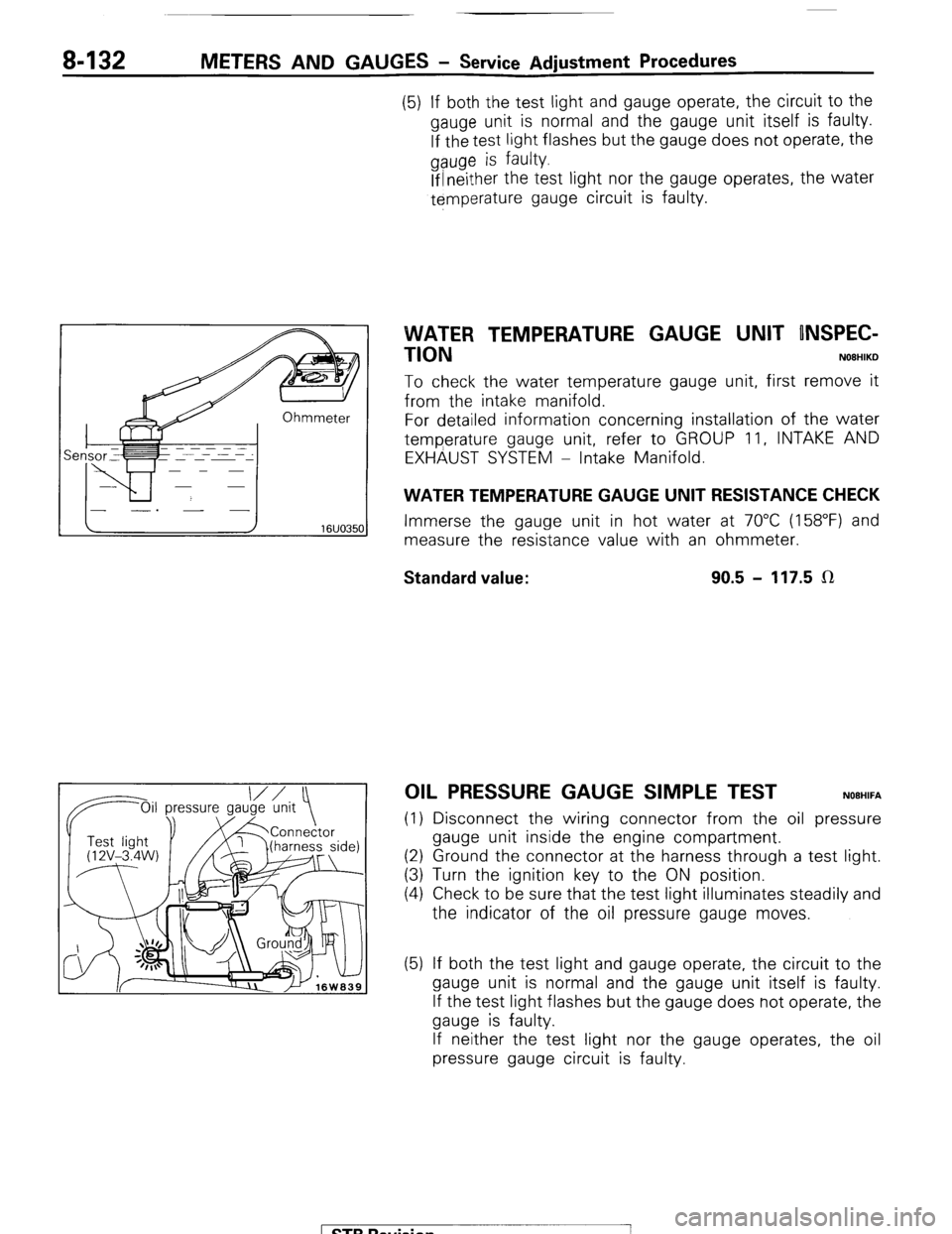

VVATER TEMPERATURE GAUGE UNIT ONSPEC-

TION

NOBHIKD

To check the water temperature gauge unit, first remove it

from the intake manifold.

For detailed information concerning installation of the water

temperature gauge unit, refer to GROUP 11, INTAKE AND

EXHAUST SYSTEM - Intake Manifold.

WATER TEMPERATURE GAUGE UNIT RESISTANCE CHECK

Immerse the gauge unit in hot water at 70°C (158°F) and

measure the resistance value with an ohmmeter.

Standard value: 90.5 - 117.5 LR

OIL PRESSURE GAUGE SIMPLE TEST NOEHIFA

(1) Disconnect the wiring connector from the oil pressure

gauge unit inside the engine compartment.

(2) Ground the connector at the harness through a test light.

(3) Turn the ignition key to the ON position.

(4) Check to be sure that the test light illuminates steadily and

the indicator of the oil pressure gauge moves.

(5) If both the test light and gauge operate, the circuit to the

gauge unit is normal and the gauge unit itself is faulty.

If the test light flashes but the gauge does not operate, the

gauge is faulty.

If neither the test light nor the gauge operates, the oil

pressure gauge circuit is faulty.

1 STB Revision

-7

Page 153 of 284

METERS AND GAUGES - Service Adjustment Procedures 8-133

IOil p Oil pressure ressure

gauge unit

1 I Test light

‘@‘(12V - 3.4 I

W)

16W1576

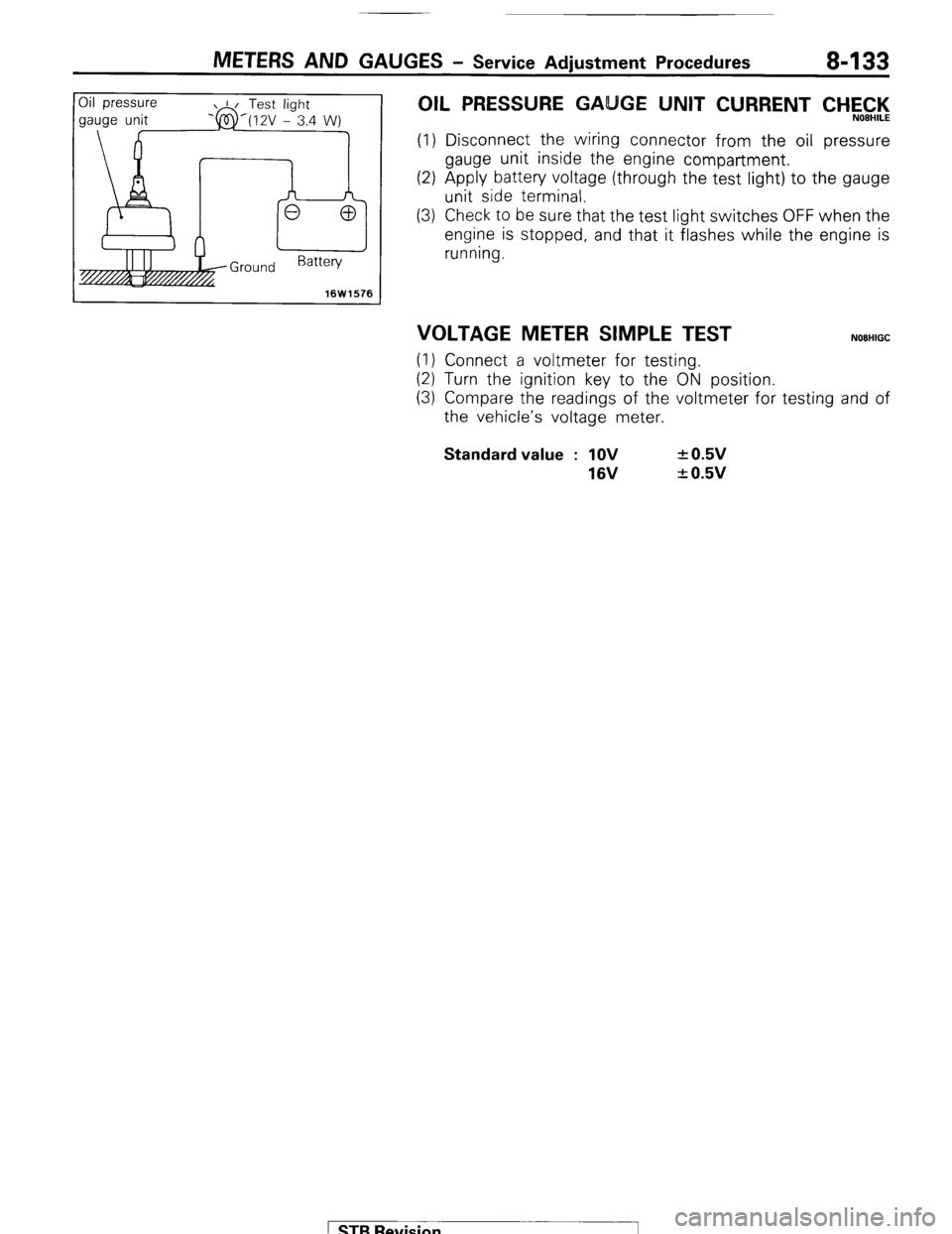

OIL PRESSURE GA GE UNIT CURRENT CHEC,‘l<,

(1) Disconnect the wiring connector from the oil pressure

gauge unit inside the engine compartment.

(2) Apply battery voltage (through the test light) to the gauge

unit side terminal.

(3) Check to be sure that the test light switches OFF when the

engine is stopped, and that it flashes while the engine is

running.

VOLTAGE METER SIMPLE TEST NOEHIGC

(1) Connect a voltmeter for testing.

(2) Turn the ignition key to the ON position.

(3) Compare the readings of the voltmeter for testing and of

the vehicle’s voltage meter. Standard value : 1OV

16V + 0.5v

+ 0.5v

1 STB Revision

Page 154 of 284

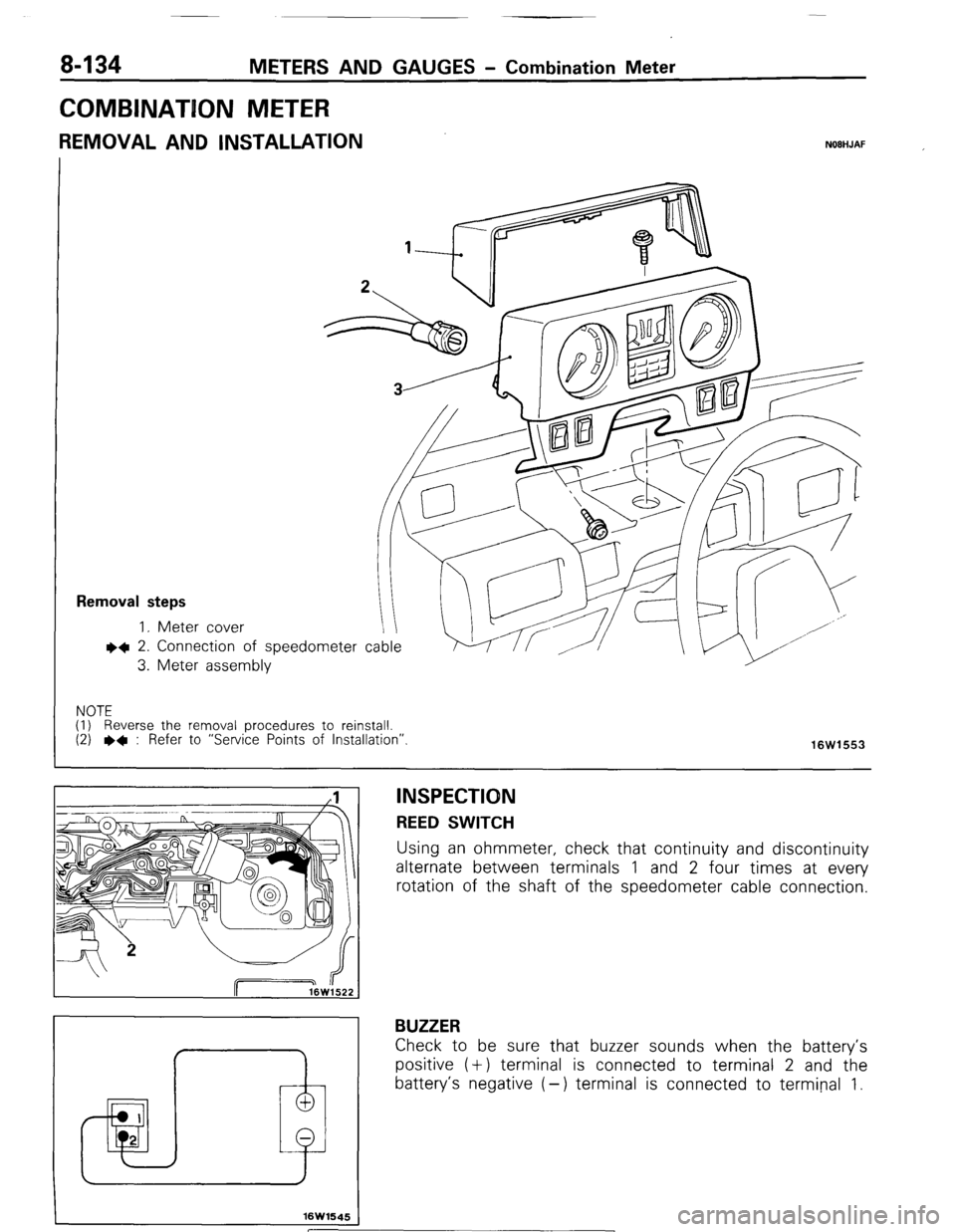

8-134 METERS AND GAUGES - Combination Meter

COMBINATION METER

REMOVAL AND INSTALLATION NOBHJAF

Removal steps

1. Meter cover

l 4 2. Connection

3. Meter asset of speedometer cable

nbly

NOTE

(I) Reverse the removal procedures to reinstall.

(2)

l + : Refer to “Service Points of Installation”.

16W1553

I 1 I

I

f

16W1645

INSPECTION REED SWITCH

Using an ohmmeter, check that continuity and discontinuity

alternate between terminals 1 and 2 four times at every

rotation of the shaft of the speedometer cable connection.

BUZZER

Check to be sure that buzzer sounds when the battery’s

positive (+) terminal is connected to terminal 2 and the

battery’s negative (-) terminal is connected to terminal 1.

[ STB Revision

Page 155 of 284

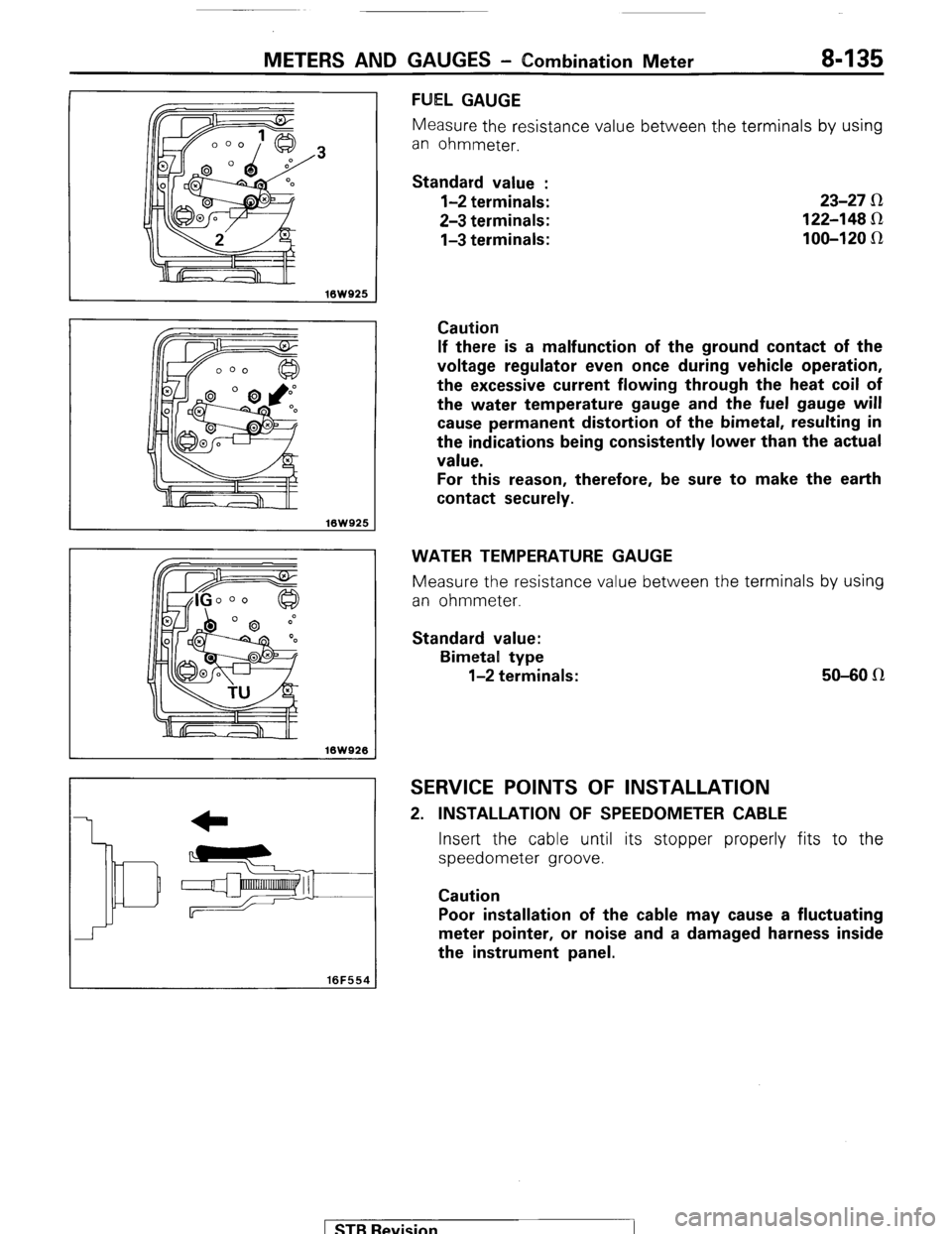

METERS AND GAUGES - Combination Meter 8-135

.3

16WQ25

16W925

10W926

16F554

FUEL GAUGE

Measure the resistance value between t.he terminals by using

an ohmmeter.

Standard value :

l-2 terminals:

2-3 terminals:

l-3 terminals: 23-27 R

122-148 Sz

100-120 IR

Caution

If there is a malfunction of the ground contact of the

voltage regulator even once during vehicle operation,

the excessive current flowing through the heat coil of

the water temperature gauge and the fuel gauge will

cause permanent distortion of the bimetal, resulting in

the indications being consistently lower than the actual

value.

For this reason, therefore, be sure to make the earth

contact securely.

WATER TEMPERATURE GAUGE

Measure the resistance value between the terminals by using

an ohmmeter.

Standard value:

Bimetal type

l-2 terminals: 50-80 n

SERVICE POINTS OF INSTALLATION

2. INSTALLATION OF SPEEDOMETER CABLE

Insert the cable until its stopper properly fits to the

speedometer groove.

Caution

Poor installation of the cable may cause a fluctuating

meter pointer, or noise and a damaged harness inside

the instrument panel.

) STB Revision

Page 164 of 284

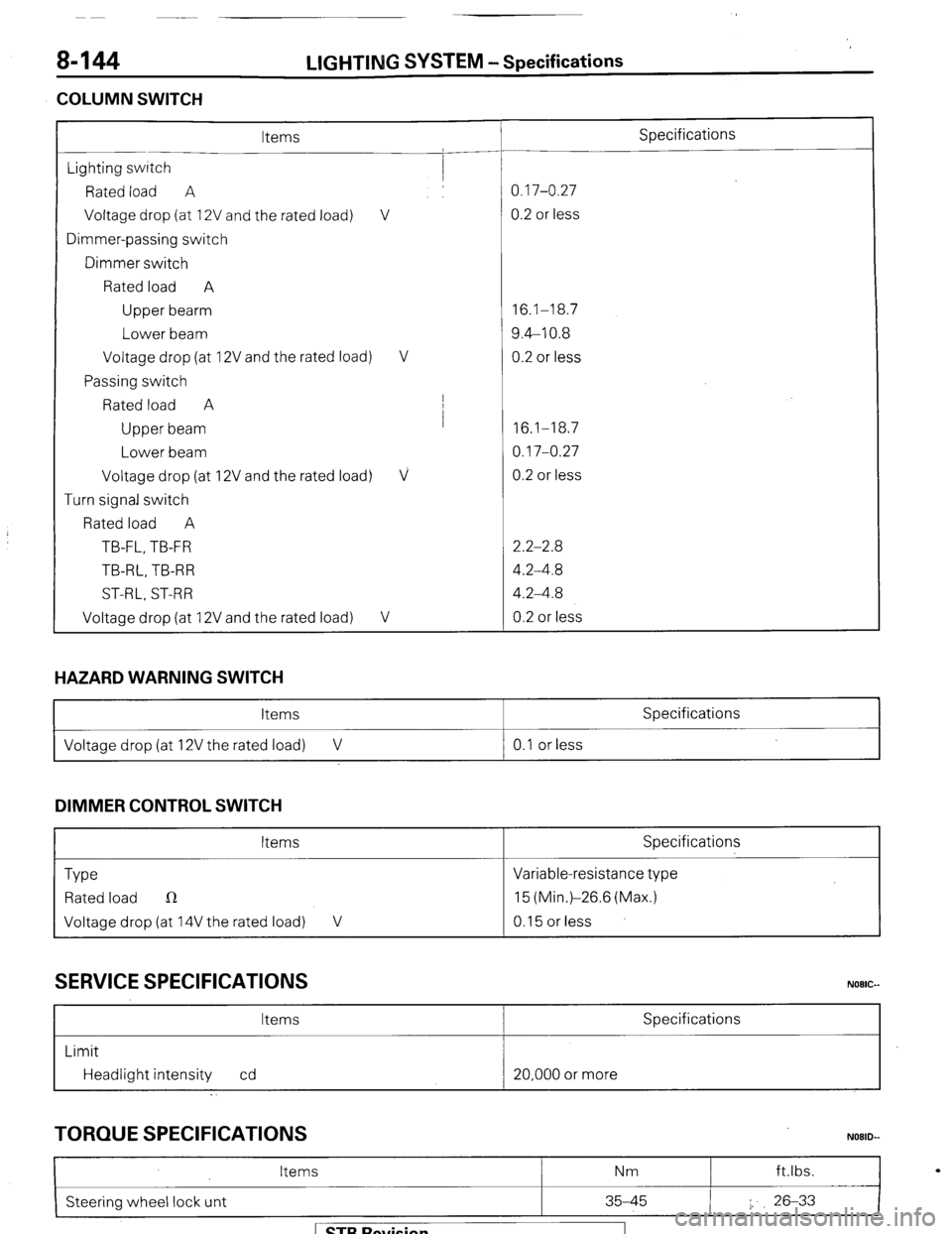

8-144

COLUMN SWITCH LIGHTING

SYSTEM -Specifications

Items Specifications

Lighting switch

Rated load A 0.17-0.27

Voltage drop (at 12V and the rated load) V 0.2 or less

Dimmer-passing switch

Dimmer switch

Rated load A

Upper bearm 16.1-18.7

Lower beam 9.4-10.8

Voltage drop (at 12V and the rated load) V 0.2 or less

Passing switch

Rated load A I

Upper beam I

16.1-18.7

Lower beam 0.17-0.27

Voltage drop (at 12V and the rated load)

V 0.2 or less

Turn signal switch

Rated load A

TB-FL, TB-FR 2.2-2.8

TB-RL, TB-R R 4.2-4.8

ST-RL, ST-RR 4.2-4.8

Voltage drop (at 12V and the rated load)

V 0.2 or less

HAZARD WARNING SWITCH

Items Specifications

I Voltage drop (at 12V the rated load) V 0.1 or less

I

DIMMER CONTROL SWITCH

Items Specifications

Type Variable-resistance type

Rated load n 15 (Min.)-26.6 (Max.)

Voltage drop (at 14V the rated load) V 0.15 or less

SERVICE SPECIFICATIONS

Items Specifications

Limit

Headlight intensity cd 20,000 or more

TORQUE SPECIFICATIONS

I

Items Nm ft.lbs.

N08lb

Steering wheel lock unt 35-45 I. 26-33

I

1 STB Revision

Page 177 of 284

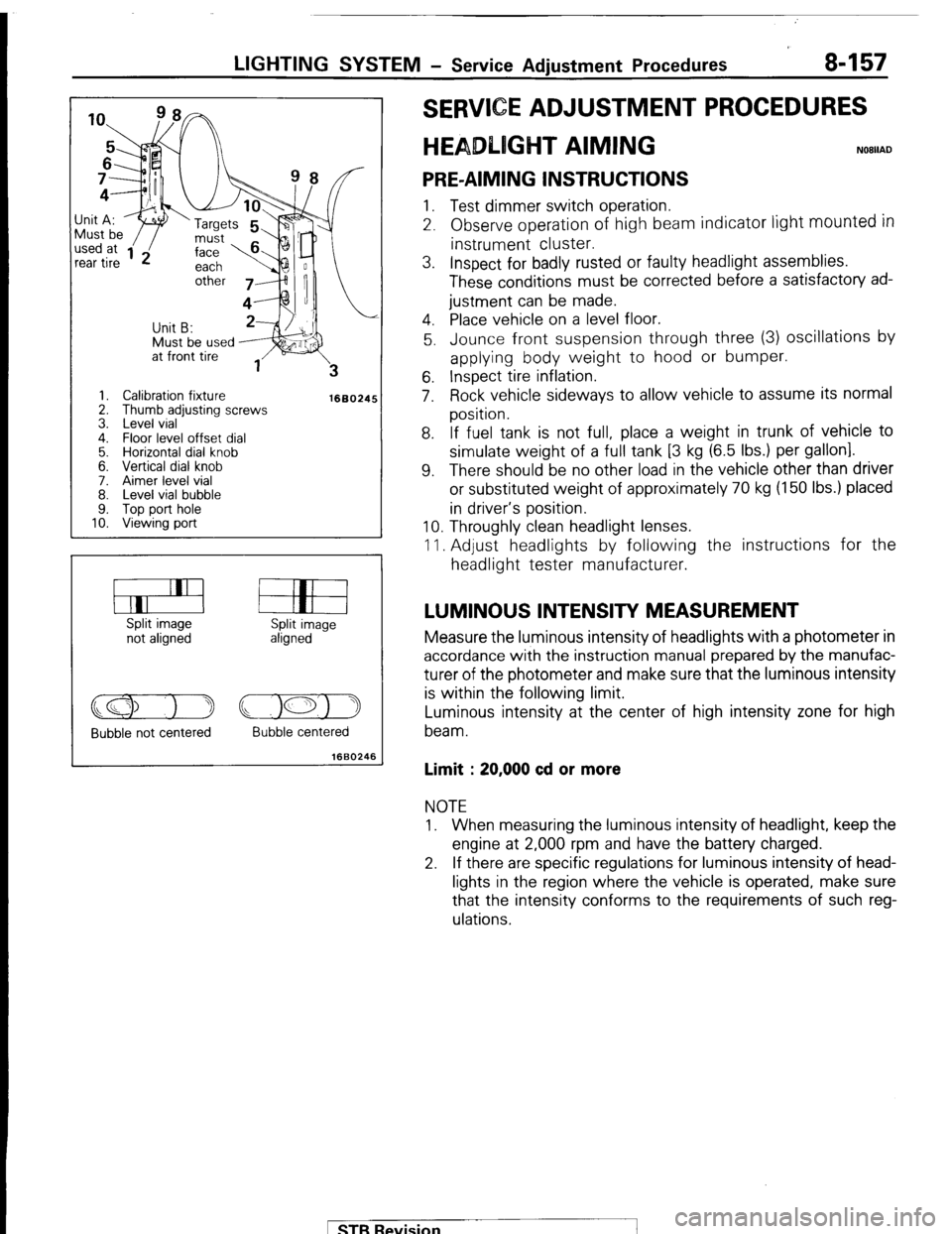

LIGHTING SYSTEM - Service Adjustment Procedures 8-157

Must be used J;it A:

I ‘w ‘Targets

1. Calibration fixture

2. Thumb adjusting screws

3. Level vial

4. Floor level offset dial

5. Horizontal dial knob

6. Vertical dial knob

7. Aimer level vial

8. Level vial bubble

9. Top port hole

10. Viewing port

1660245

Split image

not aligned Split image

aligned

Bubble not centered Bubble centered

1660246

E ADJUSTMENT PROCEDURES

T AIMING

PRE-AIMING INSTRUCTIONS 1. Test dimmer switch operation.

2. Observe operation of high beam indicator light

mounted in instrument cluster.

3. Inspect for badly rusted or faulty headlight assemblies.

These conditions must be corrected before a satisfactory ad-

justment can be made.

4. Place vehicle on a level floor.

5. Jounce front suspension through three (3) oscillations by

applying body weight to hood or bumper.

6. Inspect tire inflation.

7. Rock vehicle sideways to allow vehicle to assume its normal

position.

8. If fuel tank is not full, place a weight in trunk of vehicle to

simulate weight of a full tank [3 kg (6.5 Ibs.) per gallon].

9. There should be no other load in the vehicle other than driver

or substituted weight of approximately 70 kg (150 Ibs.) placed

in driver’s position.

10. Throughly clean headlight lenses.

11. Adjust headlights by following the instructions for the

headlight tester manufacturer.

LUMINOUS INTENSITY MEASUREMENT Measure the luminous intensity of headlights with a photometer in

accordance with the instruction manual prepared by the manufac-

turer of the photometer and make sure that the luminous intensity

is within the following limit.

Luminous intensity at the center of high intensity zone for high

beam.

Limit : 20,000 cd or more NOTE

1. When measuring the luminous intensity of headlight, keep the

engine at 2,000 rpm and have the battery charged.

2. If there are specific regulations for luminous intensity of head-

lights in the region where the vehicle is operated, make sure

that the intensity conforms to the requirements of such reg-

ulations.

pTB Revision

Page 179 of 284

LIGHTING SYSTEM - Column Switch 8-159

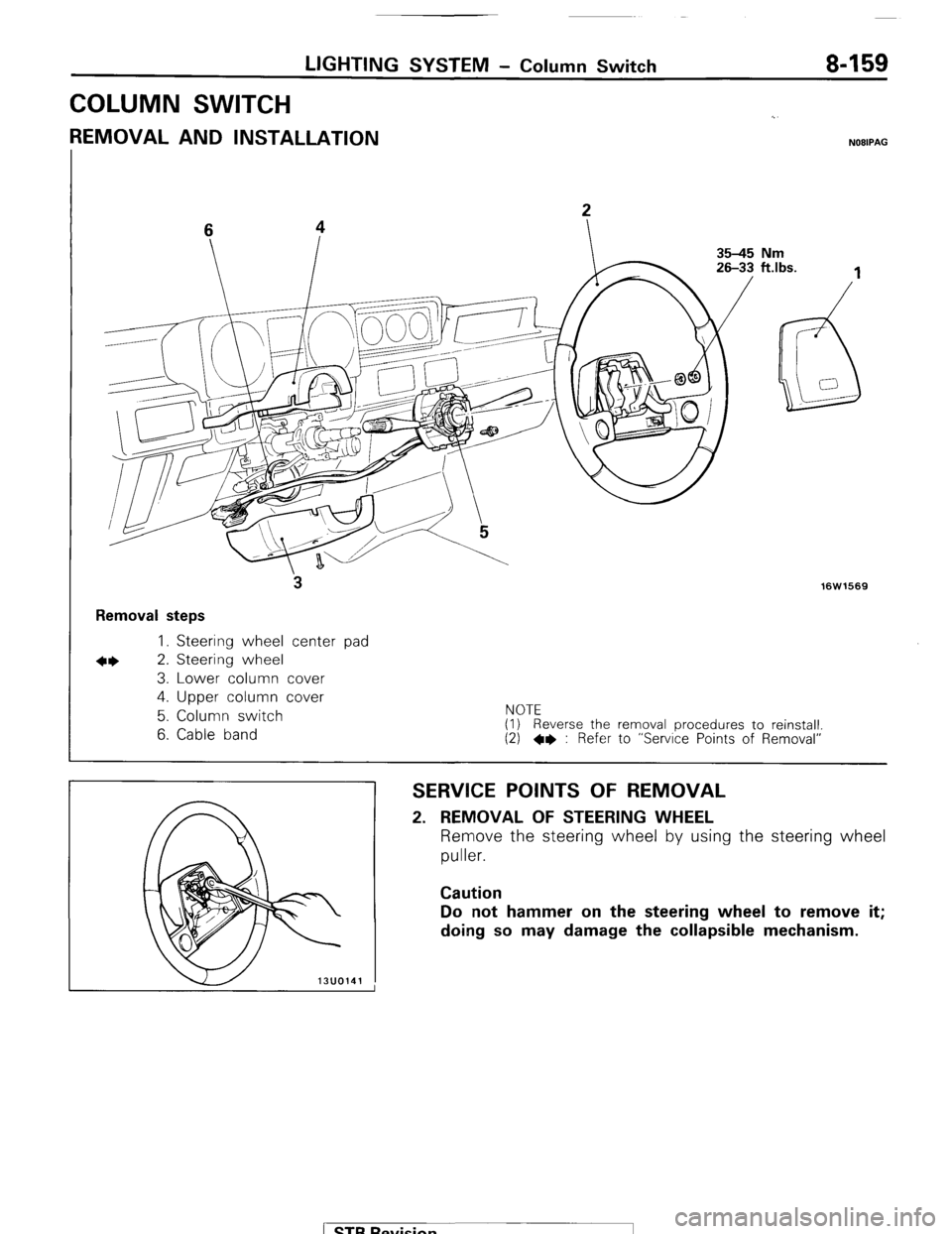

COLUMN SWITCH

REMOVAL AND INSTALLATION NOBIPAG

3

Removal steps

I. Steering wheel center pad

*I) 2. Steering wheel

3. Lower column cover

4. Upper column cover

hlnTC

16W1569

5. Column switch

6. Cable band I\I”IC (I) Reverse the removal procedures to reinstall.

(2) l * : Refer to “Service Points of Removal”

SERVICE POINTS OF REMOVAL 2. REMOVAL OF STEERING WHEEL

Remove the steering wheel by using the steering wheel

puller. Caution

Do not hammer on the steering wheel to remove it;

doing so may damage the collapsible mechanism.

) STB Revision

Page 190 of 284

8-170 WIPER AND WASHER SYSTEM - Service Adjustment Procedures

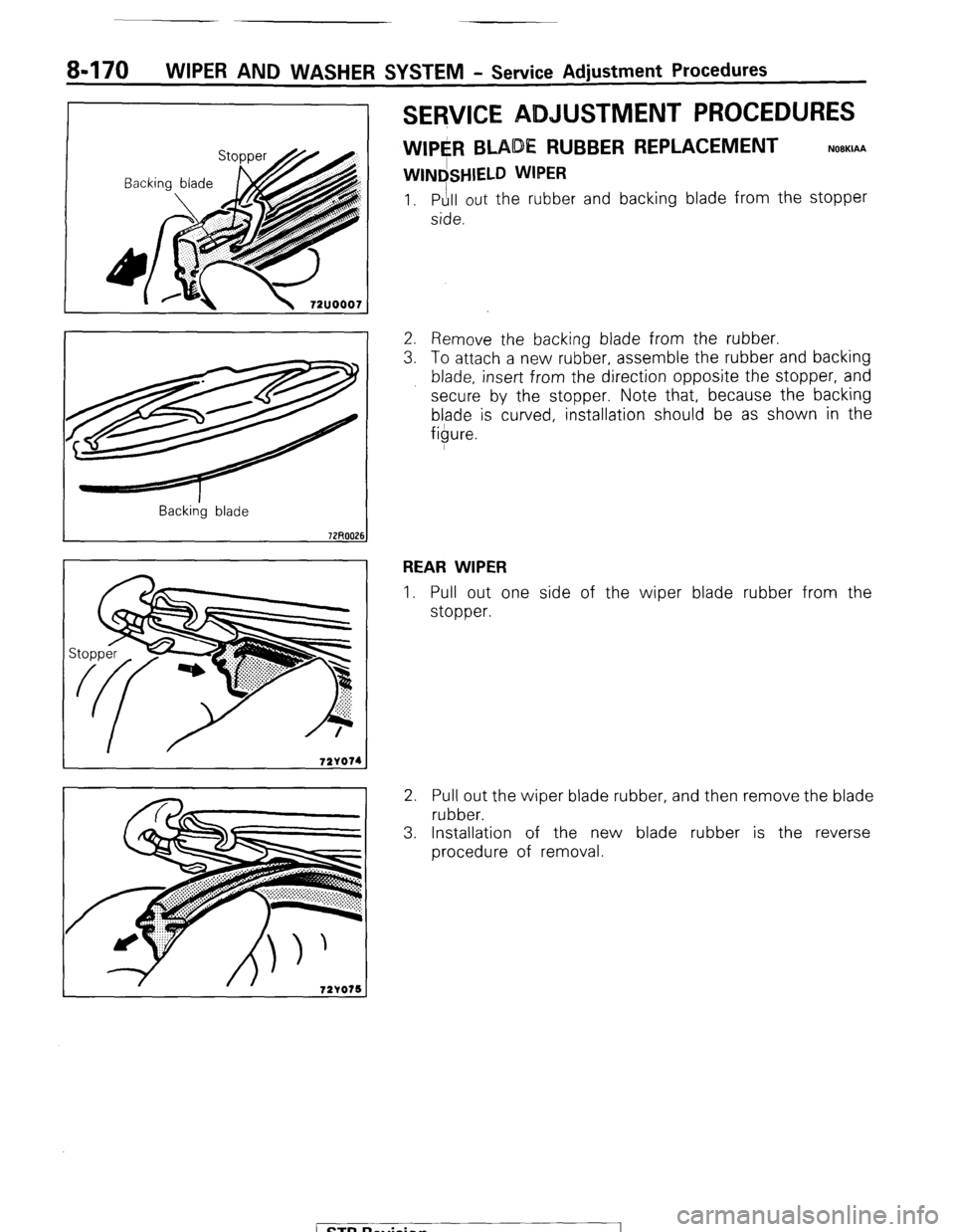

SERVICE ADJUSTMENT PROCEDURES

WIPE#l BLADE RUBBER REPLACEMENT

WINdSHIELD WIPER

NOBKIAA

1. Pull out the rubber and backing blade from the stopper

side.

Back&g blade

2. Remove the backing blade from the rubber.

3. To attach a new rubber, assemble the rubber and backing

blade, insert from the direction opposite the stopper, and

secure by the stopper. Note that, because the backing

blade is curved, installation should be as shown in the

figure.

REAR WIPER

1. Pull out one side of the wiper blade rubber from the

stopper.

2. Pull out the wiper blade rubber, and then remove the blade

rubber.

3. Installation of the new blade rubber is the reverse

procedure of removal.

( ST6 Revision