MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: sensor, washer fluid, cruise control, fuel consumption, parking sensors, turn signal, coolant level

Page 1341 of 2103

AUTOMATIC TRANSAXLE.

OVERHAUL Transaxle

59

I I I

front

I

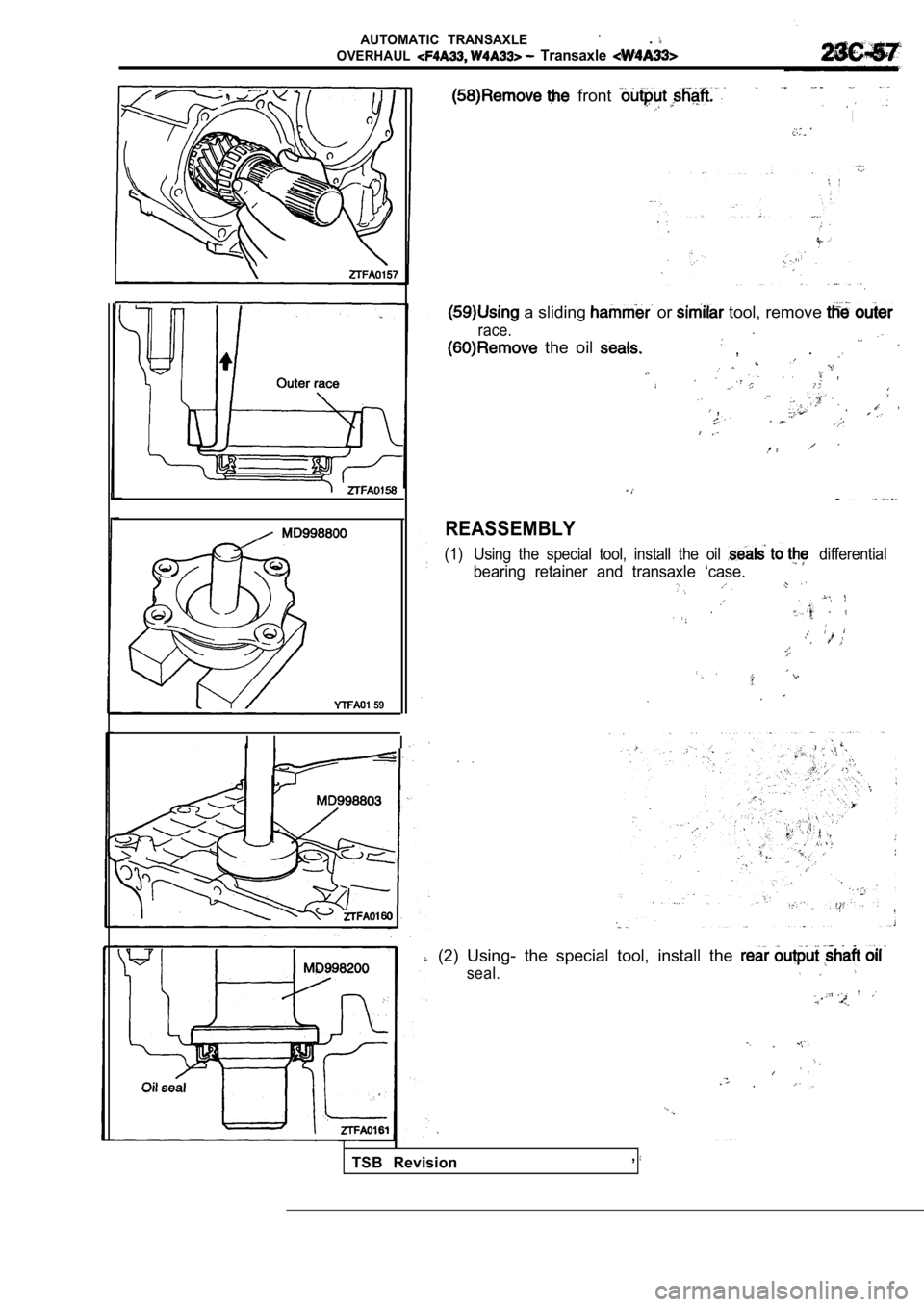

a sliding or tool, remove

race.

the oil , .

,

REASSEMBLY

(1) Using the special tool, install the oil differential

bearing retainer and transaxle ‘case.

.

(2) Using- the special tool, install the

seal.

TSB Revision,

Page 1342 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL Transaxle

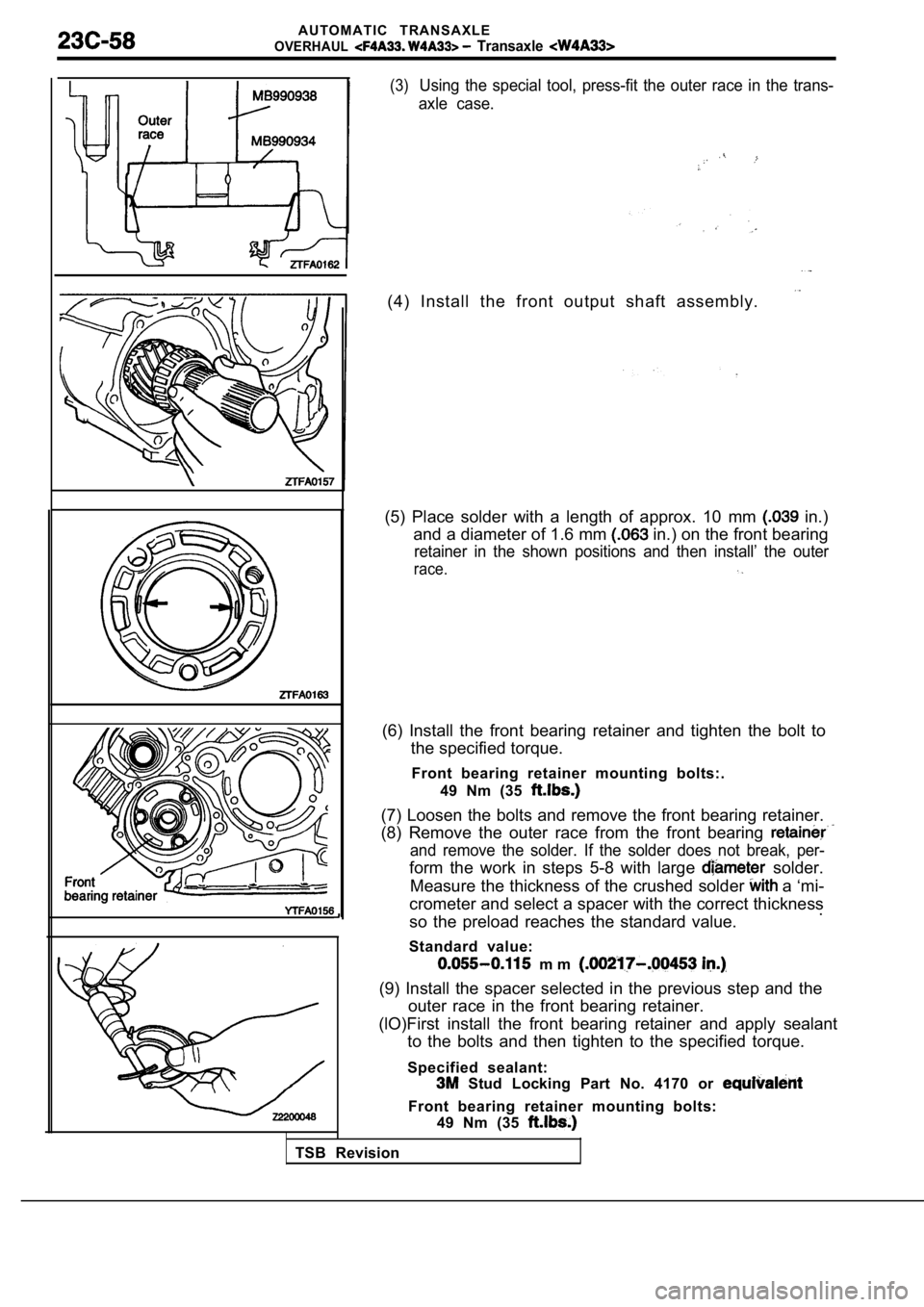

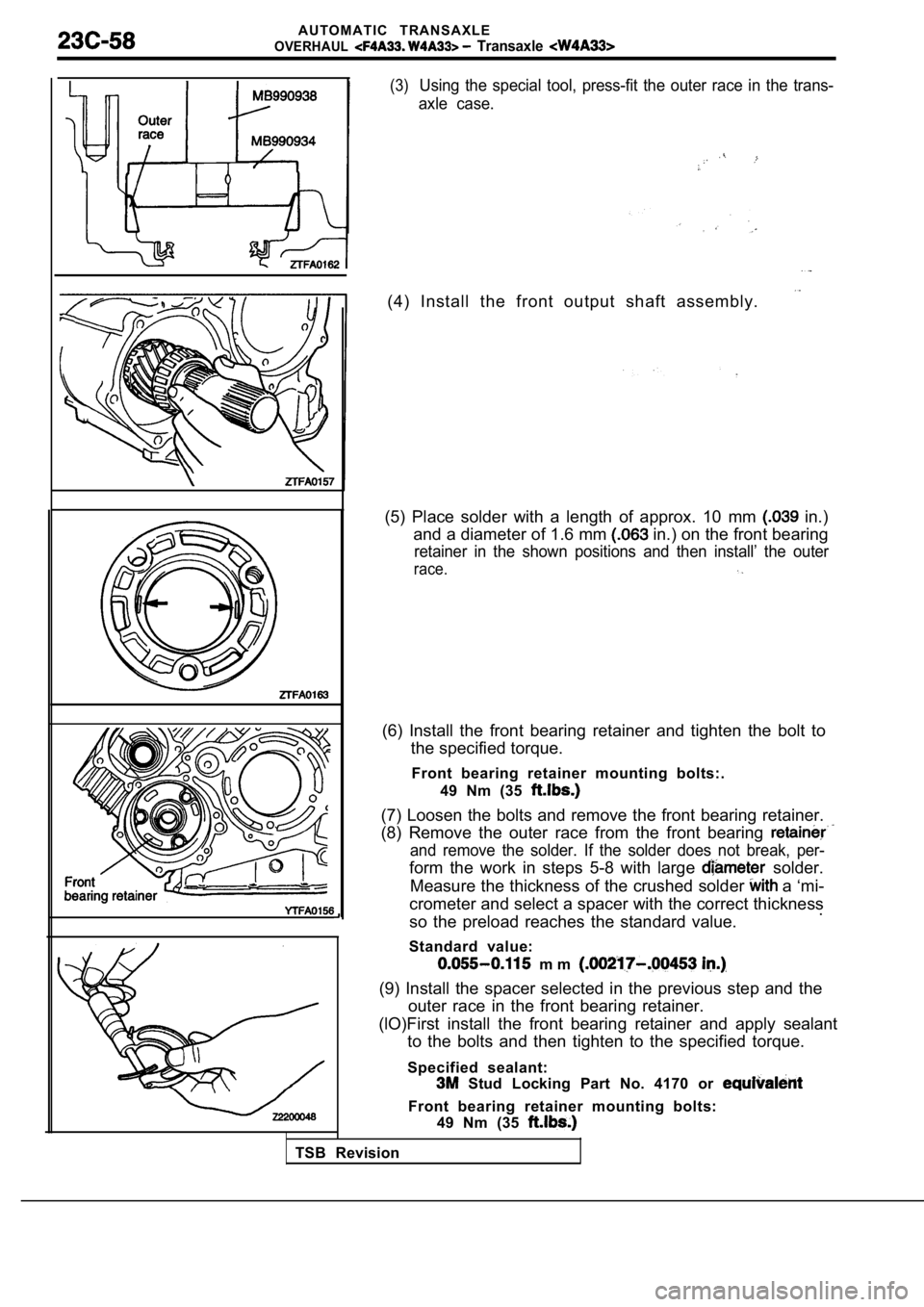

(3)Using the special tool, press-fit the outer race in the trans-

axle case.

(4) Install the front output shaft assembly.

(5) Place solder with a length of approx. 10 mm in.)

and a diameter of 1.6 mm

in.) on the front bearing

retainer in the shown positions and then install’ t he outer

race.

(6) Install the front bearing retainer and tighten the bolt to

the specified torque.

Front bearing retainer mounting bolts:. 49 Nm (35

(7) Loosen the bolts and remove the front bearing r etainer.

(8) Remove the outer race from the front bearing

and remove the solder. If the solder does not break , per-

form the work in steps 5-8 with large solder.

Measure the thickness of the crushed solder

a ‘mi-

crometer and select a spacer with the correct thick ness

so the preload reaches the standard value. .

Standard value:

m m

(9) Install the spacer selected in the previous ste p and the

outer race in the front bearing retainer.

(lO)First install the front bearing retainer and ap ply sealant

to the bolts and then tighten to the specified torq ue.

Specified sealant:

Stud Locking Part No. 4170 or

Front bearing retainer mounting bolts: 49 Nm (35

TSB Revision

Page 1343 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

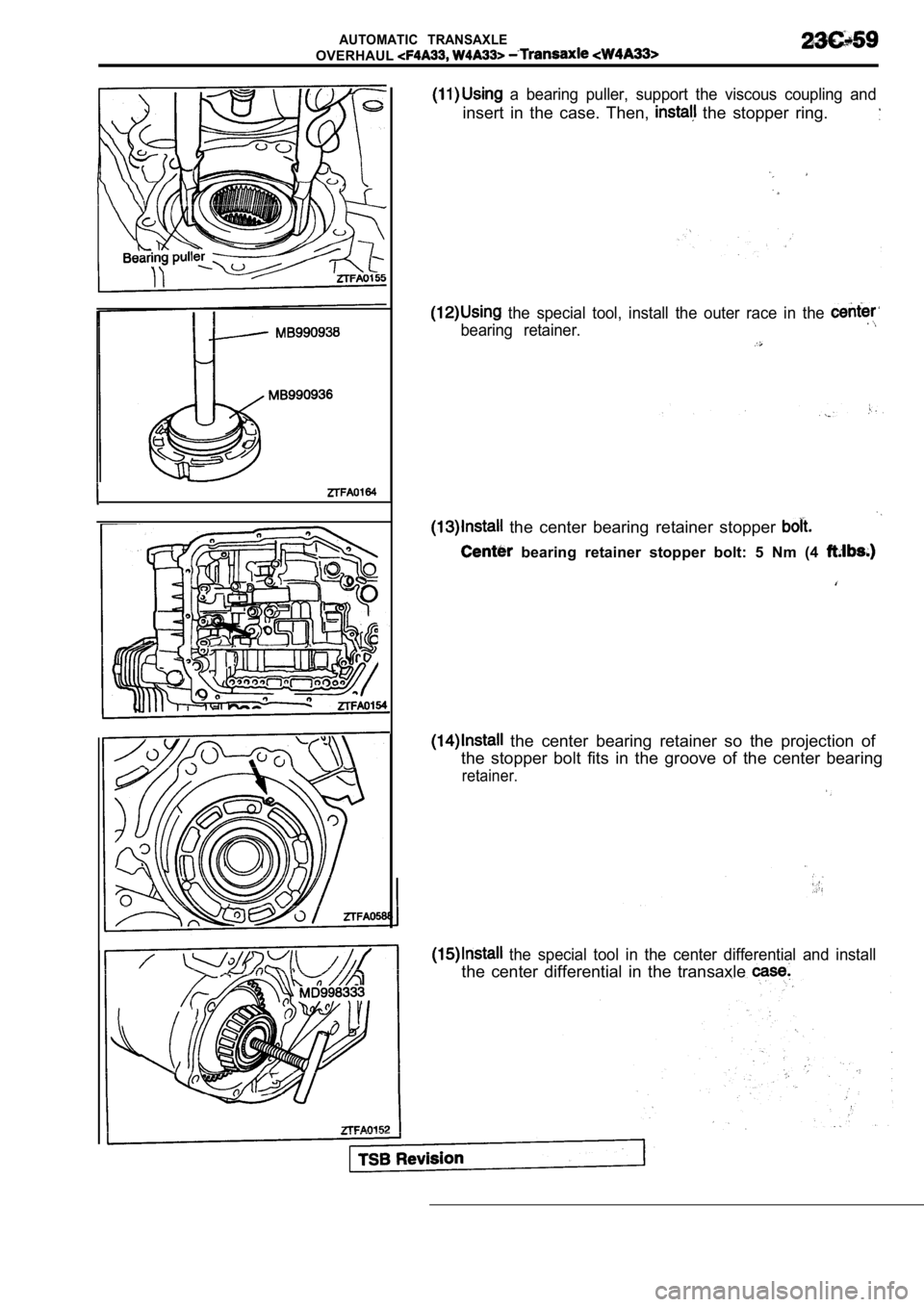

a bearing puller, support the viscous coupling and

insert in the case. Then, the stopper ring.

the special tool, install the outer race in the

bearing retainer..

the center bearing retainer stopper

bearing retainer stopper bolt: 5 Nm (4

the center bearing retainer so the projection of

the stopper bolt fits in the groove of the center b earing

retainer.

the special tool in the center differential and install

the center differential in the transaxle

Page 1344 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL -Transaxle

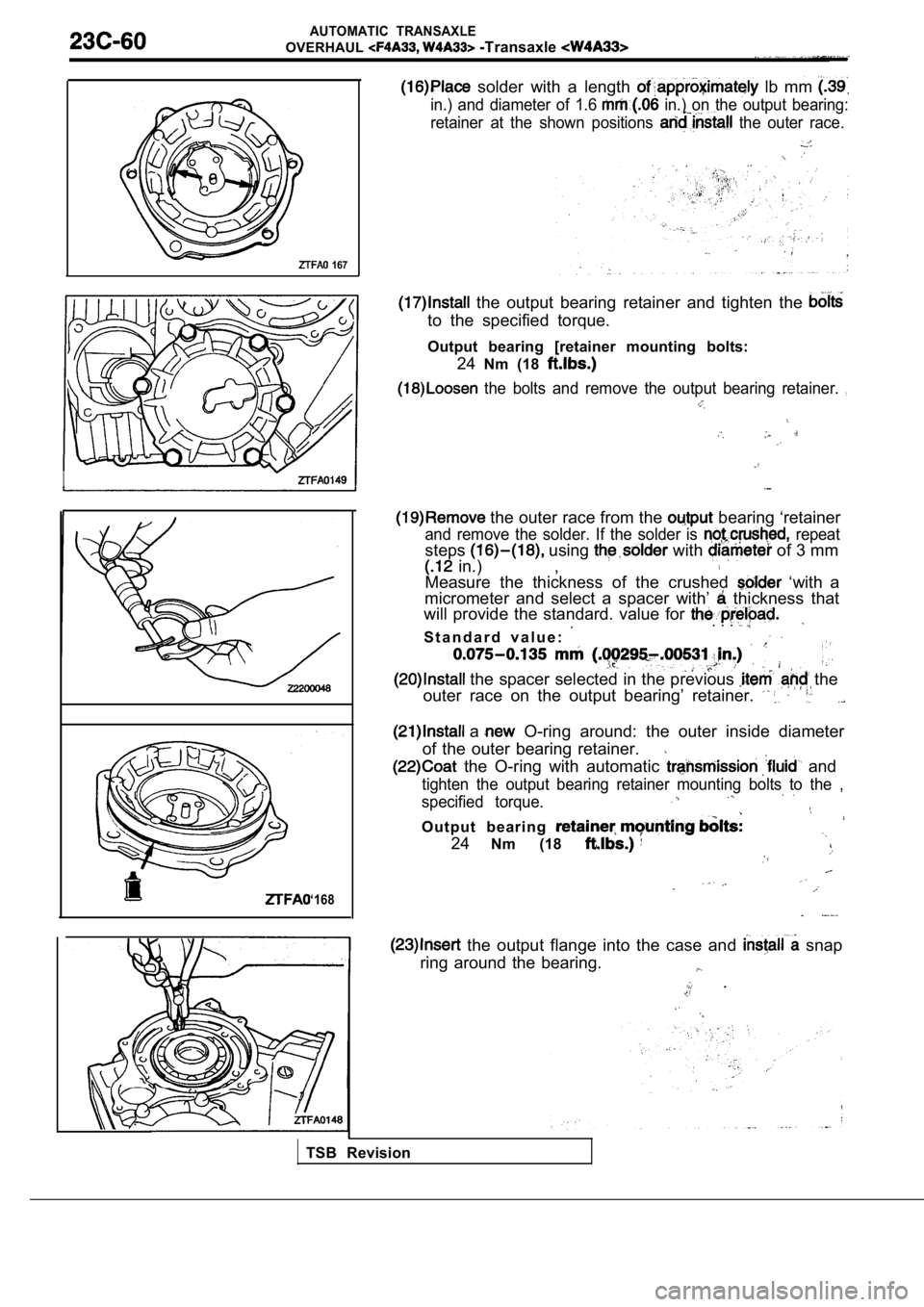

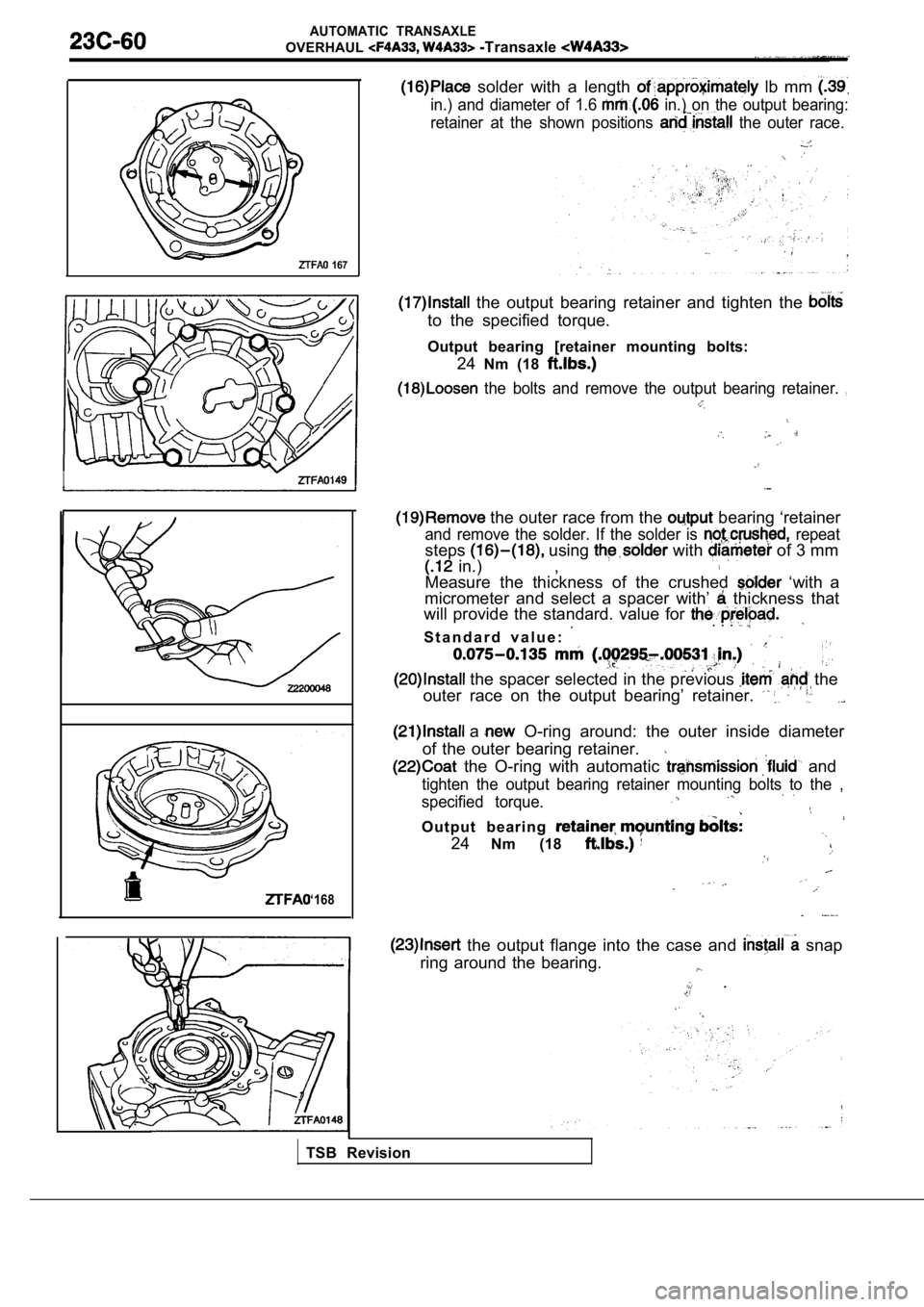

solder with a length lb mm

in.) and diameter of 1.6 in.) on the output bearing:

retainer at the shown positions

the outer race.

167

I

‘168

the output bearing retainer and tighten the

to the specified torque.

Output bearing [retainer mounting bolts: 24Nm (18

the bolts and remove the output bearing retainer.

the outer race from the bearing ‘retainer

and remove the solder. If the solder is repeat

steps using with of 3 mm

in.) ,

Measure the thickness of the crushed ‘with a

micrometer and select a spacer with’

thickness that

will provide the standard. value for

S t a n d a r d v a l u e :

. . .

the spacer selected in the previous the

outer race on the output bearing’ retainer.

a O-ring around: the outer inside diameter

of the outer bearing retainer.

the O-ring with automatic and

tighten the output bearing retainer mounting bolts to the ,

specified torque.

Output bearing

24 Nm (18

the output flange into the case and snap

ring around the bearing.

.

TSB Revision

Page 1345 of 2103

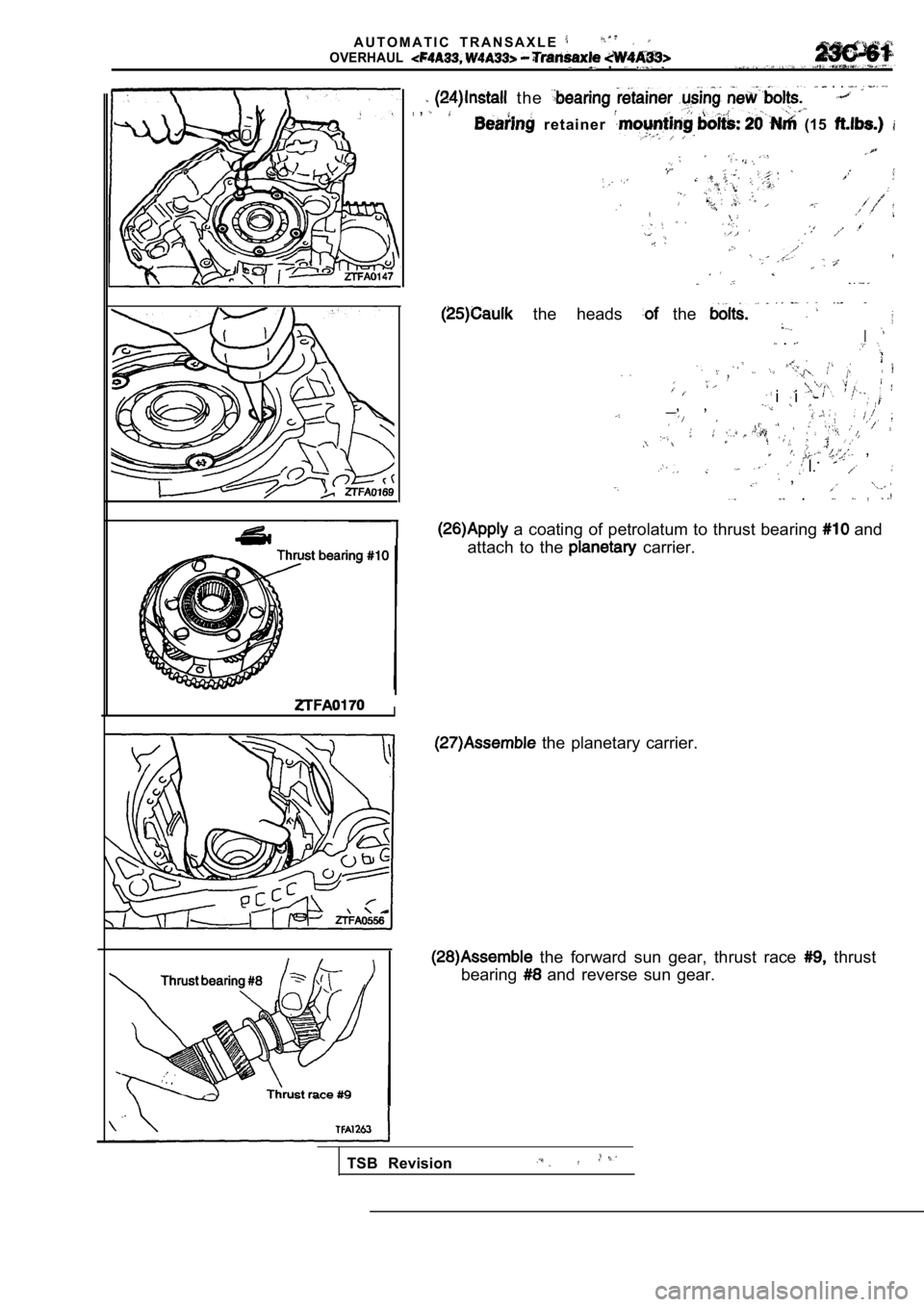

A U T O M A T I C T R A N S A X L E OVERHAUL ,

I

the

. .

,

r e t a i n e r (15

the heads the

I .

i i -

_, ,

, .

, I.

.,

a coating of petrolatum to thrust bearing and

attach to the

carrier.

the planetary carrier.

the forward sun gear, thrust race thrust

bearing

and reverse sun gear.

TSB Revision

Page 1346 of 2103

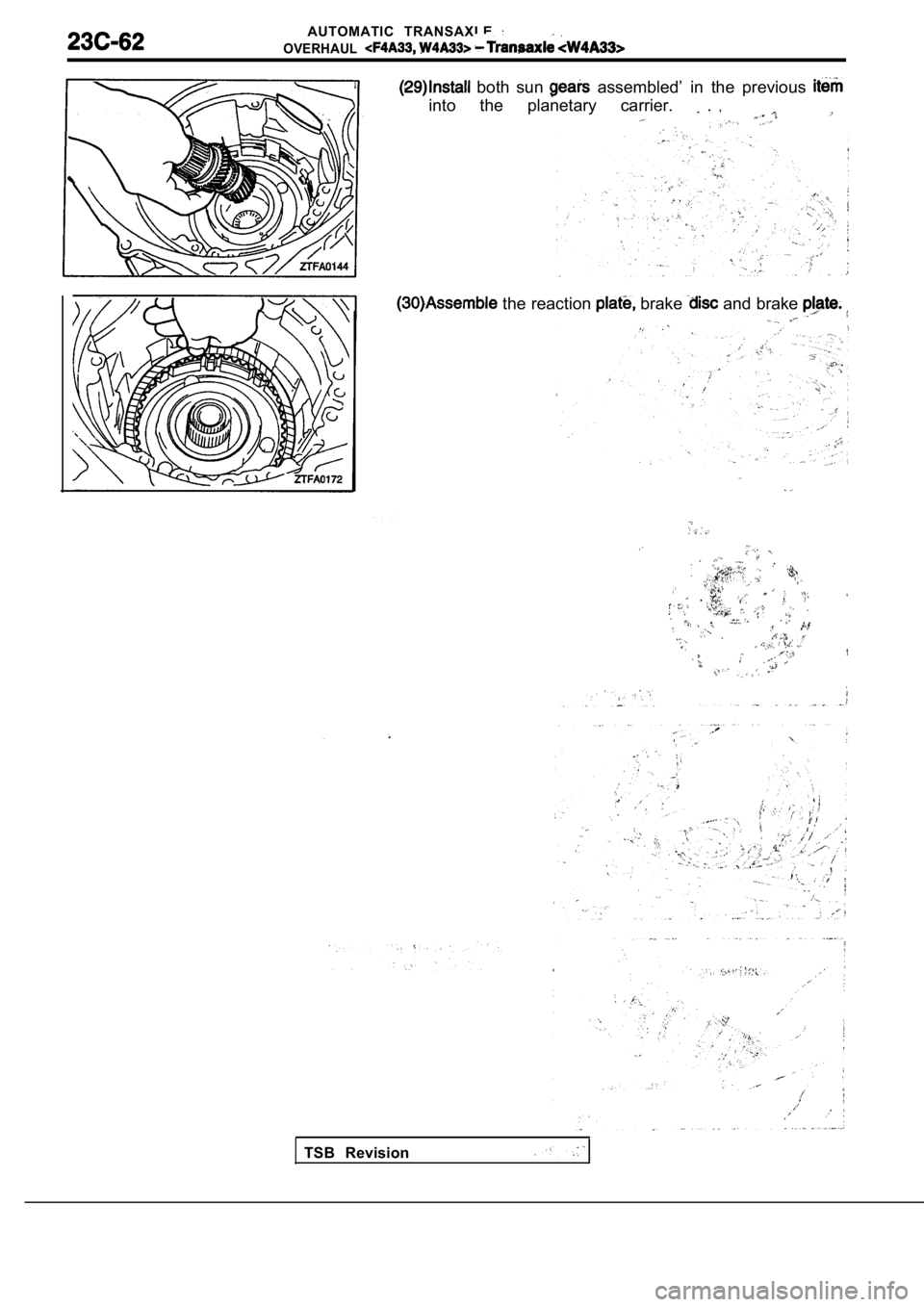

AUTOMATIC TRANSAXLE

OVERHAUL

both sun assembled’ in the previous

into the planetary carrier. .

the reaction brake and brake

TSB Revision

Page 1347 of 2103

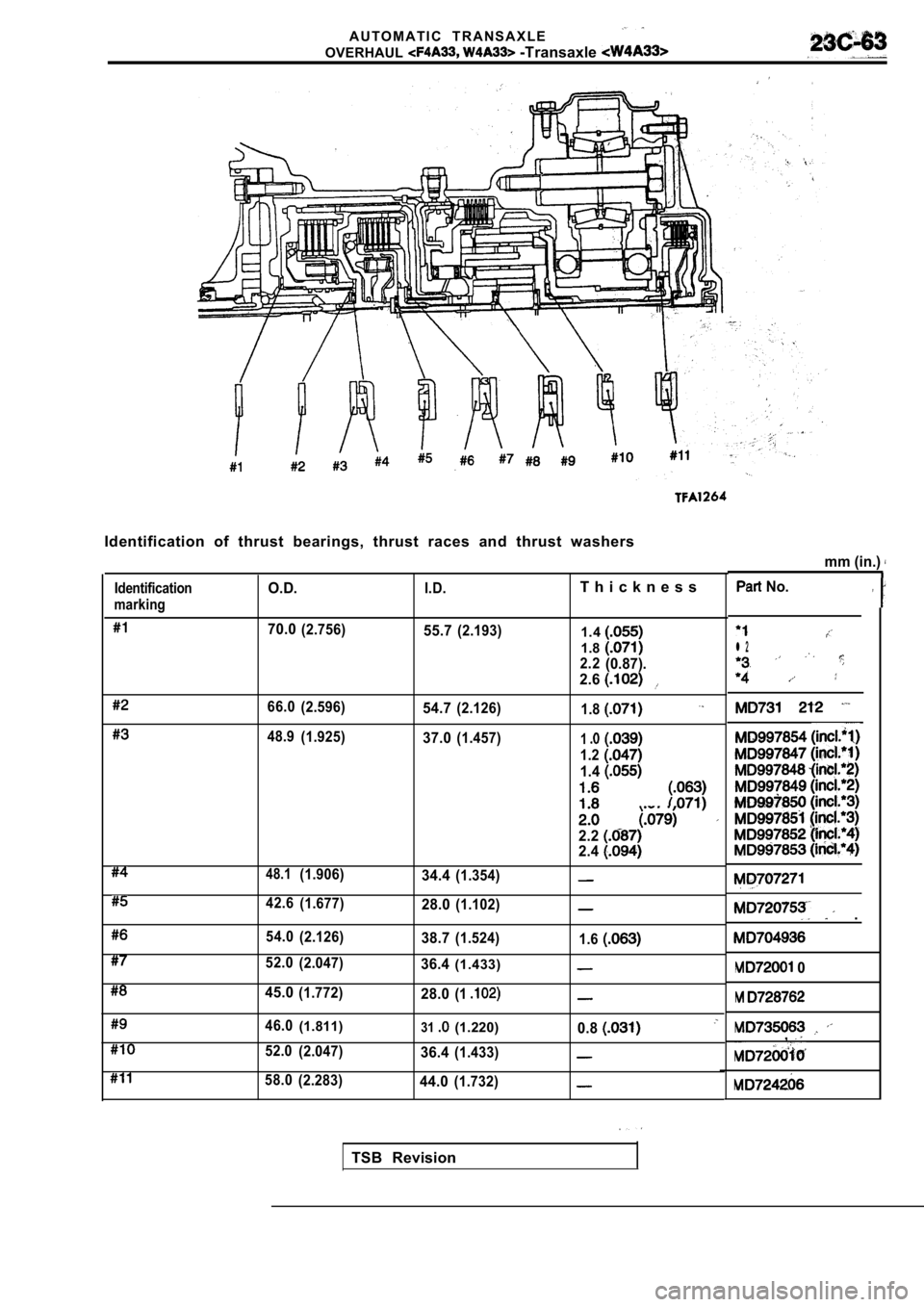

A U T O M A T I C T R A N S A X L E

OVERHAUL

-Transaxle

Identification

markingO.D.I.D.T h i c k n e s s

70.0(2.756)55.7(2.193)1.4

1.8

2.2(0.87).

2.6

66.0 (2.596)54.7(2.126)

1.8

48.9(1.925)37.0(1.457)1

1.2

1.4

2.22.4

48.1(1.906)34.4(1.354)

42.6 (1.677)28.0(1.102)

54.0(2.126)38.7(1.524)

1.6

52.0(2.047)36.4(1.433)

45.0(1.772)28.0(1

46.0(1.811)31(1.220)0.8

52.0(2.047)36.4(1.433)

58.0(2.283)44.0(1.732)

TSB Revision

Identification of thrust bearings, thrust races and thrust washers

mm (in.)

No.

l 2

.

0

,

Page 1348 of 2103

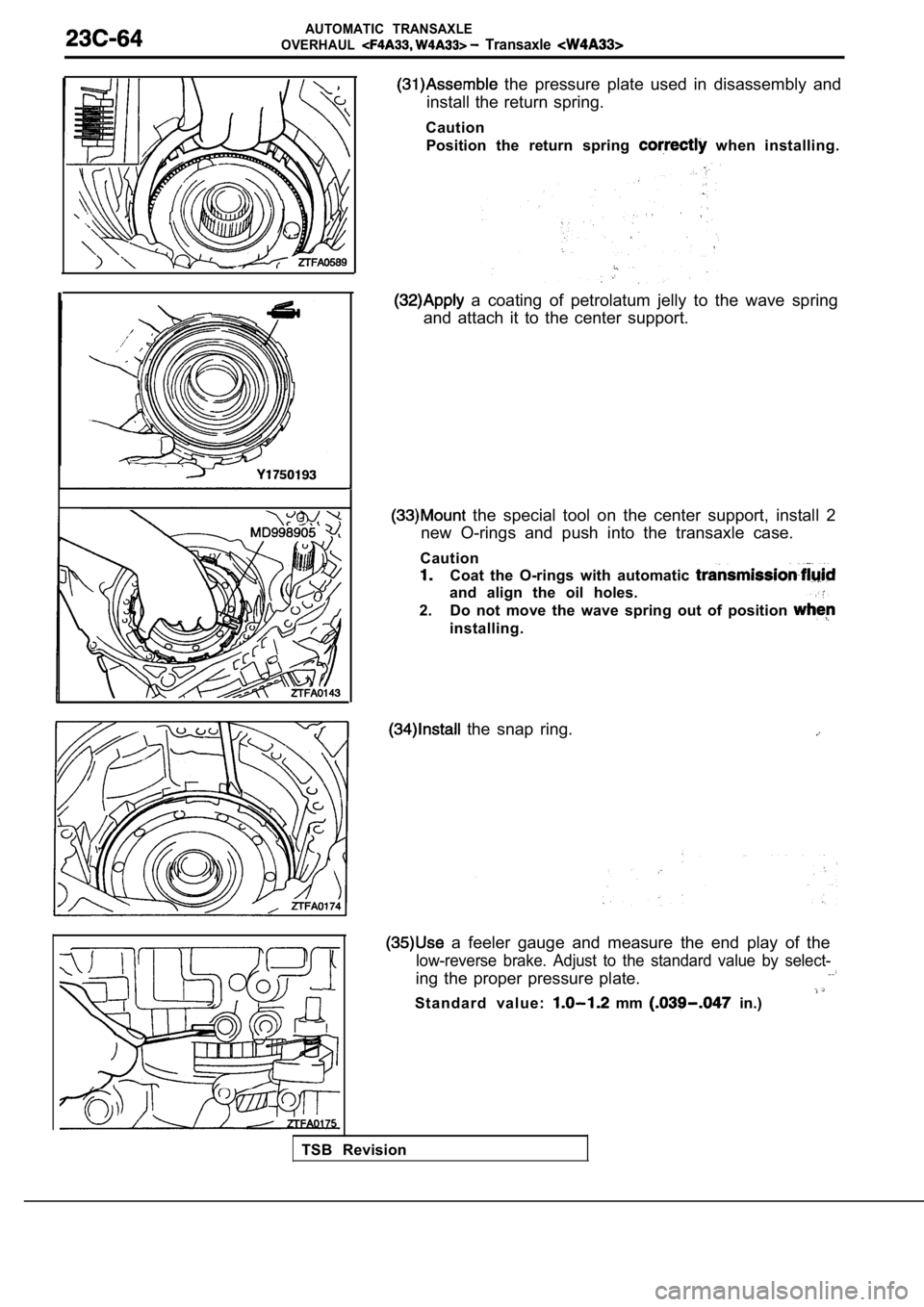

AUTOMATIC TRANSAXLE

OVERHAUL

Transaxle

the pressure plate used in disassembly and

install the return spring.

Caution Position the return spring

when installing.

a coating of petrolatum jelly to the wave spring

and attach it to the center support.

the special tool on the center support, install 2

new O-rings and push into the transaxle case.

Caution

Coat the O-rings with automatic

and align the oil holes.

2. Do not move the wave spring out of position

installing.

the snap ring.

TSB Revision

a feeler gauge and measure the end play of the

low-reverse brake. Adjust to the standard value by select-

ing the proper pressure plate.

S t a n d a r d v a l u e : mm in.)

Page 1349 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

Transaxle

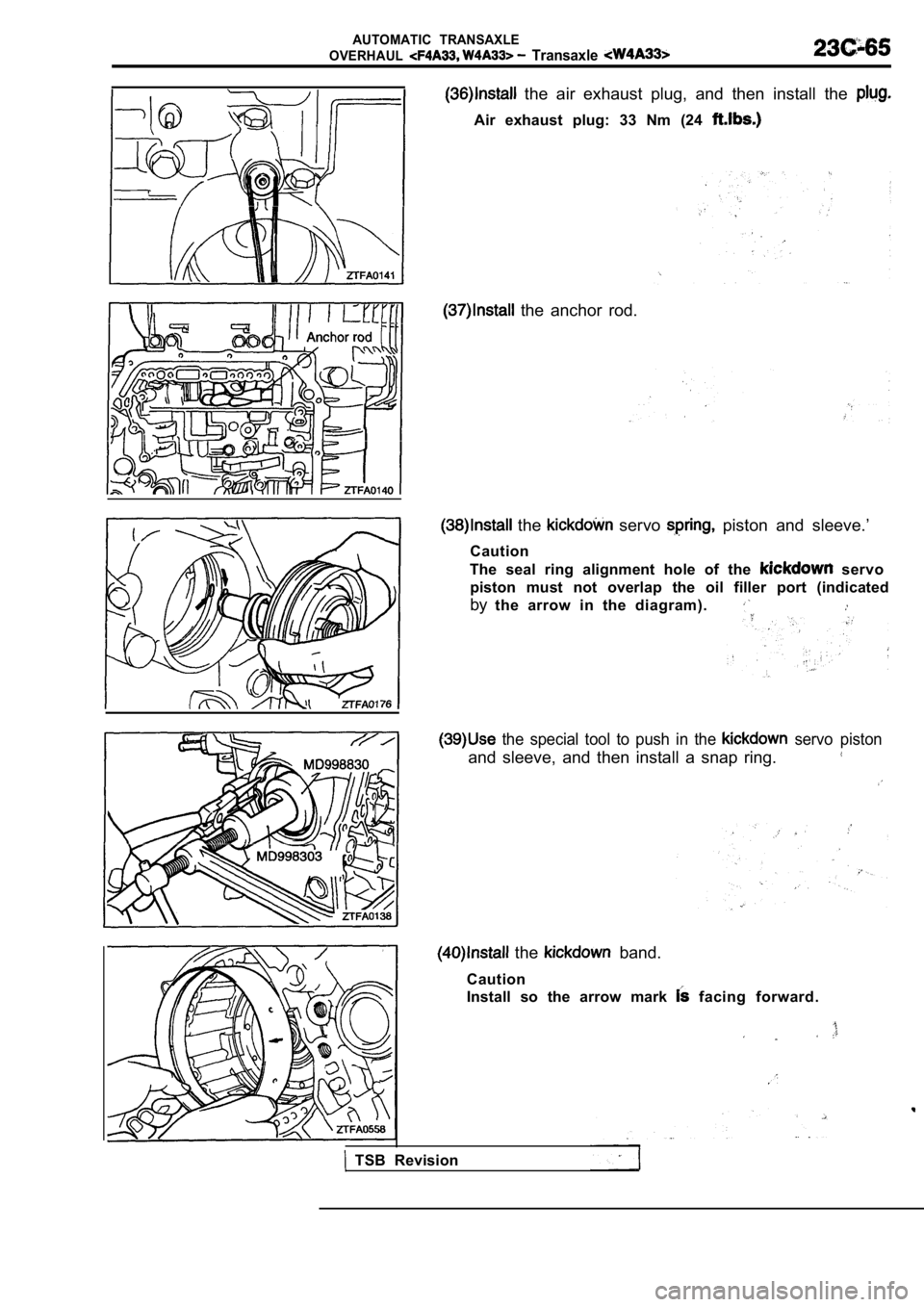

the air exhaust plug, and then install the

Air exhaust plug: 33 Nm (24

the anchor rod.

the servo piston and sleeve.’

Caution

The seal ring alignment hole of the

servo

piston must not overlap the oil filler port (indica ted

by the arrow in the diagram).

the special tool to push in the servo piston

and sleeve, and then install a snap ring.

the band.

Caution

Install so the arrow mark

facing forward.

TSB Revision

Page 1350 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL -Transaxle

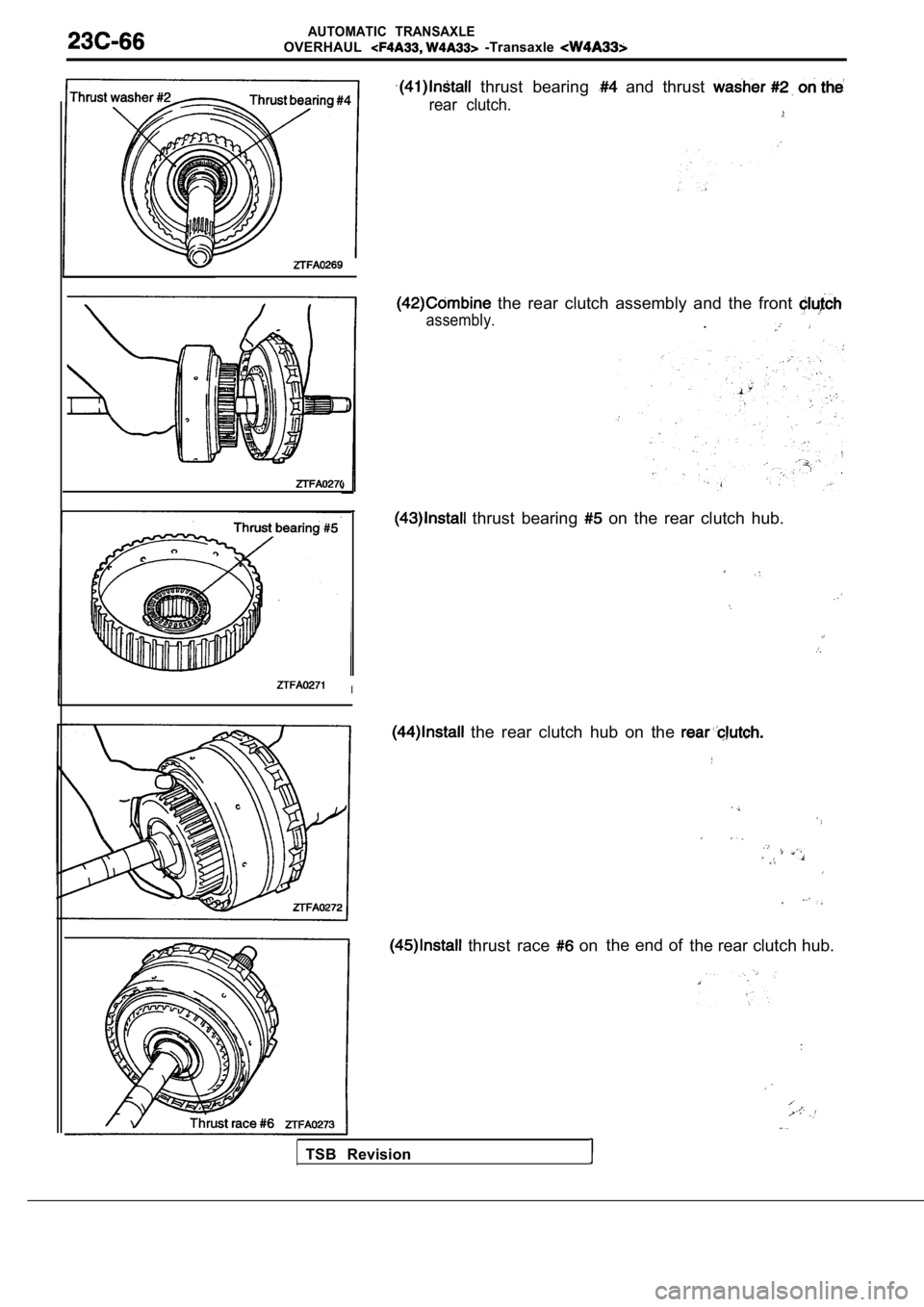

thrust bearing and thrust

rear clutch.

the rear clutch assembly and the front

assembly..

thrust bearing on the rear clutch hub.

I

the rear clutch hub on the

thrust race onthe end of

the rear clutch hub.

TSB Revision

Trending: trailer, fuel filter, instrument panel, timing belt, battery, fuse chart, ESP