MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: cooling, washer fluid, service schedule, trunk release, fuel consumption, octane, engine oil

Page 1361 of 2103

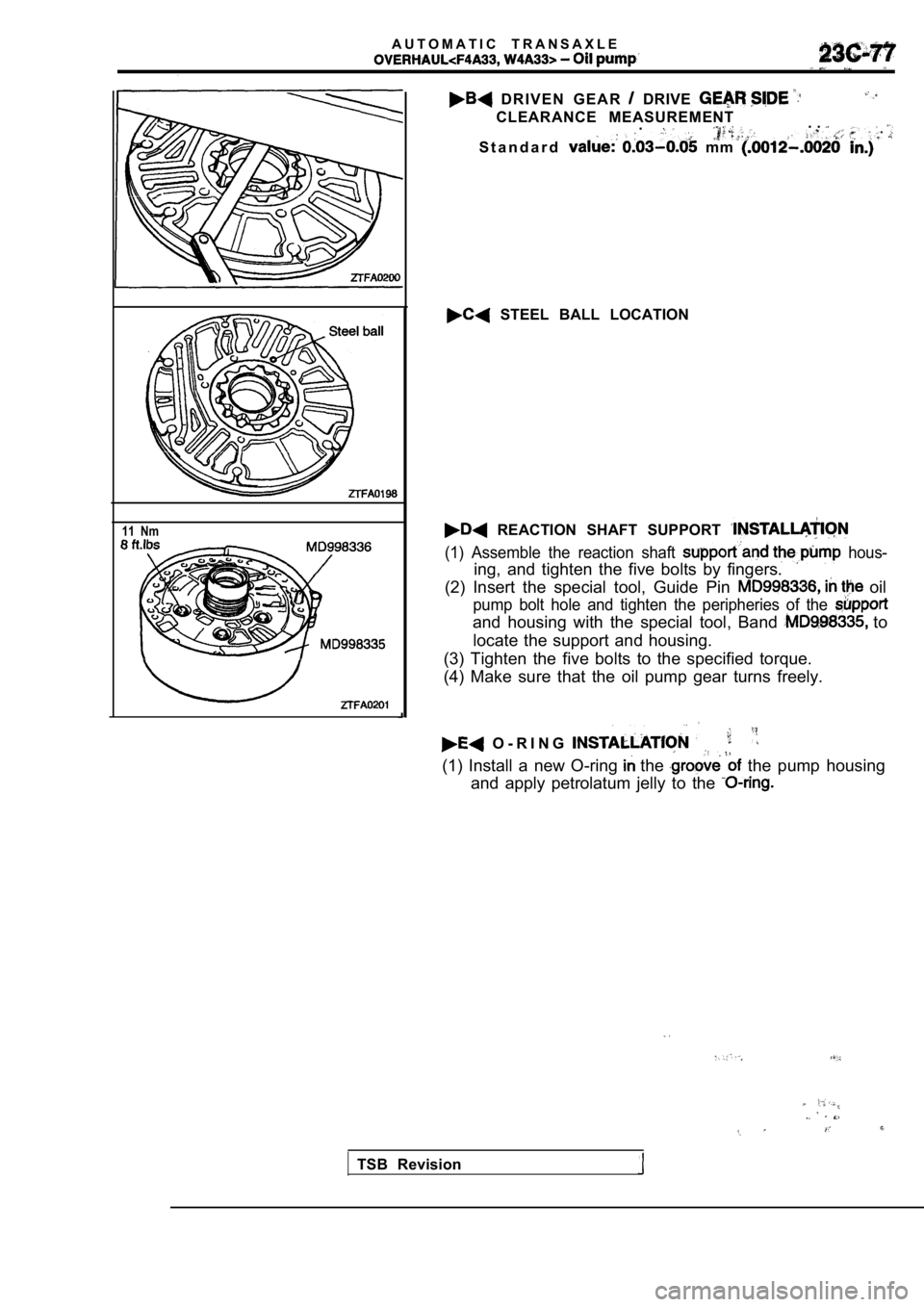

A U T O M A T I C T R A N S A X L E

11 Nm

D R I V E N G E A R DRIVE

CLEARANCE MEASUREMENT.. .

S t a n d a r d mm

STEEL BALL LOCATION

REACTION SHAFT SUPPORT

(1) Assemble the reaction shaft hous-

ing, and tighten the five bolts by fingers.

(2) Insert the special tool, Guide Pin

oil

pump bolt hole and tighten the peripheries of the

and housing with the special tool, Band to

locate the support and housing.

(3) Tighten the five bolts to the specified torque.

(4) Make sure that the oil pump gear turns freely.

O - R I N G

(1) Install a new O-ring the the pump housing

and apply petrolatum jelly to the

TSB Revision

Page 1362 of 2103

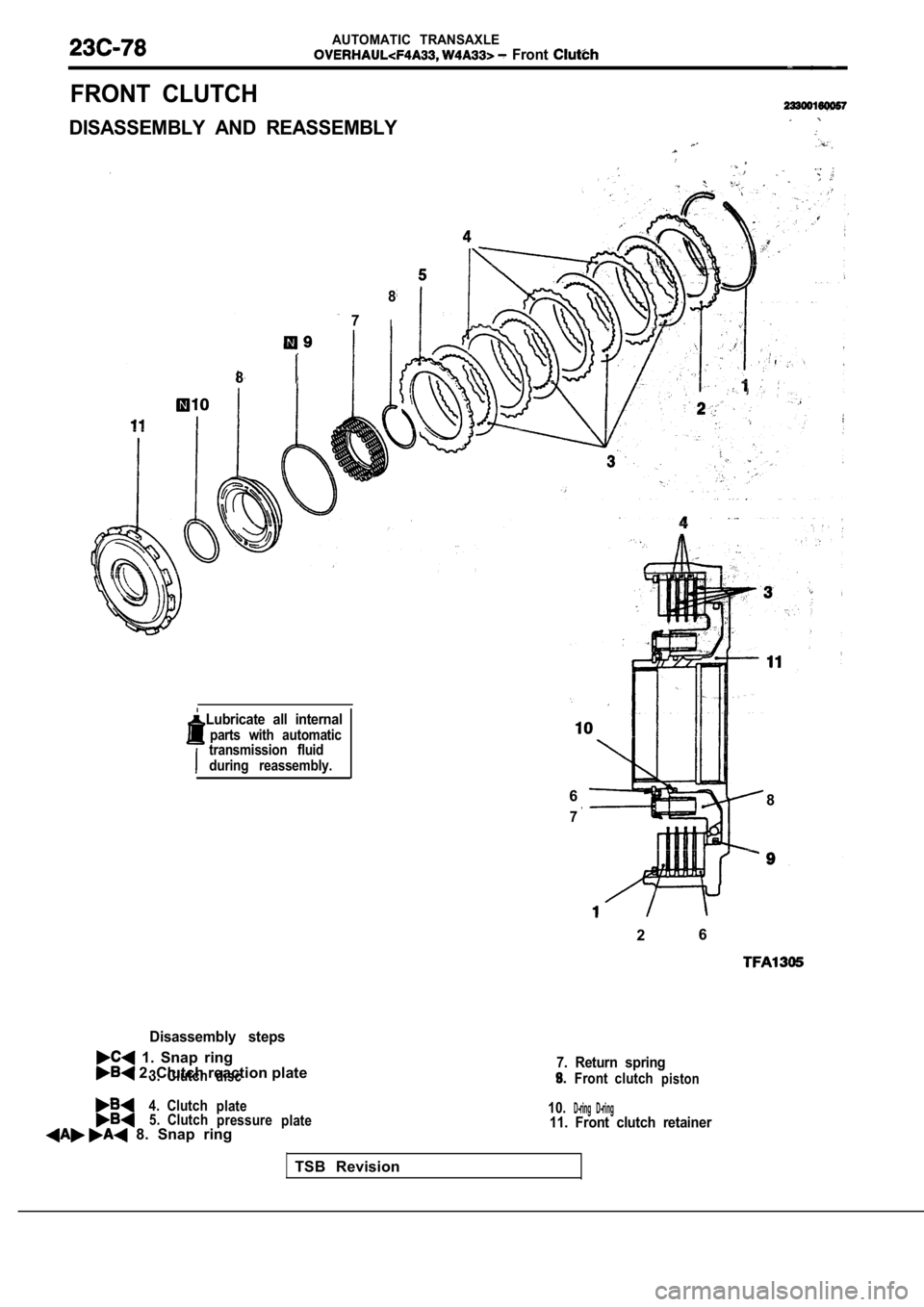

AUTOMATIC TRANSAXLE Front ,

FRONT CLUTCH

DISASSEMBLY AND REASSEMBLY

8

8

7I

Disassembly steps

1. Snap ring 2. Clutch reaction plate3.Clutchdisc

4. Clutchplate5. Clutchpressureplate 8. Snap ring

7. Return spring

8.Front clutchpiston9.

10.

D-ring D-ring11. Front clutch retainer

TSB Revision

Lubricate all internal

parts with automatictransmission fluid

during reassembly.

6

7

8

2 6

Page 1363 of 2103

A U T O M A T I C “ T R A N S A X L E .

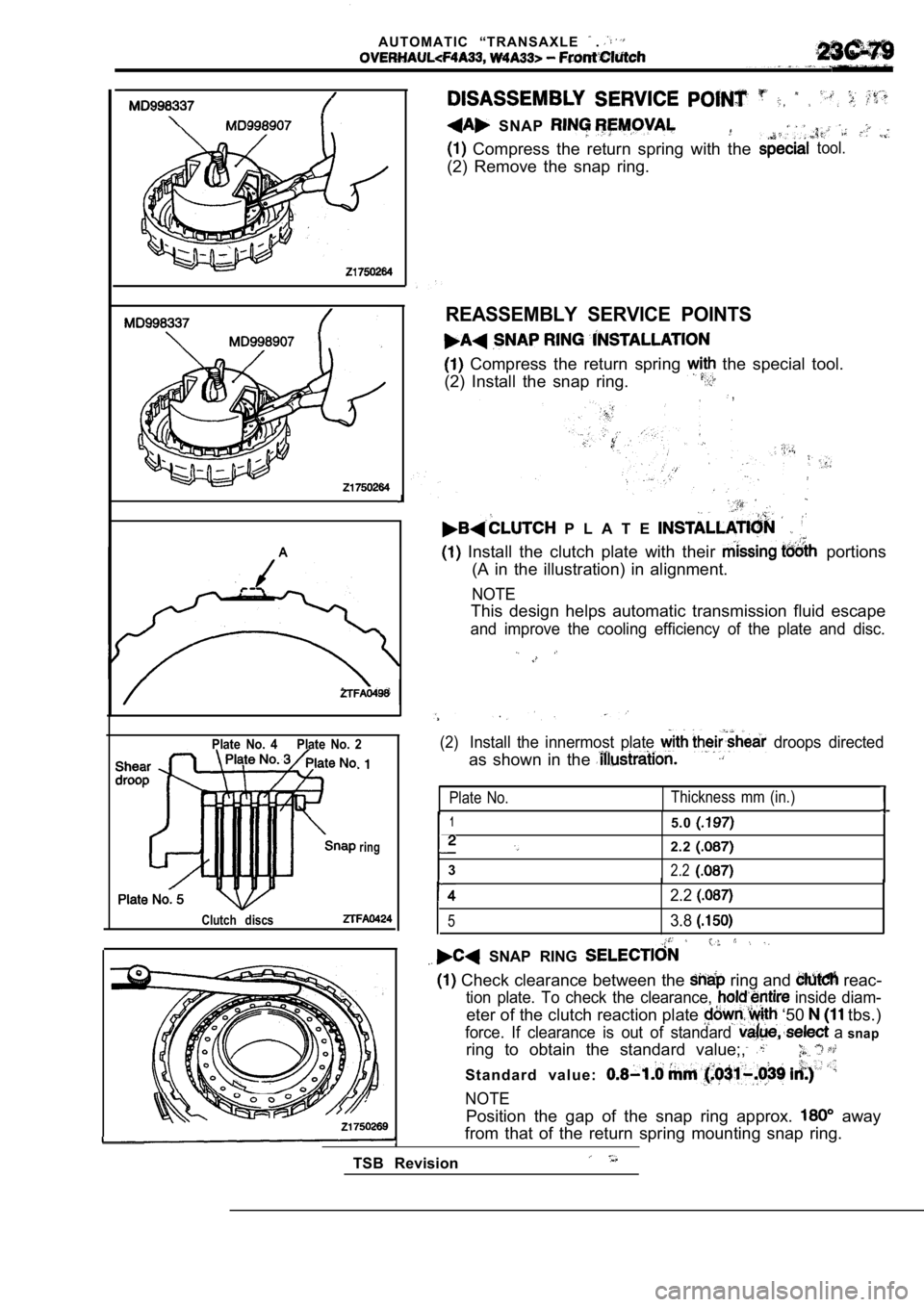

SNAP

Compress the return spring with thetool.

(2) Remove the snap ring.

REASSEMBLY SERVICE POINTS

Compress the return spring the special tool.

(2) Install the snap ring.

,

P L A T E

Install the clutch plate with their portions

(A in the illustration) in alignment.

NOTE

This design helps automatic transmission fluid esca pe

and improve the cooling efficiency of the plate and disc.

Plate No. 4 Plate No. 2

ring

Clutch discs

(2)Install the innermost plate droops directed

as shown in the

Plate No.Thickness mm (in.)

15.0

2.2

32.2

Position the gap of the snap ring approx. away

from that of the return spring mounting snap ring.

TSB Revision

2.2

53.8

SNAP RING

Check clearance between the ring and reac-

tion plate. To check the clearance, inside diam-

eter of the clutch reaction plate ‘50 tbs.)

force. If clearance is out of standard a snap

ring to obtain the standard value;,

S t a n d a r d v a l u e :

NOTE

Page 1364 of 2103

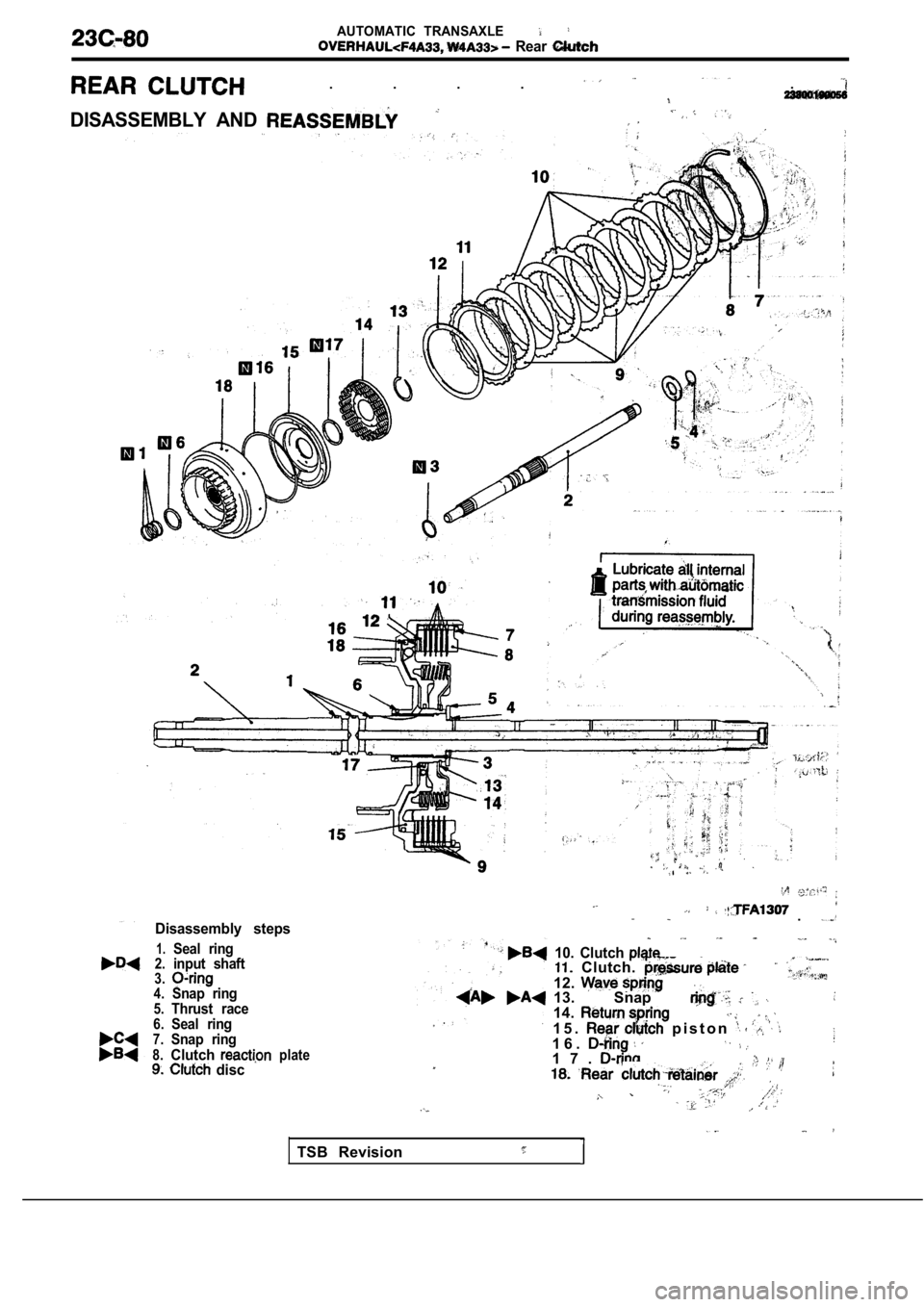

AUTOMATIC TRANSAXLE

Rear

. . . . .

DISASSEMBLY AND

Disassembly steps

1.Seal ring2.input shaft3.

4.

5.Snap ring

Thrust race

6.

7.Seal ring

8.

Snap ring

Clutch discplate

.

10. Clutch Clutch.

12.13. Snap 14.

1 5 . p i s t o n 1 6 .1 7 .

TSB Revision

Page 1365 of 2103

A U T O M A T I C

Rear

,

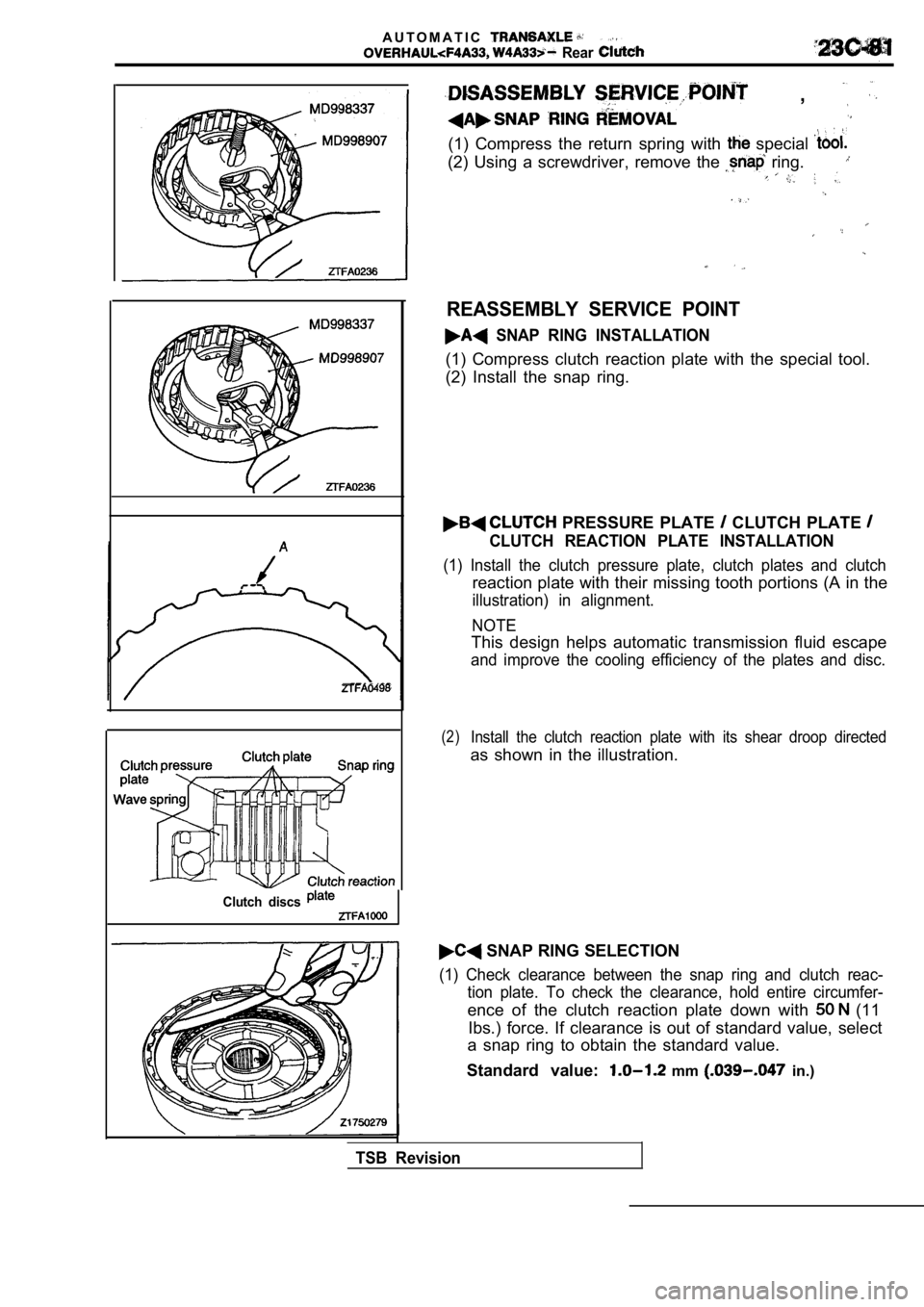

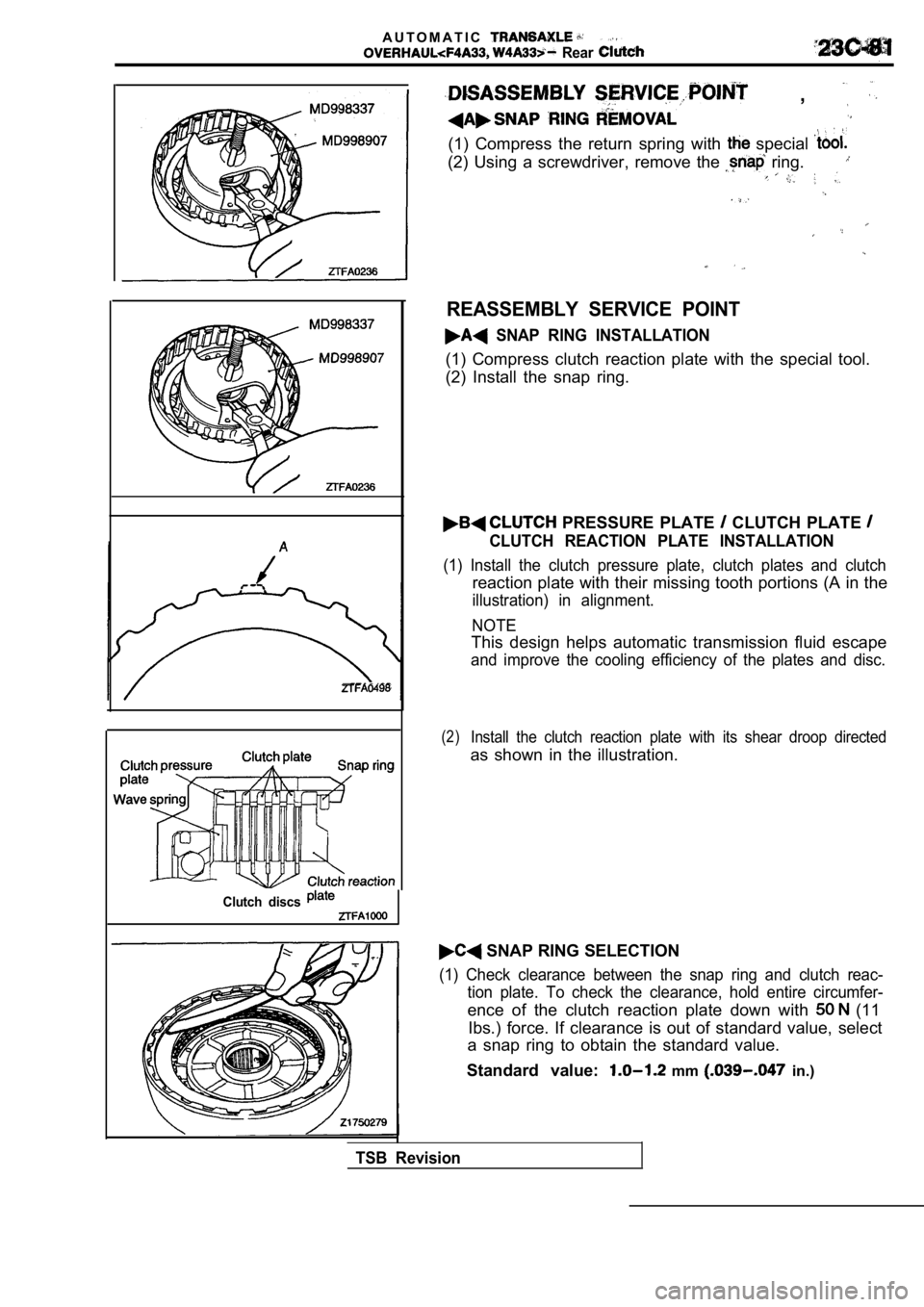

(1) Compress the return spring with special

(2) Using a screwdriver, remove the ring.

Clutch discs

REASSEMBLY SERVICE POINT

SNAP RING INSTALLATION

(1) Compress clutch reaction plate with the special tool.

(2) Install the snap ring.

PRESSURE PLATE CLUTCH PLATE

CLUTCH REACTION PLATE INSTALLATION

(1) Install the clutch pressure plate, clutch plate s and clutch

reaction plate with their missing tooth portions (A in the

illustration) in alignment.

NOTE

This design helps automatic transmission fluid esca pe

and improve the cooling efficiency of the plates and disc.

(2)Install the clutch reaction plate with its shear droop directed

as shown in the illustration.

SNAP RING SELECTION

(1) Check clearance between the snap ring and clutc h reac-

tion plate. To check the clearance, hold entire cir cumfer-

ence of the clutch reaction plate down with (11

Ibs.) force. If clearance is out of standard value, select

a snap ring to obtain the standard value.

Standard value:

mm in.)

TSB Revision

Page 1366 of 2103

AUTOMATIC TRANSAXLE

Rear

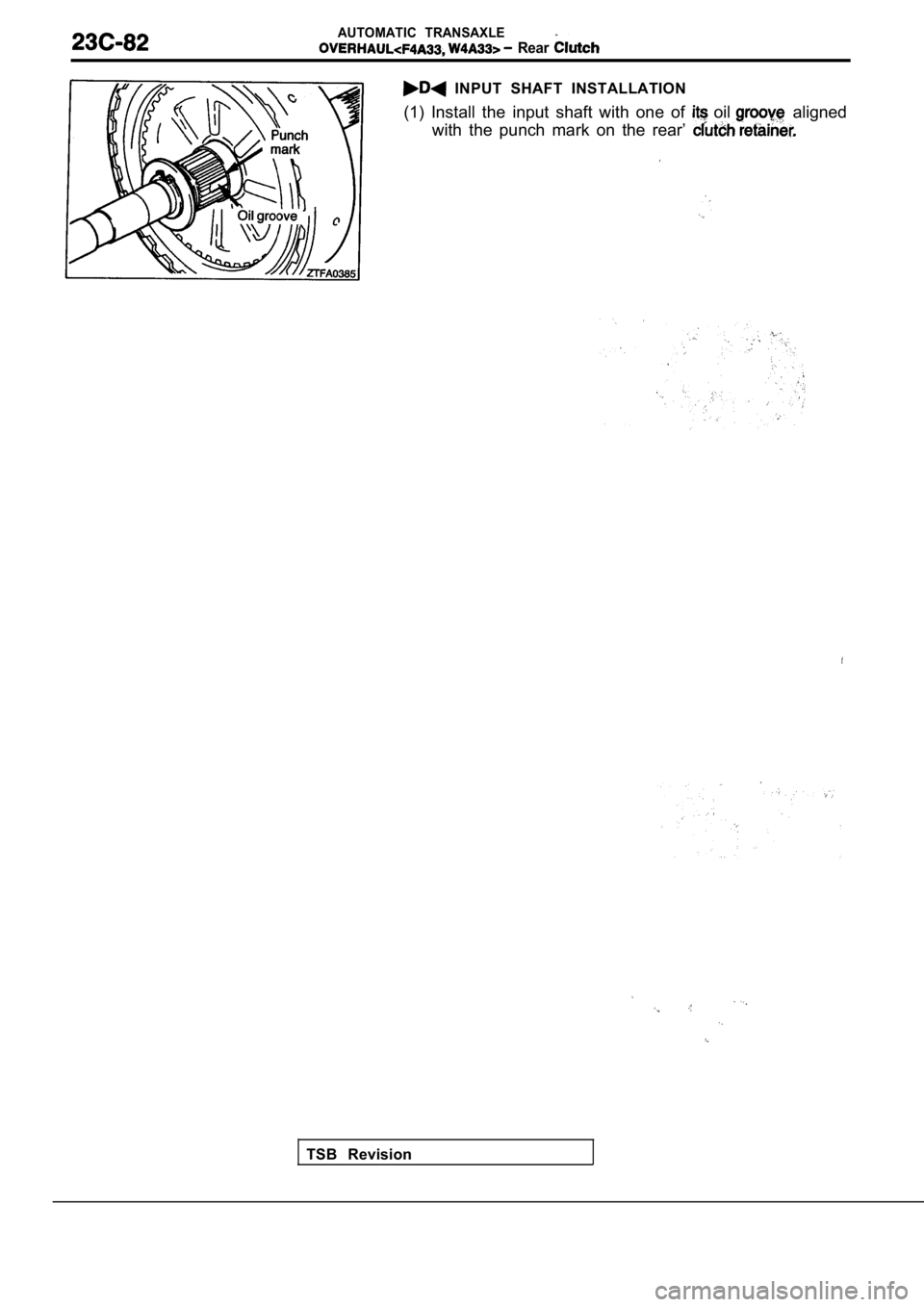

INPUT SHAFT INSTALLATION

(1) Install the input shaft with one of

oil aligned

with the punch mark on the rear’

TSB Revision

Page 1367 of 2103

A U T O M A T I C T R A N S A X L E

End Clutch

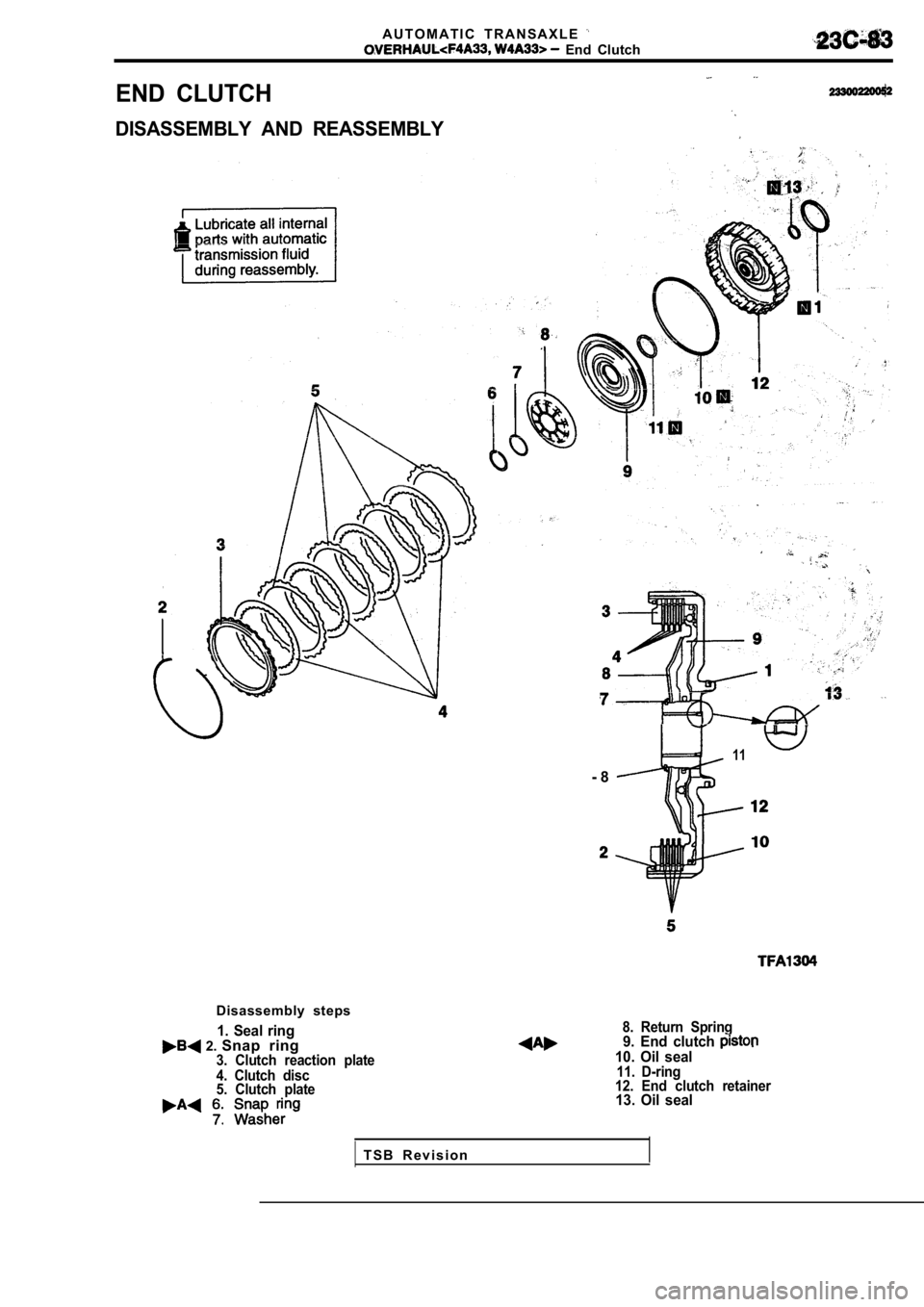

END CLUTCH

DISASSEMBLY AND REASSEMBLY

11

- 8

Disassembly steps

1. Seal ring 2. Snap ring3. Clutch reaction plate

4. Clutch disc

5. Clutch plate

8. Return Spring9. End clutch 10. Oil seal11. D-ring

12. End clutch retainer

13. Oil seal

T S B R e v i s i o n

Page 1368 of 2103

AUTOMATIC TRANSAXLE

End

T S B R e v i s i o n

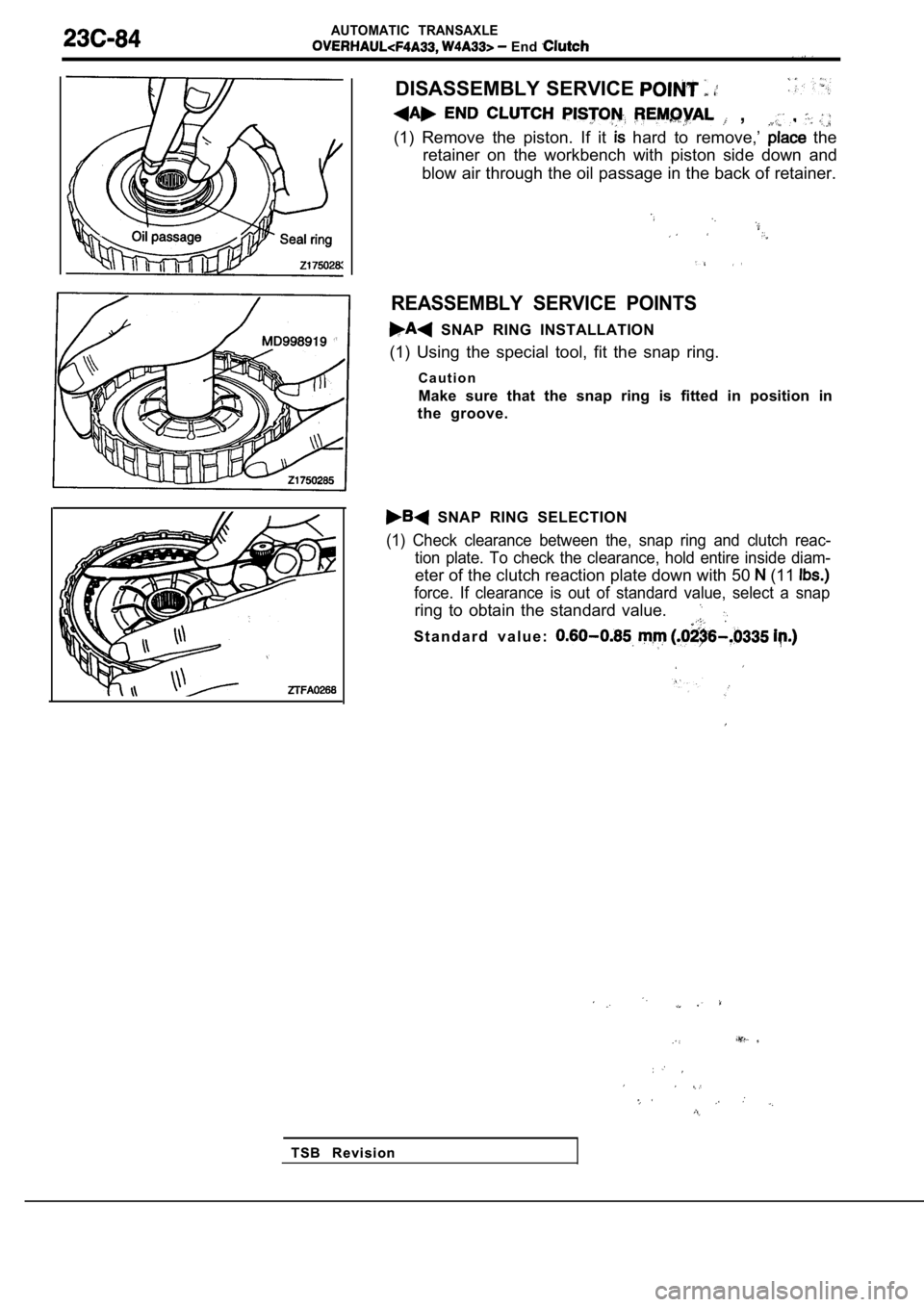

T S B R e v i s i o n DISASSEMBLY SERVICE

, ,

(1) Remove the piston. If it hard to remove,’ the

retainer on the workbench with piston side down and

blow air through the oil passage in the back of ret ainer.

REASSEMBLY SERVICE POINTS

SNAP RING INSTALLATION

(1) Using the special tool, fit the snap ring.

C a u t i o n

Make sure that the snap ring is fitted in position in

the groove.

SNAP RING SELECTION

(1) Check clearance between the, snap ring and clut ch reac-

tion plate. To check the clearance, hold entire ins ide diam-

eter of the clutch reaction plate down with 50 (11

force. If clearance is out of standard value, selec t a snap

ring to obtain the standard value.

S t a n d a r d v a l u e :

Page 1369 of 2103

AUTOMATIC

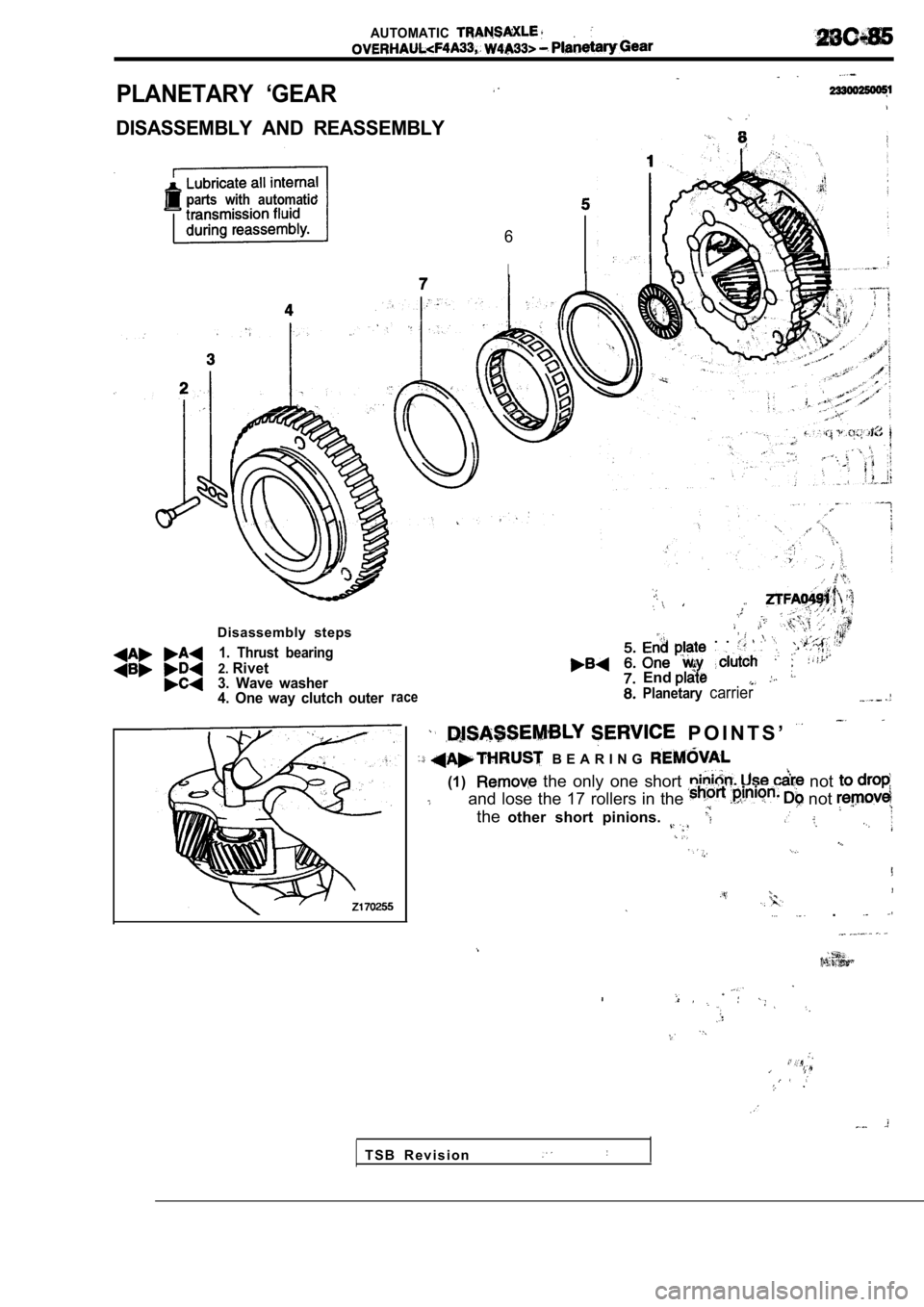

PLANETARY ‘GEAR

DISASSEMBLY AND REASSEMBLY

parts with automatic

6

I

Disassembly steps

1. Thrust bearing

2.Rivet

3. Wave washer

4. One way clutch outer

race

. .

End

Planetarycarrier

P O I N T S ’

B E A R I N G

(1) the only one short not

and lose the 17 rollers in the not

the other short pinions.

.

T S B R e v i s i o n

Page 1370 of 2103

AUTOMATIC TRANSAXLE

Planetary Gear

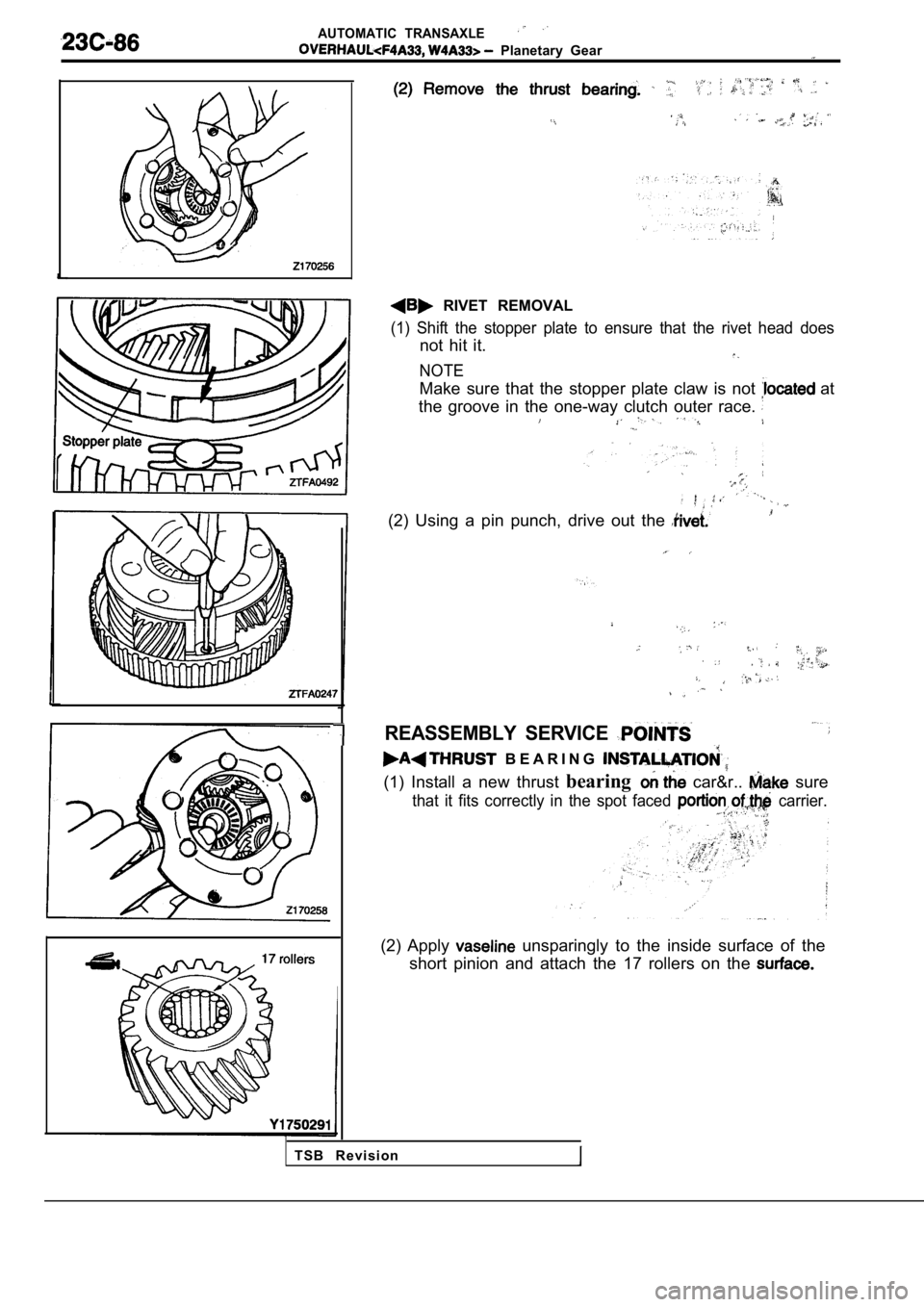

RIVET REMOVAL

(1) Shift the stopper plate to ensure that the rivet head does

not hit it.

NOTE

Make sure that the stopper plate claw is not at

the groove in the one-way clutch outer race.

(2) Using a pin punch, drive out the

REASSEMBLY SERVICE

B E A R I N G

(1) Install a new thrust bearing car&r.. sure

that it fits correctly in the spot faced carrier..

(2) Apply unsparingly to the inside surface of the

short pinion and attach the 17 rollers on the

T S B R e v i s i o n

Trending: check engine, fuel pump, trailer, radiator, gas type, spark plugs, torque