MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: boot, fuel tank removal, change wheel, parking sensors, weight, manual transmission, heater

Page 1381 of 2103

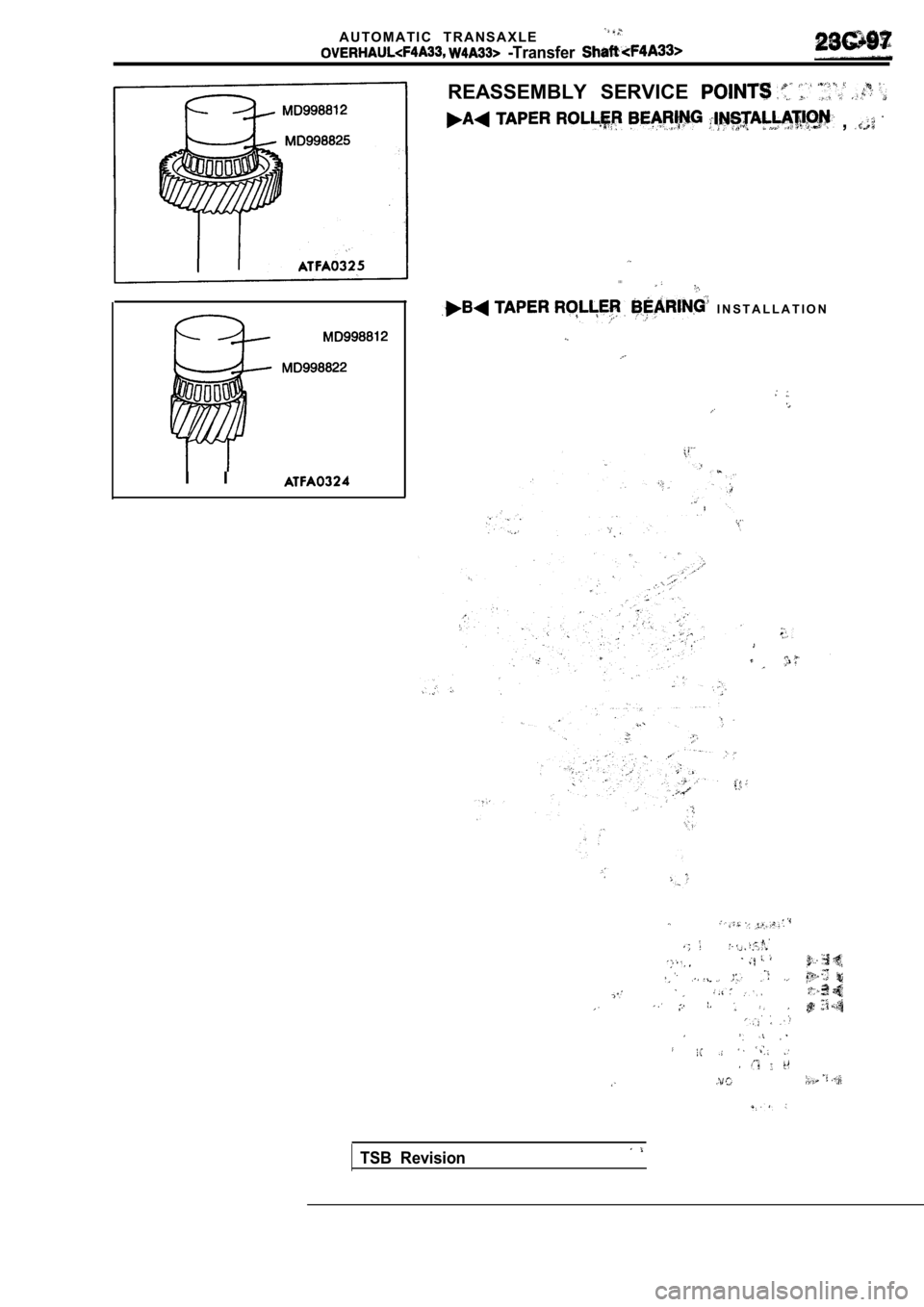

A U T O M A T I C T R A N S A X L E

-Transfer

REASSEMBLY SERVICE

,

. . . .

I I

I N S T A L L A T I O N

TSB Revision

Page 1382 of 2103

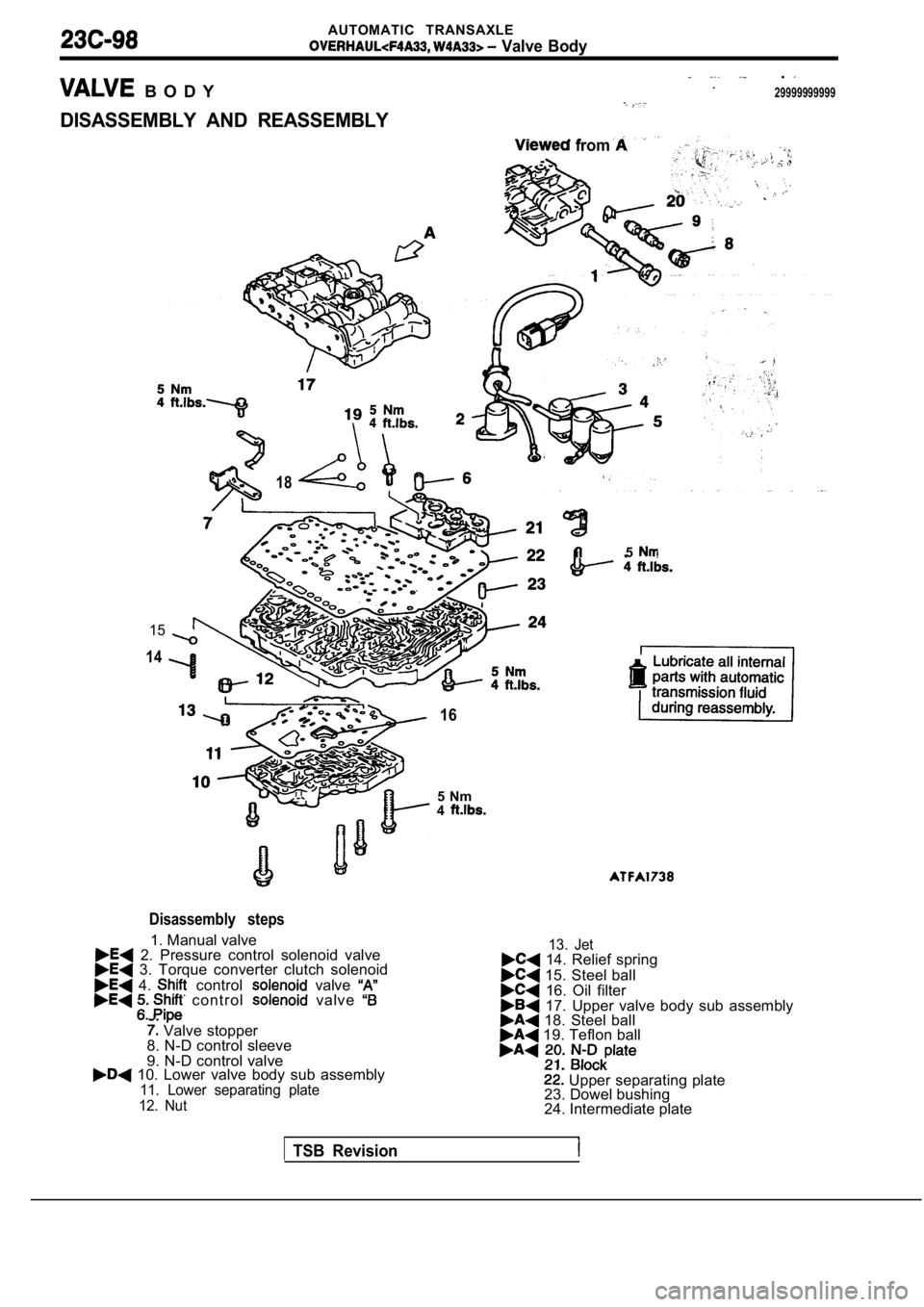

AUTOMATIC TRANSAXLE

Valve Body

B O D Y

.

29999999999

DISASSEMBLY AND REASSEMBLY

15

14

from

18

Disassembly steps

1. Manual valve 2. Pressure control solenoid valve 3. Torque converter clutch solenoid

4. control valve c o n t r o l valve

Valve stopper

8. N-D control sleeve

9. N-D control valve

10. Lower valve body sub assembly11. Lower separating plate

12. Nut

16

5

5 Nm

4

13. Jet 14. Relief spring

15. Steel ball 16. Oil filter 17. Upper valve body sub assembly 18. Steel ball 19. Teflon ball

Upper separating plate

23. Dowel bushing

24. Intermediate plate

TSB Revision

Page 1383 of 2103

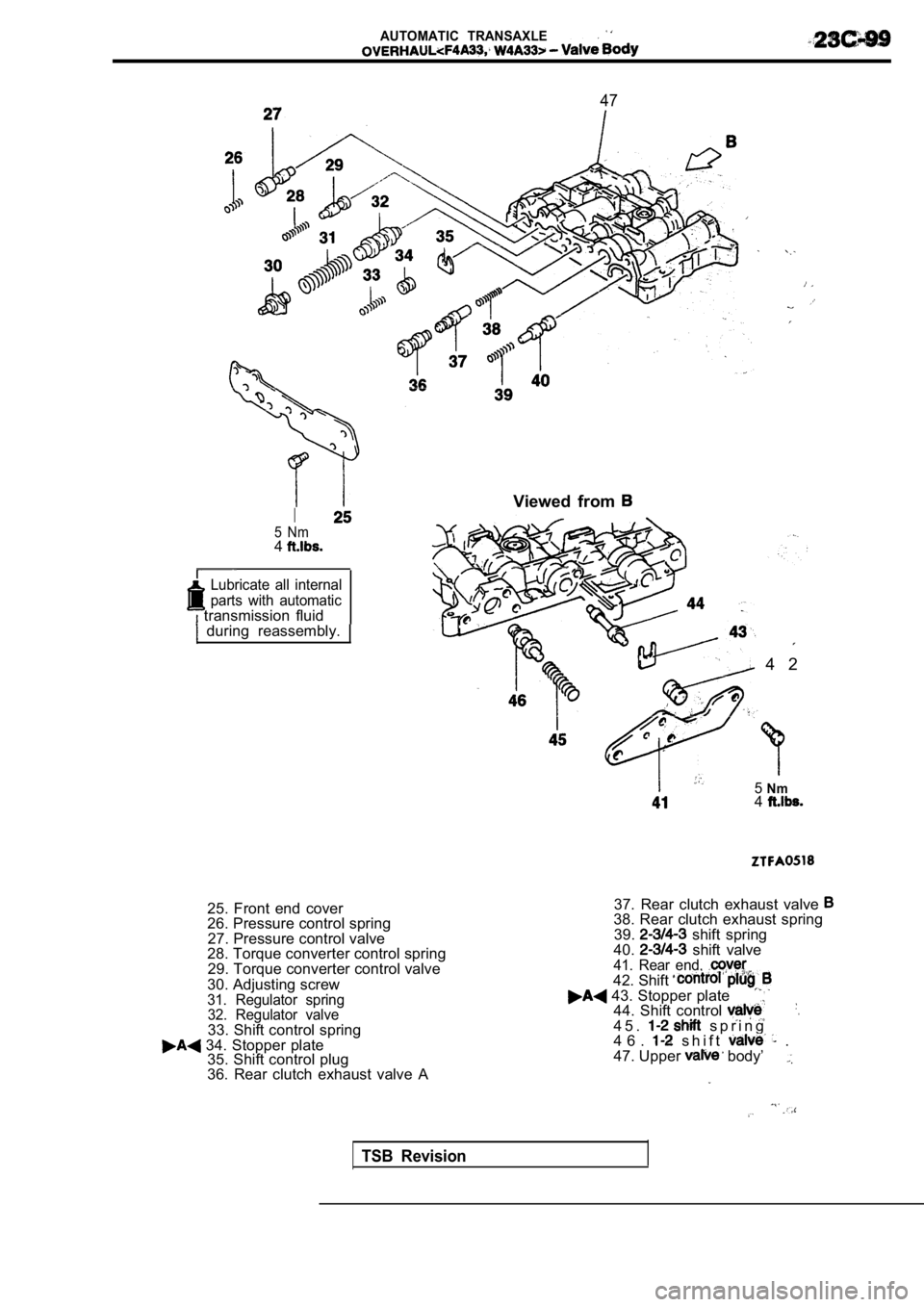

AUTOMATIC TRANSAXLE

47

I5 Nm4

Viewed from

Lubricate all internal

parts with automatic

transmission fluid during reassembly.

5Nm4

25. Front end cover

26. Pressure control spring27. Pressure control valve

28. Torque converter control spring

29. Torque converter control valve

30. Adjusting screw

31. Regulator spring 32. Regulator valve

33. Shift control spring 34. Stopper plate 35. Shift control plug

36. Rear clutch exhaust valve A 37. Rear clutch exhaust valve

38. Rear clutch exhaust spring

39. shift spring

40. shift valve41. Rear end, 42. Shift 43. Stopper plate44. Shift control .

4 5 . s p r i n g

4 6 . s h i f t .

47. Upper body’

TSB Revision

4 2

Page 1384 of 2103

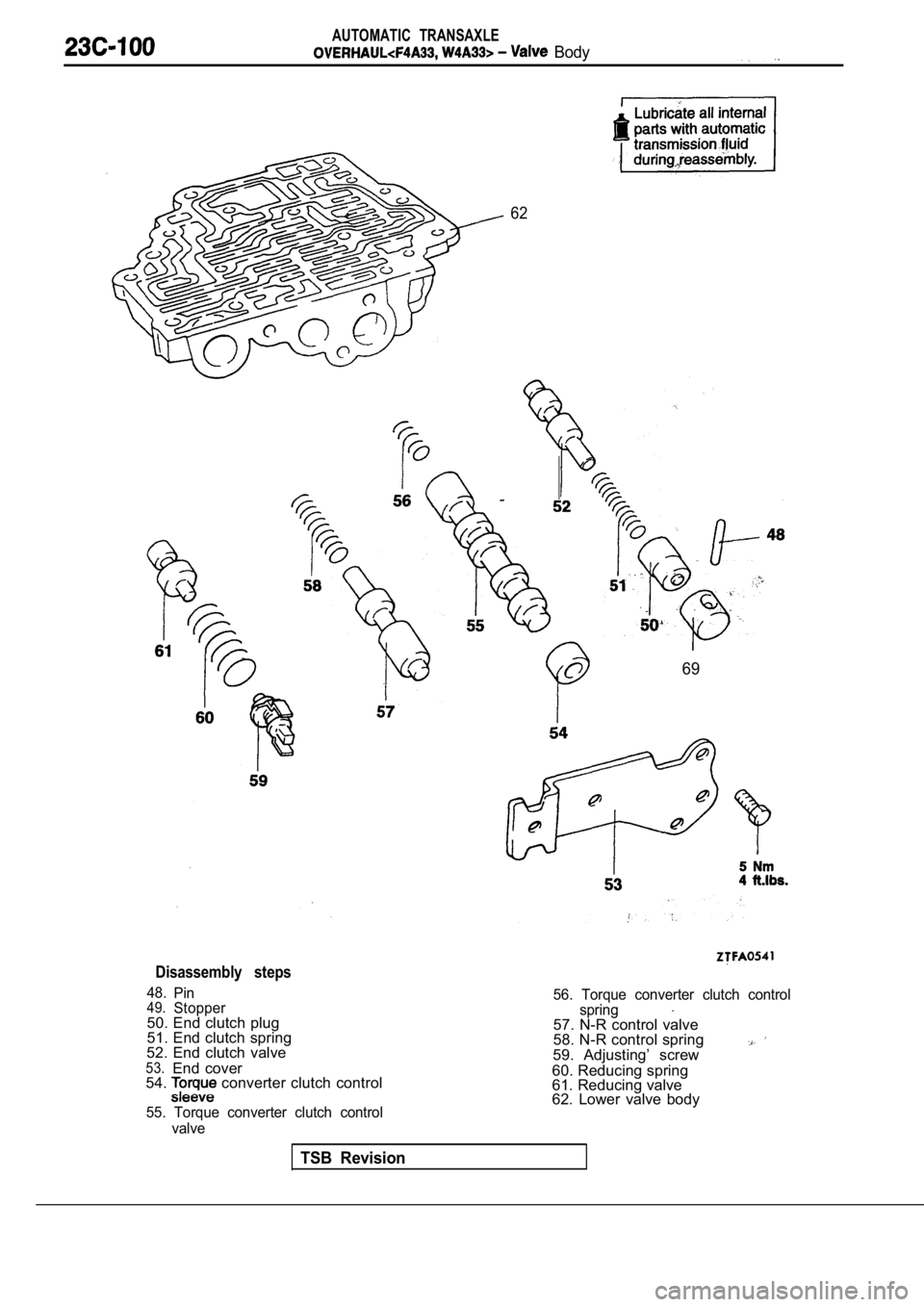

AUTOMATIC TRANSAXLE

Body

62

69

Disassembly steps

48.Pin49.Stopper50. End clutch plug

51. End clutch spring

52. End clutch valve

53.End cover

54. converter clutch control

55. Torque converter clutch control

56. Torque converter clutch control

spring

57. N-R control valve

58. N-R control spring

59. Adjusting’ screw

60. Reducing spring

61. Reducing valve

62. Lower valve body

valve

TSB Revision

Page 1385 of 2103

AUTOMATIC TRANSAXLE

I

I

‘Id

0

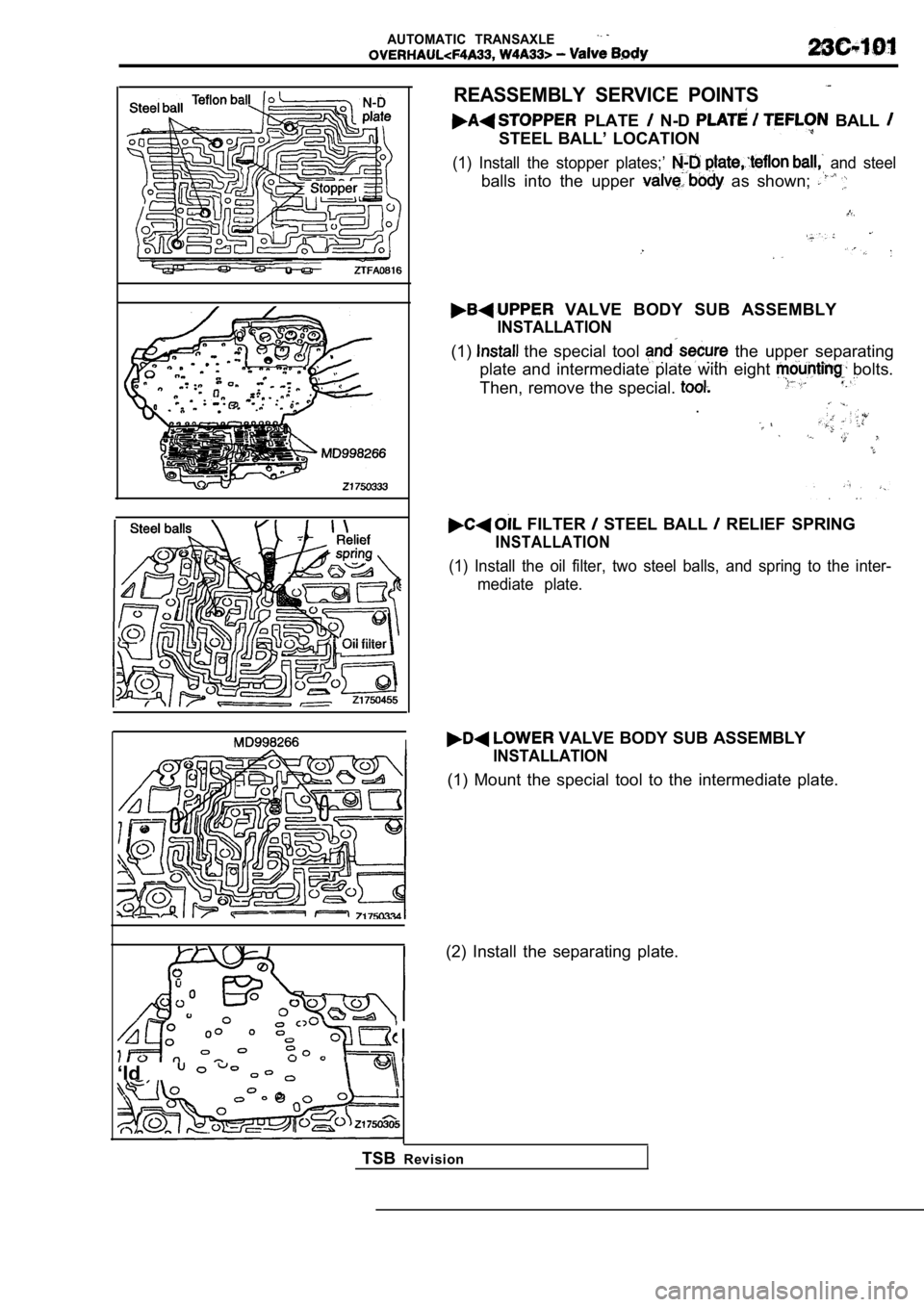

REASSEMBLY SERVICE POINTS

PLATE N-D BALL

STEEL BALL’ LOCATION

(1) Install the stopper plates;’ and steel

balls into the upper as shown;

VALVE BODY SUB ASSEMBLY

INSTALLATION

(1) the special tool the upper separating

plate and intermediate plate with eight

bolts.

Then, remove the special.

.

FILTER STEEL BALL RELIEF SPRING

INSTALLATION

(1) Install the oil filter, two steel balls, and sp ring to the inter-

mediate plate.

VALVE BODY SUB ASSEMBLY

INSTALLATION

(1) Mount the special tool to the intermediate plat e.

(2) Install the separating plate.

TSB Revision

Page 1386 of 2103

AUTOMATIC TRANSAXLE

Valve Body

solenoid

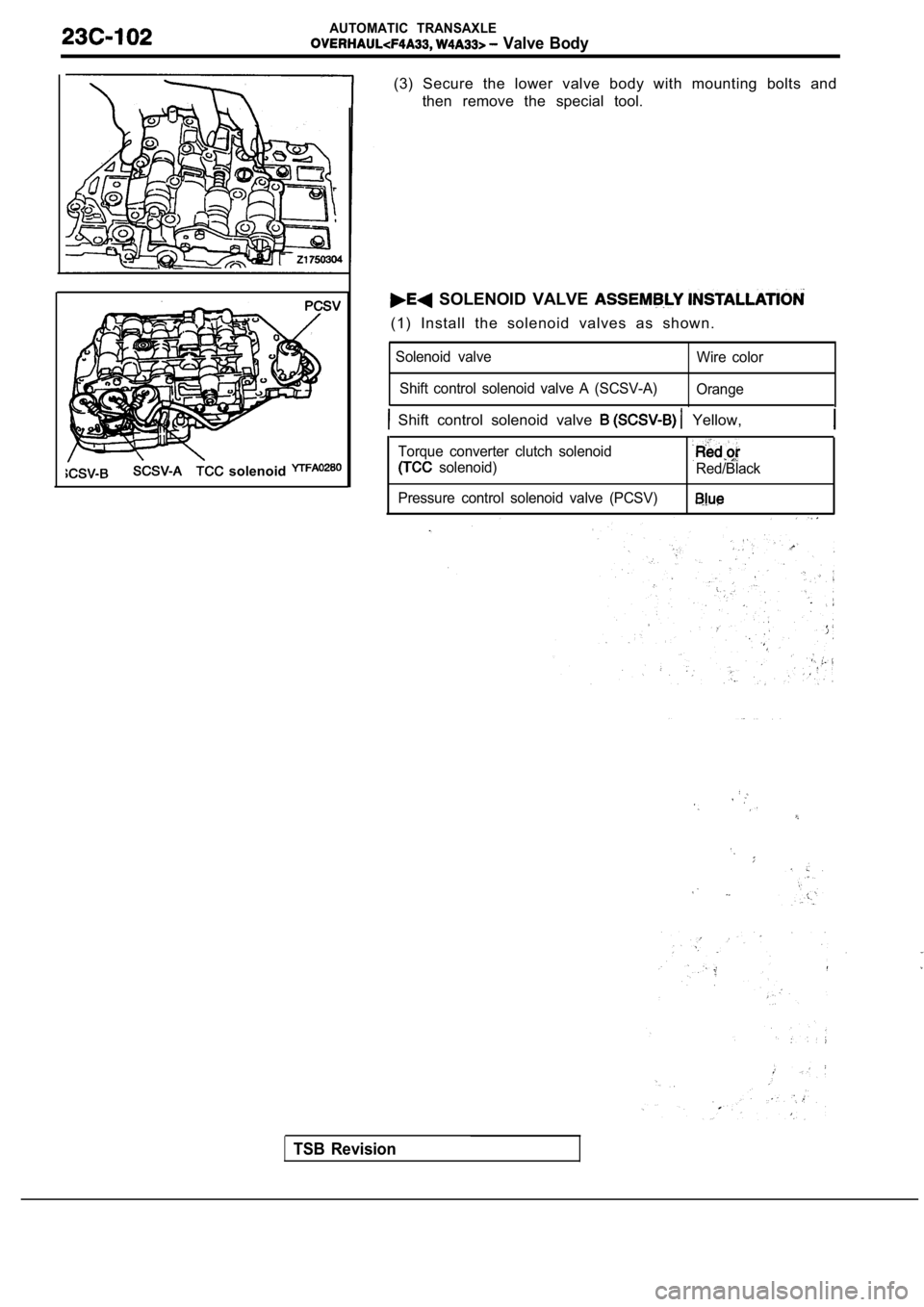

(3) Secure the lower valve body with mounting bolts and

then remove the special tool.

SOLENOID VALVE

(1) Install the solenoid valves as shown.

Solenoid valve

Shift control solenoid valve A (SCSV-A) Wire color

Orange

Shift control solenoid valve Yellow,

Torque converter clutch solenoid

solenoid)Red/Black

Pressure control solenoid valve (PCSV)

TSB Revision

Page 1387 of 2103

AUTOMATIC TRANSAXLE

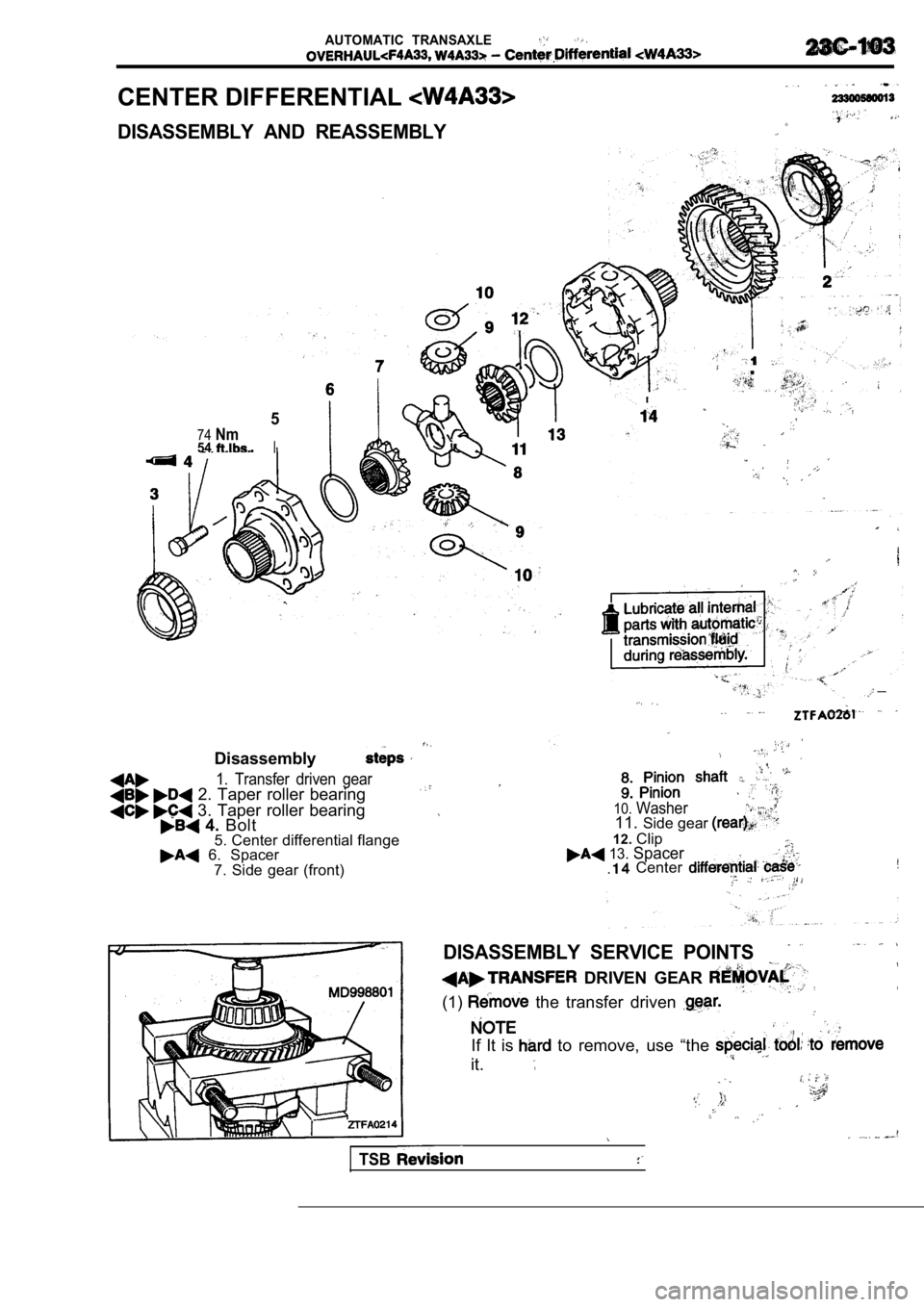

CENTER DIFFERENTIAL ,

DISASSEMBLY AND REASSEMBLY. . .

5

74Nm54I

Disassembly

1. Transfer driven gear 2. Taper roller bearing

3. Taper roller bearing 4. Bolt

5. Center differential flange

6. Spacer

7. Side gear (front)

_ _

10.Washer11. Side gear

12.Clip 13. Spacer Center .

DISASSEMBLY SERVICE POINTS

DRIVEN GEAR

(1) the transfer driven

If It is to remove, use “the

it.

TSB

Page 1388 of 2103

AUTOMATIC TRANSAXLE

. .

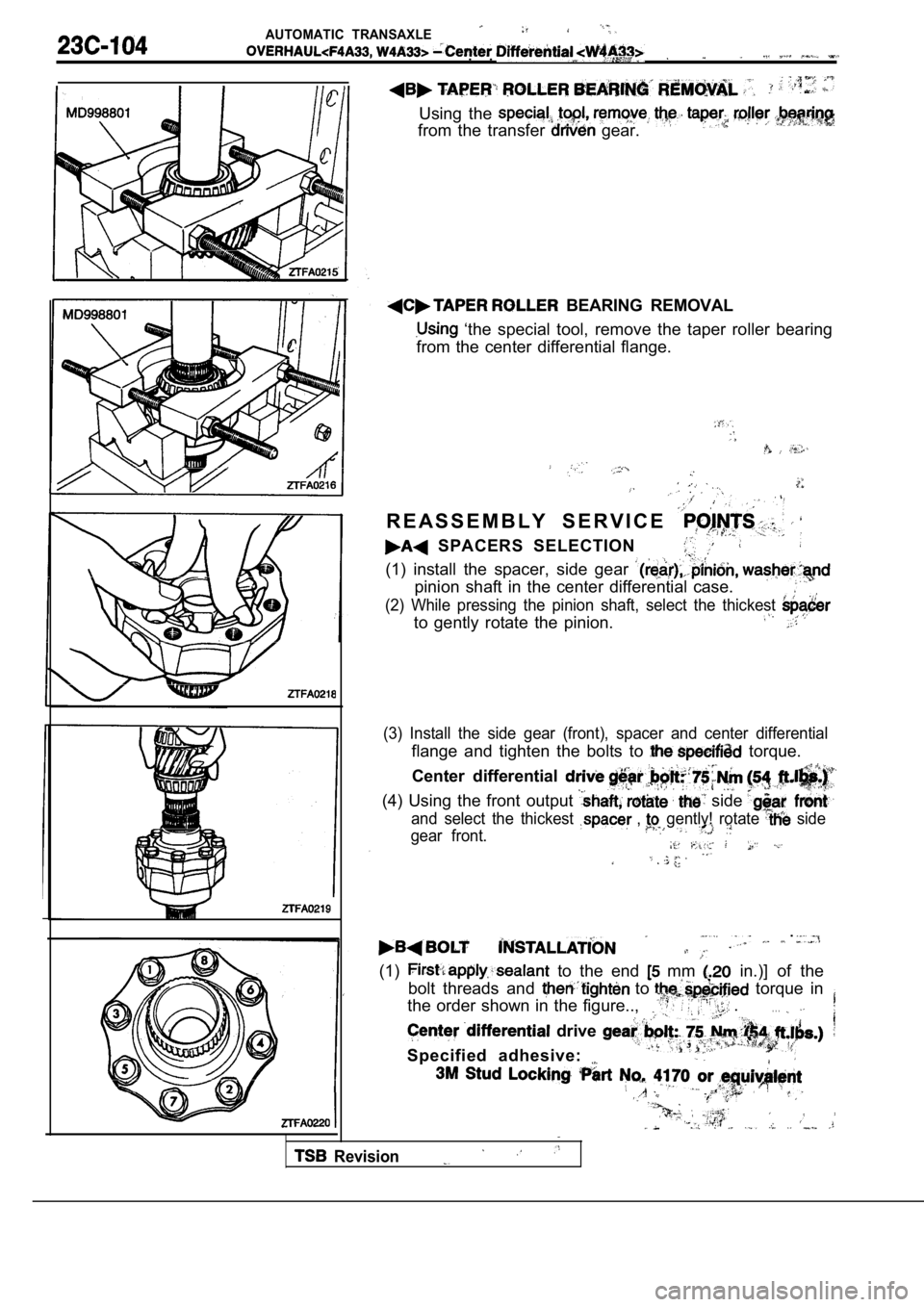

Using the

from the transfer gear.

BEARING REMOVAL

‘the special tool, remove the taper roller bearing

from the center differential flange.

R E A S S E M B L Y S E R V I C E

SPACERS SELECTION

(1) install the spacer, side gear

pinion shaft in the center differential case.

(2) While pressing the pinion shaft, select the thi ckest

to gently rotate the pinion.

(3) Install the side gear (front), spacer and cente r differential

flange and tighten the bolts to torque.

Center differential

(4) Using the front output side

and select the thickest , gently! rotate side

gear front.

.

(1) to the end mm in.)] of the

bolt threads and

to torque in

the order shown in the figure..,

.. . .

drive

Specified adhesive:

,

Revision

Page 1389 of 2103

AUTOMATIC TRANSAXLE

-Cent&

. .

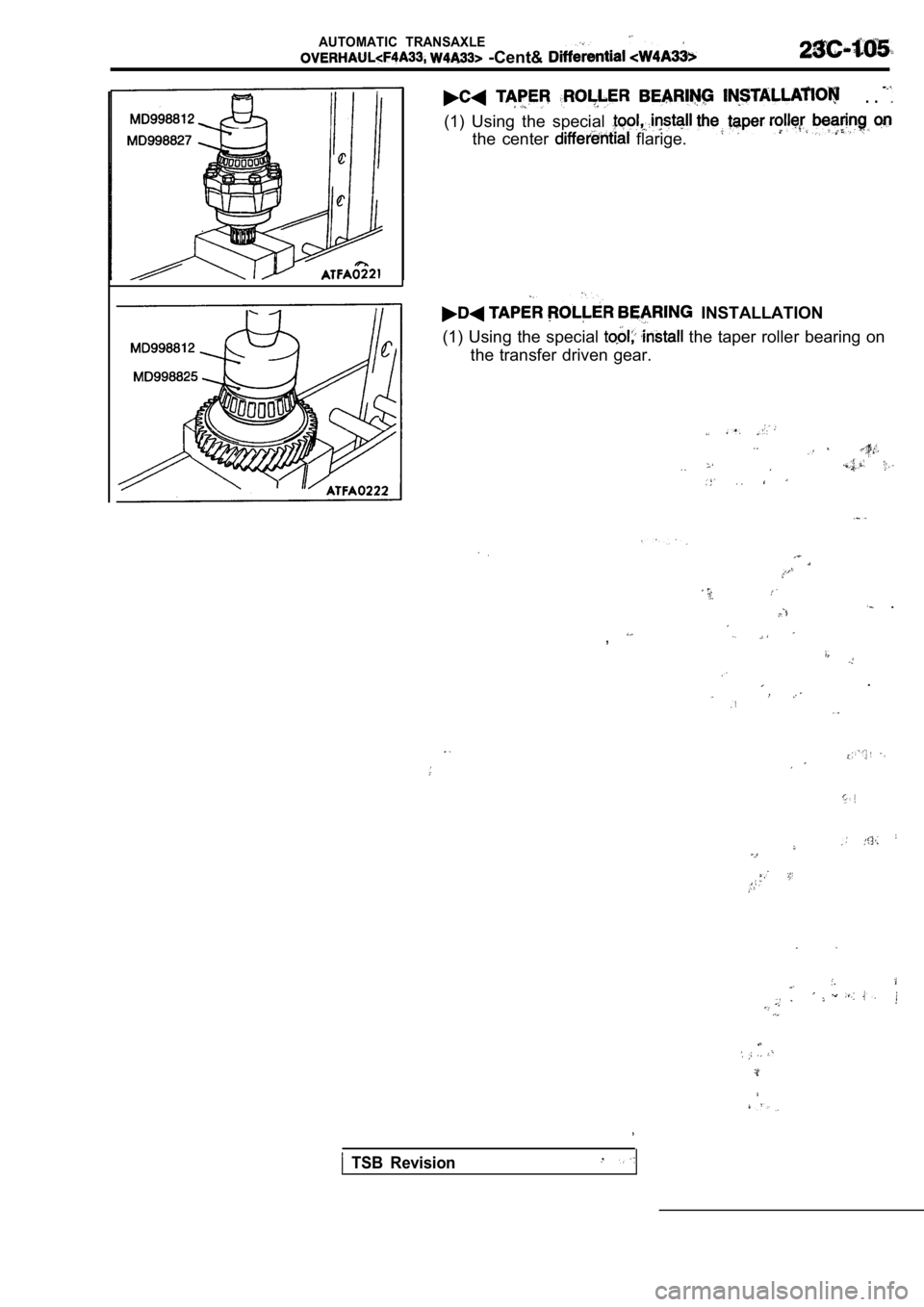

(1) Using the special

the center flarige.

INSTALLATION

(1) Using the special

the taper roller bearing on

the transfer driven gear.

.

,

.

TSB Revision

Page 1390 of 2103

AUTOMATIC TRANSAXLE

Front Output Shaft ,

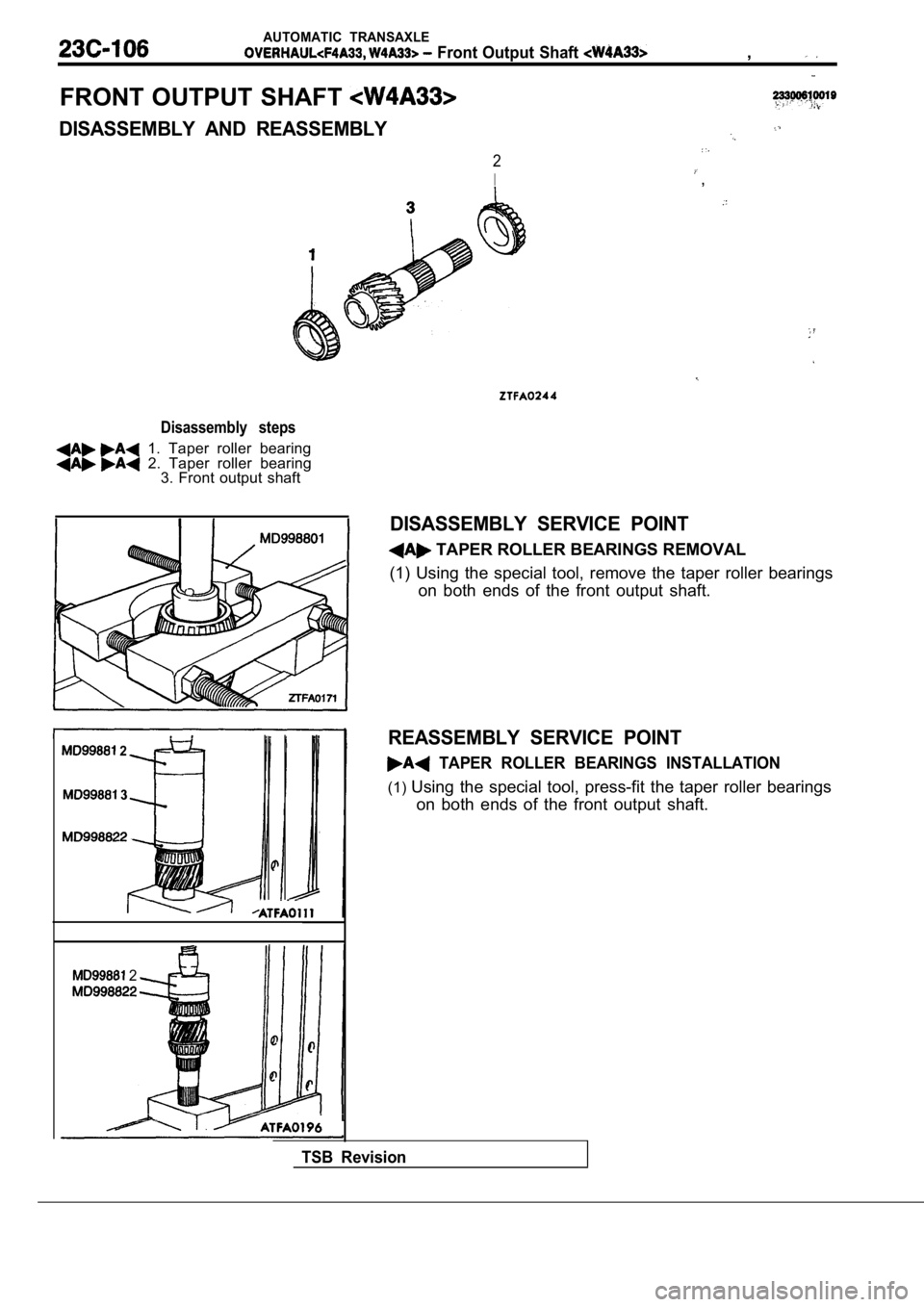

FRONT OUTPUT SHAFT

DISASSEMBLY AND REASSEMBLY

2

I,

Disassembly steps

1. Taper roller bearing 2. Taper roller bearing3. Front output shaft

2

3

2

DISASSEMBLY SERVICE POINT

TAPER ROLLER BEARINGS REMOVAL

(1) Using the special tool, remove the taper roller bearings

on both ends of the front output shaft.

REASSEMBLY SERVICE POINT

TAPER ROLLER BEARINGS INSTALLATION

(1) Using the special tool, press-fit the taper roller bearings

on both ends of the front output shaft.

TSB Revision

Trending: fuel pressure, set clock, torque, wheel, headlights, seats, ad blue