MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: child lock, sunroof, fuel filter location, trunk, air filter, power steering fluid, fuse

Page 1611 of 2103

Compression Lower and

FRONT SUSPENSION

Lower Arm

COMPRESSION LOWER ARM AND LATERAL ARM

ASSEMBLIES

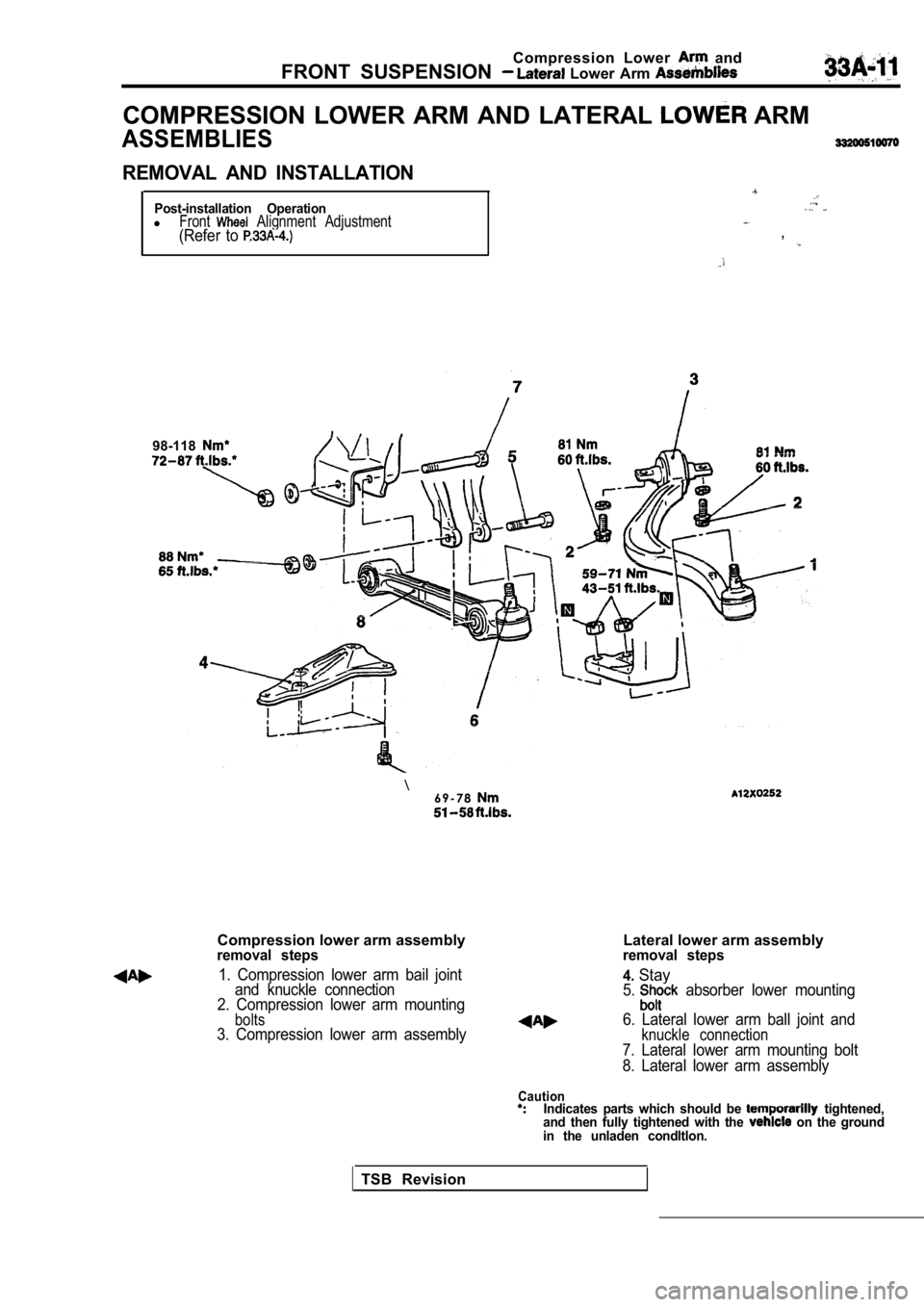

REMOVAL AND INSTALLATION

Post-installation OperationlFront Alignment Adjustment(Refer to ,

98-118

\ 6 9 - 7 8

Compression lower arm assemblyremoval steps

1. Compression lower arm bail joint

and knuckle connection

2. Compression lower arm mounting

bolts3. Compression lower arm assembly

Lateral lower arm assemblyremoval steps

4.

Stay5. absorber lower mounting

6. Lateral lower arm ball joint and

knuckle connection7. Lateral lower arm mounting bolt

8. Lateral lower arm assembly

CautionIndicates parts which should be tightened,

and then fully tightened with the on the ground

in the unladen condltlon.

TSB Revision

Page 1612 of 2103

FRONT SUSPENSION

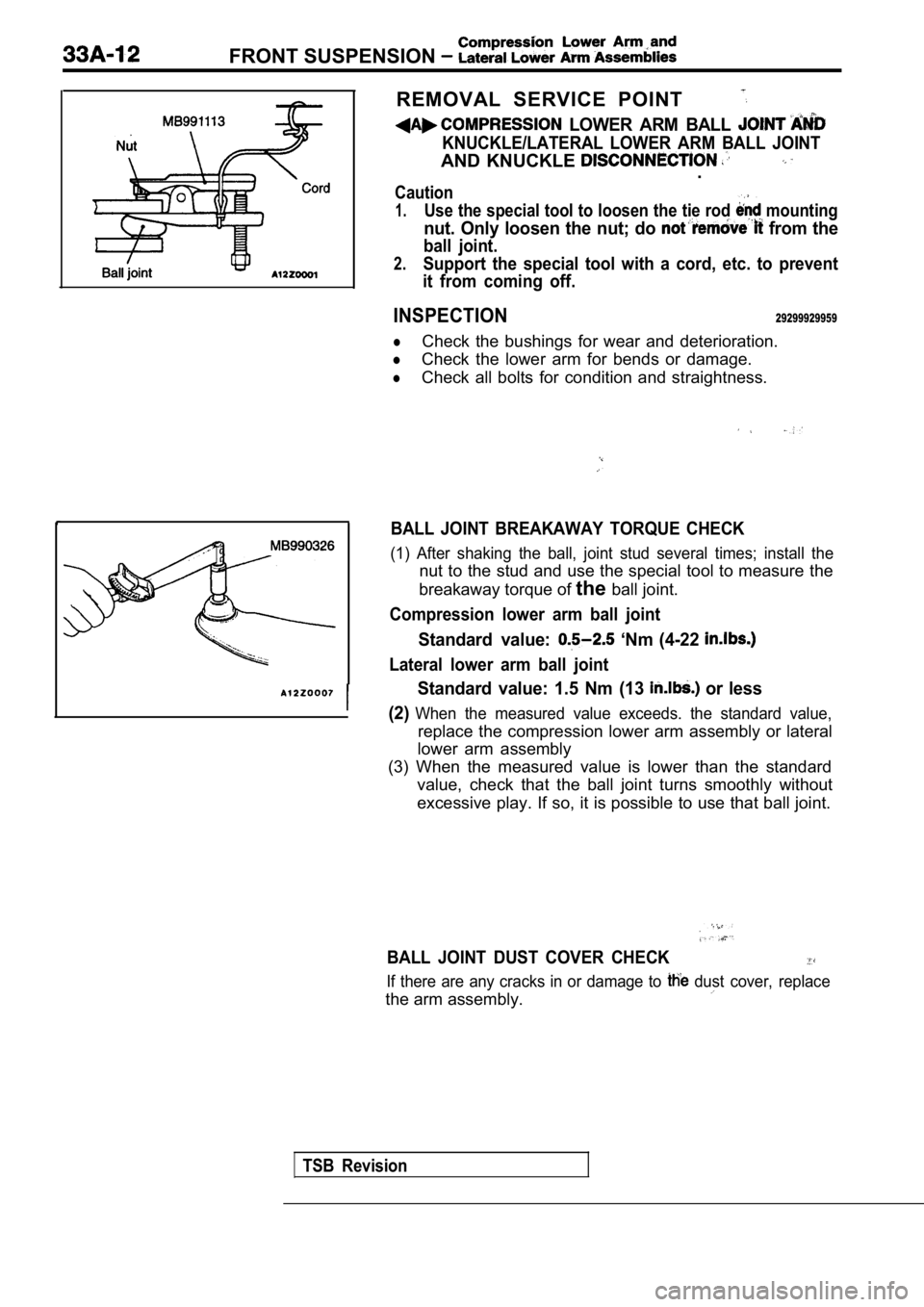

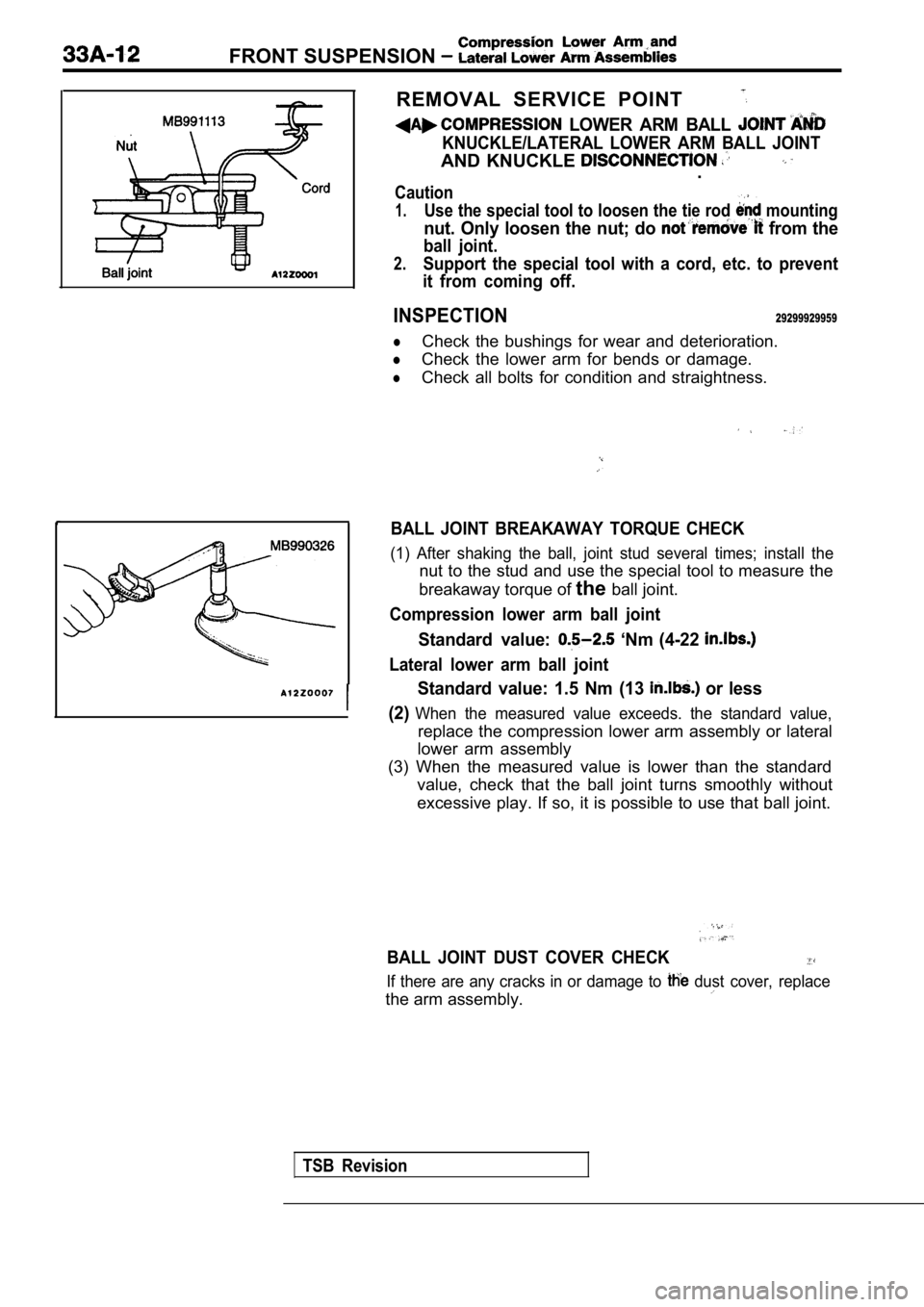

REMOVAL SERVICE POINT

LOWER ARM BALL

KNUCKLE/LATERAL LOWER ARM BALL JOINT

AND KNUCKLE .

Caution

1.Use the special tool to loosen the tie rod mounting

nut. Only loosen the nut; do from the

ball joint.

2.Support the special tool with a cord, etc. to prevent

it from coming off.

INSPECTION29299929959

lCheck the bushings for wear and deterioration.

lCheck the lower arm for bends or damage.

lCheck all bolts for condition and straightness.

BALL JOINT BREAKAWAY TORQUE CHECK

(1) After shaking the ball, joint stud several time s; install the

nut to the stud and use the special tool to measure the

breakaway torque of theball joint.

Compression lower arm ball joint

Standard value: ‘Nm (4-22

Lateral lower arm ball joint

Standard value: 1.5 Nm (13 or less

(2)

When the measured value exceeds. the standard value ,

replace the compression lower arm assembly or lateral

lower arm assembly

(3) When the measured value is lower than the stand ard

value, check that the ball joint turns smoothly wit hout

excessive play. If so, it is possible to use that b all joint.

BALL JOINT DUST COVER CHECK

If there are any cracks in or damage to dust cover, replace

the arm assembly.

TSB Revision

Page 1613 of 2103

Compression Arm and

FRONT SUSPENSION Lateral Lower Arm Assemblies,

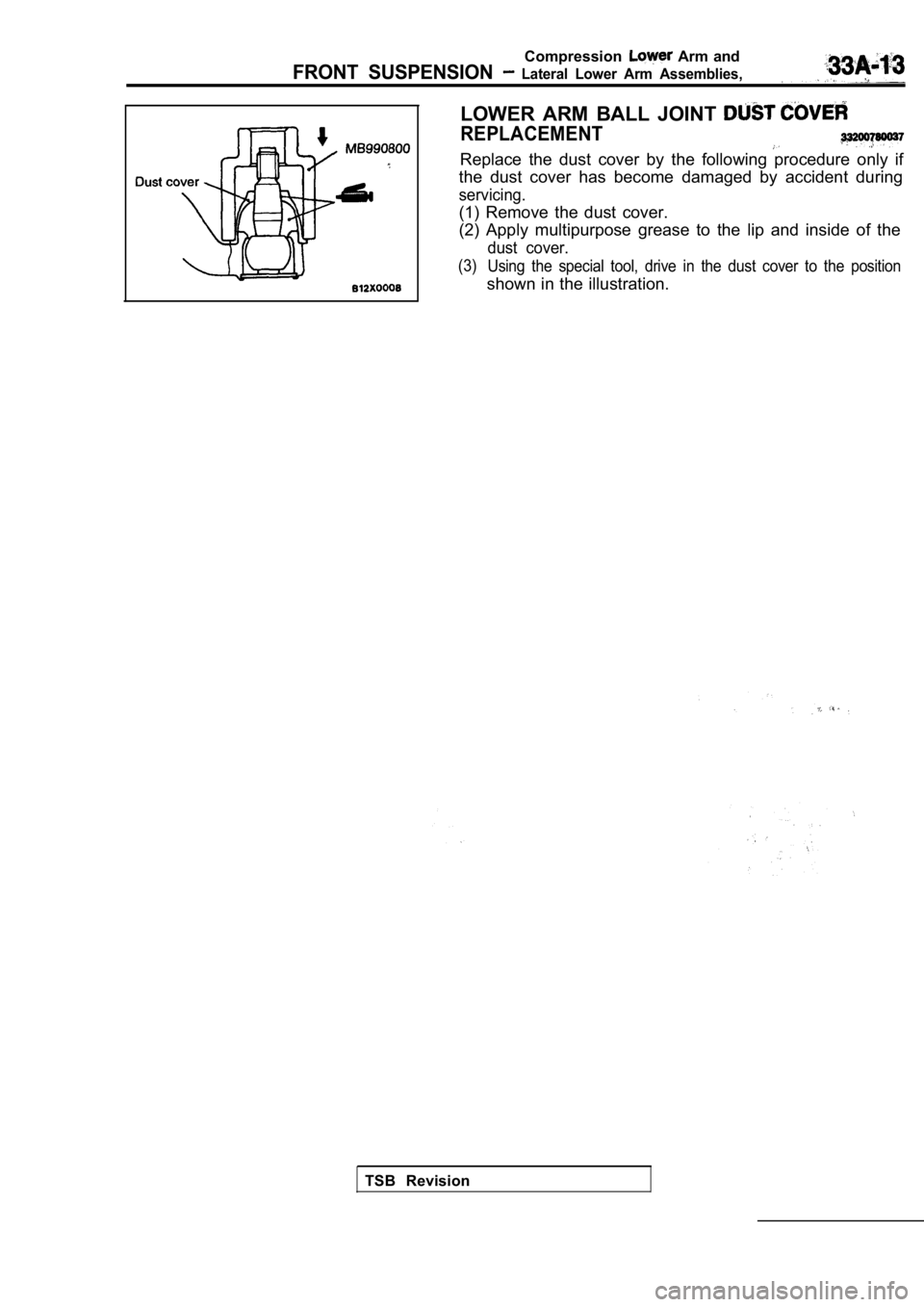

LOWER ARM BALL JOINT

REPLACEMENT

Replace the dust cover by the following procedure only if

the dust cover has become damaged by accident durin g

servicing.

(1) Remove the dust cover.

(2) Apply multipurpose grease to the lip and inside of the

dust cover.

(3)

Using the special tool, drive in the dust cover to the position

shown in the illustration.

TSB Revision

Page 1614 of 2103

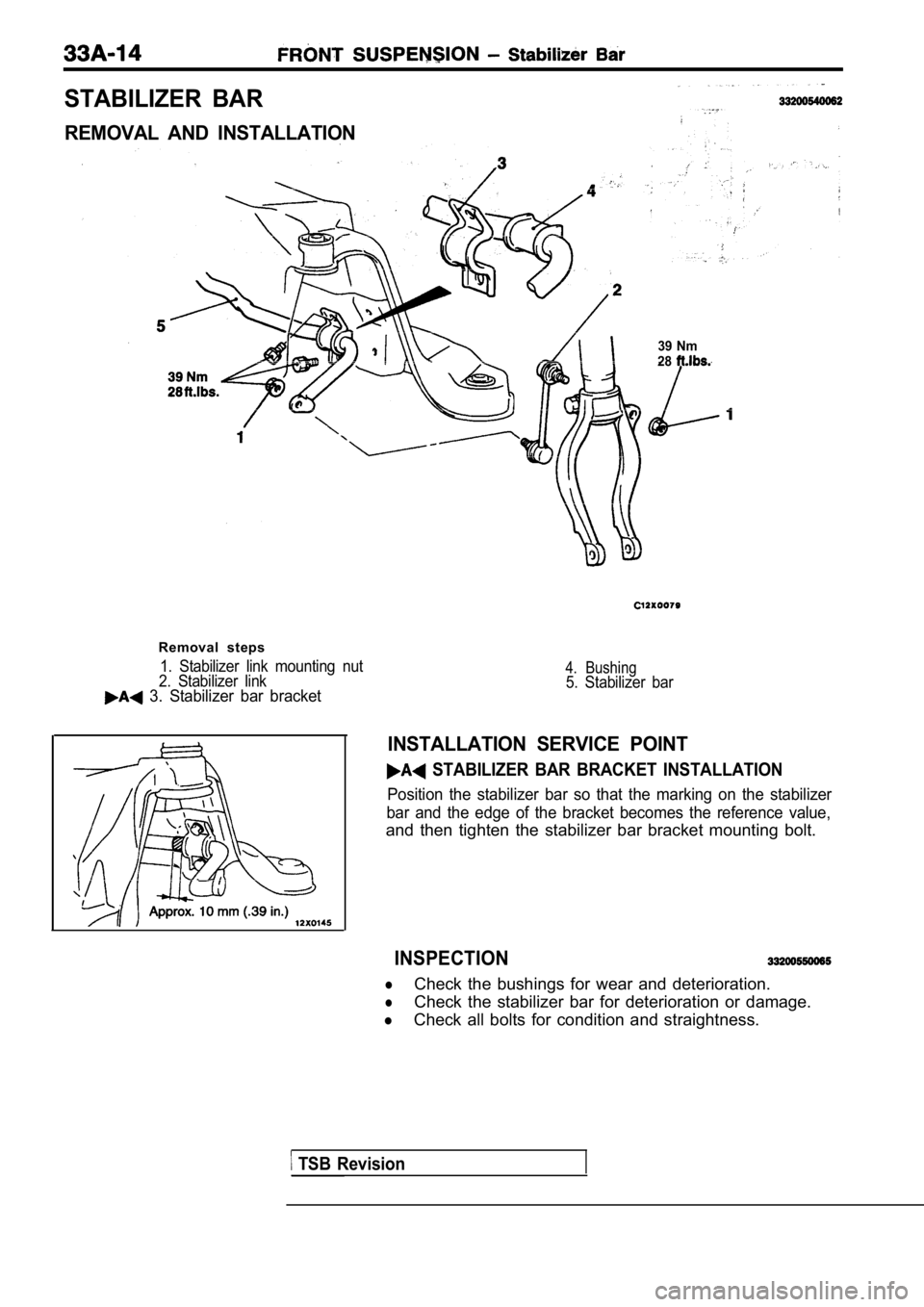

STABILIZER BAR

REMOVAL AND INSTALLATION

Removal steps

1. Stabilizer link mounting nut

2. Stabilizer link

3. Stabilizer bar bracket

39 Nm

28

4. Bushing5. Stabilizer bar

INSTALLATION SERVICE POINT

STABILIZER BAR BRACKET INSTALLATION

Position the stabilizer bar so that the marking on the stabilizer

bar and the edge of the bracket becomes the referen ce value,

and then tighten the stabilizer bar bracket mounting bolt.

INSPECTION

lCheck the bushings for wear and deterioration.

lCheck the stabilizer bar for deterioration or damag e.

lCheck all bolts for condition and straightness.

TSB Revision

Page 1615 of 2103

FRONT SUSPENSION , ,

Al

Clip ring ends onopposite side also possible)

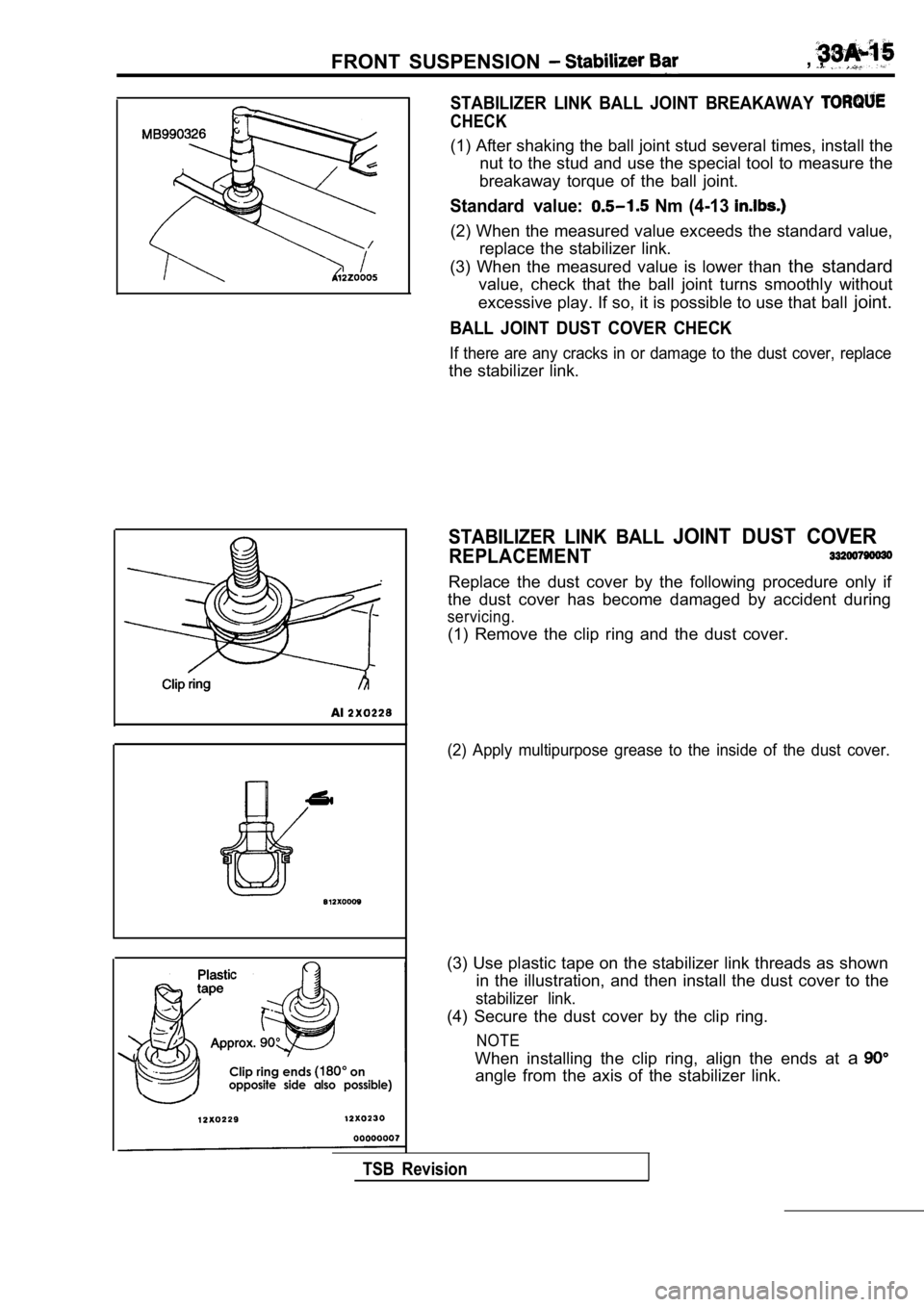

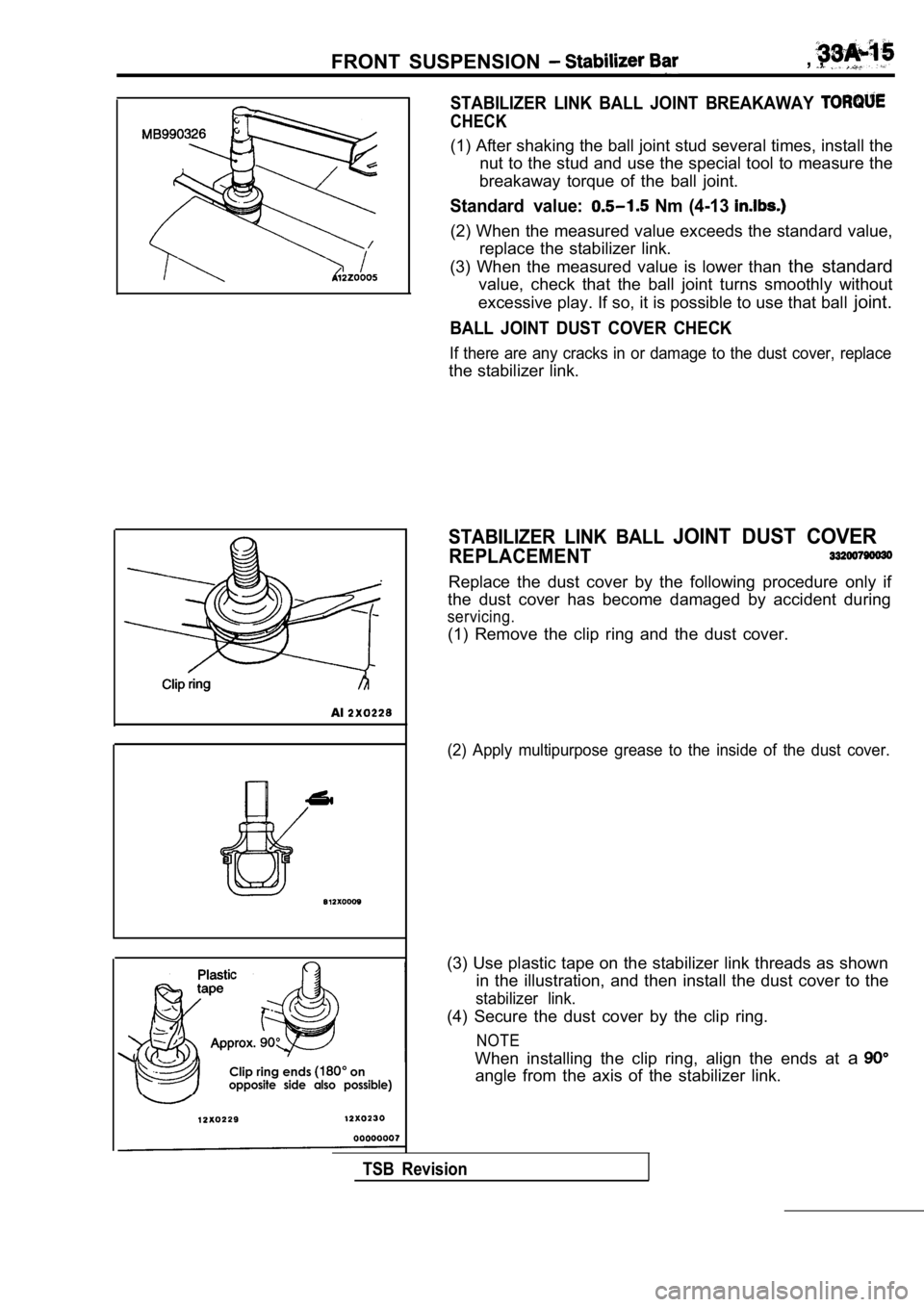

STABILIZER LINK BALL JOINT BREAKAWAY

CHECK

(1) After shaking the ball joint stud several times, install the

nut to the stud and use the special tool to measure the

breakaway torque of the ball joint.

Standard value: Nm (4-13

(2) When the measured value exceeds the standard va lue,

replace the stabilizer link.

(3) When the measured value is lower than the standard

value, check that the ball joint turns smoothly wit hout

excessive play. If so, it is possible to use that b all joint.

BALL JOINT DUST COVER CHECK

If there are any cracks in or damage to the dust co ver, replace

the stabilizer link.

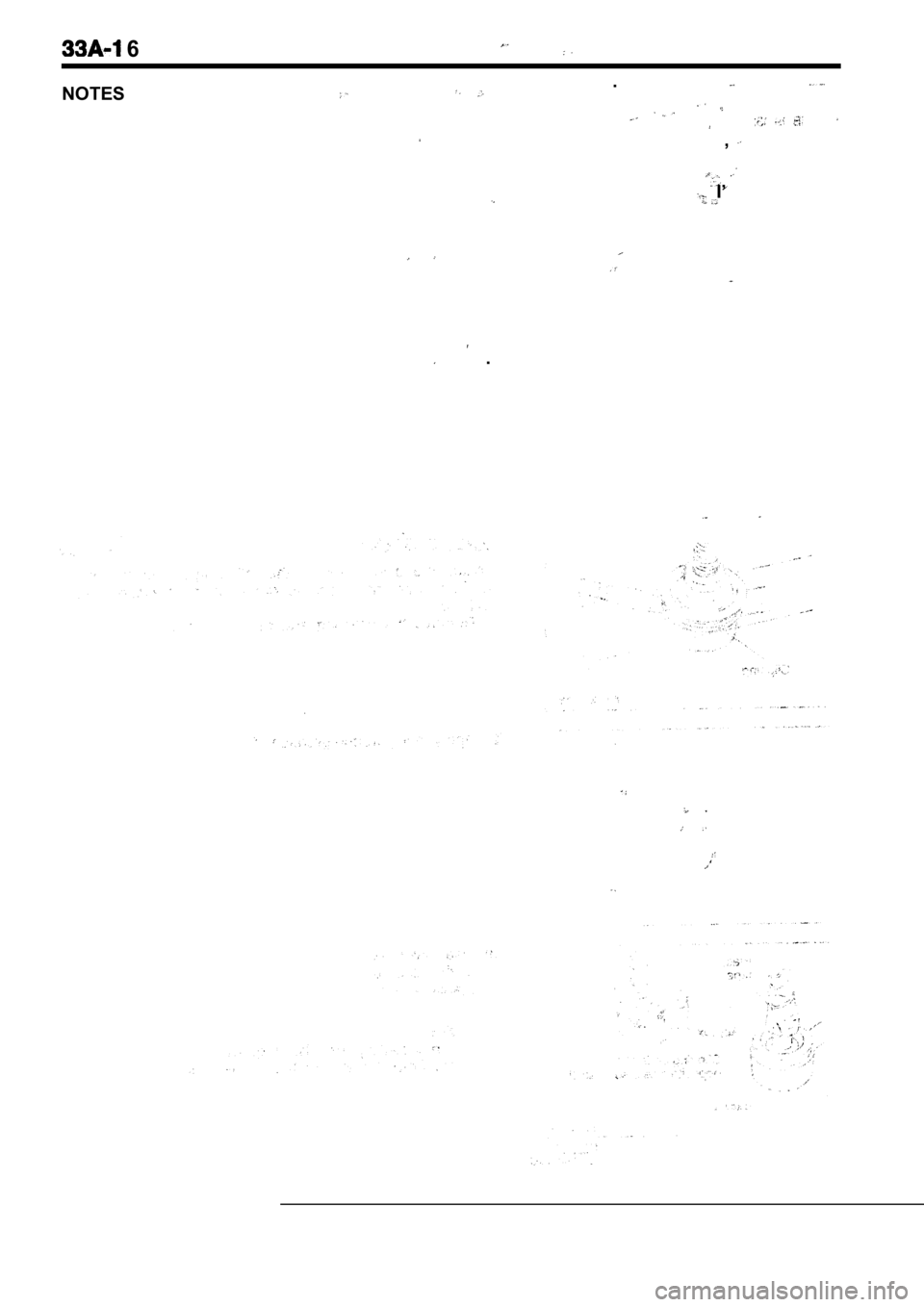

STABILIZER LINK BALL JOINT DUST COVER

REPLACEMENT

Replace the dust cover by the following procedure o nly if

the dust cover has become damaged by accident durin g

servicing.

(1) Remove the clip ring and the dust cover.

(2) Apply multipurpose grease to the inside of the dust cover.

(3) Use plastic tape on the stabilizer link threads as shown

in the illustration, and then install the dust cove r to the

stabilizer link.

(4) Secure the dust cover by the clip ring.

NOTE

When installing the clip ring, align the ends at a

angle from the axis of the stabilizer link.

TSB Revision

Page 1616 of 2103

Page 1617 of 2103

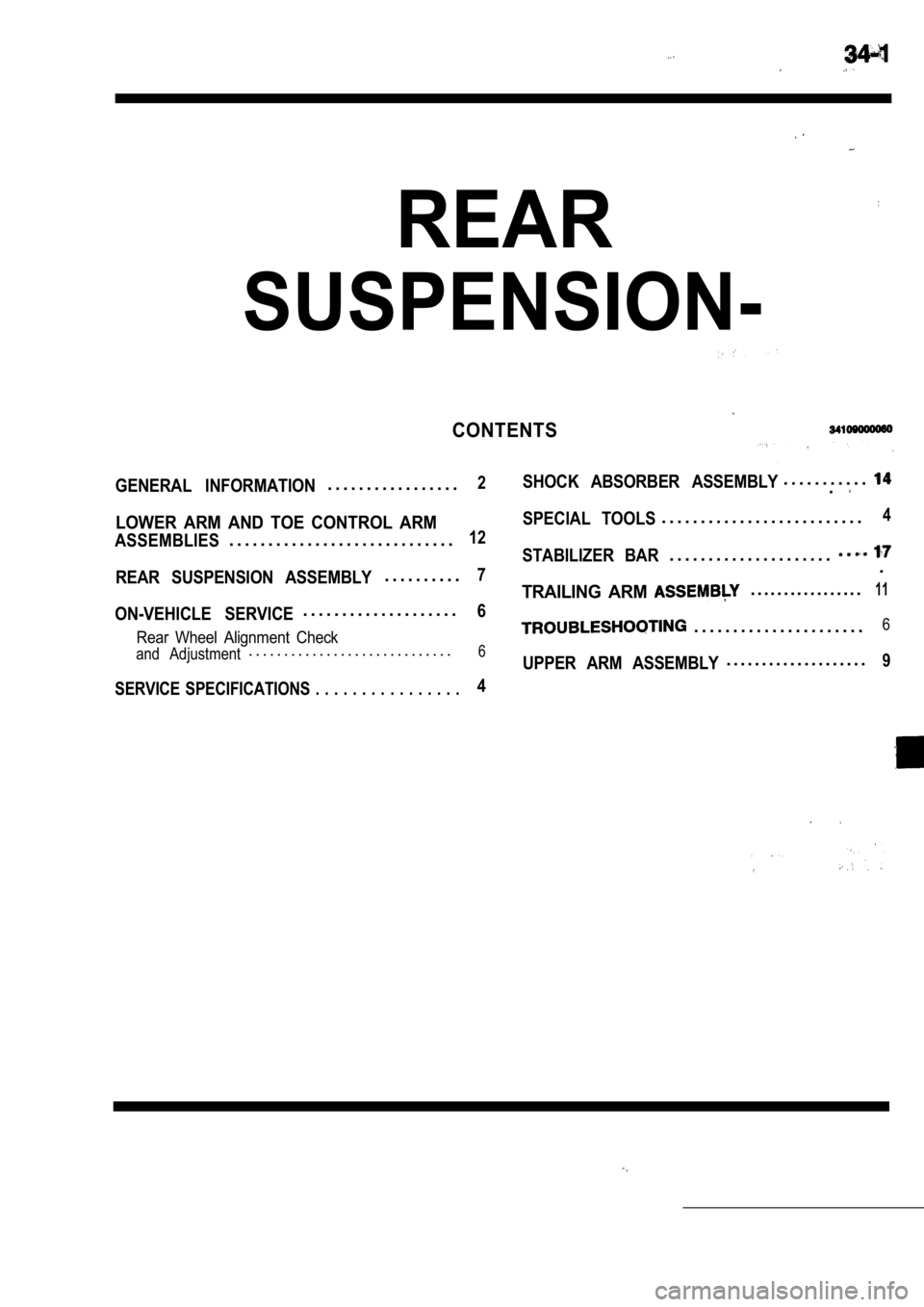

REAR

SUSPENSION-

CONTENTS

GENERAL INFORMATION2SHOCK ABSORBER ASSEMBLY. . . . . . . . . . .. . . . . . . . . . . . . . . . ..

LOWER ARM AND TOE CONTROL ARMSPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . .4

ASSEMBLIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

STABILIZER BAR. . . . . . . . . . . . . . . . . . . . .

REAR SUSPENSION ASSEMBLY. . . . . . . . . .7.

TRAILING ARM . . . . . . . . . . . . . . . . .11

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . . . . .6

Rear Wheel Alignment Check. . . . . . . . . . . . . . . . . . . . . .6

and Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .6UPPER ARM ASSEMBLY. . . . . . . . . . . . . . . . . . . .9

SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . .

4

Page 1618 of 2103

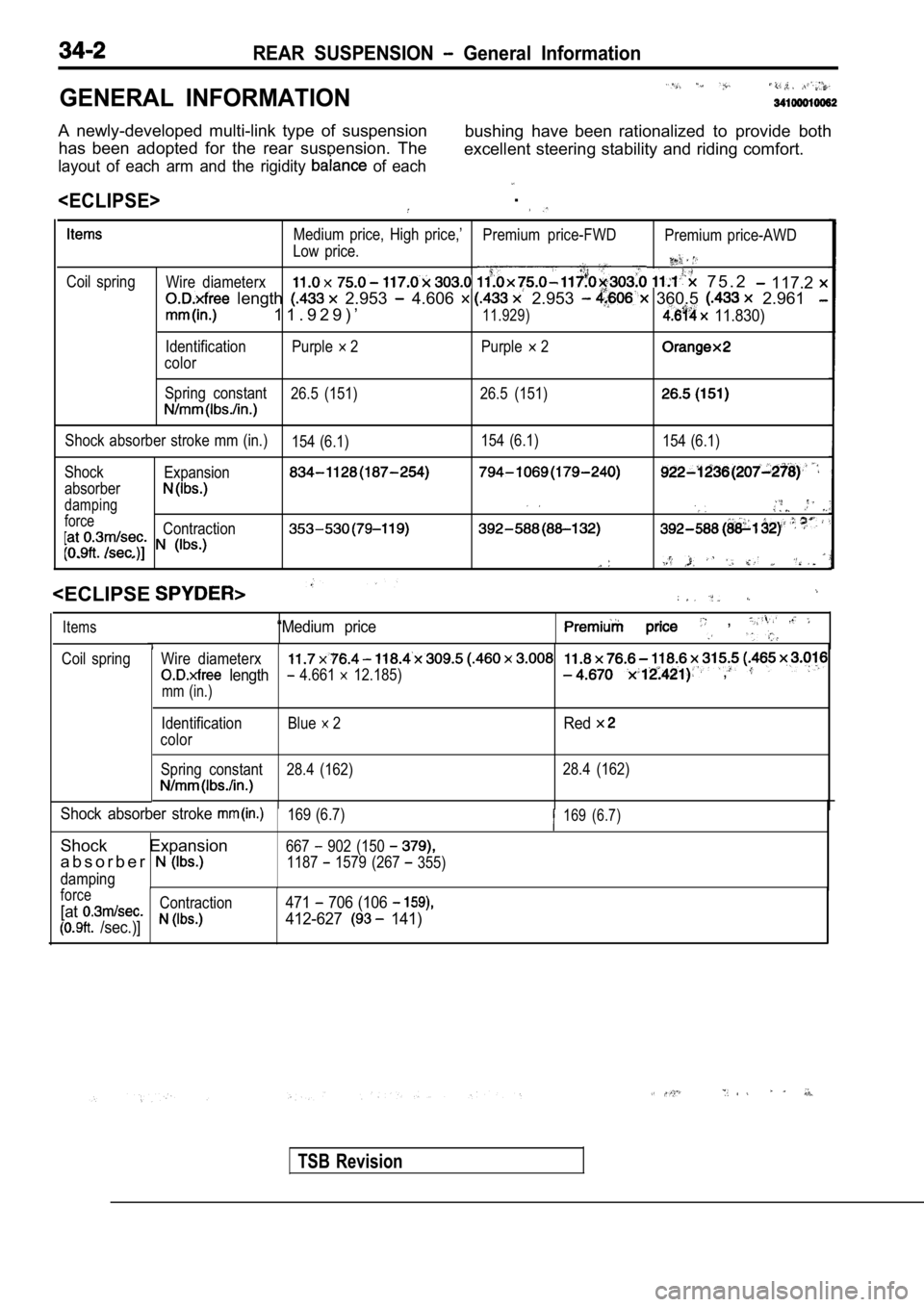

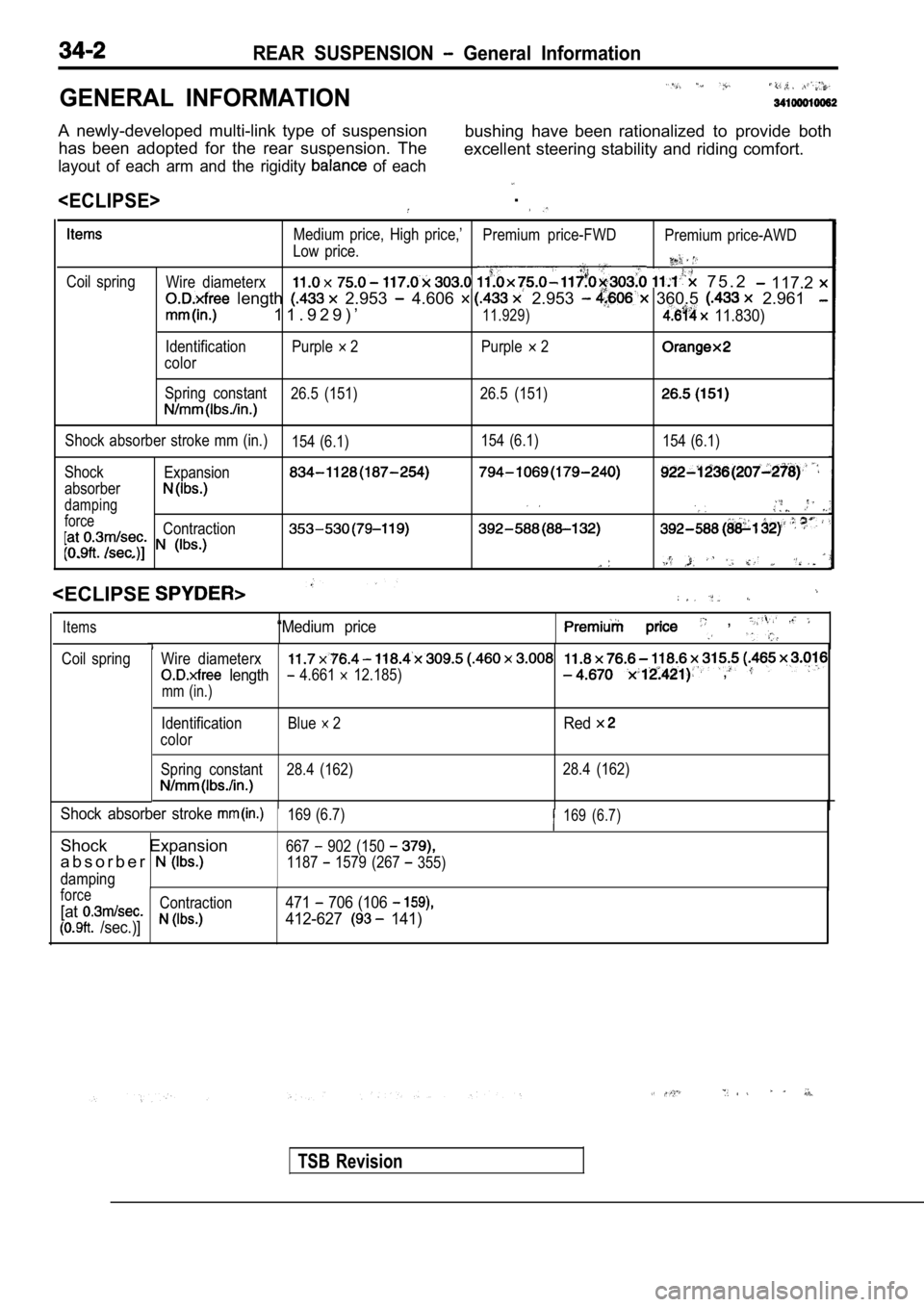

REAR SUSPENSION General Information

GENERAL INFORMATION

A newly-developed multi-link type of suspensionhas been adopted for the rear suspension. The bushing have been rationalized to provide both

excellent steering stability and riding comfort.

layout of each arm and the rigidity of each

.

Coil spring Medium price, High price,’

Premium price-FWDPremium price-AWD

Low price.Wire diameterx 7 5 . 2 117.2

length 2.953 4.606 2.953 360.5 2.961

1 1 . 9 2 9 ) ’11.929) 11.830)

Identification Purple 2 Purple 2

color

Spring constant 26.5 (151) 26.5 (151)

Shock absorber stroke mm (in.)

154 (6.1)154 (6.1)

154 (6.1)

Shock Expansion

absorber

damping

forceContraction

. . .

“Medium price ,

Wire diameterx

length 4.661 12.185) ,

mm (in.)

Items

Coil spring

TSB Revision

Identification

color Blue 2Red

Spring constant 28.4 (162)

28.4 (162)

Shock absorber stroke 169 (6.7)169 (6.7)

Shock Expansion667 902 (150

a b s o r b e r1187 1579 (267 355)

damping

force

[atContraction471 706 (106

/sec.)]412-627 141)

Page 1619 of 2103

REAR SUSPENSION General Information

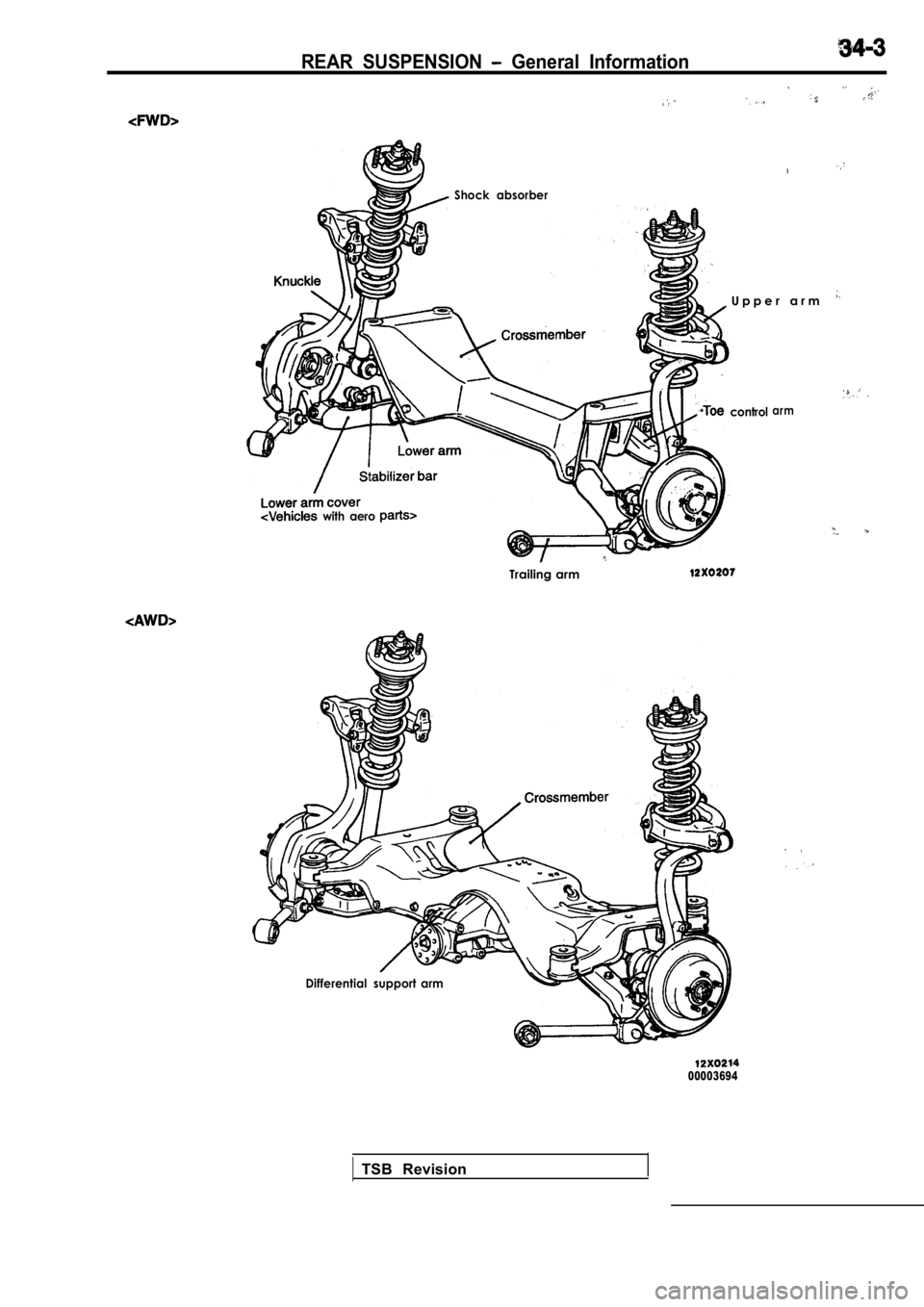

Shock absorber

U p p e r a r m

control

with aero

arm

Trailing arm

Differential support arm

00003694

TSB Revision

Page 1620 of 2103

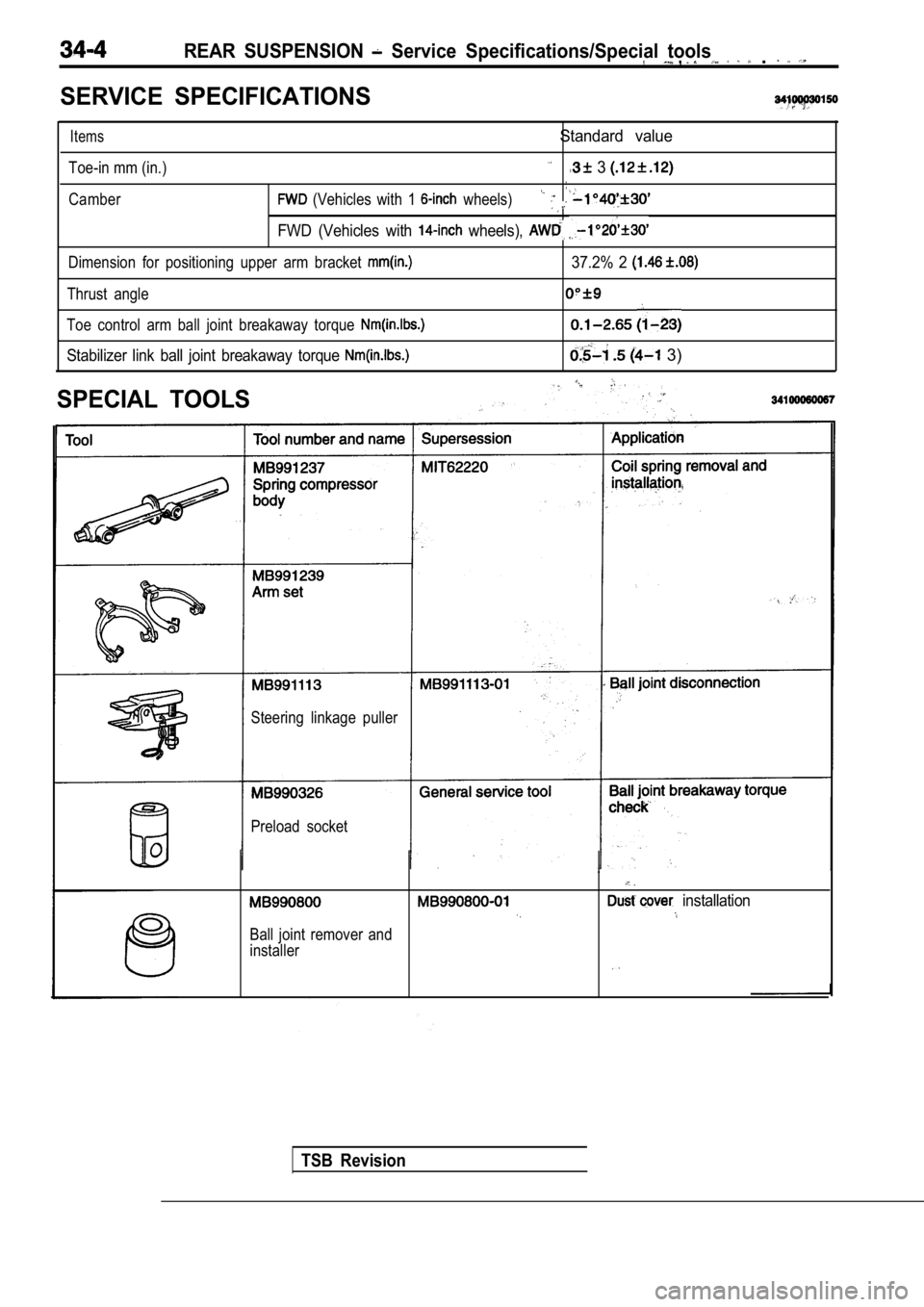

REAR SUSPENSION Service Specifications/Special tools, , .

SERVICE SPECIFICATIONS

Items

Toe-in mm (in.)

Standard value

3

Camber (Vehicles with 1 wheels)

FWD (Vehicles with wheels),

Dimension for positioning upper arm bracket

Thrust angle

Toe control arm ball joint breakaway torque

Stabilizer link ball joint breakaway torque

SPECIAL TOOLS

37.2% 2

3)

Steering linkage puller

Preload socket

.

installation

Ball joint remover and

installer

TSB Revision

Trending: washer fluid, fuel pump, instrument panel, fuel consumption, mirror, spare tire, change wheel