MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1831 of 2103

BODY and Window Glass

SERVICE SPECIFICATIONS ,

Items

Difference in quarter window glass height from door window glass height mm (in.)

Clearance between quarter window glass sash weather strip and door window glass

mm (in.).Standard’ value 8.3 2.0

Distances between quarter window glass and quarter

Front of quarter window

belt moulding and between quarter window glass and glass

quarter belt line outer weatherstrip flushness mm (in.)Rear of quarter window

glass9.0 2.0

Quarter window glass tilt mm (in.) 3.0 2.0

SEALANTS AND ADHESIVES

Items

Windshield

Quarter window glass

Specified sealants and adhesives

No. 8609 Super Fast Urethane

Part No. 8608 Super Fast Urethane Primer or equiva lent

glass

Windshield to molding

glass to molding

ATD Part No. 6382 or

,. . , . .

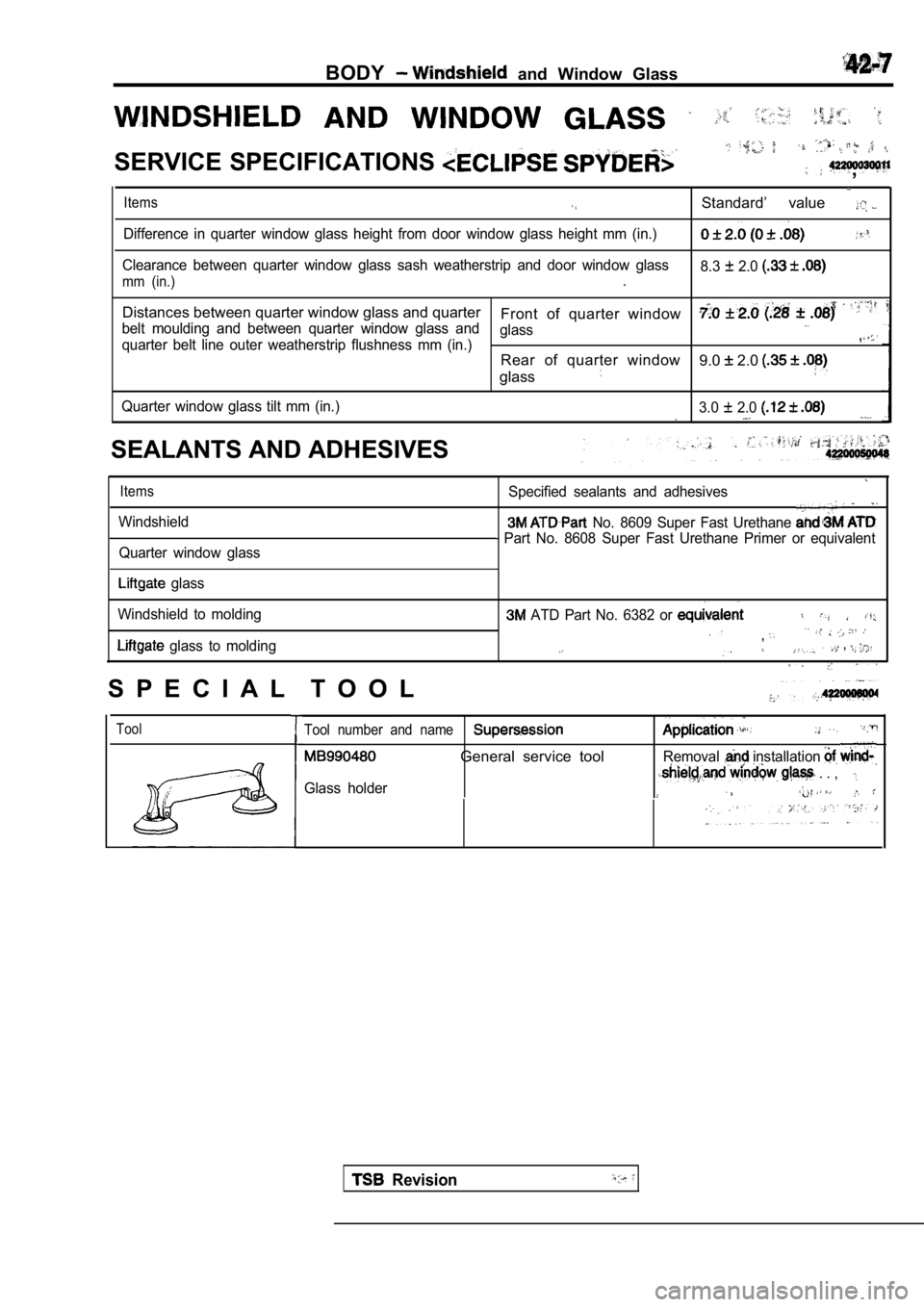

S P E C I A L T O O L

ToolTool number and name

General service toolRemoval installation

Glass holder . . ,

Revision

Page 1832 of 2103

BODY Windshield and Window Glass

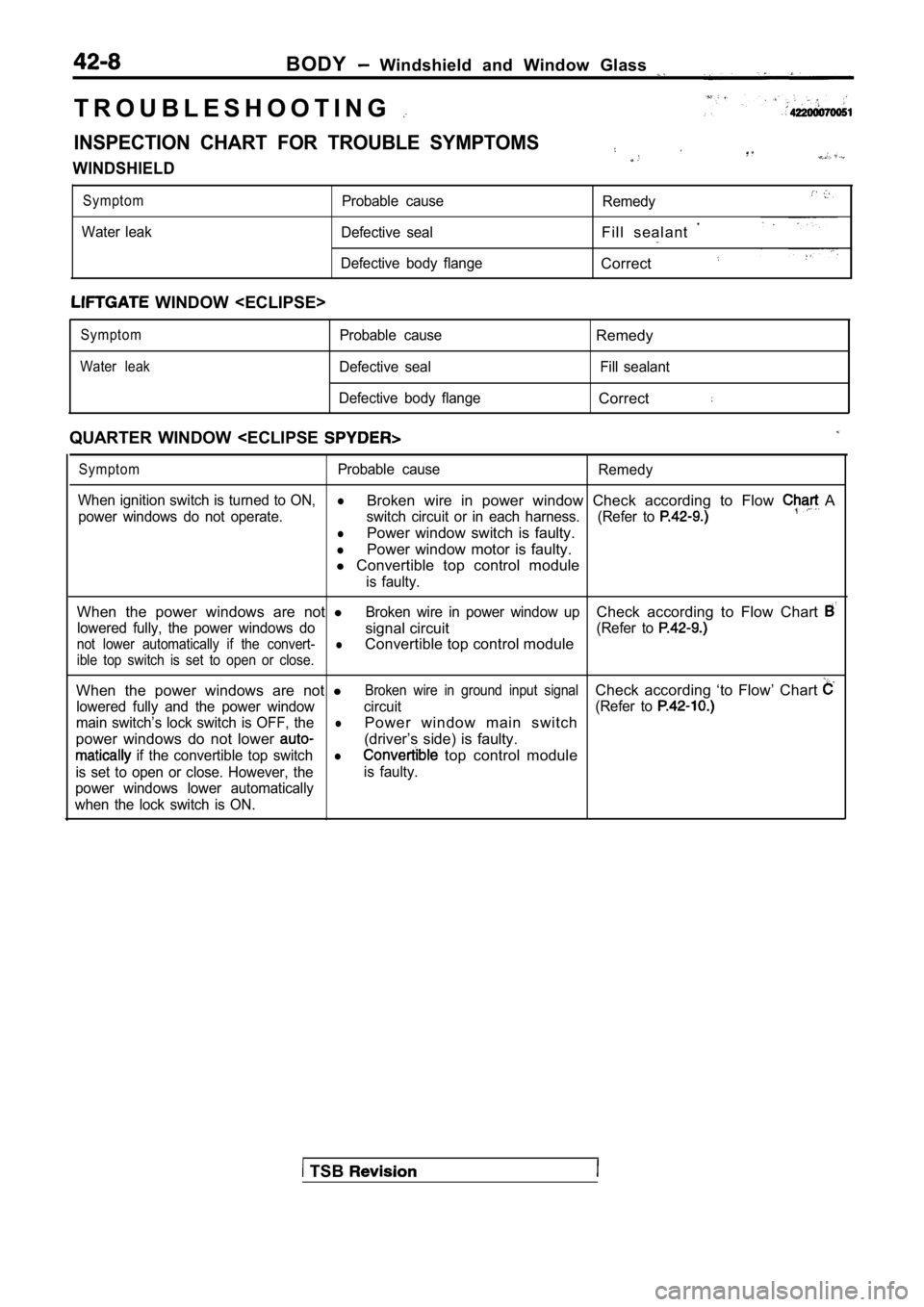

T R O U B L E S H O O T I N G

INSPECTION CHART FOR TROUBLE SYMPTOMS

WINDSHIELD

Symptom

Water leakProbable cause

Defective seal

Defective body flange RemedyF i l l s e a l a n t

Correct

WINDOW

Symptom

Water leakProbable causeRemedy

Defective seal Fill sealant

Defective body flange

Correct

QUARTER WINDOW

When ignition switch is turned to ON,

l

power windows do not operate.

Broken wire in power window Check according to Flow A

switch circuit or in each harness. (Refer to

lPower window switch is faulty.

lPower window motor is faulty.

l Convertible top control module

is faulty.

When the power windows are not lBroken wire in power window upCheck according to Flow Chart

lowered fully, the power windows dosignal circuit(Refer to

not lower automatically if the convert-lConvertible top control module

ible top switch is set to open or close.

When the power windows are not lBroken wire in ground input signalCheck according ‘to Flow’ Chart

lowered fully and the power window circuit (Refer to

main switch’s lock switch is OFF, thelPower window main switch

power windows do not lower

(driver’s side) is faulty.

if the convertible top switchl top control module

is set to open or close. However, the is faulty.

power windows lower automatically

when the lock switch is ON.

TSB

Page 1833 of 2103

BODY Windshield and Window Glass

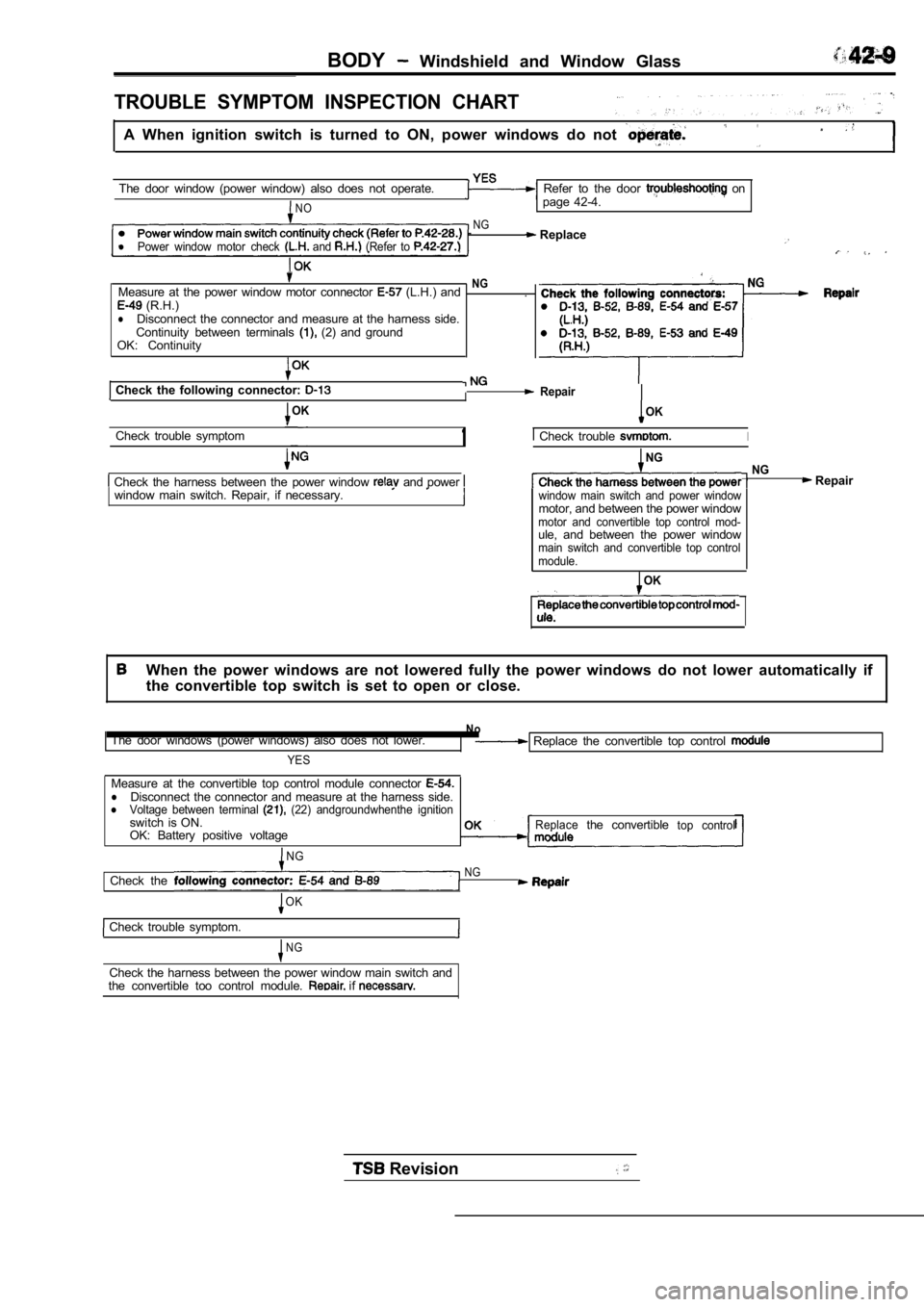

TROUBLE SYMPTOM INSPECTION CHART

A When ignition switch is turned to ON, power windows do not

The door window (power window) also does not operate. Refer to the door on

NOpage 42-4.

NG ReplacelPower window motor check and (Refer to

NGMeasure at the power window motor connector (L.H.) and

. (R.H.)lDisconnect the connector and measure at the harness side.

Continuity between terminals (2) and ground

OK: Continuity

Check the following connector:

OKI Repair

OK

Check the following connectors:

Check trouble symptom1

Check the harness between the power window and power window main switch. Repair, if necessary.

Check trouble I

NG NG

window main switch and power windowmotor, and between the power windowmotor and convertible top control mod-ule, and between the power windowmain switch and convertible top control

module.

Repair

OK

Revision

When the power windows are not lowered fully the po wer windows do not lower automatically if

the convertible top switch is set to open or close.

NoThe door windows (power windows) also does not lowe r.

YES

Replace the convertible top control

Measure at the convertible top control module connector lDisconnect the connector and measure at the harness side.lVoltage between terminal (22) andgroundwhenthe ignitionswitch is ON.

the convertiblecontrolOK: Battery positive voltageReplacetop

NG

Check the NG

OK

Check trouble symptom.

NG

Check the harness between the power window main swi tch and

the convertible too control module. if

Page 1834 of 2103

BODY Windshield and Window Glass

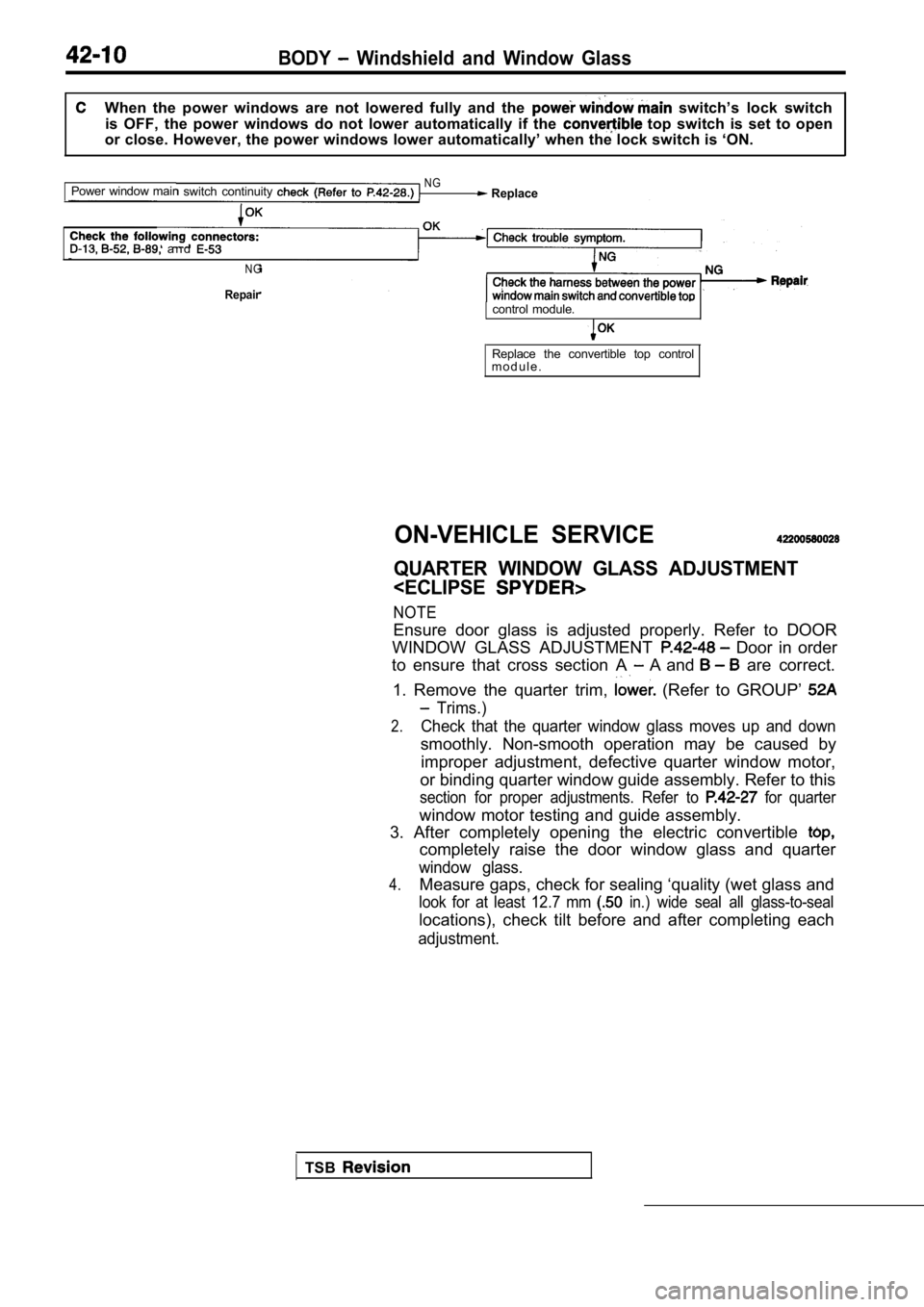

When the power windows are not lowered fully and the switch’s lock switch

is OFF, the power windows do not lower automaticall y if the

top switch is set to open

or close. However, the power windows lower automati cally’ when the lock switch is ‘ON.

Power window mair

switch continuity NG Replace

a n d

N G

Repaircontrol module.

Replace the convertible top control

m o d u l e .

ON-VEHICLE SERVICE

QUARTER WINDOW GLASS ADJUSTMENT

Ensure door glass is adjusted properly. Refer to DO OR

WINDOW GLASS ADJUSTMENT

Door in order

to ensure that cross section A

A and are correct.

1. Remove the quarter trim,

(Refer to GROUP’

Trims.)

2.Check that the quarter window glass moves up and do wn

smoothly. Non-smooth operation may be caused by

improper adjustment, defective quarter window motor ,

or binding quarter window guide assembly. Refer to this

section for proper adjustments. Refer to for quarter

window motor testing and guide assembly.

3. After completely opening the electric convertibl e

completely raise the door window glass and quarter

window glass.

4.Measure gaps, check for sealing ‘quality (wet glass and

look for at least 12.7 mm in.) wide seal all glass-to-seal

locations), check tilt before and after completing each

adjustment.

TSB

Page 1835 of 2103

and Window Glass

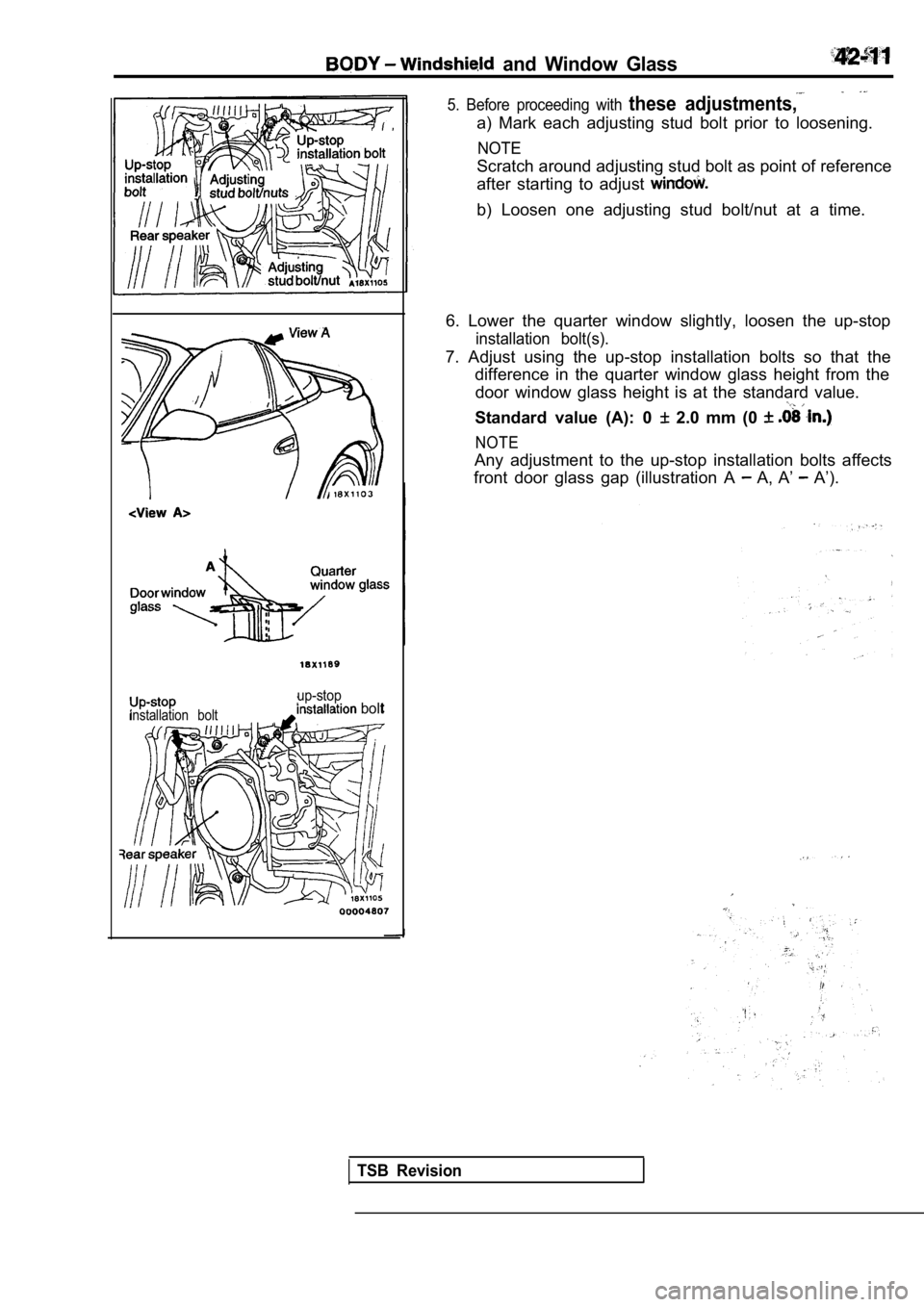

installation bolt

up-stop bolt

5. Before proceeding with these adjustments,

a) Mark each adjusting stud bolt prior to loosening.

NOTE

Scratch around adjusting stud bolt as point of reference

after starting to adjust

b) Loosen one adjusting stud bolt/nut at a time.

6. Lower the quarter window slightly, loosen the up -stop

installation bolt(s).

7. Adjust using the up-stop installation bolts so that the

difference in the quarter window glass height from the

door window glass height is at the standard value.

Standard value (A): 0 2.0 mm (0

NOTE

Any adjustment to the up-stop installation bolts af fects

front door glass gap (illustration A

A, A’ A’).

TSB Revision

Page 1836 of 2103

BODY Windshield and Window Glass

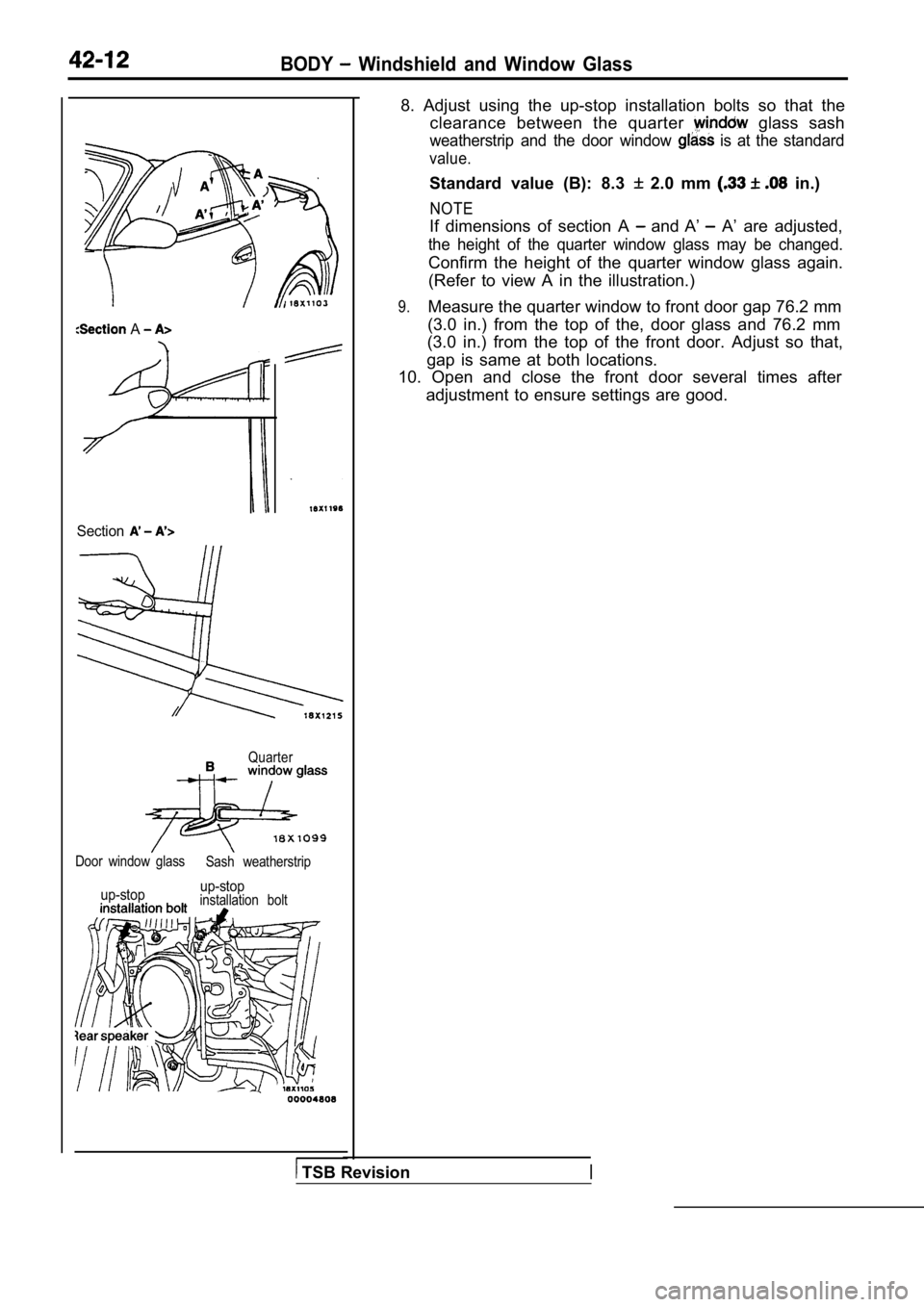

A

Section

Quarter

Door window glassSash weatherstrip

up-stopup-stopinstallation bolt

8. Adjust using the up-stop installation bolts so t

hat the

clearance between the quarter

glass sash

weatherstrip and the door window is at the standard

value.

Standard value (B): 8.3 2.0 mm in.)

NOTE

If dimensions of section A and A’ A’ are adjusted,

the height of the quarter window glass may be chang ed.

Confirm the height of the quarter window glass again.

(Refer to view A in the illustration.)

9.Measure the quarter window to front door gap 76.2 m m

(3.0 in.) from the top of the, door glass and 76.2 mm

(3.0 in.) from the top of the front door. Adjust so that,

gap is same at both locations.

10. Open and close the front door several times aft er

adjustment to ensure settings are good.

TSB Revision

Page 1837 of 2103

BODY Windshield Window

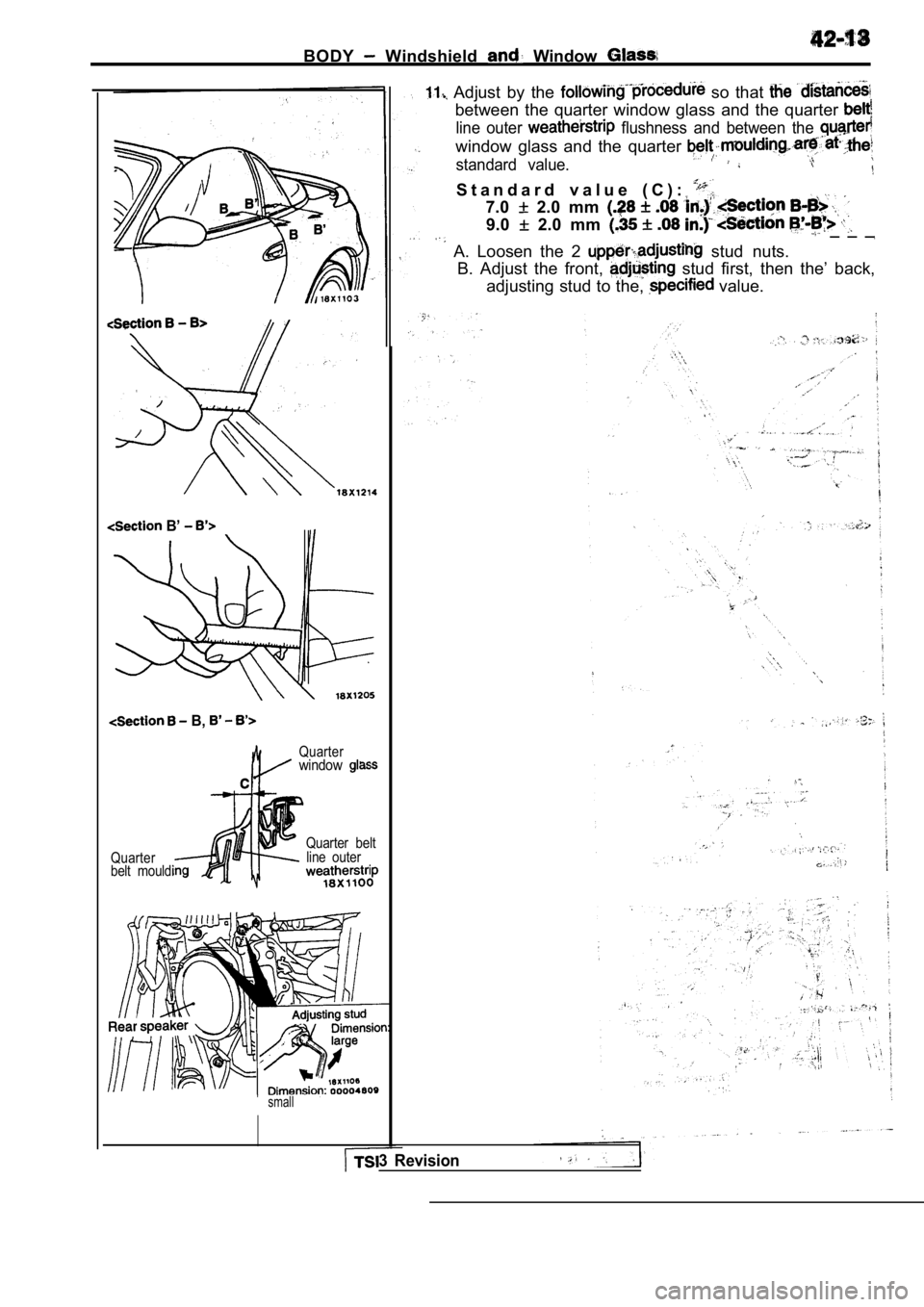

Adjust by the so that

between the quarter window glass and the quarter

line outer flushness and between the

window glass and the quarter

standard value.

B’

B,

Quarterwindow

Quarter

belt mouldiQuarter belt

line outer

small

S t a n d a r d v a l u e ( C ) :

7.0 2.0 mm

9.0 2.0 mm _ _ _

A. Loosen the 2 stud nuts.

B. Adjust the front, stud first, then the’ back,

adjusting stud to the,

value.

3 Revision

Page 1838 of 2103

42-14BODY Windshield and Window Glass

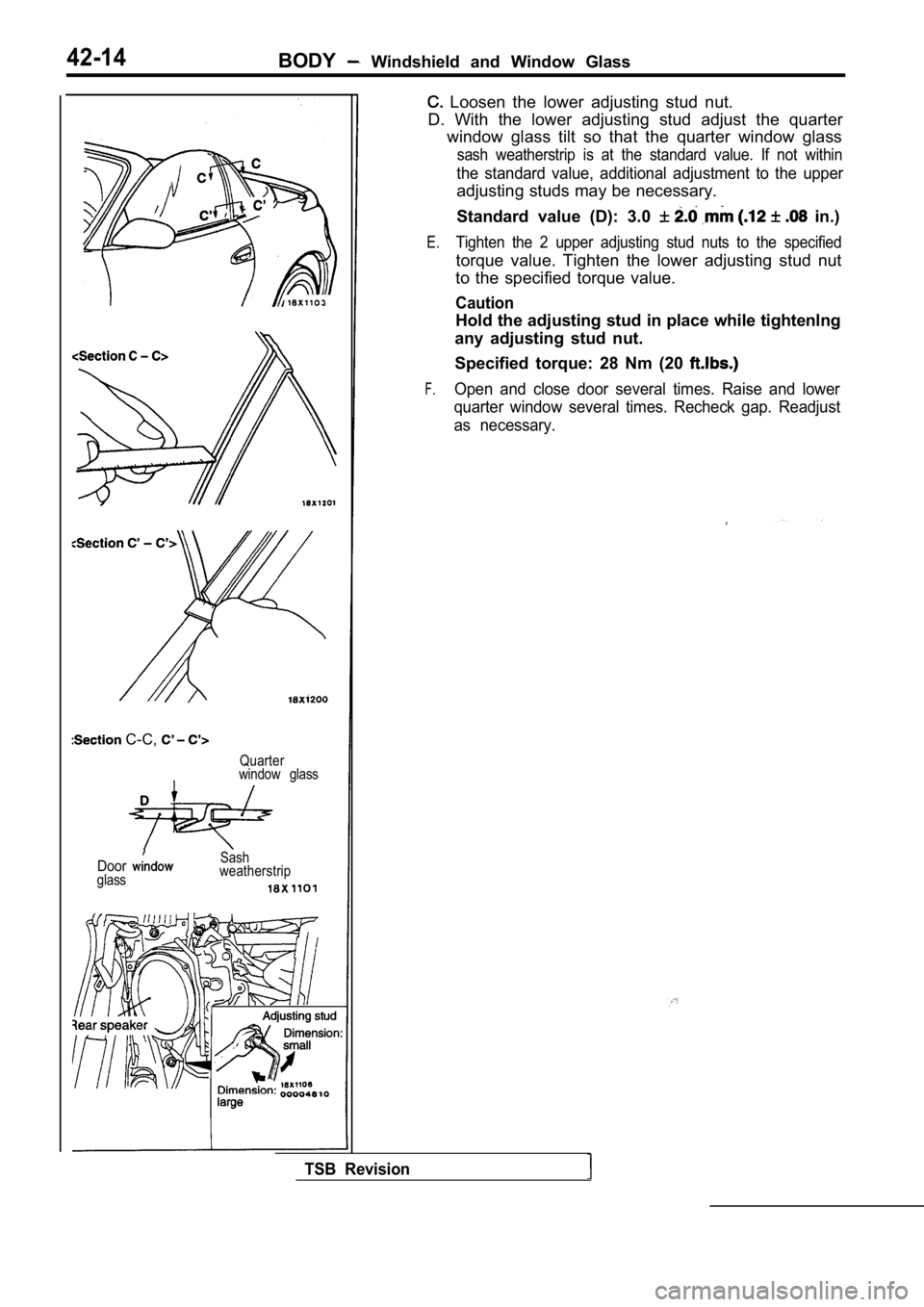

C-C,

Quarter

window glass

Doorglass Sash

weatherstrip

Loosen the lower adjusting stud nut.

D. With the lower adjusting stud adjust the quarter window glass tilt so that the quarter window glass

sash weatherstrip is at the standard value. If not within

the standard value, additional adjustment to the upper

adjusting studs may be necessary.

Standard value (D): 3.0

in.)

E.Tighten the 2 upper adjusting stud nuts to the spec ified

torque value. Tighten the lower adjusting stud nut

to the specified torque value.

Caution

Hold the adjusting stud in place while tightenlng

any adjusting stud nut.

Specified torque: 28 Nm (20

F.Open and close door several times. Raise and lower

quarter window several times. Recheck gap. Readjust

as necessary.

TSB Revision

Page 1839 of 2103

BODY Windshield and Window

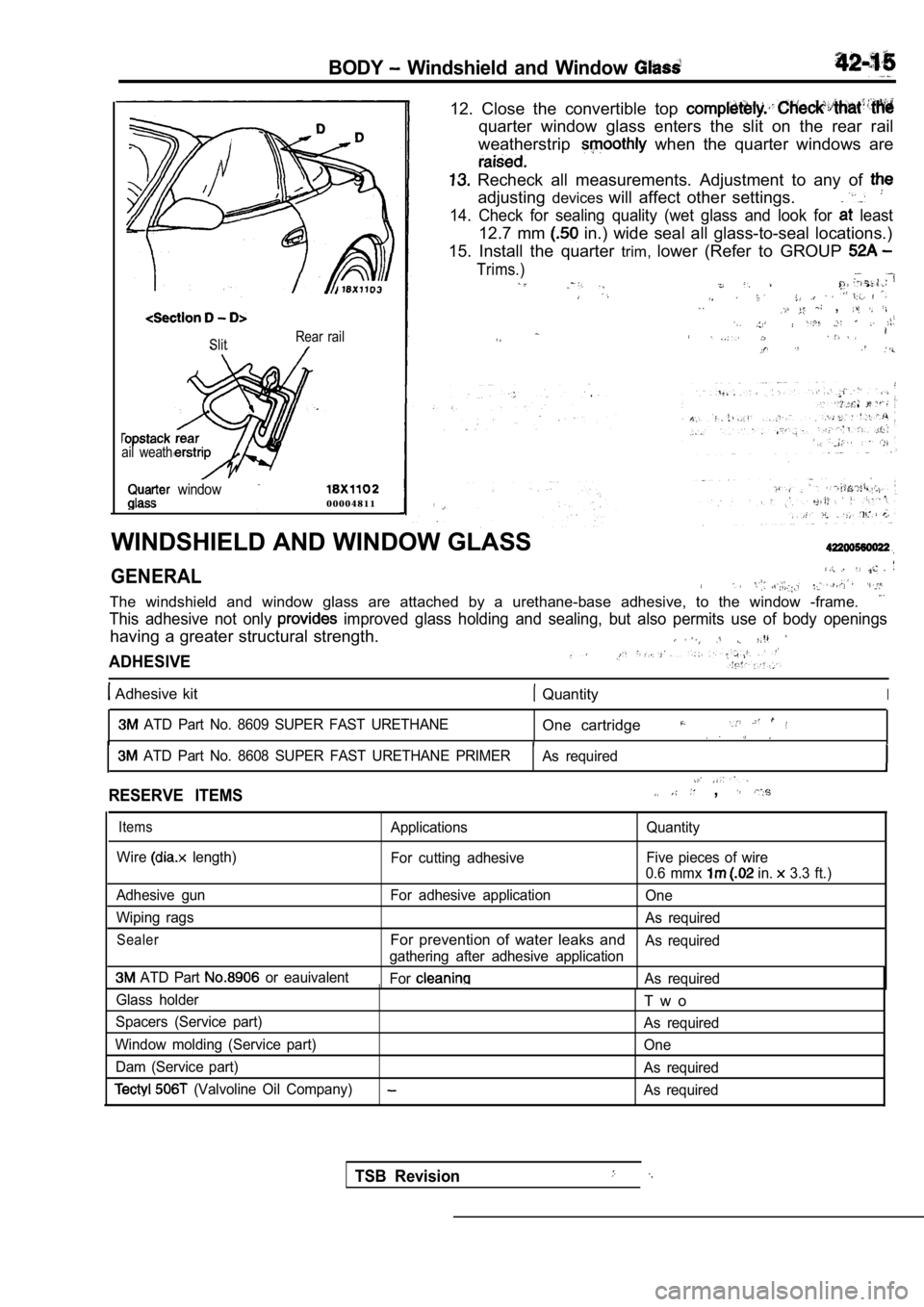

SlitRear rail

ail weath

window0 0 0 0 4 8 1 1 12. Close the convertible top

quarter window glass enters the slit on the rear ra

il

weatherstrip

when the quarter windows are

Recheck all measurements. Adjustment to any of

adjusting deviceswill affect other settings.

14. Check for sealing quality (wet glass and look f or least

12.7 mm in.) wide seal all glass-to-seal locations.)

15. Install the quarter trim,lower (Refer to GROUP

Trims.)

,

WINDSHIELD AND WINDOW GLASS

GENERAL. .

The windshield and window glass are attached by a urethane-base adhesive, to the window -frame.

This adhesive not only improved glass holding and sealing, but also permi ts use of body openings

having a greater structural strength.

ADHESIVE

Adhesive kit QuantityI

ATD Part No. 8609 SUPER FAST URETHANEOne cartridge

ATD Part No. 8608 SUPER FAST URETHANE PRIMER

As required

RESERVE ITEMS

Items

Wire length)

Adhesive gun

Wiping rags

Sealer

ATD Part or eauivalent

Glass holder

Spacers (Service part)

Window molding (Service part) Dam (Service part)

(Valvoline Oil Company)

,

Applications Quantity

For cutting adhesive Five pieces of wire

0.6 mmx

in. 3.3 ft.)

For adhesive application One

As required

For prevention of water leaks andAs required

gathering after adhesive application

For

As required

T w o

As required

One

As required

As required

TSB Revision

Page 1840 of 2103

BODY Windshield and Window Glass

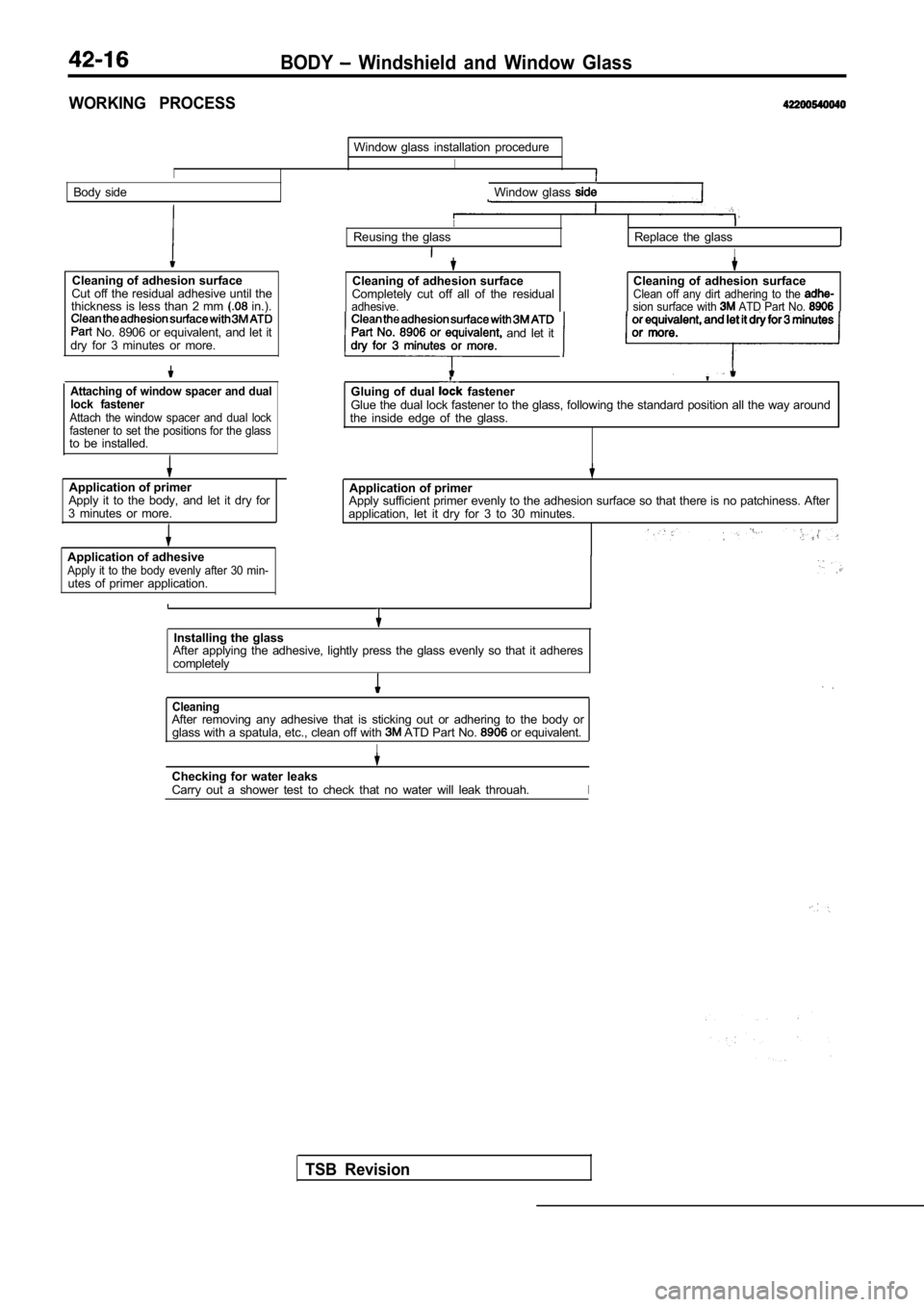

WORKING PROCESS

I

Window glass installation procedure

I

Body sideWindow glass

Cleaning of adhesion surface

Cut off the residual adhesive until the

thickness is less than 2 mm

in.).

No. 8906 or equivalent, and let it

dry for 3 minutes or more.

Attaching of window spacer and dual

lock fastener

Attach the window spacer and dual lock

fastener to set the positions for the glass

to be installed.

Application of primer Application of primer

Apply it to the body, and let it dry for

3 minutes or more. Apply sufficient primer evenly to the adhesion surf

ace so that there is no patchiness. After

application, let it dry for 3 to 30 minutes.

Application of adhesive

Apply it to the body evenly after 30 min-utes of primer application.

IReusing the glassReplace the glass

I

Cleaning of adhesion surface

Completely cut off all of the residual

adhesive.

Cleaning of adhesion surfaceClean off any dirt adhering to the sion surface with ATD Part No. or equivalent, and let it dry for 3 minutesPart No. 8906 or equivalent and let it

Gluing of dual fastenerGlue the dual lock fastener to the glass, following the standard position all the way around

the inside edge of the glass.

Installing the glass

After applying the adhesive, lightly press the glas s evenly so that it adheres

completely

TSB Revision

CleaningAfter removing any adhesive that is sticking out or adhering to the body or

glass with a spatula, etc., clean off with ATD Part No. or equivalent.

I

Checking for water leaks

Carry out a shower test to check that no water will leak throuah.I