MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1801 of 2103

S T E E R I N G-- Gear

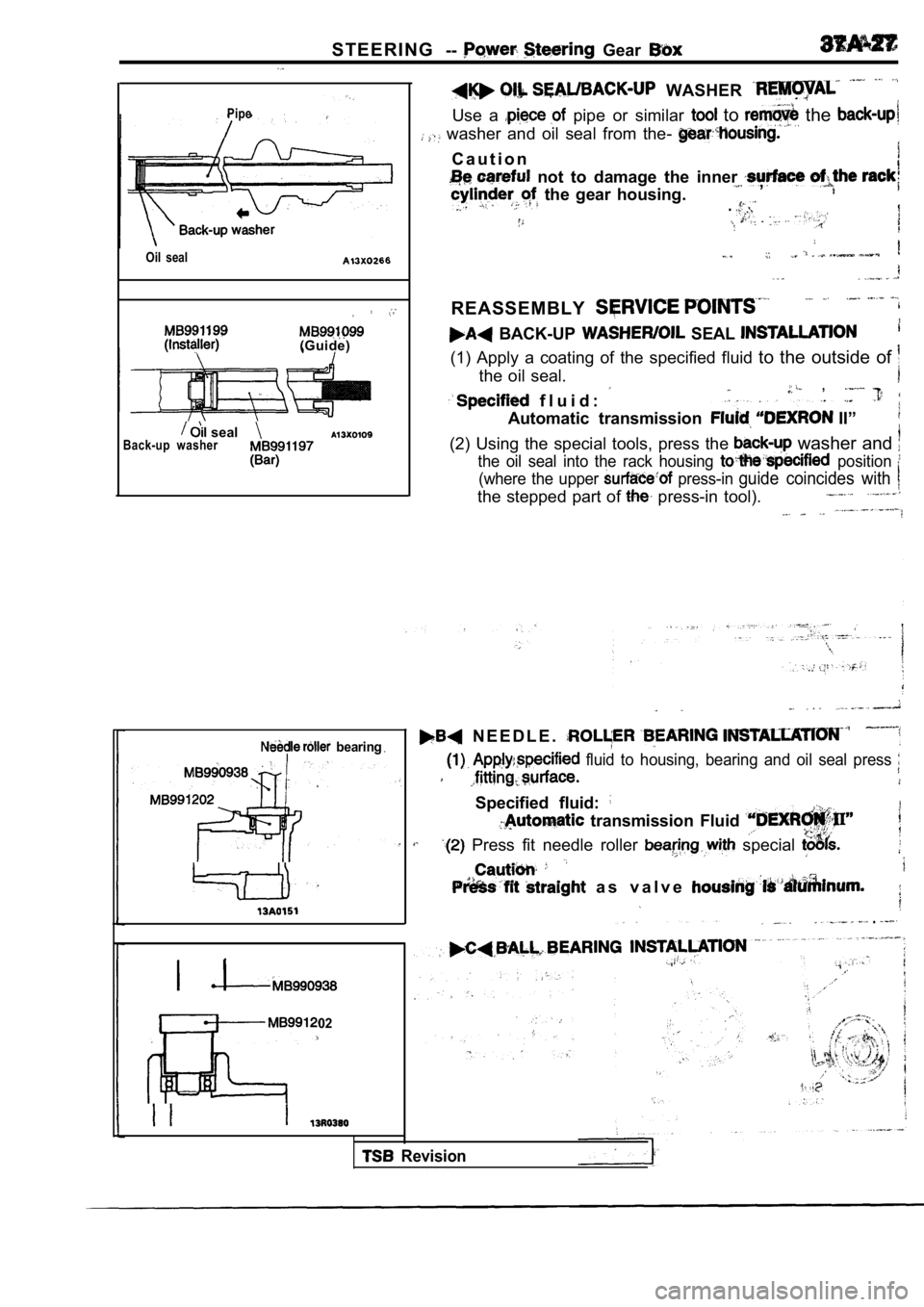

Pipe

Oil seal

(Guide)

sealBack-up washer

WASHER

Use a pipe or similar to the

washer and oil seal from the-

C a u t i o n

not to damage the inner , the gear housing..

REASSEMBLY

BACK-UP SEAL

(1) Apply a coating of the specified fluid to the outside of

the oil seal.

f l u i d :

,

Automatic transmission II”

(2) Using the special tools, press the washer and

the oil seal into the rack housing position

(where the upper press-in guide coincides with

the stepped part of press-in tool).

bearing

202

, N E E D L E .

fluid to housing, bearing and oil seal press

Specified fluid:

transmission Fluid

Press fit needle roller special

a s v a l v e

.

Revision

Page 1802 of 2103

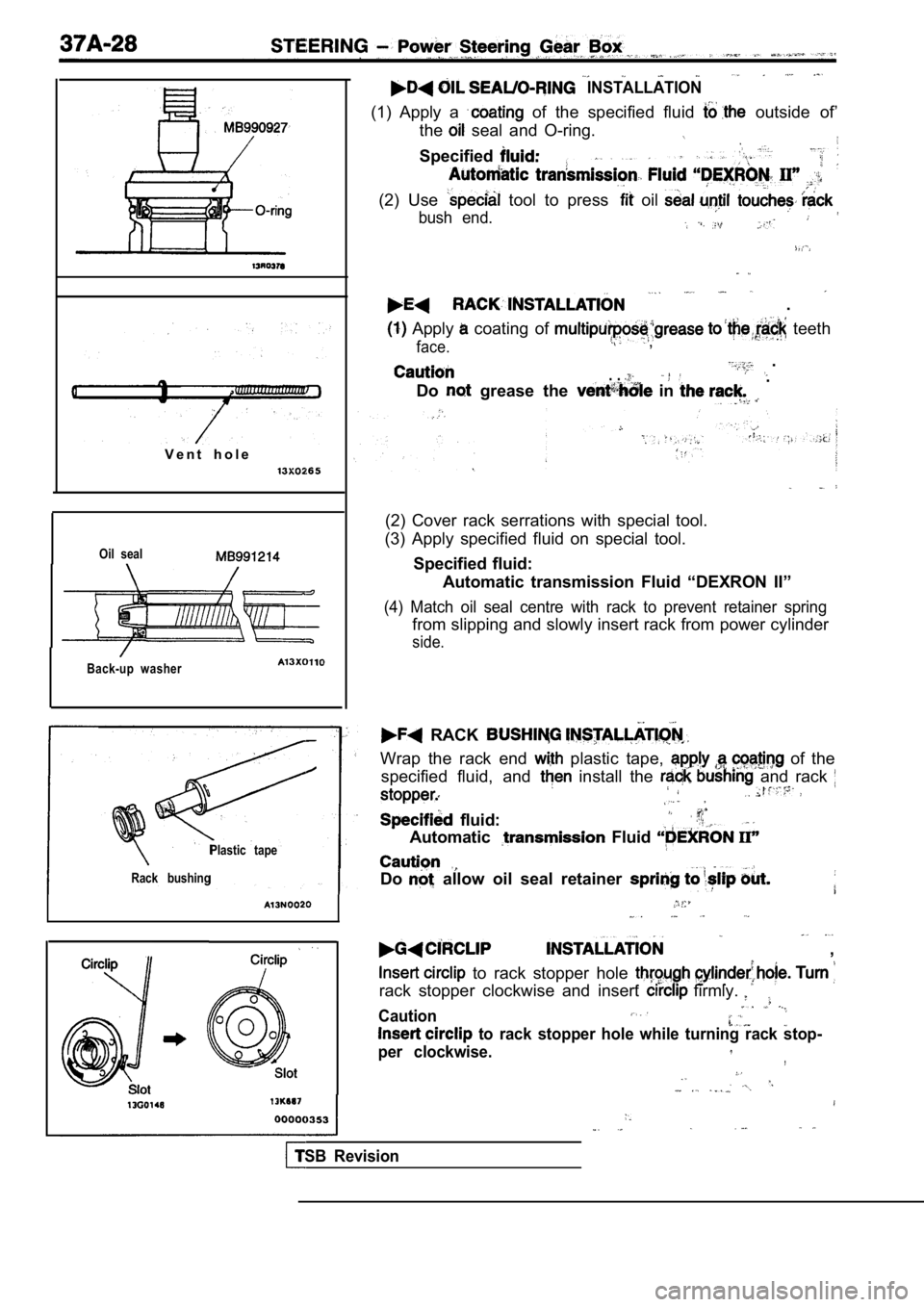

V e n t h o l e

Oil seal

Back-up washer

INSTALLATION

(1) Apply a of the specified fluid outside of’

the

seal and O-ring.

Specified

(2) Use tool to press oil

bush end.

.

Apply coating of teeth

face. ,

.. . .

Do grease the in

(2) Cover rack serrations with special tool.

(3) Apply specified fluid on special tool.

Specified fluid: Automatic transmission Fluid “DEXRON II”

(4) Match oil seal centre with rack to prevent reta iner spring

from slipping and slowly insert rack from power cylinder

side.

Plastic tape

Rack bushing

RACK

Wrap the rack end plastic tape, of the

specified fluid, and

install the and rack

fluid:

Automatic Fluid

Do allow oil seal retainer

,

to rack stopper hole

rack stopper clockwise and insert firmly.

Caution

to rack stopper hole while turning rack stop-

per clockwise.

,

TSB Revision

Page 1803 of 2103

S T E E R I N G P o w e r S t e e r i n g ,

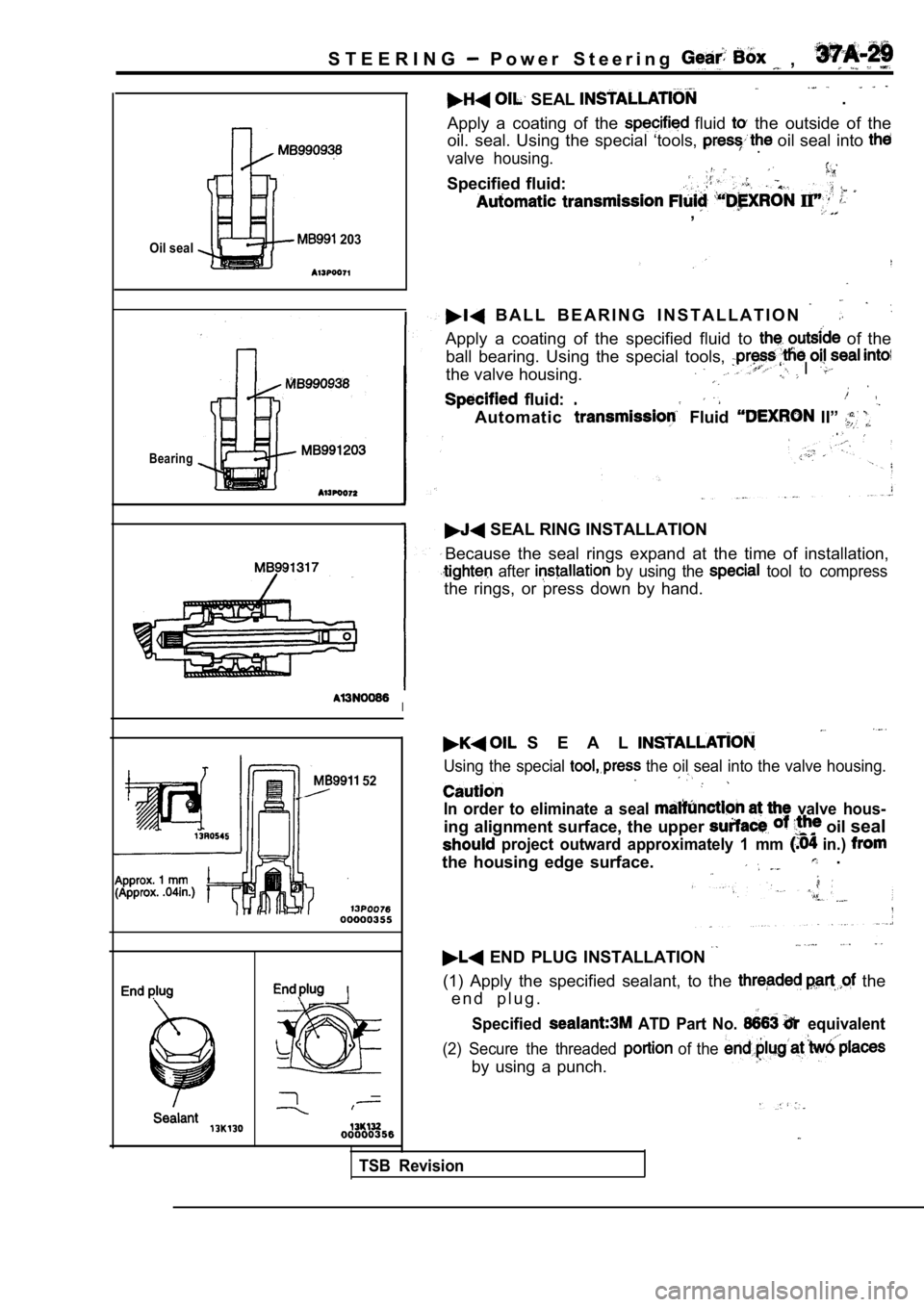

Oil seal 203

Bearing

52

. SEAL

Apply a coating of the fluid the outside of the

oil. seal. Using the special ‘tools,

oil seal into

valve housing..

Specified fluid:

,

B A L L B E A R I N G I N S T A L L A T I O N

Apply a coating of the specified fluid to of the

ball bearing. Using the special tools,

the valve housing.‘ I

fluid:

Automatic Fluid II” .

SEAL RING INSTALLATION

Because the seal rings expand at the time of instal lation,

after by using the tool to compress

the rings, or press down by hand.

I

S E A L

Using the special the oil seal into the valve housing.

In order to eliminate a seal valve hous-

ing alignment surface, the upper oil seal

project outward approximately 1 mm in.)

the housing edge surface. .

END PLUG INSTALLATION

(1) Apply the specified sealant, to the the

e n d p l u g .

Specified ATD Part No. equivalent

(2) Secure the threaded of the

by using a punch.

TSB Revision

Page 1804 of 2103

STEERING Power Steering Gear Box

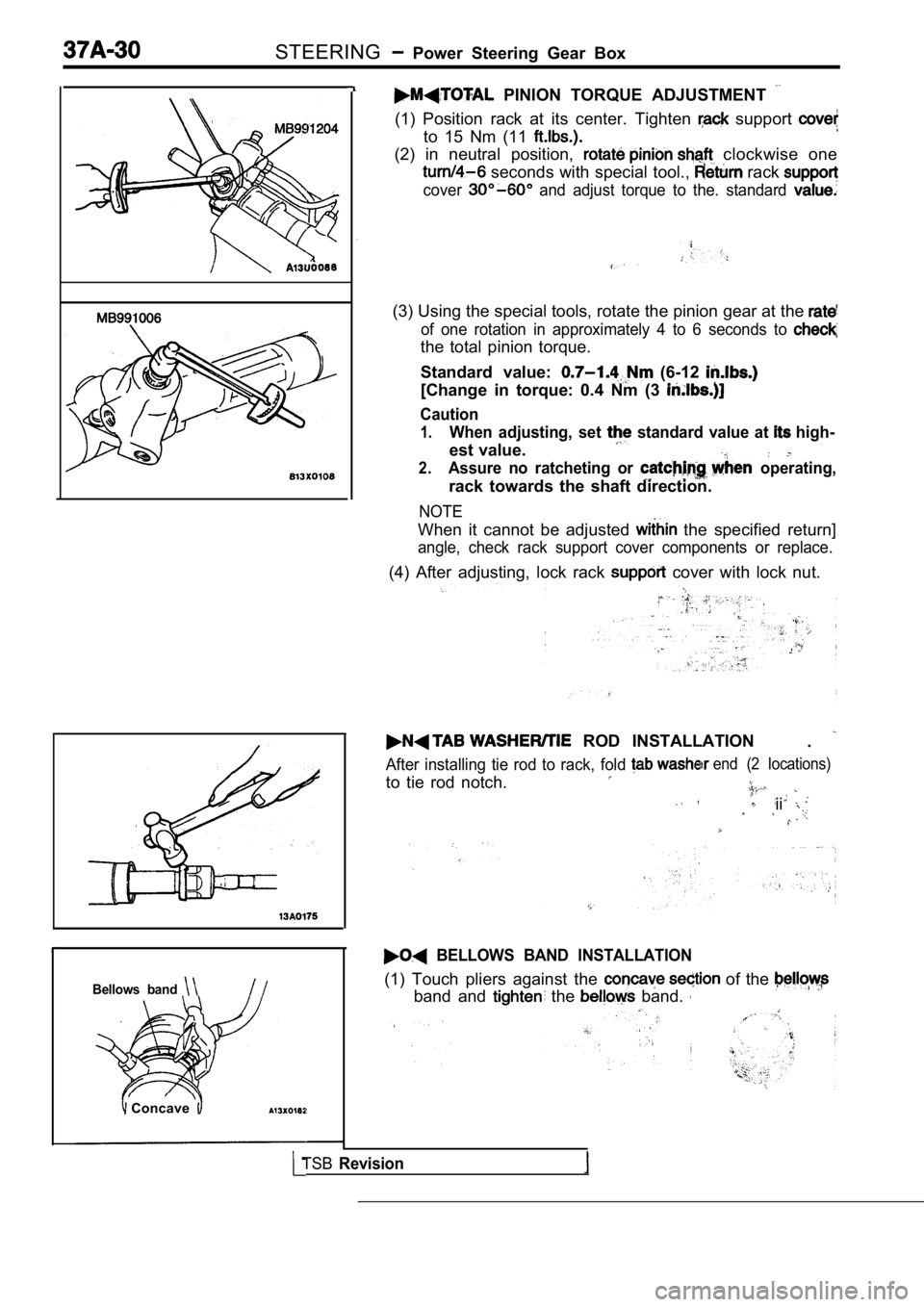

Bellows band

Concave

PINION TORQUE ADJUSTMENT

(1) Position rack at its center. Tighten support

to 15 Nm (11

(2) in neutral position, clockwise one

seconds with special tool., rack

cover and adjust torque to the. standard

(3) Using the special tools, rotate the pinion gear at the

of one rotation in approximately 4 to 6 seconds to

the total pinion torque.

Standard value:

(6-12

[Change in torque: 0.4 Nm (3

Caution

1.When adjusting, set standard value at high-

est value.

2.Assure no ratcheting or operating,

rack towards the shaft direction.

NOTE

When it cannot be adjusted the specified return]

angle, check rack support cover components or repla ce.

(4) After adjusting, lock rack cover with lock nut.

ROD INSTALLATION

.

After installing tie rod to rack, fold

to tie rod notch.

end (2 locations)

ii

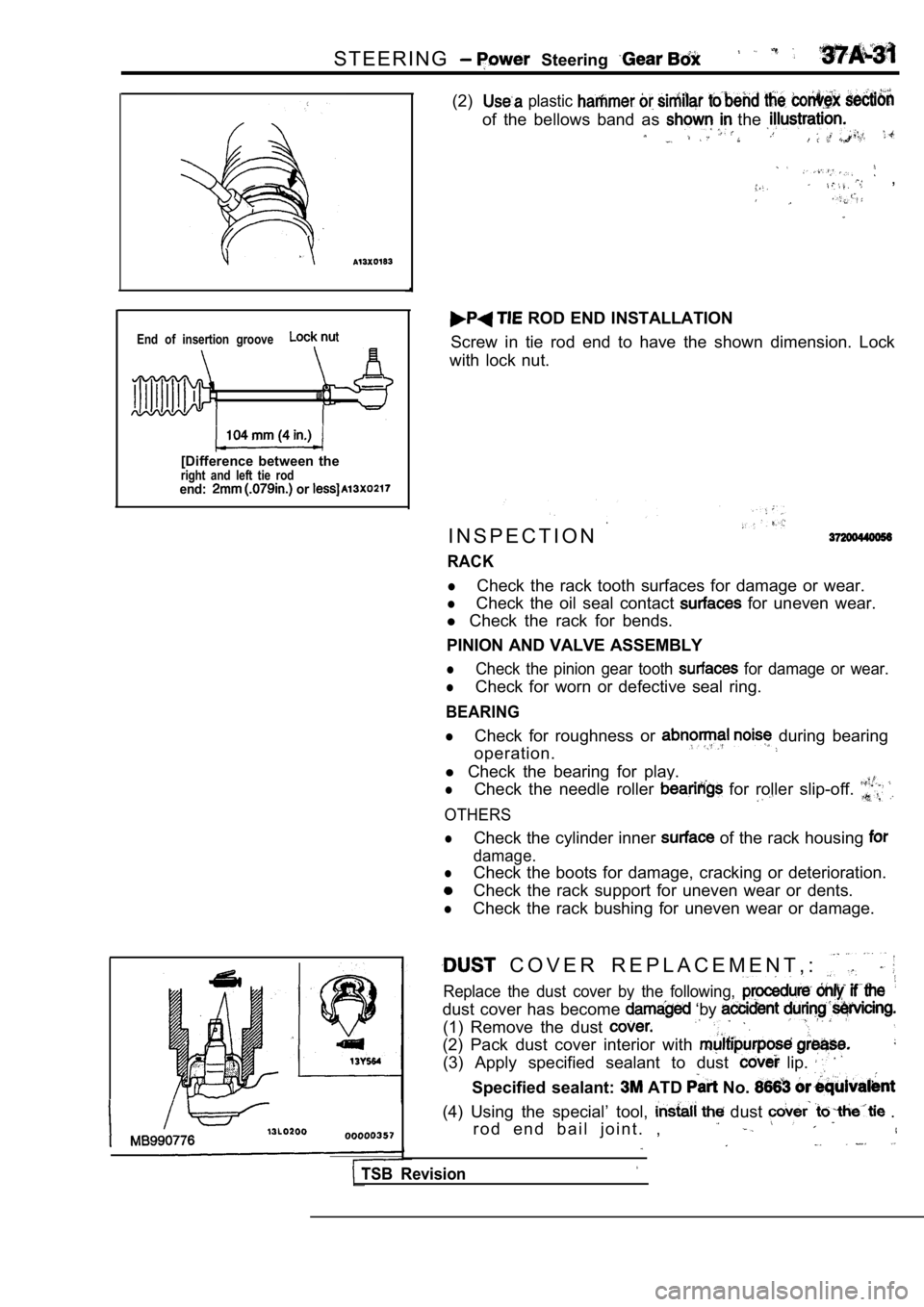

BELLOWS BAND INSTALLATION

(1) Touch pliers against the of the

band and the band.

TSBRevision

Page 1805 of 2103

S T E E R I N G Steering

End of insertion groove

[Difference between theright and left tie rodend: or

(2) plastic

of the bellows band as the

,

ROD END INSTALLATION

Screw in tie rod end to have the shown dimension. L ock

with lock nut.

I N S P E C T I O N

RACK

lCheck the rack tooth surfaces for damage or wear.

lCheck the oil seal contact for uneven wear.

l Check the rack for bends.

PINION AND VALVE ASSEMBLY

lCheck the pinion gear tooth for damage or wear.

lCheck for worn or defective seal ring.

BEARING

lCheck for roughness or during bearing

operation.

l Check the bearing for play.

lCheck the needle roller for roller slip-off.

OTHERS

lCheck the cylinder inner of the rack housing

damage.

lCheck the boots for damage, cracking or deteriorati on.

Check the rack support for uneven wear or dents.

lCheck the rack bushing for uneven wear or damage.

C O V E R R E P L A C E M E N T , :

Replace the dust cover by the following,

dust cover has become ‘by

(1) Remove the dust

(2) Pack dust cover interior with

(3) Apply specified sealant to dust lip.

Specified sealant: ATD No.

(4) Using the special’ tool, dust .

r o d e n d b a i l j o i n t . ,

TSB Revision

Page 1806 of 2103

STEERING Power Steering OilPump Engine,

POWER STEERING OIL PUMP

. . . .

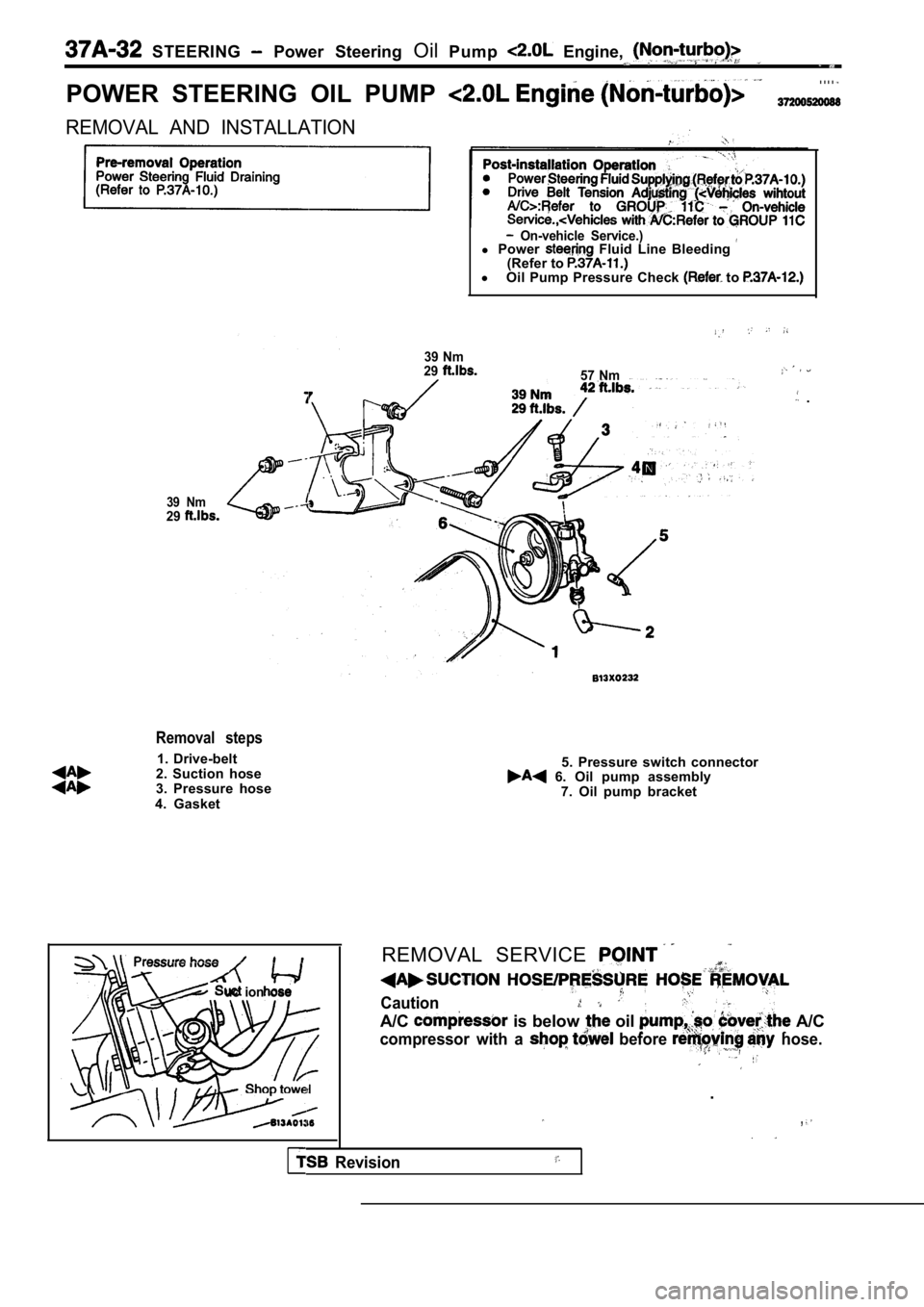

REMOVAL AND INSTALLATION

On-vehicle Service.)l Power Fluid Line Bleeding (Refer to l

Oil Pump Pressure Check to

39 Nm

29

57 Nm

.

39 Nm29

Removal steps

1. Drive-belt

2. Suction hose

3. Pressure hose

4. Gasket

uc ion ose

5. Pressure switch connector 6. Oil pump assembly 7. Oil pump bracket

REMOVAL SERVICE

Caution

A/C is below oil A/C

compressor with a before hose.

.

,

Revision

Page 1807 of 2103

STEERING Power Steering Oil Pump

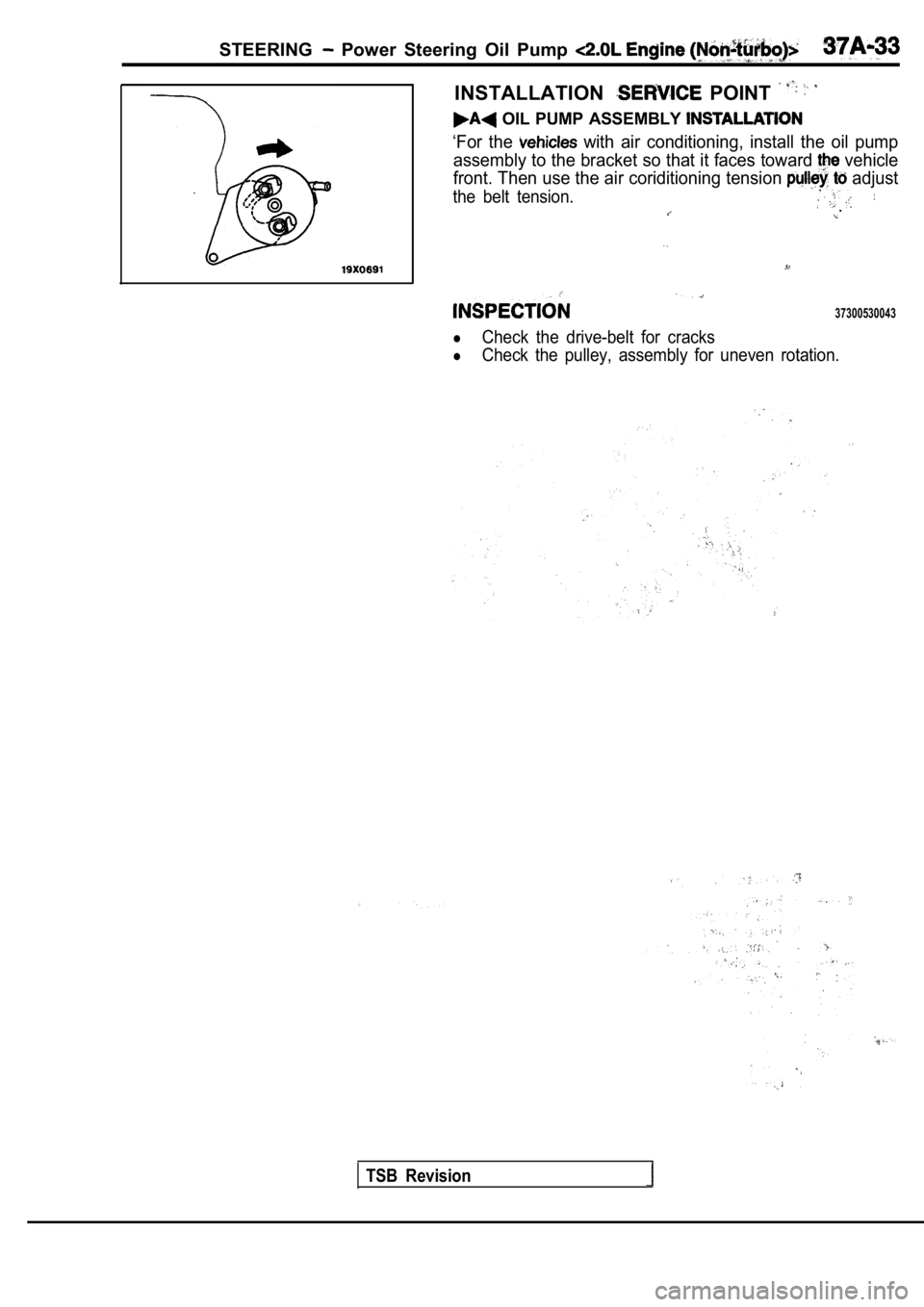

INSTALLATION POINT

OIL PUMP ASSEMBLY

‘For the with air conditioning, install the oil pump

assembly to the bracket so that it faces toward

vehicle

front. Then use the air coriditioning tension

adjust

the belt tension..

37300530043

�Check the drive-belt for cracks

�Check the pulley, assembly for uneven rotation.

TSB Revision

Page 1808 of 2103

STEERING Power Steering Pump Engine

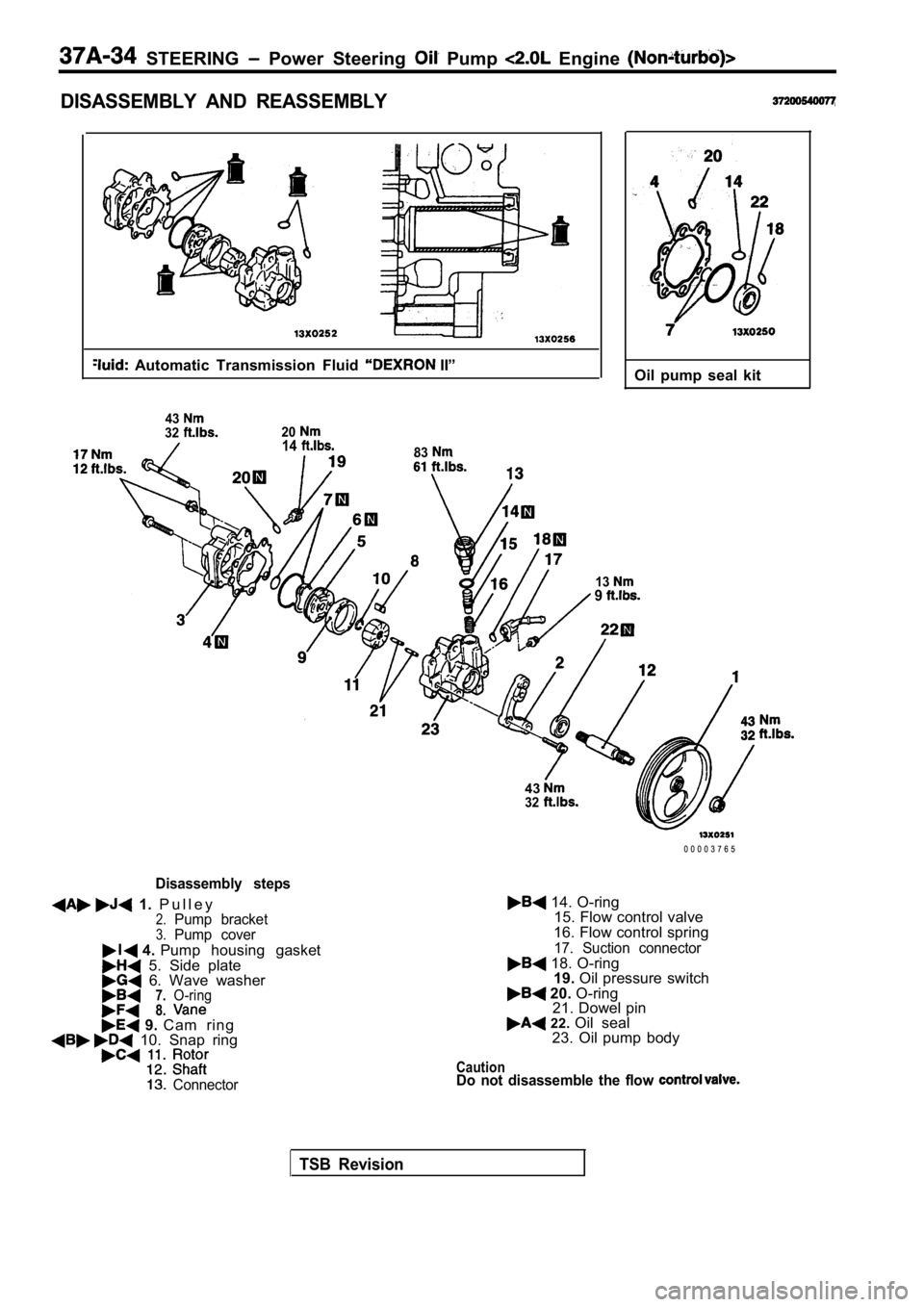

DISASSEMBLY AND REASSEMBLY

Automatic Transmission Fluid II”

4332201483

139

Oil pump seal kit

43

32

Disassembly steps

1. P u l l e y2.Pump bracket3.Pump cover

4. Pump housing gasket 5. Side plate 6. Wave washer7.O-ring8. 9. Cam ring 10. Snap ring

Connector

0 0 0 0 3 7 6 5

14. O-ring

15. Flow control valve

16. Flow control spring

17. Suction connector 18. O-ring 19. Oil pressure switch

20. O-ring

21. Dowel pin

22. Oil seal

23. Oil pump body

CautionDo not disassemble the flow

TSB Revision

Page 1809 of 2103

S T E E R I N G Power Steering Oil Pump Engine

9or

PressureportunionOilswitch

3

Rear pump housing,

Side plate

4

Suction port union

5 ’

TSB

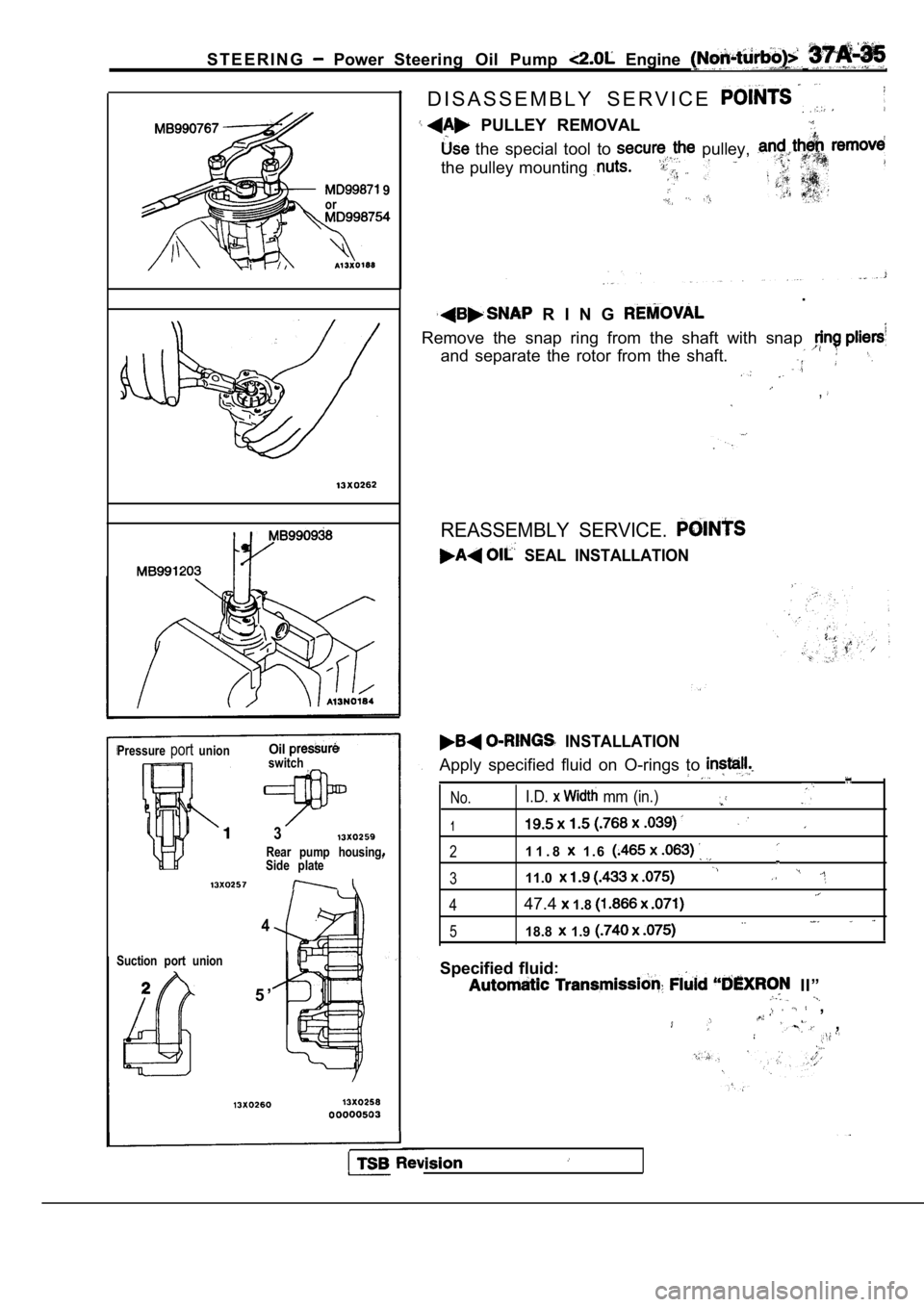

D I S A S S E M B L Y S E R V I C E

PULLEY REMOVAL

the special tool to pulley,

the pulley mounting

.

R I N G

Remove the snap ring from the shaft with snap

and separate the rotor from the shaft.

,

REASSEMBLY SERVICE.

SEAL INSTALLATION

INSTALLATION

Apply specified fluid on O-rings to

No.I.D. mm (in.)

1

21 1 . 8 1 . 6

311.0

447.4 1.8

518.8 1.9

Specified fluid:

II”

,

,

Page 1810 of 2103

STEERING Power Steering Oil Pump Engine (Non-turbo)>

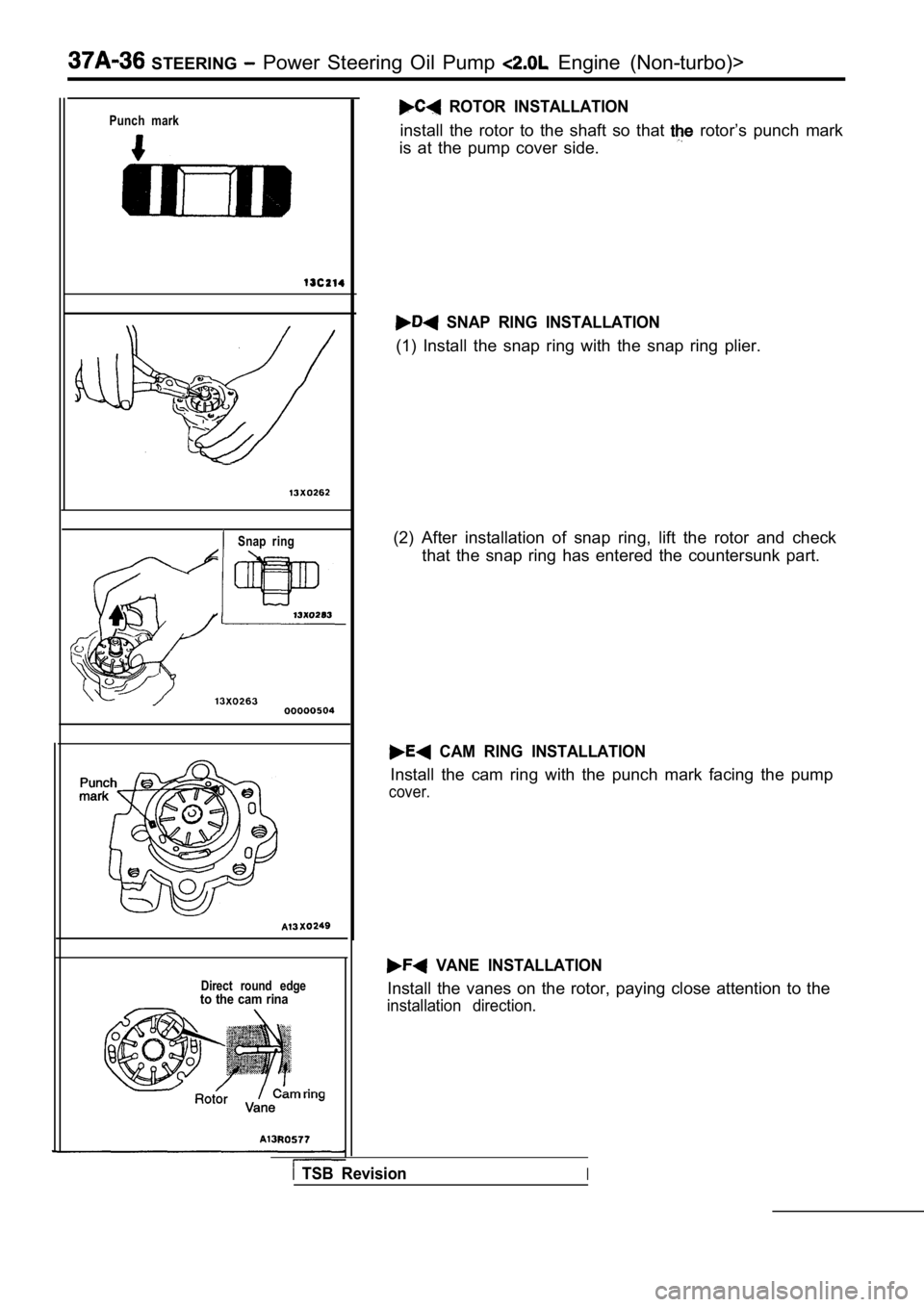

Punch mark

Snap ring

Direct round edgeto the cam rina

ROTOR INSTALLATION

install the rotor to the shaft so that rotor’s punch mark

is at the pump cover side.

SNAP RING INSTALLATION

(1) Install the snap ring with the snap ring plier.

(2) After installation of snap ring, lift the rotor and check

that the snap ring has entered the countersunk part .

CAM RING INSTALLATION

Install the cam ring with the punch mark facing the pump

cover.

VANE INSTALLATION

Install the vanes on the rotor, paying close attention to the

installation direction.

TSB RevisionI