MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1791 of 2103

S T E E R I N G Steerina Wheel and S h a f t

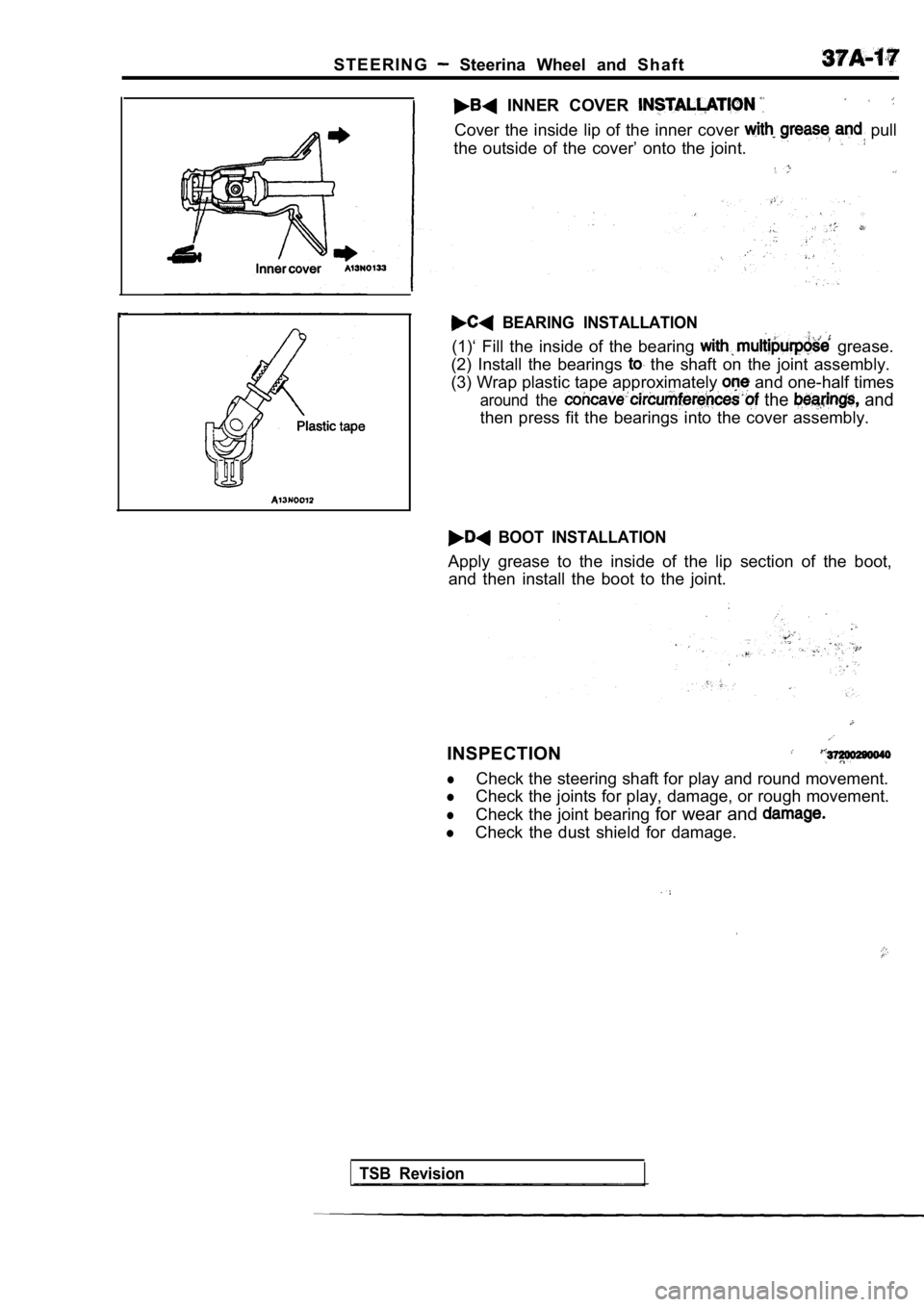

INNER COVER

Cover the inside lip of the inner cover pull

the outside of the cover’ onto the joint.

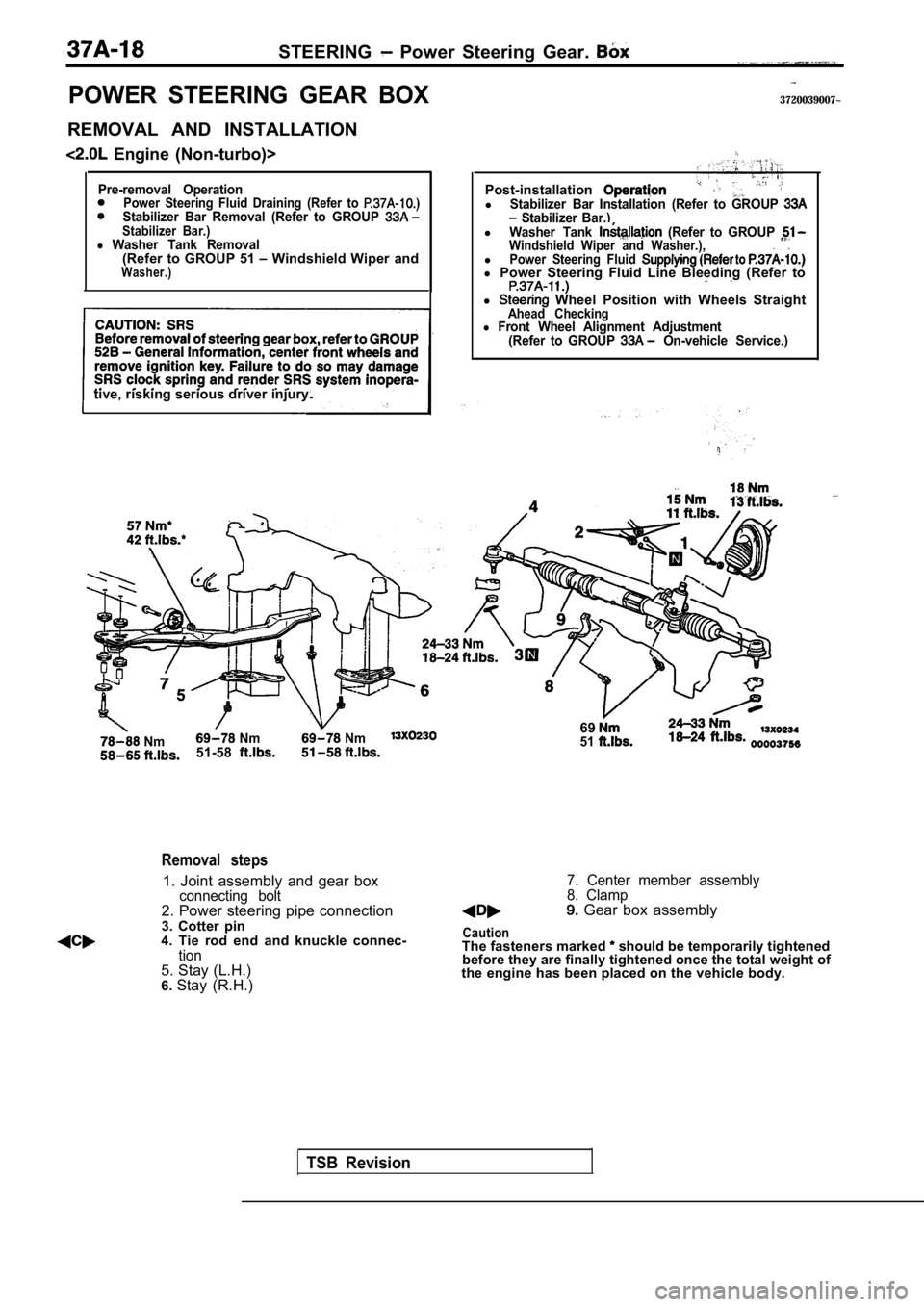

BEARING INSTALLATION

(1)‘ Fill the inside of the bearing grease.

(2) Install the bearings

the shaft on the joint assembly.

(3) Wrap plastic tape approximately

and one-half times

around the the and

then press fit the bearings into the cover assembly .

BOOT INSTALLATION

Apply grease to the inside of the lip section of th e boot,

and then install the boot to the joint.

INSPECTION

lCheck the steering shaft for play and round movemen t.

lCheck the joints for play, damage, or rough movemen t.

lCheck the joint bearing for wear and

lCheck the dust shield for damage.

TSB Revision

Page 1792 of 2103

STEERING Power Steering Gear.

POWER STEERING GEAR BOX

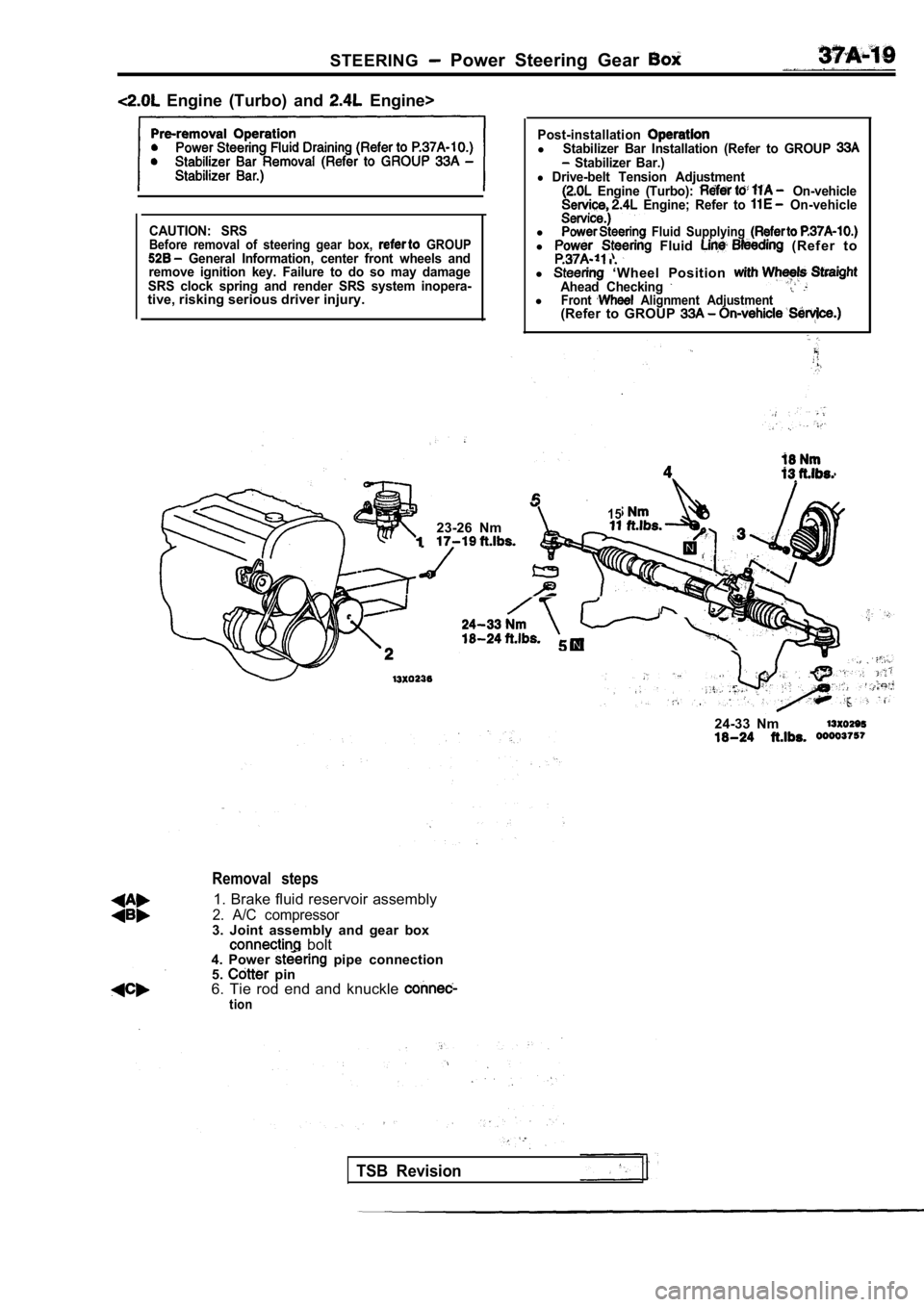

REMOVAL AND INSTALLATION

Engine (Non-turbo)>

Pre-removal OperationPower Steering Fluid Draining (Refer to Stabilizer Bar Removal (Refer to GROUP Stabilizer Bar.)l Washer Tank Removal(Refer to GROUP 51 Windshield Wiper andWasher.)

tive, risking serious driver injury.

Nm Nm Nm51-58

3720039007~

TSB Revision

Removal steps

1. Joint assembly and gear boxconnecting bolt2. Power steering pipe connection

3. Cotter pin

4. Tie rod end and knuckle connec-

tion5. Stay (L.H.)

6. Stay (R.H.) Post-installation

lStabilizer Bar Installation (Refer to GROUP Stabilizer Bar.)lWasher Tank (Refer to GROUP Windshield Wiper and Washer.),lPower Steering Fluid l

Power Steering Fluid Line Bleeding (Refer to

l Wheel Position with Wheels StraightAhead Checkingl Front Wheel Alignment Adjustment

(Refer to GROUP On-vehicle Service.)

6951

7. Center member assembly

8. Clamp

Gear box assembly

CautionThe fasteners marked should be temporarily tightened

before they are finally tightened once the total we ight of

the engine has been placed on the vehicle body.

Page 1793 of 2103

STEERING Power Steering Gear

Engine (Turbo) and Engine>

CAUTION: SRSBefore removal of steering gear box, GROUP General Information, center front wheels and

remove ignition key. Failure to do so may damage

SRS clock spring and render SRS system inopera-

tive, risking serious driver injury.

Post-installationlStabilizer Bar Installation (Refer to GROUP Stabilizer Bar.)l Drive-belt Tension Adjustment Engine (Turbo): On-vehicle Engine; Refer to On-vehicle

l Fluid Supplying l Fluid (Refer to

.

l ‘Wheel Position Ahead Checking lFront Alignment Adjustment(Refer to GROUP

1523-26 Nm

24-33 Nm

Removal steps

1. Brake fluid reservoir assembly

2. A/C compressor3. Joint assembly and gear box bolt 24-33 Nm4. Power pipe connection

5. pin

6. Tie rod end and knuckle

tion

TSB Revision

Page 1794 of 2103

STEERING Power Steerina

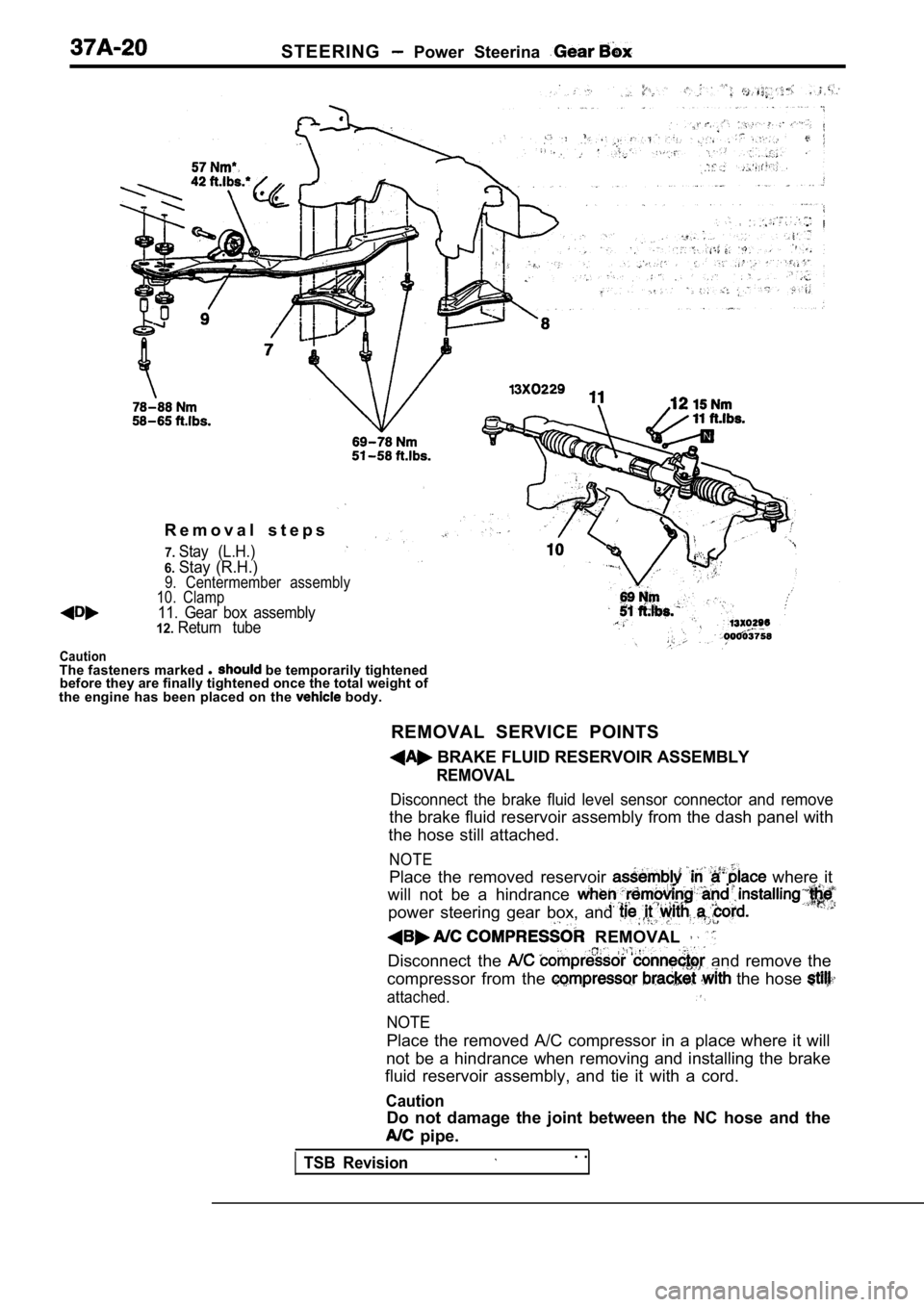

R e m o v a l s t e p s

7.Stay (L.H.)

6.Stay (R.H.)

Caution

9. Centermember assembly

10. Clamp

11. Gear box assembly12.Return tube

The fasteners marked l be temporarily tightened

before they are finally tightened once the total we ight of

the engine has been placed on the

body.

REMOVAL SERVICE POINTS

BRAKE FLUID RESERVOIR ASSEMBLY

REMOVAL

Disconnect the brake fluid level sensor connector a nd remove

the brake fluid reservoir assembly from the dash pa nel with

the hose still attached.

NOTE

Place the removed reservoir where it

will not be a hindrance

power steering gear box, and

REMOVAL

Disconnect the and remove the

compressor from the

the hose

attached.

NOTE

Place the removed A/C compressor in a place where i t will

not be a hindrance when removing and installing the brake

fluid reservoir assembly, and tie it with a cord.

Caution

Do not damage the joint between the NC hose and the

pipe.

TSB Revision. .

Page 1795 of 2103

STEERING, Power . . , , ,

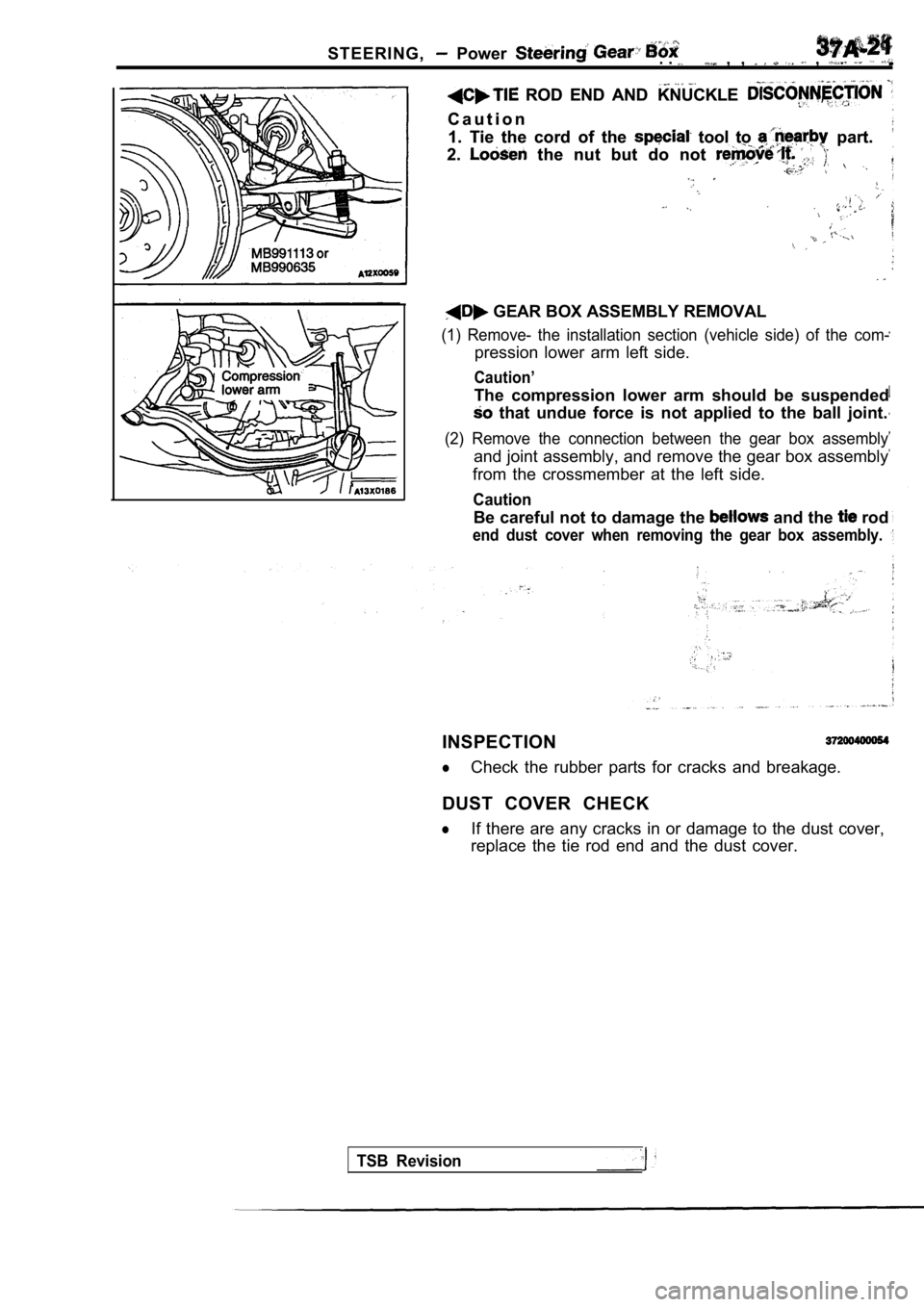

ROD END AND KNUCKLE ROD END AND KNUCKLE

C a u t i o n

C a u t i o n

1. Tie the cord of the

tool to part.

1. Tie the cord of the tool to part.

2.

the nut but do not 2. the nut but do not ,,

GEAR BOX ASSEMBLY REMOVAL

(1) Remove- the installation section (vehicle side) of the com-

pression lower arm left side.

Caution’

The compression lower arm should be suspended

that undue force is not applied to the ball joint.

(2) Remove the connection between the gear box asse mbly

and joint assembly, and remove the gear box assembly

from the crossmember at the left side.

Caution

Be careful not to damage the and the rod

end dust cover when removing the gear box assembly.

INSPECTION

lCheck the rubber parts for cracks and breakage.

DUST COVER CHECK

lIf there are any cracks in or damage to the dust co ver,

replace the tie rod end and the dust cover.

TSB Revision

Page 1796 of 2103

S T E E R I N G

TSB Revision

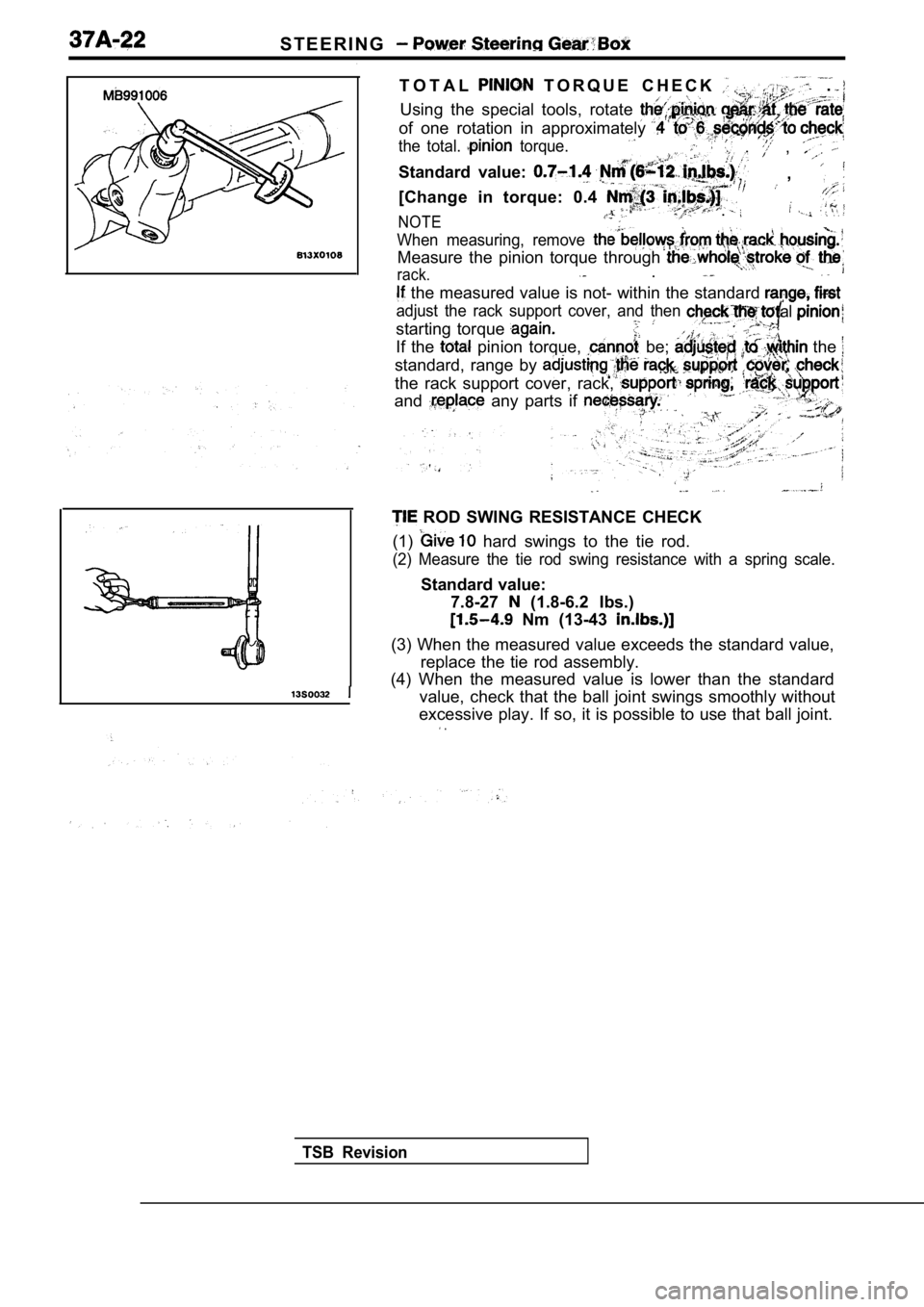

T O T A L T O R Q U E C H E C K .

Using the special tools, rotate

of one rotation in approximately

the total. torque. , ,

Standard value: ,

[Change in torque: 0.4

NOTE.

When measuring, remove

Measure the pinion torque through

rack. .

the measured value is not- within the standard

adjust the rack support cover, and then

starting torque

al

If the pinion torque, be; the

standard, range by

the rack support cover, rack,

and any parts if

ROD SWING RESISTANCE CHECK

(1)

hard swings to the tie rod.

(2) Measure the tie rod swing resistance with a spr ing scale.

Standard value:

7.8-27

(1.8-6.2 Ibs.)

Nm (13-43

(3) When the measured value exceeds the standard va lue,

replace the tie rod assembly.

(4) When the measured value is lower than the stand ard

value, check that the ball joint swings smoothly wi thout

excessive play. If so, it is possible to use that b all joint.

.

Page 1797 of 2103

Power Steering Gear

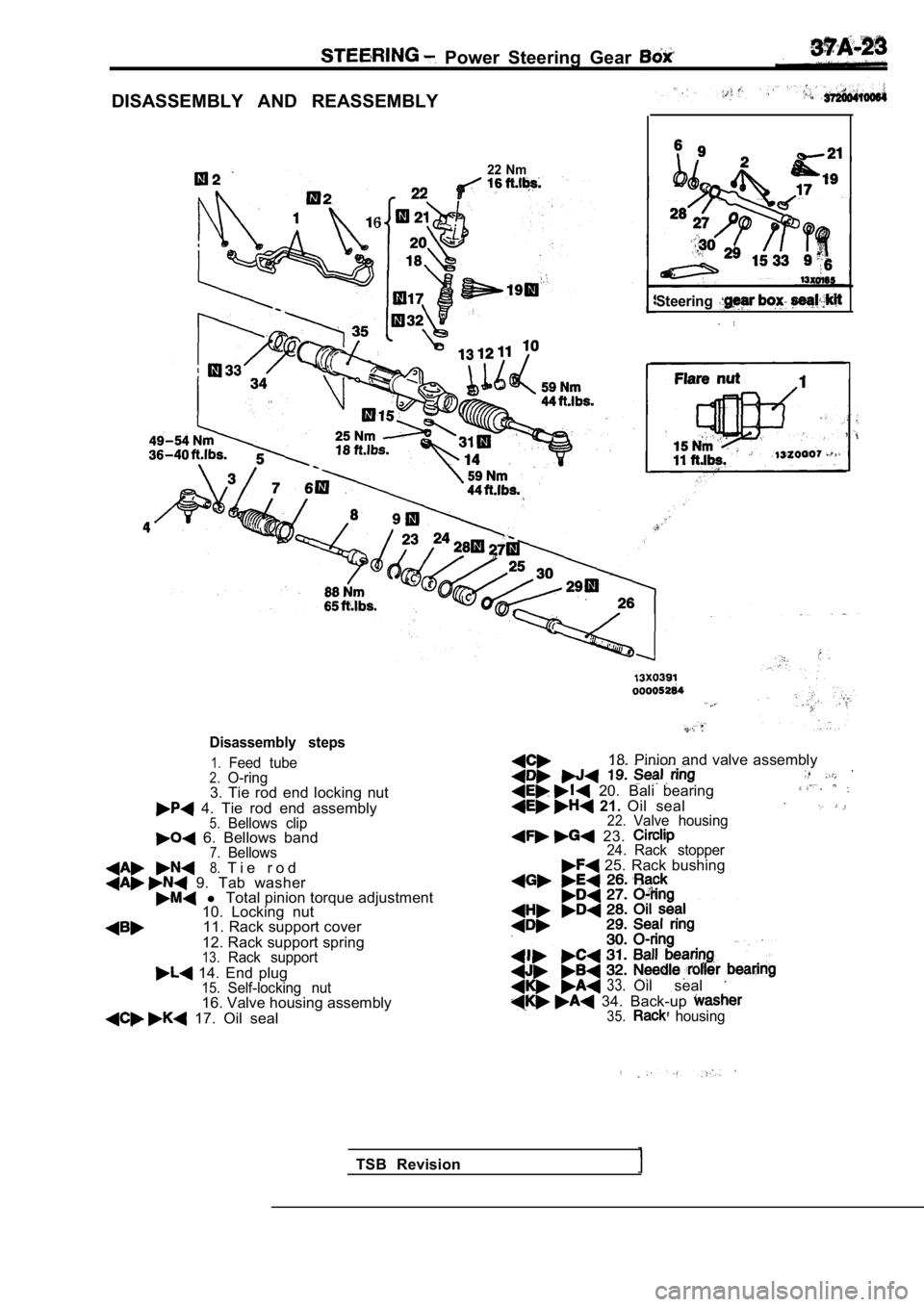

DISASSEMBLY AND REASSEMBLY

6

22 Nm

Steering

Disassembly steps

1.Feed tube2.O-ring3. Tie rod end locking nut

4. Tie rod end assembly5.Bellows clip 6. Bellows band7.Bellows8.T i e r o d 9. Tab washer l Total pinion torque adjustment

10. Locking nut

11. Rack support cover

12. Rack support spring

13.Rack support

14. End plug15.Self-locking nut16. Valve housing assembly

17. Oil seal 18. Pinion and valve assembly

20. Bali bearing 21.

Oil seal22.Valve housing

23. 24. Rack stopper 25. Rack bushing

33.Oil seal

34. Back-up 35. housing

TSB Revision

Page 1798 of 2103

S T E E R I N G Power Steering ,

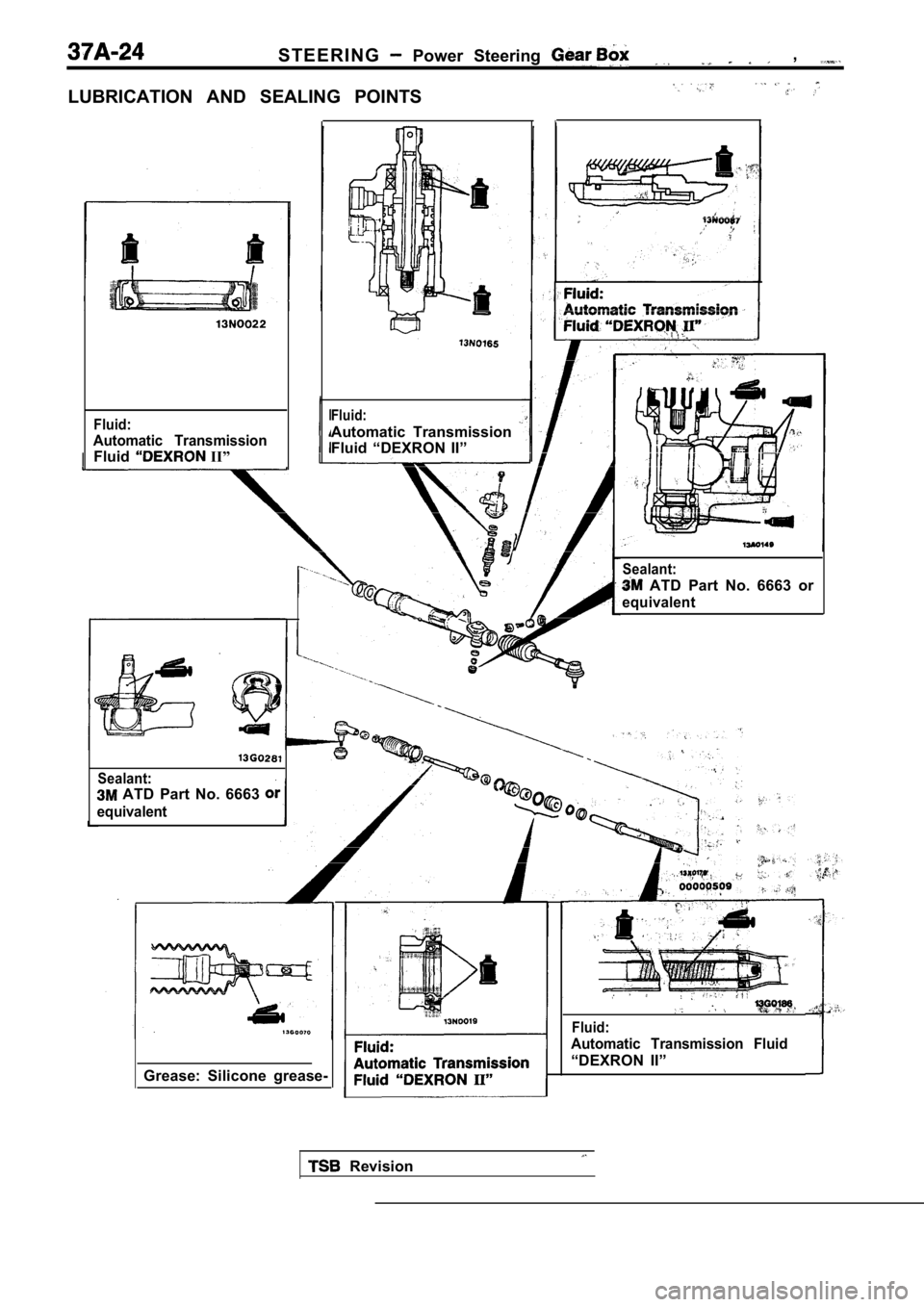

LUBRICATION AND SEALING POINTS

Fluid:

Automatic Transmission

Fluid II”

Grease: Silicone grease-

Fluid:

Automatic Transmission

Fluid “DEXRON II”

Sealant:

ATD Part No. 6663 or

equivalent

Sealant:

ATD Part No. 6663

equivalent

Fluid:

Automatic Transmission Fluid

“DEXRON II”

Revision

Page 1799 of 2103

STEERINGPower Gear ,

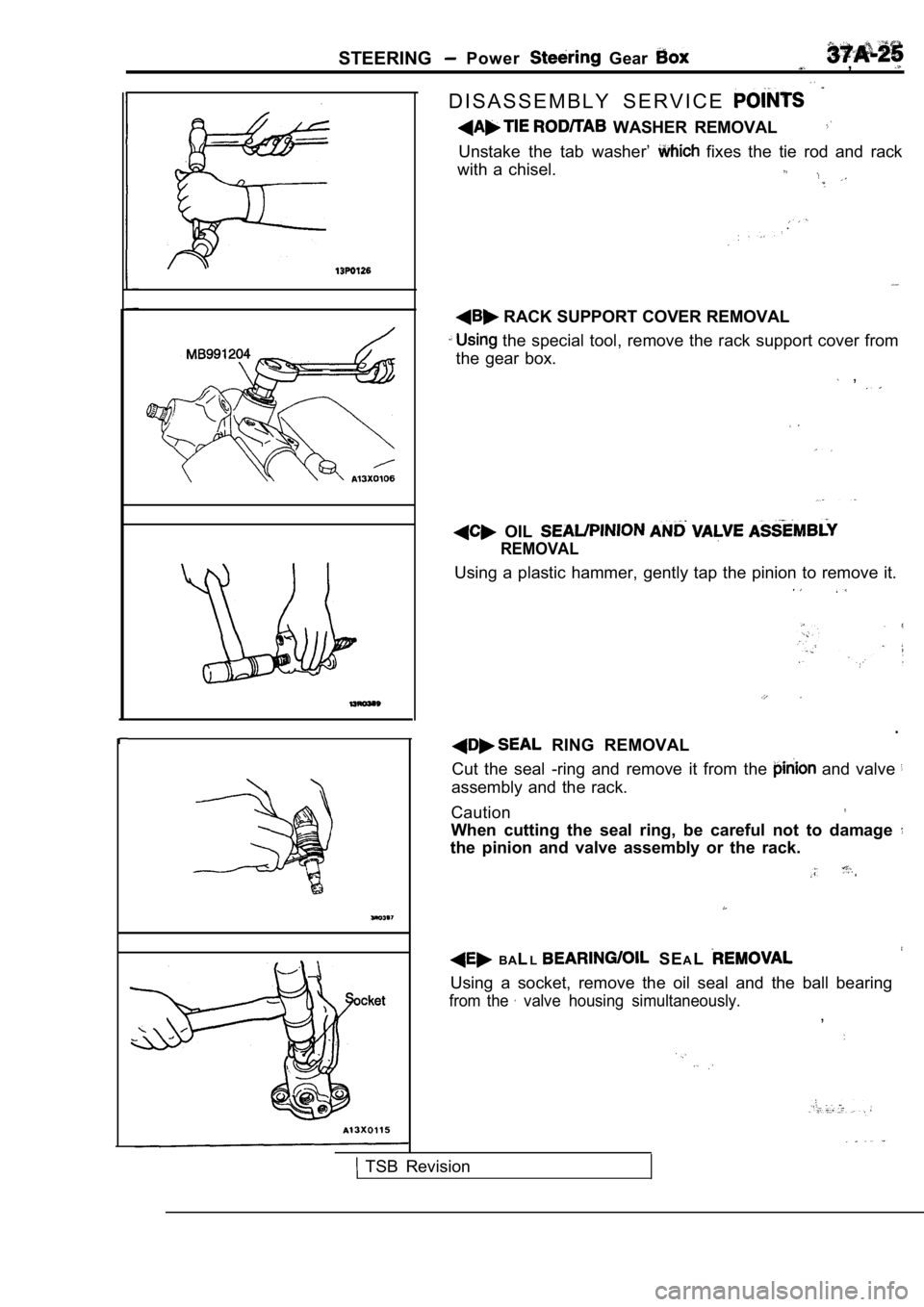

D I S A S S E M B L Y S E R V I C E

WASHER REMOVAL

Unstake the tab washer’ fixes the tie rod and rack

with a chisel.

RACK SUPPORT COVER REMOVAL

the special tool, remove the rack support cover fr om

the gear box.

,

OIL

REMOVAL

Using a plastic hammer, gently tap the pinion to re move it.

.

RING REMOVAL

Cut the seal -ring and remove it from the

and valve

assembly and the rack.

Caution

When cutting the seal ring, be careful not to damag e

the pinion and valve assembly or the rack.

BALL SE AL

Using a socket, remove the oil seal and the ball be aring

from the valve housing simultaneously.,

TSB Revision

Page 1800 of 2103

STEERING Power Steering Box

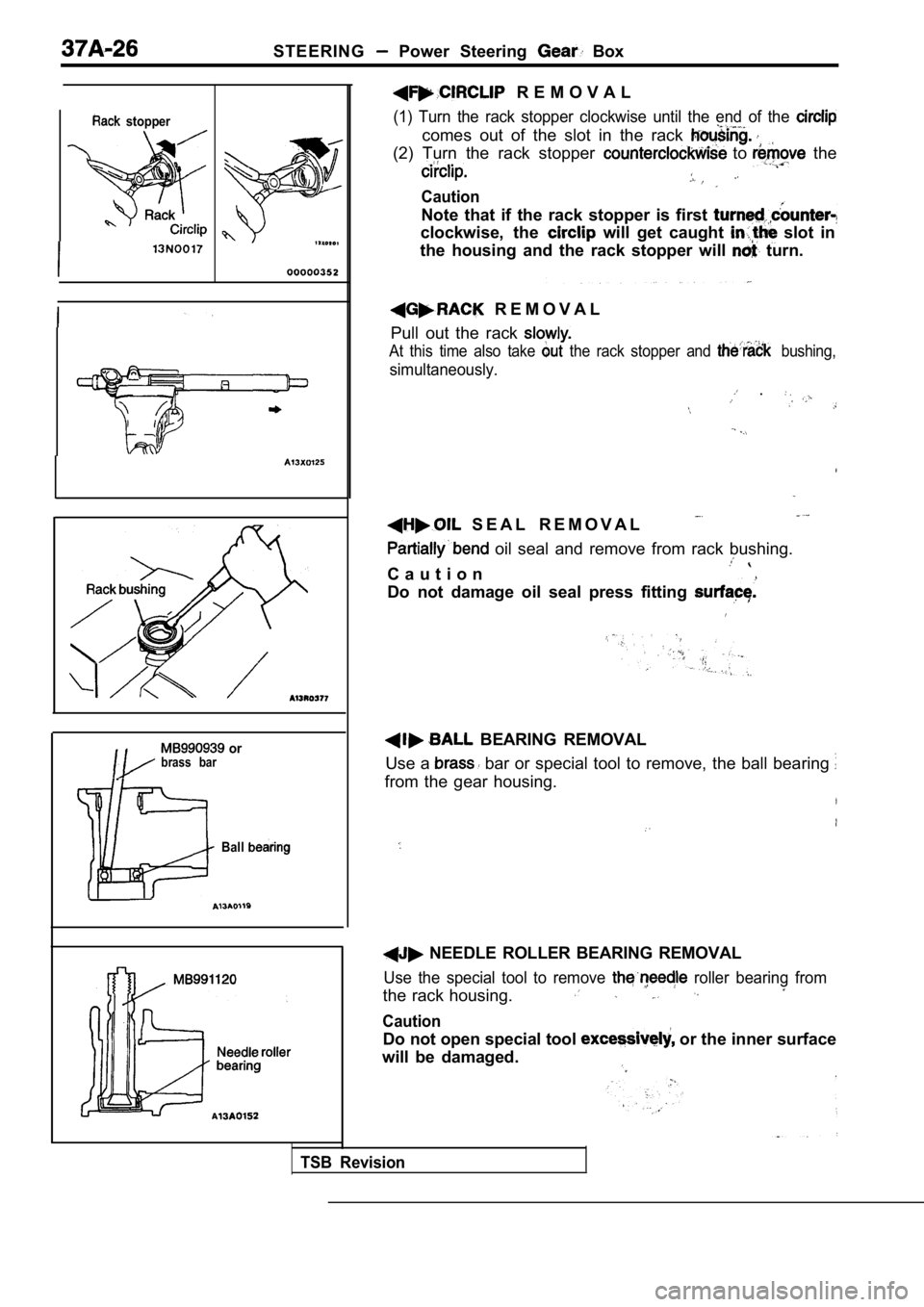

stopper

orbrass bar

Ball

R E M O V A L

(1) Turn the rack stopper clockwise until the end of the

comes out of the slot in the rack

(2) Turn the rack stopper to the

Caution

Note that if the rack stopper is first

clockwise, the will get caught slot in

the housing and the rack stopper will

turn.

R E M O V A L

Pull out the rack

At this time also take the rack stopper and bushing,

simultaneously.

.

S E A L R E M O V A L

oil seal and remove from rack bushing.

C a u t i o n

Do not damage oil seal press fitting

BEARING REMOVAL

Use a

bar or special tool to remove, the ball bearing

from the gear housing.

TSB Revision

NEEDLE ROLLER BEARING REMOVAL

Use the special tool to remove roller bearing from

the rack housing.

Caution

Do not open special tool or the inner surface

will be damaged.