MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1841 of 2103

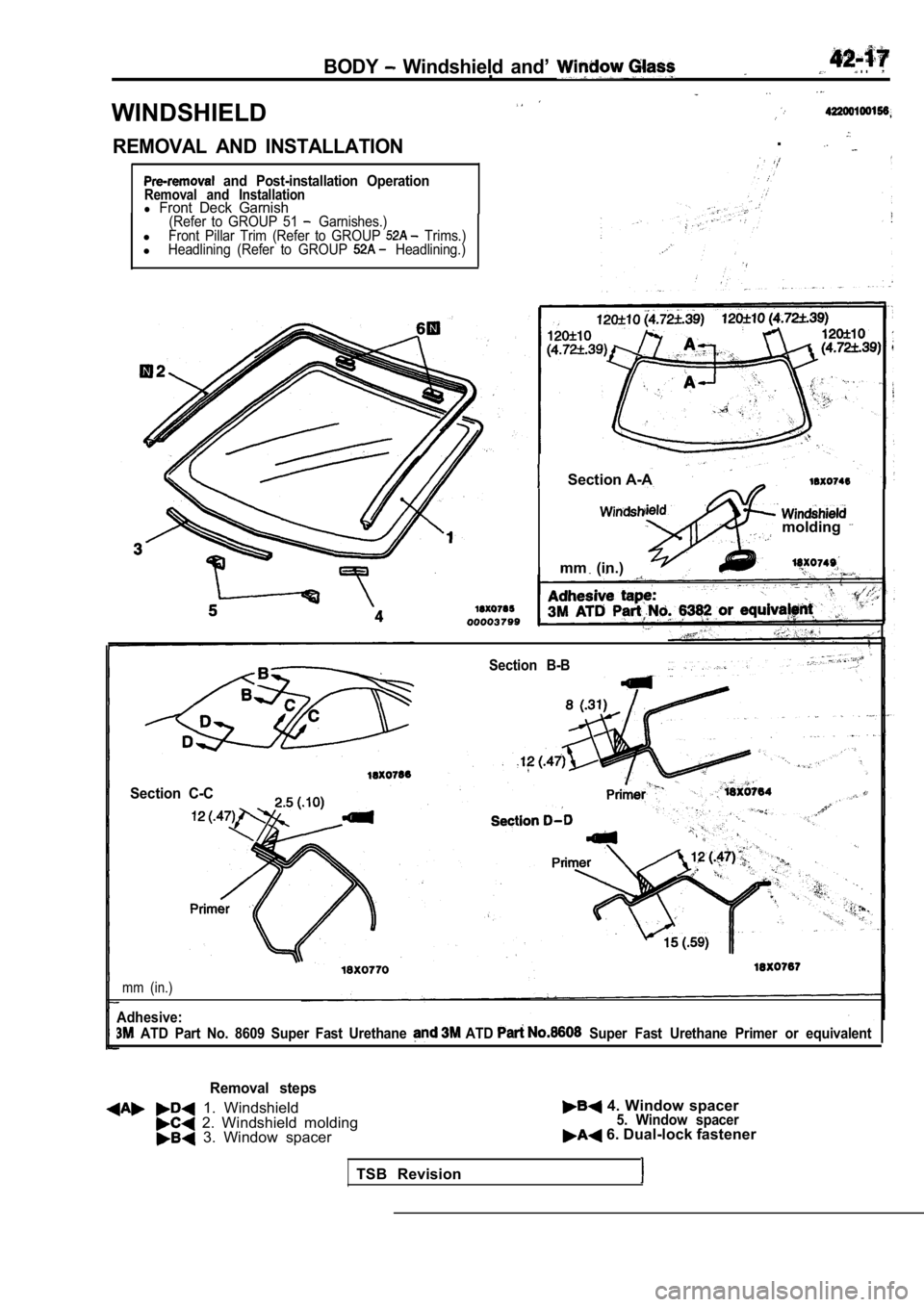

BODY Windshield and’ . ..

WINDSHIELD

REMOVAL AND INSTALLATION.

and Post-installation OperationRemoval and Installationl Front Deck Garnish(Refer to GROUP 51 Garnishes.)lFront Pillar Trim (Refer to GROUP Trims.)lHeadlining (Refer to GROUP Headlining.)

Section A-A

molding

mm (in.)

Section B-B

Section C-C

mm (in.)

Adhesive:

ATD Part No. 8609 Super Fast Urethane ATD Super Fast Urethane Primer or equivalent

Removal steps

1. Windshield 4. Window spacer

2. Windshield molding5. Window spacer

3. Window spacer 6. Dual-lock fastener

TSB Revision

Page 1842 of 2103

42-18BODY Windshield and Window Glass

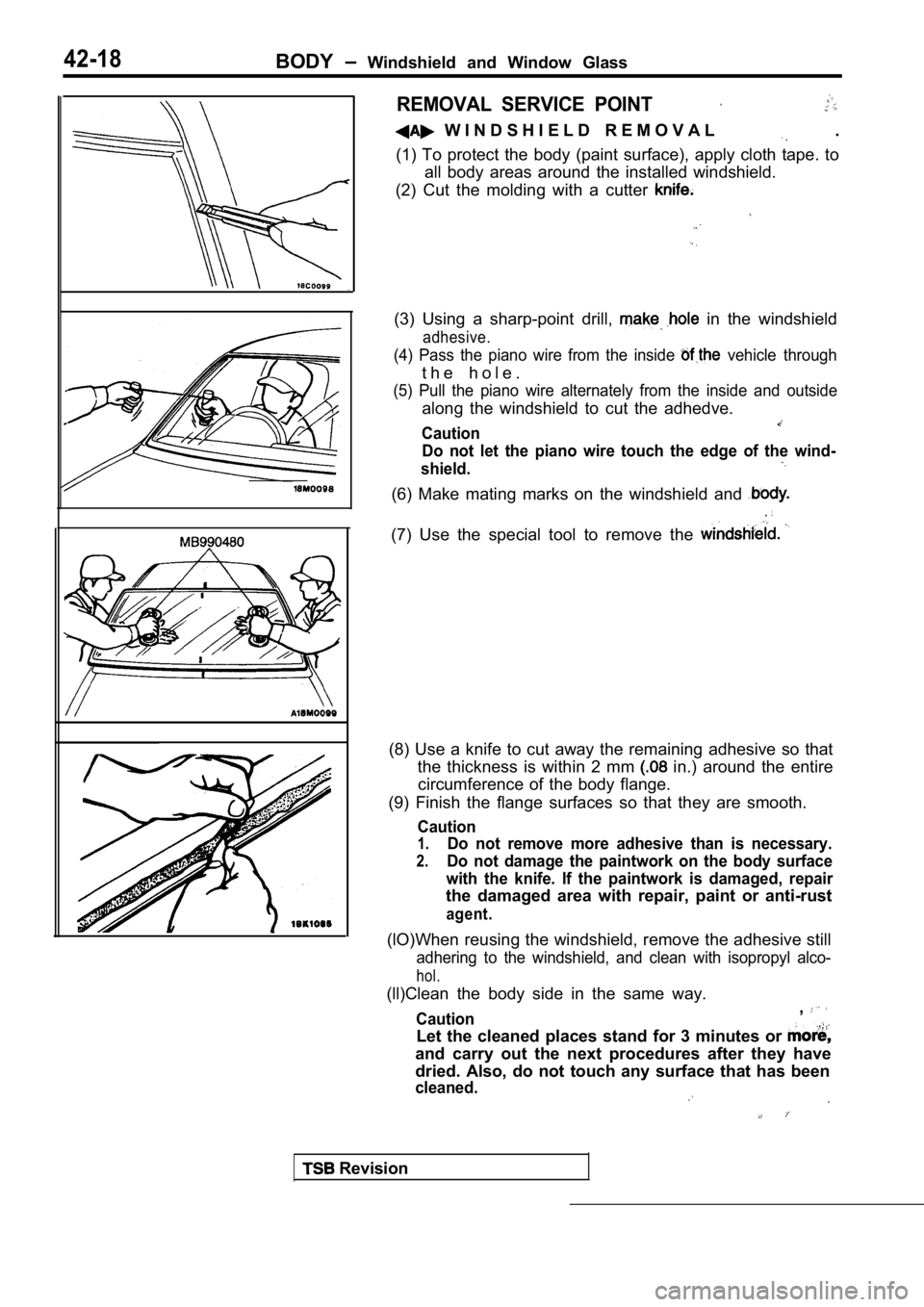

REMOVAL SERVICE POINT

W I N D S H I E L D R E M O V A L .

(1) To protect the body (paint surface), apply clot h tape. to

all body areas around the installed windshield.

(2) Cut the molding with a cutter

(3) Using a sharp-point drill, in the windshield

adhesive.

(4) Pass the piano wire from the inside vehicle through

t h e h o l e .

(5) Pull the piano wire alternately from the inside and outside

along the windshield to cut the adhedve.

Caution

Do not let the piano wire touch the edge of the win d-

shield.

(6) Make mating marks on the windshield and

.

(7) Use the special tool to remove the

(8) Use a knife to cut away the remaining adhesive so that

the thickness is within 2 mm

in.) around the entire

circumference of the body flange.

(9) Finish the flange surfaces so that they are smo oth.

Caution

1.Do not remove more adhesive than is necessary.

2.Do not damage the paintwork on the body surface

with the knife. If the paintwork is damaged, repair

the damaged area with repair, paint or anti-rust

agent.

(lO)When reusing the windshield, remove the adhesiv e still

adhering to the windshield, and clean with isopropyl alco-

hol.

(ll)Clean the body side in the same way.

Caution,

Let the cleaned places stand for 3 minutes or

and carry out the next procedures after they have

dried. Also, do not touch any surface that has been

cleaned.

Revision

Page 1843 of 2103

B O D Y Windshield and

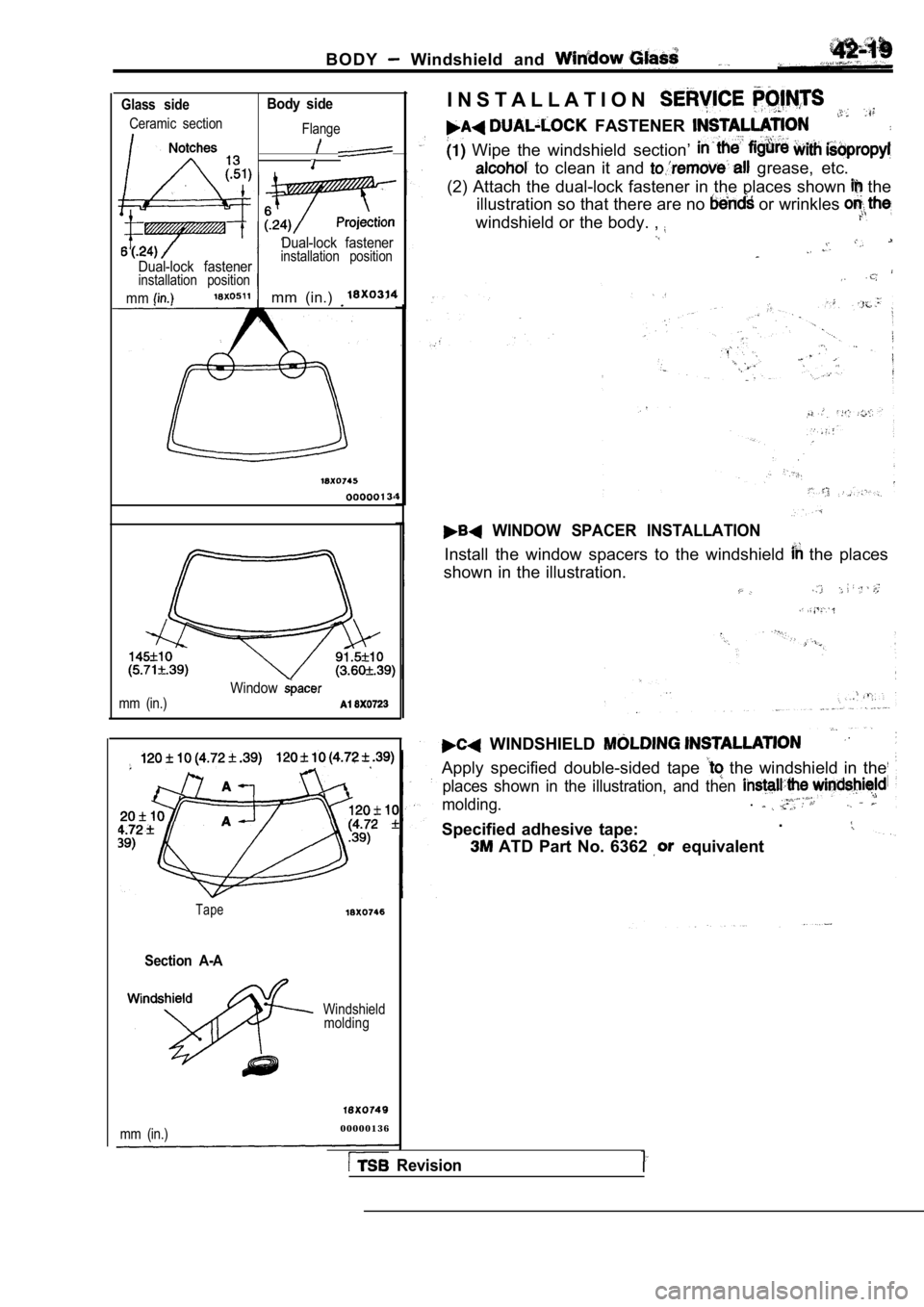

Glass side

Ceramic section

Dual-lock fastenerinstallation position

mm

Body side

Flange

Dual-lock fastenerinstallation position

mm (in.)

mm (in.)Window

Tape

Section A-A

Windshieldmolding

mm (in.)

0 0 0 0 0 1 3 6 I N S T A L L A T I O N

FASTENER

Wipe the windshield section’

to clean it and grease, etc.

(2) Attach the dual-lock fastener in the places sho wn

the

illustration so that there are no

or wrinkles

windshield or the body. ,

WINDOW SPACER INSTALLATION

Install the window spacers to the windshield the places

shown in the illustration.

WINDSHIELD

Apply specified double-sided tape the windshield in the

places shown in the illustration, and then

molding..

Specified adhesive tape: .

ATD Part No. 6362 equivalent

Revision

Page 1844 of 2103

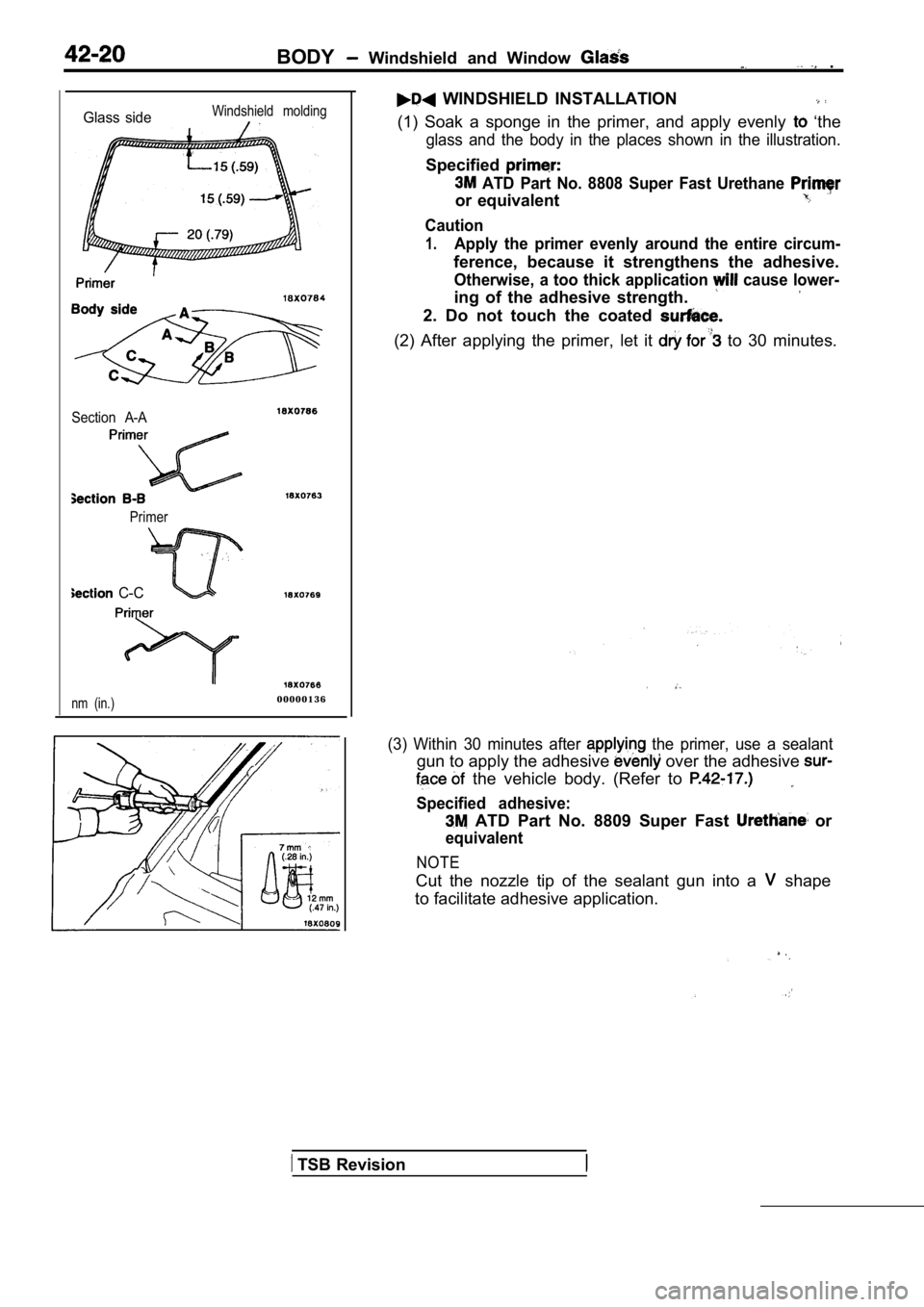

BODY Windshield and Window .

Glass sideWindshield molding

Section A-A

Primer

C-C

nm (in.)0 0 0 0 0 1 3 6

WINDSHIELD INSTALLATION

(1) Soak a sponge in the primer, and apply evenly ‘the

glass and the body in the places shown in the illustration.

Specified

ATD Part No. 8808 Super Fast Urethane

or equivalent

Caution

1.Apply the primer evenly around the entire circum-

ference, because it strengthens the adhesive.

Otherwise, a too thick application cause lower-

ing of the adhesive strength.

2. Do not touch the coated

(2) After applying the primer, let it to 30 minutes.

(3) Within 30 minutes after the primer, use a sealant

gun to apply the adhesive over the adhesive

the vehicle body. (Refer to

Specified adhesive:

ATD Part No. 8809 Super Fast or

equivalent

NOTE

Cut the nozzle tip of the sealant gun into a shape

to facilitate adhesive application.

TSB Revision

Page 1845 of 2103

B O D Y and Window

(4) aligning

and evenly so that” it “adheres completely.

glass), place it somewhere where it will not disturbed,

Caution

If heat is applied with an infra-red light to shorten

the setting time, keep the surface temperature of t he

a d h e s i v e

(6) After attaching the windshield to the body, let it stand

far 30 minutes or more, then test for water leakage.

1. If moving the vehicle: should be done gently.

2.When testing for water do not pinch the

end of the to spray the water.

TSB Revision

Page 1846 of 2103

BODY Windshield and Window Glass

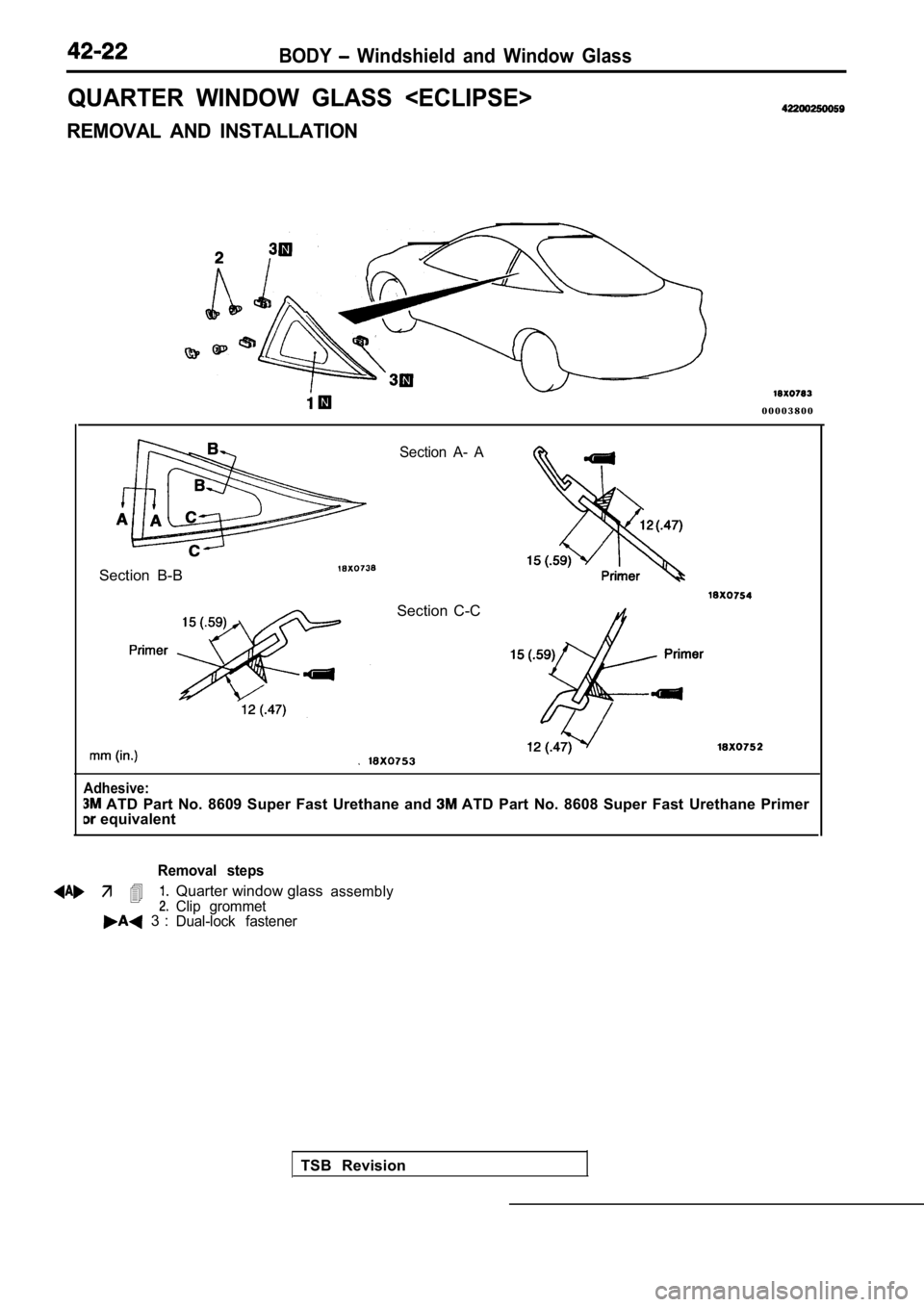

QUARTER WINDOW GLASS

REMOVAL AND INSTALLATION

0 0 0 0 3 8 0 0

Section A- A

Section B-B

Section C-C

TSB Revision

Adhesive:

ATD Part No. 8609 Super Fast Urethane and ATD Part No. 8608 Super Fast Urethane Primer equivalent

Removal steps

Page 1847 of 2103

IIII

B O D YWindshieldand Window

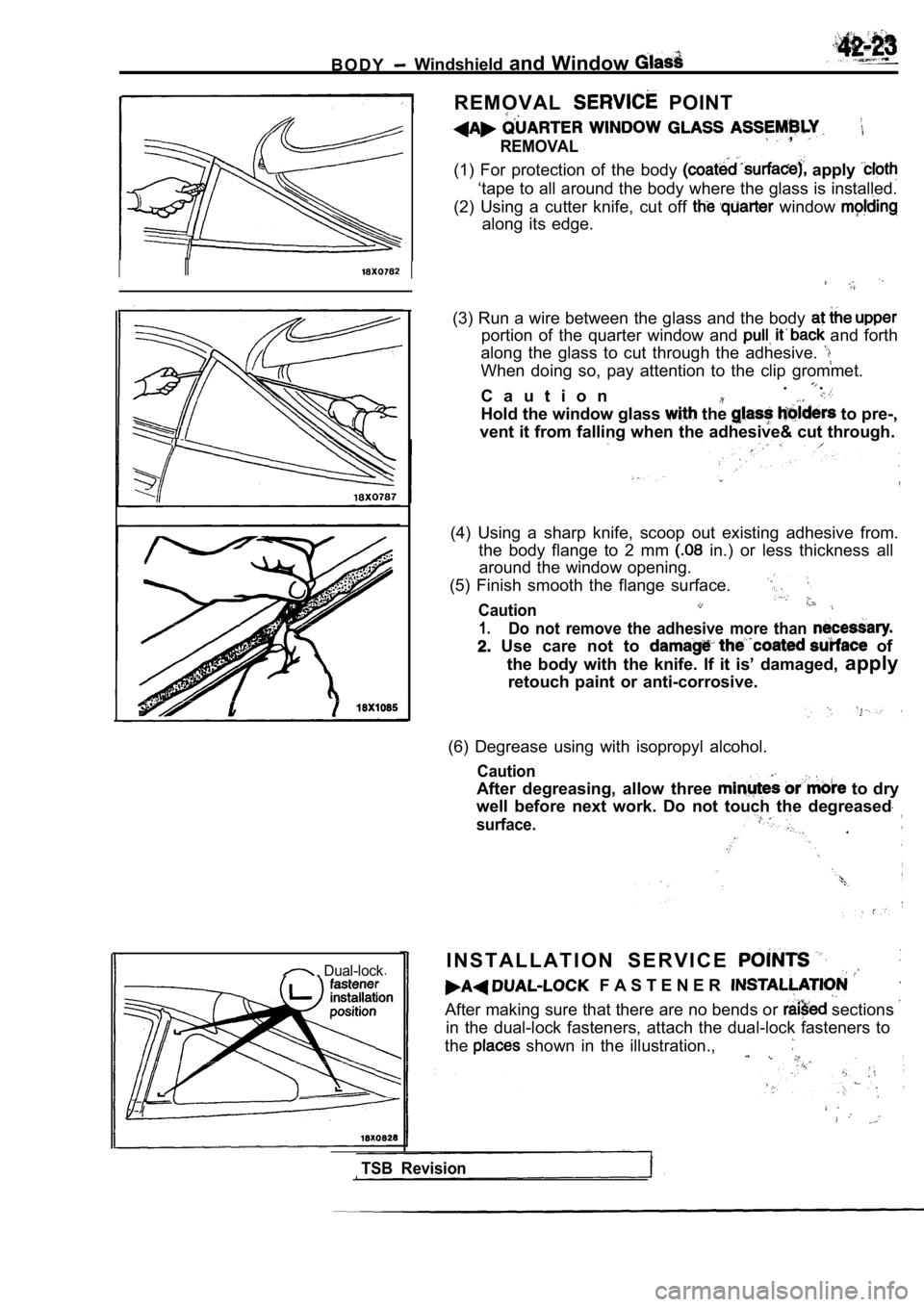

R E M O V A L POINT

,REMOVAL

(1) For protection of the body apply

‘tape to all around the body where the glass is ins talled.

(2) Using a cutter knife, cut off

window

along its edge.

Dual-lock

(3) Run a wire between the glass and the body

portion of the quarter window and and forth

along the glass to cut through the adhesive.

When doing so, pay attention to the clip grommet.

C a u t i o n . .

Hold the window glass the to pre-,

vent it from falling when the adhesive& cut through .

(4) Using a sharp knife, scoop out existing adhesiv e from.

the body flange to 2 mm

in.) or less thickness all

around the window opening.

(5) Finish smooth the flange surface.

Caution

1.Do not remove the adhesive more than

Use care not to of

the body with the knife. If it is’ damaged, apply

retouch paint or anti-corrosive.

(6) Degrease using with isopropyl alcohol.

Caution

After degreasing, allow three to dry

well before next work. Do not touch the degreased

surface.

TSB Revision

I N S T A L L A T I O N S E R V I C E

F A S T E N E R

After making sure that there are no bends or sections

in the dual-lock fasteners, attach the dual-lock fa steners to

the

shown in the illustration.,

Page 1848 of 2103

BODY Windshield and Window Glass

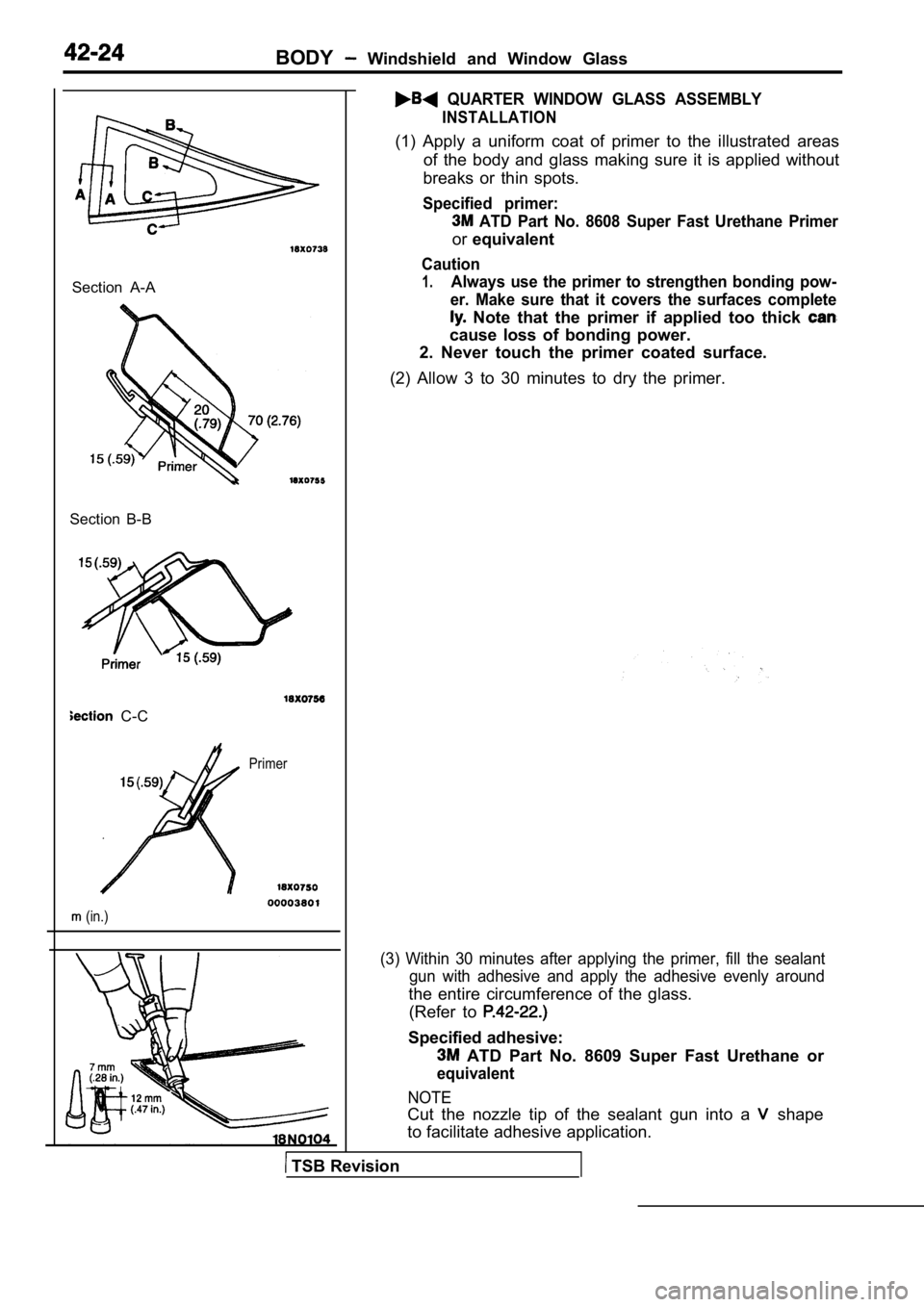

QUARTER WINDOW GLASS ASSEMBLY

INSTALLATION

Section A-A

Section B-B

C-C

Primer

(in.)

(1) Apply a uniform coat of primer to the illustrat ed areas

of the body and glass making sure it is applied wit hout

breaks or thin spots.

Specified primer:

ATD Part No. 8608 Super Fast Urethane Primer

or equivalent

Caution

1.Always use the primer to strengthen bonding pow-

er. Make sure that it covers the surfaces complete

Note that the primer if applied too thick

cause loss of bonding power.

2. Never touch the primer coated surface.

(2) Allow 3 to 30 minutes to dry the primer.

(3) Within 30 minutes after applying the primer, fi ll the sealant

gun with adhesive and apply the adhesive evenly aro und

the entire circumference of the glass.

(Refer to

Specified adhesive:

ATD Part No. 8609 Super Fast Urethane or

equivalent

NOTE

Cut the nozzle tip of the sealant gun into a shape

to facilitate adhesive application.

TSB Revision

Page 1849 of 2103

BODY Windshield and Window

(4) After

and onto the body

Remove the adhesive

b o d y

clean.

(6) After the

to until the adhesive

C a u t i o n

When using an infrared lamp or other means for quick-

er hardening, keep the surface temperature

or lower.

(7) After about 30 minutes or more following bondin g of the

quarter glass to the body, check for water leaks.

Caution

1. If the vehicle is to be moved, do so gently.

2. When

for water leaks, do not squeeze

the

end.

TSB Revision

Page 1850 of 2103

BODY Windshield and Window Glass

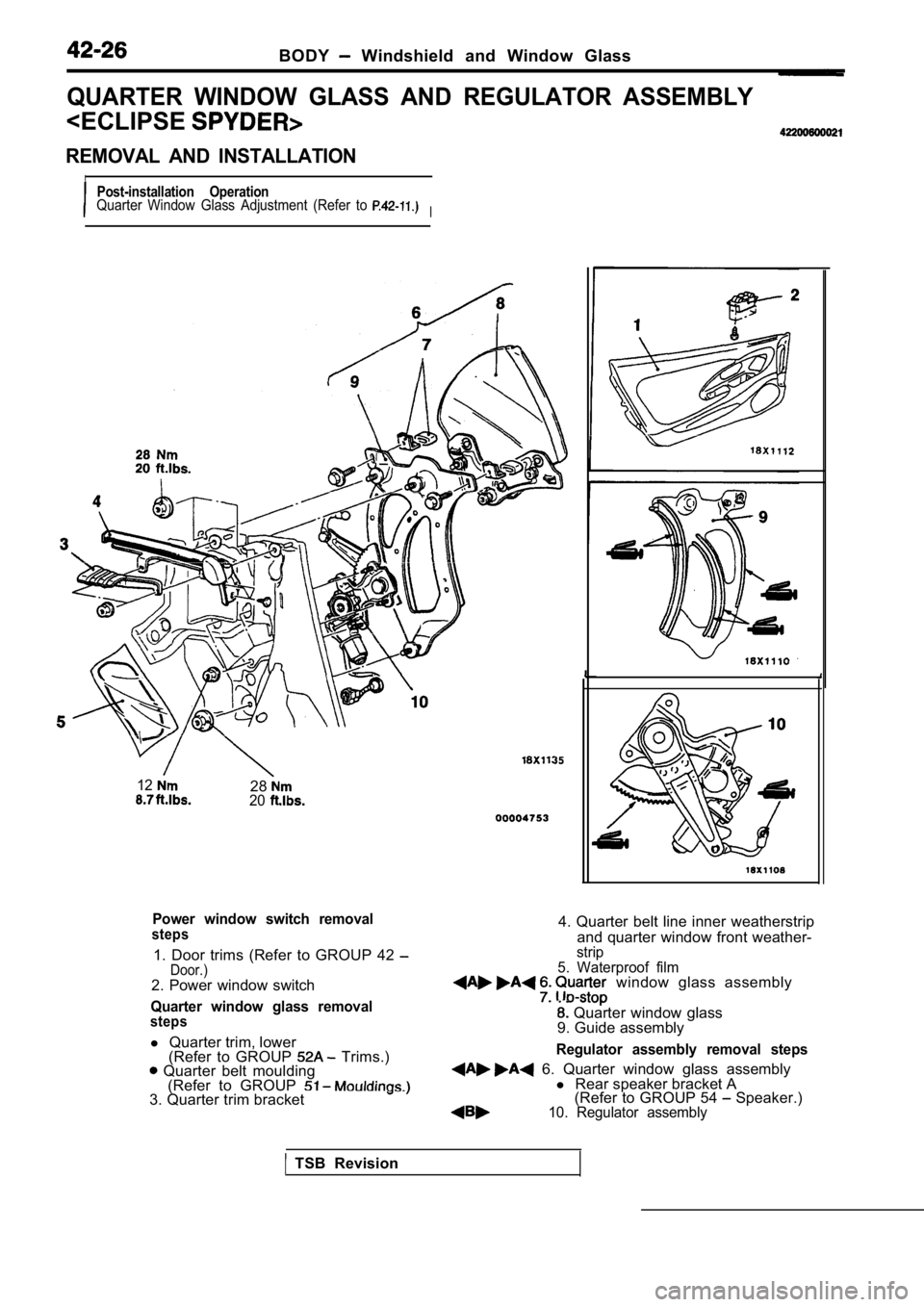

QUARTER WINDOW GLASS AND REGULATOR ASSEMBLY

IPost-installation OperationQuarter Window Glass Adjustment (Refer to I

122820

Power window switch removalsteps

1. Door trims (Refer to GROUP 42 Door.)2. Power window switch

Quarter window glass removalsteps

l Quarter trim, lower

(Refer to GROUP Trims.) Quarter belt moulding (Refer to GROUP

3. Quarter trim bracket

4. Quarter belt line inner weatherstrip

and quarter window front weather-

strip

5. Waterproof film

window glass assembly

Quarter window glass

9. Guide assembly

Regulator assembly removal steps

6. Quarter window glass assembly l Rear speaker bracket A

(Refer to GROUP 54 Speaker.)10. Regulator assembly

TSB Revision