MITSUBISHI SPYDER 1990 Service Service Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 41 of 2103

GENERAL Maintenance Service

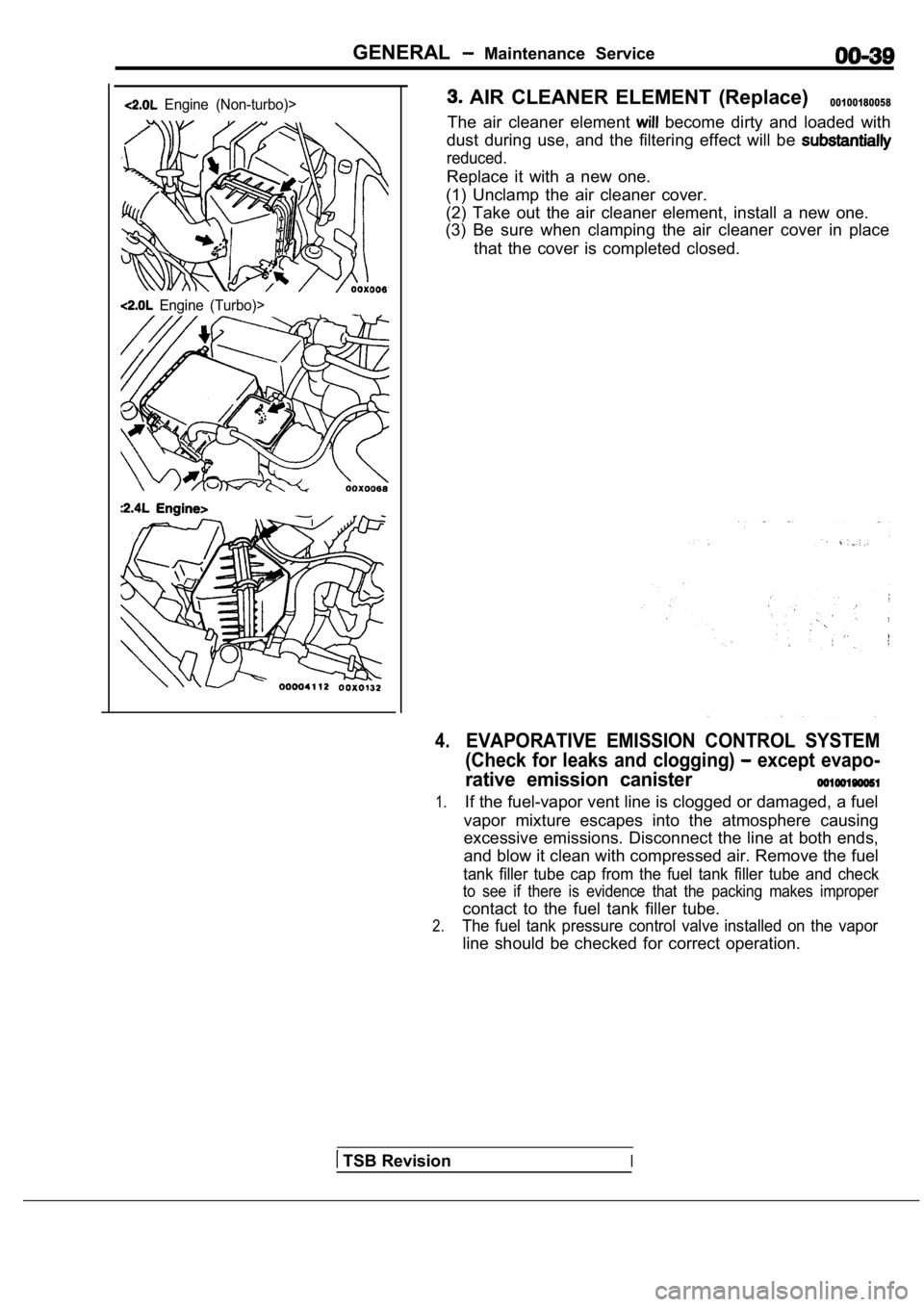

Engine (Non-turbo)>

Engine (Turbo)>

AIR CLEANER ELEMENT (Replace)00100180058

The air cleaner element become dirty and loaded with

dust during use, and the filtering effect will be

reduced.

Replace it with a new one.

(1) Unclamp the air cleaner cover.

(2) Take out the air cleaner element, install a new one.

(3) Be sure when clamping the air cleaner cover in place

that the cover is completed closed.

4.EVAPORATIVE EMISSION CONTROL SYSTEM

(Check for leaks and clogging)

except evapo-

rative emission canister

1.If the fuel-vapor vent line is clogged or damaged, a fuel

vapor mixture escapes into the atmosphere causing

excessive emissions. Disconnect the line at both en ds,

and blow it clean with compressed air. Remove the f uel

tank filler tube cap from the fuel tank filler tube and check

to see if there is evidence that the packing makes improper

contact to the fuel tank filler tube.

2.The fuel tank pressure control valve installed on the vapor

line should be checked for correct operation.

TSB RevisionI

Page 42 of 2103

GENERAL Maintenance

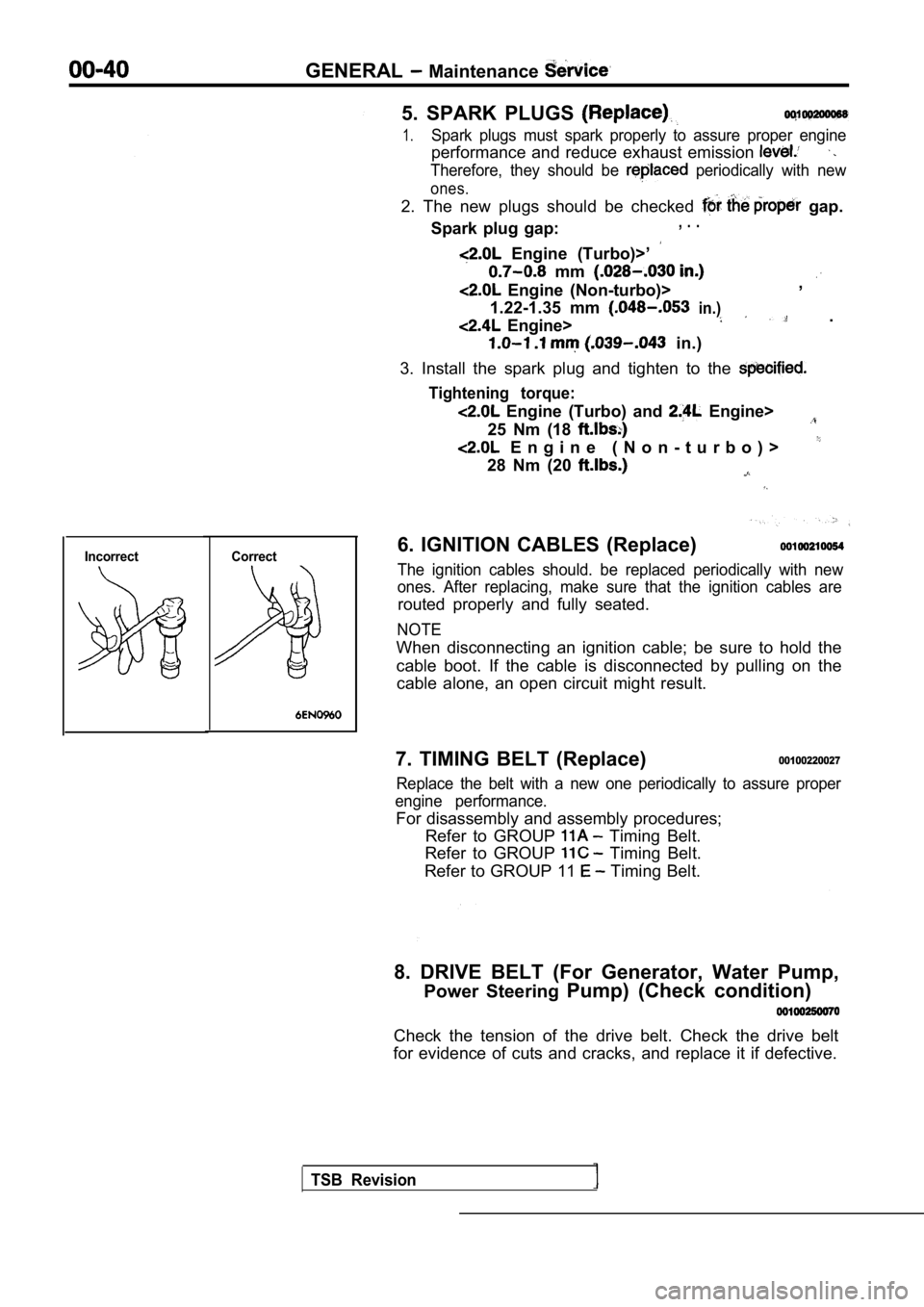

Incorrect Correct

5. SPARK PLUGS

1.Spark plugs must spark properly to assure proper engine

performance and reduce exhaust emission

Therefore, they should be periodically with new

ones.

2. The new plugs should be checked gap.

Spark plug gap:, . .

Engine (Turbo)>’

mm

Engine (Non-turbo)> ,

1.22-1.35 mm

in.)

Engine> .

in.)

3. Install the spark plug and tighten to the

Tightening torque:

Engine (Turbo) and Engine>

25 Nm (18

E n g i n e ( N o n - t u r b o ) >

28 Nm (20

6. IGNITION CABLES (Replace)

The ignition cables should. be replaced periodicall y with new

ones. After replacing, make sure that the ignition cables are

routed properly and fully seated.

NOTE

When disconnecting an ignition cable; be sure to ho ld the

cable boot. If the cable is disconnected by pulling on the

cable alone, an open circuit might result.

7. TIMING BELT (Replace)

00100220027

Replace the belt with a new one periodically to ass ure proper

engine performance.

For disassembly and assembly procedures; Refer to GROUP

Timing Belt.

Refer to GROUP

Timing Belt.

Refer to GROUP 11

Timing Belt.

8. DRIVE BELT (For Generator, Water Pump, Power Steering Pump) (Check condition)

Check the tension of the drive belt. Check the driv e belt

for evidence of cuts and cracks, and replace it if defective.

TSB Revision

Page 43 of 2103

GENERAL Maintenance

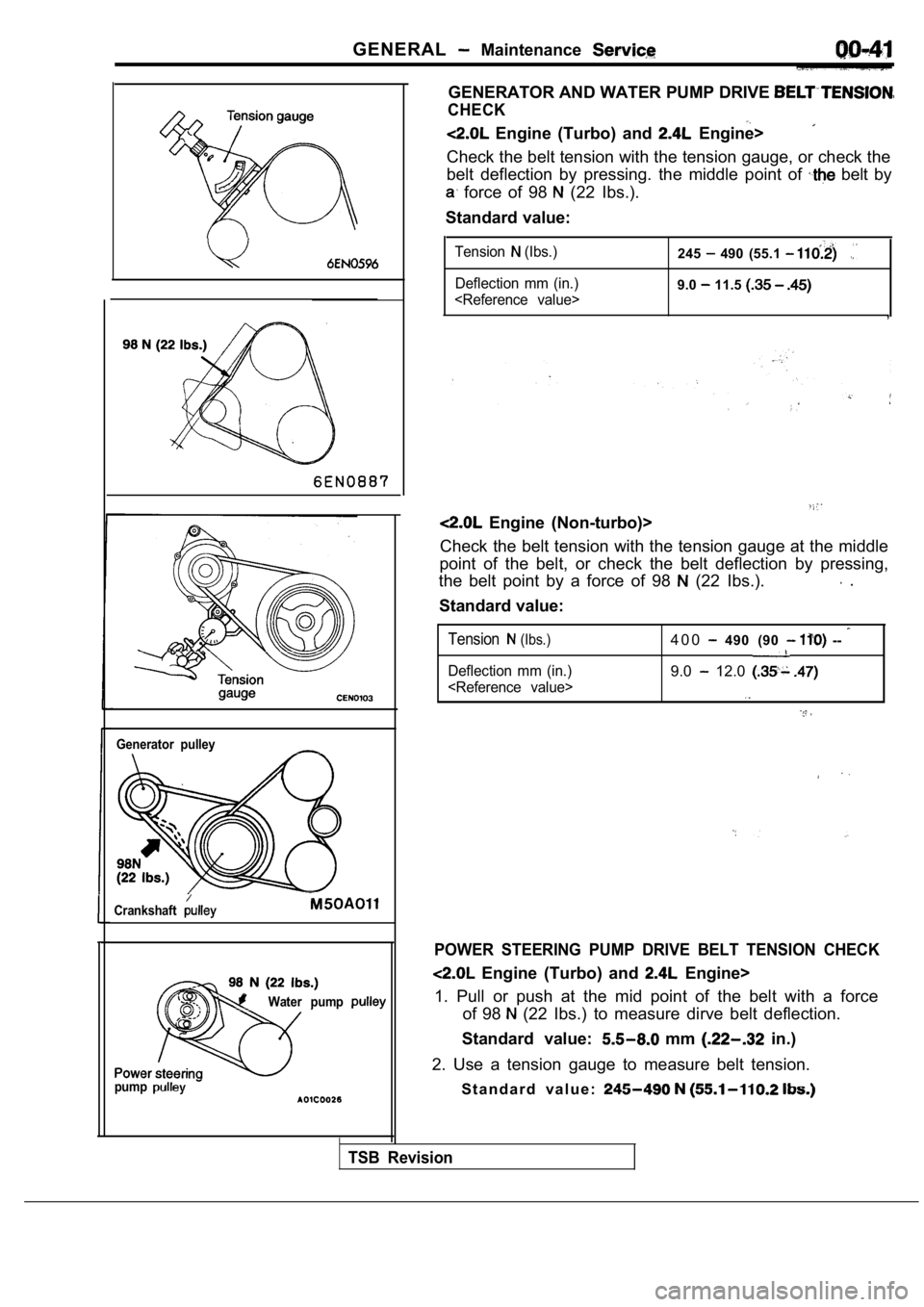

Generator pulley

Crankshaft

Water pump

pump

GENERATOR AND WATER PUMP DRIVE

CHECK

Engine (Turbo) and Engine>

Check the belt tension with the tension gauge, or c heck the

belt deflection by pressing. the middle point of

belt by

force of 98 (22 Ibs.).

Standard value:

Tension (Ibs.)

Deflection mm (in.)

9.0 11.5

,

Engine (Non-turbo)>

Check the belt tension with the tension gauge at th e middle

point of the belt, or check the belt deflection by pressing,

the belt point by a force of 98

(22 Ibs.). .

Standard value:

Tension (Ibs.)

Deflection mm (in.)

4 0 0 490 (90 --

9.0 12.0

POWER STEERING PUMP DRIVE BELT TENSION CHECK

Engine (Turbo) and Engine>

1. Pull or push at the mid point of the belt with a force

of 98

(22 Ibs.) to measure dirve belt deflection.

Standard value:

mm in.)

2. Use a tension gauge to measure belt tension. S t a n d a r d v a l u e :

TSB Revision

Page 44 of 2103

GENERALMaintenanceService

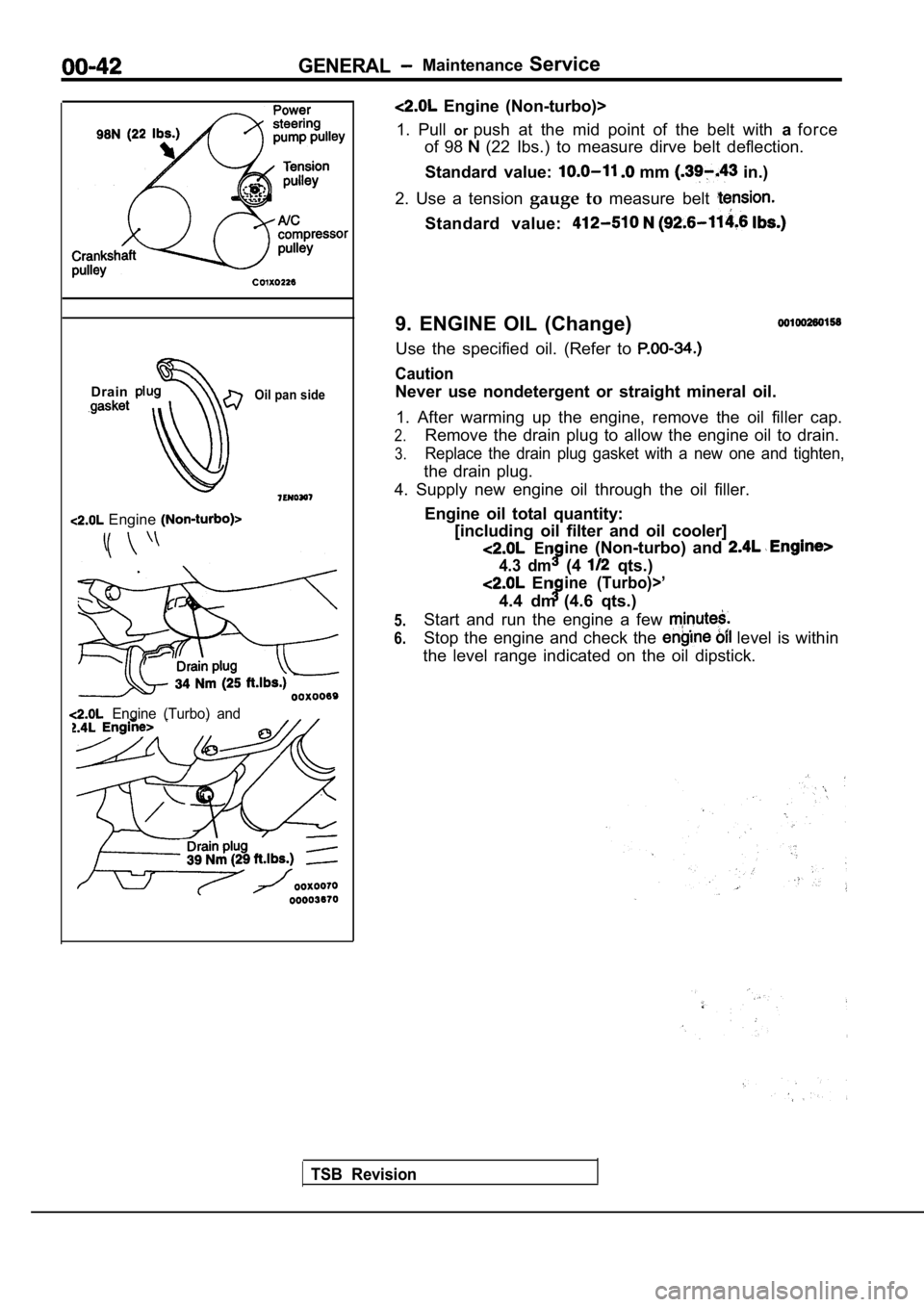

Drain

Oil pan side

Engine

Engine (Turbo) and

TSB Revision

Engine (Non-turbo)>

1. Pull orpush at the mid point of the belt with aforce

of 98

(22 Ibs.) to measure dirve belt deflection.

Standard value:

mm in.)

2. Use a tension gauge to measure belt

Standard value:

9. ENGINE OIL (Change)

Use the specified oil. (Refer to

Caution

Never use nondetergent or straight mineral oil.

1. After warming up the engine, remove the oil fill er cap.

2.Remove the drain plug to allow the engine oil to drain.

3.Replace the drain plug gasket with a new one and ti ghten,

the drain plug.

4. Supply new engine oil through the oil filler.

Engine oil total quantity:[including oil filter and oil cooler]

Enine (Non-turbo) and

4.3 dm(4 qts.)

Enine (Turbo)>’

4.4 dm (4.6 qts.)

Start and run the engine a few

Stop the engine and check the level is within

the level range indicated on the oil dipstick.

5.

6.

Page 45 of 2103

GENERAL Maintenance Service

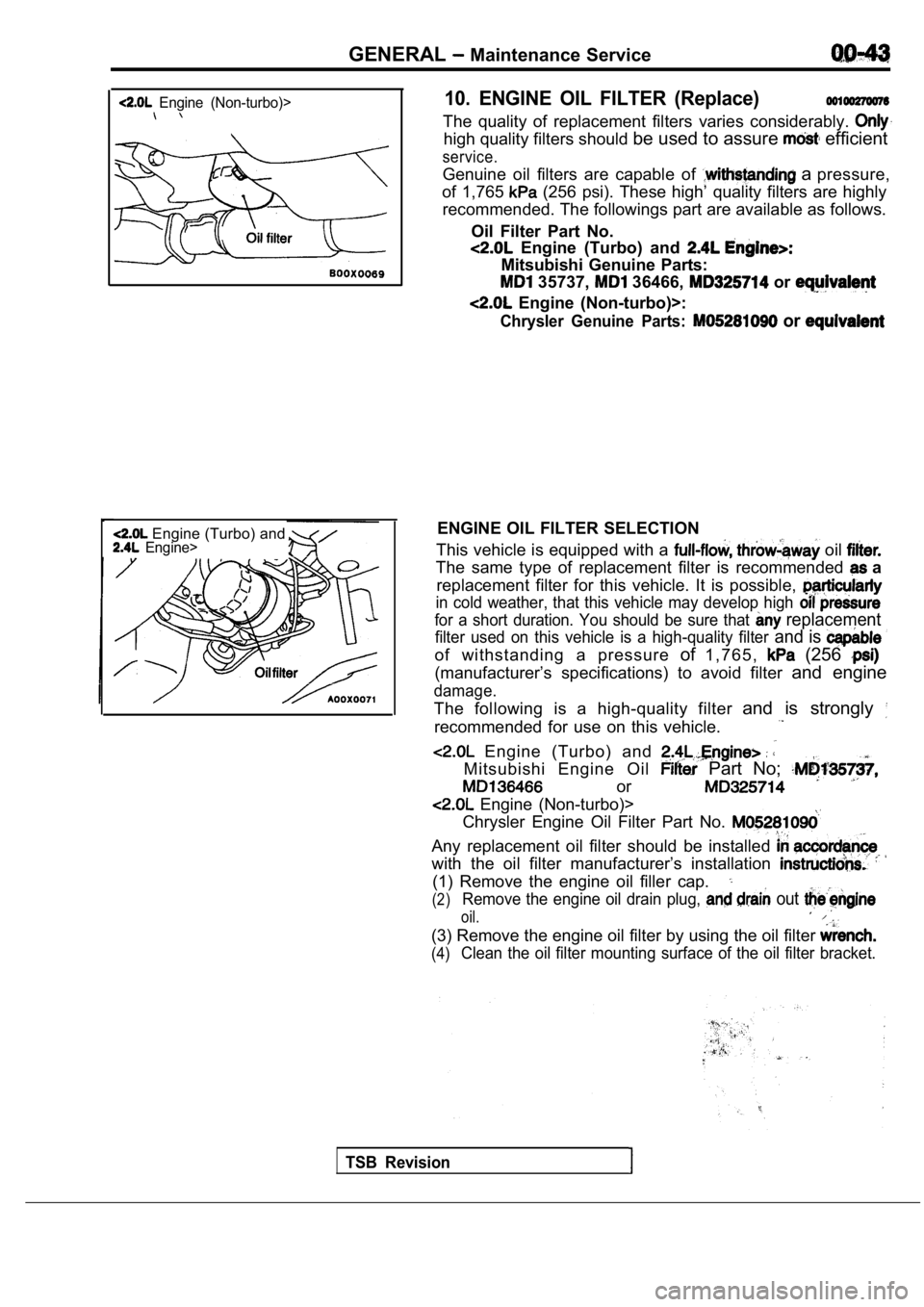

Engine (Non-turbo)>

Engine (Turbo) and Engine>

10. ENGINE OIL FILTER (Replace)

The quality of replacement filters varies considerably.

high quality filters should be used to assure efficient

service.

Genuine oil filters are capable of a pressure,

of 1,765

(256 psi). These high’ quality filters are highly

recommended. The followings part are available as f ollows.

Oil Filter Part No.

Engine (Turbo) and

Mitsubishi Genuine Parts:

35737, 36466, or

Engine (Non-turbo)>:

Chrysler Genuine Parts: or

ENGINE OIL FILTER SELECTION

This vehicle is equipped with a

oil

The same type of replacement filter is recommended a

replacement filter for this vehicle. It is possible ,

in cold weather, that this vehicle may develop high

for a short duration. You should be sure that replacement

filter used on this vehicle is a high-quality filter and is

of withstanding a pressure of1 , 7 6 5 , (256

(manufacturer’s specifications) to avoid filter and engine

damage.

The following is a high-quality filter and is strongly

recommended for use on this vehicle.

Engine (Turbo) and

Mitsubishi Engine Oil Part No;

or

Engine (Non-turbo)>

Chrysler Engine Oil Filter Part No.

Any replacement oil filter should be installed

with the oil filter manufacturer’s installation

(1) Remove the engine oil filler cap.

(2)Remove the engine oil drain plug, out

oil.

(3) Remove the engine oil filter by using the oil f ilter

(4)Clean the oil filter mounting surface of the oil filter bracket.

TSB Revision

Page 46 of 2103

GENERAL

Oil level

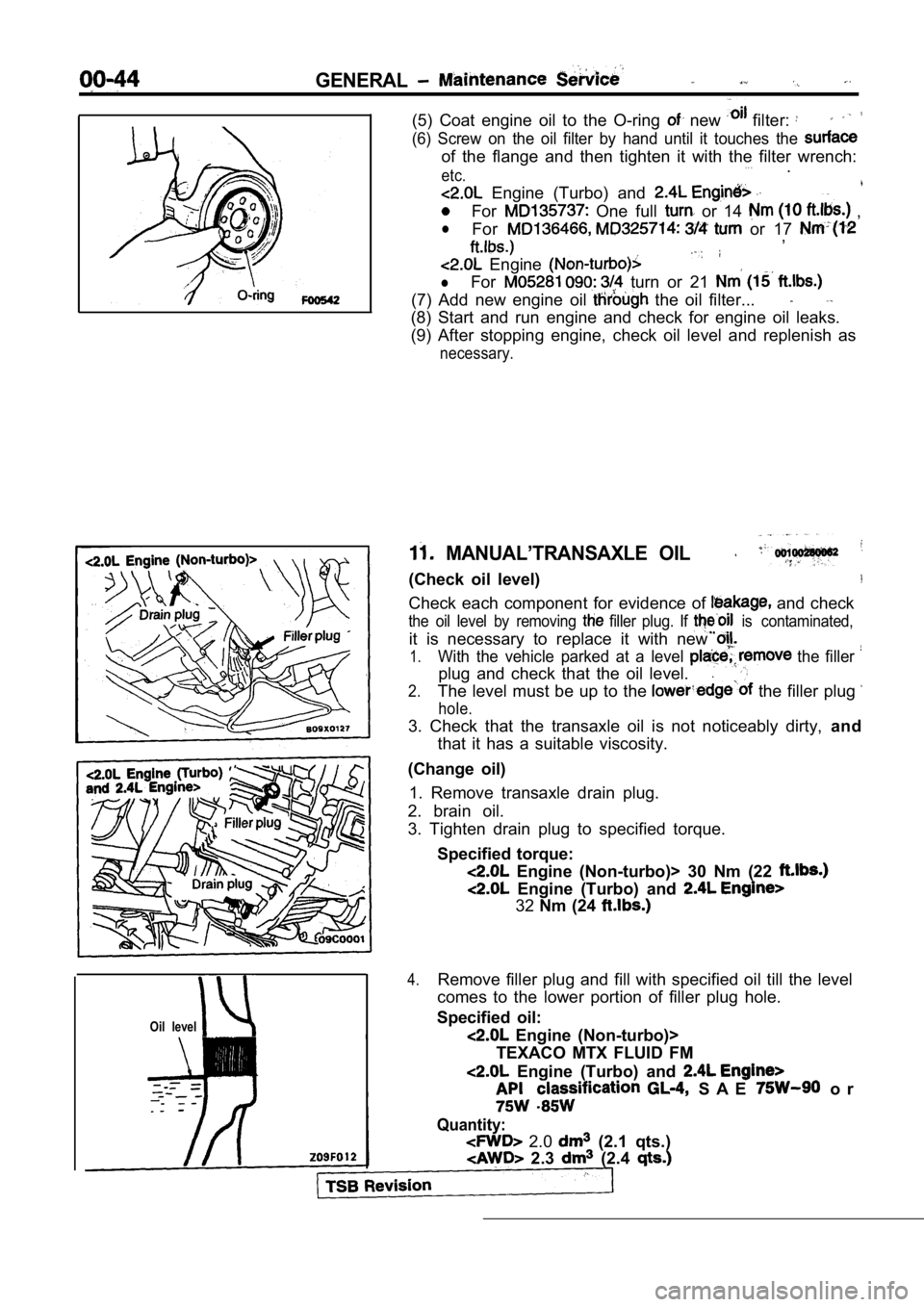

(5) Coat engine oil to the O-ring new filter:

(6) Screw on the oil filter by hand until it touches the

of the flange and then tighten it with the filter w rench:. . .etc..

Engine (Turbo) and

For One full or 14 ,

lFor or 17 ,

Engine

lFor turn or 21

(7) Add new engine oil the oil filter...

(8) Start and run engine and check for engine oil l eaks.

(9) After stopping engine, check oil level and repl enish as

necessary.

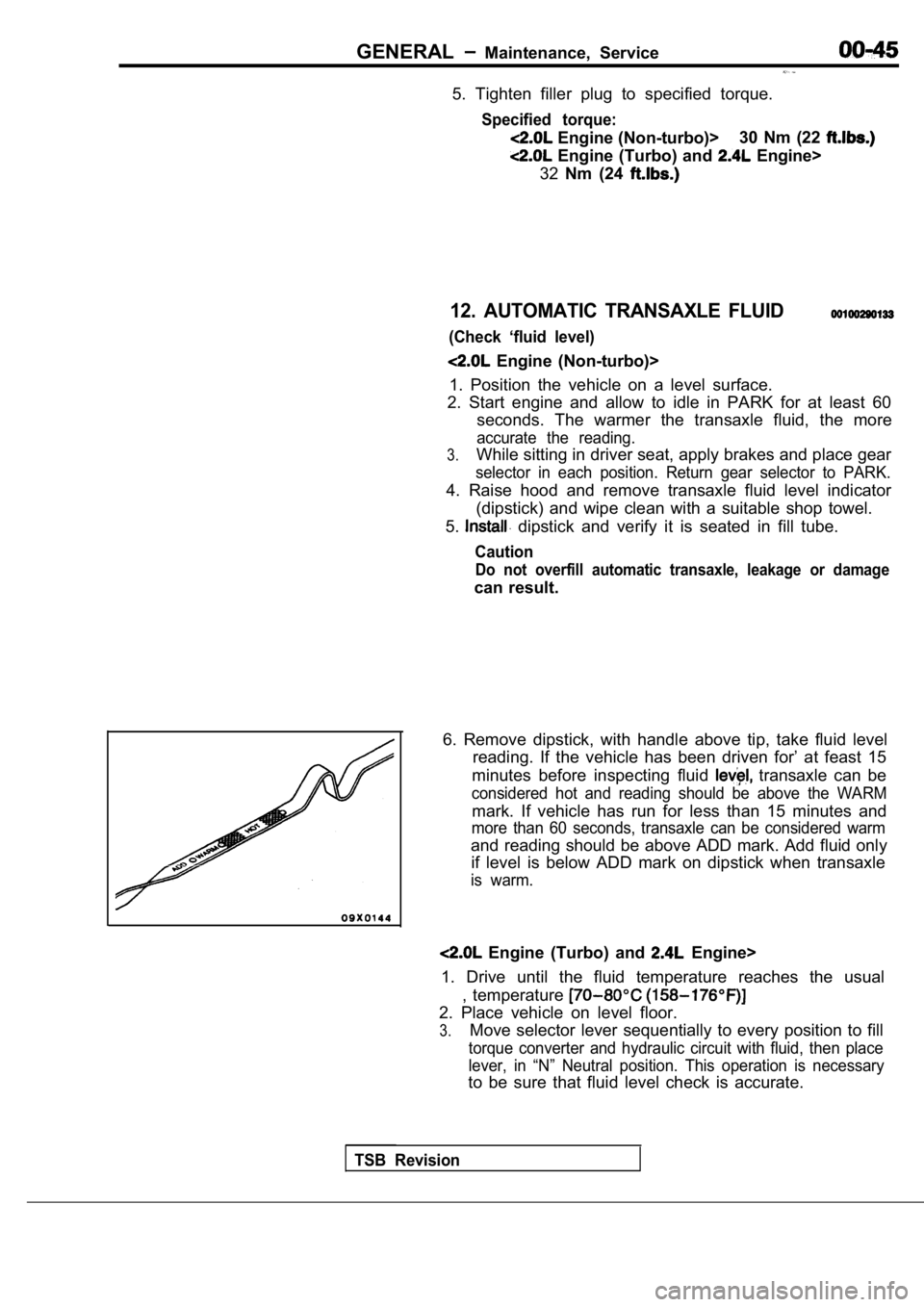

MANUAL’TRANSAXLE OIL

(Check oil level)

Check each component for evidence of and check

the oil level by removing filler plug. If is contaminated,

it is necessary to replace it with new

1.With the vehicle parked at a level the filler

plug and check that the oil level..

2.The level must be up to the the filler plug

hole.

3. Check that the transaxle oil is not noticeably d irty, and

that it has a suitable viscosity.

(Change oil) 1. Remove transaxle drain plug.

2. brain oil.

3. Tighten drain plug to specified torque.

Specified torque:

Engine (Non-turbo)> 30 Nm (22

Engine (Turbo) and

32Nm (24

4.Remove filler plug and fill with specified oil till the level

comes to the lower portion of filler plug hole.

Specified oil:

Engine (Non-turbo)>

TEXACO MTX FLUID FM

Engine (Turbo) and

S A E o r

Quantity:

2.0 (2.1 qts.)

2.3 (2.4

Page 47 of 2103

GENERAL Maintenance, Service

5. Tighten filler plug to specified torque.

Specified torque:

Engine (Non-turbo)>30 Nm (22

Engine (Turbo) and Engine>

32 Nm (24

12. AUTOMATIC TRANSAXLE FLUID

(Check ‘fluid level)

Engine (Non-turbo)>

1. Position the vehicle on a level surface.

2. Start engine and allow to idle in PARK for at le ast 60

seconds. The warmer the transaxle fluid, the more

accurate the reading.

3.While sitting in driver seat, apply brakes and plac e gear

selector in each position. Return gear selector to PARK.

4. Raise hood and remove transaxle fluid level indi cator

(dipstick) and wipe clean with a suitable shop towe l.

5.

dipstick and verify it is seated in fill tube.

Caution

Do not overfill automatic transaxle, leakage or dam age

can result.

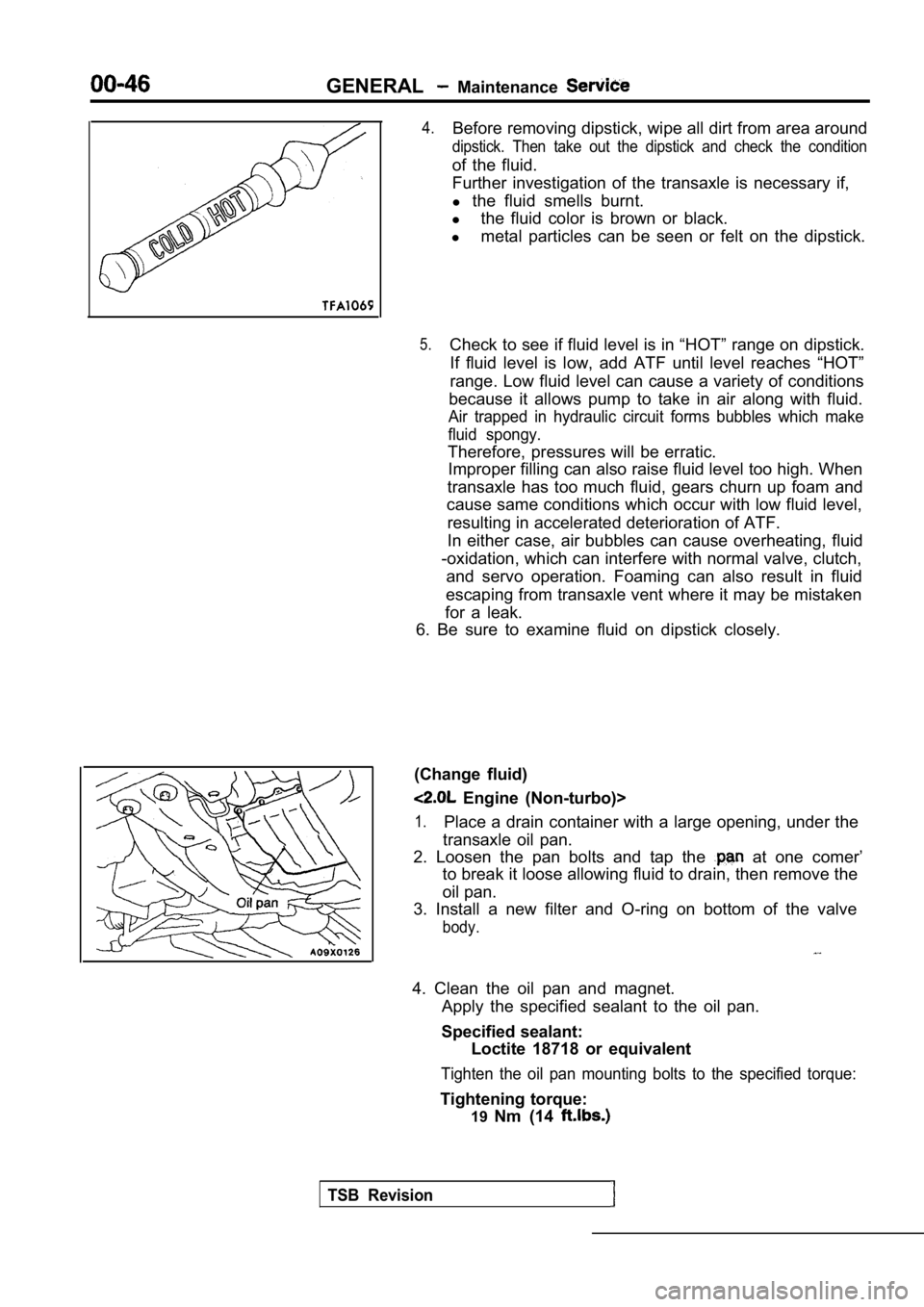

6. Remove dipstick, with handle above tip, take flu id level

reading. If the vehicle has been driven for’ at fea st 15

minutes before inspecting fluid

transaxle can be

considered hot and reading should be above the WARM

mark. If vehicle has run for less than 15 minutes a nd

more than 60 seconds, transaxle can be considered w arm

and reading should be above ADD mark. Add fluid onl y

if level is below ADD mark on dipstick when transax le

is warm.

Engine (Turbo) and Engine>

1. Drive until the fluid temperature reaches the us ual

, temperature

2. Place vehicle on level floor.

3.Move selector lever sequentially to every position to fill

torque converter and hydraulic circuit with fluid, then place

lever, in “N” Neutral position. This operation is n ecessary

to be sure that fluid level check is accurate.

TSB Revision

Page 48 of 2103

GENERAL Maintenance

4.Before removing dipstick, wipe all dirt from area around

dipstick. Then take out the dipstick and check the condition

of the fluid.

Further investigation of the transaxle is necessary if,

l the fluid smells burnt.

l the fluid color is brown or black.

l metal particles can be seen or felt on the dipstick .

5.Check to see if fluid level is in “HOT” range on dipstick.

If fluid level is low, add ATF until level reaches “HOT”

range. Low fluid level can cause a variety of condi tions

because it allows pump to take in air along with fl uid.

Air trapped in hydraulic circuit forms bubbles which make

fluid spongy.

Therefore, pressures will be erratic. Improper filling can also raise fluid level too hig h. When

transaxle has too much fluid, gears churn up foam a nd

cause same conditions which occur with low fluid le vel,

resulting in accelerated deterioration of ATF.

In either case, air bubbles can cause overheating, fluid

-oxidation, which can interfere with normal valve, clutch,

and servo operation. Foaming can also result in flu id

escaping from transaxle vent where it may be mistak en

for a leak.

6. Be sure to examine fluid on dipstick closely.

(Change fluid)

Engine (Non-turbo)>

1.Place a drain container with a large opening, under the

transaxle oil pan.

2. Loosen the pan bolts and tap the

at one comer’

to break it loose allowing fluid to drain, then rem ove the

oil pan.

3. Install a new filter and O-ring on bottom of the valve

body.

4. Clean the oil pan and magnet.

Apply the specified sealant to the oil pan.

Specified sealant: Loctite 18718 or equivalent

Tighten the oil pan mounting bolts to the specified torque:

Tightening torque:

19Nm (14

TSB Revision

Page 49 of 2103

GENERALMaintenance Service

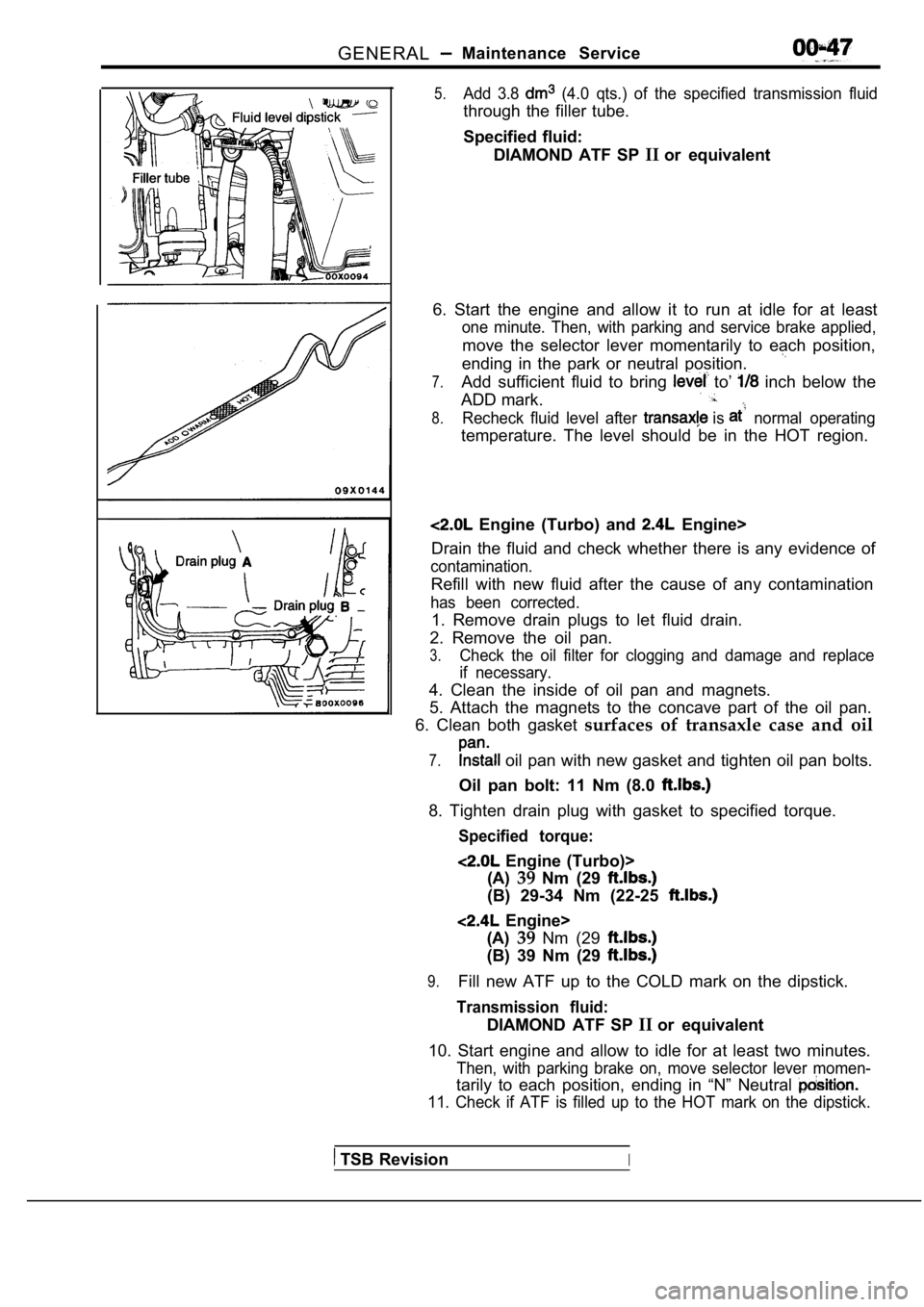

5.Add 3.8 (4.0 qts.) of the specified transmission fluid

through the filler tube.

Specified fluid:DIAMOND ATF SP IIor equivalent

6. Start the engine and allow it to run at idle for at least

one minute. Then, with parking and service brake ap plied,

move the selector lever momentarily to each positio n,

ending in the park or neutral position.

7.Add sufficient fluid to bring to’ inch below the

ADD mark.

8.Recheck fluid level after is normal operating

temperature. The level should be in the HOT region.

Engine (Turbo) and Engine>

Drain the fluid and check whether there is any evid ence of

contamination.

Refill with new fluid after the cause of any contam ination

has been corrected.

1. Remove drain plugs to let fluid drain.

2. Remove the oil pan.

3.Check the oil filter for clogging and damage and re place

if necessary.

4. Clean the inside of oil pan and magnets.

5. Attach the magnets to the concave part of the oi l pan.

6. Clean both gasket surfaces of transaxle case and oil

7. oil pan with new gasket and tighten oil pan bolts.

Oil pan bolt: 11 Nm (8.0

8. Tighten drain plug with gasket to specified torq ue.

Specified torque:

Engine (Turbo)>

(A) 39Nm (29

(B) 29-34 Nm (22-25

Engine>

(A) 39Nm (29

(B) 39 Nm (29

9.Fill new ATF up to the COLD mark on the dipstick.

Transmission fluid:

DIAMOND ATF SP IIor equivalent

10. Start engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector lever mo men-

tarily to each position, ending in “N” Neutral

11. Check if ATF is filled up to the HOT mark on the dipstick.

TSB RevisionI

Page 50 of 2103

GENERAL Maintenance Service

,

Revision

Drain Plug

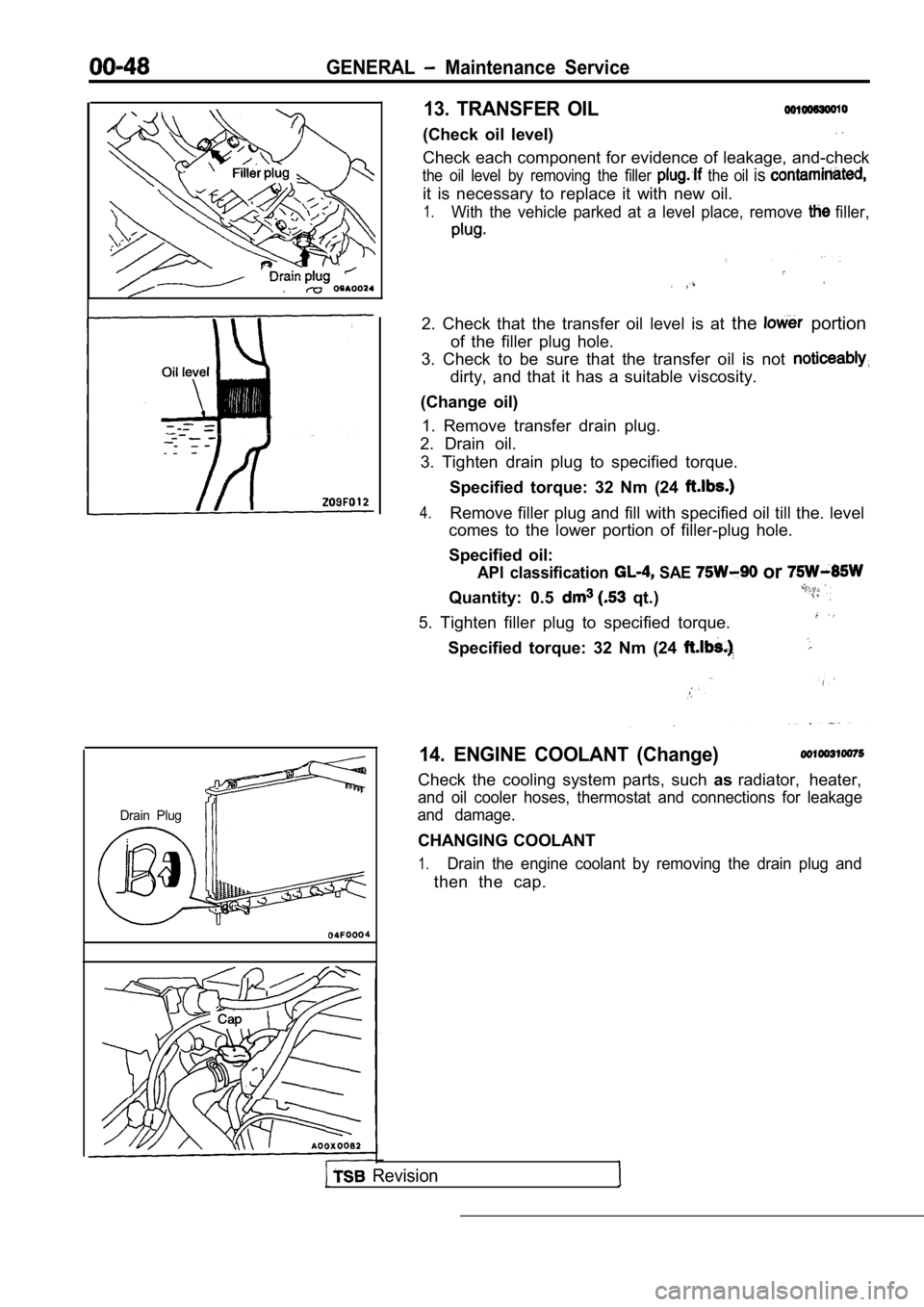

13. TRANSFER OIL

(Check oil level)

Check each component for evidence of leakage, and-check

the oil level by removing the filler the oil is

it is necessary to replace it with new oil.

1.With the vehicle parked at a level place, remove filler,

2. Check that the transfer oil level is at the portion

of the filler plug hole.

3. Check to be sure that the transfer oil is not

dirty, and that it has a suitable viscosity.

(Change oil) 1. Remove transfer drain plug.

2. Drain oil.

3. Tighten drain plug to specified torque.

Specified torque: 32 Nm (24

4.Remove filler plug and fill with specified oil till the. level

comes to the lower portion of filler-plug hole.

Specified oil:

API classification SAE or

Quantity: 0.5 qt.)

5. Tighten filler plug to specified torque.

Specified torque: 32 Nm (24

14. ENGINE COOLANT (Change)

Check the cooling system parts, such asradiator, heater,

and oil cooler hoses, thermostat and connections fo r leakage

and damage.

CHANGING COOLANT

1.Drain the engine coolant by removing the drain plug and

then the cap.