MITSUBISHI SPYDER 1990 Service Manual PDF

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 71 of 2103

ENGINE On-vehicle

8. If the standard value is exceeded, check the following

items:

l Diagnostic output

l Closed-loop control (When the closed-loop control

is carried out normally, the output signal of the h eated

oxygen sensor repeats between and

,000 at idle.)

l Fuel pressure

I n j e c t o r

lIgnition coil, spark plug cable, spark plug

lEGR system and the EGR valve leak

l Evaporative emission control system

Compression pressure

NOTE

Replace the catalyst whenever the

HC contents do not remain inside the standard value .

(even though the result of the inspection is

all items.).

C O M P R E S S I O N

CHECK

1.Before inspection, check that the engine-oil, start er

battery are normal. Also, set the to the

condition:

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicles with

2. Disconnect the spark plug cables.

3. Remove all of the spark plugs.

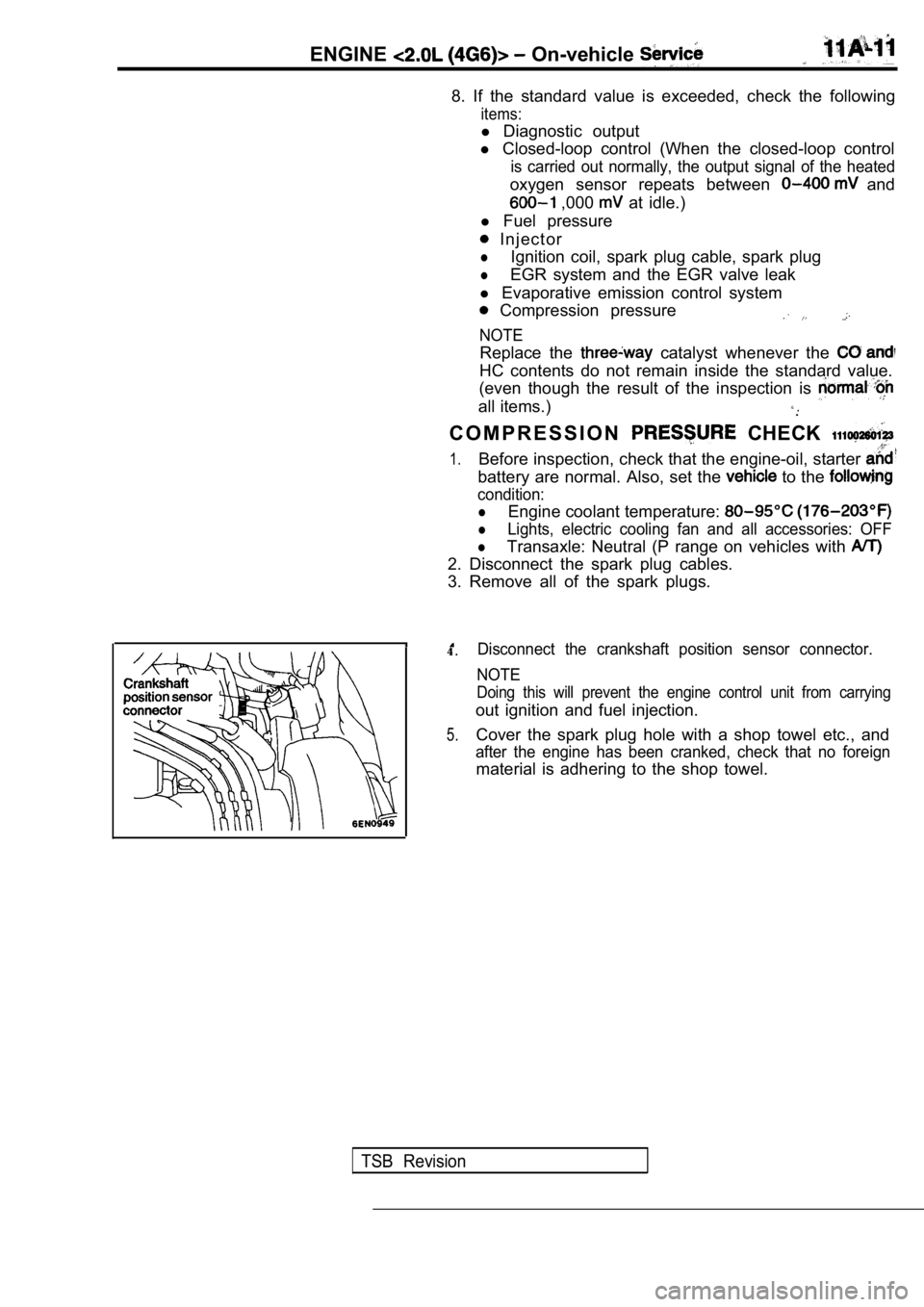

4.

5.

Disconnect the crankshaft position sensor connector .

NOTE

Doing this will prevent the engine control unit fro m carrying

out ignition and fuel injection.

Cover the spark plug hole with a shop towel etc., a nd

after the engine has been cranked, check that no fo reign

material is adhering to the shop towel.

TSB Revision

Page 72 of 2103

ENGINE On-vehicle

Caution

1.Keep away from the spark plug hole when crank-

ing.

2. If compression is measured with water, oil, fuel,

etc., that has come from cracks inside the cylinder ,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

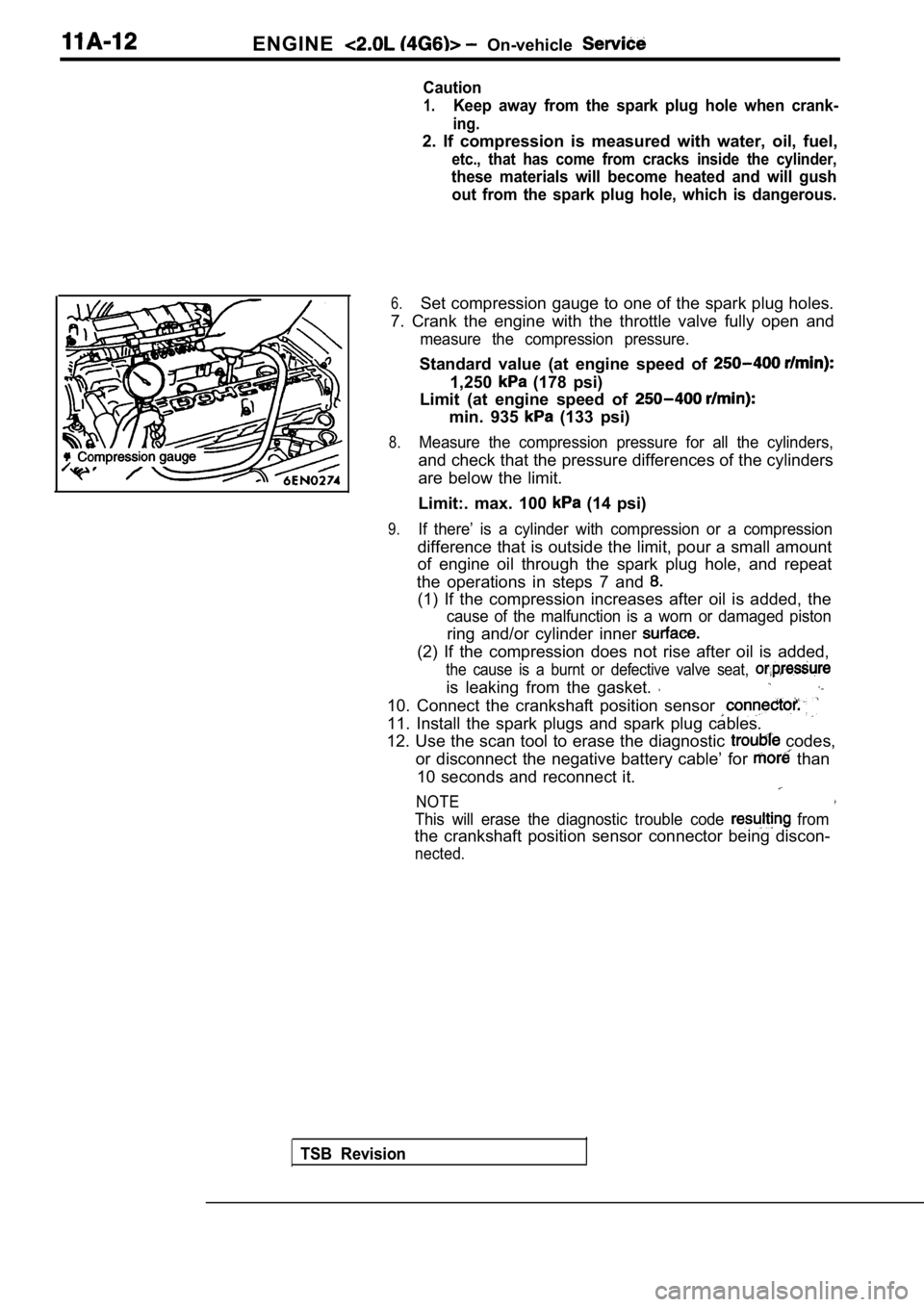

6.Set compression gauge to one of the spark plug hole s.

7. Crank the engine with the throttle valve fully o pen and

measure the compression pressure.

Standard value (at engine speed of

1,250 (178 psi)

Limit (at engine speed of

min. 935 (133 psi)

8.Measure the compression pressure for all the cylind ers,

and check that the pressure differences of the cylinders

are below the limit.

Limit:. max. 100

(14 psi)

9.If there’ is a cylinder with compression or a compr ession

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repe at

the operations in steps 7 and

(1) If the compression increases after oil is added , the

cause of the malfunction is a worn or damaged pisto n

ring and/or cylinder inner

(2) If the compression does not rise after oil is added,

the cause is a burnt or defective valve seat,

is leaking from the gasket.

10. Connect the crankshaft position sensor

11. Install the spark plugs and spark plug cables.

12. Use the scan tool to erase the diagnostic

codes,

or disconnect the negative battery cable’ for

than

10 seconds and reconnect it.

NOTE

This will erase the diagnostic trouble code from

the crankshaft position sensor connector being disc on-

nected.

TSB Revision

Page 73 of 2103

ENGINE On-vehicle Service

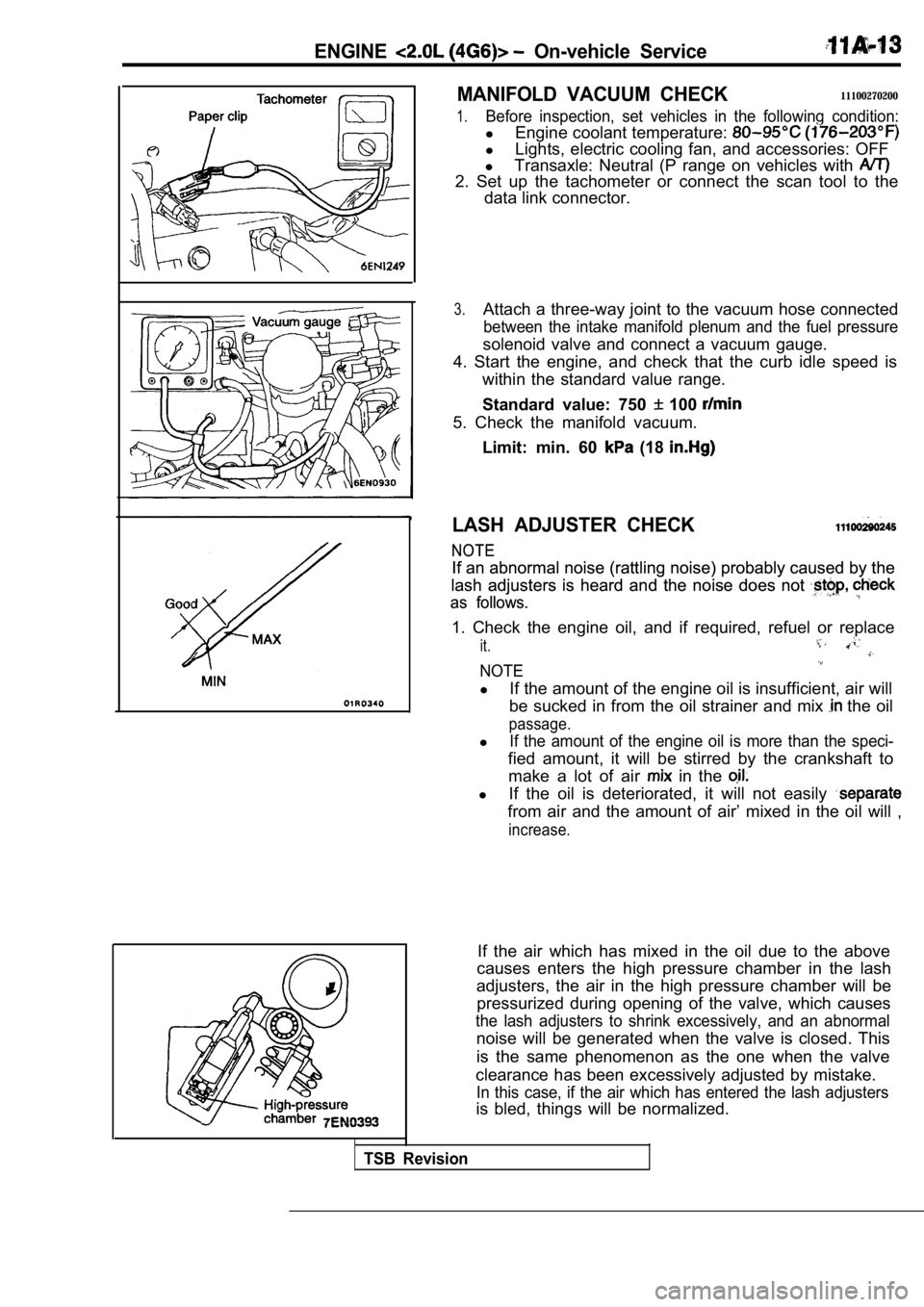

MANIFOLD VACUUM CHECK11100270200

1.Before inspection, set vehicles in the following condition:

lEngine coolant temperature:

lLights, electric cooling fan, and accessories: OFF

l Transaxle: Neutral (P range on vehicles with

2. Set up the tachometer or connect the scan tool t o the

data link connector.

3.Attach a three-way joint to the vacuum hose connect ed

between the intake manifold plenum and the fuel pressure

solenoid valve and connect a vacuum gauge.

4. Start the engine, and check that the curb idle s peed is

within the standard value range.

Standard value: 750

100

5. Check the manifold vacuum.

Limit: min. 60

(18

LASH ADJUSTER CHECK

NOTE

NOTE

If an abnormal noise (rattling noise) probably caus ed by the

If an abnormal noise (rattling noise) probably caus ed by the

lash adjusters is heard and the noise does not

lash adjusters is heard and the noise does not

as follows.

as follows.

1. Check the engine oil, and if required, refuel or replace

it.

NOTE

lIf the amount of the engine oil is insufficient, ai r will

be sucked in from the oil strainer and mix

the oil

passage.

lIf the amount of the engine oil is more than the sp eci-

fied amount, it will be stirred by the crankshaft to

make a lot of air

in the

l If the oil is deteriorated, it will not easily

from air and the amount of air’ mixed in the oil wi ll ,

increase.

If the air which has mixed in the oil due to the ab ove

causes enters the high pressure chamber in the lash

adjusters, the air in the high pressure chamber wil l be

pressurized during opening of the valve, which caus es

the lash adjusters to shrink excessively, and an abnormal

noise will be generated when the valve is closed. T his

is the same phenomenon as the one when the valve

clearance has been excessively adjusted by mistake.

In this case, if the air which has entered the lash adjusters

is bled, things will be normalized.

TSB Revision

Page 74 of 2103

ENGINE On-vehicle Service

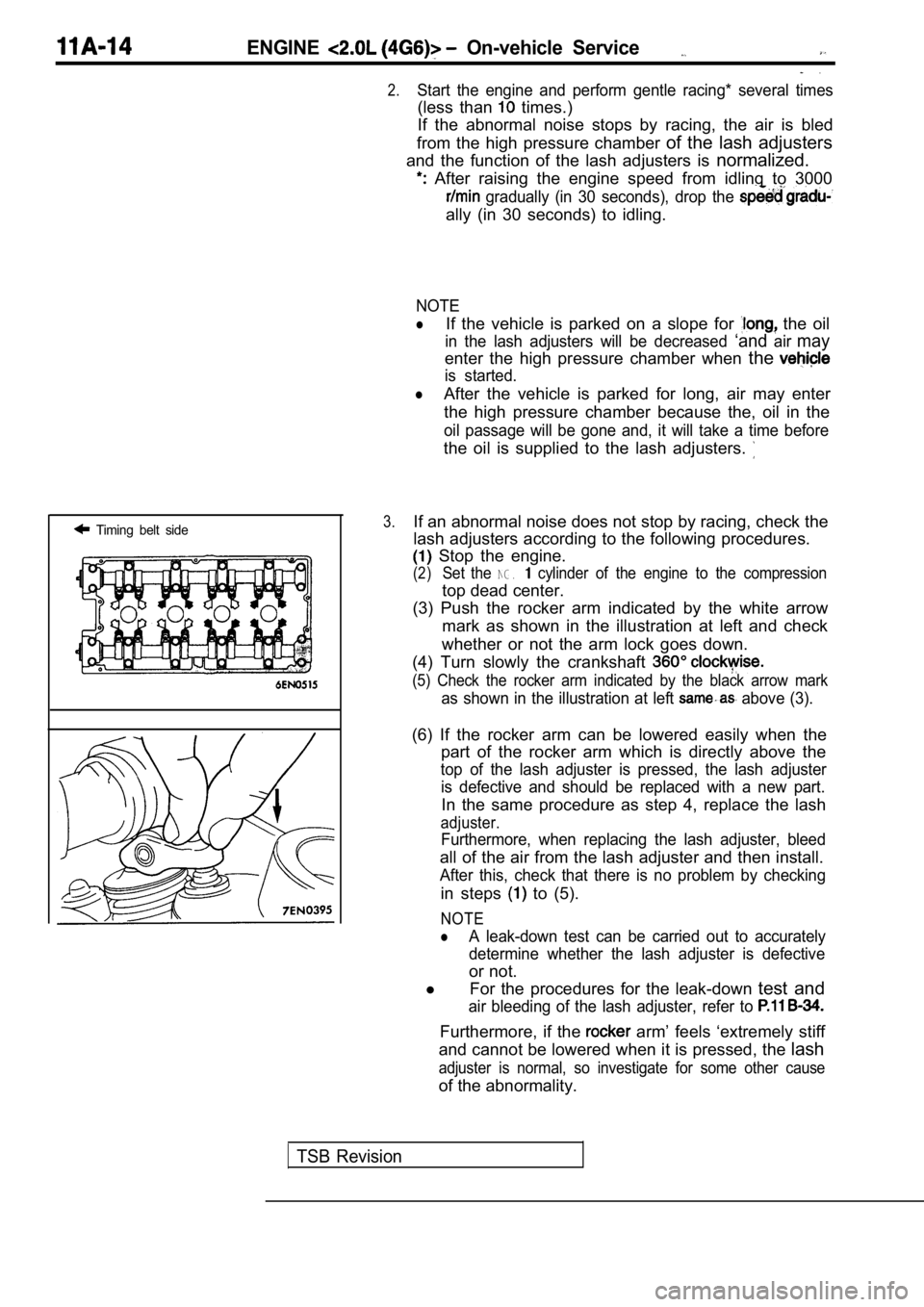

Timing belt side

.

2.Start the engine and perform gentle racing* several times

(less than times.)

If the abnormal noise stops by racing, the air is b led

from the high pressure chamber of the lash adjusters

and the function of the lash adjusters is normalized.

After raising the engine speed from idling to 3000

gradually (in 30 seconds), drop the

ally (in 30 seconds) to idling.

NOTE

lIf the vehicle is parked on a slope for the oil

in the lash adjusters will be decreased ‘andairmay

enter the high pressure chamber when the

is started.

lAfter the vehicle is parked for long, air may enter

the high pressure chamber because the, oil in the

oil passage will be gone and, it will take a time b efore

the oil is supplied to the lash adjusters.

3.If an abnormal noise does not stop by racing, check the

lash adjusters according to the following procedure s.

Stop the engine.

(2)Set the NG. cylinder of the engine to the compression

top dead center.

(3) Push the rocker arm indicated by the white arro w

mark as shown in the illustration at left and check

whether or not the arm lock goes down.

(4) Turn slowly the crankshaft

(5) Check the rocker arm indicated by the black arr ow mark

as shown in the illustration at left above (3).

(6) If the rocker arm can be lowered easily when th e

part of the rocker arm which is directly above the

top of the lash adjuster is pressed, the lash adjus ter

is defective and should be replaced with a new part .

In the same procedure as step 4, replace the lash

adjuster.

Furthermore, when replacing the lash adjuster, bleed

all of the air from the lash adjuster and then install.

After this, check that there is no problem by check ing

in steps to (5).

NOTE

lA leak-down test can be carried out to accurately

determine whether the lash adjuster is defective

or not.

l For the procedures for the leak-down test and

air bleeding of the lash adjuster, refer to

Furthermore, if the arm’ feels ‘extremely stiff

and cannot be lowered when it is pressed, the lash

adjuster is normal, so investigate for some other c ause

of the abnormality.

TSB Revision

Page 75 of 2103

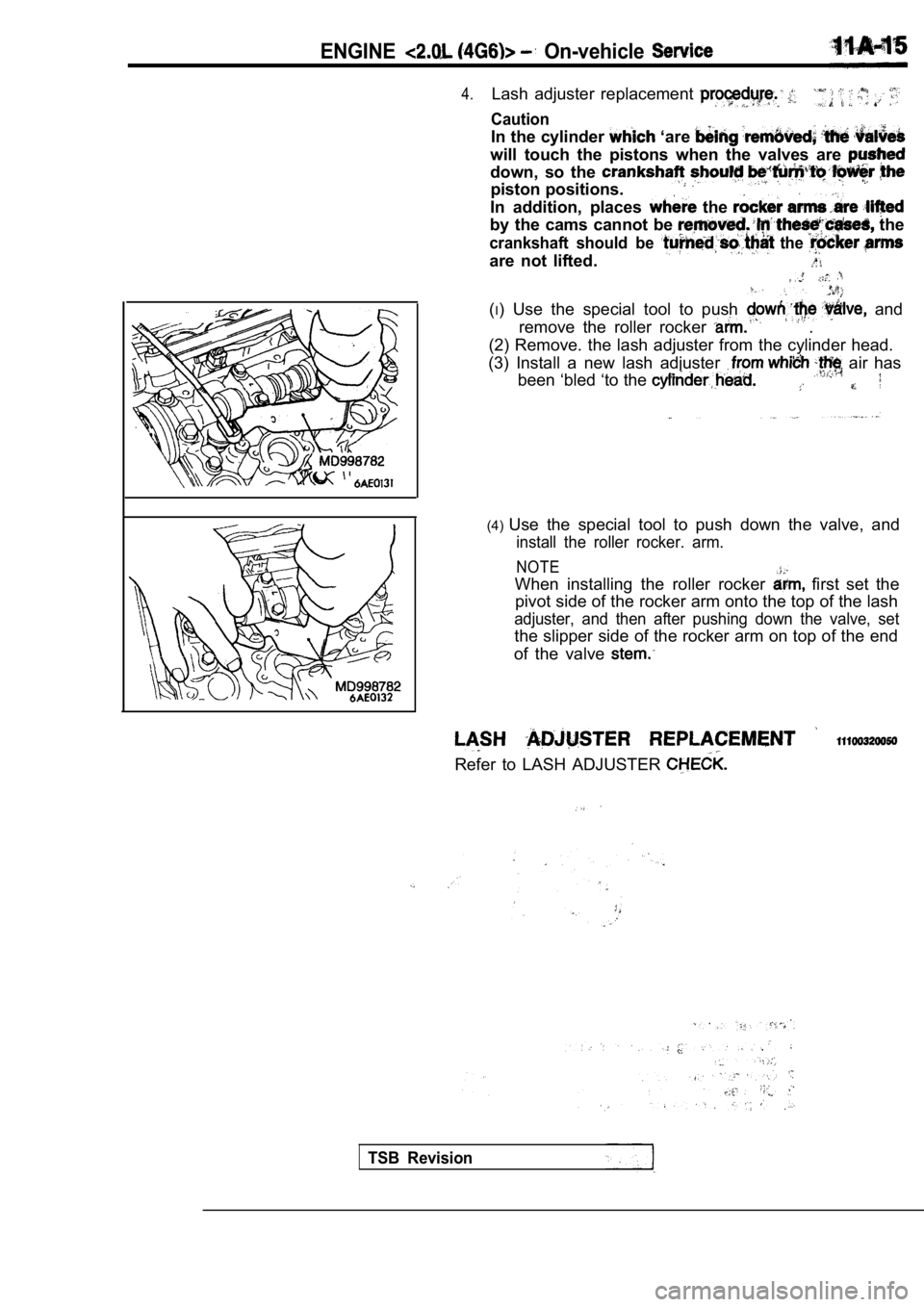

ENGINE On-vehicle

4.Lash adjuster replacement

Caution

In the cylinder ‘are

will touch the pistons when the valves are

down, so the

piston positions.

In addition, places the

by the cams cannot be the

crankshaft should be the

are not lifted.

(I) Use the special tool to push and

remove the roller rocker

.

(2) Remove. the lash adjuster from the cylinder hea d.

(3) Install a new lash adjuster

air has

been ‘bled ‘to the

(4) Use the special tool to push down the valve, and

install the roller rocker. arm.

NOTE

When installing the roller rocker first set the

pivot side of the rocker arm onto the top of the la sh

adjuster, and then after pushing down the valve, se t

the slipper side of the rocker arm on top of the end

of the valve

Refer to LASH ADJUSTER

TSB Revision

Page 76 of 2103

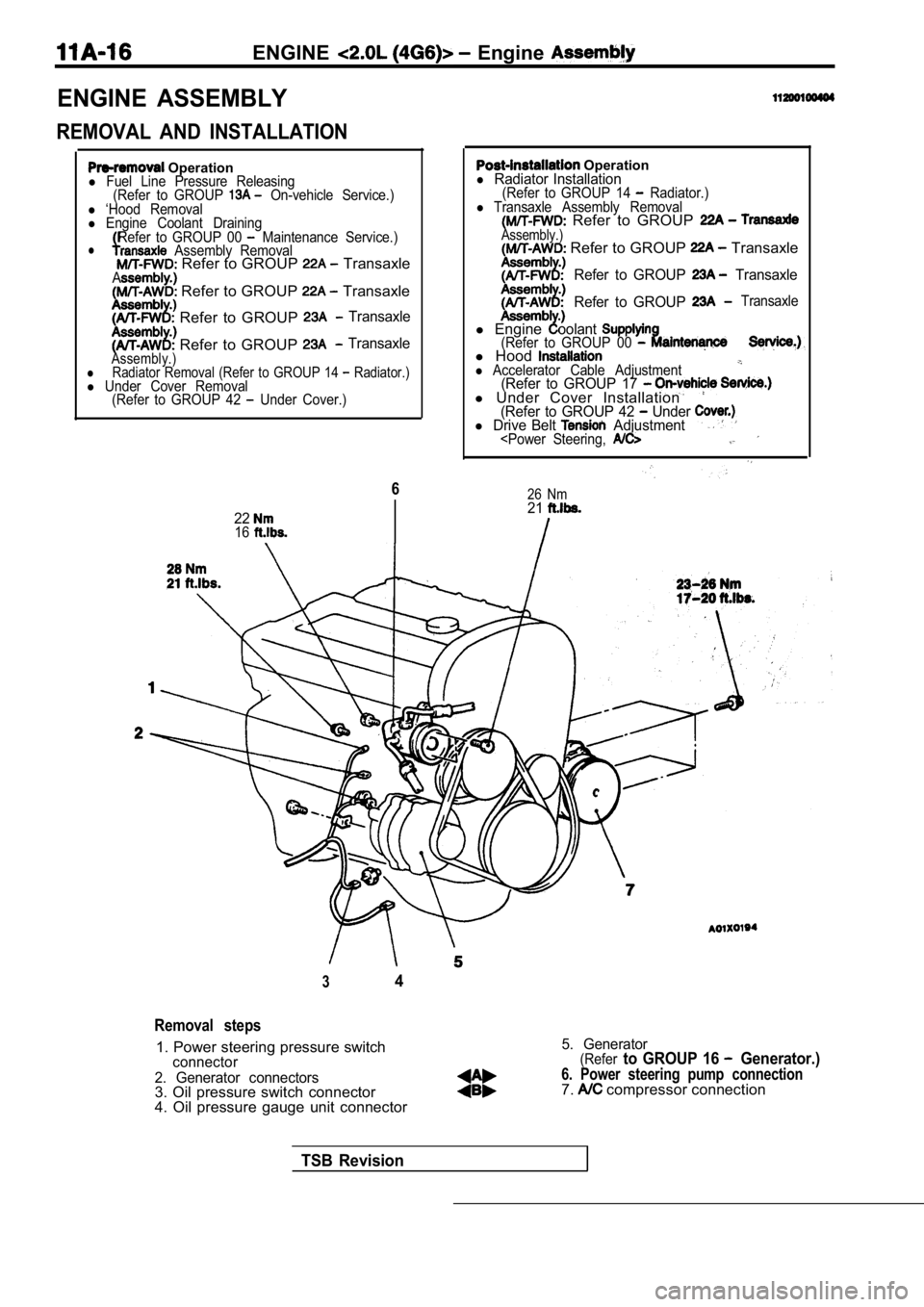

ENGINE Engine

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Operationl Fuel Line Pressure Releasing(Refer to GROUP On-vehicle Service.)l ‘Hood Removall Engine Coolant DrainingRefer to GROUP 00 Maintenance Service.)l Assembly Removal Refer to GROUP TransaxleA Refer to GROUP Transaxle

Refer to GROUP Transaxle

Refer to GROUP TransaxleAssembly.)lRadiator Removal (Refer to GROUP 14 Radiator.)l Under Cover Removal (Refer to GROUP 42 Under Cover.)

6

2216

Operationl Radiator Installation(Refer to GROUP 14 Radiator.)l Transaxle Assembly Removal Refer to GROUP Assembly.) Refer to GROUP Transaxle

Refer to GROUP Transaxle

Refer to GROUP

Transaxle

l Engineoolant(Refer to GROUP 00 l Hoodl Accelerator Cable Adjustment(Refer to GROUP 17 l Under Cover Installation(Refer to GROUP 42 Under l Drive Belt Adjustment

34

Removal steps

1. Power steering pressure switchconnector

2. Generator connectors

3. Oil pressure switch connector

4. Oil pressure gauge unit connector

5. Generator(Referto GROUP 16 Generator.)

6. Power steering pump connection7. compressor connection

TSB Revision

Page 77 of 2103

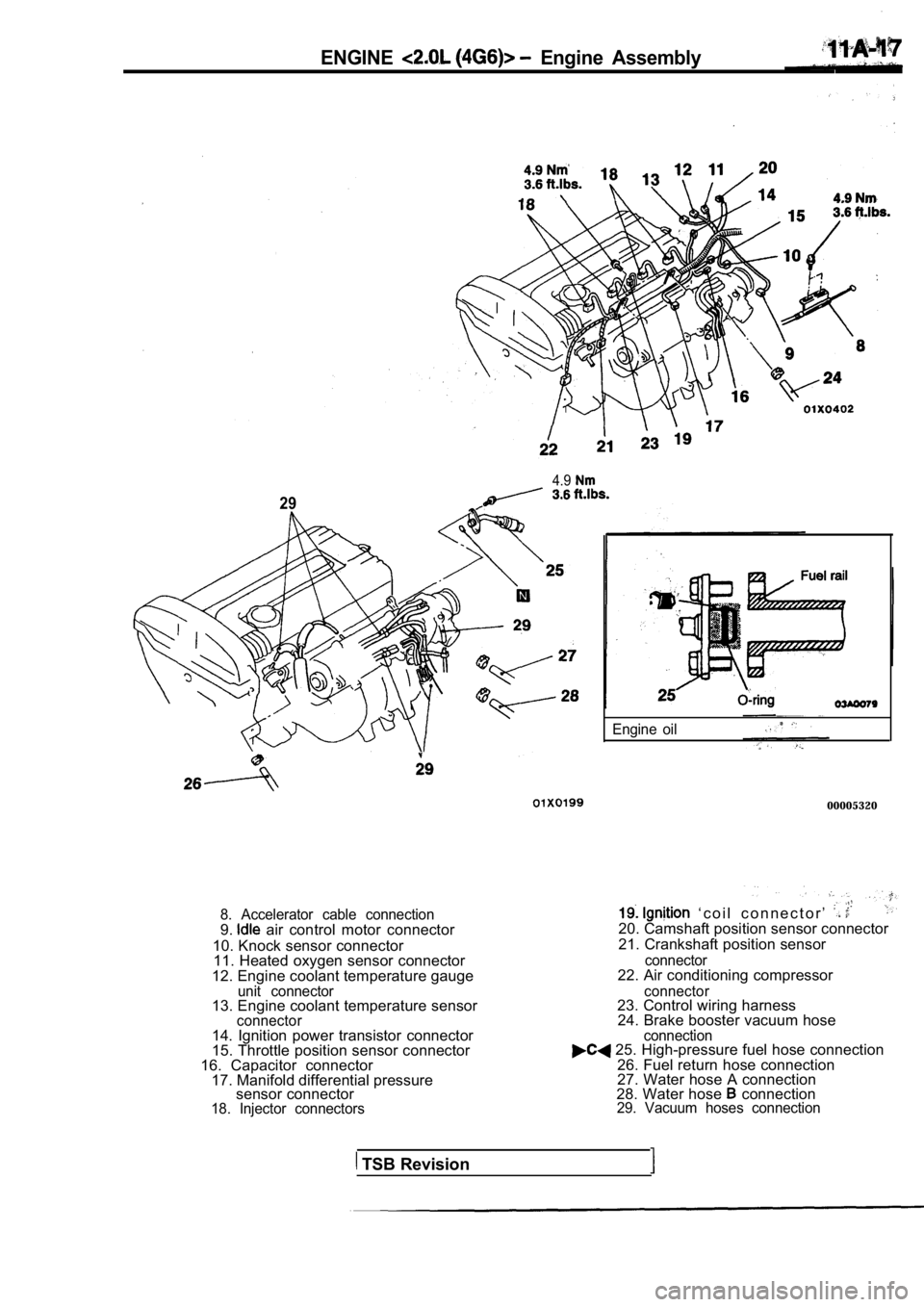

ENGINE Engine Assembly

4.9

29

8. Accelerator cable connection9. air control motor connector

10. Knock sensor connector 11. Heated oxygen sensor connector

12. Engine coolant temperature gauge

unit connector13. Engine coolant temperature sensorconnector

Engine oil

00005320

‘ c o i l c o n n e c t o r ’ 20. Camshaft position sensor connector

21. Crankshaft position sensor

connector22. Air conditioning compressor

connector23. Control wiring harness 24. Brake booster vacuum hose .

14. Ignition power transistor connector

15. Throttle position sensor connector

16. Capacitor connector 17. Manifold differential pressure sensor connector

18. Injector connectors connection

25. High-pressure fuel hose connection

26. Fuel return hose connection

27. Water hose A connection

28. Water hose

connection29. Vacuum hoses connection

TSB Revision

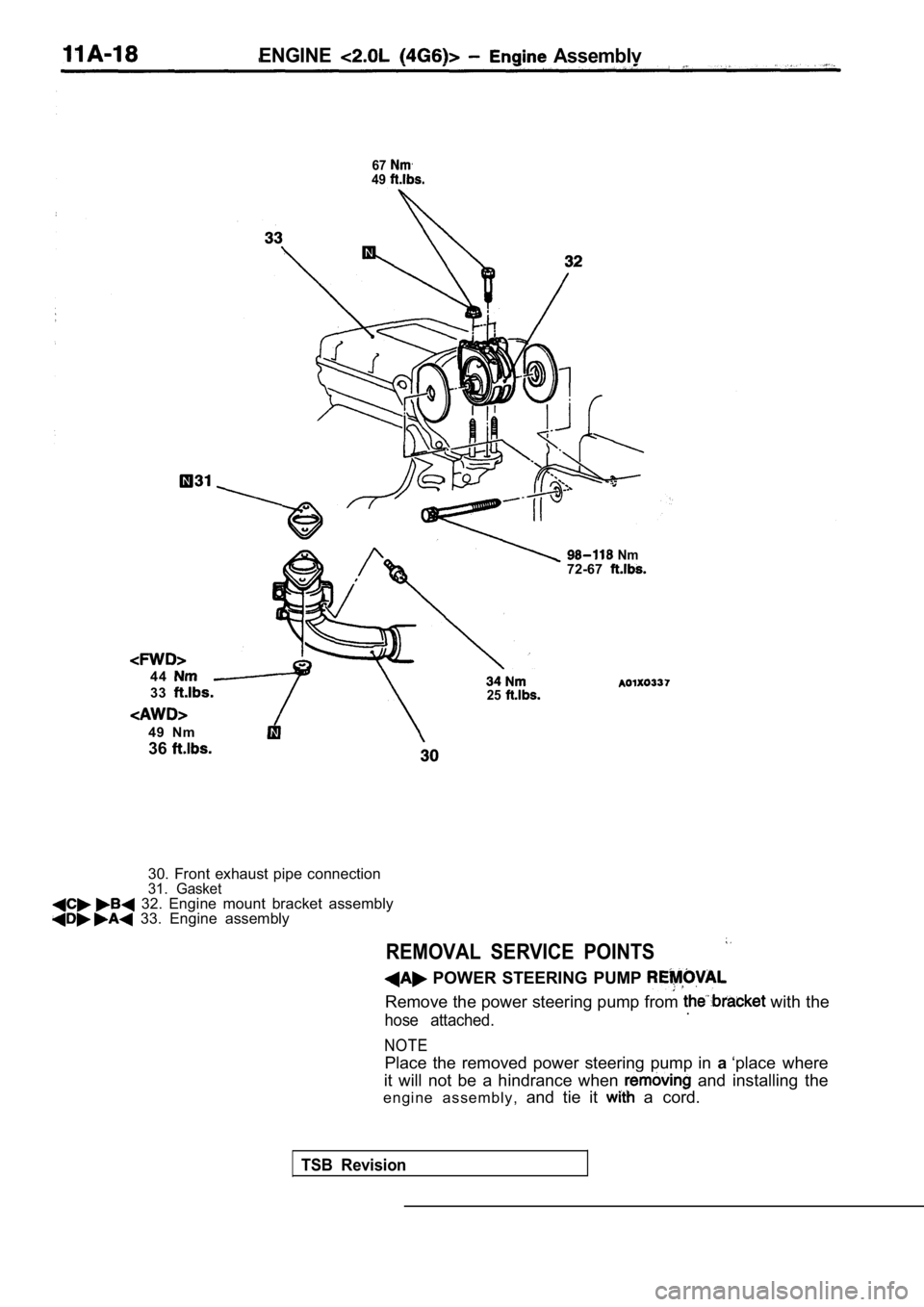

Page 78 of 2103

ENGINE Assemblv

6749

4 4

3325

Nm72-67

49 Nm

36

30. Front exhaust pipe connection31. Gasket 32. Engine mount bracket assembly 33. Engine assembly

REMOVAL SERVICE POINTS

POWER STEERING PUMP

Remove the power steering pump from with the

hose attached..

NOTE

Place the removed power steering pump in a‘place where

it will not be a hindrance when

and installing the

engine assembly, and tie it

a cord.

TSB Revision

Page 79 of 2103

ENGINE -‘Engine Assembly

COMPRESSOR

Disconnect the compressor connector and remove the

compressor from the compressor bracket

the hose

attached.

NOTE

Place the removed A/C compressor in a where it will

not be a hindrance when removing ‘and installing th e engine

assembly, and tie it with a cord:

Caution

Do not bend the joint the A/C hose and the

pipe by force.

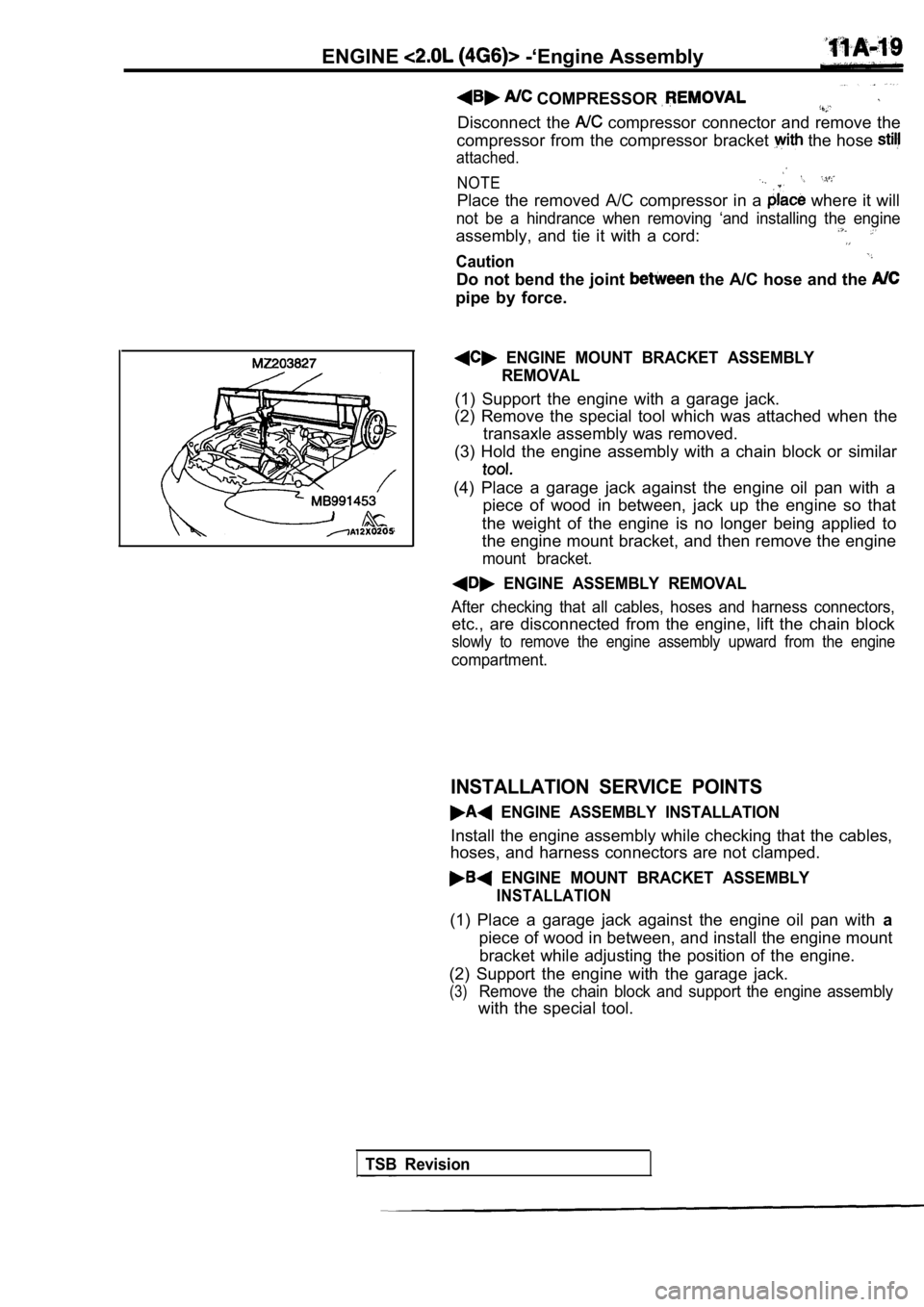

ENGINE MOUNT BRACKET ASSEMBLY

REMOVAL

(1) Support the engine with a garage jack.

(2) Remove the special tool which was attached when the

transaxle assembly was removed.

(3) Hold the engine assembly with a chain block or similar

(4) Place a garage jack against the engine oil pan with a

piece of wood in between, jack up the engine so tha t

the weight of the engine is no longer being applied to

the engine mount bracket, and then remove the engin e

mount bracket.

ENGINE ASSEMBLY REMOVAL

After checking that all cables, hoses and harness connectors,

etc., are disconnected from the engine, lift the chain block

slowly to remove the engine assembly upward from th e engine

compartment.

INSTALLATION SERVICE POINTS

ENGINE ASSEMBLY INSTALLATION

Install the engine assembly while checking that the cables,

hoses, and harness connectors are not clamped.

ENGINE MOUNT BRACKET ASSEMBLY

INSTALLATION

(1) Place a garage jack against the engine oil pan with a

piece of wood in between, and install the engine mo unt

bracket while adjusting the position of the engine.

(2) Support the engine with the garage jack.

(3)Remove the chain block and support the engine assem bly

with the special tool.

TSB Revision

Page 80 of 2103

ENGINE Engine ,

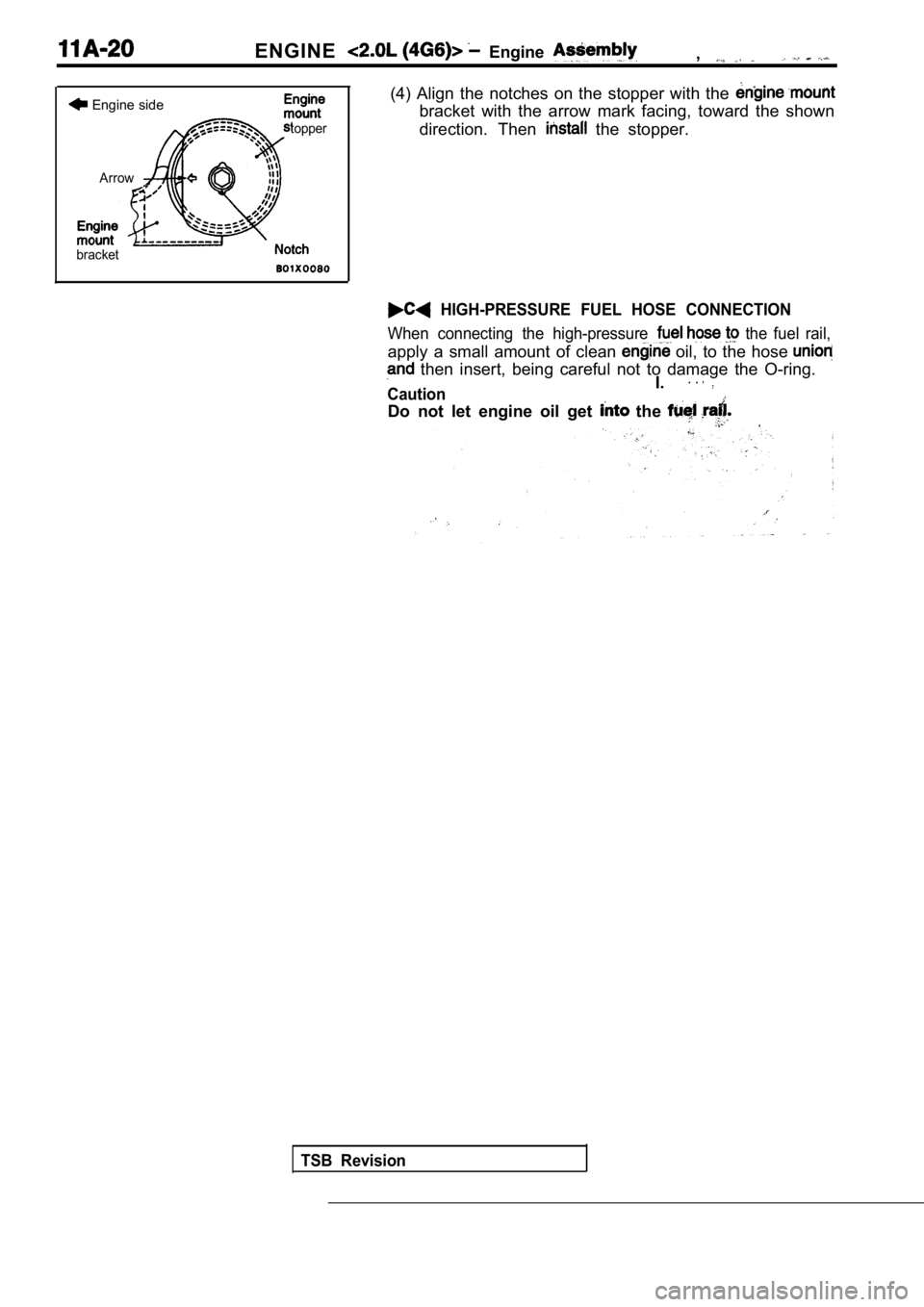

Engine side

Arrow

topper

bracket

(4) Align the notches on the stopper with the

bracket with the arrow mark facing, toward the show n

direction. Then

the stopper.

HIGH-PRESSURE FUEL HOSE CONNECTION

When connecting the high-pressure the fuel rail,

apply a small amount of clean oil, to the hose

then insert, being careful not to damage the O-rin g.. .

CautionI.

Do not let engine oil get the .

TSB Revision