MITSUBISHI SPYDER 1990 Service Manual PDF

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 61 of 2103

ENGINE

CONTENTS

CAMSHAFT AND CAMSHAFT OIL

SEAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

CRANKSHAFT FRONT OIL SEAL . . . . . . . 28

CRANKSHAFT PULLEY . . . . . . . . . . . . . . . . . 21

CRANKSHAFT REAR OIL SEAL. . . . . . . .29

Curb Speed Check. . . . . . . . . . . . . . . . . .10

Drive Belt Tension Check and

Adjustment . , . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mixture Check . . . . . . . . . . . . . . . . . .

. . . . .10

Ignition Timing Check. . . . . . . . . . . .. . . . . . . . .

Lash Adjuster Check . . . . . . . . . . . . . . . .

CYLINDER HEAD GASKET . . . . . . . . . . . . .31

ENGINE ASSEMBLY. . . . . . . . . . . . . . . . . . . .16

GENERAL INFORMATION. . . . . . . . . . . . . . . .2

OIL PAN AND OIL SCREEN . . . . . . . . . . . .26

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . .7

Basic Idle Speed Adjustment

. . . . . . . . . . . . . . . . . . . . . . Refer to GROUP

Lash Adjuster Replacement. . . . . . . .. . . .15

Manifold Vacuum Check. . . . . . . . . . . . . . . ....13

SEALANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SPECIFICATIONS. . . . . . . . . . . . . .3

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . .4

BELT. . . . . . . . . . . . . . . . . . . . . . . . . . .36

TIMING BELT . . . . . . . . . . . . . . . . . . . . . . . .41

Compression Pressure Check . . . . . . . . . . . .

. . 11TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . 6

Page 62 of 2103

ENGINE General Information

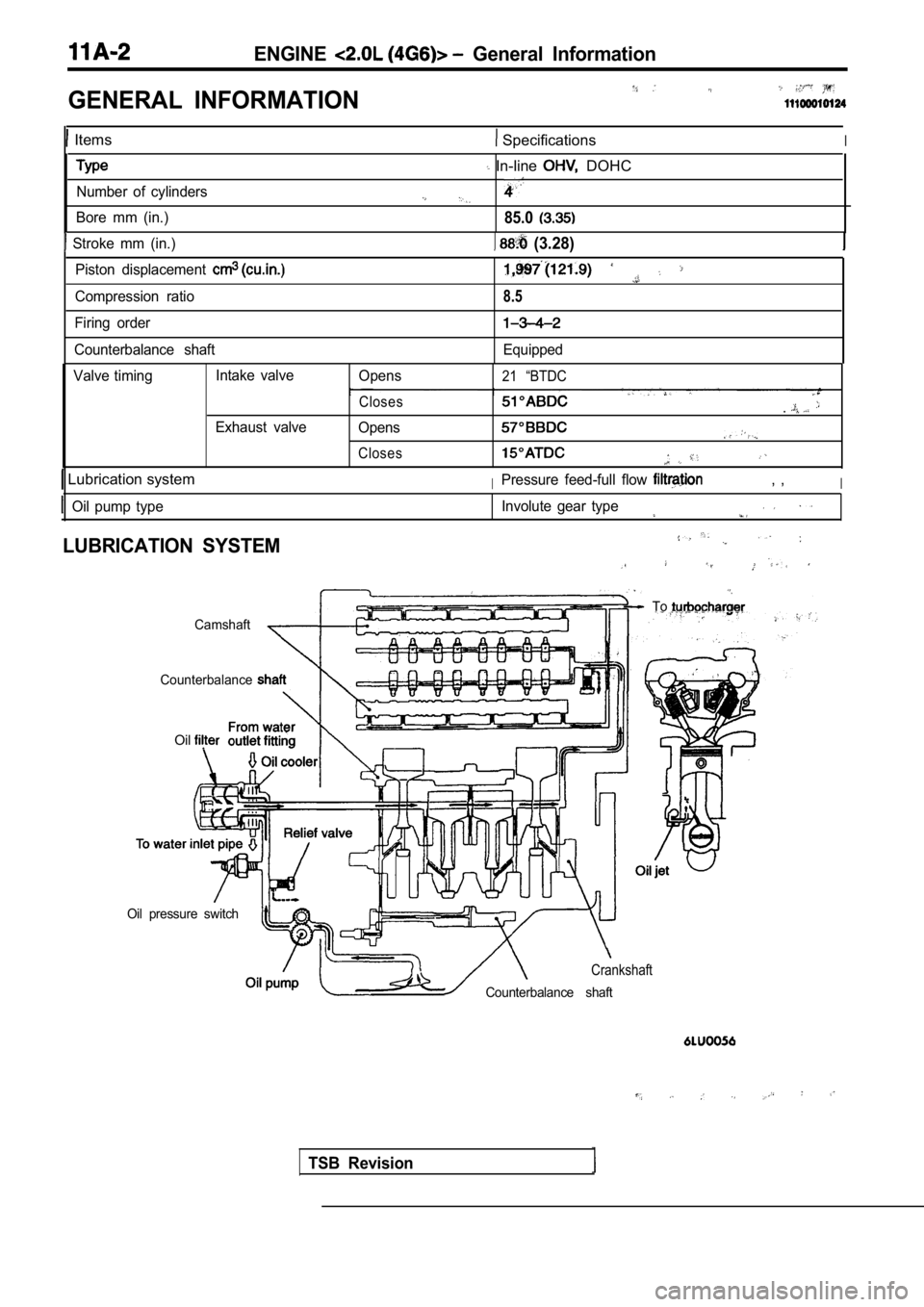

GENERAL INFORMATION

Items SpecificationsI

Number of cylinders

Bore mm (in.)

Stroke mm (in.)

In-line DOHC

85.0

(3.28)

Piston displacement

Compression ratio

Firing order

Counterbalance shaft8.5

Equipped

Valve timing Intake valve

Exhaust valve Opens

Closes

Opens

Closes 21 “BTDC

.

Lubrication systemIPressure feed-full flow , ,I

Oil pump type

LUBRICATION SYSTEM

Involute gear type

To

Camshaft

Counterbalance

TSB Revision

Oil

Oil pressure switch

Crankshaft

Counterbalance shaft

Page 63 of 2103

ENGINE Service Specifications

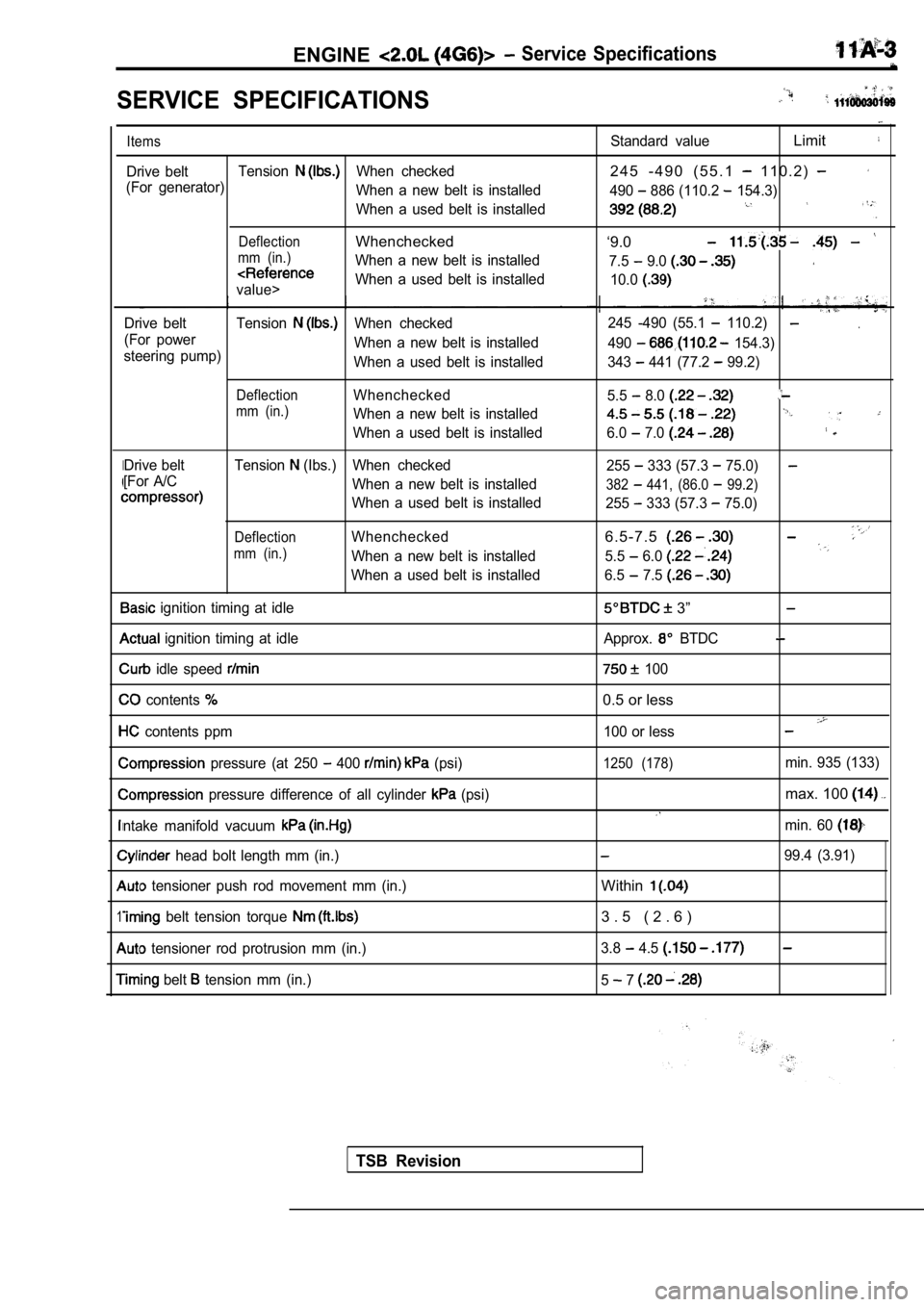

SERVICE SPECIFICATIONS

I

1

Items

Drive beltTensionWhen checked

(For generator) When a new belt is installed

When a used belt is installed

DeflectionWhenchecked

mm (in.)When a new belt is installed

value>When a used belt is installed

Drive belt Tension

When checked

(For power When a new belt is installed

steering pump) When a used belt is installed

DeflectionWhenchecked

mm (in.)When a new belt is installed

When a used belt is installed

Drive belt Tension

(Ibs.) When checked

[For A/C When a new belt is installed

When a used belt is installed

DeflectionWhenchecked

mm (in.)When a new belt is installed

When a used belt is installed

ignition timing at idle

ignition timing at idle

idle speed

contents

contents ppm

pressure (at 250 400 (psi)

pressure difference of all cylinder (psi)

ntake manifold vacuum

head bolt length mm (in.)

tensioner push rod movement mm (in.)

belt tension torque

tensioner rod protrusion mm (in.)

belt tension mm (in.)

Standard valueLimit

2 4 5 - 4 9 0 ( 5 5 . 1 1 1 0 . 2 )

490 886 (110.2 154.3)

‘9.0

7.5 9.0

10.0

.245 -490 (55.1 110.2)

490 154.3)

343

441 (77.2 99.2)

5.5

8.0

6.0 7.0

255 333 (57.3 75.0)

382 441, (86.0 99.2)

255 333 (57.3 75.0)

6 . 5 - 7 . 5

5.5 6.0

6.5 7.5

3”

Approx. BTDC

100

0.5 or less

100 or less

1250 (178)min. 935 (133)

max. 100

min. 60

99.4 (3.91)

Within

3 . 5 ( 2 . 6 )

3.8 4.5

5 7

TSB Revision

Page 64 of 2103

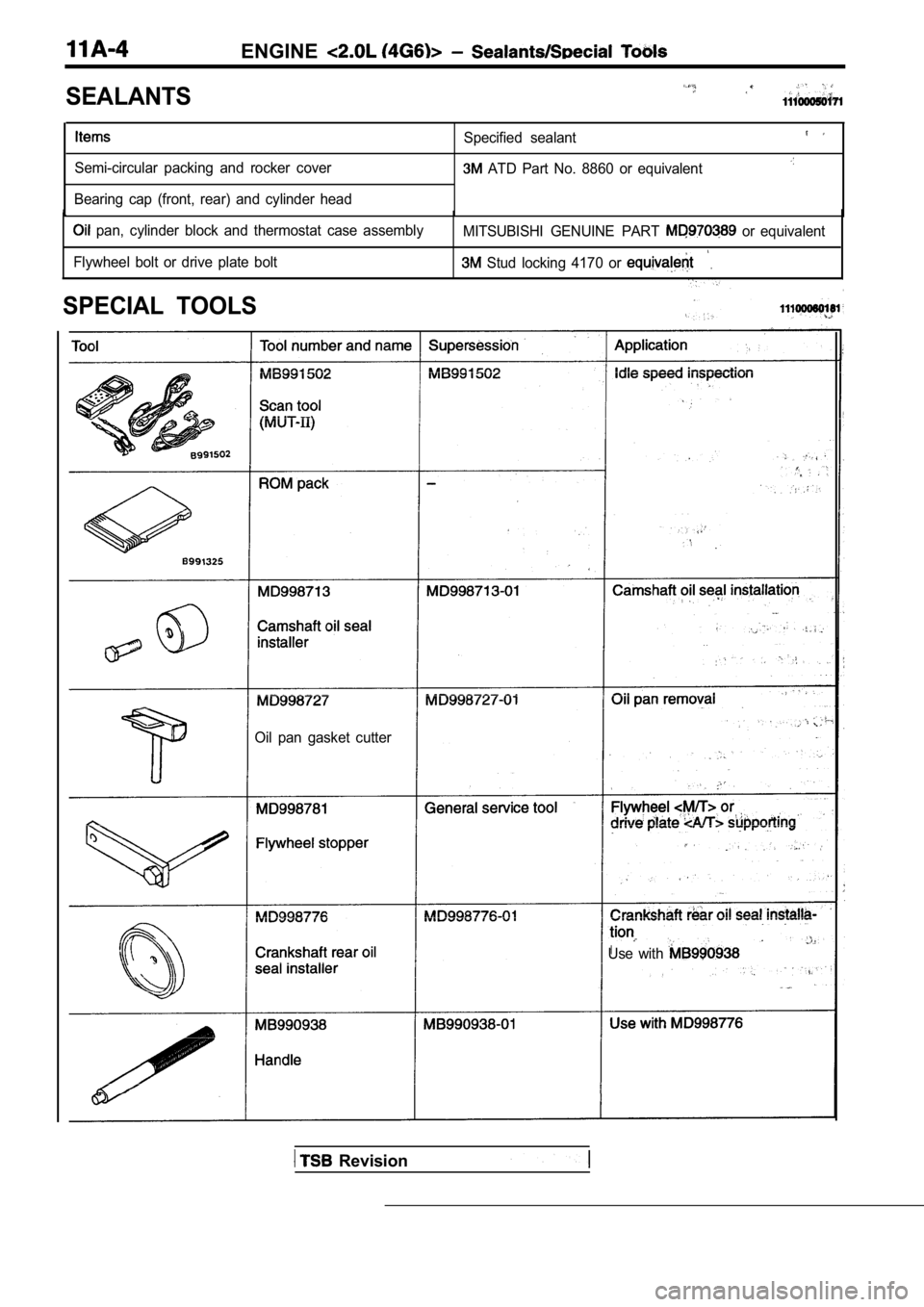

ENGINE

SEALANTS

Semi-circular packing and rocker cover

Bearing cap (front, rear) and cylinder head Specified sealant ATD Part No. 8860 or equivalent

pan, cylinder block and thermostat case assembly

MITSUBISHI GENUINE PART or equivalent

Flywheel bolt or drive plate bolt Stud locking 4170 or .

SPECIAL TOOLS

Oil pan gasket cutter

Use with

Revision

Page 65 of 2103

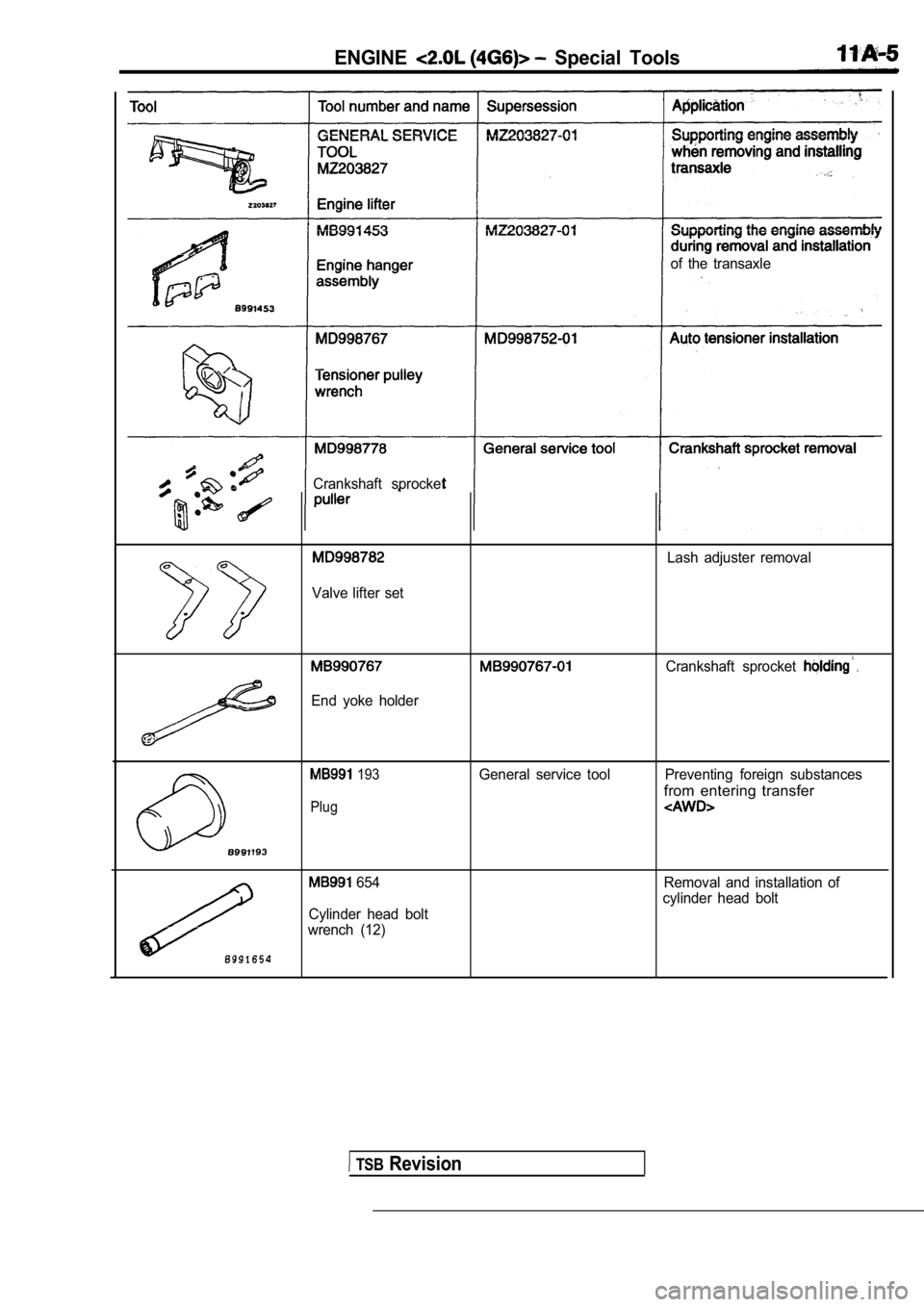

ENGINE Special Tools

of the transaxle

Crankshaft sprocket

Lash adjuster removal

Valve lifter set

. .

End yoke holder

Crankshaft sprocket

193General service tool Preventing foreign substances

from entering transfer

Plug

654

Cylinder head bolt

wrench (12) Removal and installation of

cylinder head bolt

TSB Revision

Page 66 of 2103

ENGINE,

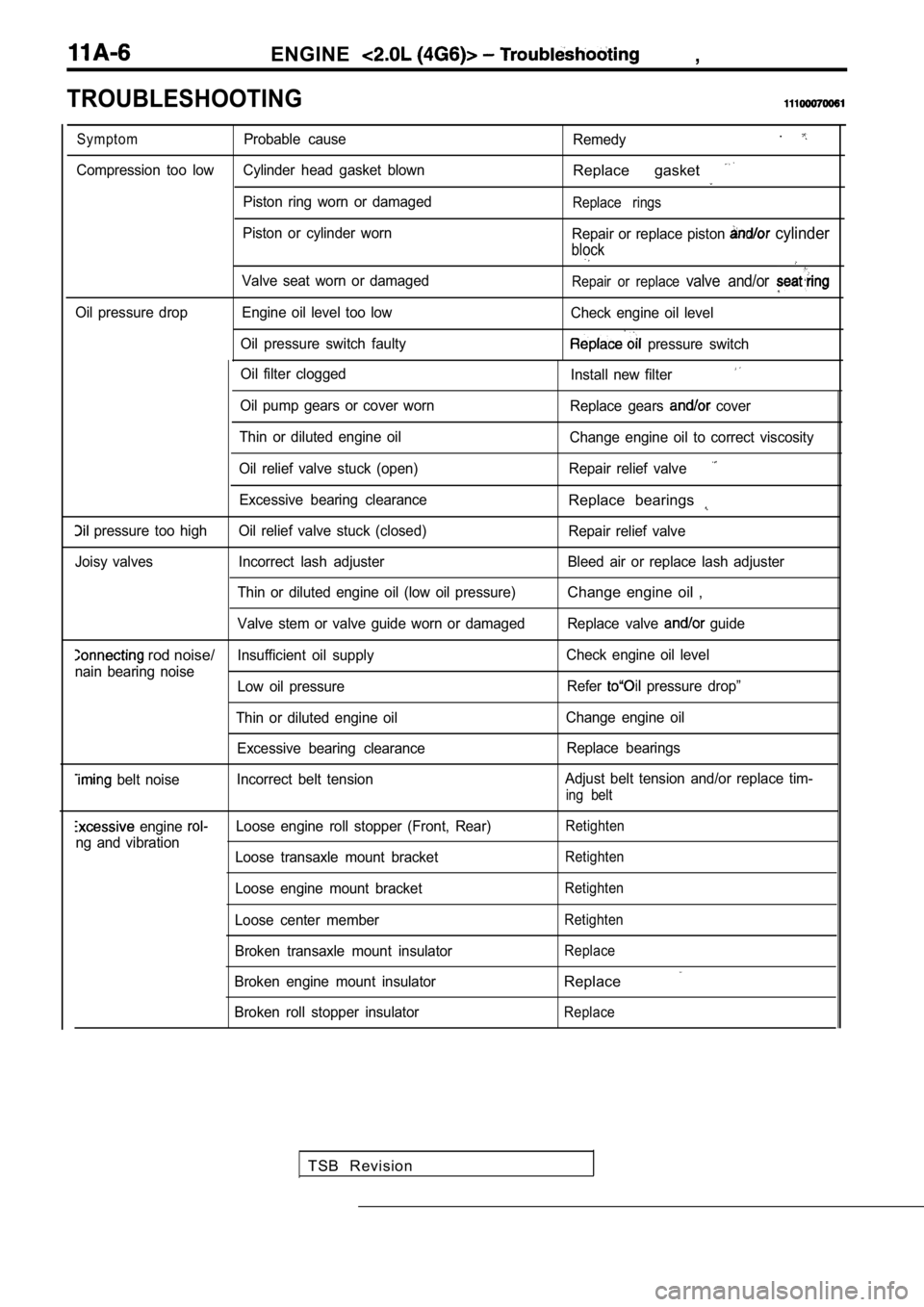

TROUBLESHOOTING

Oil filter cloggedInstall new filter

Oil pump gears or cover wornReplace gears cover

Thin or diluted engine oil Change engine oil to correct viscosity

Oil relief valve stuck (open) Repair relief valve

Excessive bearing clearanceReplace bearings

pressure too high Oil relief valve stuck (closed) Repair relief valve

Joisy valves Incorrect lash adjuster Bleed air or rep lace lash adjuster

Thin or diluted engine oil (low oil pressure)

Change engine oil ,

Valve stem or valve guide worn or damaged Replace va lve guide

rod noise/Insufficient oil supplyCheck engine oil level

nain bearing noise Low oil pressure Refer

pressure drop”

Thin or diluted engine oil Change engine oil

Excessive bearing clearance Replace bearings

belt noiseIncorrect belt tension Adjust belt tension and/or replace tim-ing belt

engine Loose engine roll stopper (Front, Rear)Retighten

ng and vibration

Loose transaxle mount bracketRetighten

Loose engine mount bracketRetighten

Loose center memberRetighten

Broken transaxle mount insulatorReplace

Broken engine mount insulatorReplace

Broken roll stopper insulatorReplace

Symptom

Probable cause

Remedy.

Compression too low Cylinder head gasket blownReplace gasket

Piston ring worn or damagedReplace rings

Piston or cylinder worn

Repair or replace piston cylinder

block

Valve seat worn or damagedRepair or replace valve and/or

Oil pressure drop Engine oil level too low Check engine oil level

Oil pressure switch faulty

pressure switch

TSB Revision

Page 67 of 2103

ENGINE On-vehicle

98 (22

Generator

pulley

pulley

v

pulley

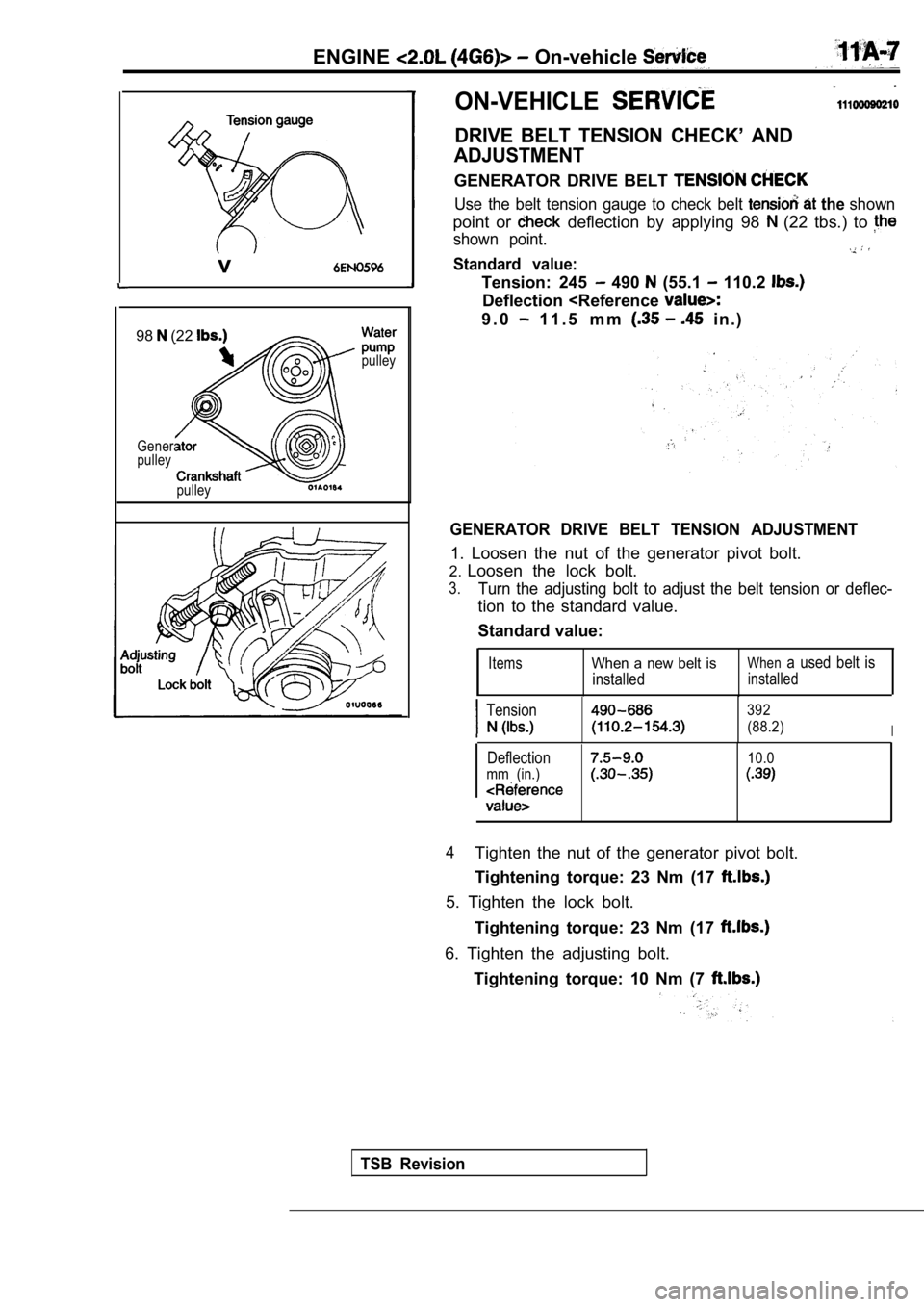

ON-VEHICLE

DRIVE BELT TENSION CHECK’ AND

ADJUSTMENT

GENERATOR DRIVE BELT

Use the belt tension gauge to check belt the shown

point or deflection by applying 98 (22 tbs.) to

shown point.

Standard value:

Tension: 245 490 (55.1 110.2

Deflection

GENERATOR DRIVE BELT TENSION ADJUSTMENT

1. Loosen the nut of the generator pivot bolt.

2. Loosen the lock bolt.

3.Turn the adjusting bolt to adjust the belt tension or deflec-

tion to the standard value.

Standard value:

ItemsWhen a new belt is

installed

Whena used belt is

installed

Tension392

(88.2)I

Deflection10.0

mm (in.)

4Tighten the nut of the generator pivot bolt.

Tightening torque: 23 Nm (17

5. Tighten the lock bolt.

Tightening torque: 23 Nm (17

6. Tighten the adjusting bolt.Tightening torque: 10 Nm (7

TSB Revision

Page 68 of 2103

ENGINE On-vehicle Service

pump pulley

Cranksh

pulley

pulley

a

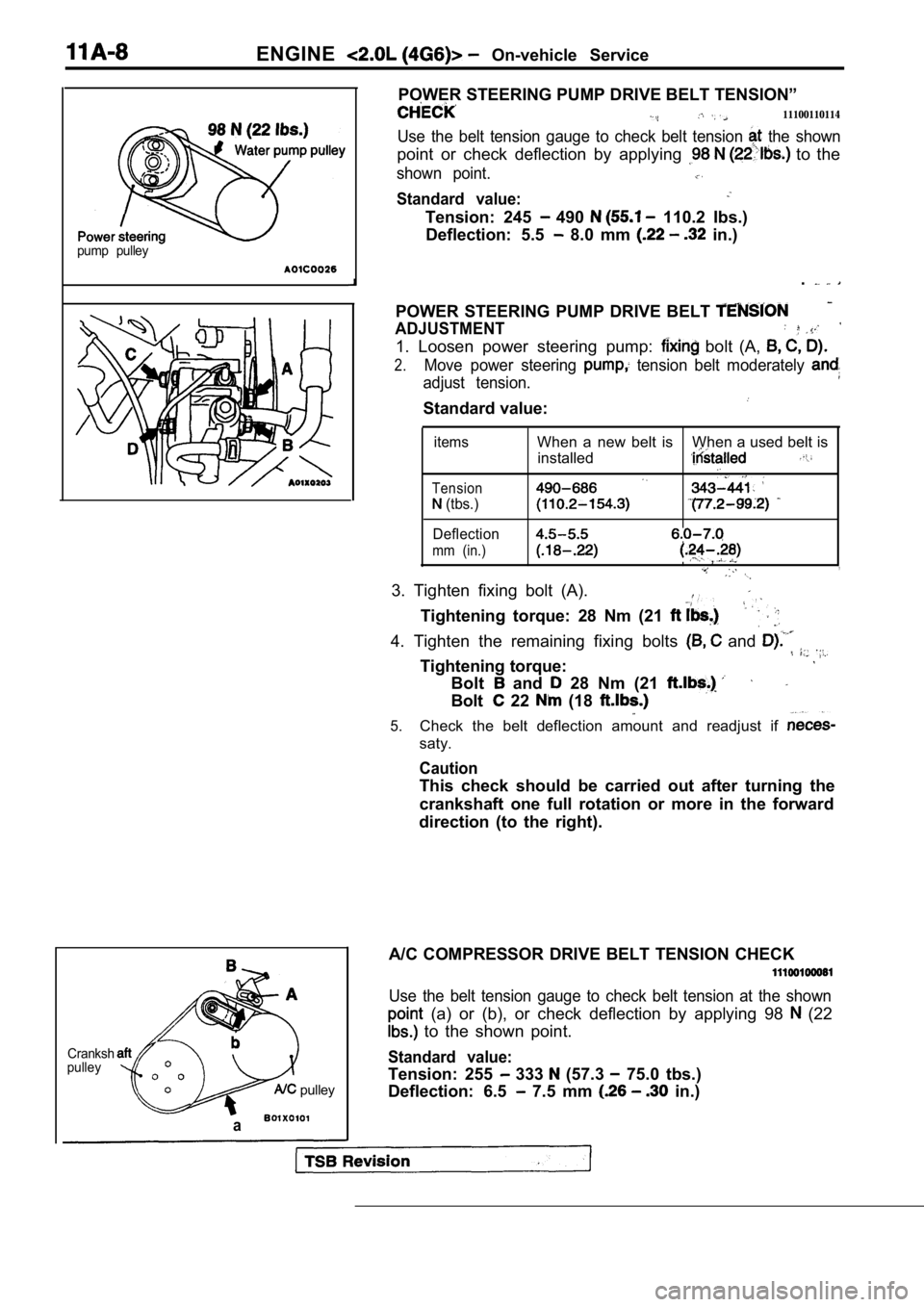

POWER STEERING PUMP DRIVE BELT TENSION”

11100110114

Use the belt tension gauge to check belt tension the shown

point or check deflection by applying to the

shown point.

Standard value:

Tension: 245 490 110.2 Ibs.)

Deflection: 5.5

8.0 mm in.)

.

POWER STEERING PUMP DRIVE BELT

ADJUSTMENT

1. Loosen power steering pump: bolt (A,

2.Move power steering tension belt moderately

adjust tension.

Standard value:

items

Tension

(tbs.)

Deflection

mm (in.)

When a new belt is When a used belt is installed

,,

3. Tighten fixing bolt (A).

Tightening torque: 28 Nm (21

4. Tighten the remaining fixing bolts and

Tightening torque:

Bolt and 28 Nm (21

Bolt 22 (18

5.Check the belt deflection amount and readjust if

saty.

Caution

This check should be carried out after turning the

crankshaft one full rotation or more in the forward

direction (to the right).

A/C COMPRESSOR DRIVE BELT TENSION CHECK

Use the belt tension gauge to check belt tension at the shown

(a) or (b), or check deflection by applying 98 (22

to the shown point.

Standard value:

Tension: 255 333 (57.3 75.0 tbs.)

Deflection: 6.5

7.5 mm in.)

Page 69 of 2103

ENGINE On-vehicle

A/C COMPRESSOR DRIVE BELT TENSION ADJUSTMENT

1. Loosen tension pulley fixing bolt A.

2. Adjust belt tension with adjusting bolt B.

Standard value:

Items

Tension

(Ibs.)

Deflection

When a new belt isWhen a used belt is

installedinstalled

382-411255-333

6.5-7.5

3. Tighten fixing nut A.

Tightening torque: 23-26 Nm

4.Check the belt deflection and readjust if neces-

sary.

Caution

This check should be carried out after turning the

crankshaft one full rotation or more in the forward

direction (to the right).

IGNITION TIMING CHECK

1.Before inspection and adjustment set vehicle in the follow-

ing condition.

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: OFF

lTransaxle: Neutral (P range on vehicles with

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Set up a timing light

4. Start the engine and run at idle.

5. Select No. 22 of the SCAN TOOL DATA LIST.

6.Check that engine idle speed is within the standard

Standard value: 750 100

7. Select No. 17 of the SCAN TOOL ACTUATOR TEST.

8. Check that basic ignition timing is within the standard

value.

Standard value: BTDC

9.If the basic ignition timing is outside the standar d value,

inspect the components by referring to GROUP

Troubleshooting.

10. Press the scan tool clear key (Select a forced driving

cancel mode) to release the ACTUATOR TEST.

NOTE

If the test is not

a forced driving will continue

for 27 minutes. Driving under this condition may damage

the engine.

11. Check that the actual ignition timing is at the standard

value.

Standard value: Approx. BTDC

TSB Revision

Page 70 of 2103

ENGINE On-vehicle Service

NOTE

1.Ignition timing is variable within about even under

operating.

2. And it is automatically further advanced by abou t

from BTDC at higher altitudes.

CURB IDLE SPEED CHECK

1. Before inspection and adjustment, set vehicles in the

following condition.

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: OFF

lTransaxle: Neutral (P range on vehicles with

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Select No. 17 of the SCAN TOOL ACTUATOR TEST.

4. Check the basic ignition timing.

Standard

BTDC

5. Run the engine at idle for 2 minutes.

6. Select No. 22 of the SCAN TOOL DATA LIST.

7. Check the curb idle speed.

Standard value: 750

100

NOTE

The idle speed is controlled automatically by the i dle air

control system.

8. If the idle speed is outside the standard value, inspect

the components by referring to GROUP Trou-

bleshooting.

IDLE MIXTURE CHECK .

1.Before inspection, set in following

lEngine coolant temperature:

lLights, electric cooling fan all

lTransaxle: Neutral (P range on

2. Turn the ignition switch to OFF and, connect the scan

tool to the data link ,

3. Select No. 17 of the SCAN TOOL

4.Check that the basic ignition

value.

Standard value: BTDC

5. Run the engine 2,500 for 2 minutes.

6. Set the CO, HC tester.

7. Check the CO contents and the HC contents, at id le.

Standard value: CO contents: 0.5% or less

HC contents: 100 rpm or less

Revision