MITSUBISHI SPYDER 1990 Service Manual Online

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 81 of 2103

ENGINE Crankshaft

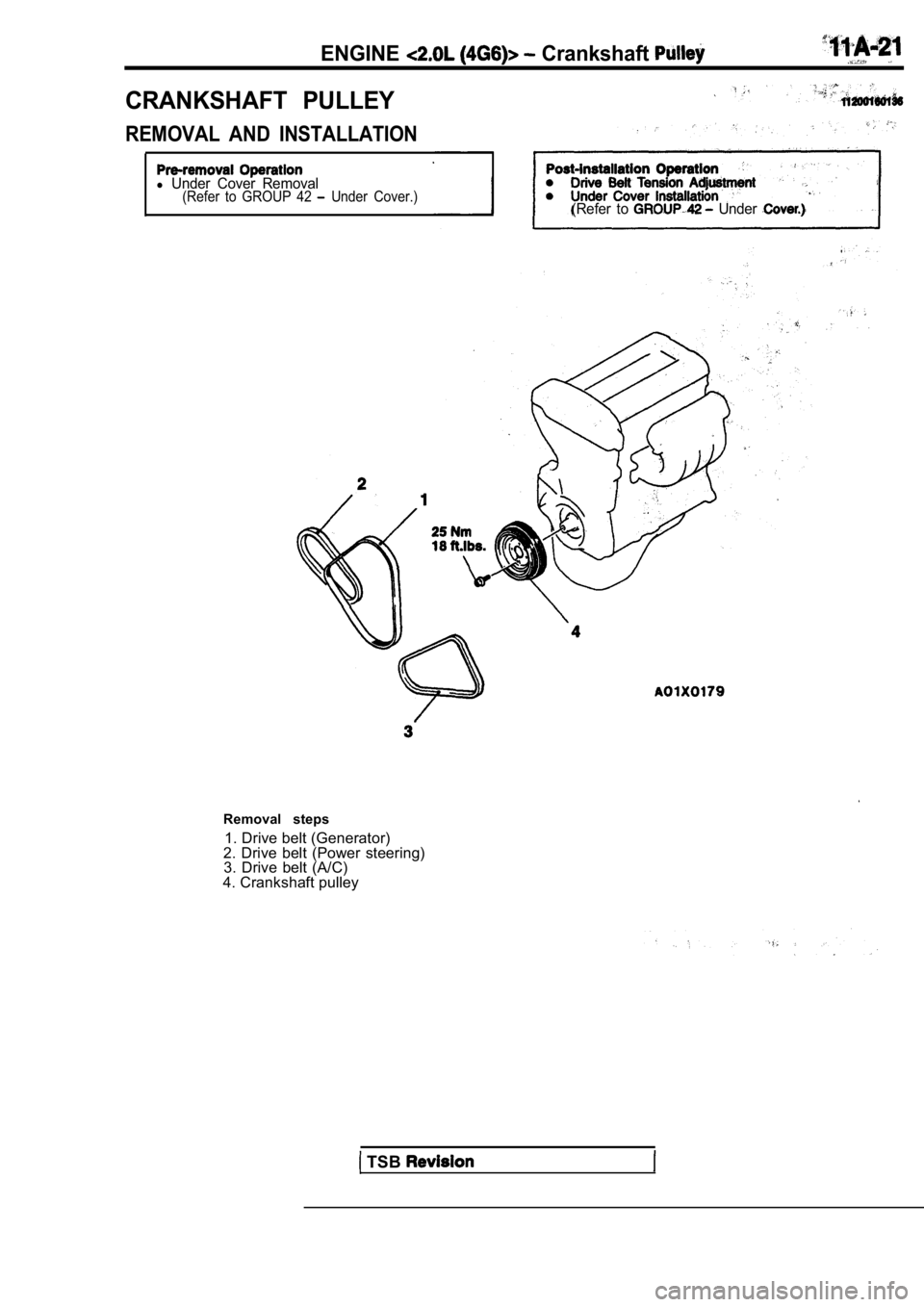

CRANKSHAFT PULLEY

REMOVAL AND INSTALLATION

l Under Cover Removal(Refer to GROUP 42 Under Cover.)(Refer to Under

Removal steps1. Drive belt (Generator)

2. Drive belt (Power steering) 3. Drive belt (A/C)

4. Crankshaft pulley

TSB

Page 82 of 2103

ENGINECamshaft and Oil Seal

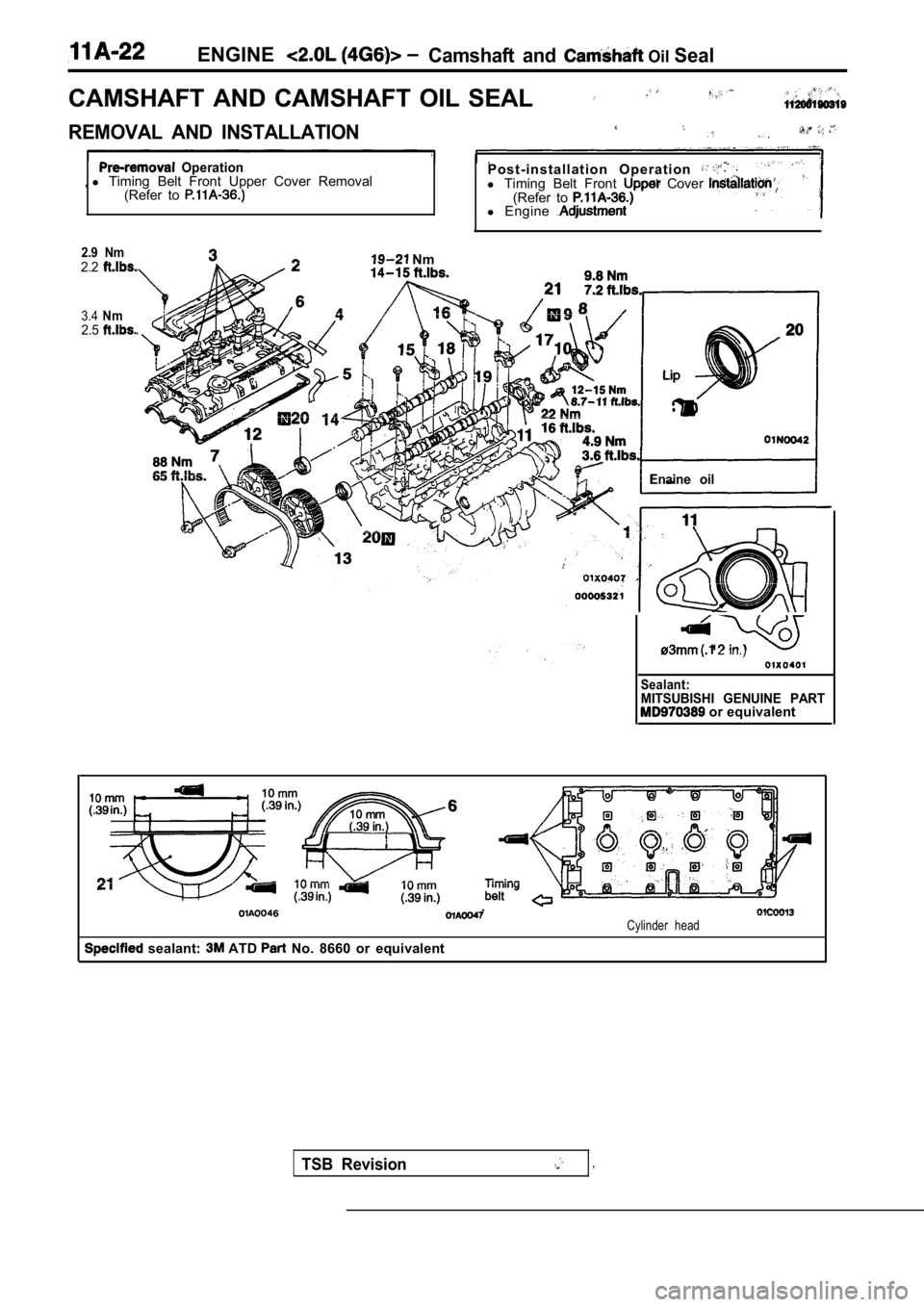

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Operation,l Timing Belt Front Upper Cover Removal

(Refer to P o s t - i n s t a l l a t i o n O p e r a t i o n l Timing Belt Front Cover (Refer to l Engine

2.9 Nm2.2

3.4Nm2.5

Nm

Enaine oil

TSB Revision

2 in.)

Sealant:MITSUBISHI GENUINE PART or equivalent

Cylinder head

sealant: ATD No. 8660 or equivalent

Page 83 of 2103

ENGINECamshaft and Camshaft ‘Oil -Seal

Removal steps

1. Accelerator cable connection2.Center cover

3. Spark plug cable

4.Breather hose5.PCV6.Rocker cover7. Timing belt (Refer to 8.Cover9.Gasket10. Camshaft position sensing cylinder 11. Camshaft position sensor support

12. Exhaust camshaft sprocket

13. Intake camshaft sprocket

14. Front camshaft bearing cap

15.Camshaft bearing cap

16. Rear camshaft bearing cap (R.H.)

17. Rear camshaft bearing cap (L.H.)

18.Exhaust camshaft19.Intake camshaft20. Camshaft oil seal21.Semi-circular packing

Installation steps. .

19. Intake camshaft 18. Exhaust camshaft Rear cap (R.H.)

16. Rear bearing cap (L.H.)

15. bearing cap 14. bearing cap

20. Camshaft 13. Intake camshaft12. Exhaust 11. Camshaft

Cover

7. Timing belt (Refer to

21. Semi-circular packing”

6. Rocker cover hose

4. Breather hose

3. Spark plug, cable2. Center cover 1. Accelerator cable .

Service.)

TSBRevision

Page 84 of 2103

ENGINECamshaft and Camshaft Oil

Plastic hammer

sideExhaust side

Slits01

Dowel pins

ExhaustsideIntake side

I

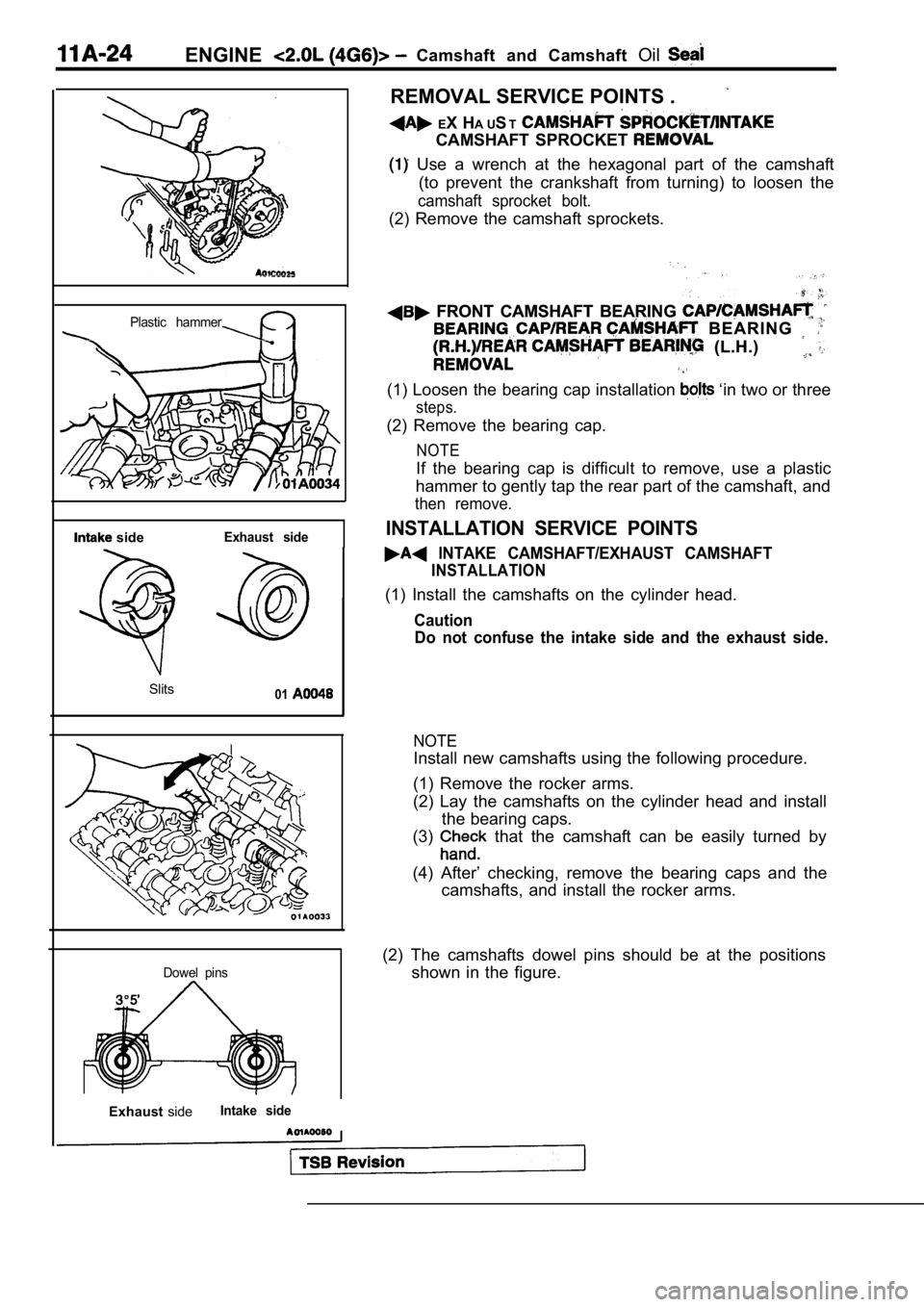

REMOVAL SERVICE POINTS .

EX H A UST

CAMSHAFT SPROCKET

Use a wrench at the hexagonal part of the camshaft

(to prevent the crankshaft from turning) to loosen the

camshaft sprocket bolt.

(2) Remove the camshaft sprockets.

FRONT CAMSHAFT BEARING FRONT CAMSHAFT BEARING

B E A R I N G B E A R I N G

(L.H.) (L.H.)

(1) Loosen the bearing cap installation ‘in two or three

steps.

(2) Remove the bearing cap.

NOTE

If the bearing cap is difficult to remove, use a plastic

hammer to gently tap the rear part of the camshaft, and

then remove.

INSTALLATION SERVICE POINTS

INTAKE CAMSHAFT/EXHAUST CAMSHAFT

INSTALLATION

(1) Install the camshafts on the cylinder head.

Caution

Do not confuse the intake side and the exhaust side .

NOTE

Install new camshafts using the following procedure.

(1) Remove the rocker arms.

(2) Lay the camshafts on the cylinder head and inst all

the bearing caps.

(3)

that the camshaft can be easily turned by

(4) After’ checking, remove the bearing caps and th e

camshafts, and install the rocker arms.

(2) The camshafts dowel pins should be at the posit ions

shown in the figure.

Page 85 of 2103

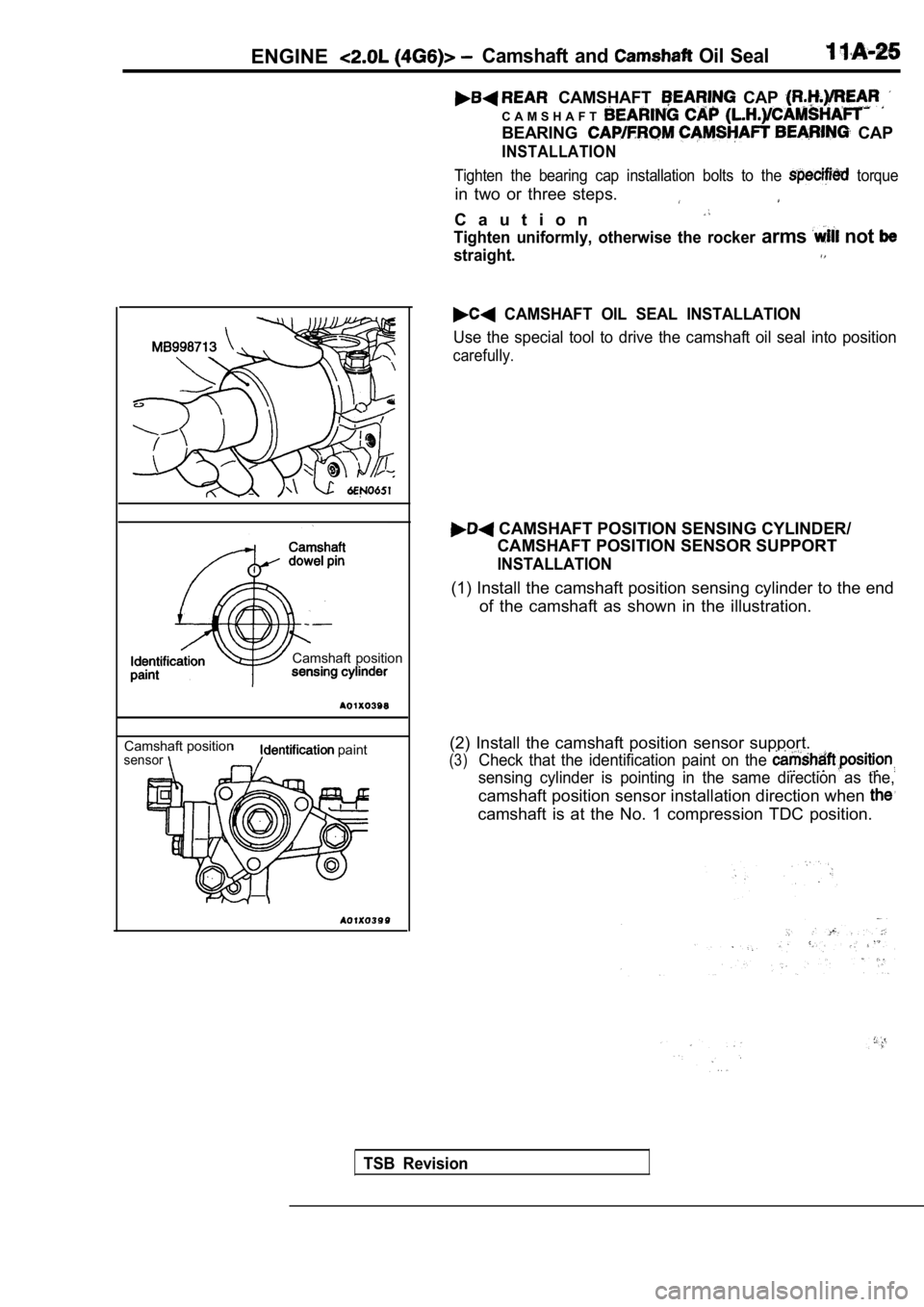

ENGINECamshaft and Oil Seal

CAMSHAFT CAP

C A M S H A F T

BEARING CAP

INSTALLATION

Tighten the bearing cap installation bolts to the torque

in two or three steps.

C a u t i o n

Tighten uniformly, otherwise the rocker arms not

straight.

Camshaft position

Camshaft positionsensor paint

CAMSHAFT OIL SEAL INSTALLATION

Use the special tool to drive the camshaft oil seal into position

carefully.

CAMSHAFT POSITION SENSING CYLINDER/

CAMSHAFT POSITION SENSOR SUPPORT

INSTALLATION

(1) Install the camshaft position sensing cylinder to the end

of the camshaft as shown in the illustration.

(2) Install the camshaft position sensor support.

(3)Check that the identification paint on the

sensing cylinder is pointing in the same direction as the,

camshaft position sensor installation direction when

camshaft is at the No. 1 compression TDC position.

TSB Revision

Page 86 of 2103

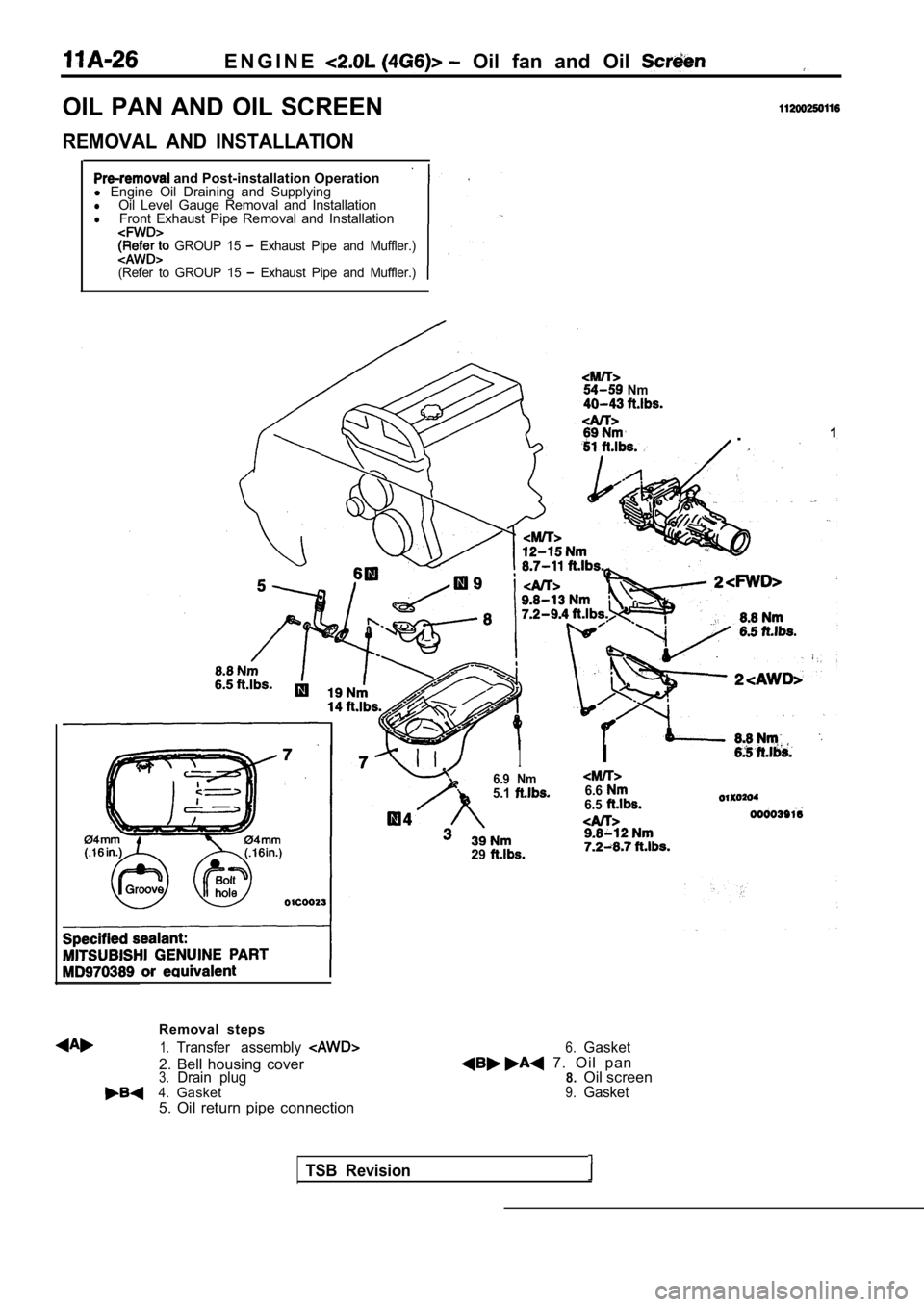

E N G I N E Oil fan and Oil

OIL PAN AND OIL SCREEN

REMOVAL AND INSTALLATION

and Post-installation Operation

l Engine Oil Draining and Supplying

lOil Level Gauge Removal and InstallationlFront Exhaust Pipe Removal and Installation

GROUP 15 Exhaust Pipe and Muffler.)

(Refer to GROUP 15

Exhaust Pipe and Muffler.)

Nm

1

I

6.9 Nm5.1

29

I

6.66.5

Removal steps

1.Transfer assembly6.Gasket

2. Bell housing cover 7. Oil pan3.Drain plug8.Oil screen4.Gasket9.Gasket

5. Oil return pipe connection

TSB Revision

Page 87 of 2103

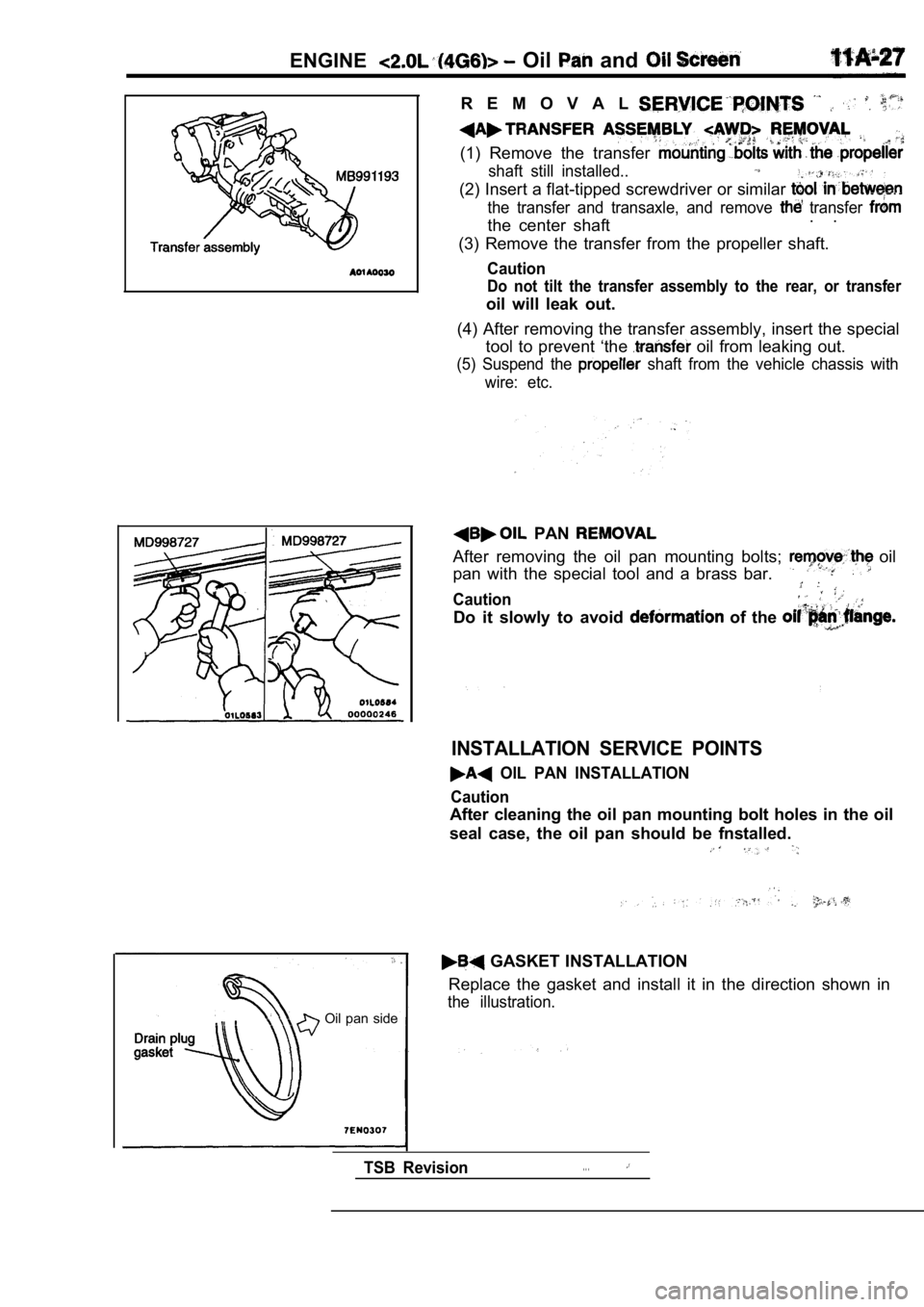

ENGINE Oil and

Oil pan side

R E M O V A L

(1) Remove the transfer

shaft still installed..

(2) Insert a flat-tipped screwdriver or similar

the transfer and transaxle, and remove transfer

the center shaft. .

(3) Remove the transfer from the propeller shaft.

Caution

Do not tilt the transfer assembly to the rear, or t ransfer

oil will leak out.

(4) After removing the transfer assembly, insert th e special

tool to prevent ‘the

oil from leaking out.

(5) Suspend the shaft from the vehicle chassis with

wire: etc.

PAN

After removing the oil pan mounting bolts; oil

pan with the special tool and a brass bar.

Caution

Do it slowly to avoid of the

INSTALLATION SERVICE POINTS

OIL PAN INSTALLATION

Caution

After cleaning the oil pan mounting bolt holes in t he oil

seal case, the oil pan should be fnstalled.

GASKET INSTALLATION

Replace the gasket and install it in the direction shown in

the illustration.

TSB Revision. . .

Page 88 of 2103

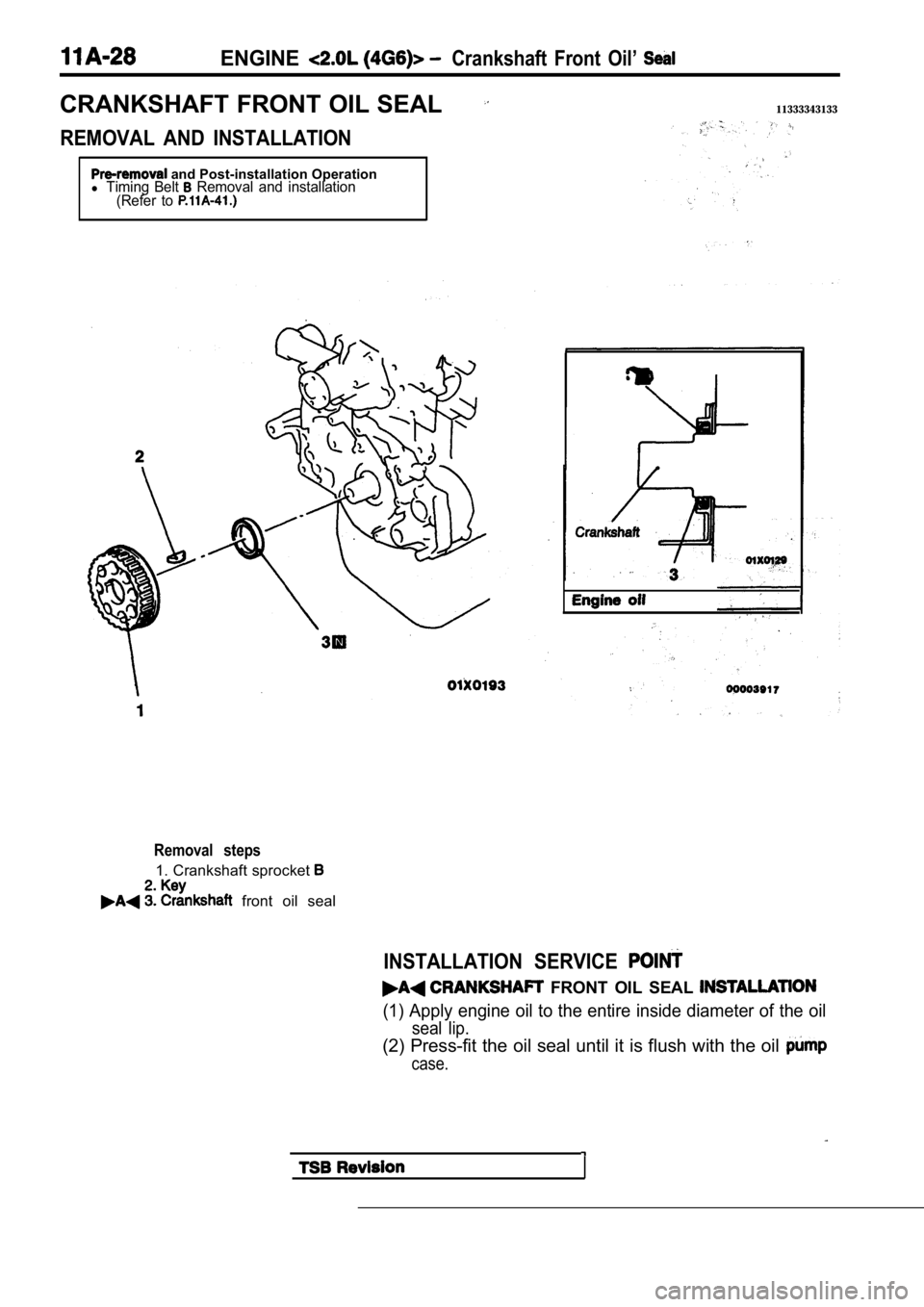

ENGINECrankshaft Front Oil’

CRANKSHAFT FRONT OIL SEAL11333343133

REMOVAL AND INSTALLATION

and Post-installation Operationl Timing Belt Removal and installation

(Refer to

Removal steps

1. Crankshaft sprocket

front oil seal

INSTALLATION SERVICE

FRONT OIL SEAL

(1) Apply engine oil to the entire inside diameter of the oil

seal lip.

(2) Press-fit the oil seal until it is flush with the oil

case.

Page 89 of 2103

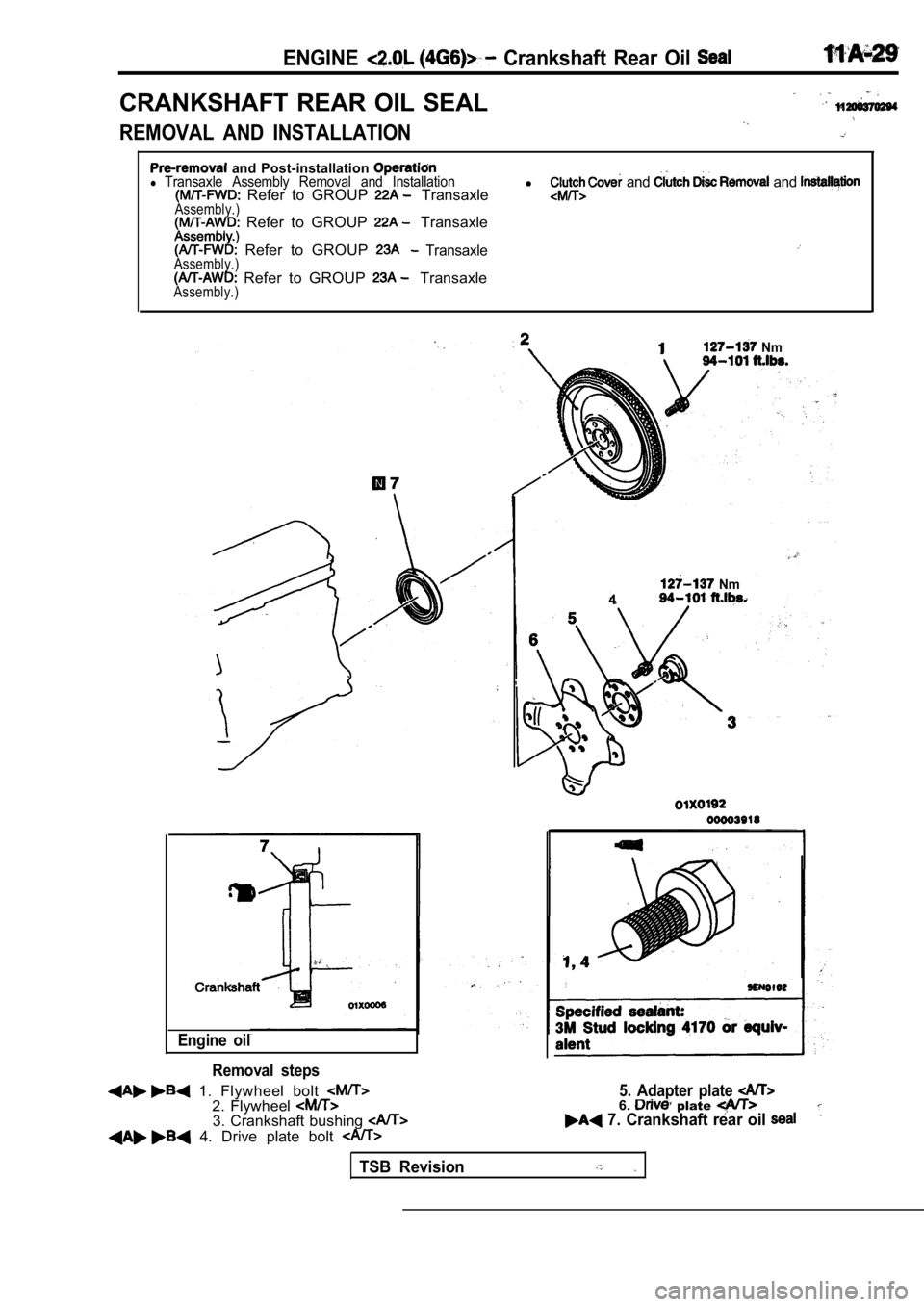

ENGINE Crankshaft Rear Oil

CRANKSHAFT REAR OIL SEAL

REMOVAL AND INSTALLATION

and Post-installation l Transaxle Assembly Removal and Installation Refer to GROUP TransaxleAssembly.)

l and and

Refer to GROUP TransaxleAssembl Refer to GROUP TransaxleAssembly.) Refer to GROUP TransaxleAssembly.)

Nm

Engine oilRemoval steps

1. Flywheel bolt 2. Flywheel 3. Crankshaft bushing

4. Drive plate bolt

Nm4

5. Adapter plate 6. plate 7. Crankshaft rear oil

TSB Revision

Page 90 of 2103

11ENGINE Crankshaft pear Oil

,

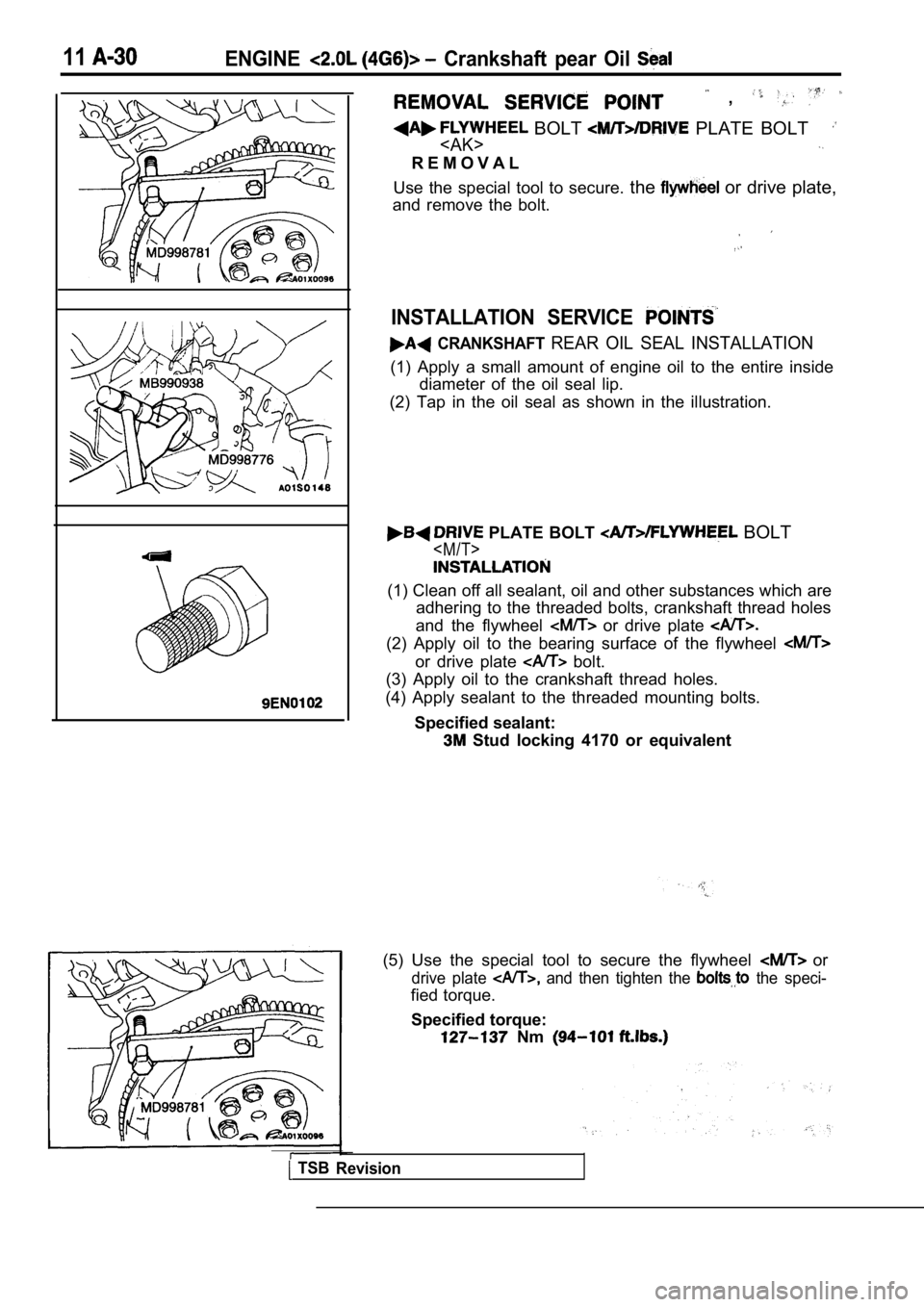

BOLT PLATE BOLT

R E M O V A L

Use the special tool to secure. the

or drive plate,

and remove the bolt.

INSTALLATION SERVICE

CRANKSHAFT REAR OIL SEAL INSTALLATION

(1) Apply a small amount of engine oil to the entir e inside

diameter of the oil seal lip.

(2) Tap in the oil seal as shown in the illustratio n.

PLATE BOLT BOLT

(1) Clean off all sealant, oil and other substances which are

adhering to the threaded bolts, crankshaft thread h oles

and the flywheel

or drive plate

(2) Apply oil to the bearing surface of the flywhee l

or drive plate bolt.

(3) Apply oil to the crankshaft thread holes.

(4) Apply sealant to the threaded mounting bolts.

Specified sealant:

Stud locking 4170 or equivalent

TSB Revision

(5) Use the special tool to secure the flywheel or

drive plate and then tighten the the speci-

fied torque.

Specified torque:

Nm