MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 501 of 2103

E N G I N E ,

FUEL PRESSURE TEST

FUEL SYSTEM PRESSURE MUST BE RELEASED BEFORE

A F U E L S Y S T E M H O S E O R C O M P O N E N T ŌĆÖ ŌĆ£ I S

DISCONNECTED.

The specifications listed in the Fuel System Pressure Chart

are determined without vacuum applied to the fuel ŌĆś pressure,

regurator.

1.

2.

3.

4.

5.

Fuel system pressure must be released each time a f uelŌĆÖ

hose is to be disconnected. Release fuel system pre ssure.,

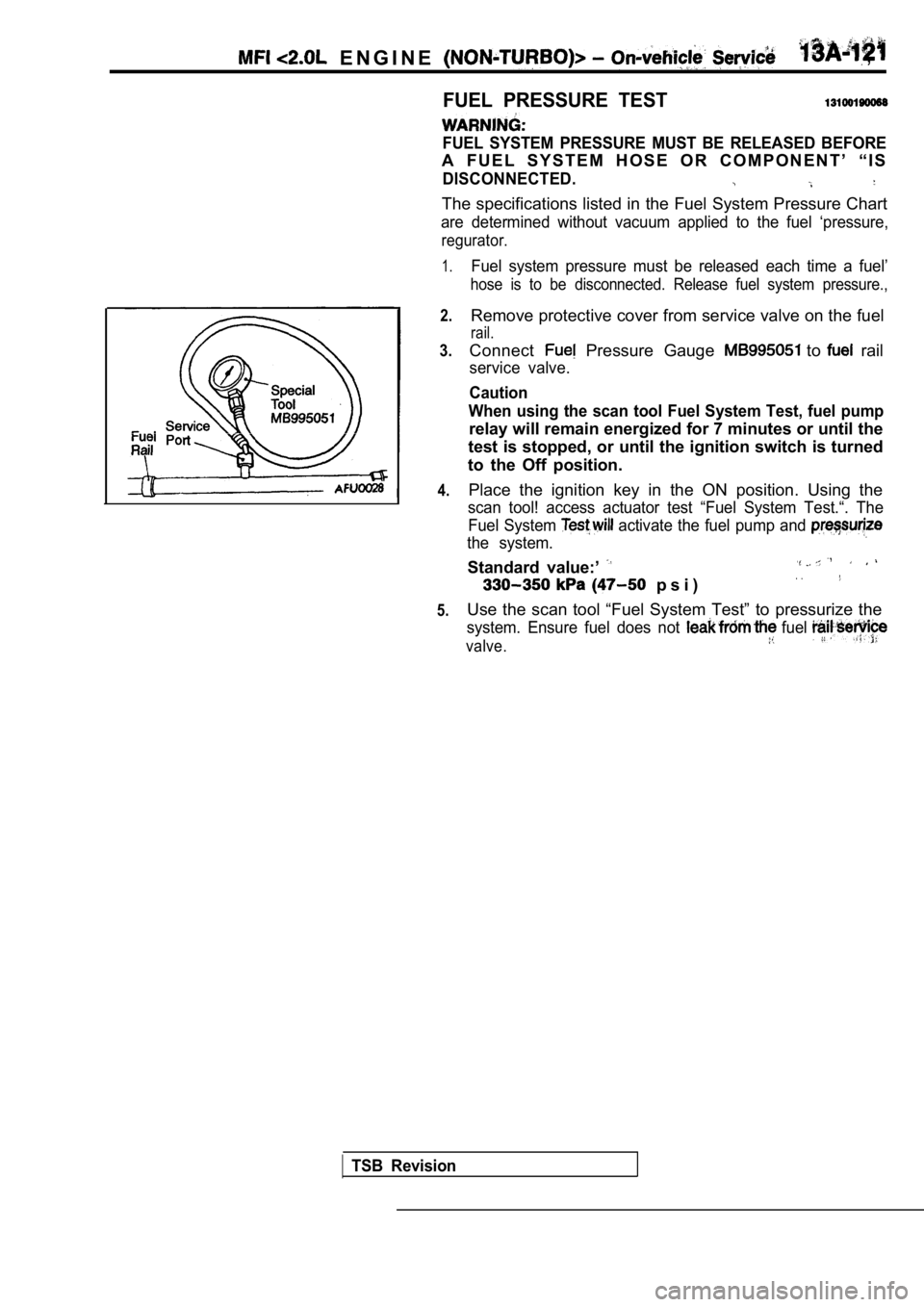

Remove protective cover from service valve on the fuel

rail.

Connect Pressure Gauge to rail

service valve.

Caution

When using the scan tool Fuel System Test, fuel pum p

relay will remain energized for 7 minutes or until the

test is stopped, or until the ignition switch is tu rned

to the Off position.

Place the ignition key in the ON position. Using th e

scan tool! access actuator test ŌĆ£Fuel System Test.ŌĆ£. The

Fuel System

activate the fuel pump and

the system.

Standard value:ŌĆÖ

p s i )

Use the scan tool ŌĆ£Fuel System TestŌĆØ to pressurize the

system. Ensure fuel does not fuel

valve.

TSB Revision

Page 502 of 2103

ENGINE

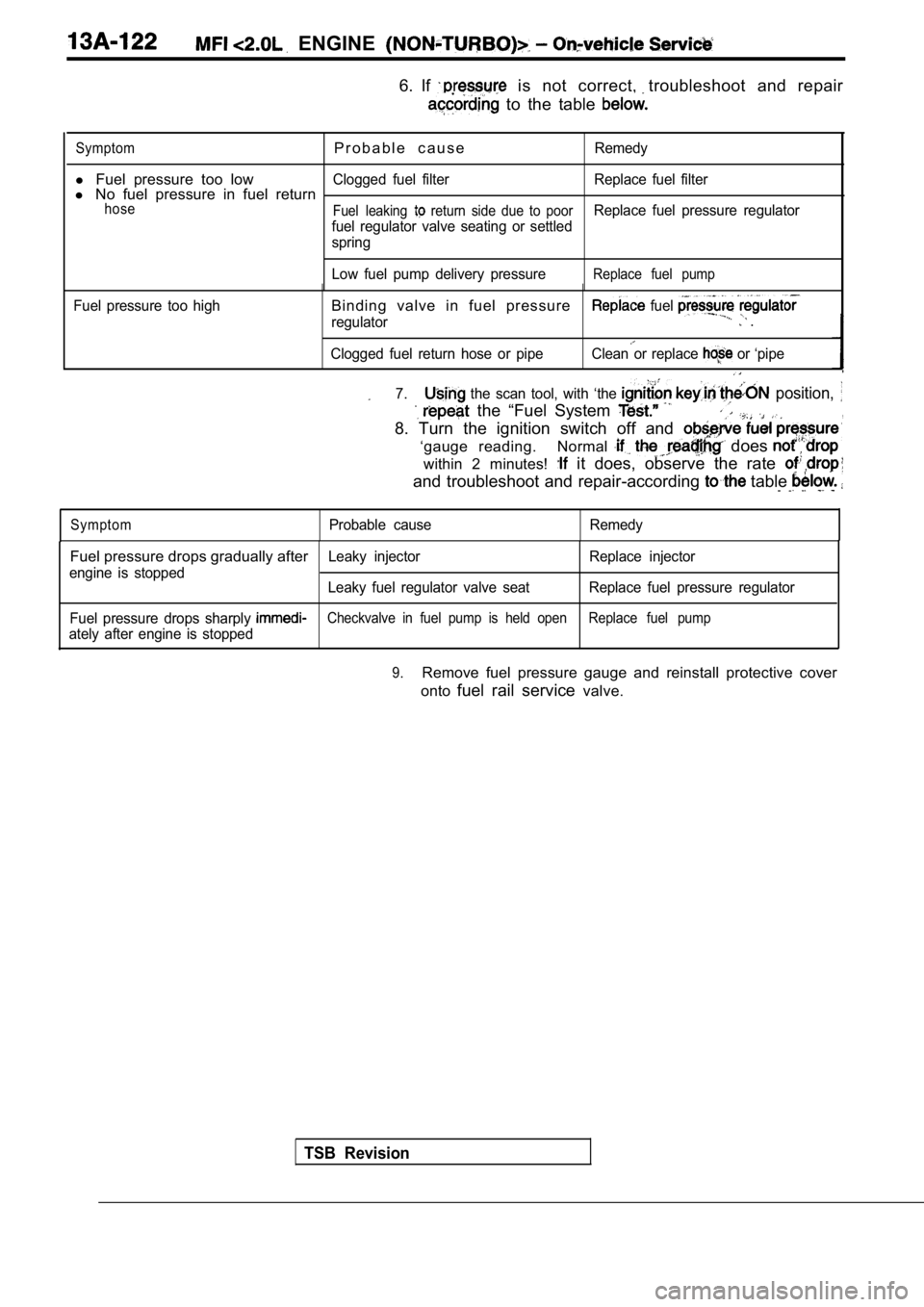

6. If is not correct, troubleshoot and repair

to the table

SymptomP r o b a b l e c a u s eRemedy

l Fuel pressure too lowClogged fuel filter Replace fuel filterl No fuel pressure in fuel returnhose

Fuel leaking return side due to poorReplace fuel pressure regulator

fuel regulator valve seating or settled

spring

Low fuel pump delivery pressure

Replace fuel pump

Fuel pressure too highBinding valve in fuel pressure

regulator

fuel .

Clogged fuel return hose or pipeClean or replace or ŌĆśpipe

7. the scan tool, with ŌĆśthe position,

the ŌĆ£Fuel System ,

8. Turn the ignition switch off and

ŌĆśgauge reading. Normal does

within 2 minutes! it does, observe the rate

and troubleshoot and repair-according table

SymptomProbable cause Remedy

Fuel pressure drops gradually afterLeaky injector Replace injector

engine is stopped Leaky fuel regulator valve seat Replace fuel pressur e regulator

Fuel pressure drops sharply

Checkvalve in fuel pump is held open Replace fuel pu mp

ately after engine is stopped

TSB Revision

9.Remove fuel pressure gauge and reinstall protective cover

onto fuel rail service valve.

Page 503 of 2103

ENGINE (NON-TURBO)> On-vehicle

FUEL PUMP

(HOW TO REDUCE FUEL LINE PRESSURE)

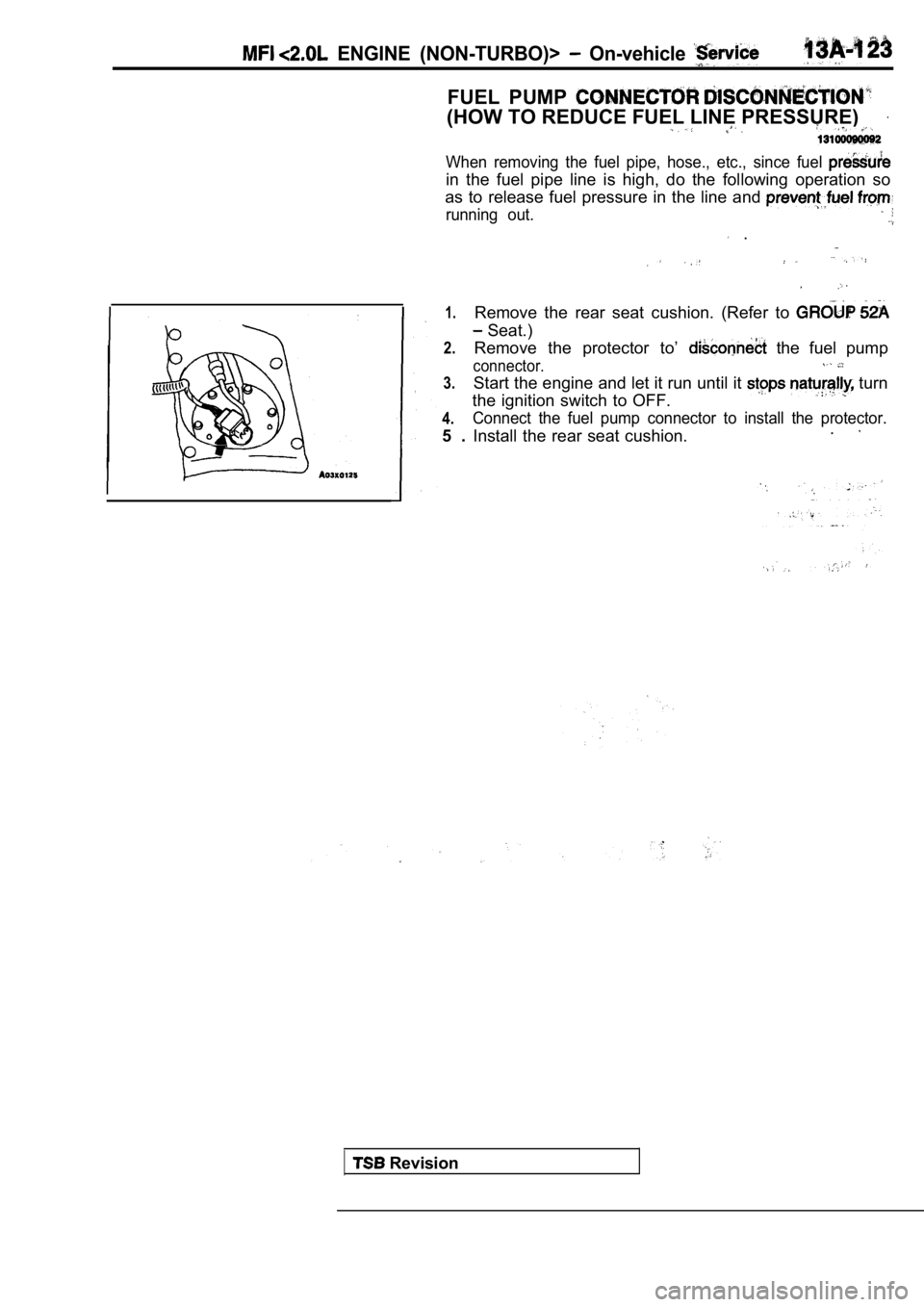

When removing the fuel pipe, hose., etc., since fuel

in the fuel pipe line is high, do the following operation so

as to release fuel pressure in the line and

running out.

.

1.

2.

3.

4.

5 . Remove the rear seat cushion. (Refer to

Seat.)

Remove the protector toŌĆÖ

the fuel pump

connector.

Start the engine and let it run until it turn

the ignition switch to OFF.

Connect the fuel pump connector to install the prot ector.

Install the rear seat cushion..

Revision

Page 504 of 2103

ENGINE (NON-TURBO)> .

13100210139

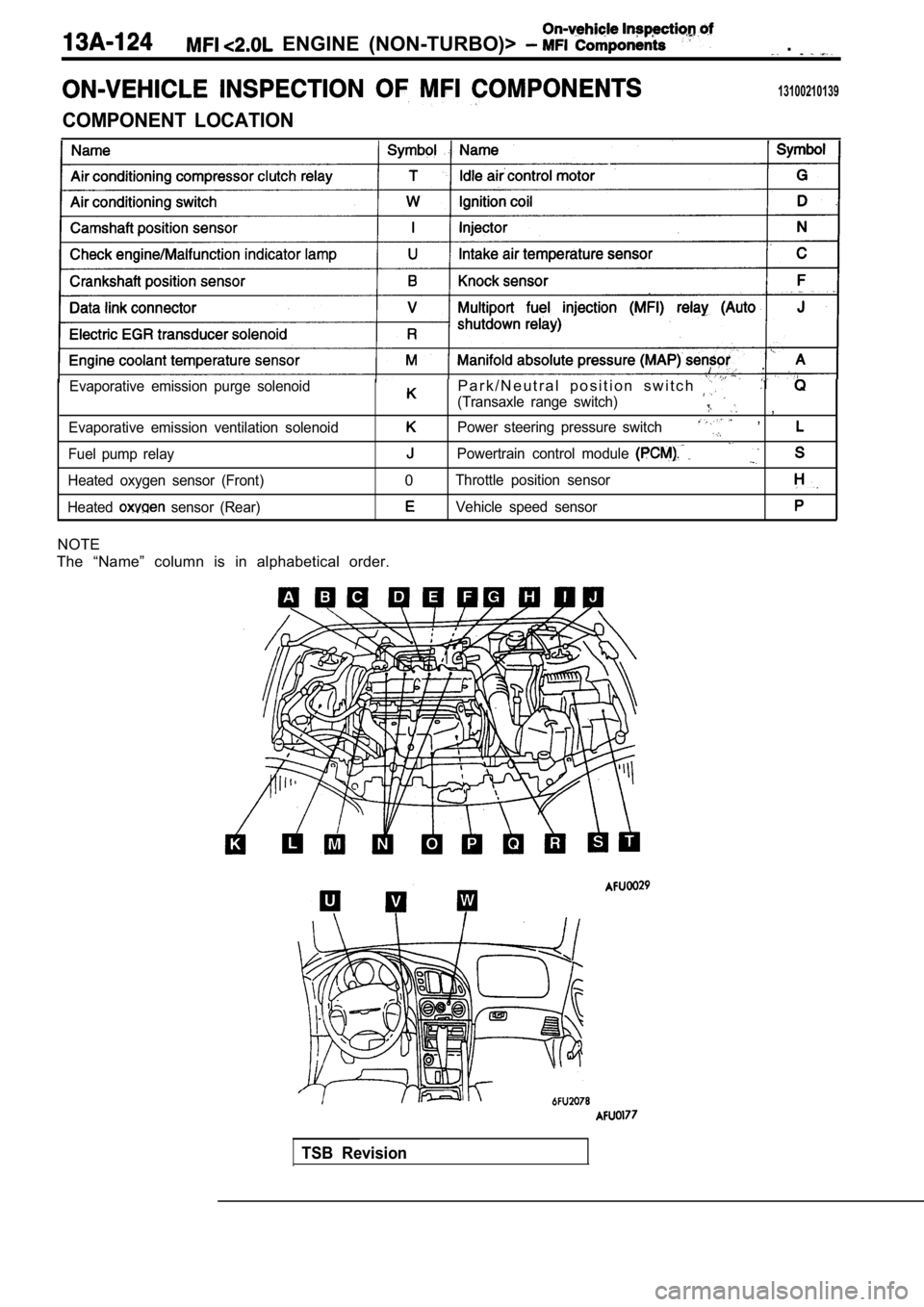

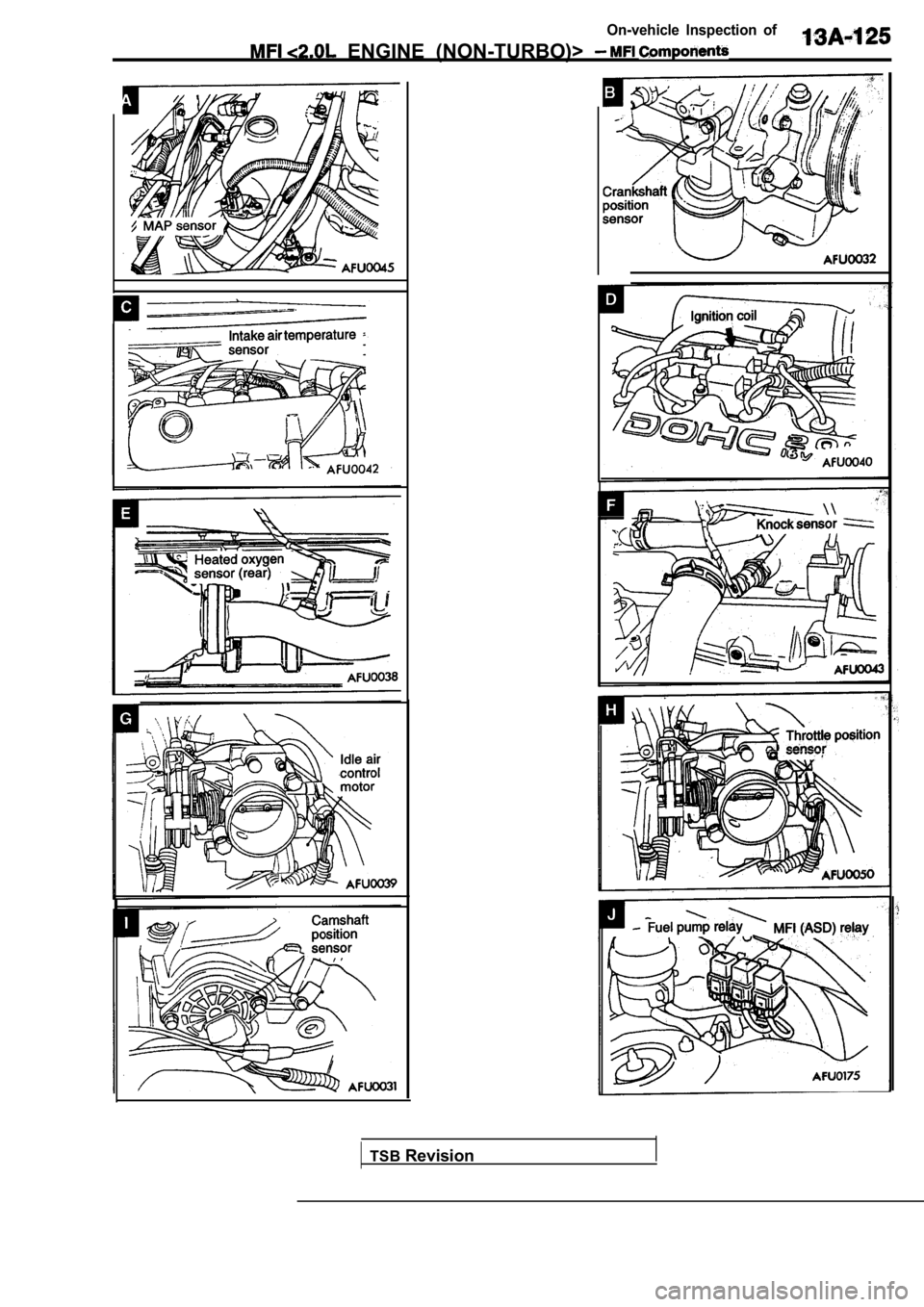

COMPONENT LOCATION

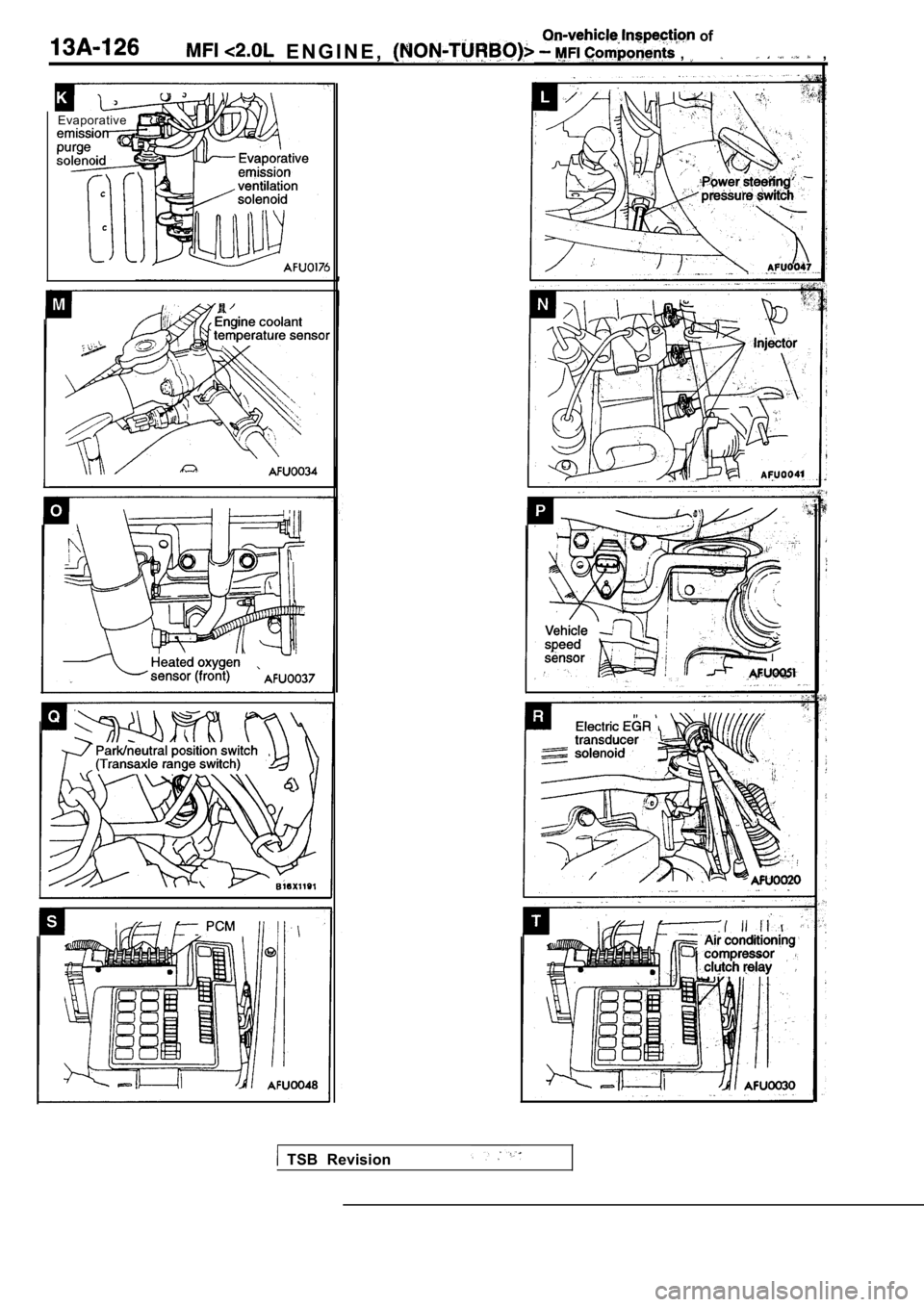

Evaporative emission purge solenoid

Evaporative emission ventilation solenoid

Fuel pump relay

Heated oxygen sensor (Front)

Heated

sensor (Rear)

P a r k / N e u t r a l p o s i t i o n s w i t c h

(Transaxle range switch) ,

Power steering pressure switch ,

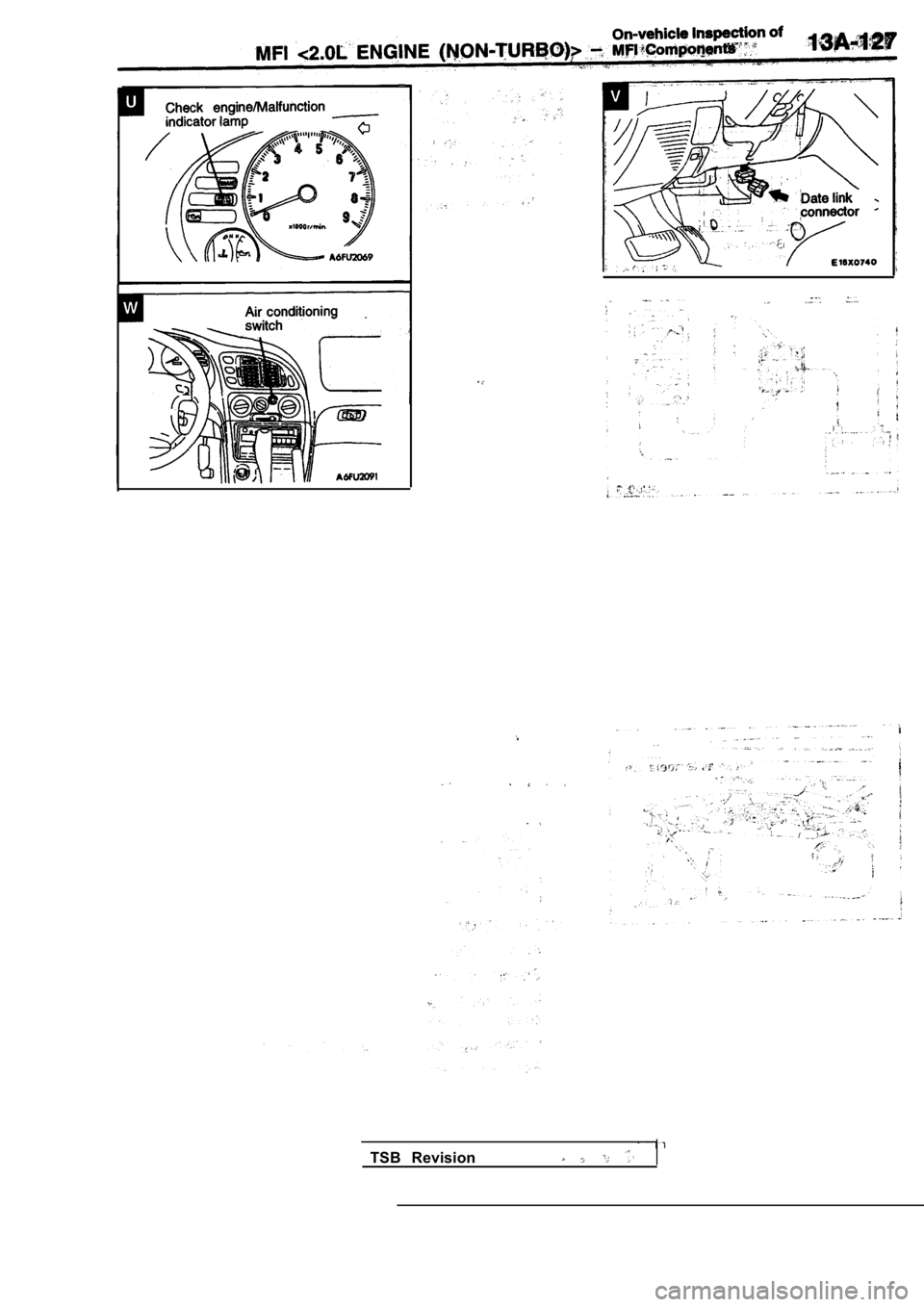

Powertrain control module

0Throttle position sensor

Vehicle speed sensor

NOTE

The ŌĆ£NameŌĆØ column is in alphabetical order.

TSB Revision

Page 505 of 2103

On-vehicle Inspection of

ENGINE (NON-TURBO)>

TSBRevision

Page 506 of 2103

of

E N G I N E , , ,

Evaporative

TSB Revision

Page 507 of 2103

TSB Revision

Page 508 of 2103

28 of

( N O N - T U R B O ) >

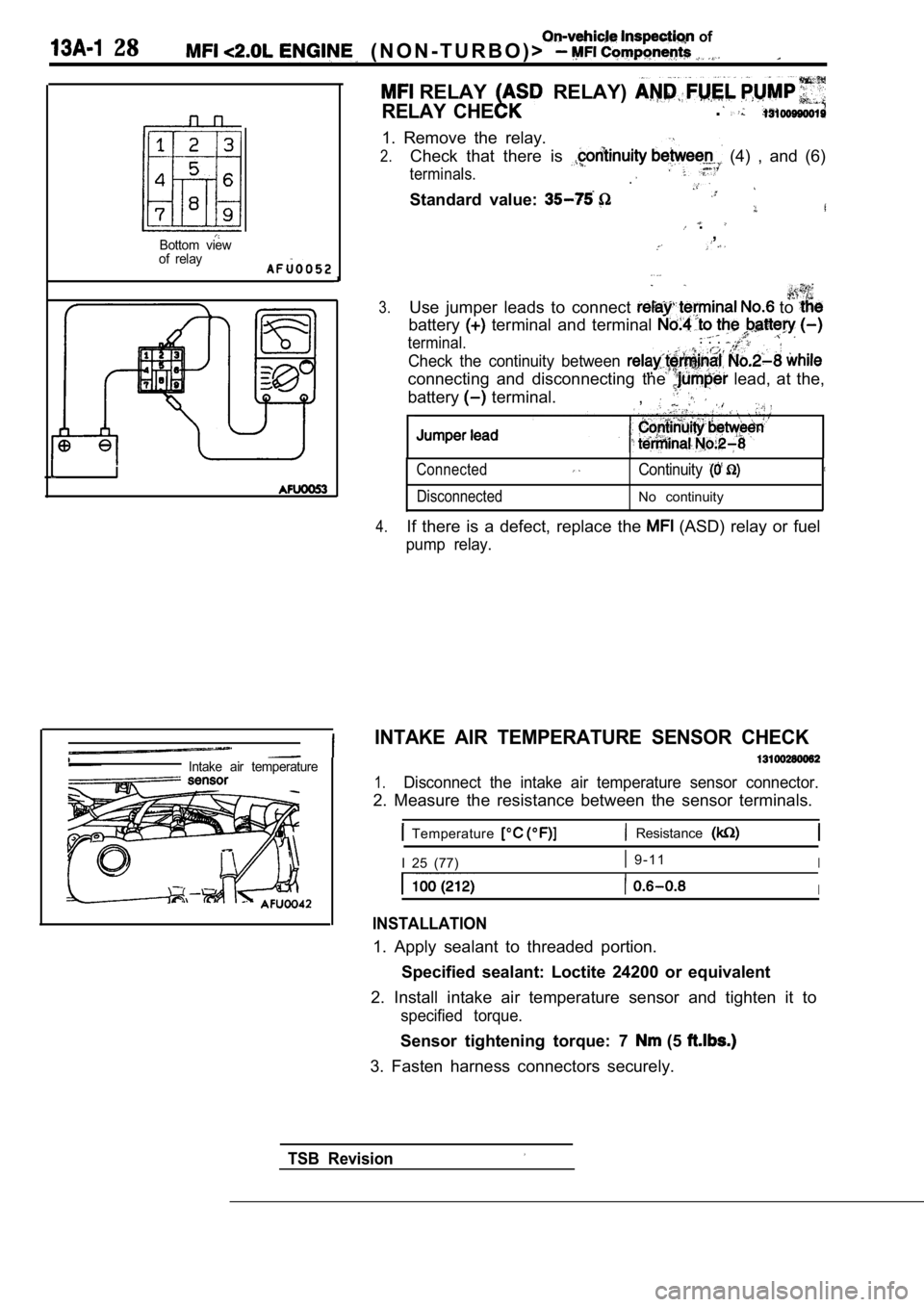

Bottom view

of relay

I

Intake air temperature

RELAY RELAY)

RELAY CHE.

1. Remove the relay.

2.Check that there is (4) , and (6)

terminals..

Standard value:

.,

3.Use jumper leads to connect to

battery terminal and terminal

terminal.. . .

Check the continuity between

connecting and disconnecting the lead, at the,

battery

terminal. ,

Connected

DisconnectedContinuity

No continuity

4.If there is a defect, replace the (ASD) relay or fuel

pump relay.

INTAKE AIR TEMPERATURE SENSOR CHECK

1.Disconnect the intake air temperature sensor connec tor.

2. Measure the resistance between the sensor terminals.

Temperature Resistance

I 25 (77) 9 - 1 1I

I

INSTALLATION

1. Apply sealant to threaded portion.

Specified sealant: Loctite 24200 or equivalent

2. Install intake air temperature sensor and tighte n it to

specified torque.

Sensor tightening torque: 7 (5

3. Fasten harness connectors securely.

TSB Revision

Page 509 of 2103

On-vehicle Inspection of

ENGINE

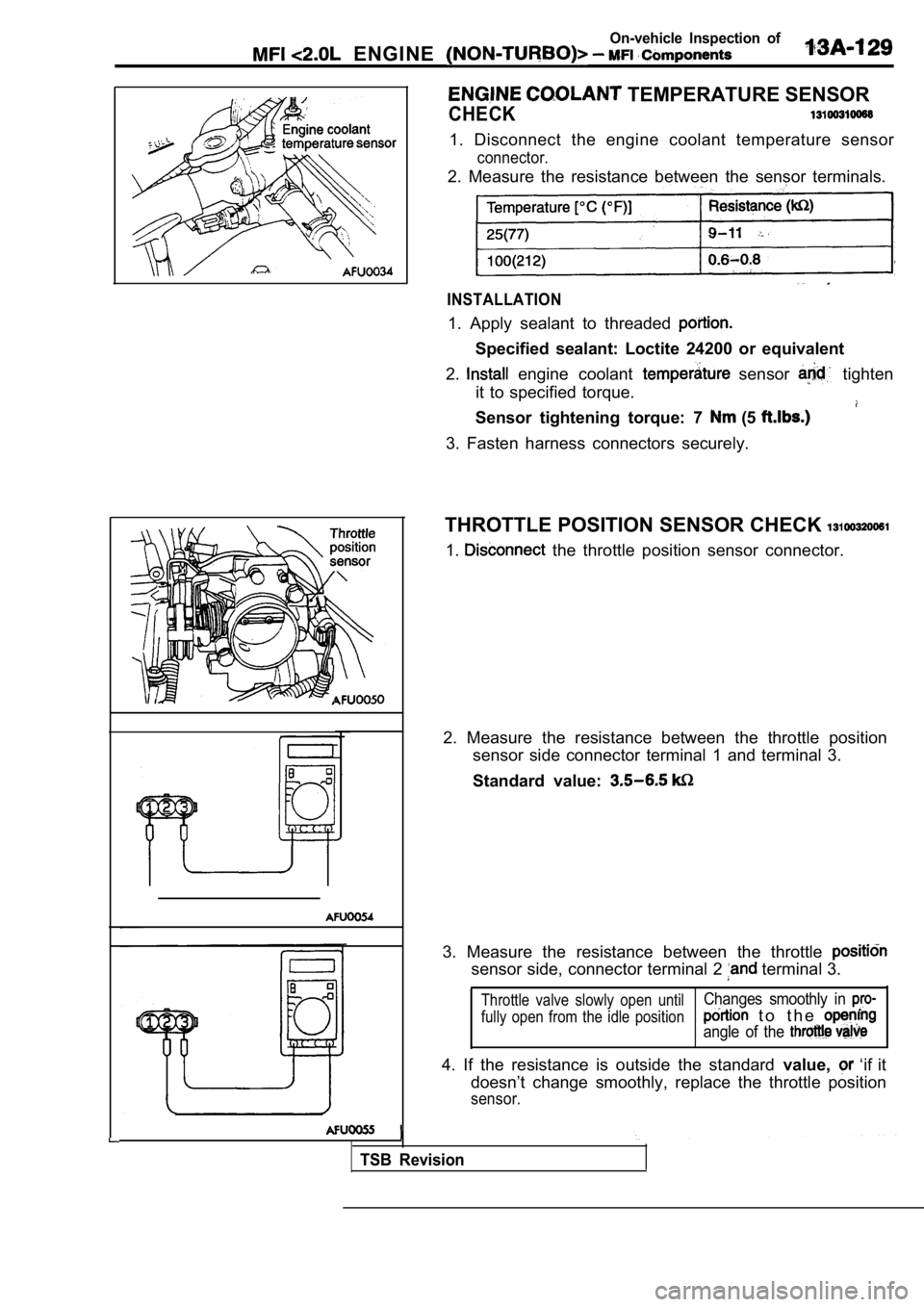

TEMPERATURE SENSOR

CHECK

1. Disconnect the engine coolant temperature sensor

connector.

2. Measure the resistance between the sensor terminals.

INSTALLATION

1. Apply sealant to threaded

Specified sealant: Loctite 24200 or equivalent

2.

engine coolant sensor tighten

it to specified torque.

Sensor tightening torque: 7 (5

3. Fasten harness connectors securely.

THROTTLE POSITION SENSOR CHECK

1. the throttle position sensor connector.

2. Measure the resistance between the throttle posi tion

sensor side connector terminal 1 and terminal 3.

Standard value:

3. Measure the resistance between the throttle

sensor side, connector terminal 2 terminal 3.

Throttle valve slowly open until

fully open from the idle positionChanges smoothly in

t o t h e

angle of the

4. If the resistance is outside the standard value, ŌĆśif it

doesnŌĆÖt change smoothly, replace the throttle posit ion

sensor.

TSB Revision

Page 510 of 2103

On-vehicle of

ENGINE ( N O N - T U R B O ) >

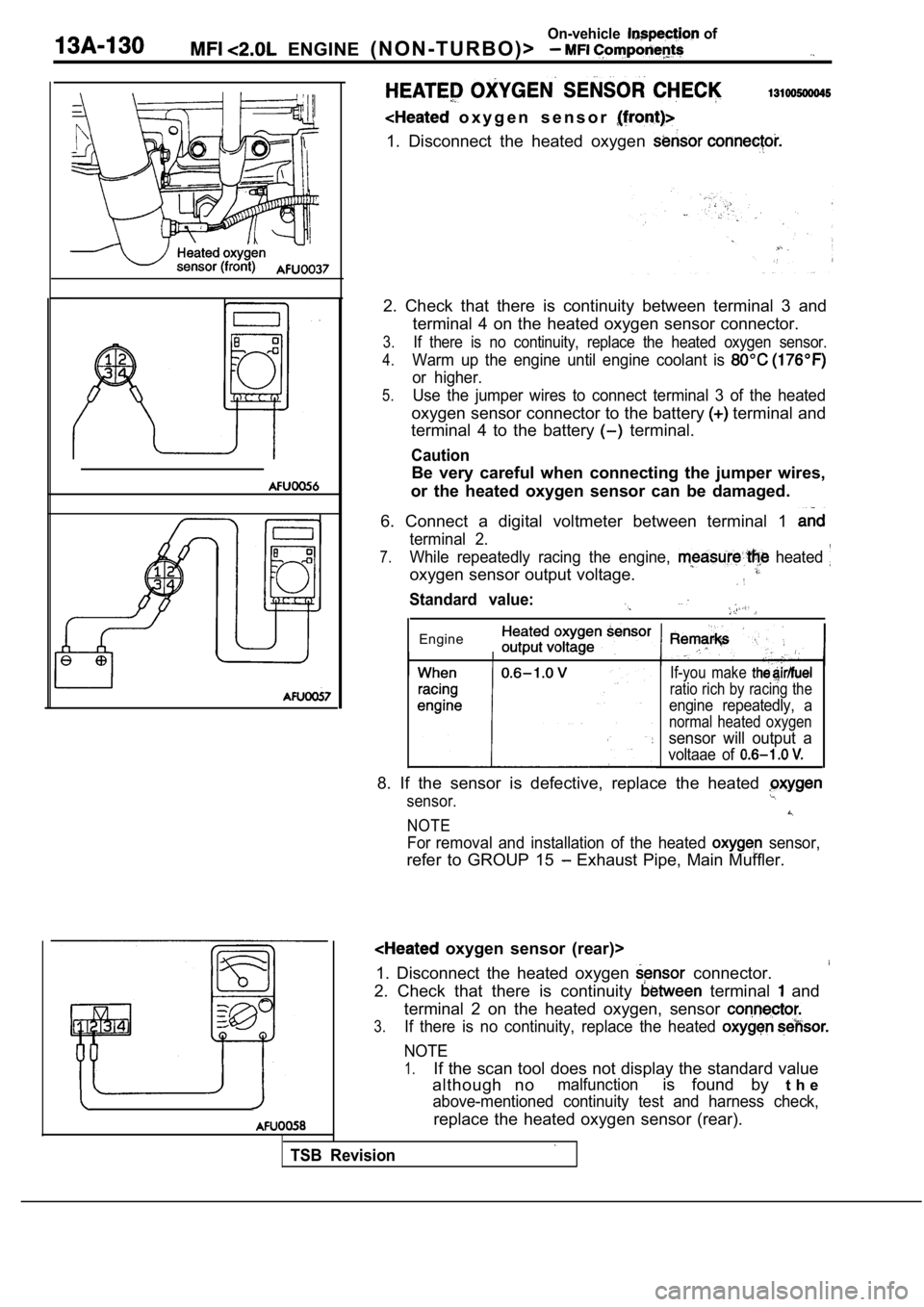

o x y g e n s e n s o r

1. Disconnect the heated oxygen

2. Check that there is continuity between terminal 3 and

terminal 4 on the heated oxygen sensor connector.

3.If there is no continuity, replace the heated oxyge n sensor.

4.Warm up the engine until engine coolant is

or higher.

5.Use the jumper wires to connect terminal 3 of the h eated

oxygen sensor connector to the battery terminal and

terminal 4 to the battery

terminal.

Caution

Be very careful when connecting the jumper wires,

or the heated oxygen sensor can be damaged.

6. Connect a digital voltmeter between terminal 1

terminal 2.

7.While repeatedly racing the engine, heated

oxygen sensor output voltage.

Standard value:

Engine

TSB Revision

If-you make

ratio rich by racing the

engine repeatedly, a

normal heated oxygen

sensor will output a

voltaae of

8. If the sensor is defective, replace the heated

sensor.

NOTE

For removal and installation of the heated sensor,

refer to GROUP 15 Exhaust Pipe, Main Muffler.

oxygen sensor (rear)>

1. Disconnect the heated oxygen

connector.

2. Check that there is continuity terminal and

terminal 2 on the heated oxygen, sensor

3.If there is no continuity, replace the heated

NOTE

1.If the scan tool does not display the standard valu e

although no

malfunctionis found by t h e

above-mentioned continuity test and harness check,

replace the heated oxygen sensor (rear).