MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 121 of 2103

ENGINE OVERHAUL Timing Belt

Semi-circularCylinder head

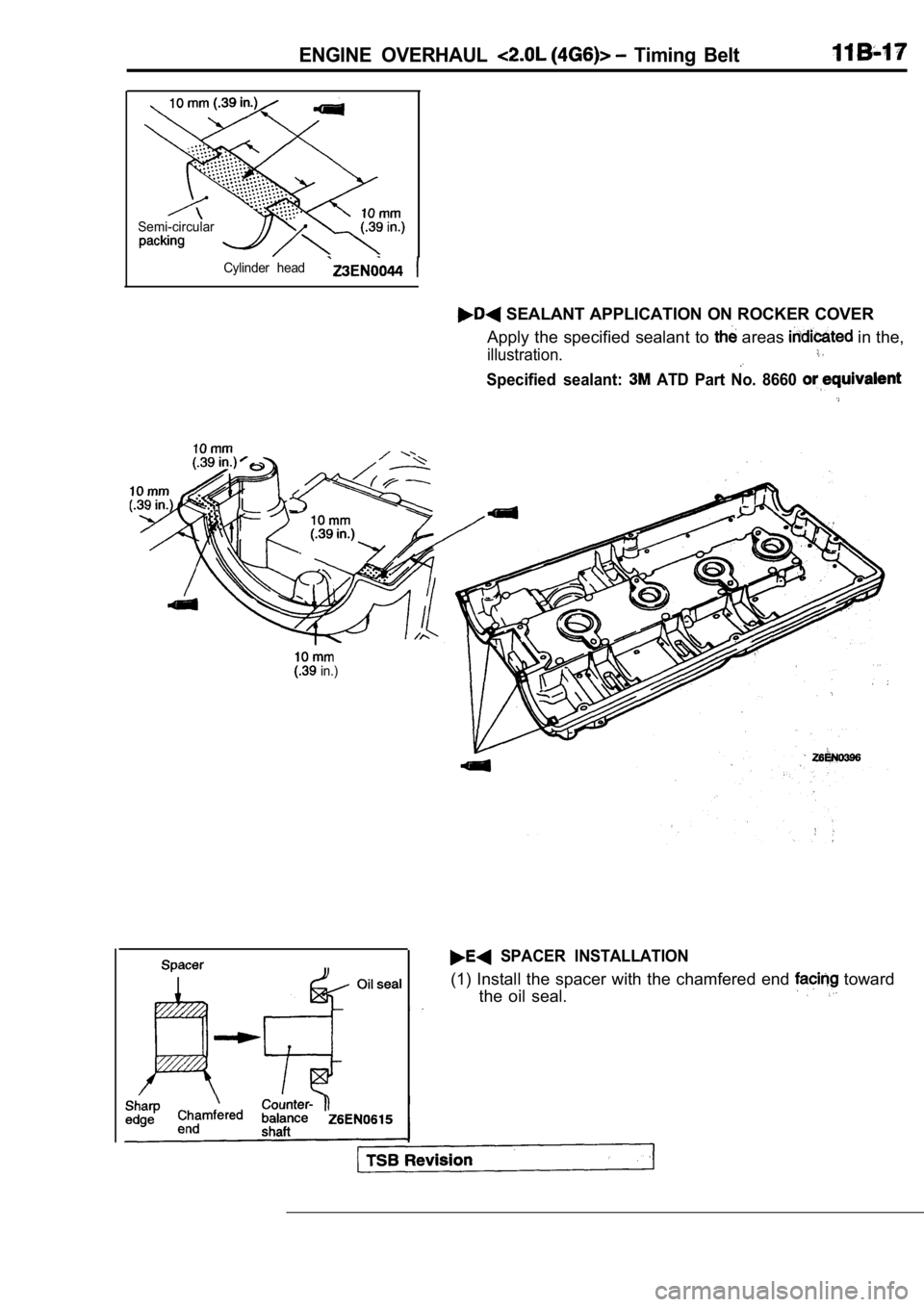

SEALANT APPLICATION ON ROCKER COVER

Apply the specified sealant to

areas in the,

illustration.

Specified sealant: ATD Part No. 8660

in.)

SPACER INSTALLATION

(1) Install the spacer with the chamfered end toward

the oil seal.

Page 122 of 2103

ENGINE OVERHAUL Timing’

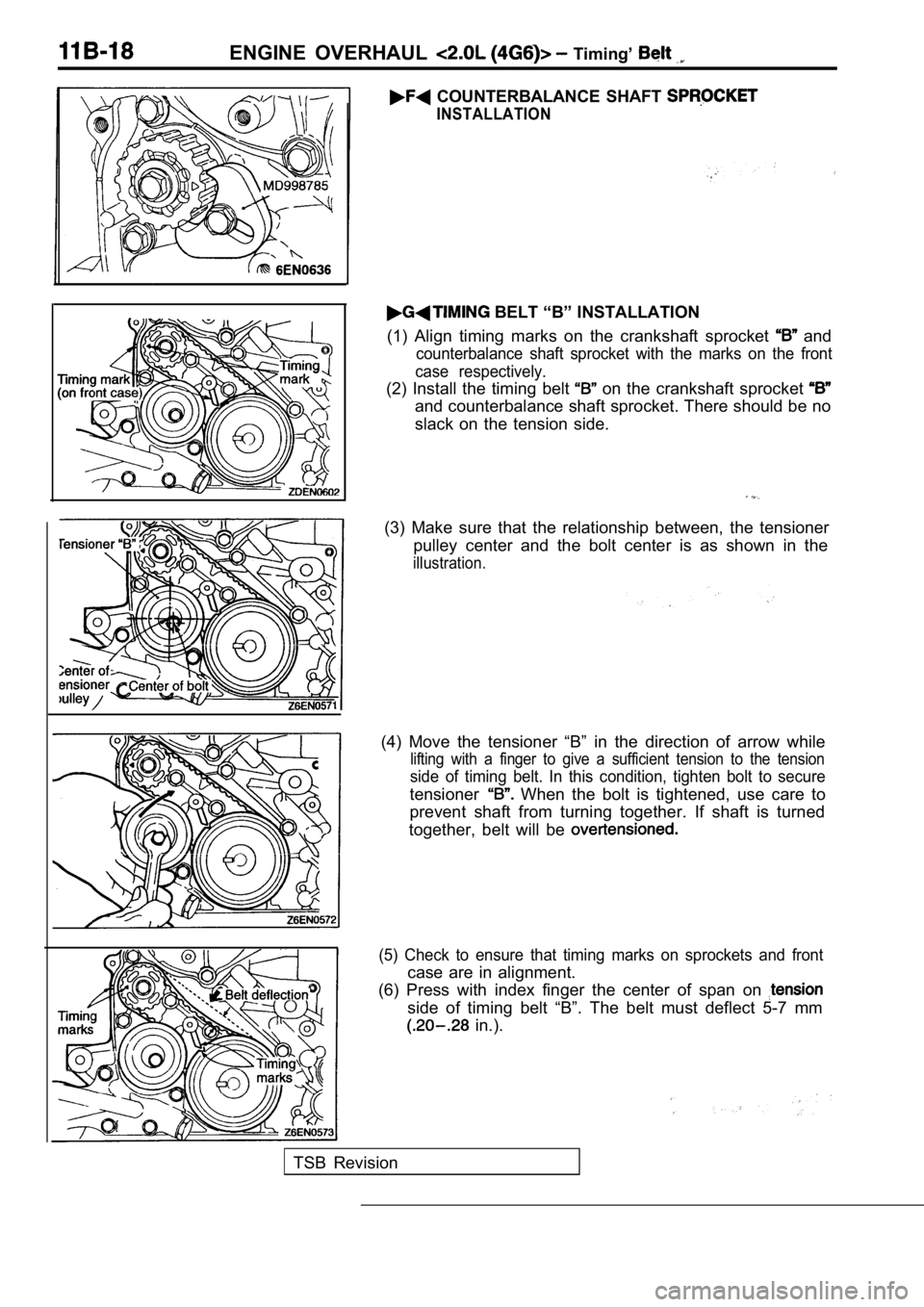

COUNTERBALANCE SHAFT

INSTALLATION

BELT “B” INSTALLATION

(1) Align timing marks on the crankshaft sprocket

and

counterbalance shaft sprocket with the marks on the front

case respectively.

(2) Install the timing belt on the crankshaft sprocket

and counterbalance shaft sprocket. There should be no

slack on the tension side.

(3) Make sure that the relationship between, the te nsioner

pulley center and the bolt center is as shown in th e

illustration.

(4) Move the tensioner “B” in the direction of arrow while

lifting with a finger to give a sufficient tension to the tension

side of timing belt. In this condition, tighten bolt to secure

tensioner When the bolt is tightened, use care to

prevent shaft from turning together. If shaft is tu rned

together, belt will be

(5) Check to ensure that timing marks on sprockets and front

case are in alignment.

(6) Press with index finger the center of span on

side of timing belt “B”. The belt must deflect 5-7 mm

in.).

TSB Revision

Page 123 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE OVERHAUL Belt

Phillips screwdriver

BOLT

O I L S P R O C K E T

(1) a Phillips screwdriver [shank diameter 8 mm

in.) shaft] through the plug hole on the the

cylinde MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE OVERHAUL Belt

Phillips screwdriver

BOLT

O I L S P R O C K E T

(1) a Phillips screwdriver [shank diameter 8 mm

in.) shaft] through the plug hole on the the

cylinde](/img/19/57345/w960_57345-122.png)

ENGINE OVERHAUL Belt

Phillips screwdriver

BOLT

O I L S P R O C K E T

(1) a Phillips screwdriver [shank diameter 8 mm

in.) shaft] through the plug hole on the the

cylinder block to block the left counterbalance sha ft.

(2)

the oil pump sprocket. .

(3) Apply a proper amount of engine oil-to the bearing

of the nuts.

(4) Tighten the nuts to the specified‘ torque.

AUTO TENSIONER INSTALLATION

(1) If the auto tensioner rod is in its fully exten ded position,

reset it as follows.

(2) Clamp the auto-tensioner in the vise

jaws.

(3) Push in the rod little by little with the vise the

hole A in the rod is aligned with the hole in the

(4) a wire mm in.) diameter] into the

(5) Unclamp the auto tensioner from the vise.

.

,

the auto tensioner to front case and tighten.

the specified torque.

Caution

Leave the wire installed the

,

. .

,

TSB Revision

Page 124 of 2103

ENGINE OVERHAUL

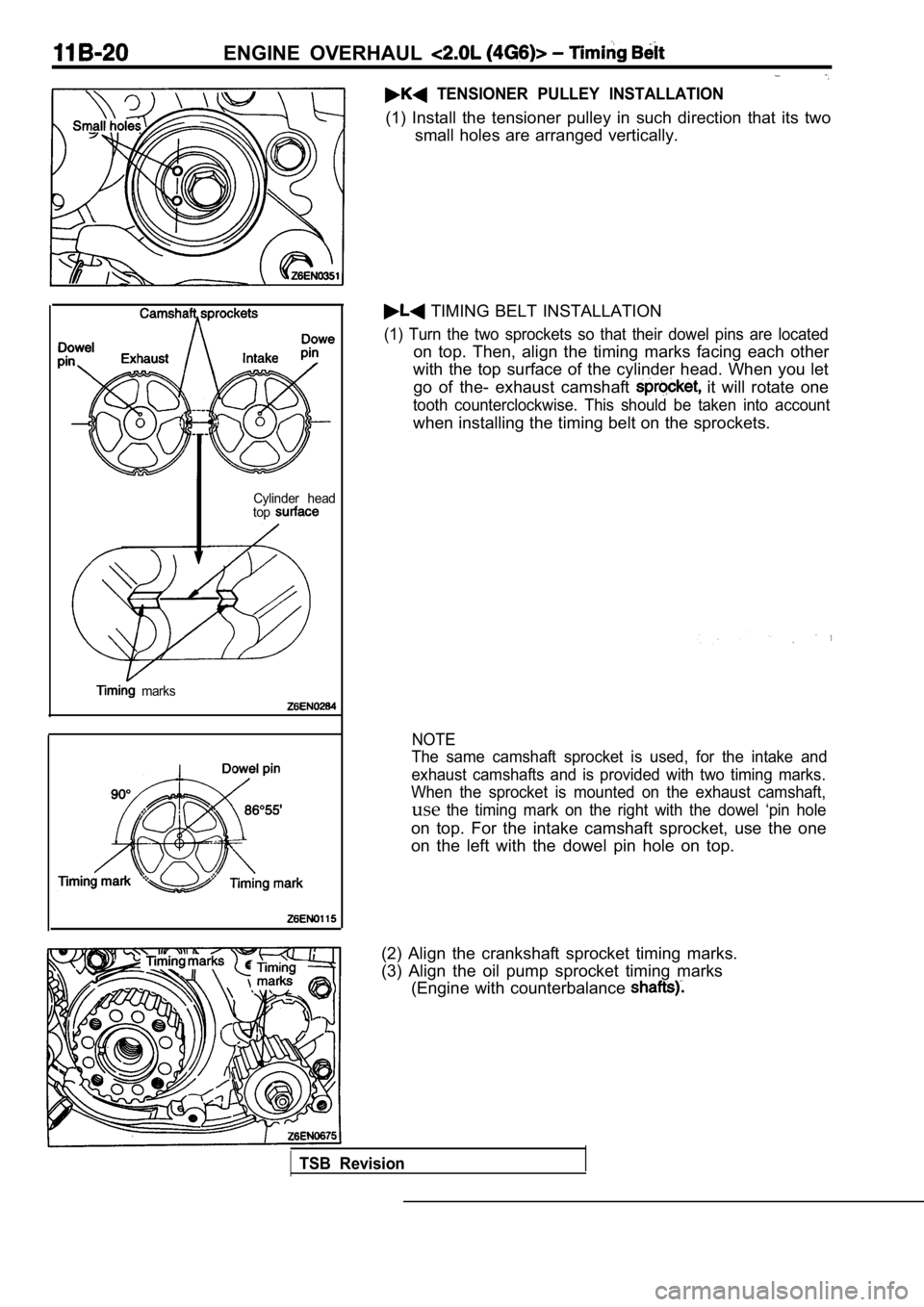

TENSIONER PULLEY INSTALLATION

(1) Install the tensioner pulley in such direction that its two

small holes are arranged vertically.

Cylinder head

top

marks

TIMING BELT INSTALLATION

(1) Turn the two sprockets so that their dowel pins are located

on top. Then, align the timing marks facing each ot her

with the top surface of the cylinder head. When you let

go of the- exhaust camshaft

it will rotate one

tooth counterclockwise. This should be taken into a ccount

when installing the timing belt on the sprockets.

NOTE

The same camshaft sprocket is used, for the intake and

exhaust camshafts and is provided with two timing m arks.

When the sprocket is mounted on the exhaust camshaf t,

usethe timing mark on the right with the dowel ‘pin hole

on top. For the intake camshaft sprocket, use the o ne

on the left with the dowel pin hole on top.

(2) Align the crankshaft sprocket timing marks.

(3) Align the oil pump sprocket timing marks (Engine with counterbalance

TSB Revision

Page 125 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE OVERHAUL Belt

Phillips screwdriver

TSBRevision

(4) a Phillips screwdriver [shank diameter 8 mm

in.)] through the hole.

If it can be inserted as deep as 60 mm (2.4 or MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE OVERHAUL Belt

Phillips screwdriver

TSBRevision

(4) a Phillips screwdriver [shank diameter 8 mm

in.)] through the hole.

If it can be inserted as deep as 60 mm (2.4 or](/img/19/57345/w960_57345-124.png)

ENGINE OVERHAUL Belt

Phillips screwdriver

TSBRevision

(4) a Phillips screwdriver [shank diameter 8 mm

in.)] through the hole.

If it can be inserted as deep as 60 mm (2.4 or more;

the timing ‘marks are correctly aligned. If the inserted

depth is only

mm in.), turn the oil’ pump

sprocket one turn and

marks. Then check

to ensure that the screwdriver can be inserted 60 m m

(2.4 in.) or more. Keep the screwdriver inserted the

installation of the timing belt is finished.

NOTE

Step (4) is performed to ensure that the oil pump sprocket

is correctly positioned with reference to the counterbal-

ance shafts.

(5) Thread the timing belt over the intake side cam shaft

sprocket and fix it at indicated position by a bulldog clip.

(6) Thread the timing belt over the exhaust side sp rocket,

aligning the timing marks with the cylinder head top surface

using two wrenches.

(7) Fix the belt at indicated, position

a bulldog clip.

Page 126 of 2103

ENGINE OVERHAUL Timing

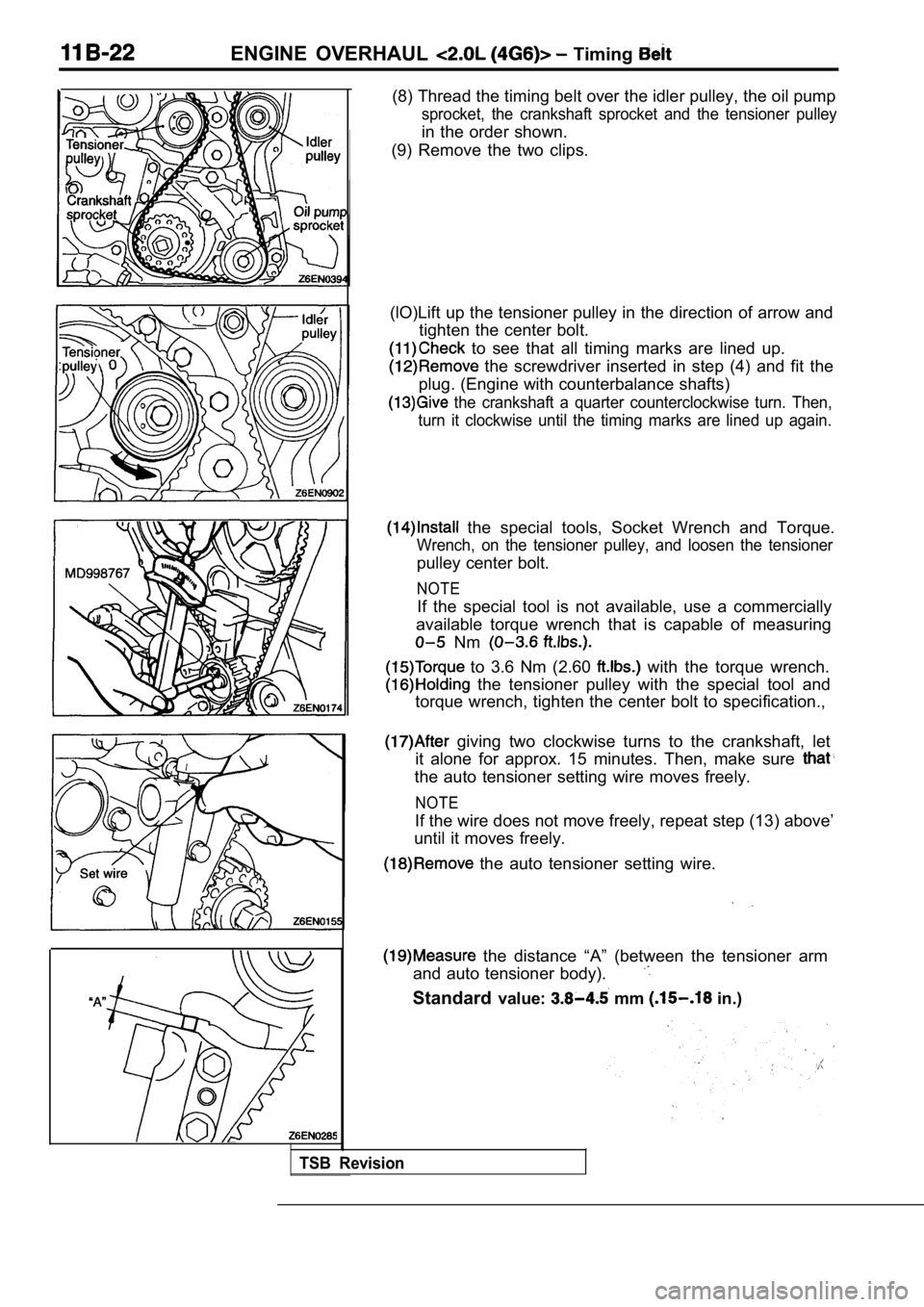

(8) Thread the timing belt over the idler pulley, the oil pump

sprocket, the crankshaft sprocket and the tensioner pulley

in the order shown.

(9) Remove the two clips.

(lO)Lift up the tensioner pulley in the direction o f arrow and

tighten the center bolt.

to see that all timing marks are lined up.

the screwdriver inserted in step (4) and fit the

plug. (Engine with counterbalance shafts)

the crankshaft a quarter counterclockwise turn. Th en,

turn it clockwise until the timing marks are lined up again.

the special tools, Socket Wrench and Torque.

Wrench, on the tensioner pulley, and loosen the ten sioner

pulley center bolt.

NOTE

If the special tool is not available, use a commercially

available torque wrench that is capable of measurin g

Nm

to 3.6 Nm (2.60 with the torque wrench.

the tensioner pulley with the special tool and

torque wrench, tighten the center bolt to specifica tion.,

giving two clockwise turns to the crankshaft, let

it alone for approx. 15 minutes. Then, make sure

the auto tensioner setting wire moves freely.

NOTE

If the wire does not move freely, repeat step (13) above’

until it moves freely.

the auto tensioner setting wire.

the distance “A” (between the tensioner arm

and auto tensioner body).

Standard value: mm in.)

TSB Revision

Page 127 of 2103

ENGINE OVERHAUL Timing

Cracks’

Rounded edgeI

Abnormal wear(Fluffy strand)

Rubber exposed

Tooth missingand canvas fibe

INSPECTION

TIMING BELT

Replace belt if any of the following conditions exi st.

(1) Hardening of back rubber.

Back side is glossy without resilience and leaves no indent

when pressed with fingernail.

(2) Cracks on rubber back.

(3) Cracks or peeling of canvas.

(4) Cracks on rib root.

(5) Cracks on belt sides.

(6) Abnormal wear of belt sides. The sides are norm al if

they are sharp as if cut by a knife.

(7) Abnormal wear on teeth.

(8) Missing tooth.

AUTO TENSIONER

(1) Check the auto tensioner for possible leaks and replace

as necessary.

(2) Check the rod end for wear or damage and replac e as

necessary.

(3) Measure the rod protrusion. If it is out of specification,

replace the auto tensioner.

Standard value: 12 mm

in.)

Page 128 of 2103

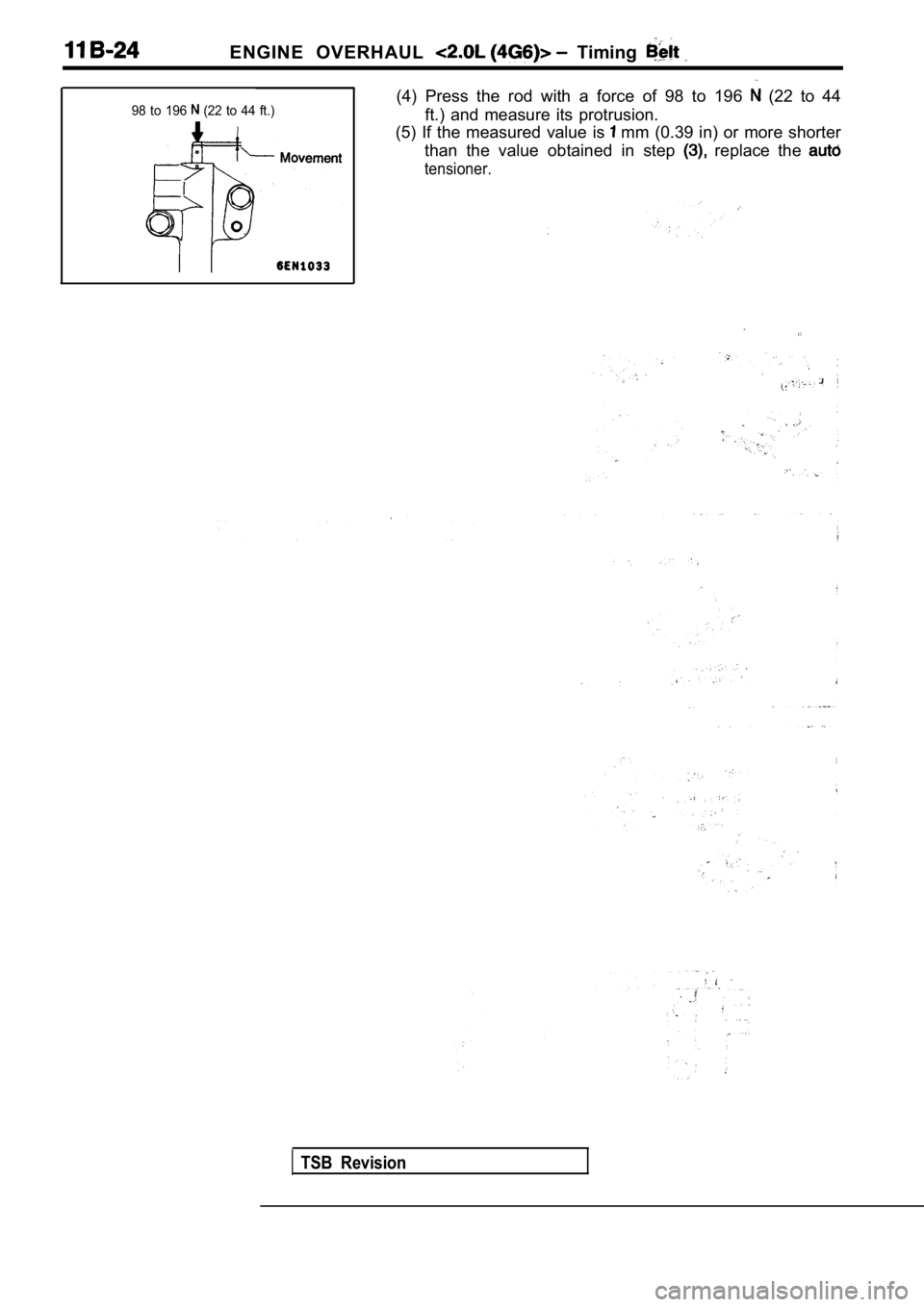

98 to 196 (22 to 44 ft.)

ENGINE OVERHAUL Timing

(4) Press the rod with a force of 98 to 196 (22 to 44

ft.) and measure its protrusion.

(5) If the measured value is

mm (0.39 in) or more shorter

than the value obtained in step

replace the

tensioner.

TSB Revision

Page 129 of 2103

ENGINE OVERHAUL

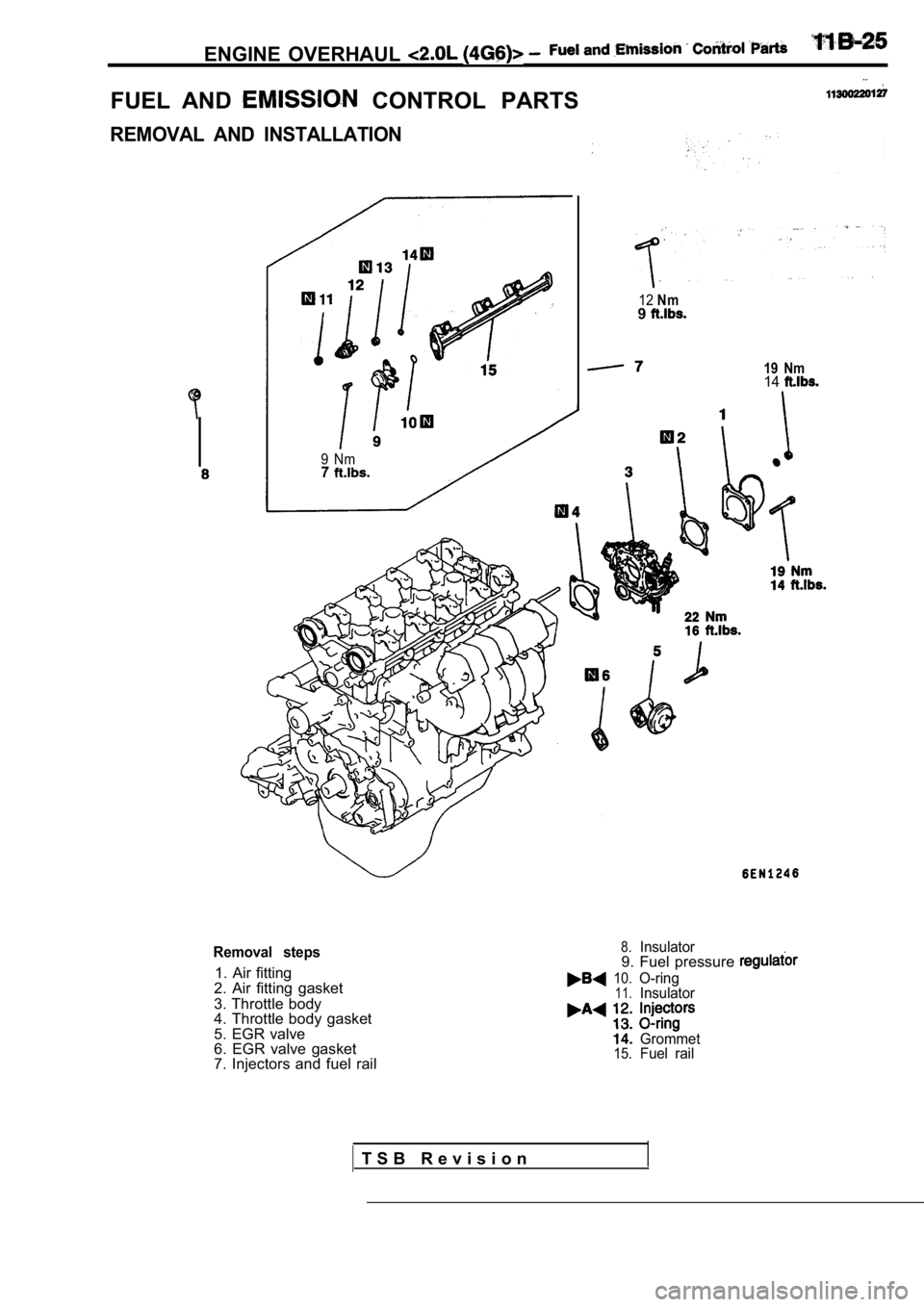

FUEL AND CONTROL PARTS

REMOVAL AND INSTALLATION

9 Nm7

Removal steps

1. Air fitting

2. Air fitting gasket

3. Throttle body

4. Throttle body gasket

5. EGR valve

6. EGR valve gasket

7. Injectors and fuel rail

12Nm9

19 Nm14

8.Insulator9. Fuel pressure

10.O-ring11.Insulator

Grommet15.Fuel rail

T S B R e v i s i o n

Page 130 of 2103

ENGINE OVERHAUL Fuel and

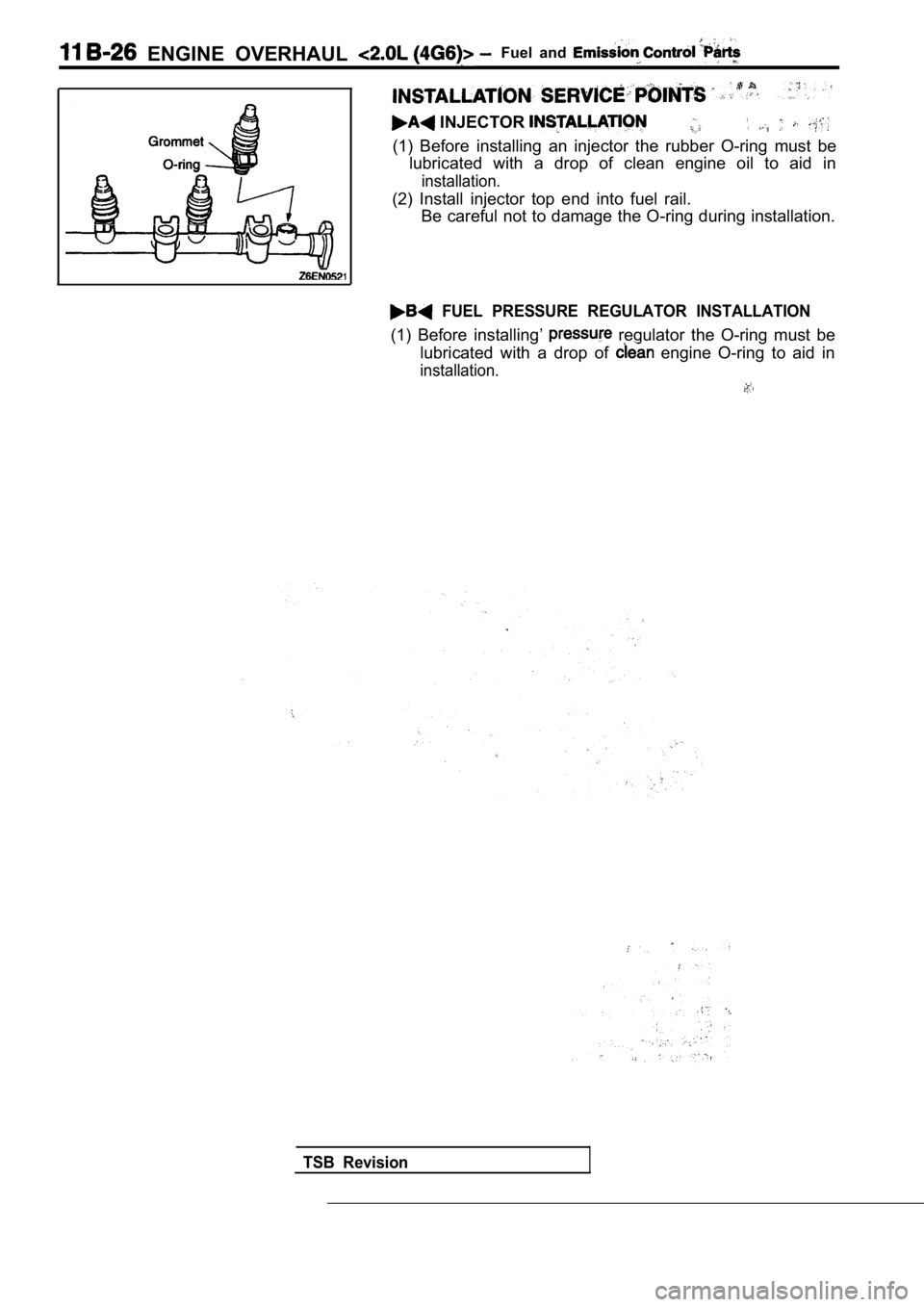

INJECTOR

(1) Before installing an injector the rubber O-ring must be

lubricated with a drop of clean engine oil to aid i n

installation.

(2) Install injector top end into fuel rail.

Be careful not to damage the O-ring during installa tion.

FUEL PRESSURE REGULATOR INSTALLATION

(1) Before installing’ regulator the O-ring must be

lubricated with a drop of

engine O-ring to aid in

installation.

TSB Revision