MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: service interval, check engine light, ignition, overheating, sensor, wipers, parking sensors

Page 111 of 2103

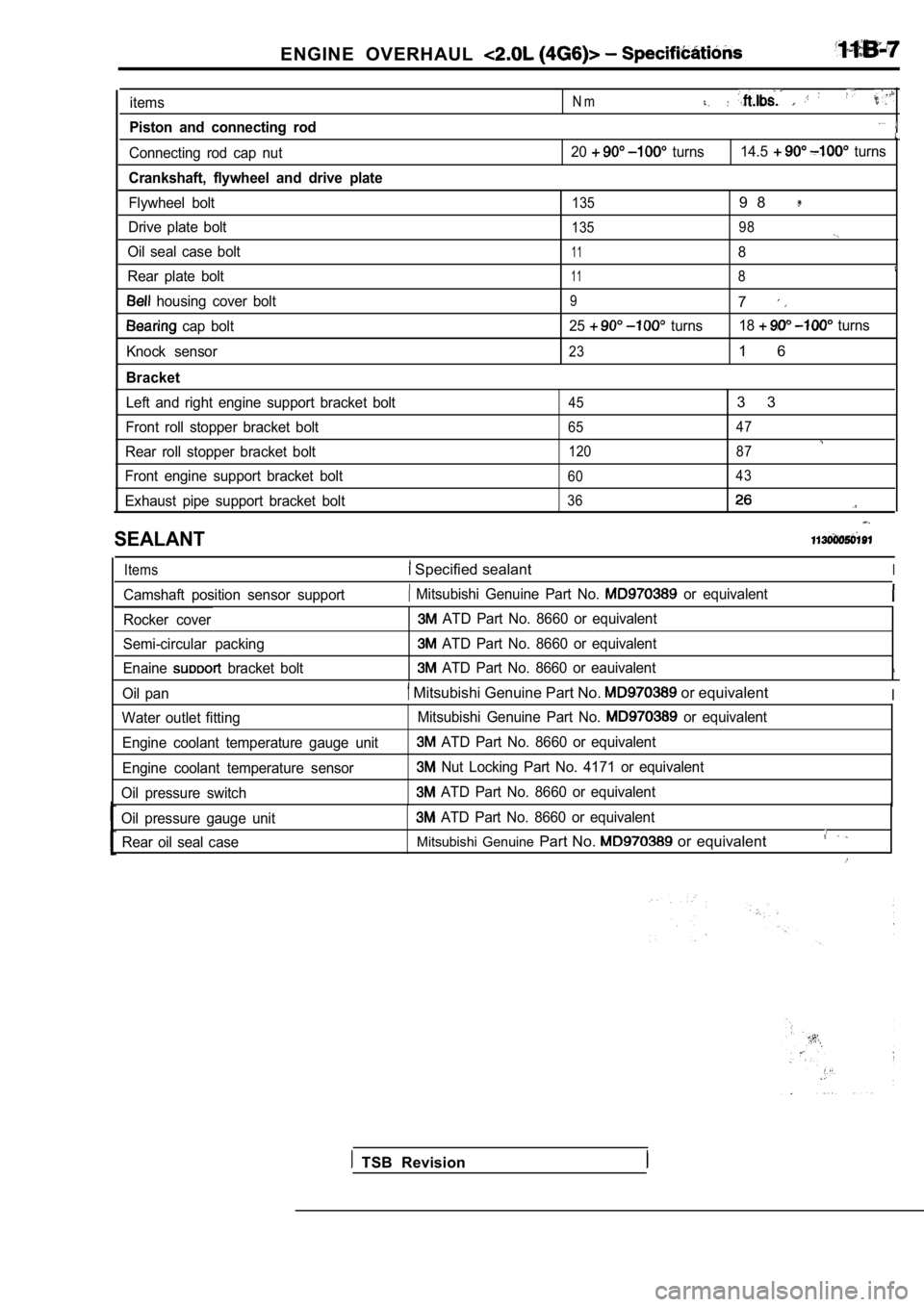

ENGINE OVERHAUL

items

Piston and connecting rod

Connecting rod cap nut

Crankshaft, flywheel and drive plate

Flywheel bolt

Drive plate bolt

Oil seal case bolt

Rear plate bolt

housing cover bolt

cap bolt

Knock sensor

Bracket

Left and right engine support bracket bolt

Front roll stopper bracket bolt

Rear roll stopper bracket bolt

Front engine support bracket bolt

Exhaust pipe support bracket bolt

N m

20 turns 14.5 turns

1359 8

135 98

118

118

97

25 turns18 turns

231 6

453 3

65 47

120 87

60 43

36

SEALANT

Items Specified sealantI

Camshaft position sensor support Mitsubishi Genuine Part No. or equivalent

Rocker cover

Semi-circular packing

Enaine

bracket bolt

ATD Part No. 8660 or equivalent

ATD Part No. 8660 or equivalent

ATD Part No. 8660 or eauivalent

Oil pan Mitsubishi Genuine Part No. or equivalentI

Water outlet fitting

Engine coolant temperature gauge unit

Engine coolant temperature sensor

Oil pressure switch Mitsubishi Genuine Part No. or equivalent

ATD Part No. 8660 or equivalent

Nut Locking Part No. 4171 or equivalent

ATD Part No. 8660 or equivalent

Oil pressure gauge unit

ATD Part No. 8660 or equivalent

Rear oil seal case

Mitsubishi Genuine Part No. or equivalent

TSB Revision

Page 112 of 2103

ENGINE OVERHAUL ,

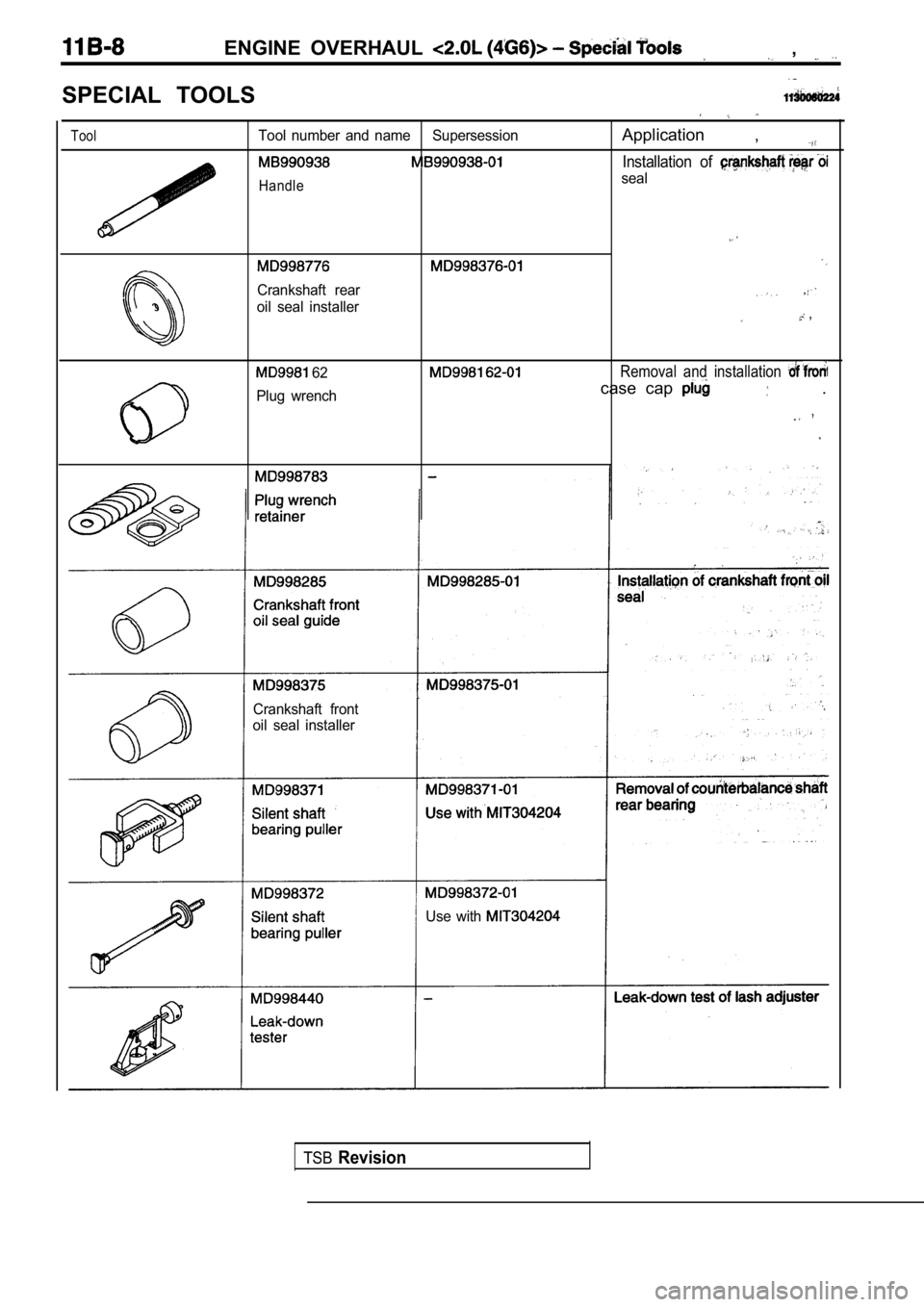

SPECIAL TOOLS

ToolTool number and name SupersessionApplication ,

Installation of

Handleseal

Crankshaft rear

oil seal installer ,

62Removal and installation

Plug wrenchcase cap .

Crankshaft front

oil seal installer

Use with

TSBRevision

Page 113 of 2103

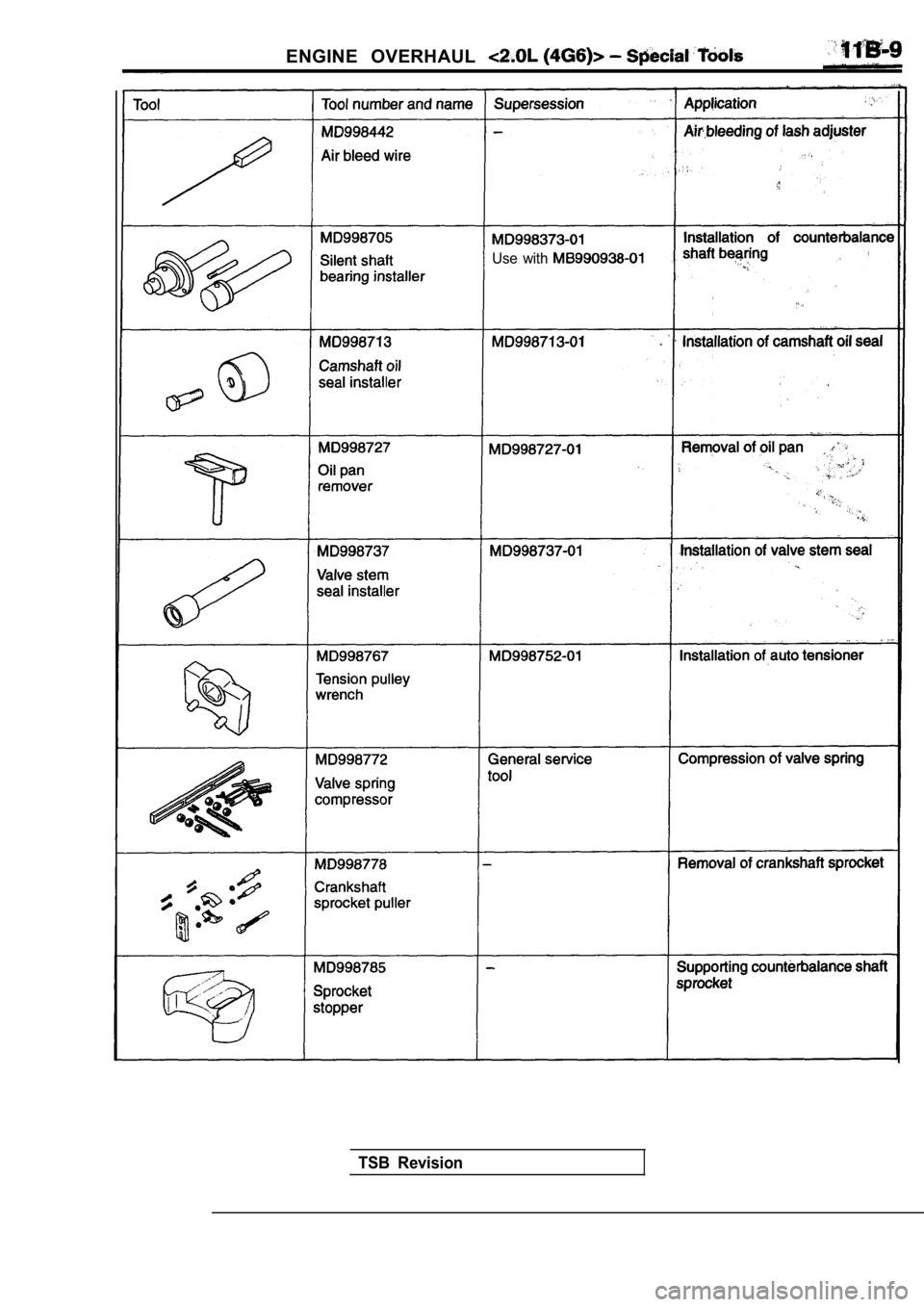

ENGINE OVERHAUL

Use with

TSB Revision

Page 114 of 2103

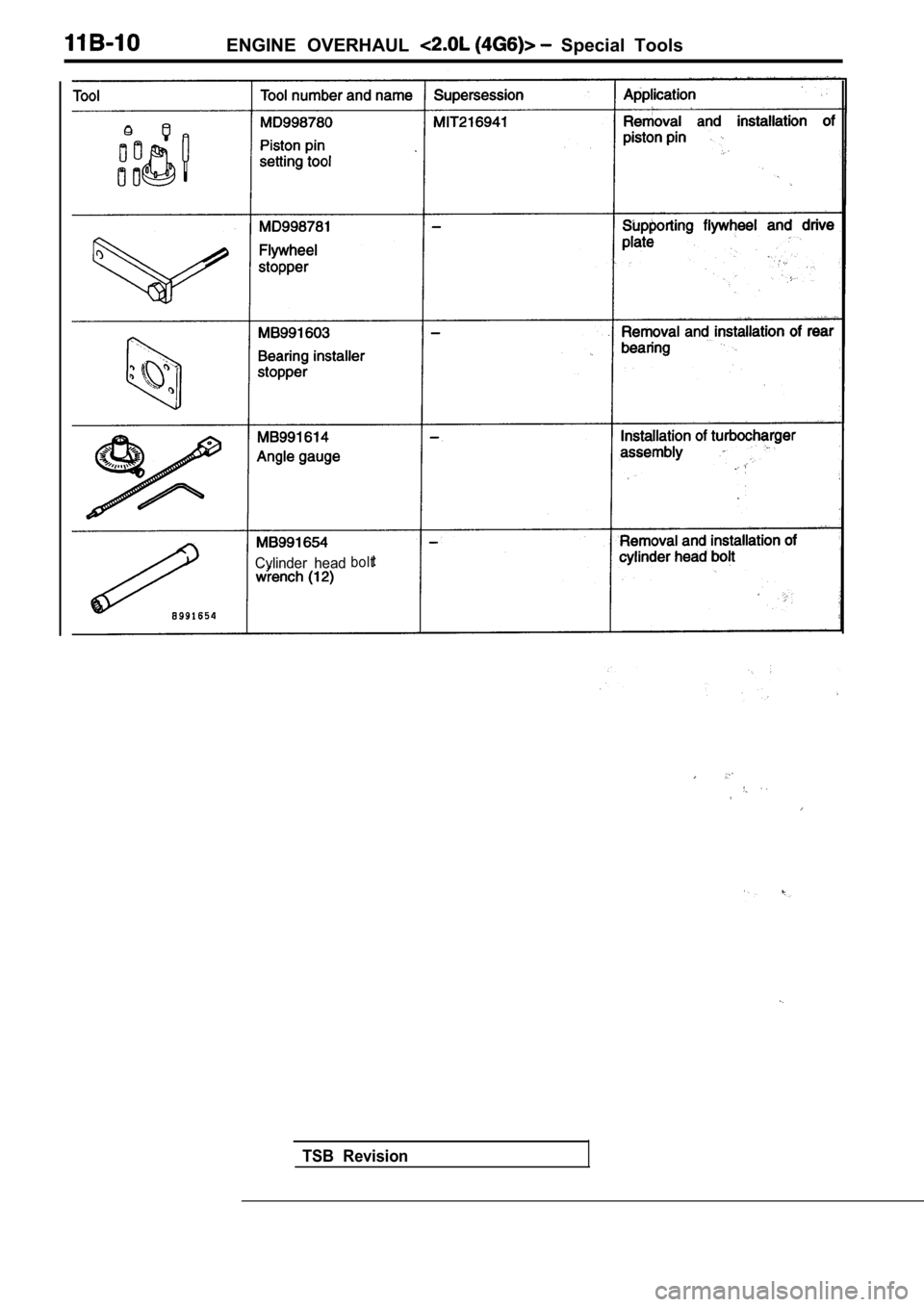

ENGINE OVERHAUL Special Tools

Cylinder headbolt

TSB Revision

Page 115 of 2103

ENGINE OVERHAUL and 11

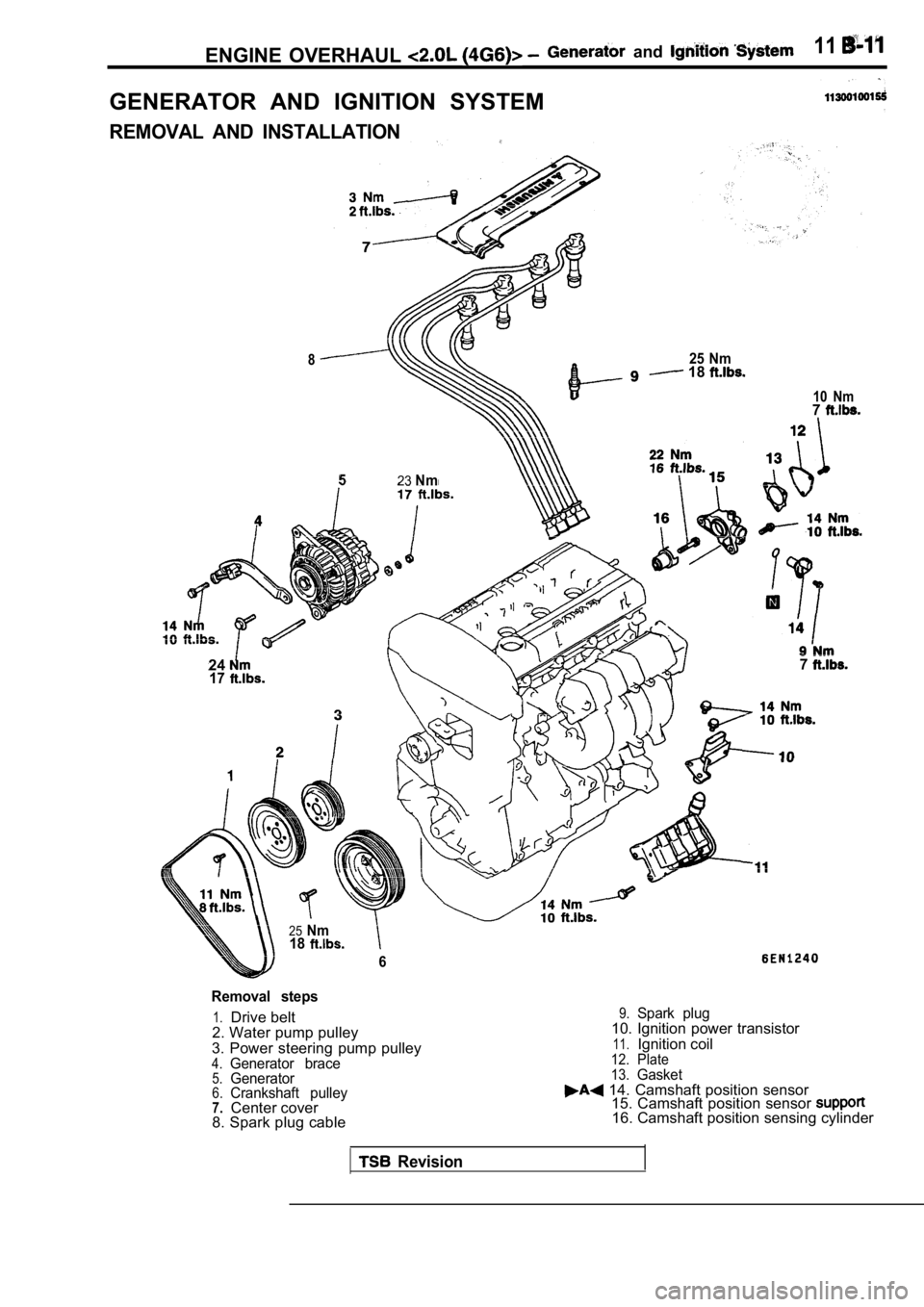

GENERATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION

825 Nm 18

523Nm

24177

25Nm18

6

10 Nm7

Removal steps

1.Drive belt

2. Water pump pulley

3. Power steering pump pulley

4.Generator brace5.Generator6.Crankshaft pulley7.Center cover

8. Spark plug cable

9.Spark plug10. Ignition power transistor

11.Ignition coil12. Plate

13.Gasket 14. Camshaft position sensor 15. Camshaft position sensor

16. Camshaft position sensing cylinder

Revision

Page 116 of 2103

ENGINE OVERHAUL Generator and

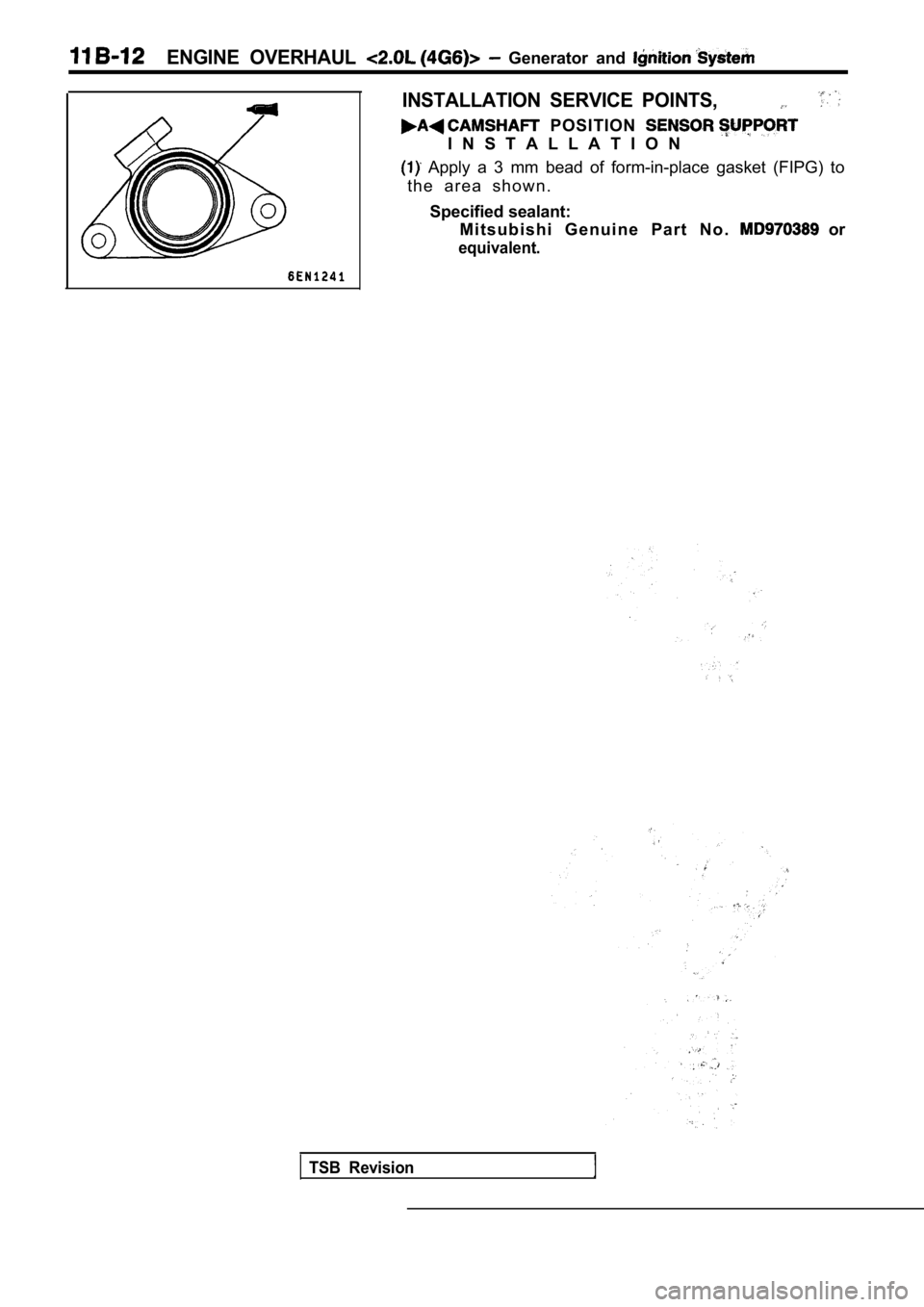

INSTALLATION SERVICE POINTS,

POSITION

I N S T A L L A T I O N

Apply a 3 mm bead of form-in-place gasket (FIPG) to

t h e a r e a s h o w n .

Specified sealant: M i t s u b i s h i G e n u i n e P a r t N o .

or

equivalent.

TSB Revision

Page 117 of 2103

ENGINE OVERHAUL

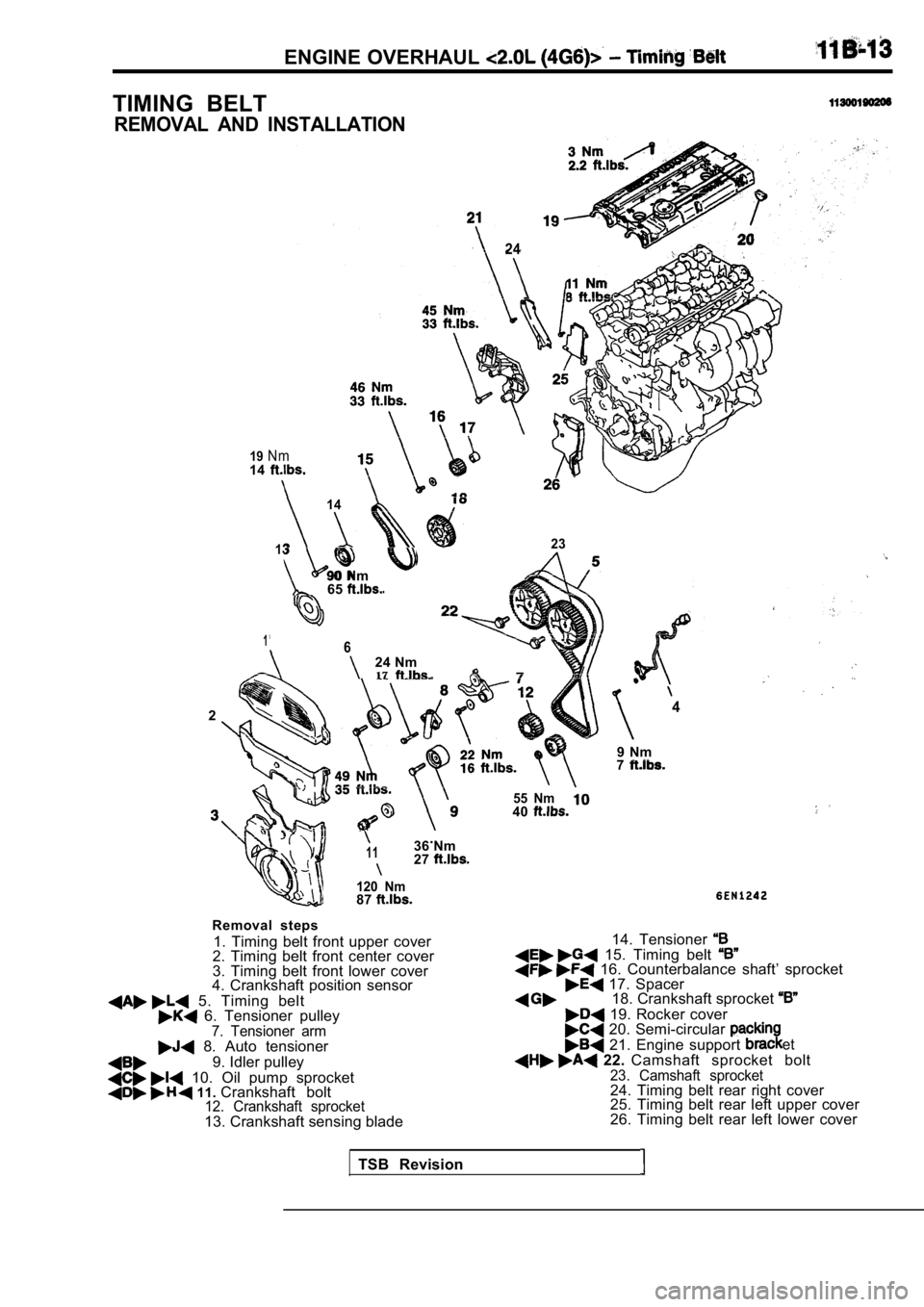

TIMING BELT

REMOVAL AND INSTALLATION

19N m

24

14

14

13

90 Nm65

23

1624 Nm17

24

9 Nm7

.1136 Nm27

120 Nm87

Removal steps

1. Timing belt front upper cover

2. Timing belt front center cover

3. Timing belt front lower cover

4. Crankshaft position sensor

5. Timing belt 6. Tensioner pulley7. Tensioner arm 8. Auto tensioner

9. Idler pulley

10. Oil pump sprocket 11. Crankshaft bolt12. Crankshaft sprocket13. Crankshaft sensing blade

55 Nm40

14. Tensioner 15. Timing belt 16. Counterbalance shaft’ sprocket 17. Spacer18. Crankshaft sprocket

19. Rocker cover 20. Semi-circular

21. Engine support et

22. Camshaft sprocket bolt23. Camshaft sprocket24. Timing belt rear right cover

25. Timing belt rear left upper cover

26. Timing belt rear left lower cover

TSB Revision

Page 118 of 2103

OVERHAUL Timing. Belt

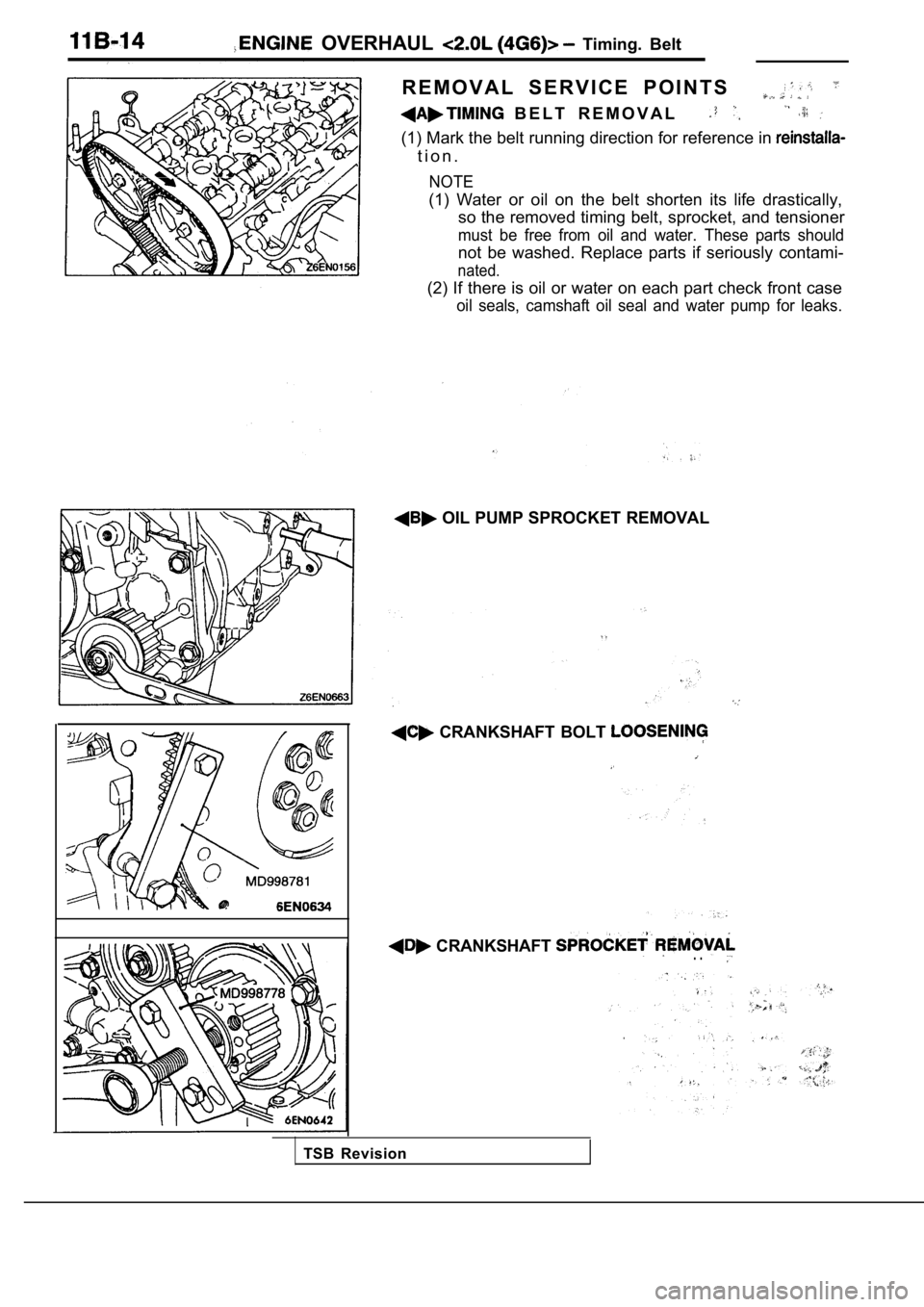

R E M O V A L S E R V I C E P O I N T S

B E L T R E M O V A L

(1) Mark the belt running direction for reference in

t i o n .

NOTE

(1) Water or oil on the belt shorten its life drast ically,

so the removed timing belt, sprocket, and tensioner

must be free from oil and water. These parts should

not be washed. Replace parts if seriously contami-

nated.

(2) If there is oil or water on each part check fro nt case

oil seals, camshaft oil seal and water pump for lea ks.

OIL PUMP SPROCKET REMOVAL

CRANKSHAFT BOLT

CRANKSHAFT . .

TSB Revision

Page 119 of 2103

OVERHAUL Timing

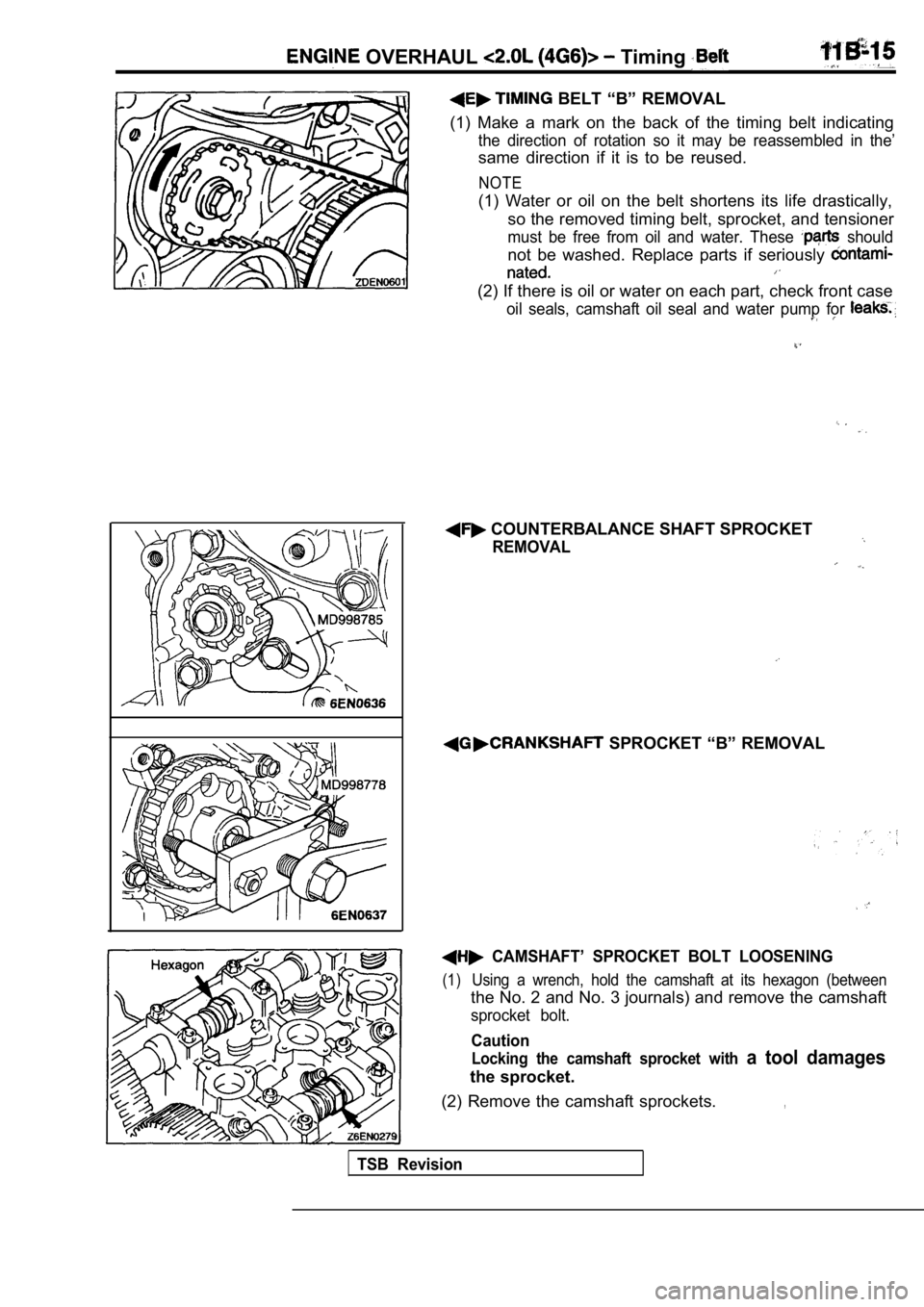

BELT “B” REMOVAL

(1) Make a mark on the back of the timing belt indi cating

the direction of rotation so it may be reassembled in the’

same direction if it is to be reused.

NOTE

(1) Water or oil on the belt shortens its life drastically,

so the removed timing belt, sprocket, and tensioner

must be free from oil and water. These should

not be washed. Replace parts if seriously

(2) If there is oil or water on each part, check fr ont case

oil seals, camshaft oil seal and water pump for

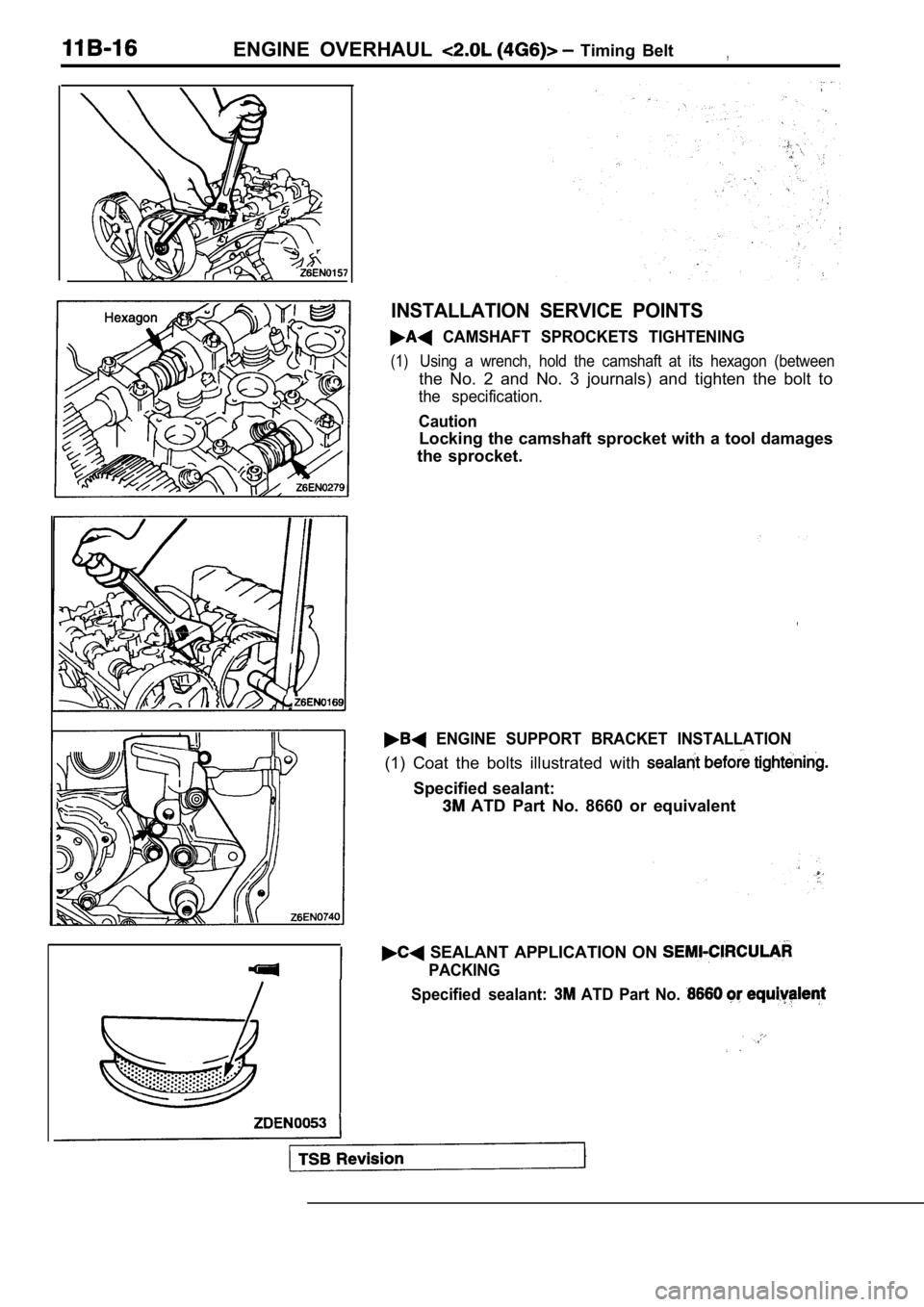

COUNTERBALANCE SHAFT SPROCKET

REMOVAL

SPROCKET “B” REMOVAL

CAMSHAFT’ SPROCKET BOLT LOOSENING

(1)Using a wrench, hold the camshaft at its hexagon (b etween

the No. 2 and No. 3 journals) and remove the camshaft

sprocket bolt.

Caution

Locking the camshaft sprocket with a tool damages

the sprocket.

(2) Remove the camshaft sprockets.

,

TSB Revision

Page 120 of 2103

ENGINE OVERHAUL Timing Belt,

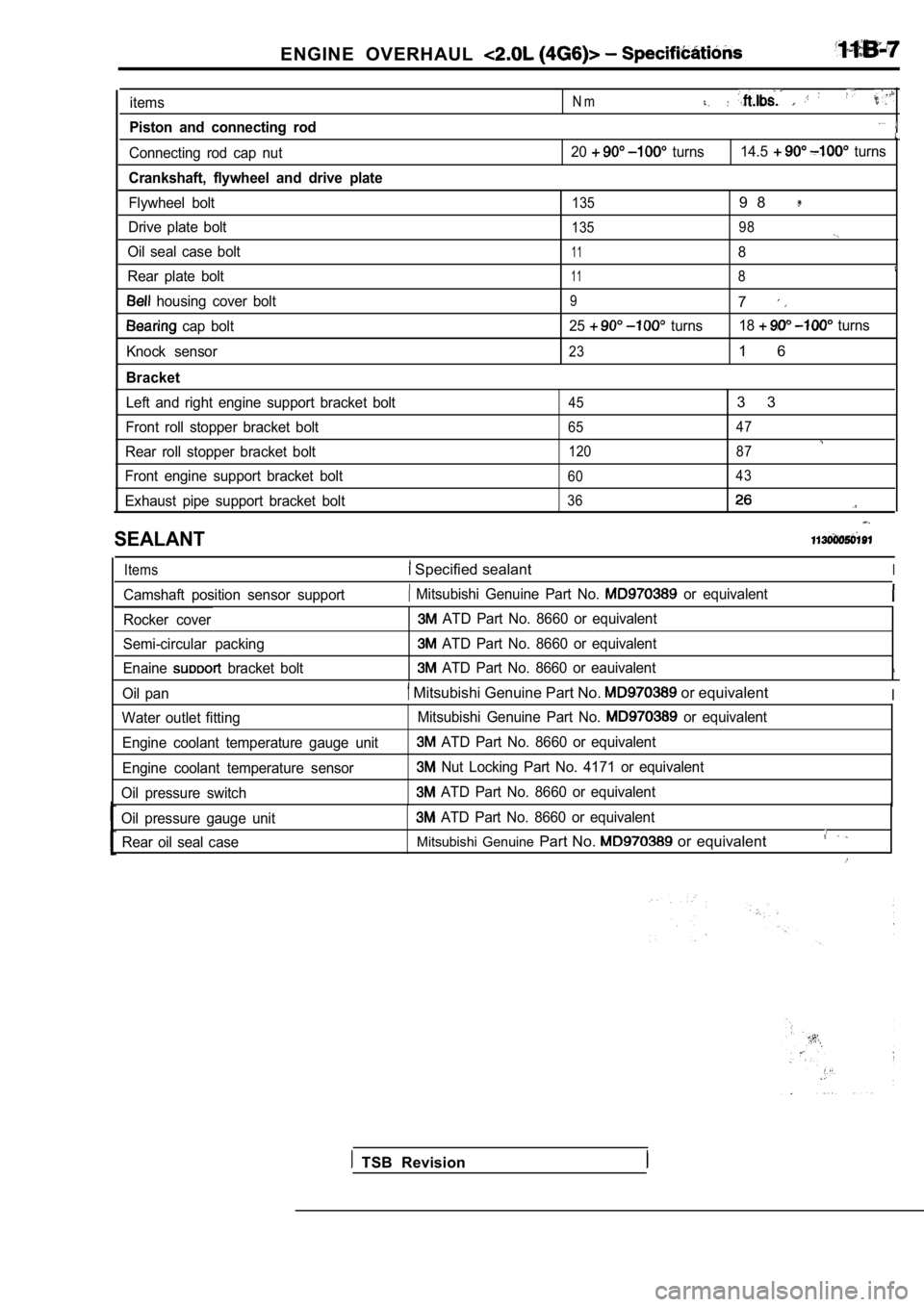

INSTALLATION SERVICE POINTS

CAMSHAFT SPROCKETS TIGHTENING

(1)Using a wrench, hold the camshaft at its hexagon (between

the No. 2 and No. 3 journals) and tighten the bolt to

the specification.

Caution

Locking the camshaft sprocket with a tool damages

the sprocket.

ENGINE SUPPORT BRACKET INSTALLATION

(1) Coat the bolts illustrated with

Specified sealant:

ATD Part No. 8660 or equivalent

SEALANT APPLICATION ON

PACKING

Specified sealant:

ATD Part No.

Trending: oil filter, low oil pressure, radio, ESP, transmission fluid, air conditioning, battery