MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 871 of 2103

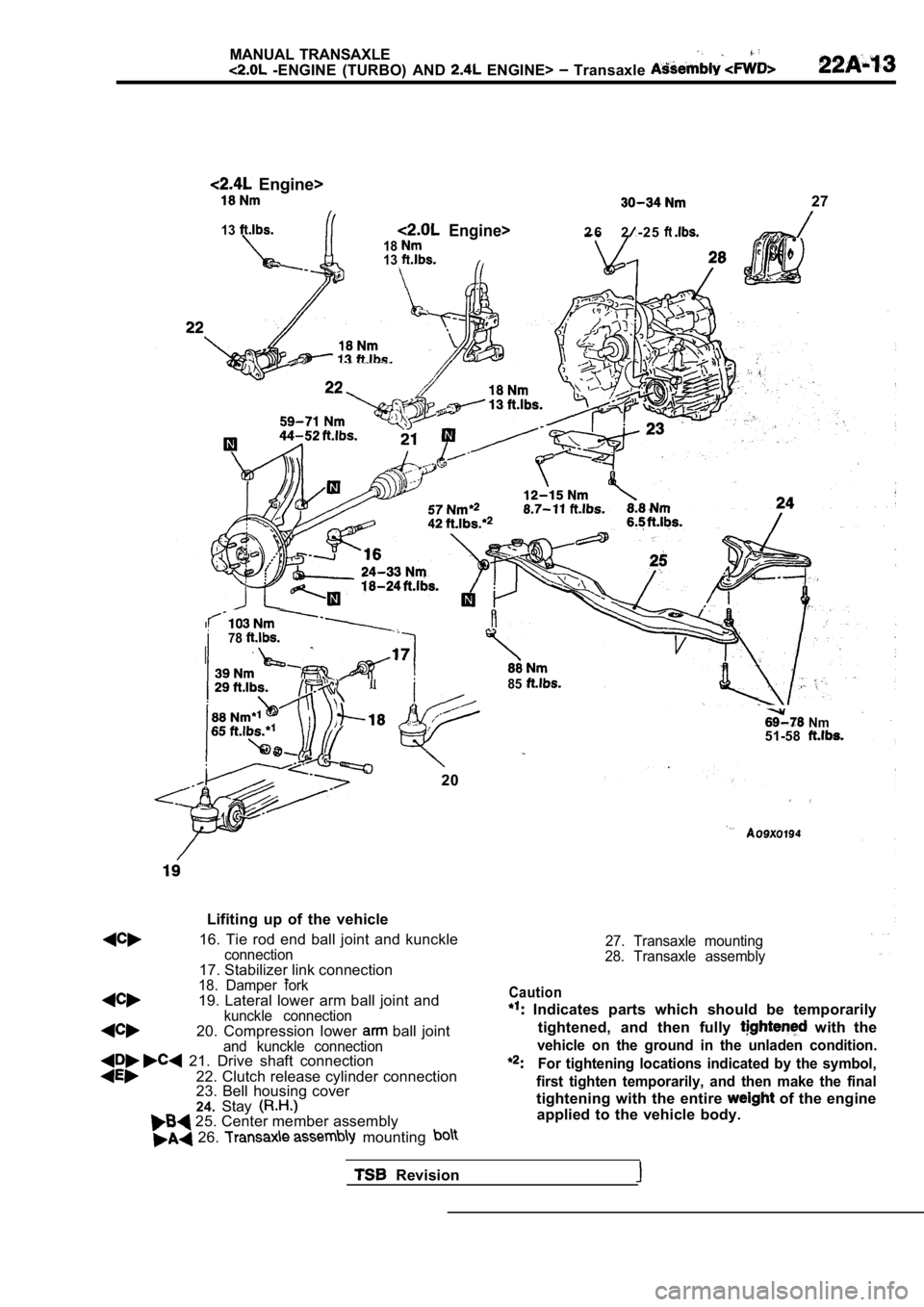

MANUAL TRANSAXLE

-ENGINE (TURBO) AND ENGINE> Transaxle

Engine>

13

27

Engine>2 2 - 2 52 61813

I

78

85

20

Nm51-58

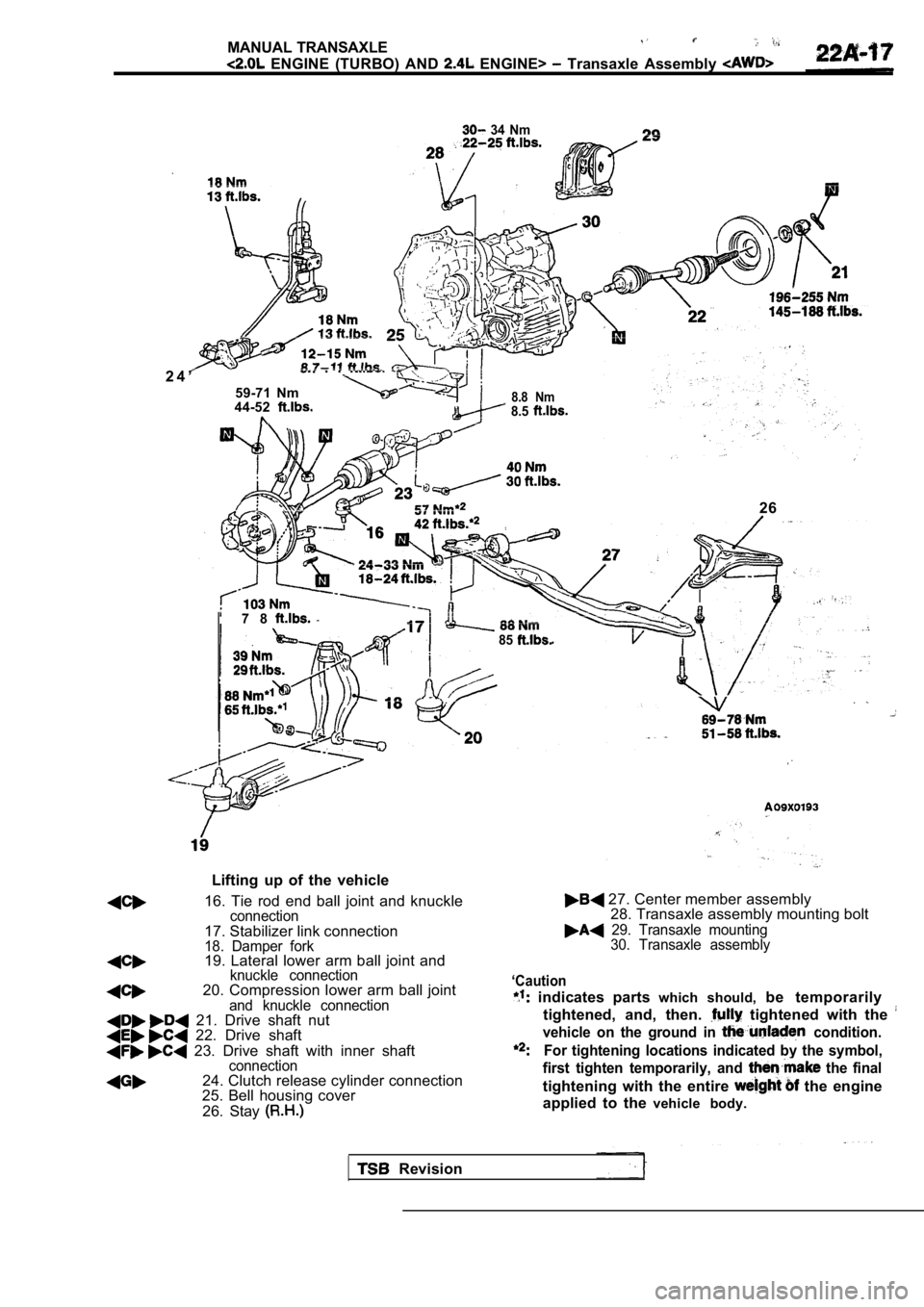

Lifiting up of the vehicle

16. Tie rod end ball joint and kunckleconnection17. Stabilizer link connection18. Damper fork19. Lateral lower arm ball joint andkunckle connection20. Compression lower ball jointand kunckle connection 21. Drive shaft connection

22. Clutch release cylinder connection

23. Bell housing cover

24.Stay

27. Transaxle mounting

28. Transaxle assembly

25. Center member assembly

26. mounting

Caution

Indicates parts which should be temporarily

tightened, and then fully

with the

vehicle on the ground in the unladen condition.

For tightening locations indicated by the symbol,

first tighten temporarily, and then make the final

tightening with the entire of the engine

applied to the vehicle body.

Revision

Page 872 of 2103

MANUAL TRANSAXLE

ENGINE AND ENGINE> Transaxle Assembly

I

Nut

ITransaxle

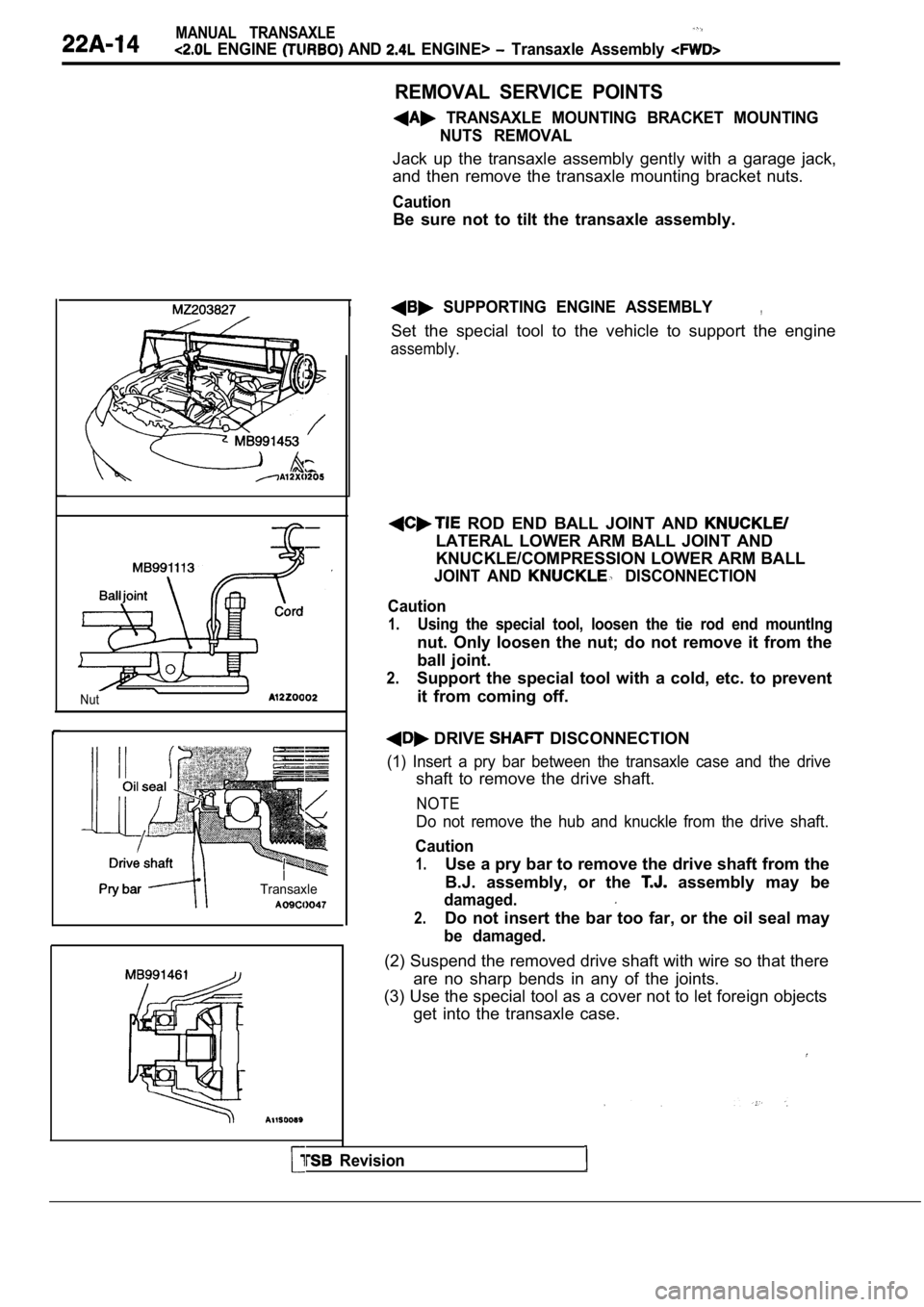

REMOVAL SERVICE POINTS

TRANSAXLE MOUNTING BRACKET MOUNTINGNUTS REMOVAL

Jack up the transaxle assembly gently with a garage jack,

and then remove the transaxle mounting bracket nuts .

Caution

Be sure not to tilt the transaxle assembly.

SUPPORTING ENGINE ASSEMBLY,

Set the special tool to the vehicle to support the engine

assembly.

ROD END BALL JOINT AND

LATERAL LOWER ARM BALL JOINT AND

KNUCKLE/COMPRESSION LOWER ARM BALL

JOINT AND DISCONNECTION

Caution

1.Using the special tool, loosen the tie rod end moun tlng

nut. Only loosen the nut; do not remove it from the

ball joint.

2.Support the special tool with a cold, etc. to prevent

it from coming off.

DRIVE DISCONNECTION

(1) Insert a pry bar between the transaxle case and the drive

shaft to remove the drive shaft.

NOTE

Do not remove the hub and knuckle from the drive sh aft.

Caution

1.Use a pry bar to remove the drive shaft from the

B.J. assembly, or the

assembly may be

damaged.

2.Do not insert the bar too far, or the oil seal may

be damaged.

(2) Suspend the removed drive shaft with wire so that there

are no sharp bends in any of the joints.

(3) Use the special tool as a cover not to let fore ign objects

get into the transaxle case.

Revision

Page 873 of 2103

MANUAL TRANSAXLE

ENGINE (TURBO) AND ENGINE> Transaxle Assembly

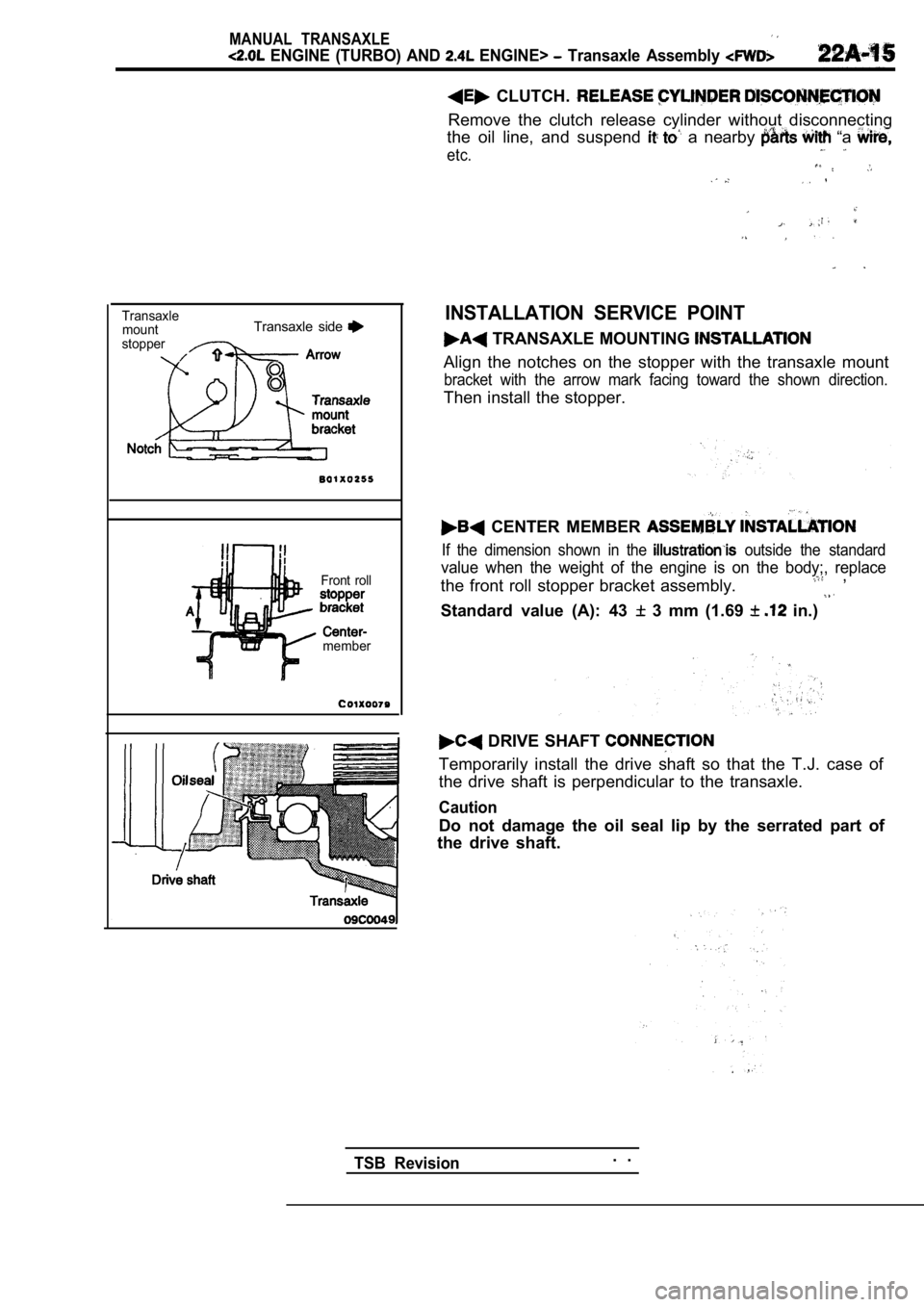

TransaxlemountTransaxle side

stopper

Front roll

member

CLUTCH.

Remove the clutch release cylinder without disconne cting

the oil line, and suspend

a nearby “a

etc.

INSTALLATION SERVICE POINT

TRANSAXLE MOUNTING

Align the notches on the stopper with the transaxle mount

bracket with the arrow mark facing toward the shown direction.

Then install the stopper.

CENTER MEMBER

If the dimension shown in the outside the standard

value when the weight of the engine is on the body;, replace

the front roll stopper bracket assembly. ,

Standard value (A): 43

3 mm (1.69 in.)

DRIVE SHAFT

Temporarily install the drive shaft so that the T.J . case of

the drive shaft is perpendicular to the transaxle.

Caution

Do not damage the oil seal lip by the serrated part of

the drive shaft.

TSB Revision. .

Page 874 of 2103

MANUAL ,

ENGINE AND Transaxle Assembly .

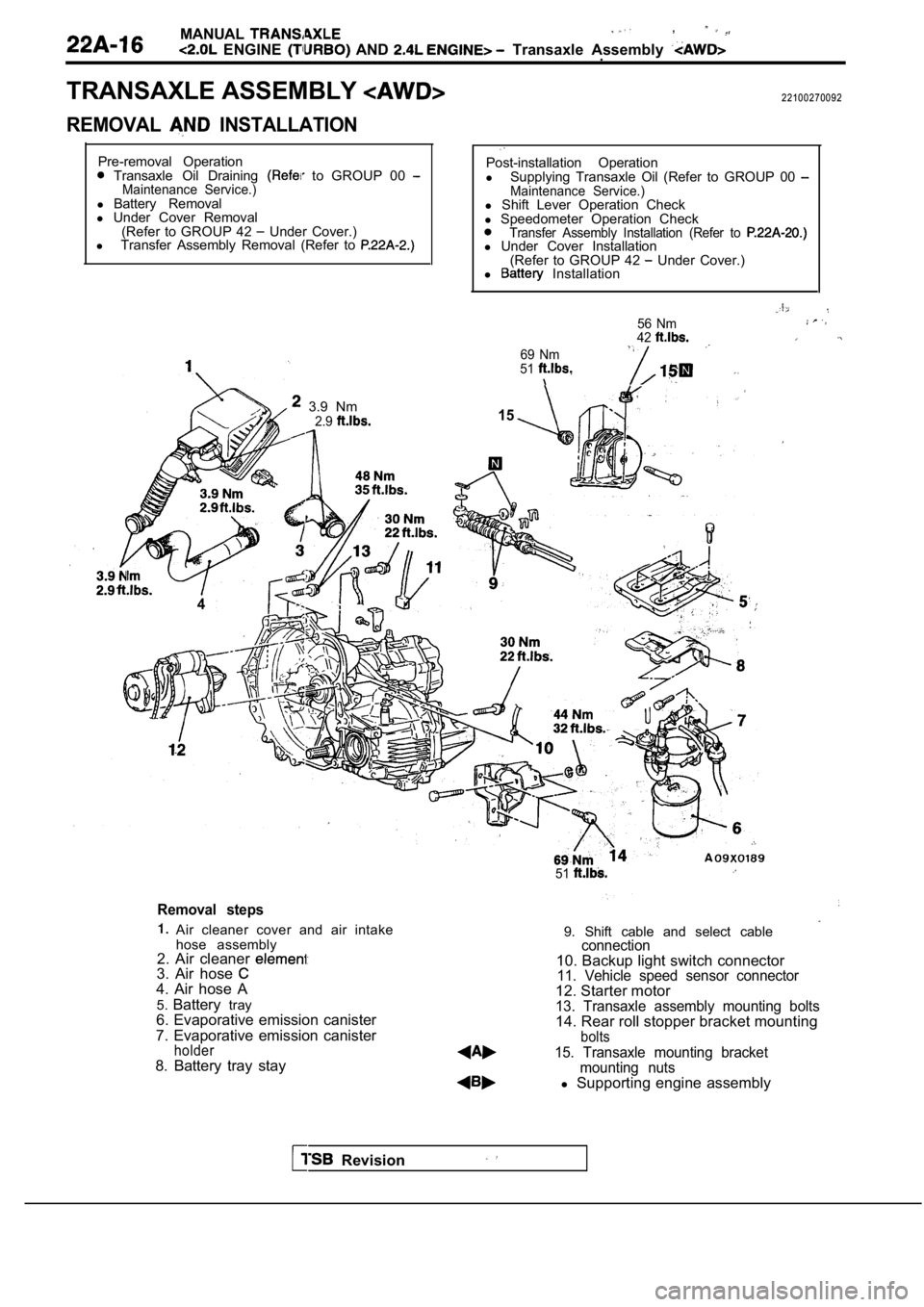

TRANSAXLE ASSEMBLY

REMOVAL INSTALLATION

22100270092

Pre-removal Operation

Transaxle Oil Draining to GROUP 00 Maintenance Service.)l Battery Removal

l Under Cover Removal

(Refer to GROUP 42

Under Cover.)

l Transfer Assembly Removal (Refer to

3.9 Nm

4

2.9

Post-installation Operation

l Supplying Transaxle Oil (Refer to GROUP 00

Maintenance Service.)l Shift Lever Operation Check

l Speedometer Operation Check

Transfer Assembly Installation (Refer to l Under Cover Installation

(Refer to GROUP 42 Under Cover.)

l Installation

69 Nm

51

56 Nm

42

15

51

Removal steps

Air cleaner cover and air intake

hose assembly

2. Air cleaner

3. Air hose 4. Air hose A

5. Battery tray

6. Evaporative emission canister

7. Evaporative emission canister

holder8. Battery tray stay 9. Shift cable and select cable

connection10. Backup light switch connector11. Vehicle speed sensor connector12. Starter motor13. Transaxle assembly mounting bolts14. Rear roll stopper bracket mountingbolts

15. Transaxle mounting bracket

mounting nuts

l Supporting engine assembly

Revision

Page 875 of 2103

MANUAL TRANSAXLE

ENGINE (TURBO) AND ENGINE> Transaxle Assembly

34 Nm

2 4 ’ . .

59-71 Nm

44-528.8 Nm8.5

26

7 8

85

Lifting up of the vehicle

16. Tie rod end ball joint and knuckle

connection17. Stabilizer link connection18. Damper fork19. Lateral lower arm ball joint and

27. Center member assembly 28. Transaxle assembly mounting bolt

29. Transaxle mounting 30. Transaxle assembly

knuckle connection

20. Compression lower arm ball jointand knuckle connection 21. Drive shaft nut 22. Drive shaft

23. Drive shaft with inner shaftconnection24. Clutch release cylinder connection

25. Bell housing cover

26. Stay

‘Caution

indicates parts which should, be temporarily

tightened, and, then.

tightened with the

vehicle on the ground in condition.

For tightening locations indicated by the symbol,

first tighten temporarily, and

the final

tightening with the entire the engine

applied to the vehicle body.

Revision

Page 876 of 2103

MANUAL TRANSAXLE

ENGINE AND ENGINE> Transaxle Assembly

I -

Cord

I’ --

Nut

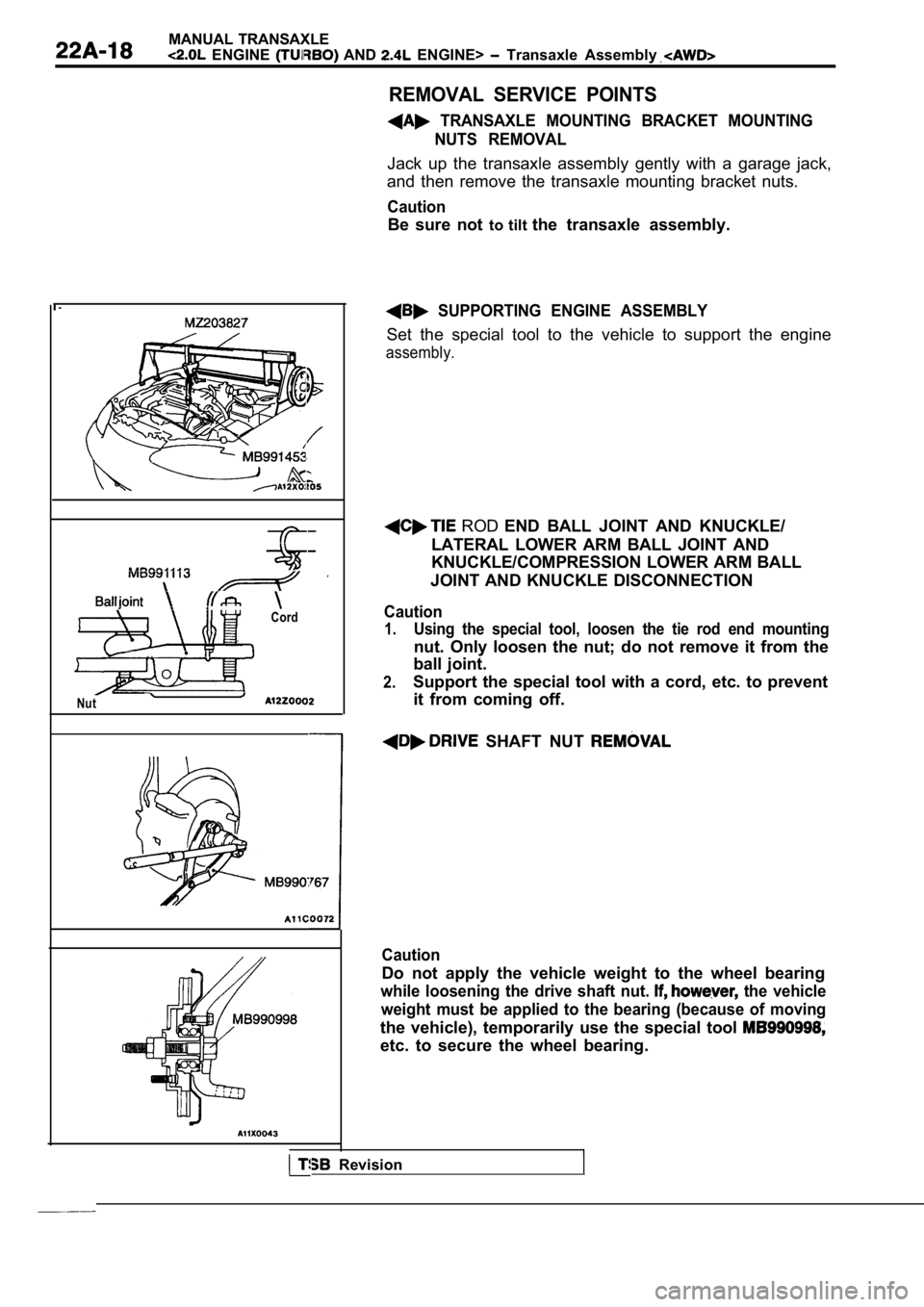

REMOVAL SERVICE POINTS

TRANSAXLE MOUNTING BRACKET MOUNTINGNUTS REMOVAL

Jack up the transaxle assembly gently with a garage jack,

and then remove the transaxle mounting bracket nuts .

Caution

Be sure not to tilt the transaxle assembly.

SUPPORTING ENGINE ASSEMBLY

Set the special tool to the vehicle to support the engine

assembly.

ROD END BALL JOINT AND KNUCKLE/

LATERAL LOWER ARM BALL JOINT AND

KNUCKLE/COMPRESSION LOWER ARM BALL

JOINT AND KNUCKLE DISCONNECTION

Caution

1.Using the special tool, loosen the tie rod end moun ting

nut. Only loosen the nut; do not remove it from the

ball joint.

2.Support the special tool with a cord, etc. to preve nt

it from coming off.

SHAFT NUT

Caution

Do not apply the vehicle weight to the wheel bearin g

while loosening the drive shaft nut. the vehicle

weight must be applied to the bearing (because of m oving

the vehicle), temporarily use the special tool

etc. to secure the wheel bearing.

I Revision

Page 877 of 2103

MANUAL TRANSAXLE

ENGINE (TURBO) AND ENGINE> Transaxle Assembly

11

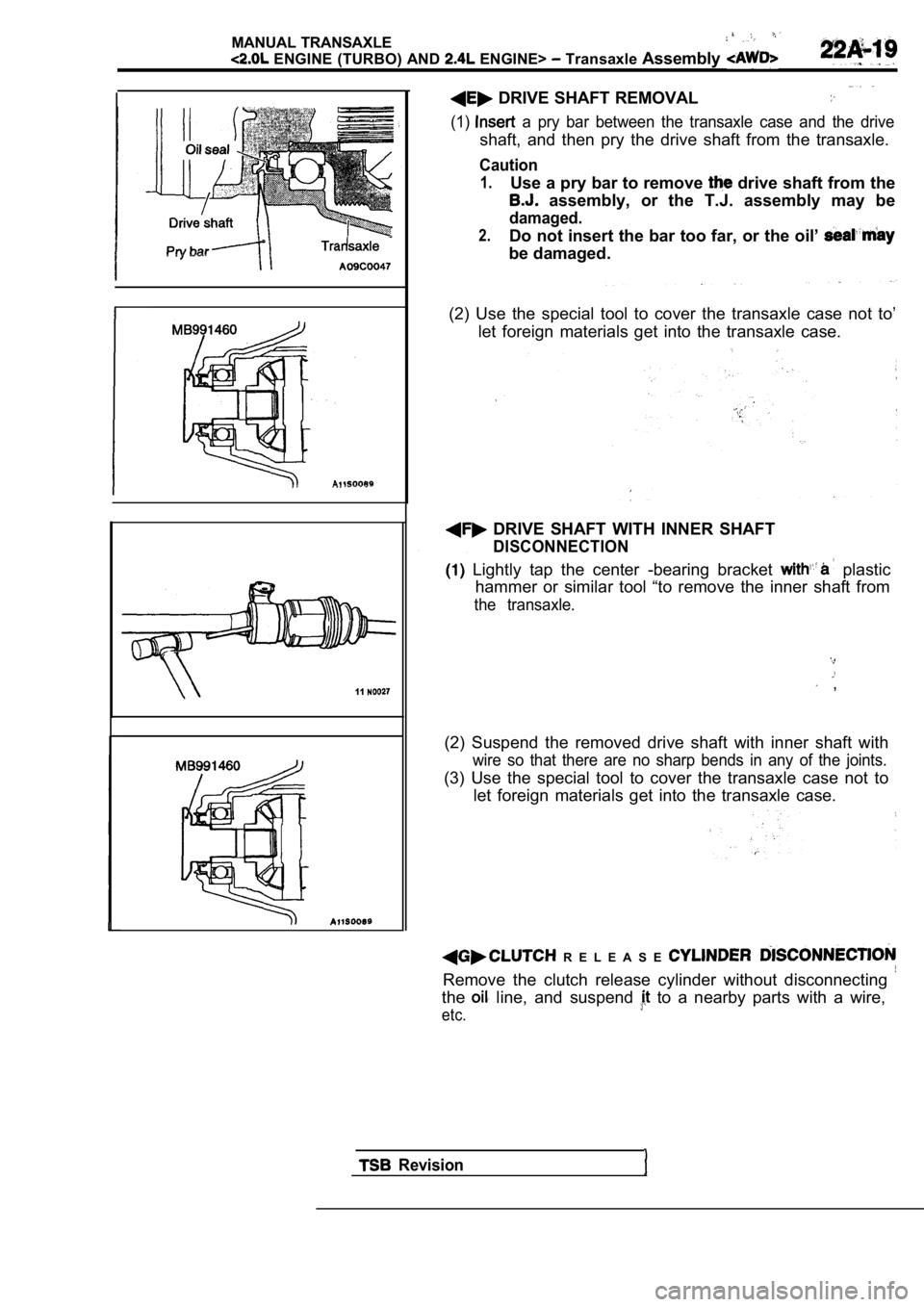

DRIVE SHAFT REMOVAL

(1) a pry bar between the transaxle case and the drive

shaft, and then pry the drive shaft from the transa xle.

Caution

1.Use a pry bar to remove drive shaft from the

assembly, or the T.J. assembly may be

damaged.

2.Do not insert the bar too far, or the oil’

be damaged.

(2) Use the special tool to cover the transaxle cas e not to’

let foreign materials get into the transaxle case.

DRIVE SHAFT WITH INNER SHAFT

DISCONNECTION

Lightly tap the center -bearing bracket plastic

hammer or similar tool “to remove the inner shaft f rom

the transaxle.

,

(2) Suspend the removed drive shaft with inner shaf t with

wire so that there are no sharp bends in any of the joints.

(3) Use the special tool to cover the transaxle case not to

let foreign materials get into the transaxle case.

R E L E A S E

Remove the clutch release cylinder without disconne cting

the line, and suspend to a nearby parts with a wire,

etc.

Revision

Page 878 of 2103

MANUAL TRANSAXLE

ENGINE (TURBO) AND ENGINE> Transaxle Assembly

TransaxlemountTransaxle side

s t o p p e r ,ArrowTransaxlemount

Frontstopperbracket

member

Revision

Washer

196-255 Nm

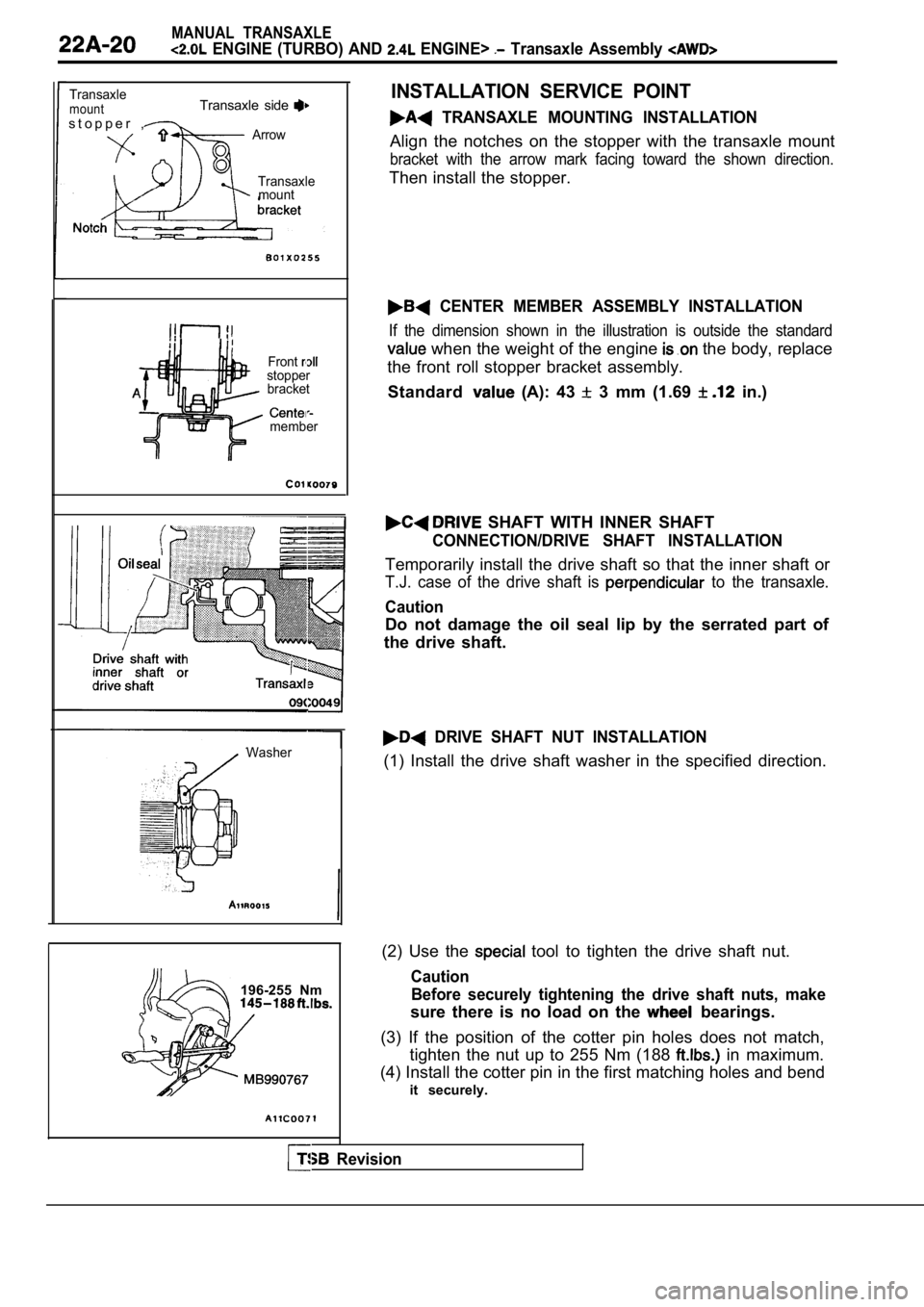

INSTALLATION SERVICE POINT

TRANSAXLE MOUNTING INSTALLATION

Align the notches on the stopper with the transaxle mount

bracket with the arrow mark facing toward the shown direction.

Then install the stopper.

CENTER MEMBER ASSEMBLY INSTALLATION

If the dimension shown in the illustration is outside the standard

when the weight of the engine the body, replace

the front roll stopper bracket assembly.

Standard

(A): 43 3 mm (1.69 in.)

SHAFT WITH INNER SHAFT

CONNECTION/DRIVE SHAFT INSTALLATION

Temporarily install the drive shaft so that the inn er shaft or

T.J. case of the drive shaft is to the transaxle.

Caution

Do not damage the oil seal lip by the serrated part of

the drive shaft.

DRIVE SHAFT NUT INSTALLATION

(1) Install the drive shaft washer in the specified direction.

(2) Use the

tool to tighten the drive shaft nut.

Caution Before securely tightening the drive shaft nuts, ma ke

sure there is no load on the bearings.

(3) If the position of the cotter pin holes does no t match,

tighten the nut up to 255 Nm (188

in maximum.

(4) Install the cotter pin in the first matching ho les and bend

it securely.

Page 879 of 2103

MANUAL TRANSAXLE ENGINE (TURBO) AND Assembly

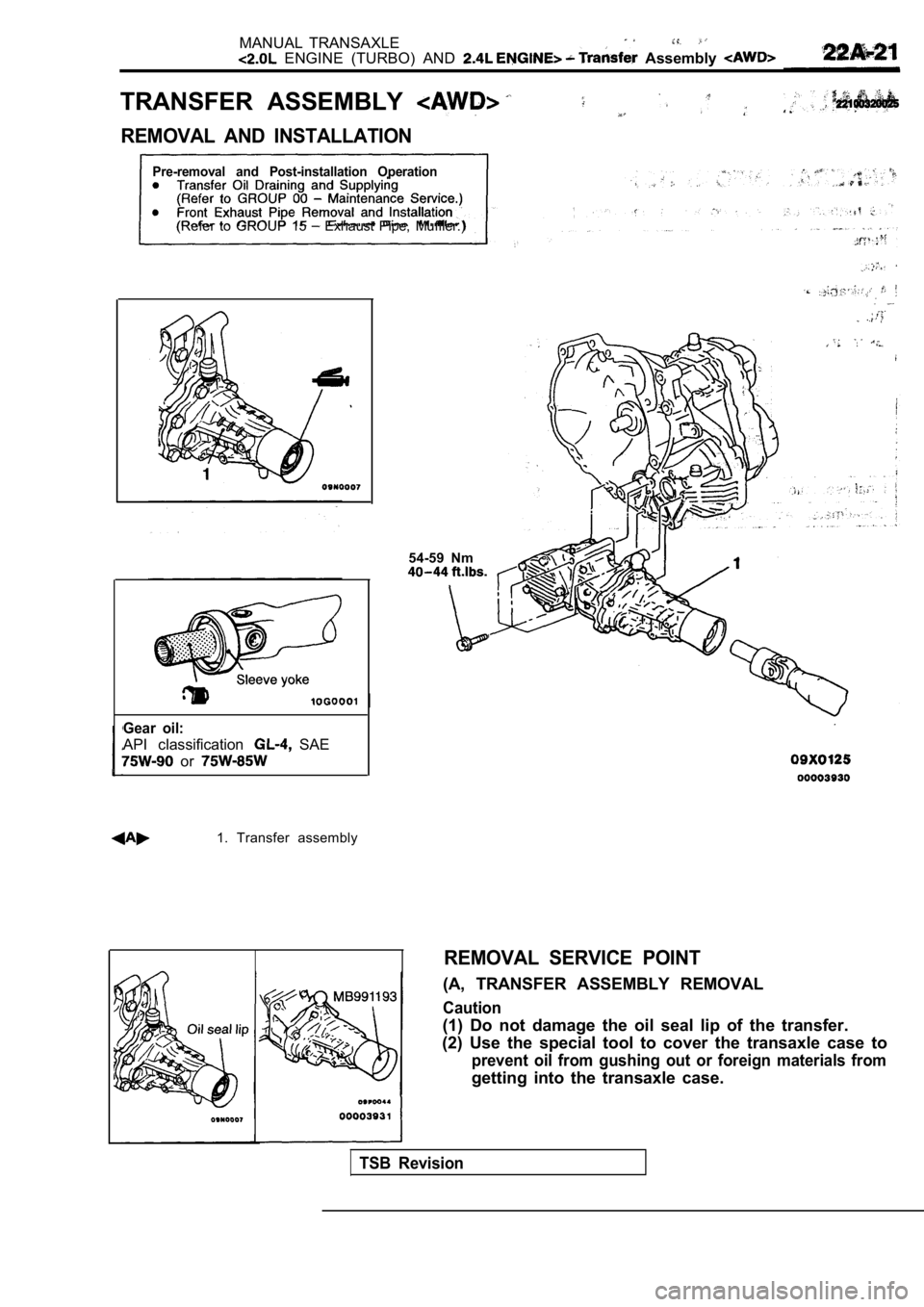

TRANSFER ASSEMBLY

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

(Refer to GROUP 15 Exhaust Pipe, Muffler.)

Gear oil:

API classification SAE

or

1. Transfer assembly

54-59 Nm

REMOVAL SERVICE POINT

(A, TRANSFER ASSEMBLY REMOVAL

Caution

(1) Do not damage the oil seal lip of the transfer.

(2) Use the special tool to cover the transaxle cas e to

prevent oil from gushing out or foreign materials from

getting into the transaxle case.

TSB Revision

Page 880 of 2103

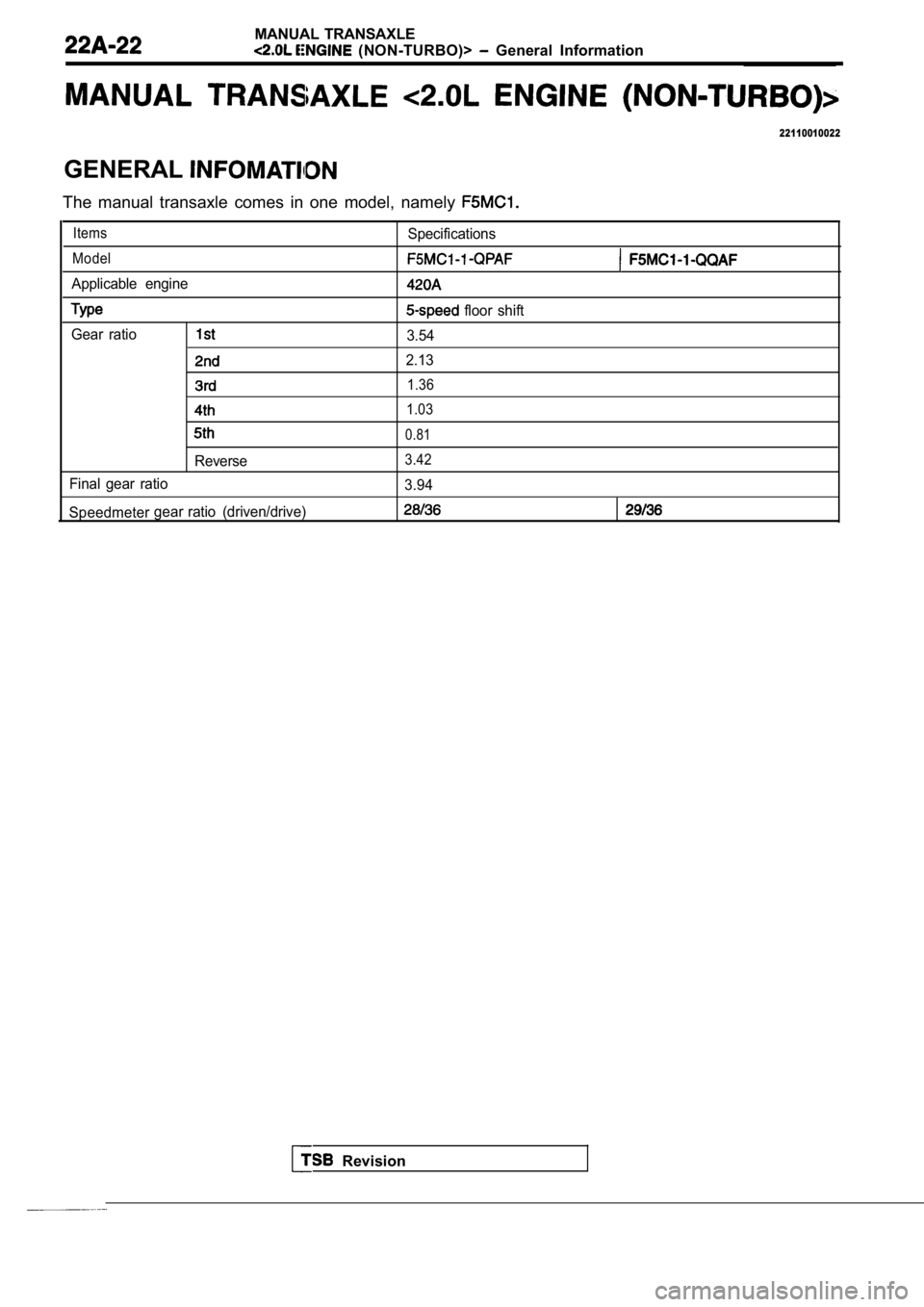

MANUAL TRANSAXLE

(NON-TURBO)> General Information

22110010022

GENERAL

The manual transaxle comes in one model, namely

ItemsSpecifications

Model

Applicable engine

floor shift

Gear ratio

3.54

2.13

1.36

1.03

0.81

Reverse3.42

Final gear ratio 3.94

Speedmeter gear ratio (driven/drive)

Revision