MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 881 of 2103

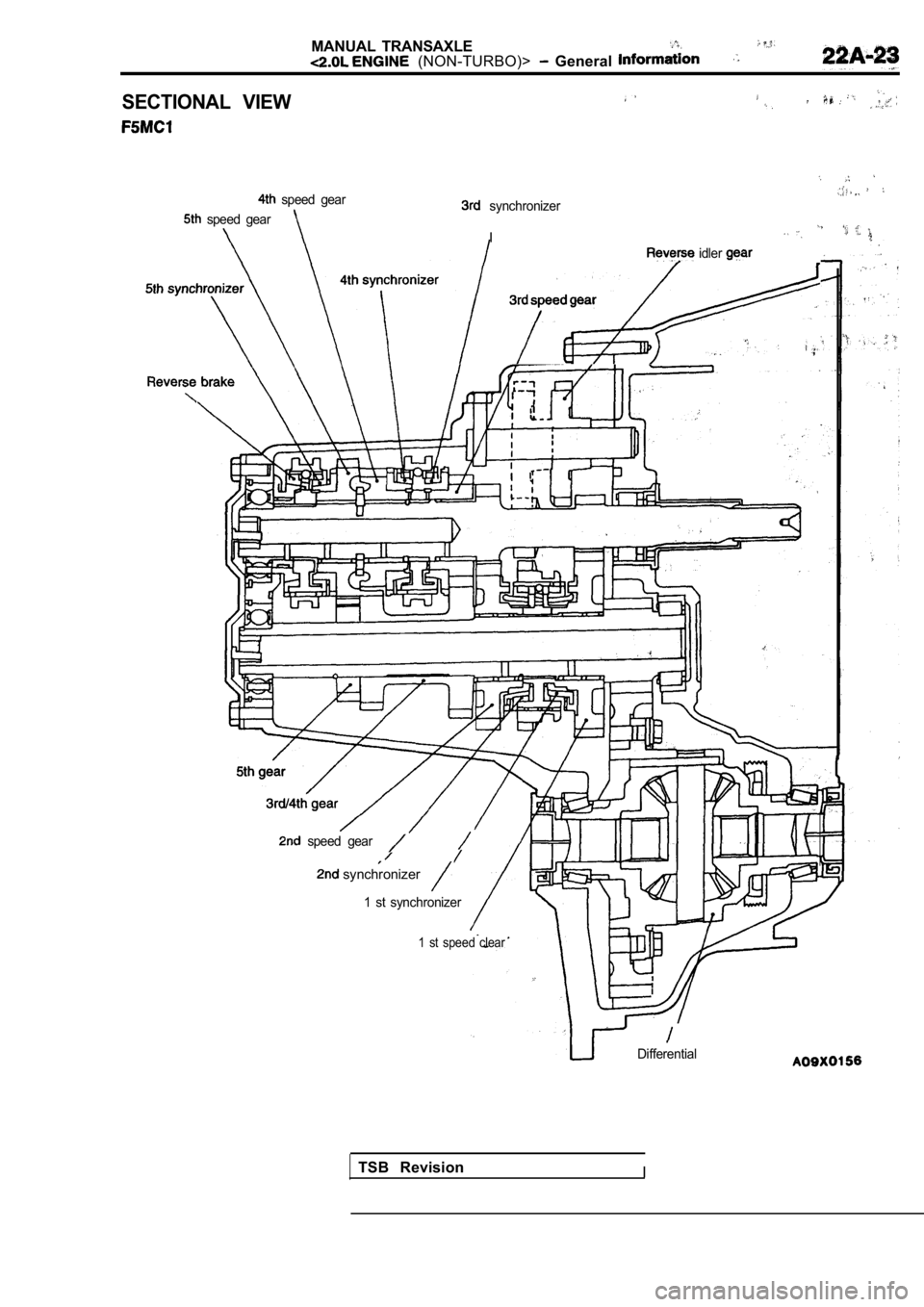

MANUAL TRANSAXLE (NON-TURBO)> General

SECTIONAL VIEW

synchronizer

I

speed gear

speed gear

idler

,

speed gear

synchronizer

1 st synchronizer

1 st speed clear

Differential

TSB RevisionI

Page 882 of 2103

MANUAL

ENGINE (NON-TURBO)>

Service Specifications/Lubricants/

Special Tools/Troubleshooting/On-vehicle Service

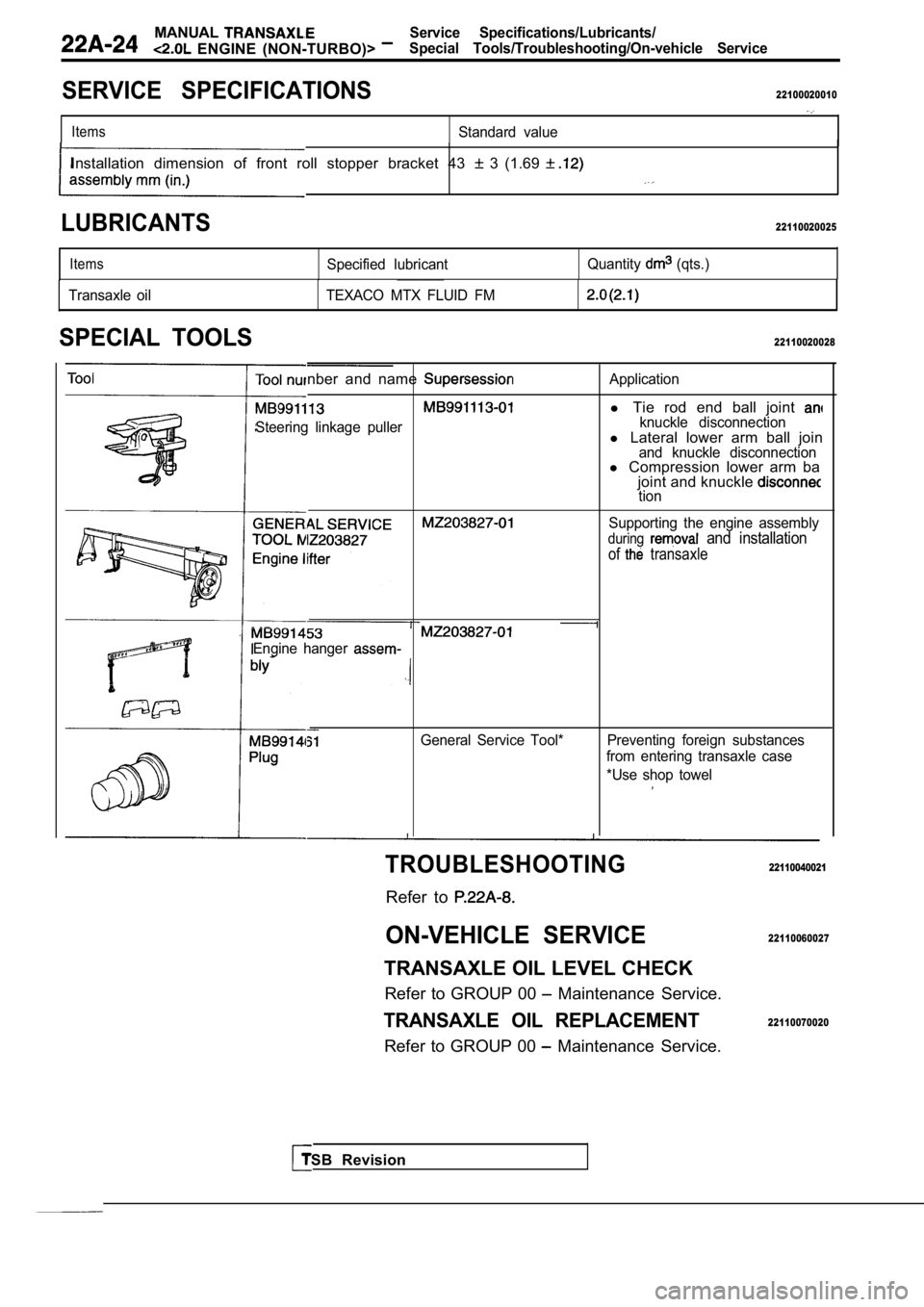

SERVICE SPECIFICATIONS22100020010

ItemsStandard value

Installation dimension of front roll stopper bracke t 43 3 (1.69

LUBRICANTS22110020025

ItemsSpecified lubricantQuantity (qts.)

Transaxle oil TEXACO MTX FLUID FM

SPECIAL TOOLS22110020028

nber and name

Steering linkage puller

Application

l Tie rod end ball joint knuckle disconnectionl Lateral lower arm ball joinand knuckle disconnectionl Compression lower arm ba

joint and knuckle

tion

Supporting the engine assembly

during and installation

of transaxle

Engine hanger

General Service Tool* Preventing foreign substances from entering transaxle case

*Use shop towel

TSB Revision

TROUBLESHOOTING

Refer to

ON-VEHICLE SERVICE

TRANSAXLE OIL LEVEL CHECK

Refer to GROUP 00

Maintenance Service.

TRANSAXLE OIL REPLACEMENT

Refer to GROUP 00 Maintenance Service.

22110040021

22110060027

22110070020

Page 883 of 2103

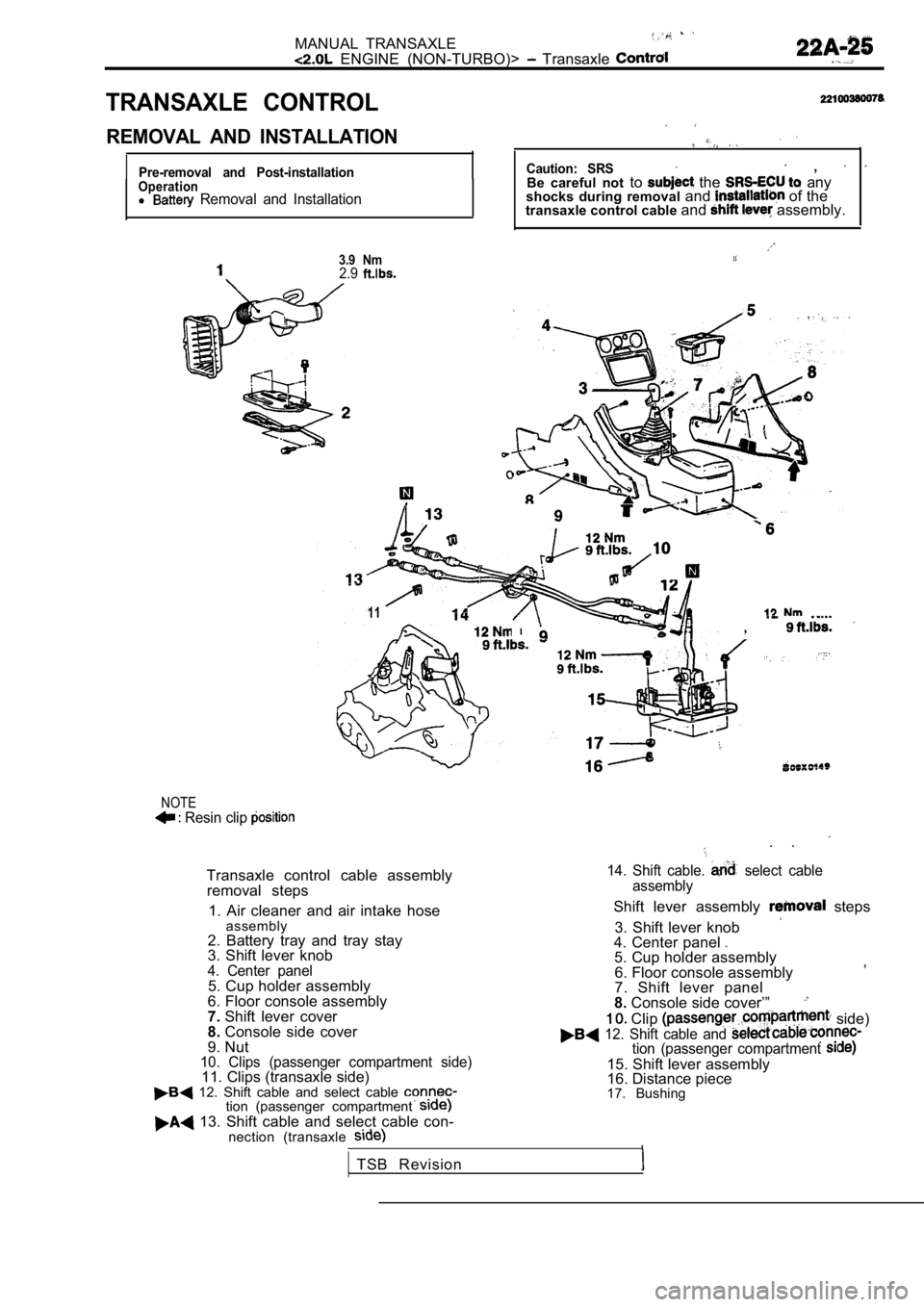

MANUAL TRANSAXLE ENGINE (NON-TURBO)> Transaxle

TRANSAXLE CONTROL

REMOVAL AND INSTALLATION

Pre-removal and Post-installationOperationl Removal and Installation

3.9 Nm2.9

,I

Caution: SRS ,

Be careful not to the any

shocks during removal and of the

transaxle control cable and assembly.

12

l 11,

NOTE Resin clip

. .

Transaxle control cable assembly

removal steps

1. Air cleaner and air intake hose assembly

2. Battery tray and tray stay

3. Shift lever knob

4. Center panel5. Cup holder assembly

6. Floor console assembly

7. Shift lever cover

8. Console side cover

9. Nut

10. Clips (passenger compartment side)11. Clips (transaxle side)

14. Shift cable. select cable

assembly

Shift lever assembly steps

3. Shift lever knob

4. Center panel

5. Cup holder assembly

6. Floor console assembly ,

7. Shift lever panel

8. Console side cover’”

Clip side) 12. Shift cable and

12. Shift cable and select cable tion (passenger compartment

13. Shift cable and select cable con-

nection (transaxle

tion (passenger compartment

15. Shift lever assembly

16. Distance piece

TSB Revision 17. Bushing

Page 884 of 2103

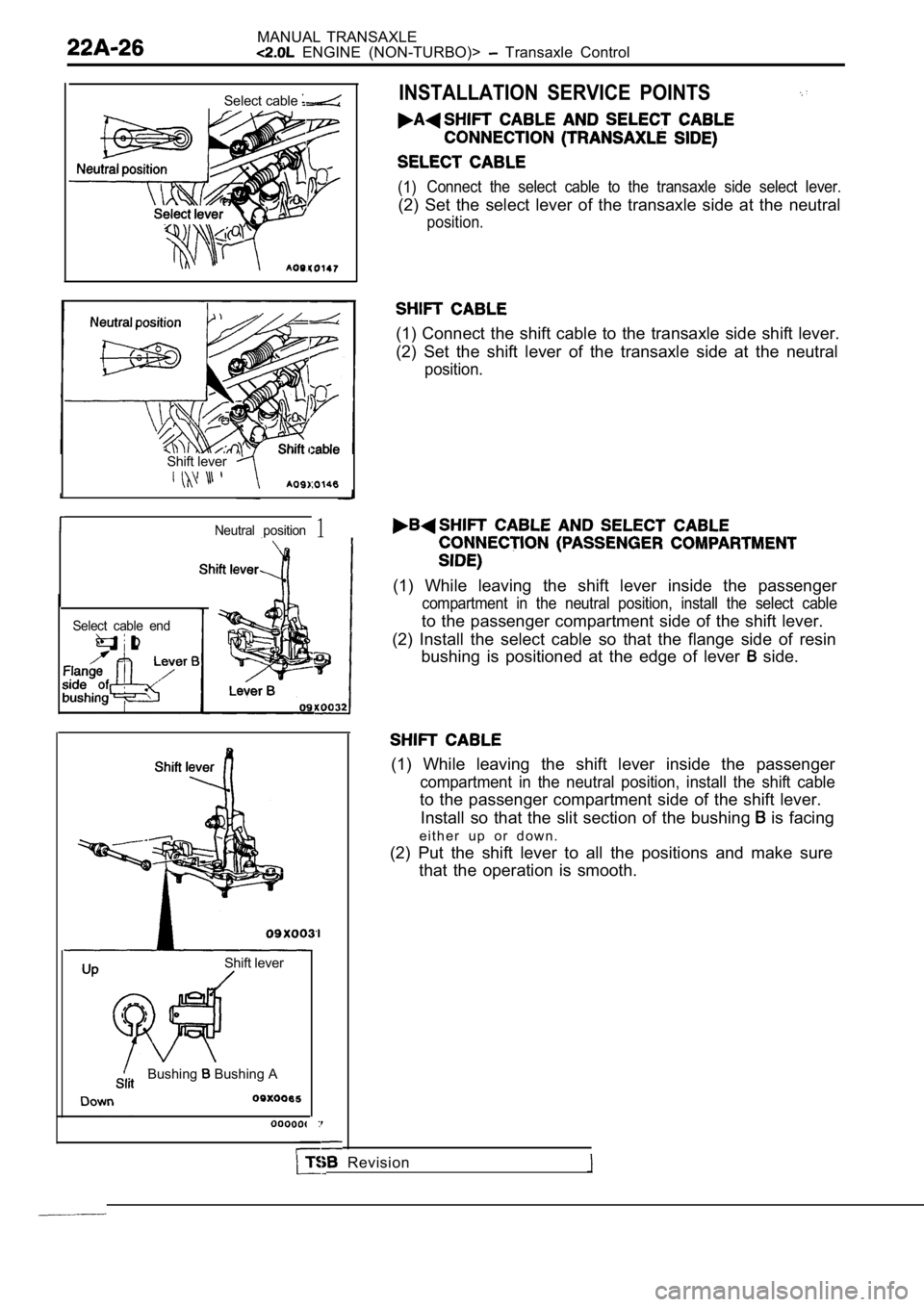

MANUAL TRANSAXLE ENGINE (NON-TURBO)> Transaxle Control

Select cable

Shift lever

Neutral position1

INSTALLATION SERVICE POINTS

(1) Connect the select cable to the transaxle side sele

ct lever.

(2) Set the select lever of the transaxle side at the neutral

position.

(1) Connect the shift cable to the transaxle side s hift lever.

(2) Set the shift lever of the transaxle side at th e neutral

position.

(1) While leaving the shift lever inside the passen ger

compartment in the neutral position, install the select cable

to the passenger compartment side of the shift leve r.

(2) Install the select cable so that the flange sid e of resin

bushing is positioned at the edge of lever

side.

Select cable end

(1) While leaving the shift lever inside the passen ger

compartment in the neutral position, install the shift cable

to the passenger compartment side of the shift leve r.

Install so that the slit section of the bushing

is facing

e i t h e r u p o r d o w n .

(2) Put the shift lever to all the positions and ma ke sure

that the operation is smooth.

Shift lever

Bushing

Bushing A

Revision

Page 885 of 2103

MANUAL TRANSAXLE .

ENGINE Transaxle

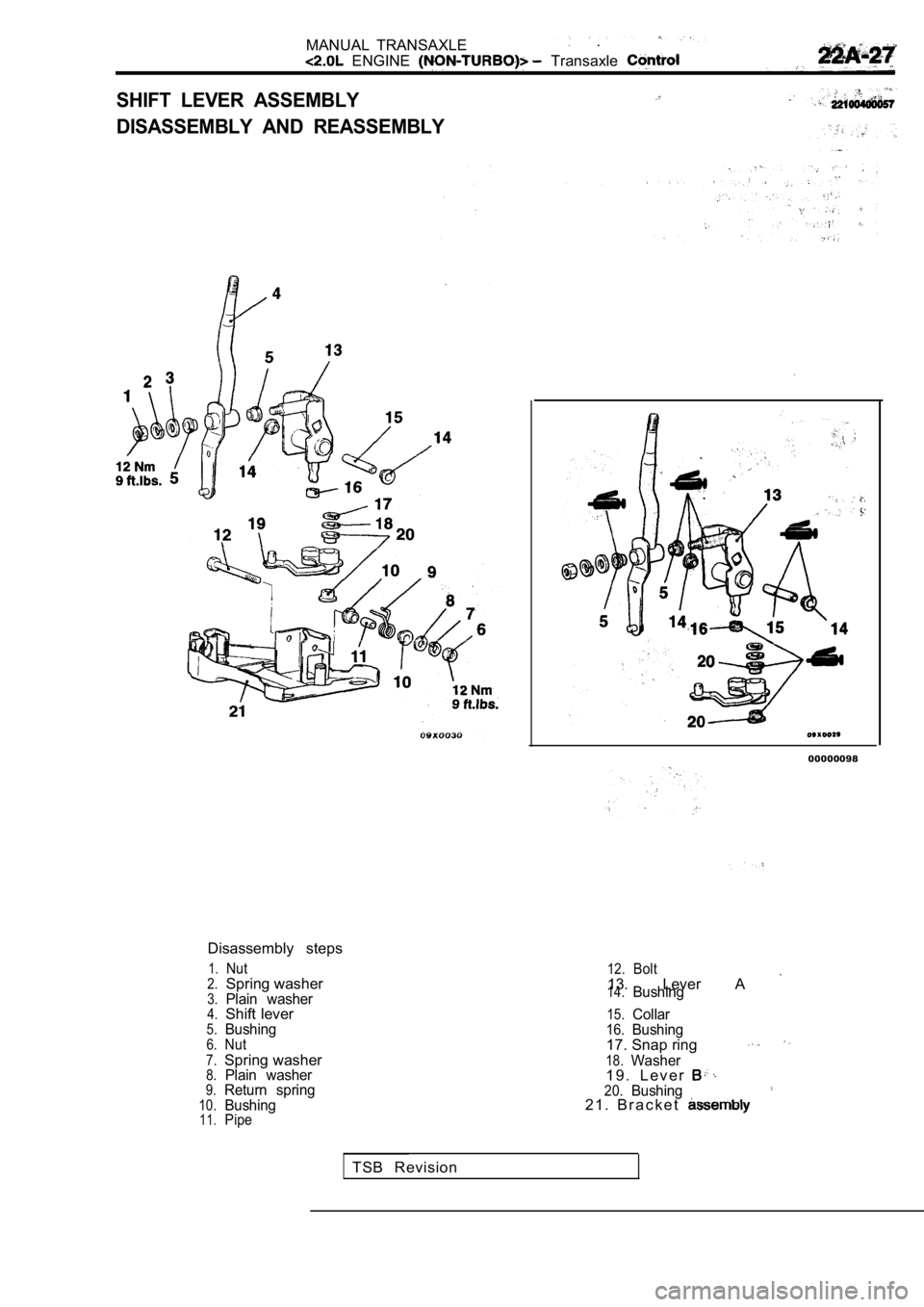

SHIFT LEVER ASSEMBLY

DISASSEMBLY AND REASSEMBLY

Disassembly steps

1.Nut2.Spring washer3.Plain washer4.Shift lever5.Bushing6.Nut

7.Spring washer8.Plain washer9.Return spring10.Bushing11.Pipe

00000098

12.Bolt13. Lever A 14.Bushing

15.Collar16.Bushing17. Snap ring

18.Washer1 9 . L e v e r 20.Bushing2 1 . B r a c k e t

TSB Revision

Page 886 of 2103

MANUAL TRANSAXLE

ENGINE (NON-TURBO)> Transaxle Control

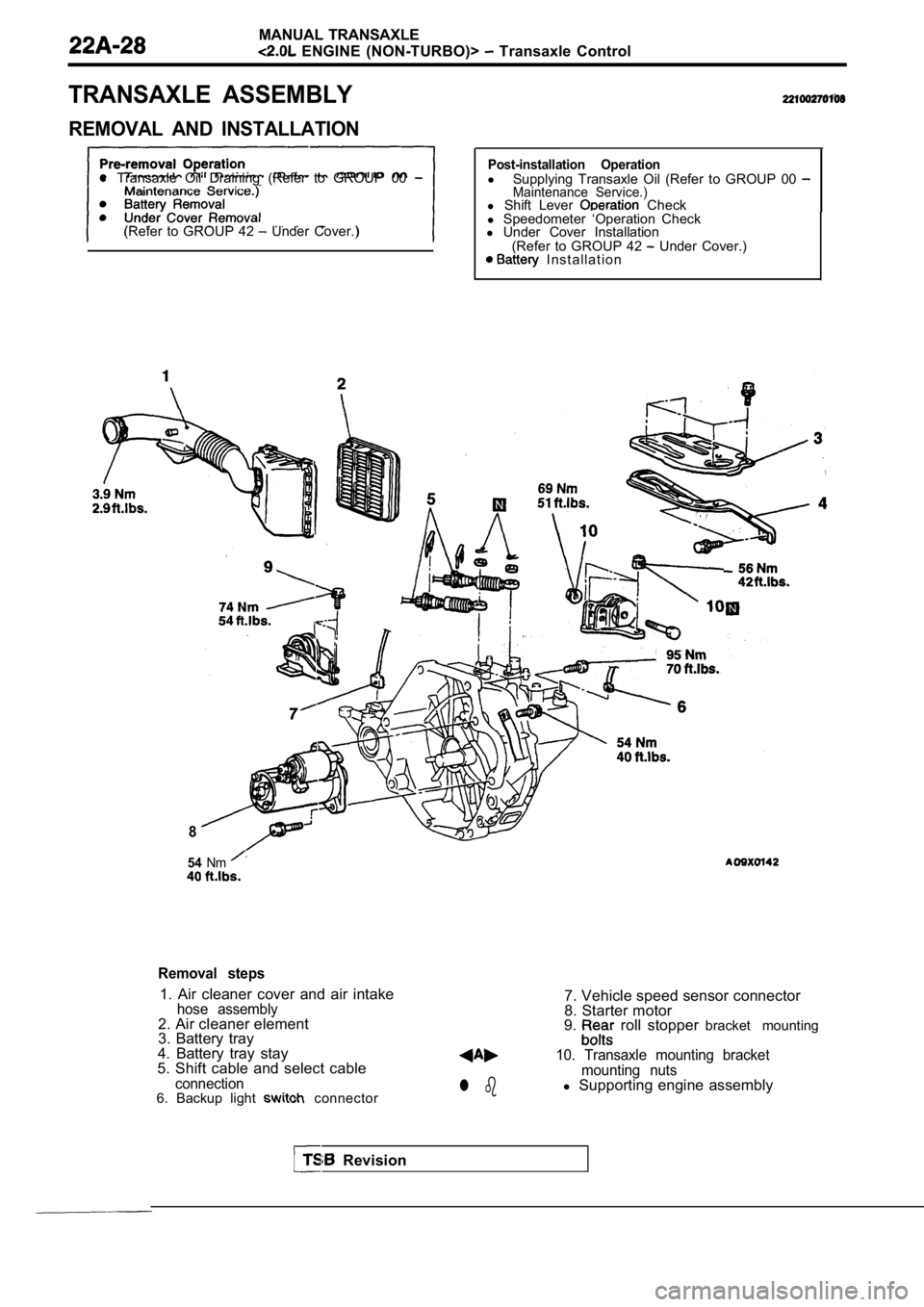

TRANSAXLE ASSEMBLY

REMOVAL AND INSTALLATION

l Transaxle Oil Draining (Refer to GROUP 00

(Refer to GROUP 42 Under Cover.)

Post-installation Operationl

Supplying Transaxle Oil (Refer to GROUP 00 Maintenance Service.)l Shift Lever Check

l Speedometer ‘Operation Check

l Under Cover Installation

(Refer to GROUP 42

Under Cover.) I n s t a l l a t i o n

8

54Nm

Removal steps

1. Air cleaner cover and air intakehose assembly2. Air cleaner element

3. Battery tray

4. Battery tray stay

5. Shift cable and select cable

connection6. Backup light connectorl b

7. Vehicle speed sensor connector

8. Starter motor

9.

roll stopper bracket mounting

10. Transaxle mounting bracket

mounting nuts

l Supporting engine assembly

Revision

Page 887 of 2103

MANUAL TRANSAXLE

ENGINE (NON-TURBO)> Transaxle

2418

75Nm5 5

59-71 NmI

13

16

Nm

65

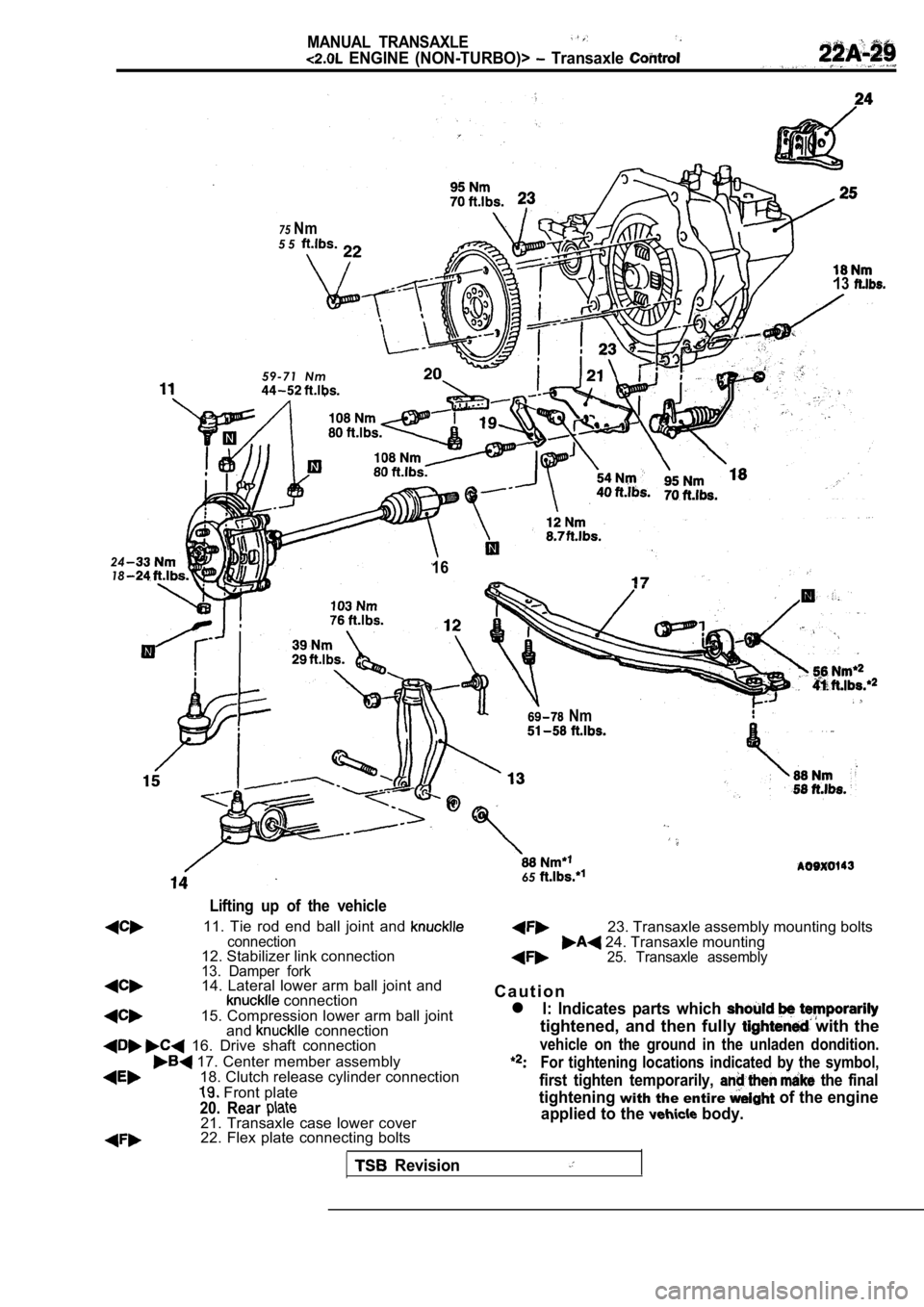

Lifting up of the vehicle

11. Tie rod end ball joint and connection12. Stabilizer link connection13. Damper fork14. Lateral lower arm ball joint and connection15. Compression lower arm ball joint

and connection 16. Drive shaft connection

17. Center member assembly18. Clutch release cylinder connection

Front plate

20. Rear 21. Transaxle case lower cover22. Flex plate connecting bolts

Revision

23. Transaxle assembly mounting bolts 24. Transaxle mounting25. Transaxle assembly

C a u t i o n

l l: Indicates parts which

tightened, and then fully with the

vehicle on the ground in the unladen dondition.

For tightening locations indicated by the symbol,

first tighten temporarily, the final

tighteningwith the entire of the engine

applied to the

body.

Page 888 of 2103

MANUAL TRANSAXLE

(NON-TURBO)> Transaxle Control

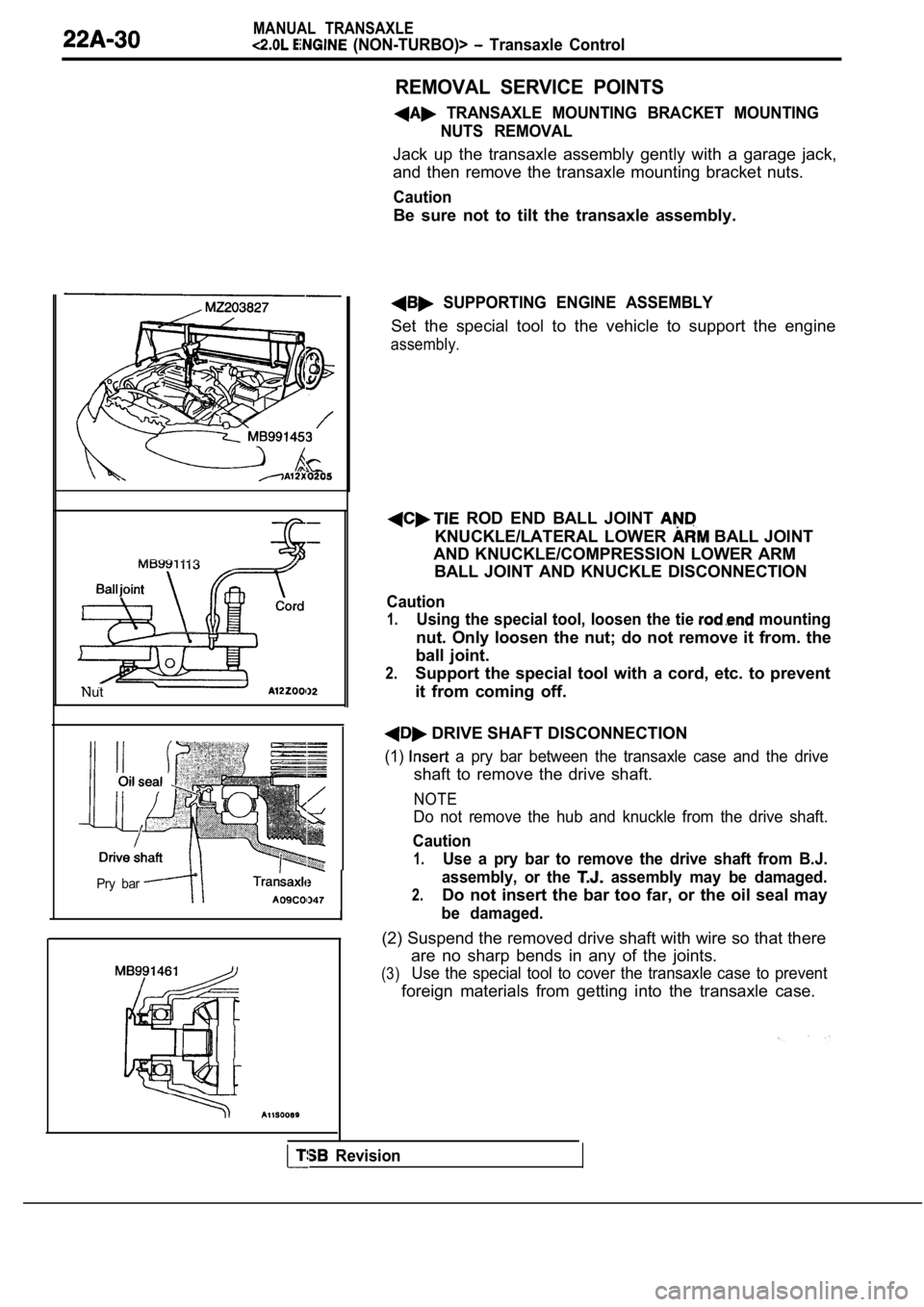

REMOVAL SERVICE POINTS

TRANSAXLE MOUNTING BRACKET MOUNTINGNUTS REMOVAL

Jack up the transaxle assembly gently with a garage jack,

and then remove the transaxle mounting bracket nuts .

Caution

Be sure not to tilt the transaxle assembly.

Nut

Pry bar

I

SUPPORTING ENGINE ASSEMBLY

Set the special tool to the vehicle to support the engine

assembly.

ROD END BALL JOINT

KNUCKLE/LATERAL LOWER BALL JOINT

AND KNUCKLE/COMPRESSION LOWER ARM BALL JOINT AND KNUCKLE DISCONNECTION

Caution

1.Using the special tool, loosen the tie mounting

nut. Only loosen the nut; do not remove it from. th e

ball joint.

2.Support the special tool with a cord, etc. to preve nt

it from coming off.

DRIVE SHAFT DISCONNECTION

(1) a pry bar between the transaxle case and the drive

shaft to remove the drive shaft.

NOTE

Do not remove the hub and knuckle from the drive sh aft.

Caution

1.Use a pry bar to remove the drive shaft from B.J.

2.

assembly, or the assembly may be damaged.

Do not insert the bar too far, or the oil seal may

be damaged.

(2) Suspend the removed drive shaft with wire so that there

(3)

are no sharp bends in any of the joints.

Use the special tool to cover the transaxle case to prevent

foreign materials from getting into the transaxle c ase.

Revision

Page 889 of 2103

MANUAL TRANSAXLE

ENGINE (NON-TURBO)>

TransaxlemountTransaxle side l

stopper.Arrow

Transaxle

mountbracket

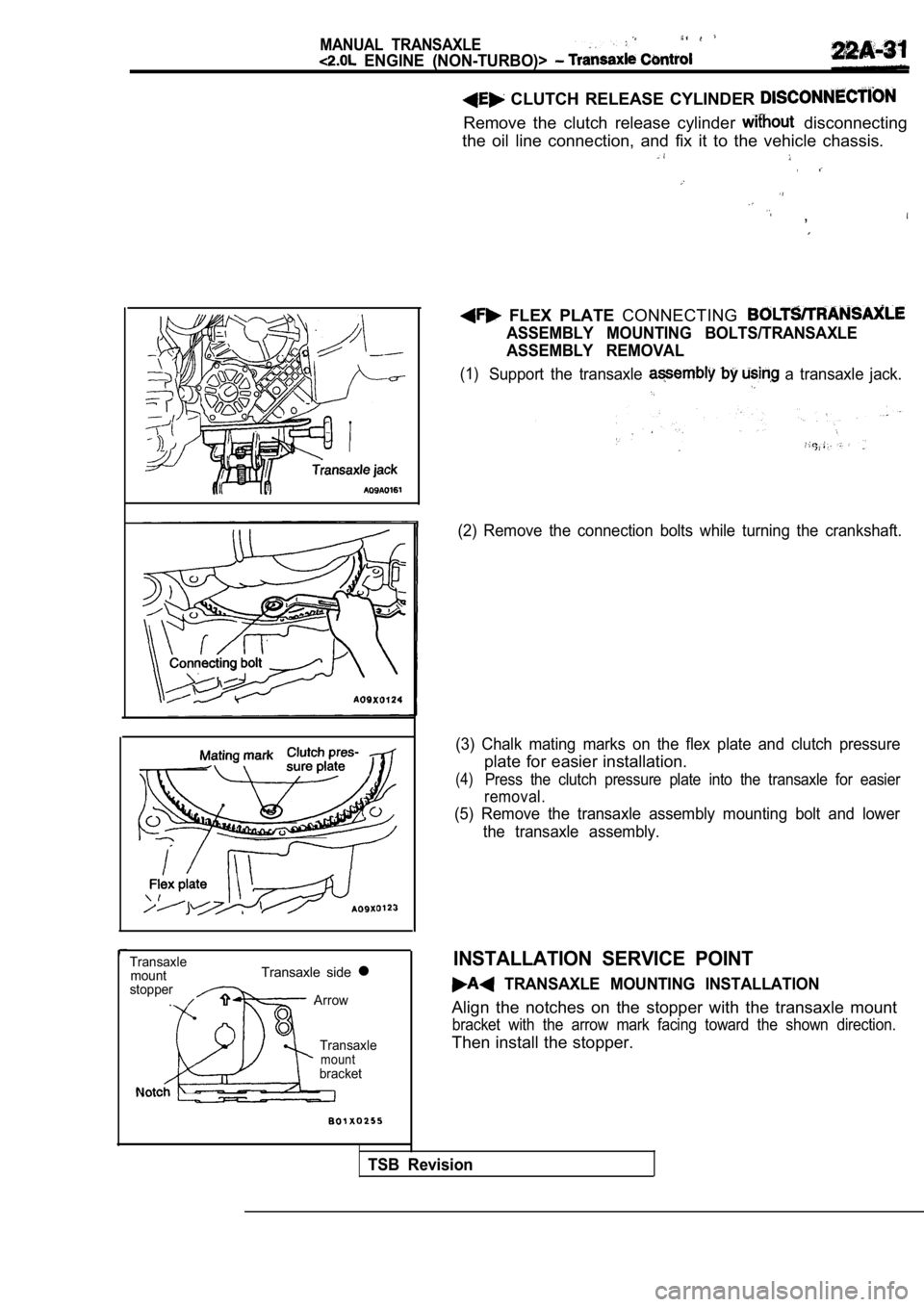

CLUTCH RELEASE CYLINDER

Remove the clutch release cylinder disconnecting

the oil line connection, and fix it to the vehicle chassis.

,

FLEX PLATE CONNECTING

ASSEMBLY MOUNTING BOLTS/TRANSAXLE

ASSEMBLY REMOVAL

(1)Support the transaxle a transaxle jack.

(2) Remove the connection bolts while turning the c rankshaft.

(3) Chalk mating marks on the flex plate and clutch pressure

plate for easier installation.

(4)Press the clutch pressure plate into the transaxle for easier

removal.

(5) Remove the transaxle assembly mounting bolt and lower

the transaxle assembly.

INSTALLATION SERVICE POINT

TRANSAXLE MOUNTING INSTALLATION

Align the notches on the stopper with the transaxle mount

bracket with the arrow mark facing toward the shown direction.

Then install the stopper.

TSB Revision

Page 890 of 2103

MANUAL. TRANSAXLE

ENGINE (NON-TURBO)> Transaxle Control

Frontstopper

bracket

member

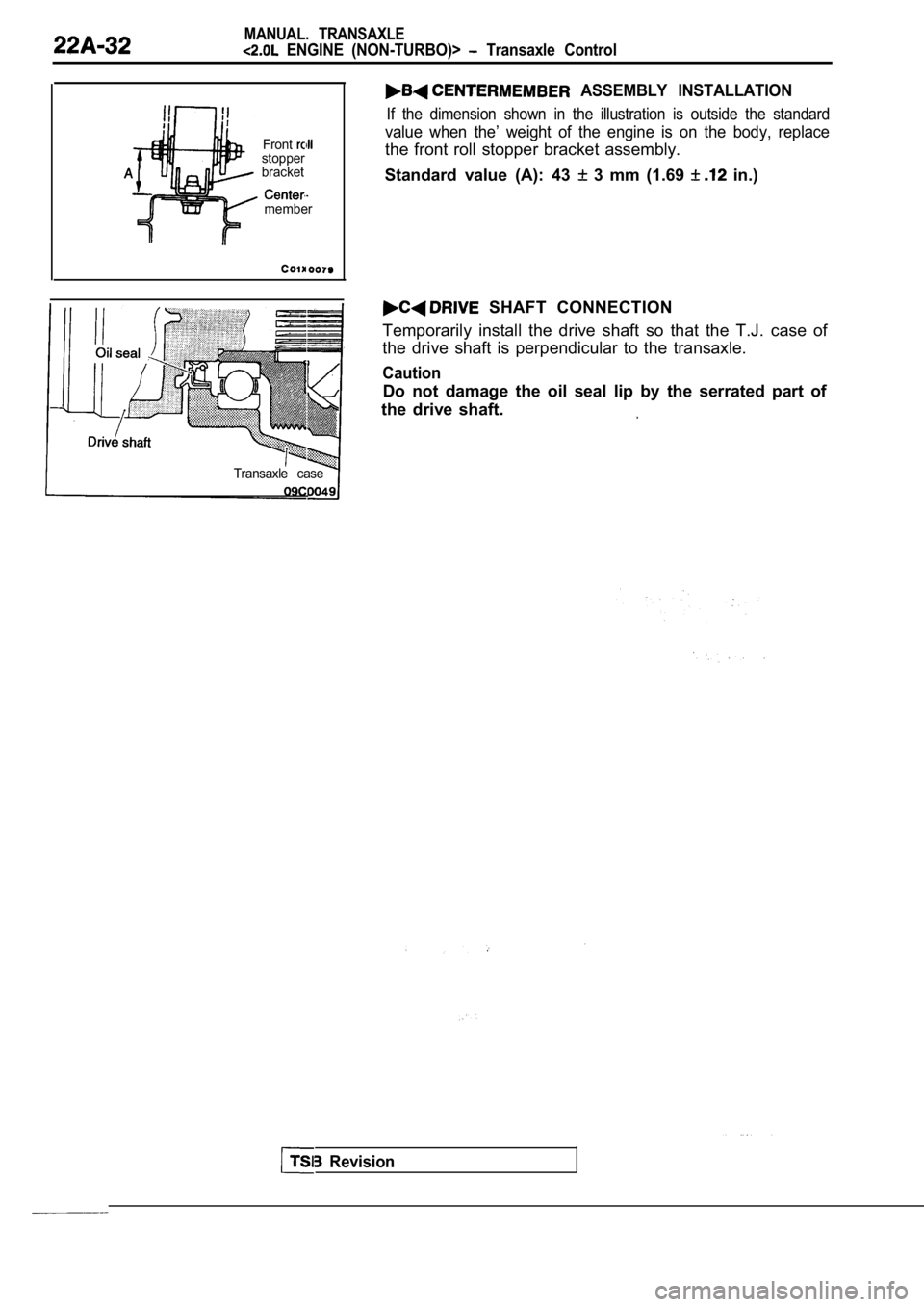

ASSEMBLY INSTALLATION

If the dimension shown in the illustration is outside the standard

value when the’ weight of the engine is on the body , replace

the front roll stopper bracket assembly.

Standard value (A): 43

3 mm (1.69 in.)

SHAFT CONNECTION

Temporarily install the drive shaft so that the T.J . case of

the drive shaft is perpendicular to the transaxle.

Caution

Do not damage the oil seal lip by the serrated part of

the drive shaft.

Transaxle case

Revision