NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1551 of 1701

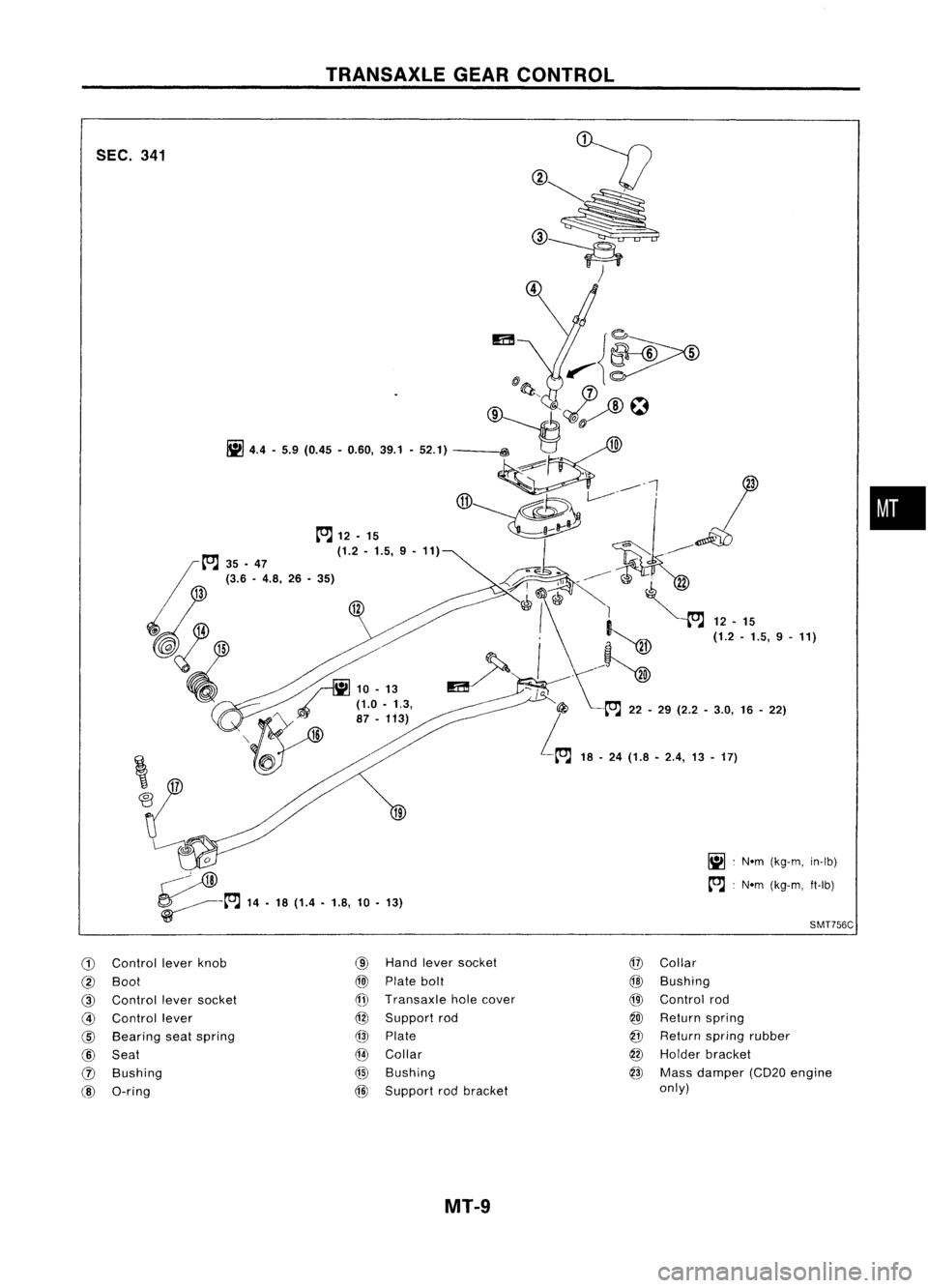

TRANSAXlEGEAR

CONTROL

•

~ .Nom (k

g-m, in-Ib)

~ :Nom (kg-m, ft-Ib)

12

~

4.4.5.9 (0.45

•060

.

,39.1. 52.1)

m

.

..--~~

~~O 't~~~

t"J t"J

12•15

(jj)~~~~l '

3

35 •47 (1.2•15

._le'

(3 6 .,9 •11)

~~

-

.

..--~

/" rIiJ

10.13 ~

I\~~ ~ ;~;

'~.5, 9•11)

, {y"'''

(1.0•

1.3, "",/'

>

"@

'\ _Y 87•113)

I

16

iI5J

t

t"J

22•29 (2.2 .

L,

3.0.16•22)

-~ 18.24(1.8 •2

.4, 13•17)

f?:!-

:g.~

~

14. 18(1

W

.4.18 1

.,

O.13)

SEC.

341

Control leverknb

Boot

0

Control leversocke

Control lever t

Bearing seats.

Seat pring

Bushing

O-ring Hand

Iever socket

Plate bolt

Transaxle hI

S

0

e cover

upport rod

Plate

Collar

Bushing

Support rodbracket

@

@

@)

@

@

@

@

Collar

Bushing

Control rod

Return spring

Return s.

pring rubb

Hold er

er bracket

Mass dame

only) pr(CD20 engine

MT-9

Page 1552 of 1701

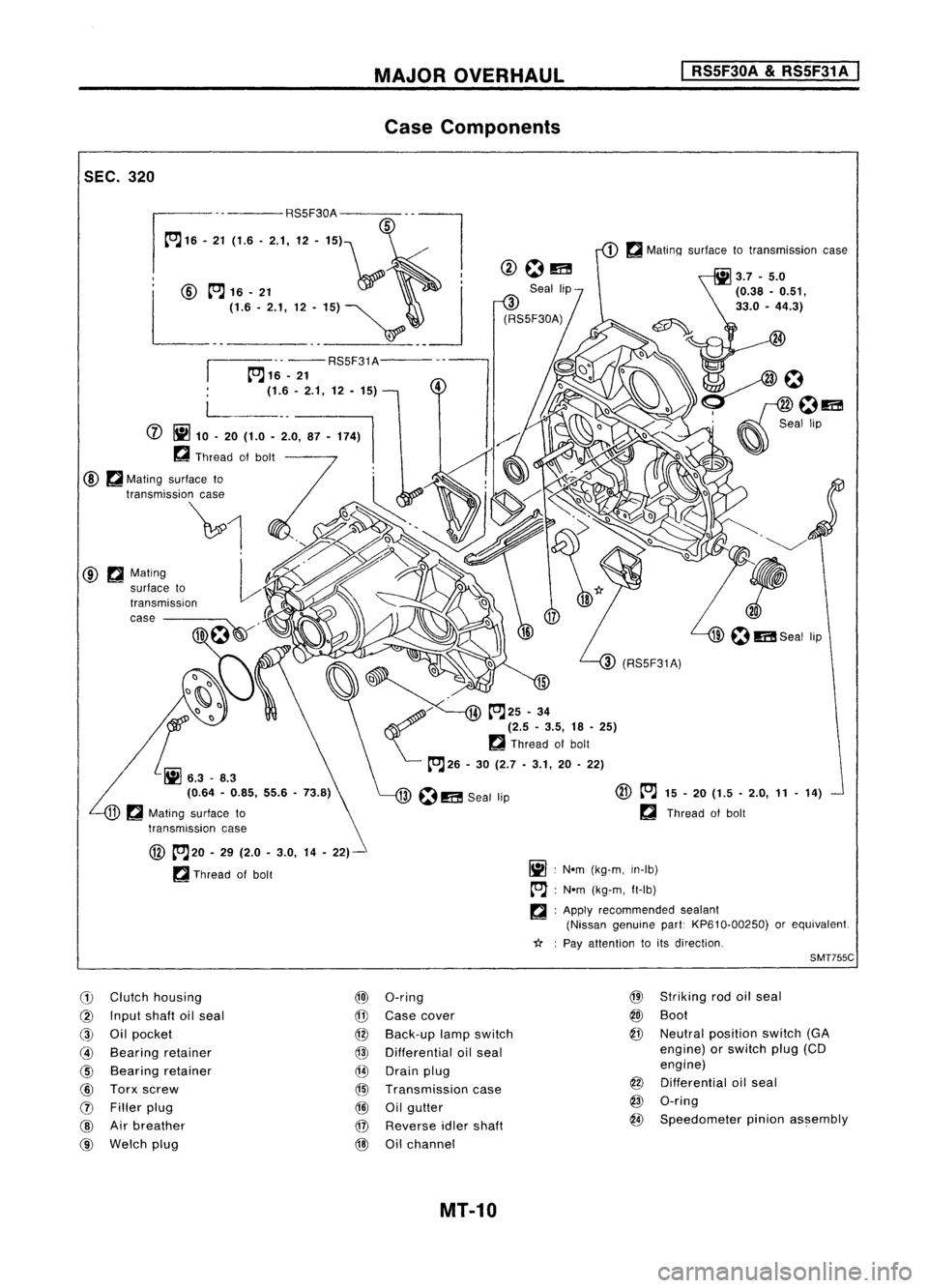

SEC.320 MAJOR

OVERHAUL

Case Components

I

RS5F30A

&

RS5F31 A

I

.. -- RS5F31A---

~16 -21

(1.6 -2.1, 12. 15)

@ ~Mating

surface to

transmiSSion

case ----

@

~20 -29 (2.0 -3.0, 14-22)-

~ Thread ofbolt

(1)

Clutch housing

@)

O-ring

@

Input shaftoilseal

@

Case cover

@

Oilpocket

@

Back-up lampswitch

@

Bearing retainer

@

Differential oilseal

@

Bearing retainer

@

Drain plug

@

Torx screw

@l

Transmission case

(J)

Filler plug

@

Oilgutter

@

Airbreather

@

Reverse idlershaft

@

Welch plug

@

Oilchannel

MT-10

@

~

15-20 (1.5 -2.0, 11-14)

~ Thread ofbolt

Ij] :

Nom (kg-m, in-Ib)

tr'J :

Nom (kg-m, ft-Ib)

~ :Apply recommended sealant

(Nissan genuine part:KP610-00250) orequivalent.

*: :

Pay attention toits direction.

SMT755C

@

Striking rodoilseal

@J

Boot

@

Neutral position switch(GA

engine) orswitch plug(CD

engine)

@

Differential oilseal

@

O-ring

@

Speedometer pinionassembly

Page 1553 of 1701

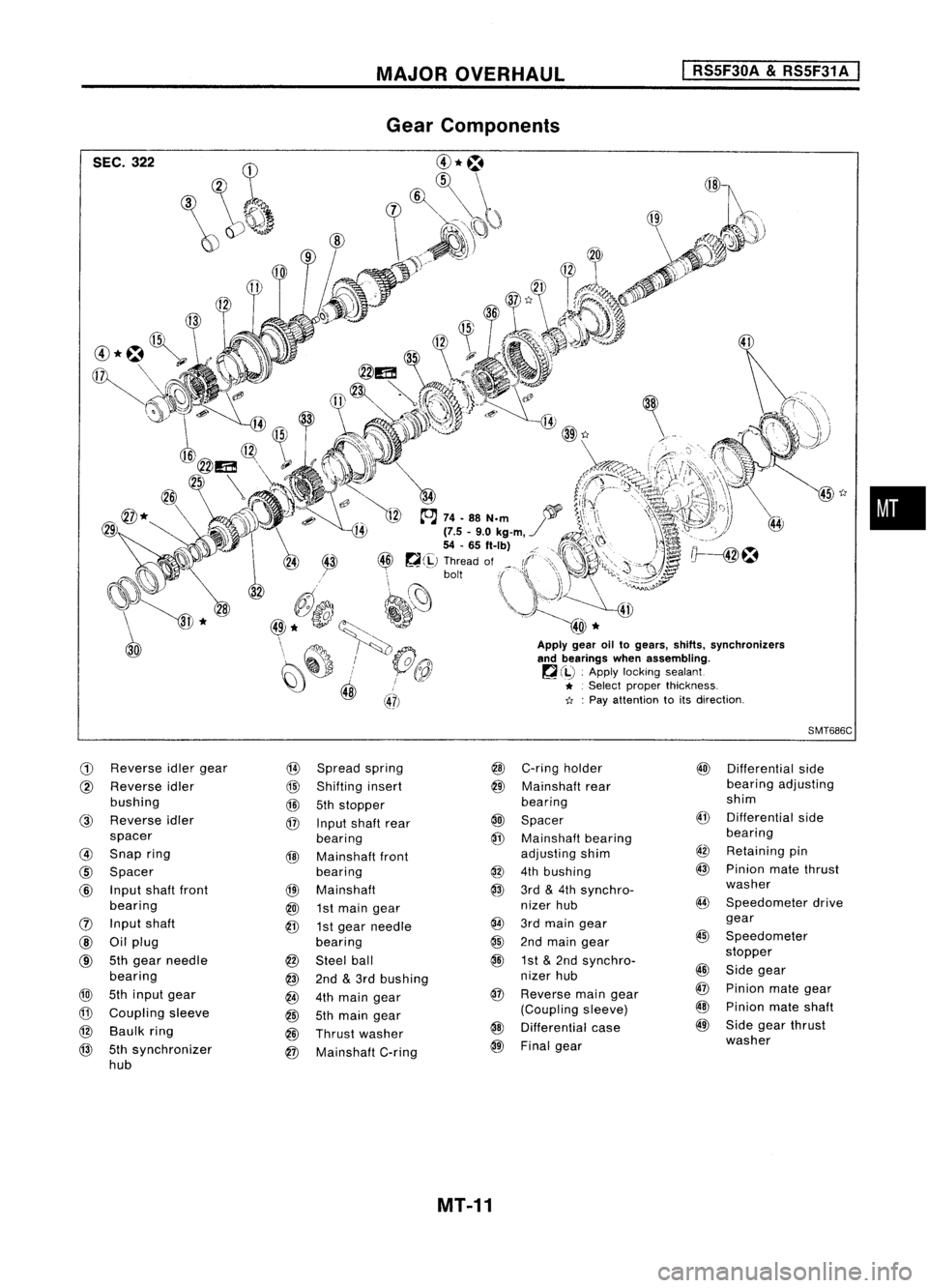

MAJOROVERHAUL

I

RS5F30A

&

RS5F31 A

I

SEC. 322

G)

Reverse

idlergear

@

Spread spring

@

Reverse idler

@

Shifting insert

bushing

@

5thstopper

@

Reverse idler

@

Input shaft rear

spacer bearing

@

Snap ring

@

Mainshaft front

@

Spacer bearing

@

Input shaftfront

@l

Mainshaft

bearing

@J

1st

main gear

(]) Input shaft

@

1stgear needle

@

Oilplug bearing

@

5th

gear needle

@

Steel ball

bearing

@

2nd

&

3rd bushing

@

5thinput gear

@

4thmain gear

@

Coupling sleeve

@

5thmain gear

@

Baulk ring

@

Thrust washer

@

5thsynchronizer

@

Mainshaft C-ring

hub

45

t:r

Apply gearoiltogears, shifts.synchronizers

and bearings whenassembling.

~ (iJ :

Apply locking sealant

* .

Select proper thickness.

11 :

Pay attention toits direction.

SMT686C

@

C-ring holder

@)

Differential side

@

Mainshaft rear bearing

adjusting

bearing shim

@

Spacer

@

Differential side

@

Mainshaft bearing bearing

adjusting shim

@

Retaining pin

@

4thbushing

@

Pinion matethrust

@

3rd

&

4th synchro- washer

nizer hub

@

Speedometer drive

@

3rdmain gear gear

@

2ndmain gear

@

Speedometer

@

1st

&

2nd synchro- stopper

nizer hub

@

Side gear

@

Reverse maingear

@

Pinion mategear

(Coupling sleeve)

@

Pinion mateshaft

@

Differential case

@

Side gearthrust

@

Final gear washer

MT-11

•

Page 1554 of 1701

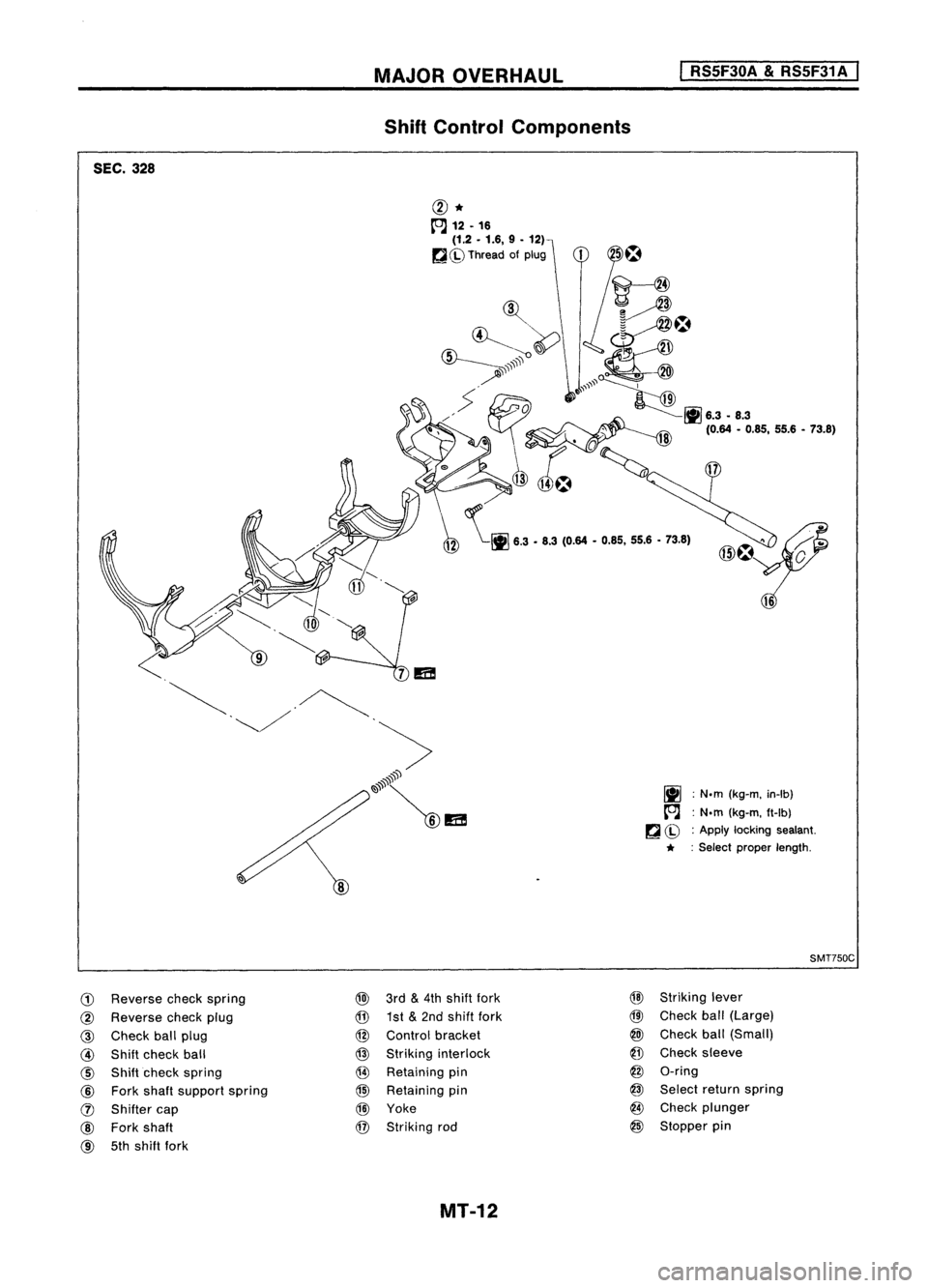

SEC.328 MAJOR

OVERHAUL

Shift Control Components

I

RS5F30A

&

RS5F31A

I

@*

[OJ

12.16

(1.2 •1.6, 9•

12)

~ Ch>

Thread ofplug

~ \~ 6.3•U (0.64 •0.6'. 55.6•13.61

~ :N.m (kg-m. in-Ib)

[OJ :

N.m (kg-m. ft-Ib)

~ Ch> :

Apply locking sealant.

* :Select proper length.

SMT750C

G)

Reverse checkspring

@

Reverse checkplug

@

Check ballplug

@

Shift check ball

@

Shiftcheck spring

@

Fork shaft support spring

(J)

Shifter cap

@

Fork shaft

@

5thshift fork

@

3rd

&

4th shift fork

@

1st

&

2nd shift fork

@

Control bracket

@

Striking interlock

@ Retaining pin

@)

Retaining pin

@)

Yoke

@

Striking rod

MT-12

@

Striking lever

@

Check ball(Large)

@J

Check ball(Small)

@

Check sleeve

@

G-ring

@

Select returnspring

@

Check plunger

@

Stopper pin

Page 1555 of 1701

DISASSEMBLV

I

RSSF30A

&

RSSF31 A

I

5th shift -

fork

Suitable

tool

SMT571

SMT082A SMT577

SMT579

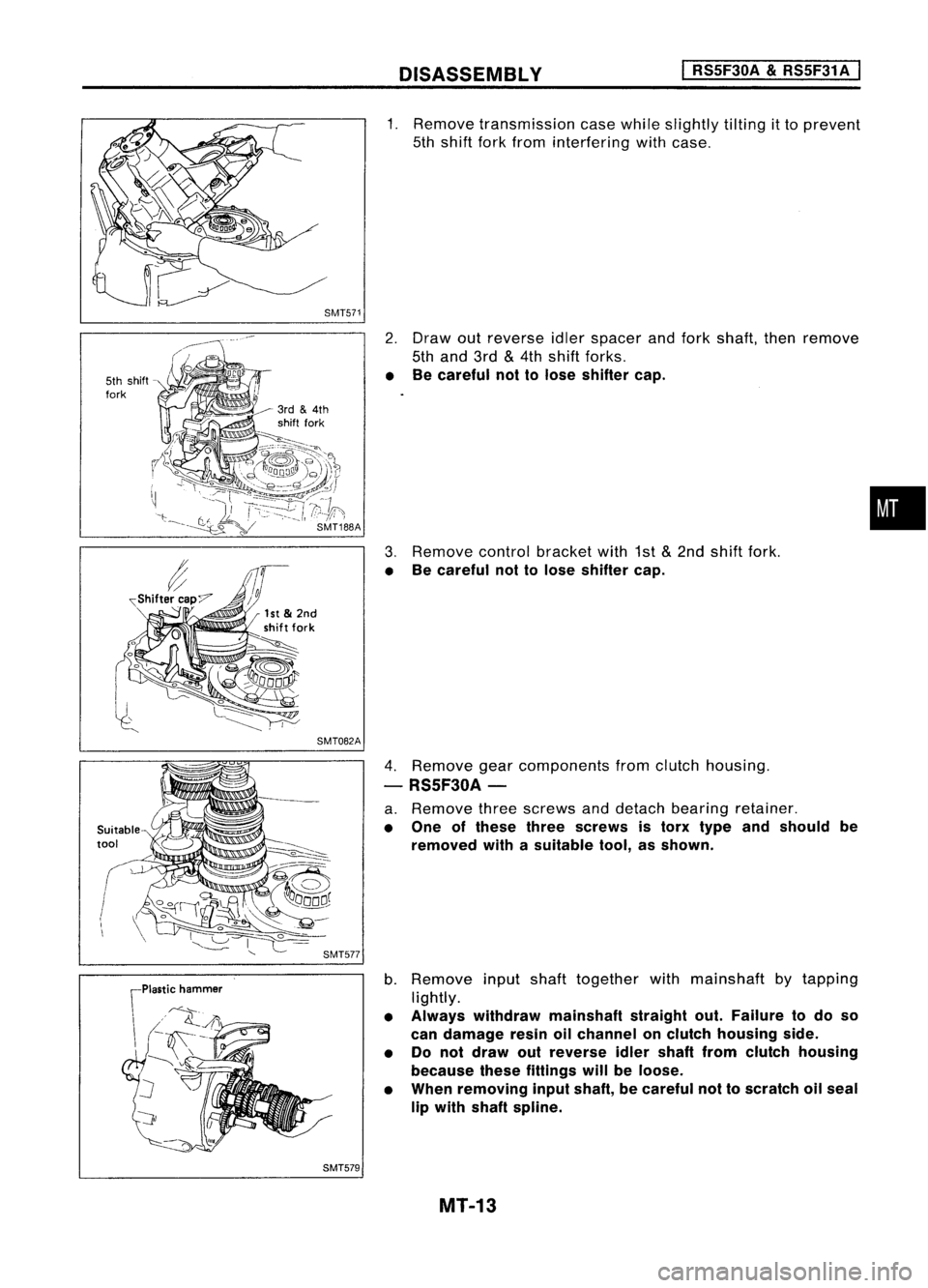

1.

Remove transmission casewhile slightly tiltingitto prevent

5th shift forkfrom interfering withcase.

2. Draw outreverse idlerspacer andfork shaft, thenremove

5th and 3rd

&

4th shift forks.

• Becareful nottolose shifter cap.

3. Remove controlbracket with1st

&

2nd shift fork.

• Becareful nottolose shifter cap.

4. Remove gearcomponents fromclutch housing.

- RS5F30A-

a. Remove threescrews anddetach bearing retainer.

• One ofthese threescrews istorx type andshould be

removed withasuitable tool,asshown.

b. Remove inputshafttogether withmainshaft bytapping

lightly.

• Always withdraw mainshaft straightout.Failure todo so

can damage resinoilchannel onclutch housing side.

• Do not draw outreverse idlershaft fromclutch housing

because thesefittings willbeloose.

• When removing inputshaft, becareful nottoscratch oilseal

lip with shaft spline.

MT-13

•

Page 1556 of 1701

DISASSEMBLY

I

RS5F30A

&

RS5F31 A

I

SMT580

SMT720

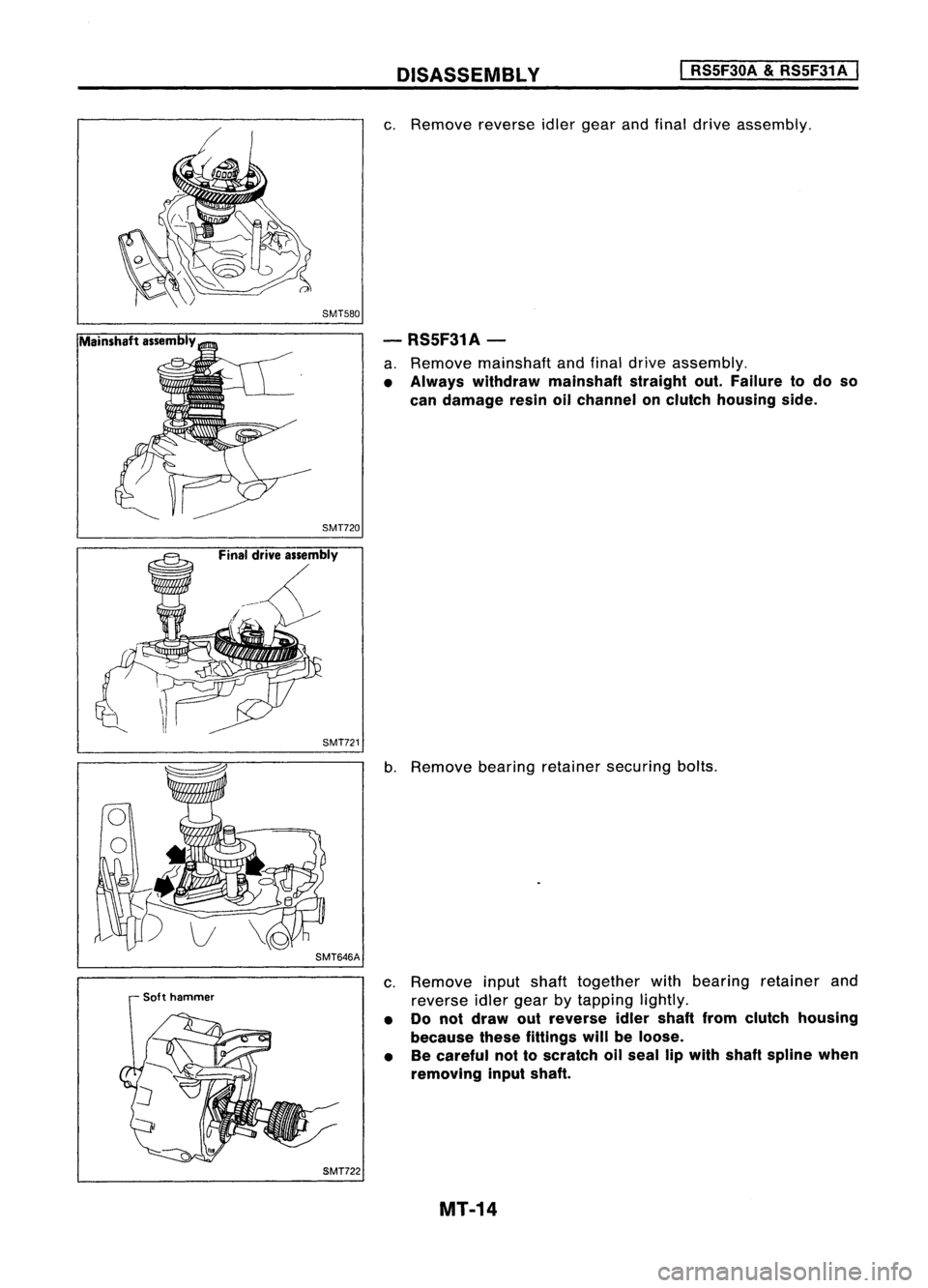

c.

Remove reverseidlergear andfinal drive assembly.

- RS5F31A-

a. Remove mainshaft andfinal drive assembly.

• Always withdraw mainshaft straightout.Failure todo so

can damage resinoilchannel onclutch housing side.

SMT721

SMT646A

Soft hammer

SMT722

b.

Remove bearingretainer securing bolts.

c. Remove inputshaft together withbearing retainer and

reverse idlergear bytapping lightly.

• Do not draw outreverse idlershaft fromclutch housing

because thesefittings willbeloose.

• Becareful nottoscratch oilseal lipwith shaft spline when

removing inputshaft.

MT-14

Page 1557 of 1701

DISASSEMBLY RS5F30A

&

RS5F31 A

SMT648AA

KV32101000

SMT599AA

SMT583

/ Reverse checkplug

~ "Reverse checkspring

S/

V

Check ball(Large)

"--_Check ball(Small)

SMT584

SMT585

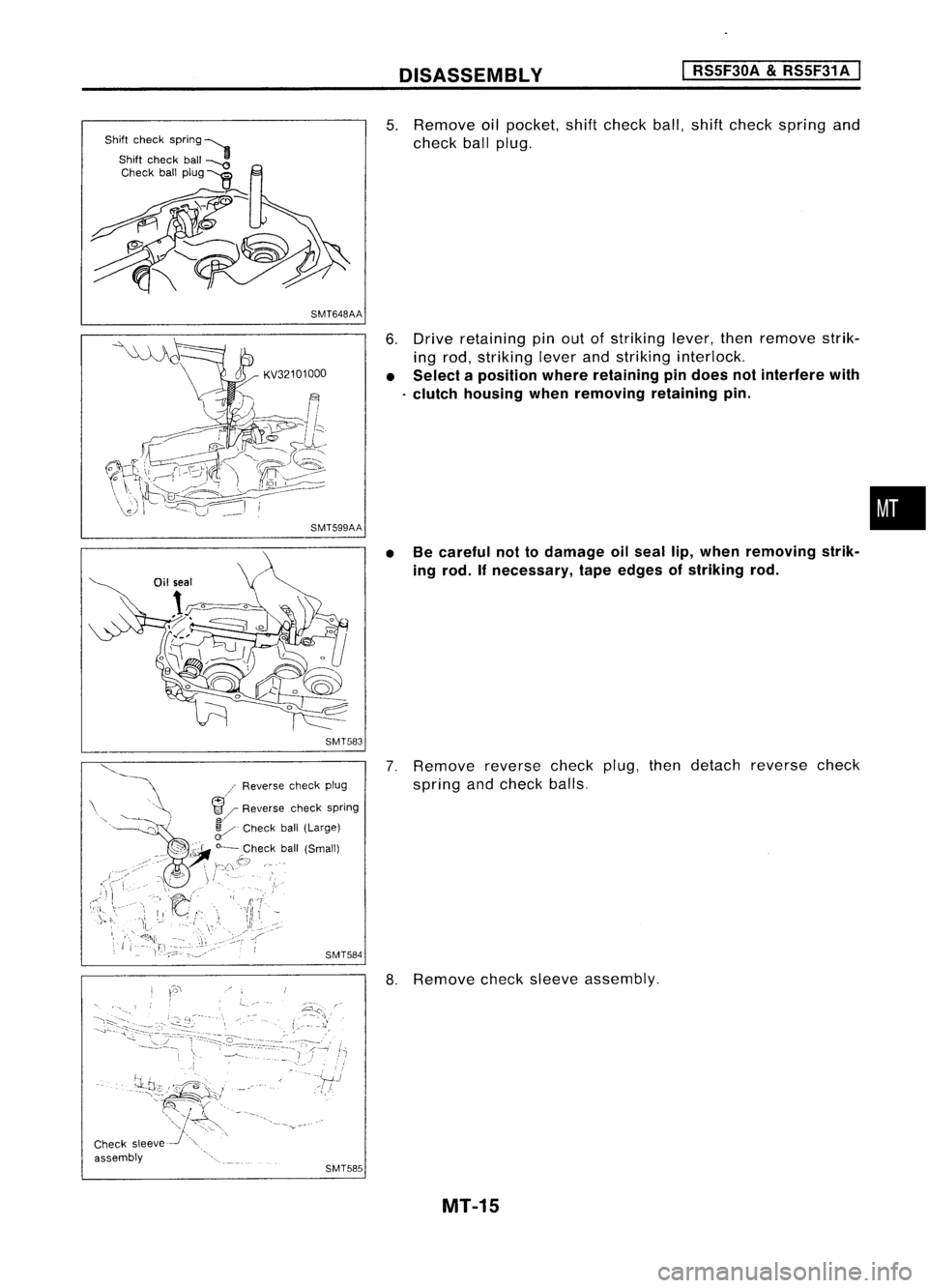

5.

Remove oilpocket, shiftcheck ball,shift check spring and

check ballplug.

6. Drive retaining pinout ofstriking lever,thenremove strik-

ing rod, striking leverandstriking interlock.

• Select aposition whereretaining pindoes notinterfere with

. clutch housing whenremoving retainingpin.

• Becareful nottodamage oilseal lip,when removing strik-

ing rod. Ifnecessary, tapeedges ofstriking rod.

7. Remove reversecheckplug,thendetach reverse check

spring andcheck balls,

8. Remove checksleeve assembly.

MT-15

•

Page 1558 of 1701

REPAIRFORCOMPONENT PARTS

I

RS5F30A

&

RS5F31 A

I

~EndPlaY

Gear

Needlebearing

SMT734A

5th synchronizer hub

Input

Shaft andGears

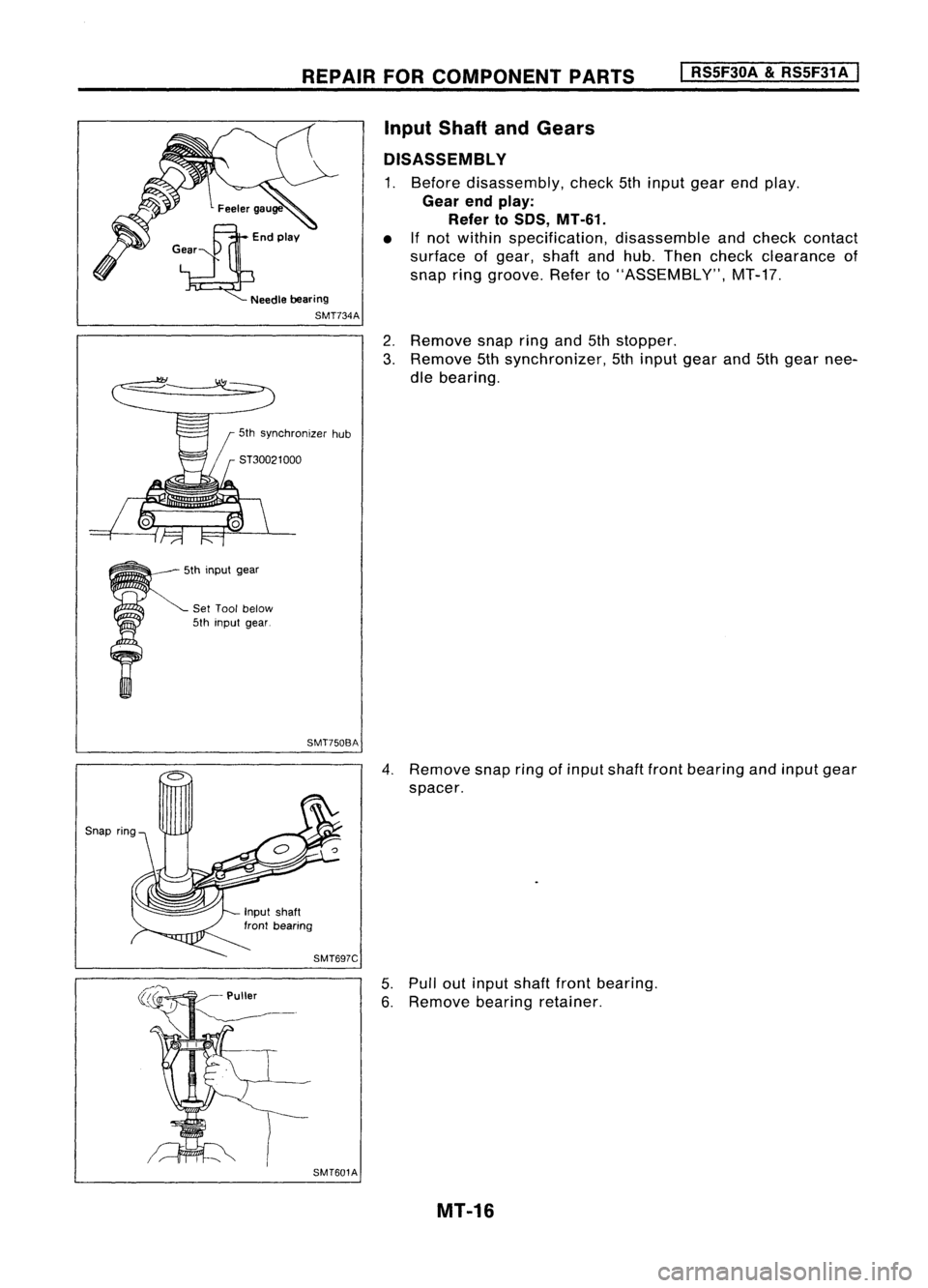

DISASSEMBLY

1. Before disassembly, check5thinput gearendplay.

Gear endplay:

Refer toSOS, MT-61.

• Ifnot within specification, disassembleandcheck contact

surface ofgear, shaftandhub. Then check clearance of

snap ringgroove. Referto"ASSEMBLY", MT-17.

2. Remove snapringand5thstopper.

3. Remove 5thsynchronizer, 5thinput gearand5thgear nee-

dle bearing.

5th input gear

Set Tool below

5th input gear.

SMT750BA

SMT601A

4.

Remove snapringofinput shaftfrontbearing andinput gear

spacer.

5. Pull outinput shaftfrontbearing.

6. Remove bearingretainer.

MT-16

Page 1559 of 1701

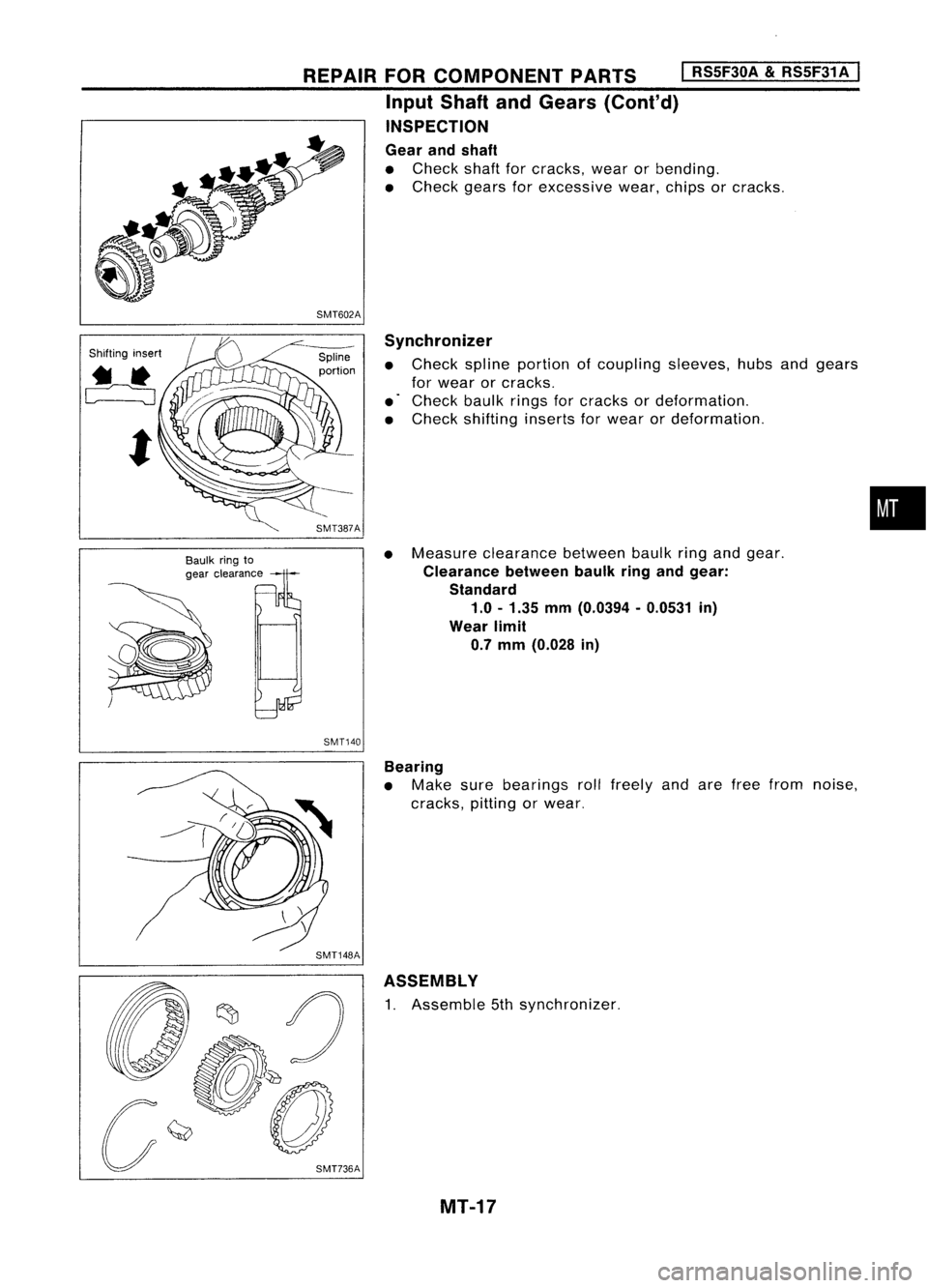

Shiftinginsert

t

Baulkringto

gear clearance

REPAIR

FORCOMPONENT PARTS

I

RS5F30A

&

RS5F31A

I

Input Shaft andGears (Cont'd)

INSPECTION

Gear andshaft

• Check shaftforcracks, wearorbending.

• Check gearsforexcessive wear,chipsorcracks.

SMT602A Synchronizer

• Check splineportion ofcoupling sleeves,hubsandgears

for wear orcracks.

• Check baulkringsforcracks ordeformation.

• Check shifting insertsforwear ordeformation.

SMT387A

•Measure clearance betweenbaulkringandgear.

Clearance betweenbaulkringandgear:

Standard 1.0 -1.35 mm(0.0394 -0.0531 in)

Wear limit

0.7 mm (0.028 in)

SMT140

•

Bearing

• Make surebearings rollfreely andarefree from noise,

cracks, pittingorwear.

SMT148A ASSEMBLY

1. Assemble 5thsynchronizer.

MT-17

Page 1560 of 1701

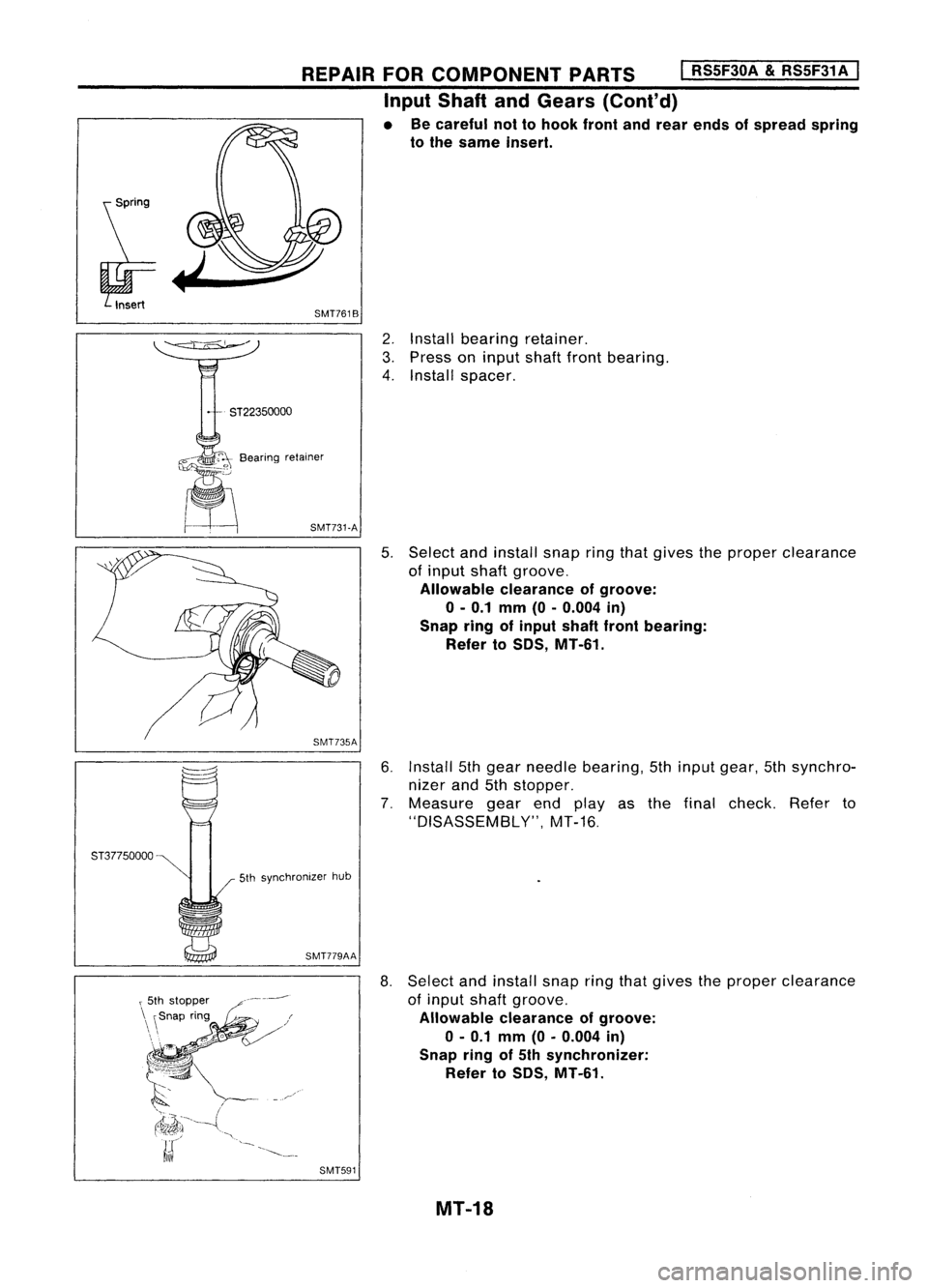

SMT7618

5T37750000

REPAIR

FORCOMPONENT PARTS

I

RS5F30A

&

RS5F31A

I

Input Shaft andGears (Cont'd)

• Becareful nottohook frontandrear ends ofspread spring

to the same insert.

2. Install bearing retainer.

3. Press oninput shaftfrontbearing.

4. Install spacer.

~" O~0Bearing retainer

~~ SMT731-A

5.Select andinstall snapringthatgives theproper clearance

of input shaftgroove.

Allowable clearanceofgroove:

o -

0.1 mm (0-0.004 in)

Snap ringofinput shaftfrontbearing:

Refer toSOS, MT-61.

6. Install 5thgear needle bearing, 5thinput gear, 5thsynchro-

nizer and5thstopper.

7. Measure gearendplayas thefinal check. Referto

"DISASSEMBLY", MT-16.

5th synchronizer hub

SMT779AA

8.Select andinstall snapringthatgives theproper clearance

of input shaftgroove.

Allowable clearanceofgroove:

0-0.1 mm(0-0.004 in)

Snap ringof5th synchronizer:

Refer toSOS, MT-61.

SMT591 MT-18