NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1561 of 1701

REPAIRFORCOMPONENT PARTS

I

RS5F30A &RS5F31 A

I

Mainshaft andGears

DISASSEMBL Y

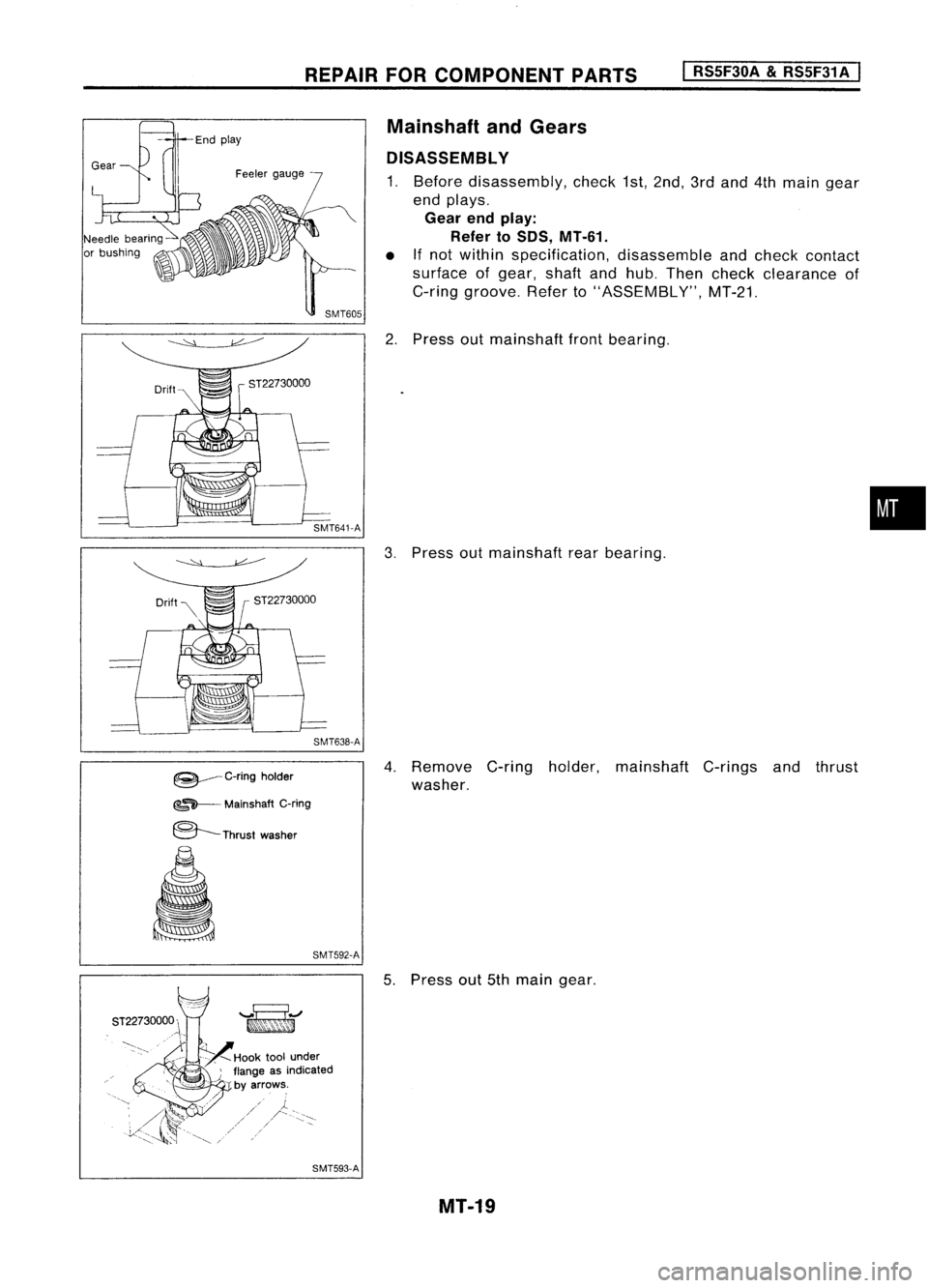

1. Before disassembly, check1st,2nd, 3rdand 4thmain gear

end plays.

Gear endplay:

Refer to50S, MT-61.

• Ifnot within specification, disassembleandcheck contact

surface ofgear, shaftandhub. Then check clearance of

C-ring groove. Referto"ASSEMBLY", MT-21.

2. Press outmainshaft frontbearing.

ST22730000

SMT641-A

3.Press outmainshaft rearbearing.

SMT638-A

•

~ C-ringholder

~~ Mainshaft C-ring

8---

Thrustwasher

SMT592-A

5T,22730, OOO~~""~/

i~;~<~:(

-----~"

"~"

-'::-.

,---'/Hooktoolunder

-', """.•".~, >~\ .

J.

flange asindicated

'. '.~ byarrows.

"-~,

",'

.'

//

" /!~'(';Y

I -\--...

Y:<"~_.

~~w"-,~

--...' ....~"'I "

SMT593-A

4.

Remove C-ringholder, mainshaft C-ringsandthrust

washer.

5. Press out5th main gear.

MT-19

Page 1562 of 1701

SMT687C

Steel

ball

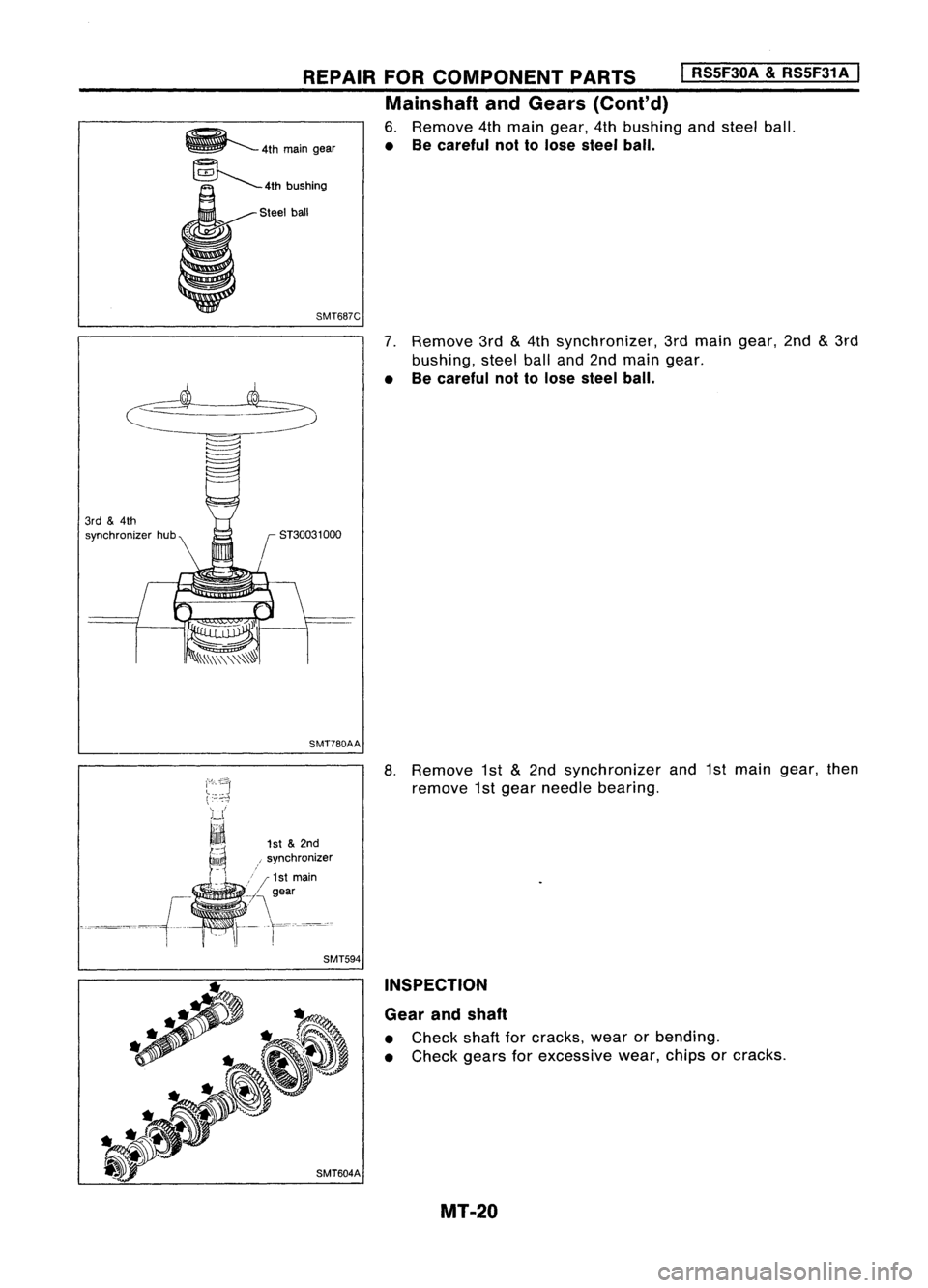

7.Remove 3rd

&

4th synchronizer, 3rdmain gear, 2nd

&

3rd

bushing, steelballand2nd main gear.

• Becareful nottolose steel ball.

REPAIR

FORCOMPONENT PARTS

I

RS5F30A

&

RS5F31A

I

Mainshaft andGears (Conl'd)

6. Remove 4thmain gear, 4thbushing andsteel ball.

• Becareful nottolose steel ball.

r

ST30031 000

3rd

&

4th

synchronizer hub

SMT780AA

8.Remove 1st

&

2nd synchronizer and1stmain gear, then

remove 1stgear needle bearing.

1st &2nd

, synchronizer

/ /1st main

.~/\ gear

t-r=-~~'c

SMT594

INSPECTION

Gear andshaft

• Check shaftforcracks, wearorbending.

• Check gearsforexcessive wear,chipsorcracks.

MT-20

Page 1563 of 1701

Shiftinginsert

t

Baulkringto

gear clearance

REPAIR

FORCOMPONENT PARTS

I

RS5F30A

&

RS5F31A

I

Mainshaft andGears (Cont'd)

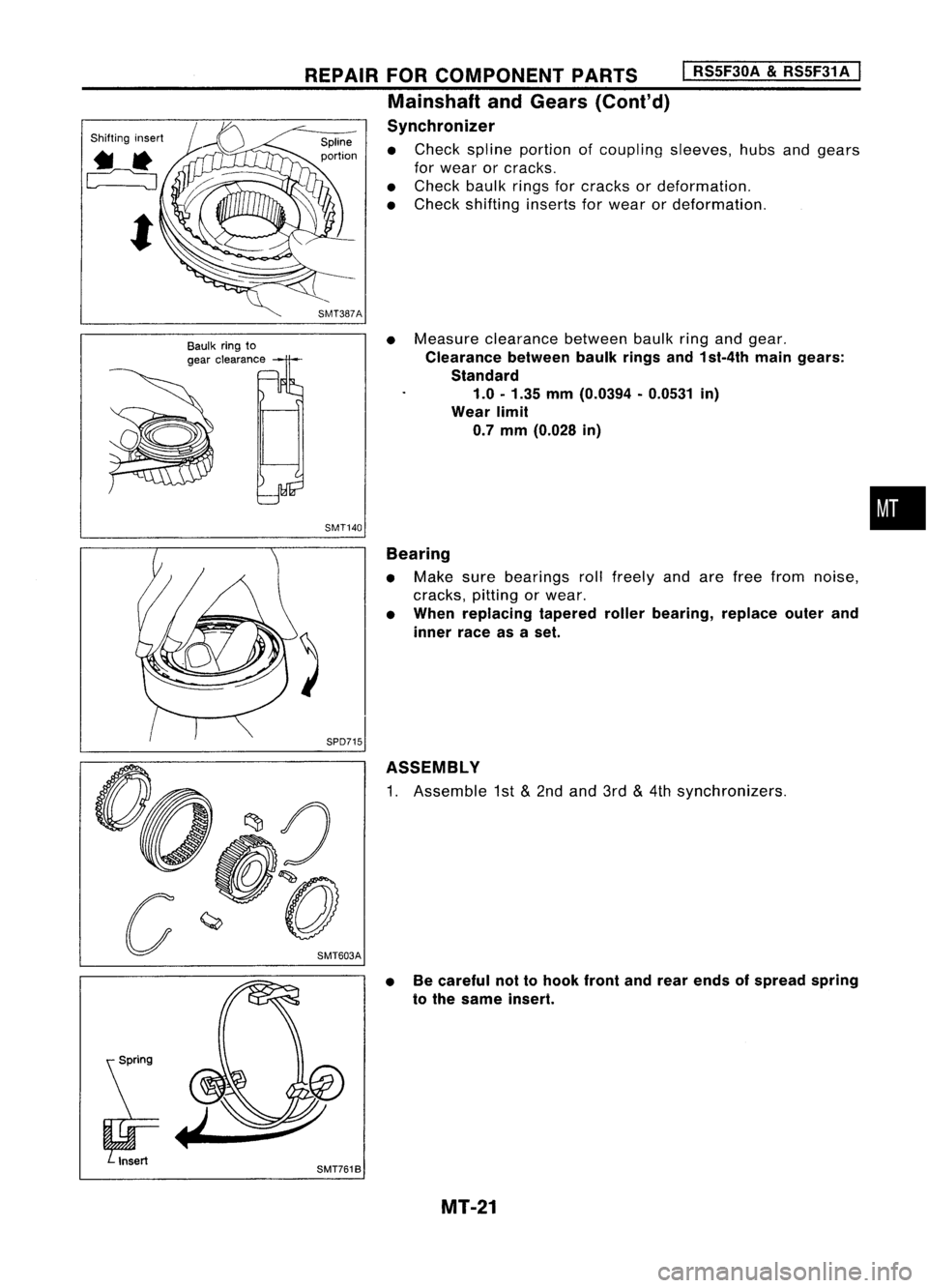

Synchronizer

• Check spline portion ofcoupling sleeves,hubsandgears

for wear orcracks.

• Check baulkringsforcracks ordeformation.

• Check shifting insertsforwear ordeformation.

• Measure clearance betweenbaulkringandgear.

Clearance betweenbaulkringsand1st-4th maingears:

Standard 1.0 -1.35 mm(0.0394 -0.0531 in)

Wear limit

0.7 mm (0.028 in)

SMT140

•

SMT761B Bearing

• Make surebearings rollfreely andarefree from noise,

cracks, pittingorwear.

• When replacing taperedrollerbearing, replaceouterand

inner raceasaset.

ASSEMBLY

1. Assemble 1st

&

2nd and 3rd

&

4th synchronizers.

• Becareful nottohook frontandrear ends ofspread spring

to the same insert.

MT-21

Page 1564 of 1701

ST22452000

ST37750000 -

3rd

&

4th

synchronizer hub

REPAIR

FORCOMPONENT PARTS

I

RS5F30A &RS5F31A

I

Mainshaft andGears (Cont'd)

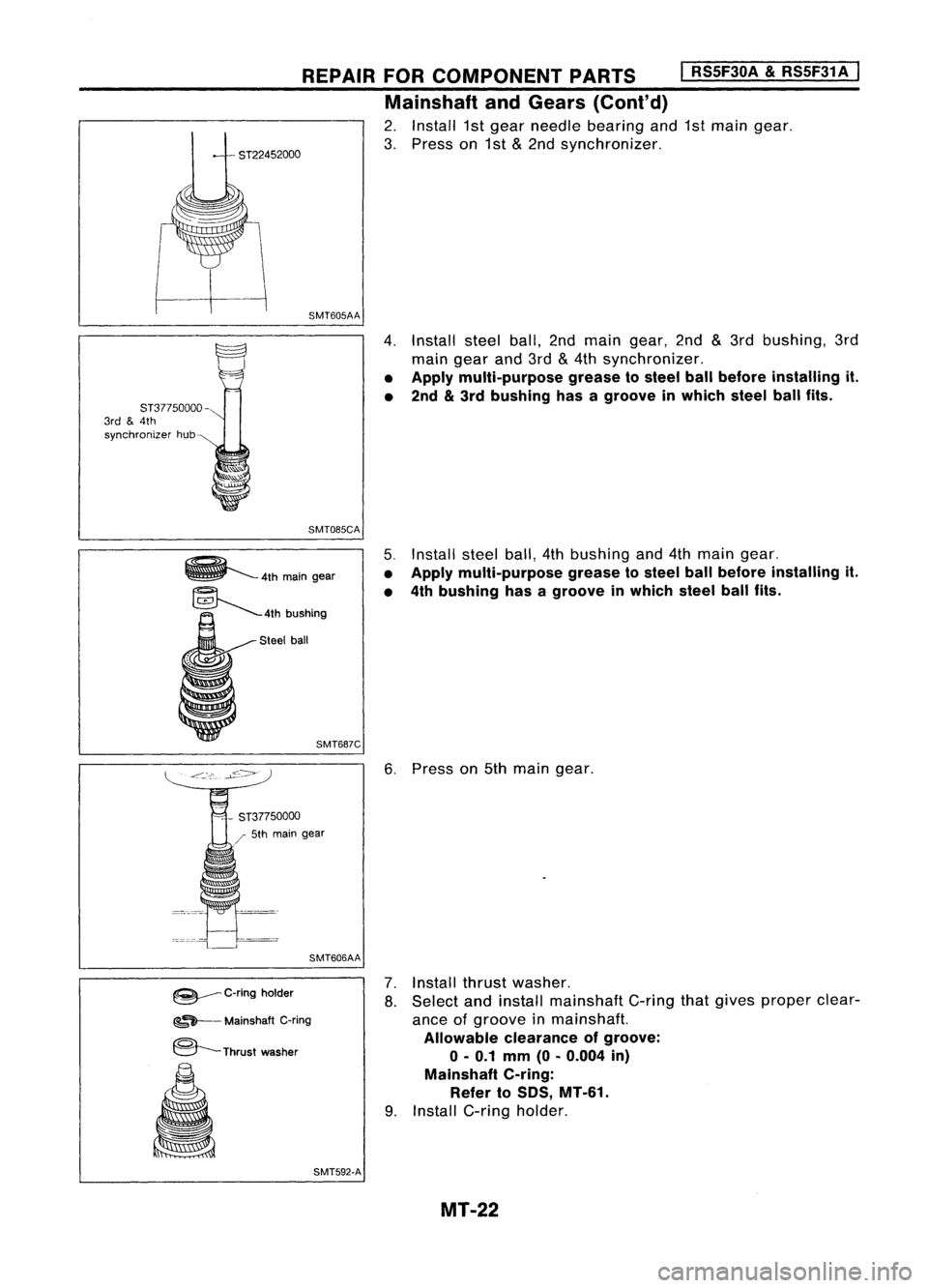

2. Install 1stgear needle bearing and1stmain gear.

3. Press on1st

&

2nd synchronizer.

SMT605AA

4.Install steelball,2ndmain gear, 2nd

&

3rd bushing, 3rd

main gearand3rd

&

4th synchronizer.

• Apply multi-purpose greasetosteel ballbefore installing it.

• 2nd

&

3rd bushing hasagroove inwhich steelballfits.

SMT085CA

5.Install steelball,4thbushing and4thmain gear.

• Apply multi-purpose greasetosteel ballbefore installing it.

• 4th bushing hasagroove inwhich steelballfits.

Steel ball

SMT687C

6.Press on5th main gear.

/ 5th main gear

SMT606AA

~ C-ringholder

~~ Mainshaft C-ring

@---Thrust washer

SMT592-A

7.

Install thrustwasher.

8. Select andinstall mainshaft C-ringthatgives proper clear-

ance ofgroove inmainshaft.

Allowable clearanceofgroove:

0-0.1 mm(O.0.004 in)

Mainshaft C-ring:

Refer to50S, MT-61.

9. Install C-ring holder.

MT-22

Page 1565 of 1701

ST22360002

REPAIR

FORCOMPONENT PARTS

I

RSSF30A

&

RSSF31A

I

Mainshaft andGears (Cont'd)

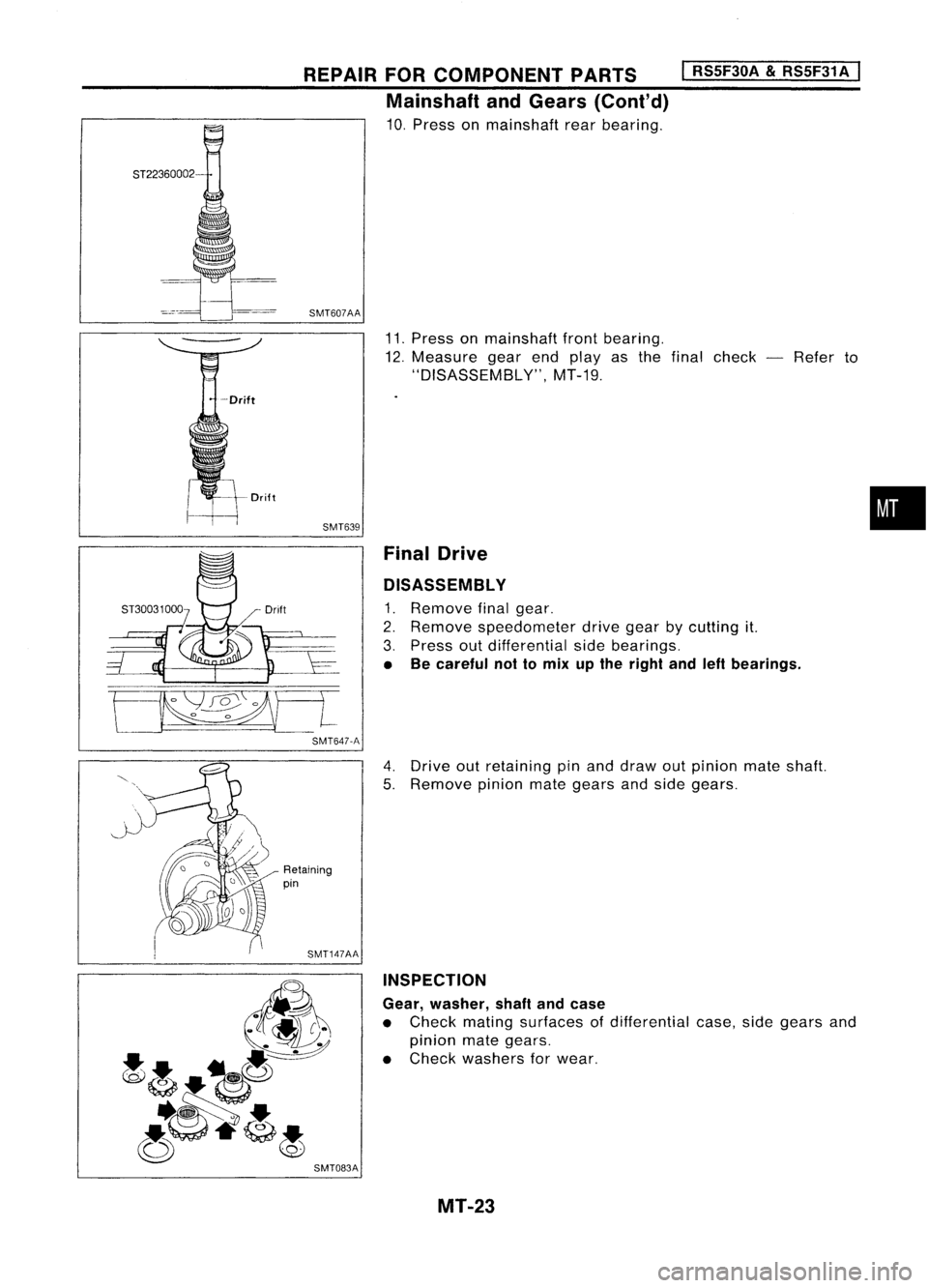

10. Press onmainshaft rearbearing.

SMT607AA

11.Press onmainshaft frontbearing.

12. Measure gearendplayas thefinal check -Refer to

"DISASSEM BL

y",

MT-19.

SMT639 FinalDrive

DISASSEMBL Y

1. Remove finalgear.

2. Remove speedometer drivegearbycutting it.

3. Press outdifferential sidebearings.

• Becareful nottomix upthe right andleftbearings.

•

[ .

SMT647-A

4.Drive outretaining pinand draw outpinion mateshaft.

5. Remove pinionmategears andside gears.

Retaining

pin

SMT147AA INSPECTION

Gear, washer, shaftandcase

• Check mating surfaces ofdifferential case,sidegears and

pinion mategears.

• Check washers forwear.

SMT083A MT-23

Page 1566 of 1701

KV38105900

REPAIR

FORCOMPONENT PARTS

I

RS5F30A

&

RS5F31A

I

Final Drive (Conl'd)

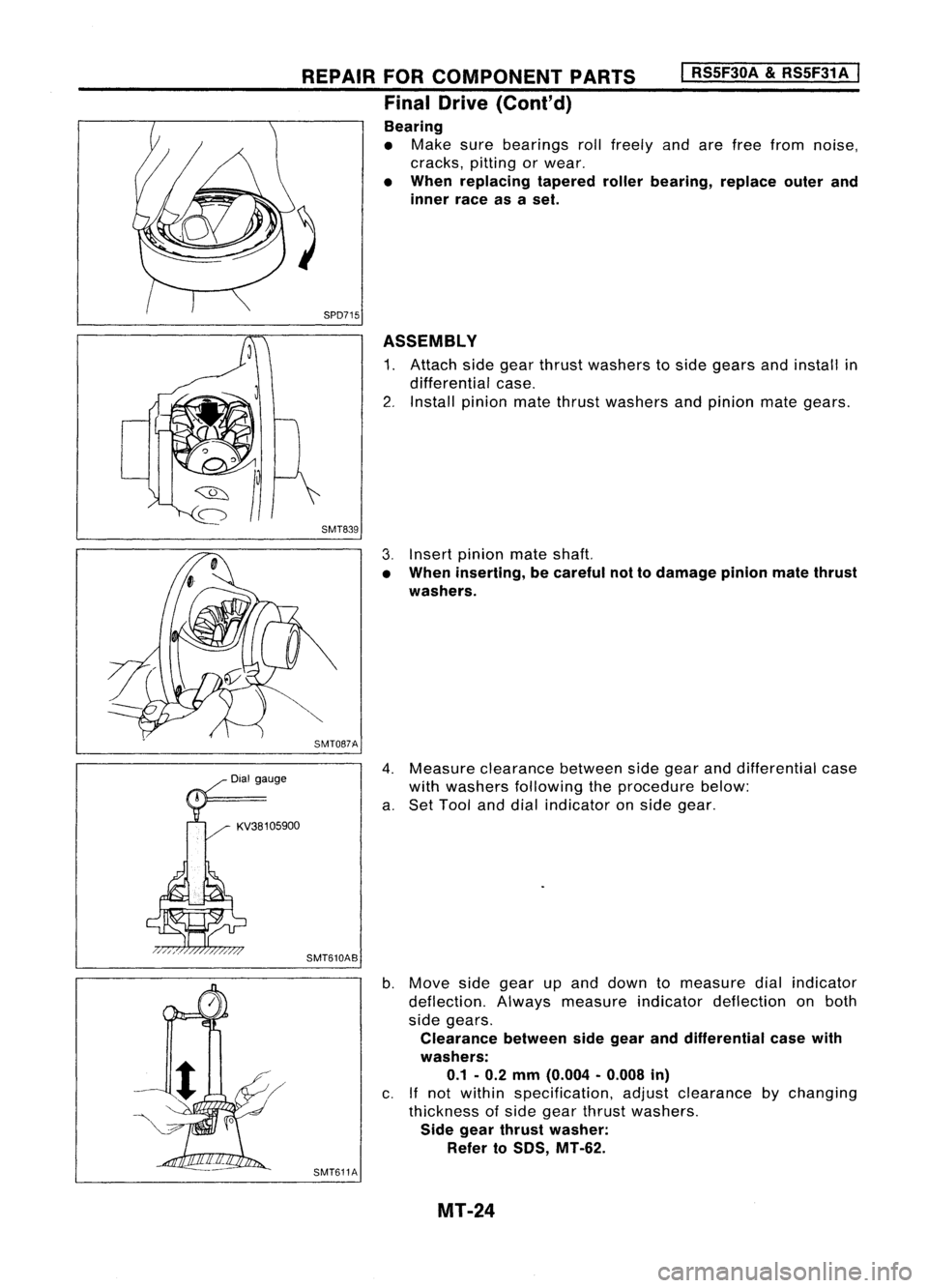

Bearing

• Make surebearings rollfreely andarefree from noise,

cracks, pittingorwear.

• When replacing taperedrollerbearing, replaceouterand

inner raceasaset.

SPD715 ASSEMBLY

1. Attach sidegear thrust washers toside gears andinstall in

differential case.

2. Install pinion matethrust washers andpinion mategears.

SMT839

3.Insert pinion mateshaft.

• When inserting, becareful nottodamage pinionmatethrust

washers.

SMT087A

4.Measure clearance betweensidegear anddifferential case

with washers following theprocedure below:

a. Set Tool anddial indicator onside gear.

SMT610AB

b.Move sidegear upand down tomeasure dialindicator

deflection. Alwaysmeasure indicatordeflection onboth

side gears.

Clearance betweensidegear anddifferential casewith

washers: 0.1 -0.2 mm (0.004 -0.008 in)

c. Ifnot within specification, adjustclearance bychanging

thickness ofside gear thrust washers.

Side gear thrust washer:

Refer to50S, MT-62.

SMT611A

MT-24

Page 1567 of 1701

1/

REPAIR

FORCOMPONENT PARTS

I

RS5F30A

&

RS5F31A

I

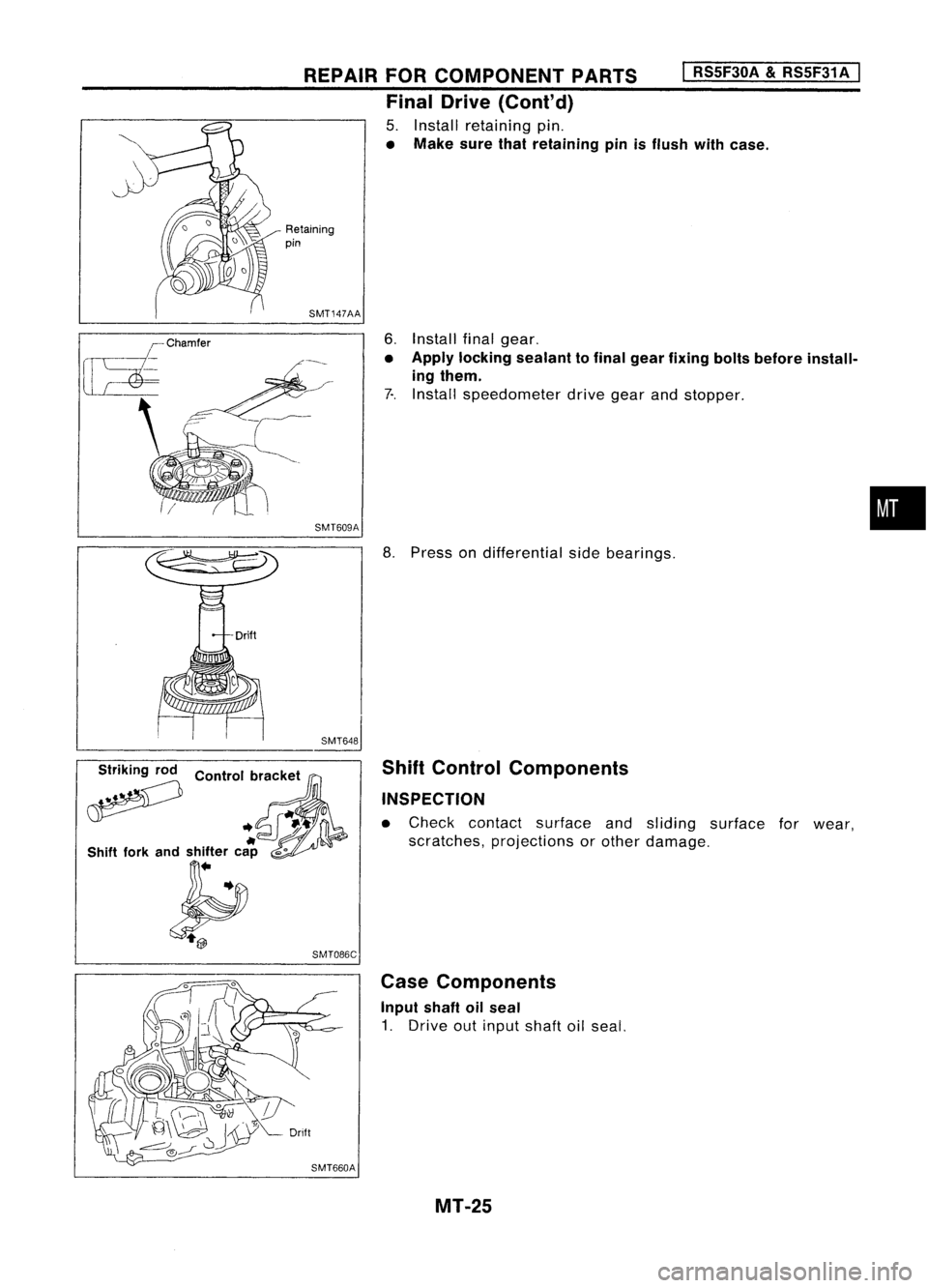

Final Drive (Cont'd)

5. Install retaining pin.

• Make surethatretaining pinisflush withcase.

Retaining

pin

SMT147AA

6.Install finalgear.

• Apply locking sealant tofinal gear fixing boltsbefore install-

ing them.

7-. Install speedometer drivegearandstopper .

SMT609A

•

;?

Control

b~'Ck:t ,

.. ~-t'

If

0

Shift forkandshifter cap

",0

~ SMT086C

8.

Press ondifferential sidebearings.

Shift Control Components

INSPECTION

• Check contact surface andsliding surface forwear,

scratches, projections orother damage.

Case Components

Input shaftoilseal

1. Drive outinput shaftoilseal.

MT-25

Page 1568 of 1701

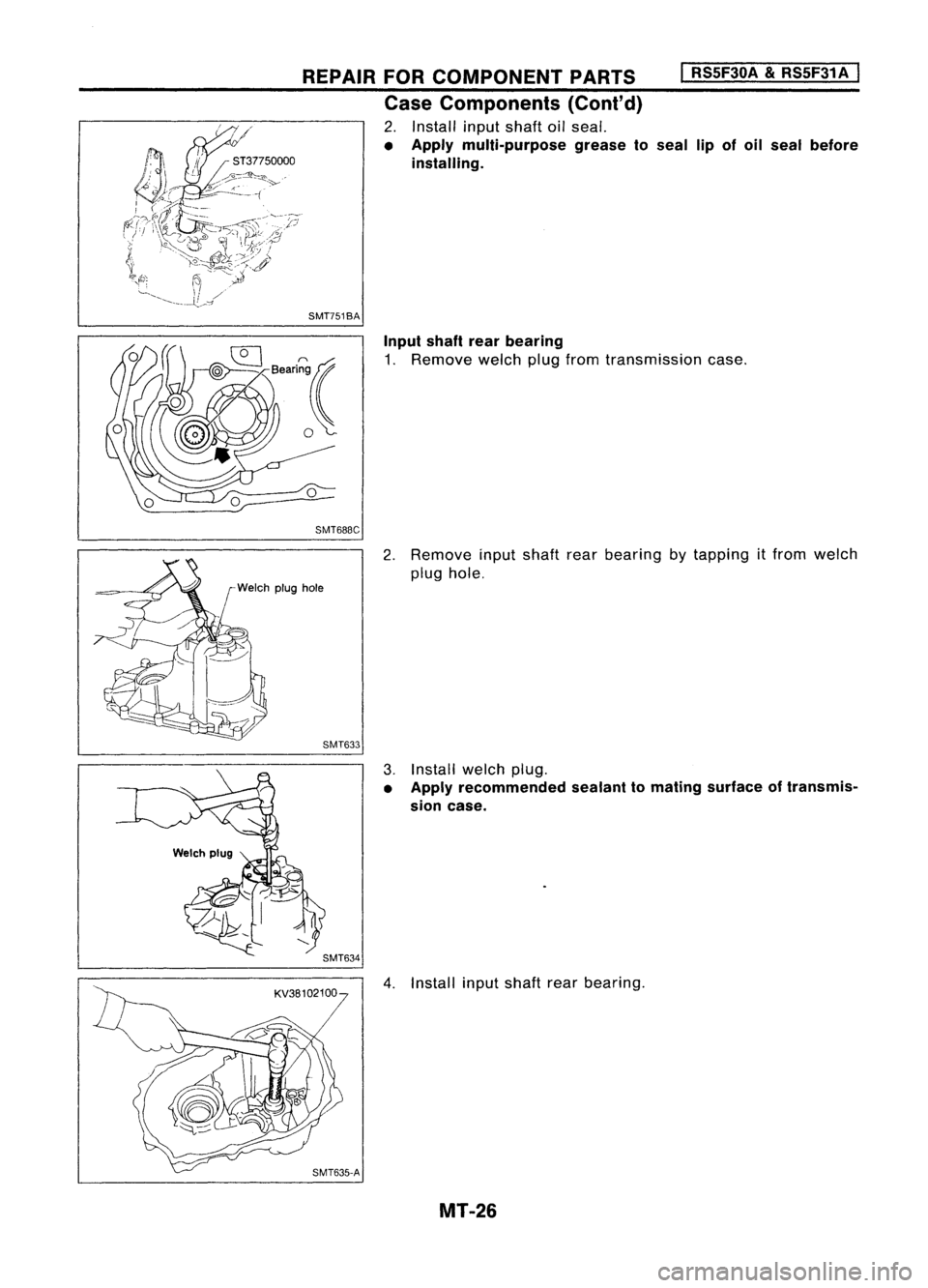

REPAIRFORCOMPONENT PARTS

Case Components (Cont'd)

2. Install inputshaft oilseal.

• Apply multi-purpose greaseto

installing.

SMT751BA

I

RSSF30A

&

RSSF31A

I

seal lipofoil seal before

Input shaftrearbearing

1. Remove welchplugfrom transmission case.

SMT688C

2.Remove inputshaft rearbearing bytapping itfrom welch

plug hole.

r

Welch plughole

SMT633

3.Install welchplug.

• Apply recommended sealanttomating surface oftransmis-

sion case.

4. Install inputshaft rearbearing.

MT-26

Page 1569 of 1701

Toward

oil pocket

REPAIR

FORCOMPONENT PARTS

I

RS5F30A

&

RS5F31A

I

Case Components (Cont'd)

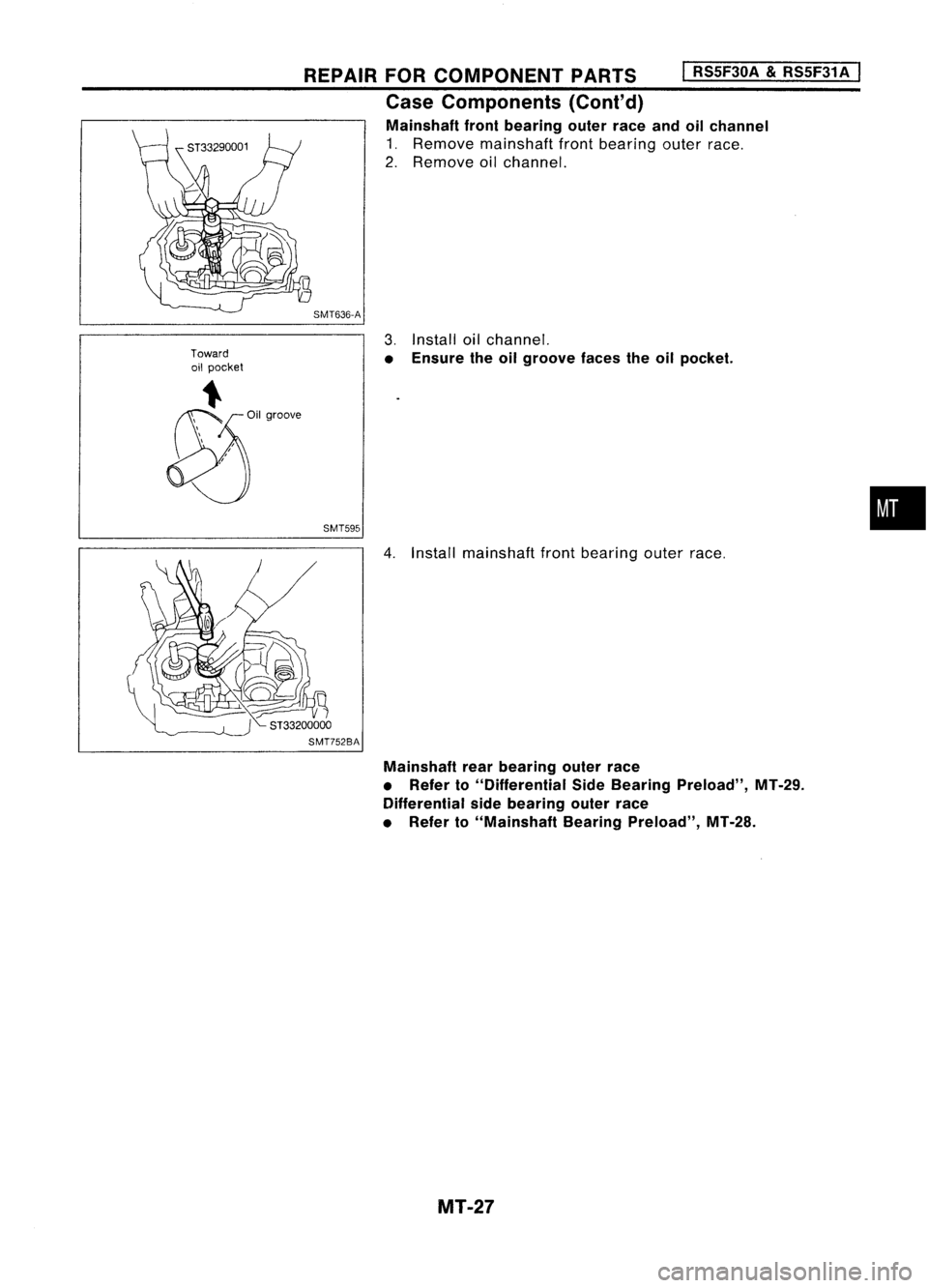

Mainshaft frontbearing outerraceandoilchannel

1. Remove mainshaft frontbearing outerrace.

2. Remove oilchannel.

SMT636-A

3.Install oilchannel.

• Ensure theoilgroove facestheoilpocket.

SMT595

•

4. Install mainshaft frontbearing outerrace.

Mainshaft rearbearing outerrace

• Refer to"Differential SideBearing Preload", MT-29.

Differential sidebearing outerrace

• Refer to"Mainshaft BearingPreload", MT-28.

MT-27

Page 1570 of 1701

ADJUSTMENT

I

RS5F30A

&

RS5F31 A

I

SMT646-A

I"

KV38106000

SMT454-ADifferential

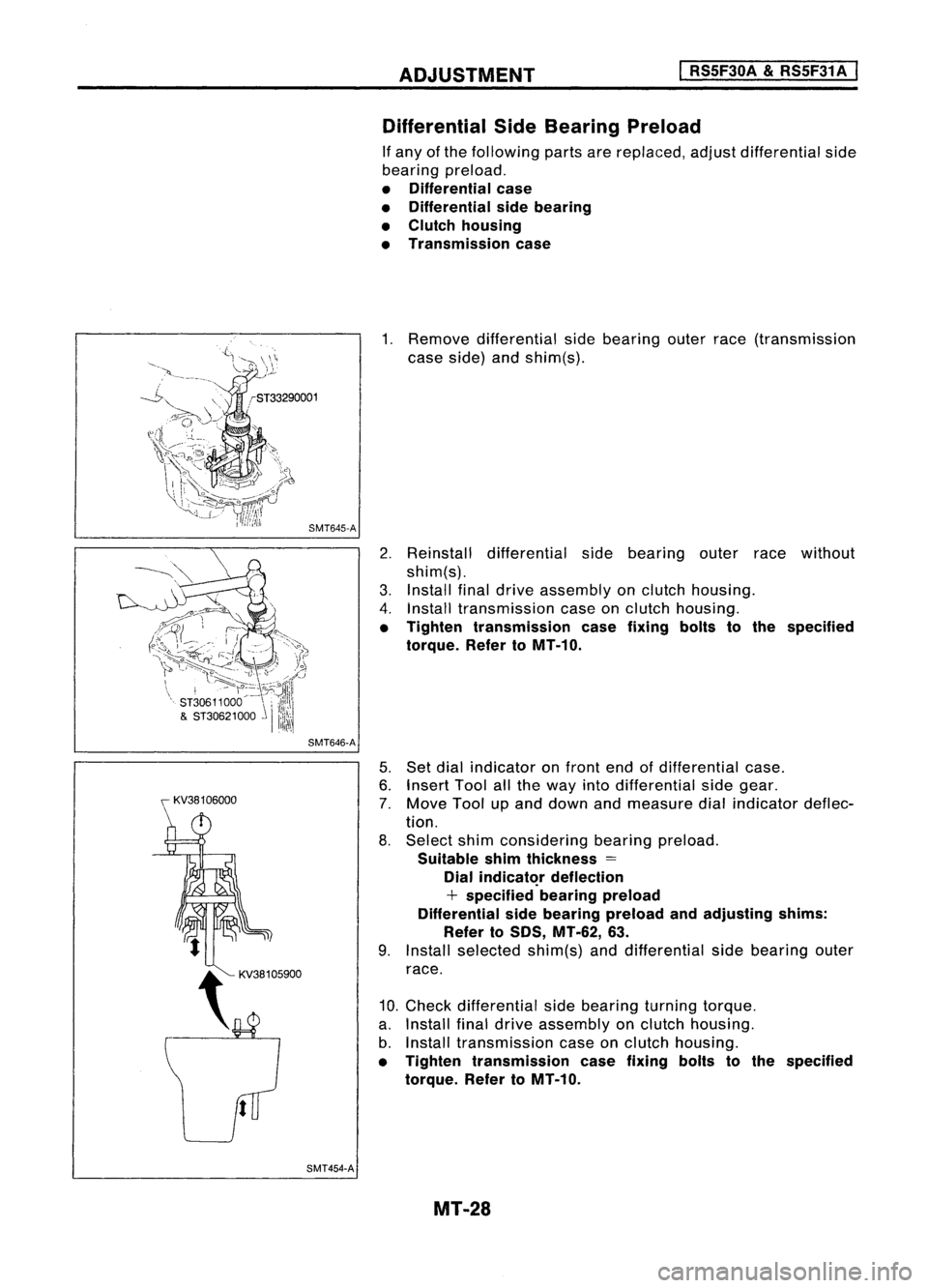

SideBearing Preload

If any ofthe following partsarereplaced, adjustdifferential side

bearing preload.

• Differential case

• Differential sidebearing

• Clutch housing

• Transmission case

1. Remove differential sidebearing outerrace(transmission

case side) andshim(s).

2. Reinstall differential sidebearing outerracewithout

shim(s).

3. Install finaldrive assembly onclutch housing.

4. Install transmission caseonclutch housing.

• Tighten transmission casefixing boltstothe specified

torque. RefertoMT-10.

5. Set dial indicator onfront endofdifferential case.

6. Insert Toolallthe way intodifferential sidegear.

7. Move Toolupand down andmeasure dialindicator deflec-

tion.

8. Select shimconsidering bearingpreload.

Suitable shimthickness =

Dial

indicat~r

deflection

+ specified bearingpreload

Differential sidebearing preload andadjusting shims:

Refer to50S, MT-62, 63.

9. Install selected shim(s)anddifferential sidebearing outer

race.

10. Check differential sidebearing turningtorque.

a. Install finaldrive assembly onclutch housing.

b. Install transmission caseonclutch housing.

• Tighten transmission casefixing boltstothe specified

torque. RefertoMT-10.

MT-28