NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1541 of 1701

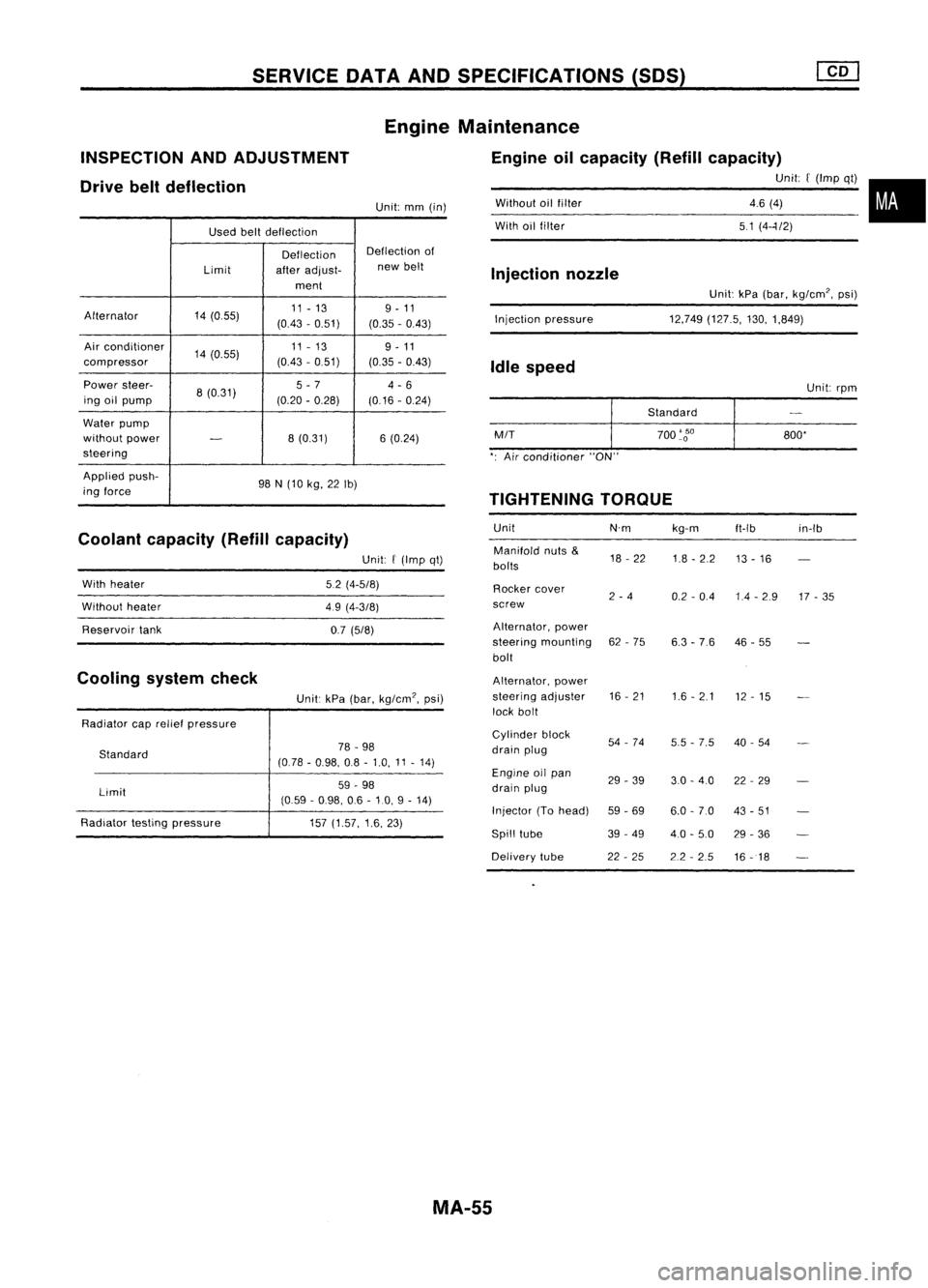

SERVICEDATAANDSPECIFICATIONS (50S)

Used beltdeflection

Deflection Deflection

of

Limit afteradjust- new

belt

ment

Alternator 14(055) 11

-13 9-11

(0.43 -0.51)

(0.35-0.43)

Air conditioner

14(0.55) 11

-13

9-11

compressor (0.43

-0.51)

(0.35-0.43)

Power steer-

8(0.31) 5

-7

4-6

ing oilpump (0.20-0.28)

(0.16-0.24)

Water pump

without power

-

8

(0.31) 6(0.24)

steering

Applied push-

98N(10 kg, 22Ib)

ing force

Coolant capacity (Refillcapacity)

INSPECTION

ANDADJUSTMENT

Drive beltdeflection

Unit:kPa(bar, kg/cm', psi)

12,749 (127.5, 130,1,849)

Without

oilfilter

With oilfilter

Injection pressure

Injection

nozzle

Idle speed

Unit:rpm

Standard

M/T

700

'go

800'

': Air conditioner "ON"

TIGHTENING TORQUE

Unit N'mkg-m

ft-Ib in-Ib

Manifold nuts

&

18-22

1.8-2.2

bolts 13

-16

Rocker cover

2-4

0.2-0.4 1.4-2.9 17-35

screw

Alternator, power

steering mounting 62-75

6.3-76 46

-55

bolt

Alternator, power

steering adjuster 16

-21

1.6-2.1

12-15

lock bolt

Cylinder block

54-74

5.5-7.5 40

-54

drain plug

Engine oilpan

29-39 3.0-4.0 22-29

drain plug

Injector (Tohead)

59-69 6.0-7.0 43-51

Spill tube 39-49

4.0-5.0 29-36

Delivery tube 22-25 2.2-2.5

16-18

Engine

Maintenance

Engine oilcapacity (Refillcapacity)

Unit:[(Imp qt)•

46 (4)

51 (4--1/2)

Unit:

mm(in)

Unit:

f

(Imp qt)

5.2 (4-5/8)

49 (4-3/8)

0.7 (5/8)

Unit: kPa(bar, kg/cm', psi)

78 -98

(0.78 -0.98, 08-1.0, 11-14)

59 -98

(0.59 -0.98, 06-10, 9-14)

157 (1.57, 1.6,23)

Standard

Limit

With

heater

Without heater

Reservoir tank

Radiator caprelief pressure

Radiator testingpressure

Cooling

systemcheck

MA-55

Page 1542 of 1701

SERVICEDATAANDSPECIFICATIONS (50S)

Chassis andBody Maintenance

INSPECTION ANDADJUSTMENT

Wheel balance

Maximum

allowable unbalance Dynamic

(At

rim flange)

g(oz)

Static g(oz)

10

(0.35) (oneside)

20 (0.71)

MA-56

Page 1543 of 1701

MANUALTRANSAXLE

SECTION

MT

CONTENTS

PREPARATION 2

Special Service Tools 2

Commercial ServiceTools 4

ON-VEHICLE SERVICE

5

Replacing OilSeal 5

Position SwitchCheck 6

REMOVAL ANDINSTAllATION 7

Removal ,7

Installation '8

TRANSAXlE GEARCONTROL 9

RS5F30A

&

RS5F31 A

MAJOR OVERHAUL 10

Case Components 10

Gear Components ,11

Shift Control Components , 12

DiSASSEMBly ,13

REPAIR FORCOMPONENT PARTS 16

Input Shaft andGears 16

Mainshaft andGears 19

Final Drive ,,23

Shift Control Components 25

Case Components ,25

ADJUSTMENT ,,.. , 28

Differential SideBearing Preload 28

Mainshaft BearingPreload ,29

ASSEMBly ,30 RS5F32A

MAJOR OVERHAUl ,,,

33

Case Components , 33

Gear Components 34

Shift Control Components 35

DiSASSEMBly ",.,., , ,36

REPAIR FORCOMPONENT PARTS 39

Input Shaft andGears 39

Mainshaft andGears 42

Final Drive .47

Shift Control Components 49

Case Components ' 51

ADJUSTMENT ,, ", 54

Differential SideBearing Preload ,54

ASSEMBLY ',

56

'----_-JI RS5F30A

&

RS5F31A

&

RS5F32A

SERVICE DATAANDSPECIFICATIONS (SDS)60

General Specifications 60

Inspection andAdjustment -RS5F30A &

RS5F31 A ' 61

Inspection andAdjustment -RS5F32A 64

•

Page 1544 of 1701

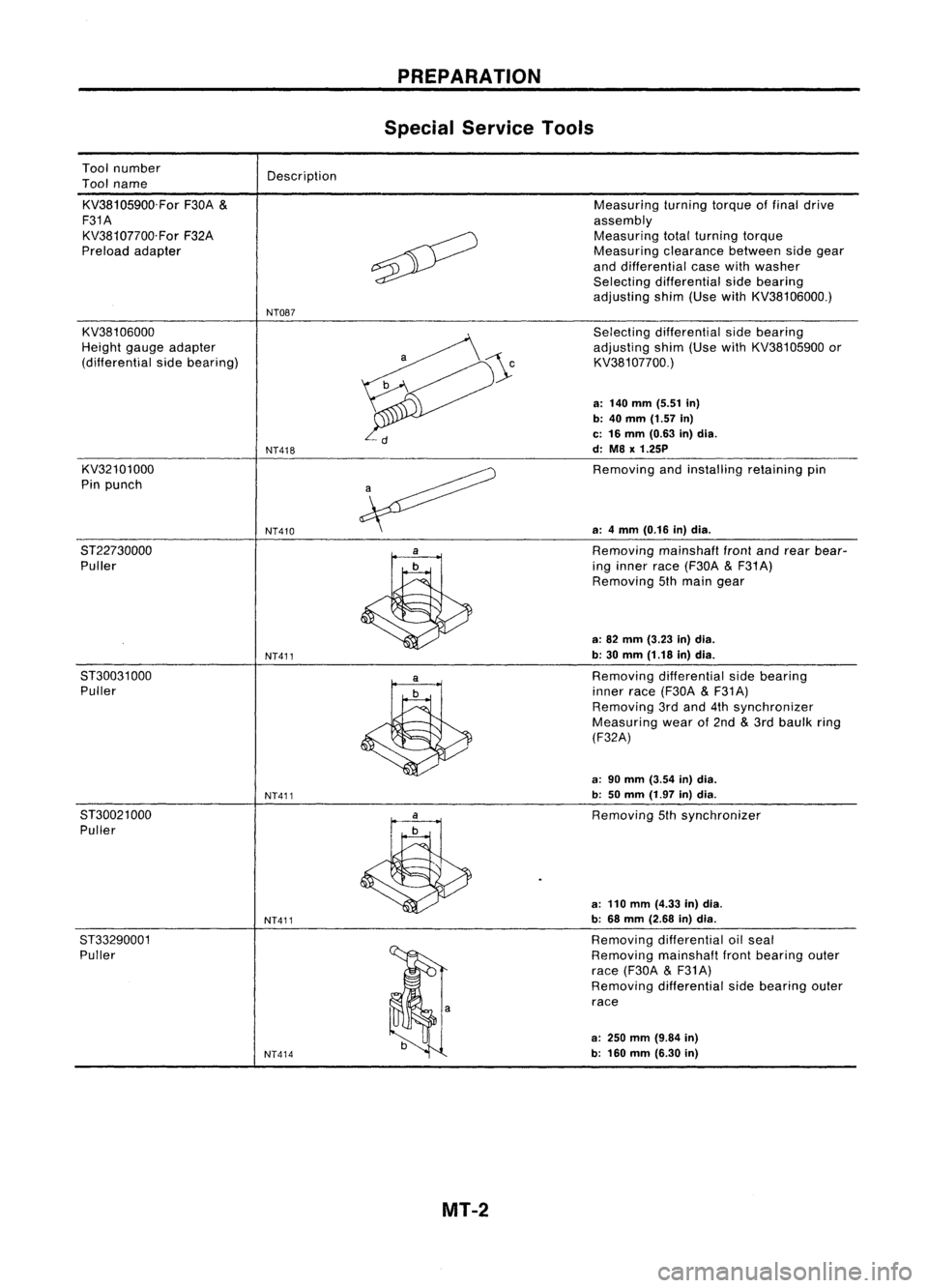

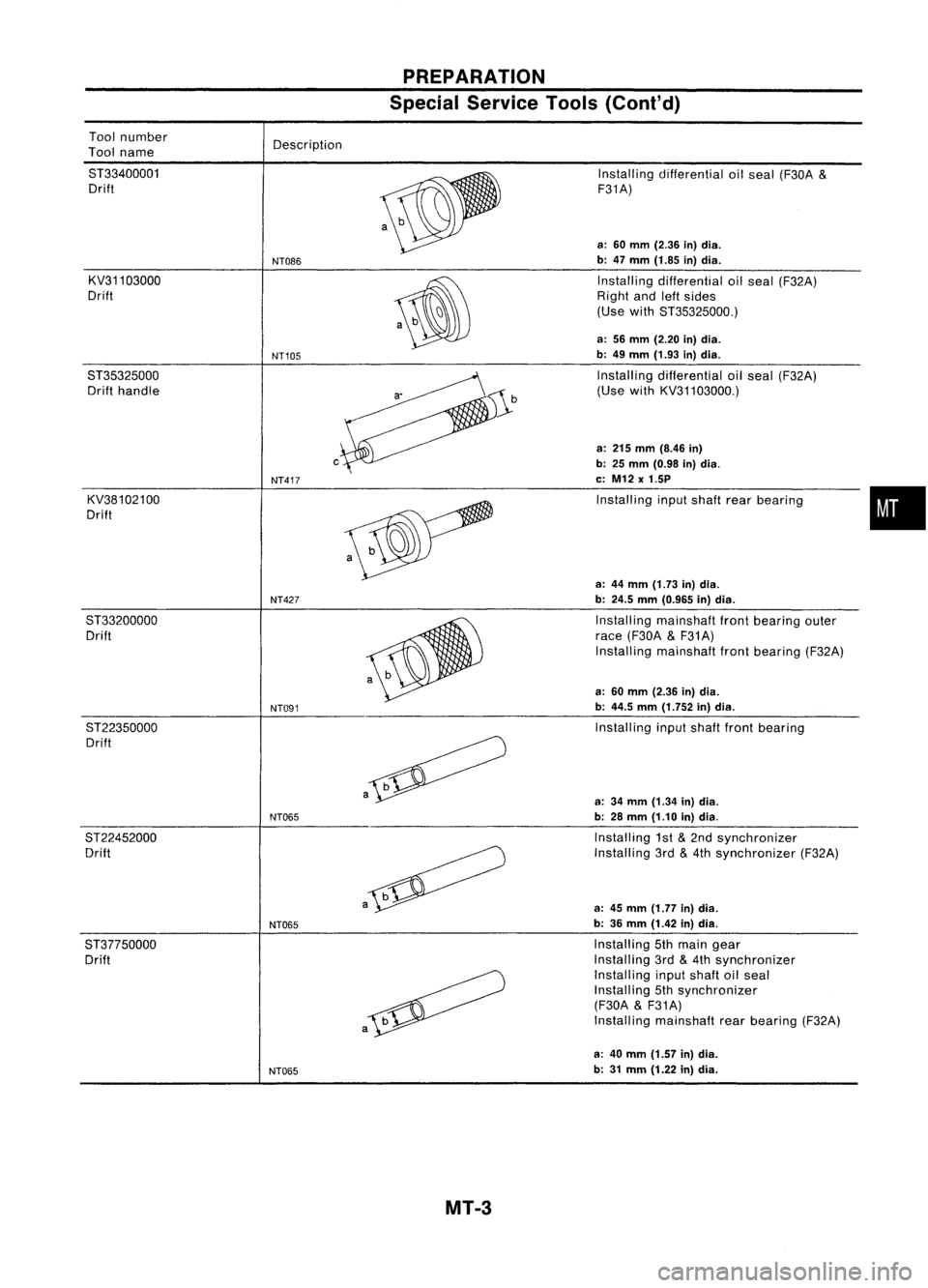

Toolnumber

Tool name

KV38105900.For F30A

&

F31A KV38107700.For F32A

Preload adapter Description

NT087 PREPARATION

Special Service Tools

Measuring turningtorqueoffinal drive

assembly Measuring totalturning torque

Measuring clearancebetweensidegear

and differential casewithwasher

Selecting differential sidebearing

adjusting shim(UsewithKV38106000.)

KV38106000

Height gaugeadapter

(differential sidebearing)

KV32101000

Pin punch

8T22730000 Puller

8T30031 000

Puller

8T30021 000

Puller

ST33290001 Puller

NT418

NT410

NT411

NT411

NT411

NT414

Selecting

differential sidebearing

adjusting shim(UsewithKV38105900 or

KV381 07700.)

a: 140 mm (5.51 in)

b: 40

mm

(1.57

in)

c: 16 mm (0.63 in)dia.

d: M8

x

1.25P

Removing andinstalling retainingpin

a: 4mm (0.16 in)dia.

Removing mainshafl

front

andrear bear-

ing inner race(F30A

&

F31 A)

Removing 5thmain gear

a: 82 mm (3.23 in)dia.

b: 30 mm (1.18 in)dia.

Removing differential sidebearing

inner race(F30A

&

F31A)

Removing 3rdand 4thsynchronizer

Measuring wearof2nd

&

3rd baulk ring

(F32A)

a: 90 mm (3.54 in)dia.

b: 50mm (1.97 in)dia.

Removing 5thsynchronizer

a: 110 mm (4.33 in)dia.

b: 68 mm (2.68 in)dia.

Removing differential oilseal

Removing mainshaflfrontbearing outer

race (F30A

&

F31A)

Removing differential sidebearing outer

race

a:

250

mm

(9.84

in)

b: 160 mm (6.30 in)

MT-2

Page 1545 of 1701

PREPARATION

Special Service Tools(Coni'd)

a-

Tool

number

Tool name

ST33400001 Drift

KV31103000

Drift

ST35325000 Drift handle

KV38102100

Drift Description

NT086

NT105

c

NT417

Installing

differential oilseal (F30A

&

F31A)

a: 60 mm (2.36 in)dia.

b: 47 mm (1.85 in)dia.

Installing differential oilseal (F32A)

Right andleftsides

(Use withST35325000.)

a: 56 mm (2.20 in)dia.

b: 49 mm (1.93 in)dia.

Installing differential oilseal (F32A)

(Use withKV31103000.)

a: 215 mm (8.46 in)

b: 25 mm (0.98 in)dia.

c: M12 x1.5P

Installing inputshaft rearbearing

•

a: 44 mm (1.73 in)dia.

NT427

b:24.5 mm(0.965 in)dia.

ST33200000 Installingmainshaft frontbearing outer

Drift race(F30A

&

F31A)

Installing mainshaft frontbearing (F32A)

a: 60 mm (2.36 in)dia.

NT091

b:

44.5 mm(1.752 in)dia.

ST22350000 Installinginputshaft frontbearing

Drift

a

a:34 mm (1.34 in)dia.

NT065

b:28 mm (1.10 in)dia.

ST22452000 Installing1st

&

2nd synchronizer

Drift Installing3rd

&

4th synchronizer (F32A)

a

a:45 mm (1.77 in)dia.

NT065

b:

36 mm (1.42 in)dia.

ST37750000 Installing5thmain gear

Drift Installing

3rd

&

4th synchronizer

Installing inputshaft oilseal

Installing 5thsynchronizer

(F30A

&

F31A)

a

Install

ingmainshaft rearbearing (F32A)

a: 40 mm (1.57 in)dia.

NT065

b:

31 mm (1.22 in)dia.

MT-3

Page 1546 of 1701

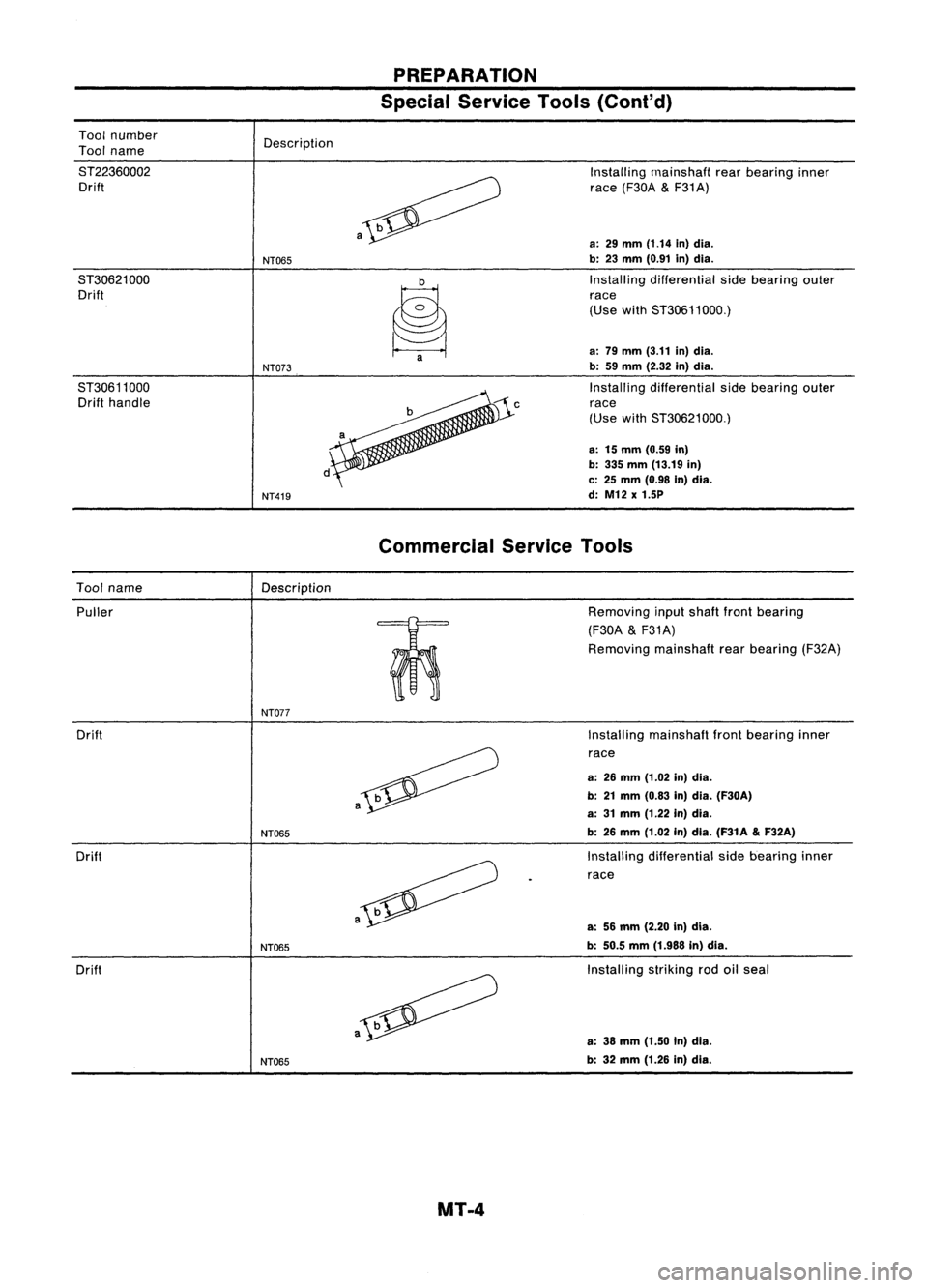

PREPARATION

Special Service Tools(Coni'd)

Tool number

Tool name

ST22360002 Drift

ST30621000 Drift

ST30611000 Drift handle Description

NT065

NT073

NT419 a

~a

Installing

rnainshaft rearbearing inner

race (F30A

&

F31A)

a:

29

mm

(1.14

in)dia.

b: 23 mm (0.91 in)dia.

Installing differential sidebearing outer

race

(Use withST30611000.)

a: 79 mm (3.11 in)dia.

b: 59mm (2.32 in)dia.

Installing differential sidebearing outer

race

(Use withST30621000.)

a: 15mm (0.59 in)

b: 335 mm (13.19 in)

c: 25 mm (0.98 In)dia.

d: M12 x1.5P

Commercial ServiceTools

Tool name

Description

Puller

m:

o

0

NT077

Drift

Drift

Drift

NT065

NT065

NT065 a

Removing

inputshaft frontbearing

(F30A

&

F31A)

Removing mainshaftrearbearing (F32A)

Installing mainshaft frontbearing inner

race

a: 26mm (1.02 in)dia.

b: 21mm (0.83 in)dia. (F30A)

a: 31mm (1.22 in)dia.

b: 26 mm (1.02 in)dia. (F31A

&

F32A)

Installing differential sidebearing inner

race

a: 56mm (2.20 In)dia.

b: 50.5 mm(1.988 in)dia.

Installing strikingrodoilseal

a: 38 mm (1.50 In)dia.

b: 32 mm (1.26 in)dla.

MT-4

Page 1547 of 1701

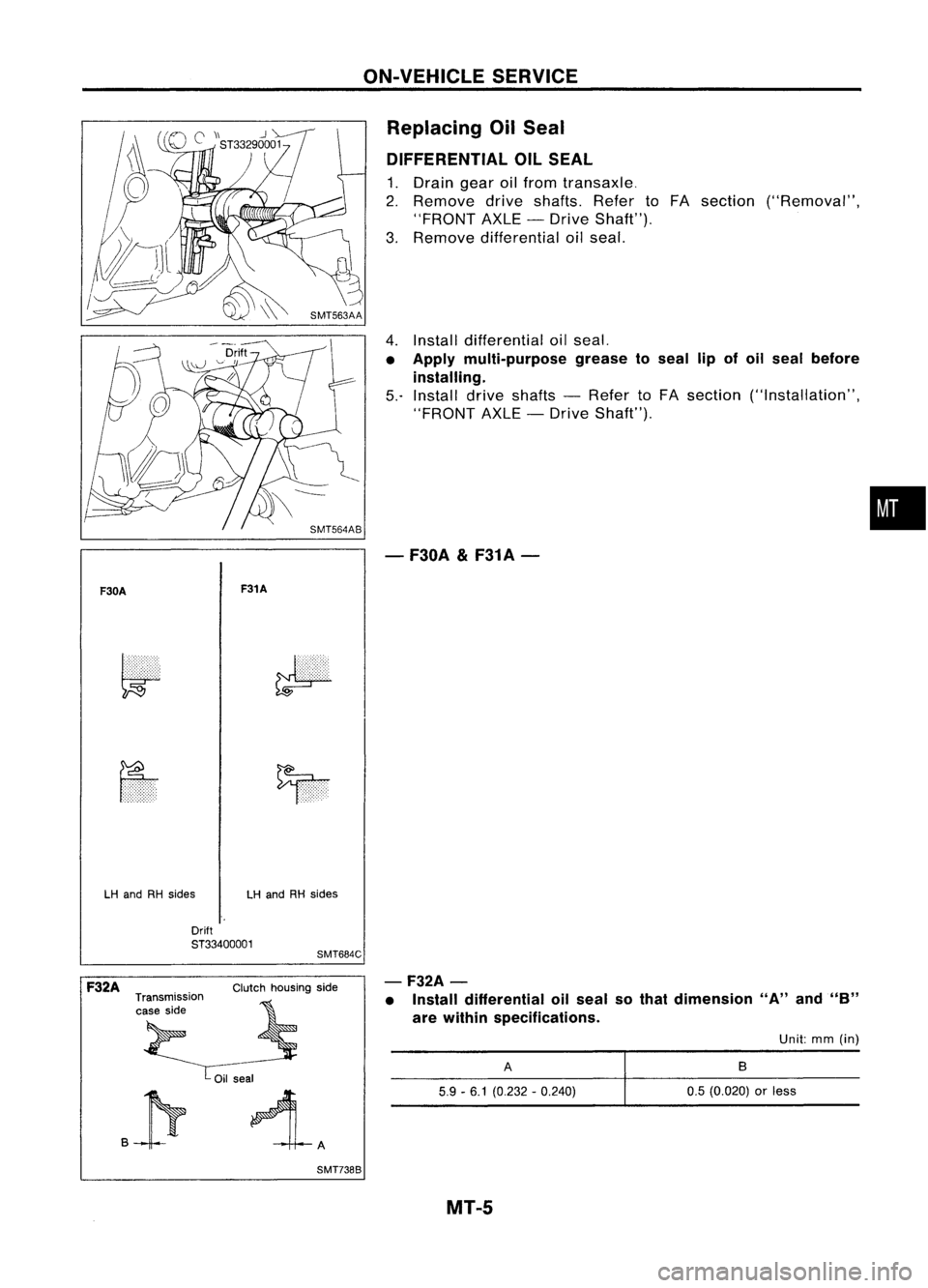

ON-VEHICLESERVICE

Replacing OilSeal

DIFFERENTIAL OILSEAL

1. Drain gearoilfrom transaxle.

2. Remove driveshafts. RefertoFA section ("Removal",

"FRONT AXLE-Drive Shaft").

3. Remove differential oilseal.

4. Install differential oilseal.

• Apply multi-purpose greasetoseal lipofoil seal before

installing.

5.- Install driveshafts -Refer toFA section ("Installation",

"FRONT AXLE-Drive Shaft").

- F30A

&

F31A-

•

F30A F31A

LH and RHsides LHand RHsides

Drift

ST33400001

SMT684C

.P

-F32A

-

• Install differential oilseal sothat dimension "A"and"B"

are within specifications.

F32A

Transmission

case side Clutch

housing side

Oil seal

SMT7388

A

5.9 -6.1 (0.232 -0.240)

MT-5

Unit:

mm(in)

B

0.5 (0.020)

or

less

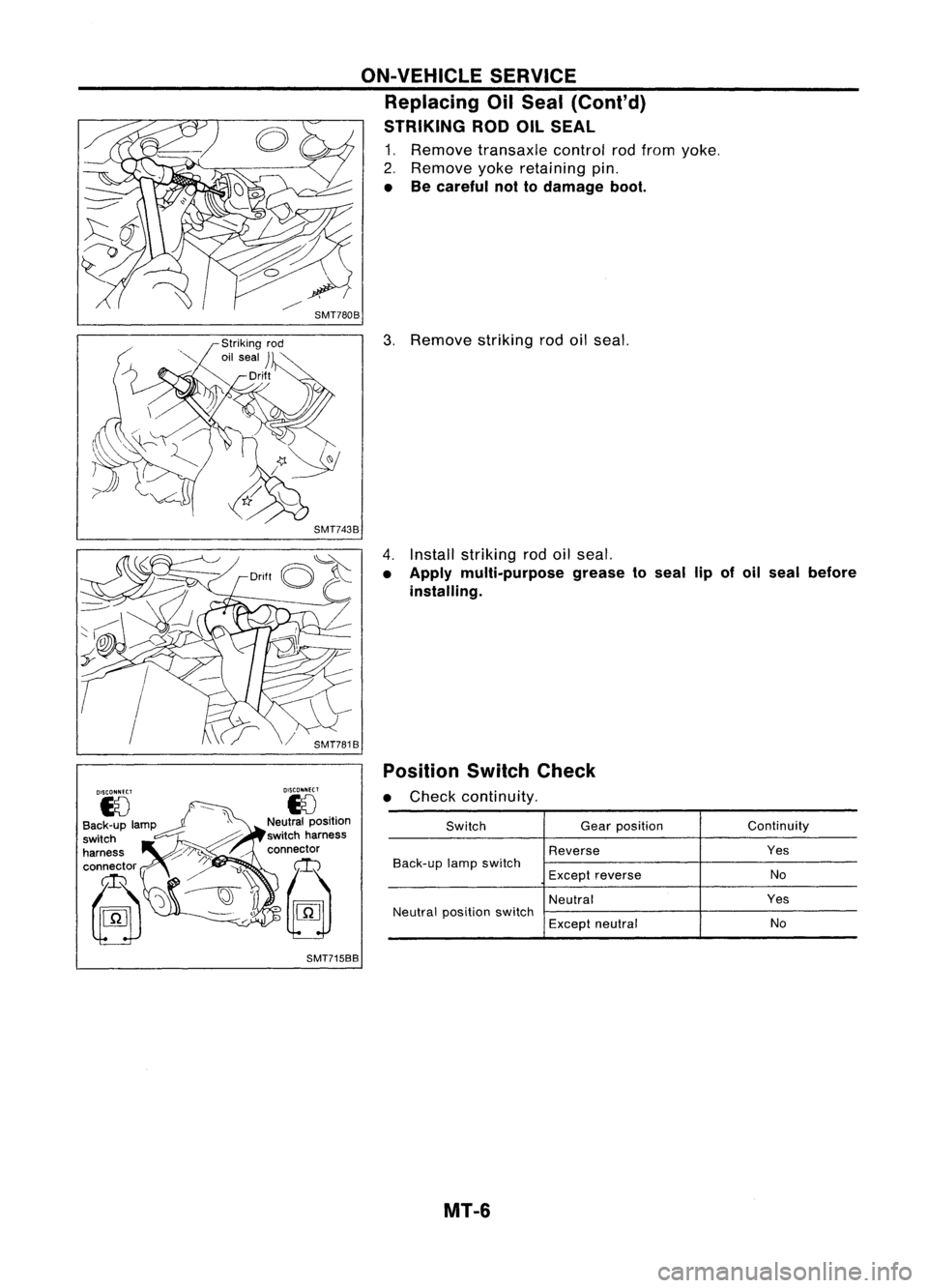

Page 1548 of 1701

SwitchGearposition Continuity

Reverse Yes

Back-up lampswitch

No

Except reverse

Neutral Yes

Neutral position switch

Exceptneutral No

3.

Remove strikingrodoilseal.

Position SwitchCheck

• Check continuity.

4.

Install striking rodoilseal.

• Apply multi-purpose greasetoseal lipofoil seal before

installing.

ON-VEHICLE

SERVICE

Replacing OilSeal (Cont'd)

STRIKING RODOILSEAL

1. Remove transaxle controlrodfrom yoke.

2. Remove yokeretaining pin.

• Becareful nottodamage boot.

DISCONNECT

eJ

Neutral position

switch harness

connector

~ SMT715BB

MT-6

Page 1549 of 1701

REMOVALANDINSTALLATION

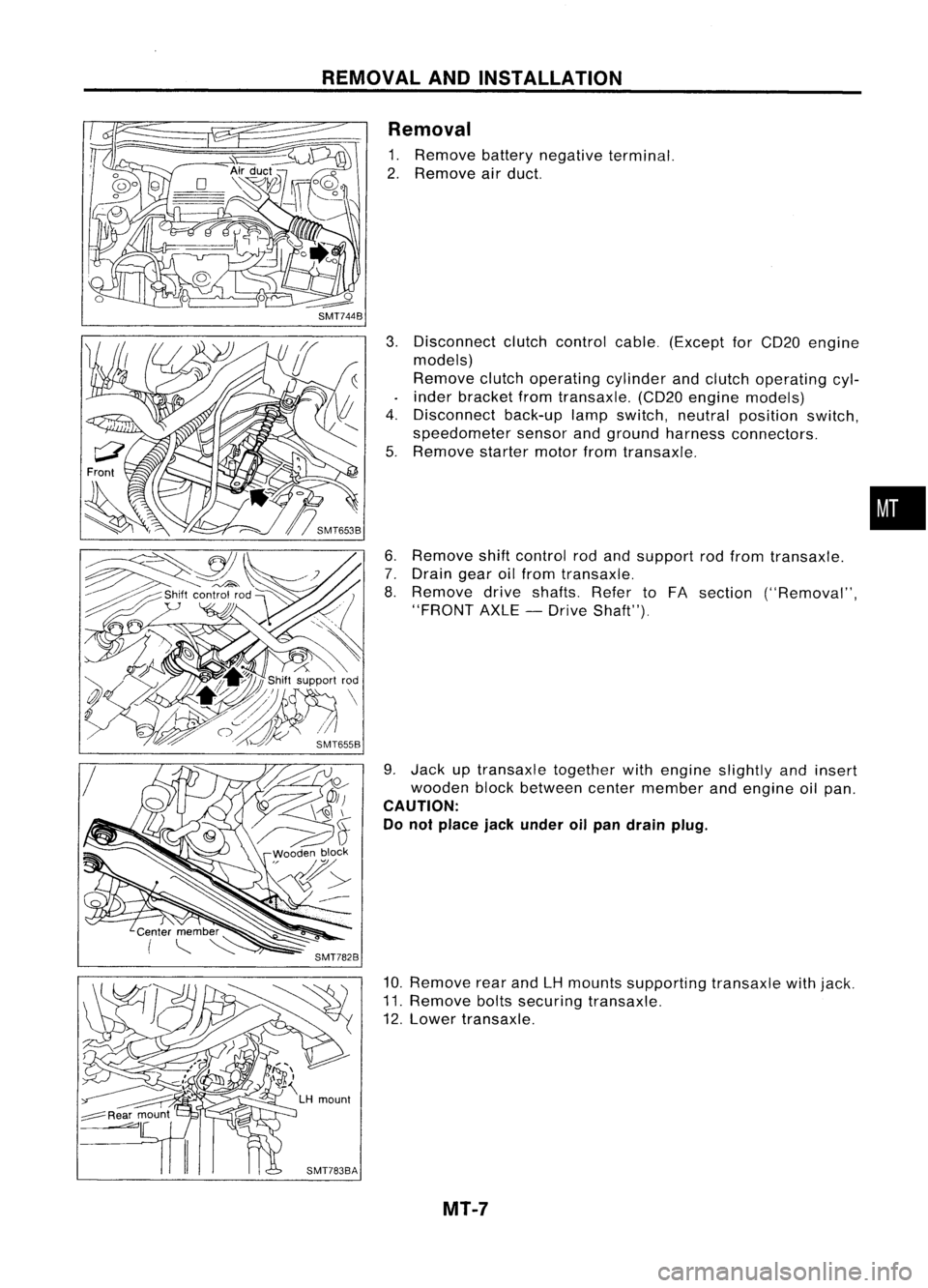

Removal

1. Remove batterynegative terminal.

2. Remove airduct.

3. Disconnect clutchcontrol cable.(Except forCD20 engine

models)

Remove clutchoperating cylinderandclutch operating cyl-

inder bracket fromtransaxle. (CD20engine models)

4. Disconnect back-uplampswitch, neutralposition switch,

speedometer sensorandground harness connectors.

5. Remove startermotorfromtransaxle.

6. Remove shiftcontrol rodand support rodfrom transaxle.

7. Drain gearoilfrom transaxle.

8. Remove driveshafts. RefertoFA section ("Removal",

"FRONT AXLE-Drive Shaft").

9. Jack uptransaxle togetherwithengine slightly andinsert

wooden blockbetween centermember andengine oilpan.

CAUTION:

Do not place jackunder oilpan drain plug.

10. Remove rearandLHmounts supporting transaxlewithjack.

11. Remove boltssecuring transaxle.

12. Lower transaxle.

MT-7

•

Page 1550 of 1701

@

M/T

toengine

CD

REMOVAL

ANDINSTAllATION

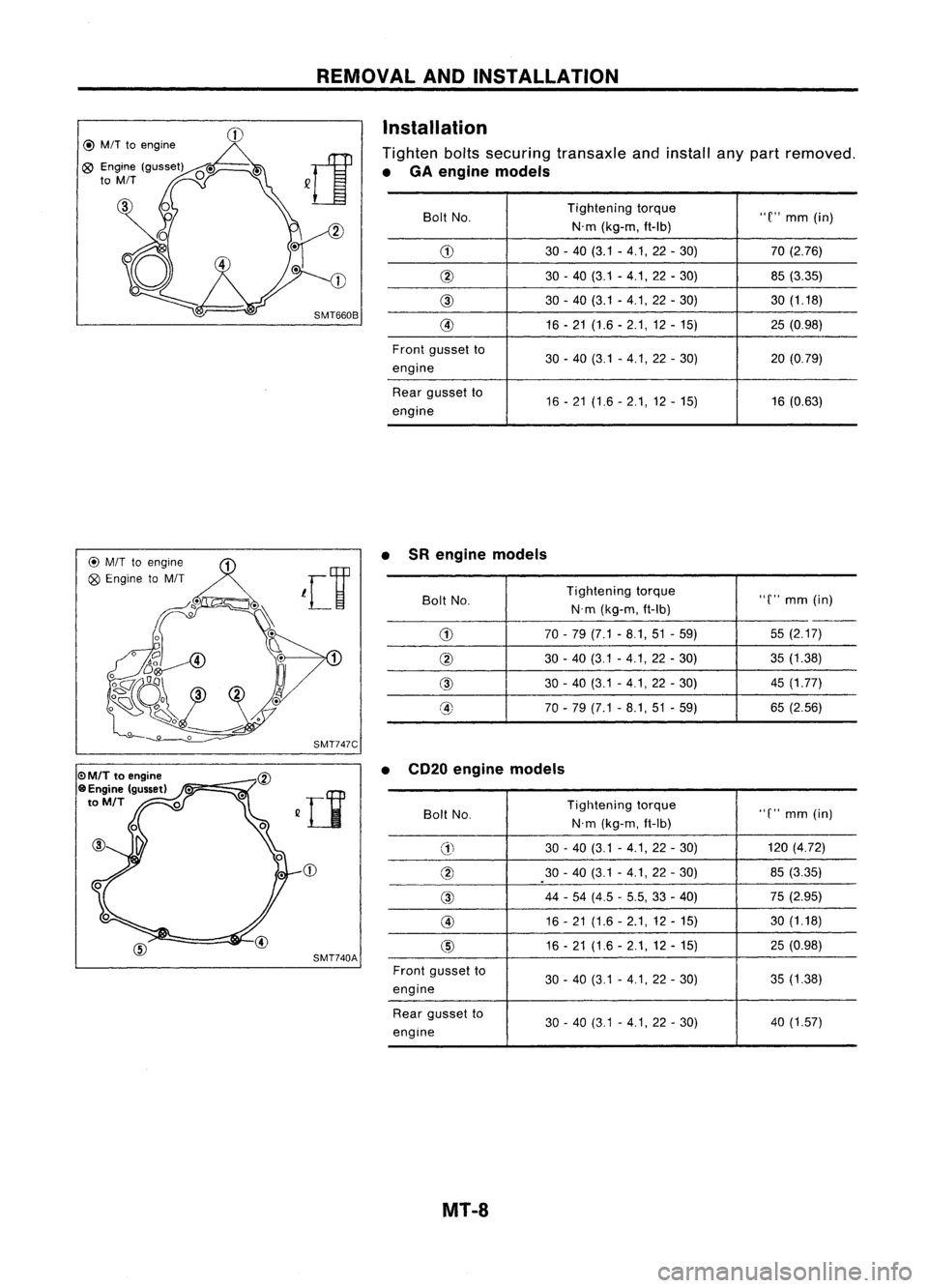

Installation

Tighten boltssecuring transaxle andinstall anypart removed.

• GA engine models

Bolt No. Tightening

torque

"C"mm (in)

N'm (kg-m, ft-Ib)

G) 30-40 (3.1 -4.1,22 -30) 70

(2.76)

@ 30-40 (3.1 -4.1,22 -30) 85(3.35)

@

30-40 (3.1 -4.1, 22-30) 30(1.18)

@ 16-21 (1.6 -2.1,12 -15) 25(0.98)

Front gusset to

30-40 (3.1 -4.1,22 -30) 20(0.79)

engine

Rear gusset to

16-21 (1.6 -2.1,12 -15) 16

(0.63)

engine

@

M/T

toengine ~

Q9

Engine toM/T

leV

~o". Q~.\

17

SMT747C

CD

SMT740A •

SRengine models

Bolt No. Tightening

torque

"C"mm (in)

N'm (kg-m, ft-Ib)

--

G)

70-79 (7.1 -8.1,51 -59) 55

(2.17)

@

30-40 (3.1 -4.1,22 -30) 35

(1.38)

@

30-40 (3.1 -4.1,22 -30) 45

(1.77)

@ 70-79 (7.1 -8.1,51 -59) 65

(2.56)

• CD20 engine models

Boll No. Tightening

torque

"C"mm (in)

N'm (kg-m, ft-Ib)

G)

30

-40 (3.1 -4.1, 22-30) 120

(4.72)

@

30-40 (3.1 -4.1,22 -30) 85

(3.35)

@

44

-54 (4.5 -5.5, 33-40) 75

(2.95)

@

16-21 (1.6 -2.1,12 -15) 30

(1.18)

@

16-21 (1.6 -2.1,12 -15) 25

(0.98)

Front gusset to

30-40 (3.1 -4.1, 22-30) 35

(1.38)

engine

Rear gusset to

30-40 (3.1 -4.1, 22-30) 40

(1.57)

engine

MT-8