NISSAN ALMERA N15 1995 Service Manual

ALMERA N15 1995

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57349/w960_57349-0.png

NISSAN ALMERA N15 1995 Service Manual

Trending: overheating, bolt pattern, fuel pump, fuse diagram, ESP, door lock, Color

Page 1591 of 1701

REPAIRFORCOMPONENT PARTS

I

RS5F32A

I

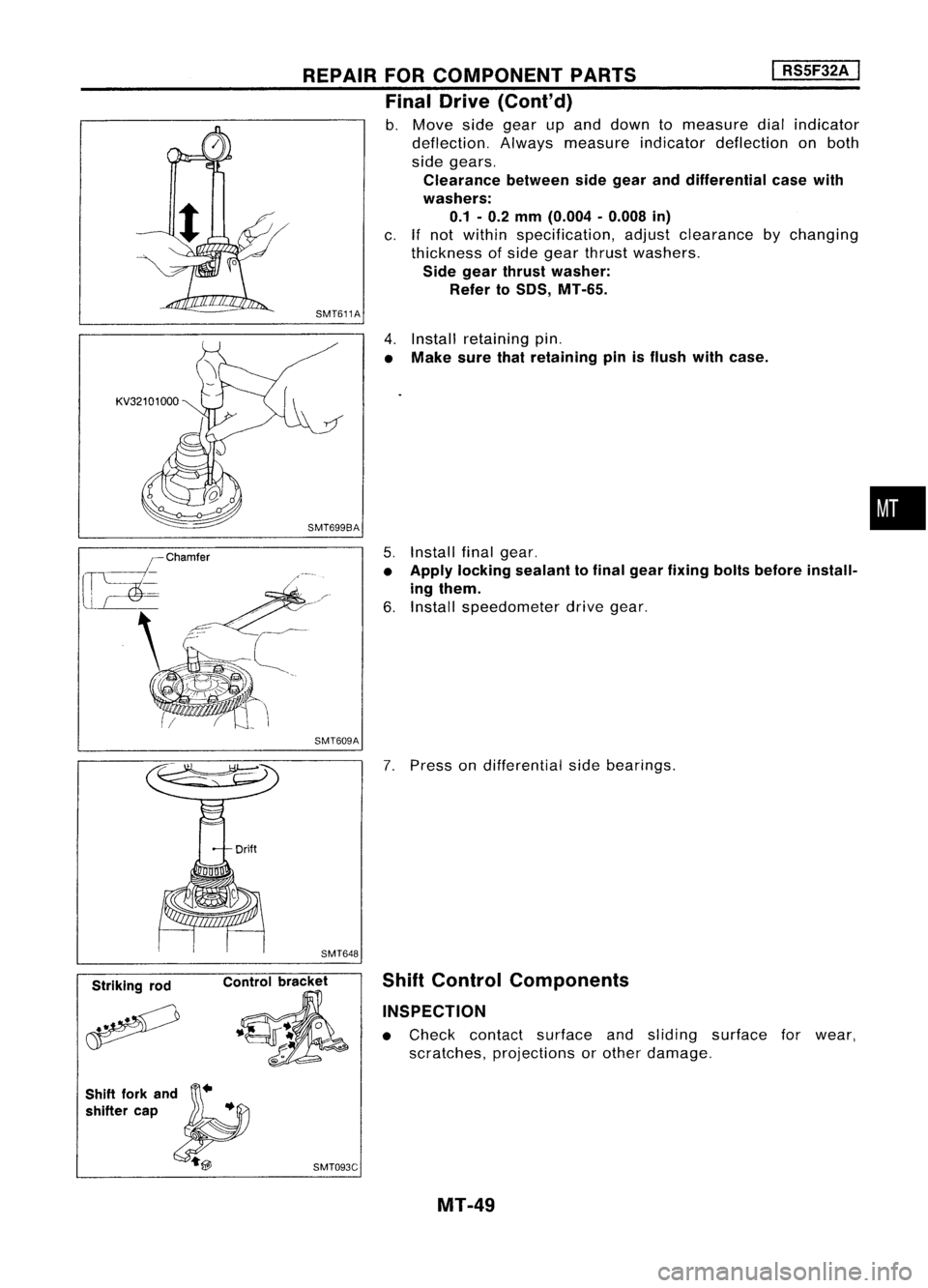

Final Drive (Cont'd)

b. Move sidegear upand down tomeasure dialindicator

deflection. Alwaysmeasure indicatordeflection onboth

side gears.

Clearance betweensidegear anddifferential casewith

washers:

0.1 -0.2

mm

(0.004 -0.008

in)

c.

If

not within specification, adjustclearance bychanging

thickness ofside gear thrust washers.

Side gear thrust washer:

Refer toSOS, MT-65.

SMT611A

4.Install retaining pin.

• Make surethatretaining pinisflush withcase.

5. Install finalgear.

• Apply locking sealant tofinal gear fixing boltsbefore install-

ing them.

6. Install speedometer drivegear.

SMT609A

•

Striking rod

_.~0

~ SMT648

Control bracket

.~

7.

Press ondifferential sidebearings.

Shift Control Components

INSPECTION

• Check contact surface andsliding surface forwear,

scratches, projections orother damage.

Shift forkan};Jd"

shifter cap •

s:;

'l@

SMT093C

MT-49

Page 1592 of 1701

Strikinglever

Reverse brakeearn REPAIR

FORCOMPONENT PARTS

Shift Control Components (Cont'd)

SMT099C I

RS5F32A

I

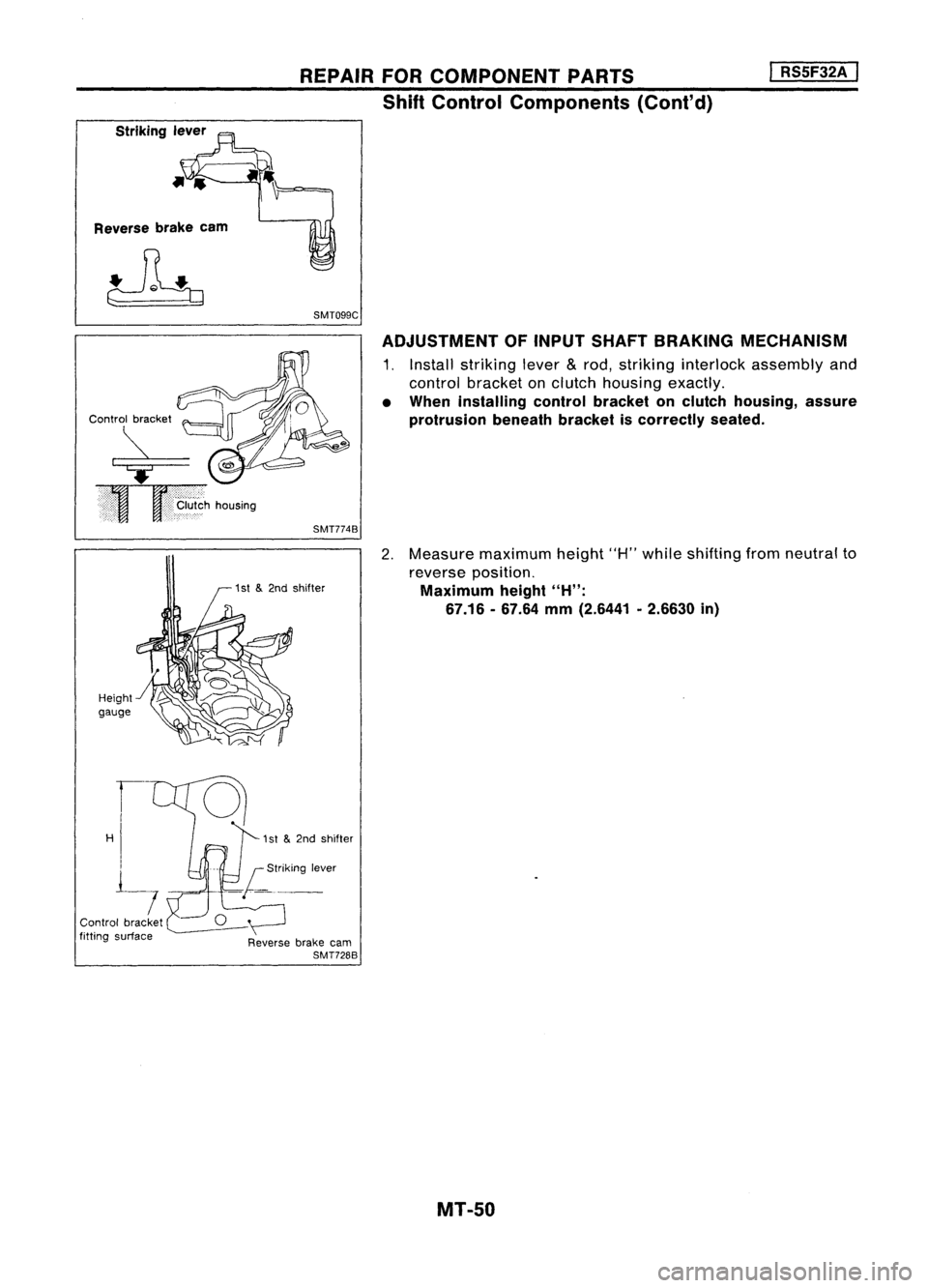

ADJUSTMENT OFINPUT SHAFT BRAKING MECHANISM

1. Install striking lever

&

rod, striking interlock assembly and

control bracket onclutch housing exactly.

• When installing controlbracket onclutch housing, assure

protrusion beneathbracketiscorrectly seated.

SMT774B

Height

gauge

2.

Measure maximum height"H"while shifting fromneutral to

reverse position.

Maximum height

"H":

67.16 -67.64

mm

(2.6441 .2.6630

in)

Control bracket

fitting surface 1

st

&

2nd shifter

~

Reverse brakecarn

SMT728B

MT-SO

Page 1593 of 1701

REPAIRFORCOMPONENT PARTS

I

RS5F32A

I

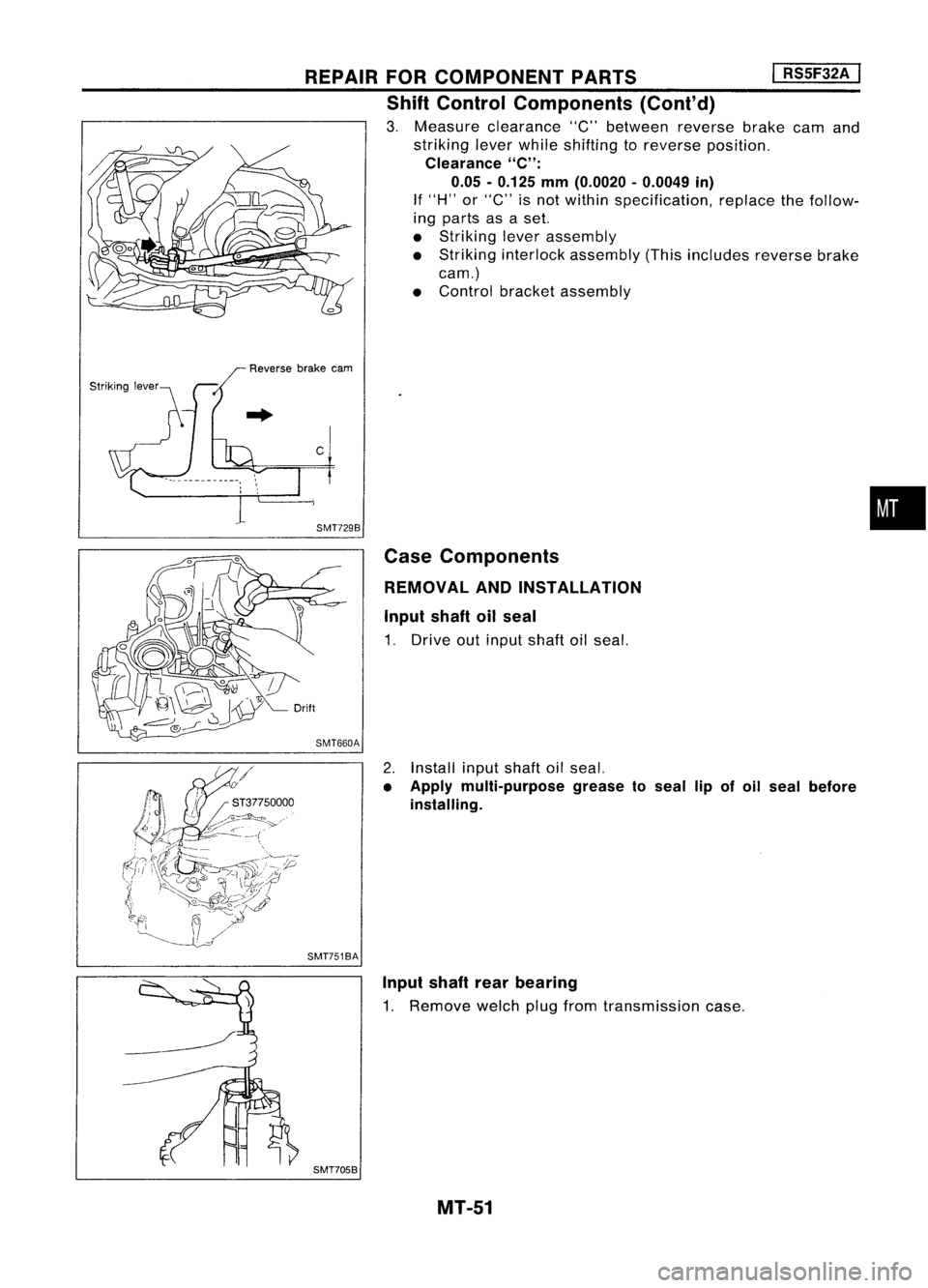

Shift Control Components (Cont'd)

3. Measure clearance "C"between reversebrakecamand

striking leverwhile shifting toreverse position.

Clearance

"C":

0.05 -0.125 mm(0.0020 -0.0049 in)

If "H" or"C" isnot within specification, replacethefollow-

ing parts asaset.

• Striking leverassembly

• Striking interlock assembly (Thisincludes reversebrake

earn.)

• Control bracketassembly

Reverse brakeeam

c SMT729B CaseComponents

REMOVAL ANDINSTALLATION

Input shaftoilseal

1. Drive outinput shaftoilseal.

2. Install inputshaftoilseal.

• Apply multi-purpose greasetoseal lipofoil seal before

installing.

SMT751BA

•

Input shaftrearbearing

1. Remove welchplugfrom transmission case.

SMT705B MT-51

Page 1594 of 1701

ST33290001

REPAIR

FORCOMPONENT PARTS

I

RS5F32A

I

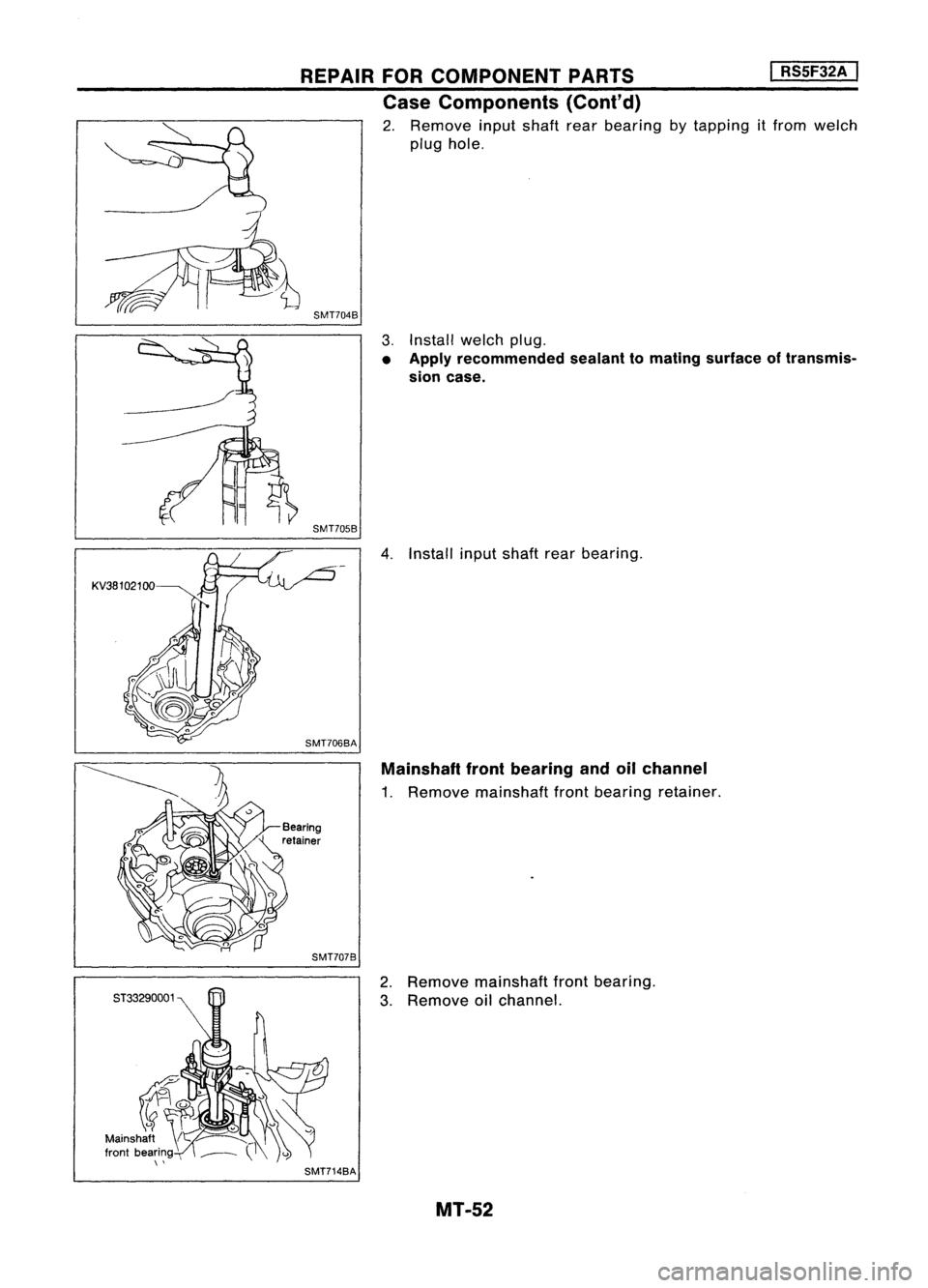

Case Components (Cont'd)

2. Remove inputshaft rearbearing bytapping itfrom welch

plug hole.

SMT704B

3.Install welchplug.

• Apply recommended sealanttomating surface oftransmis-

sion case.

SMT705B

4.Install inputshaft rearbearing.

SMT706BA Mainshaft frontbearing andoilchannel

1. Remove mainshaft frontbearing retainer.

SMT707B

2.Remove mainshaft frontbearing.

3. Remove oilchannel.

SMT714BA MT-52

Page 1595 of 1701

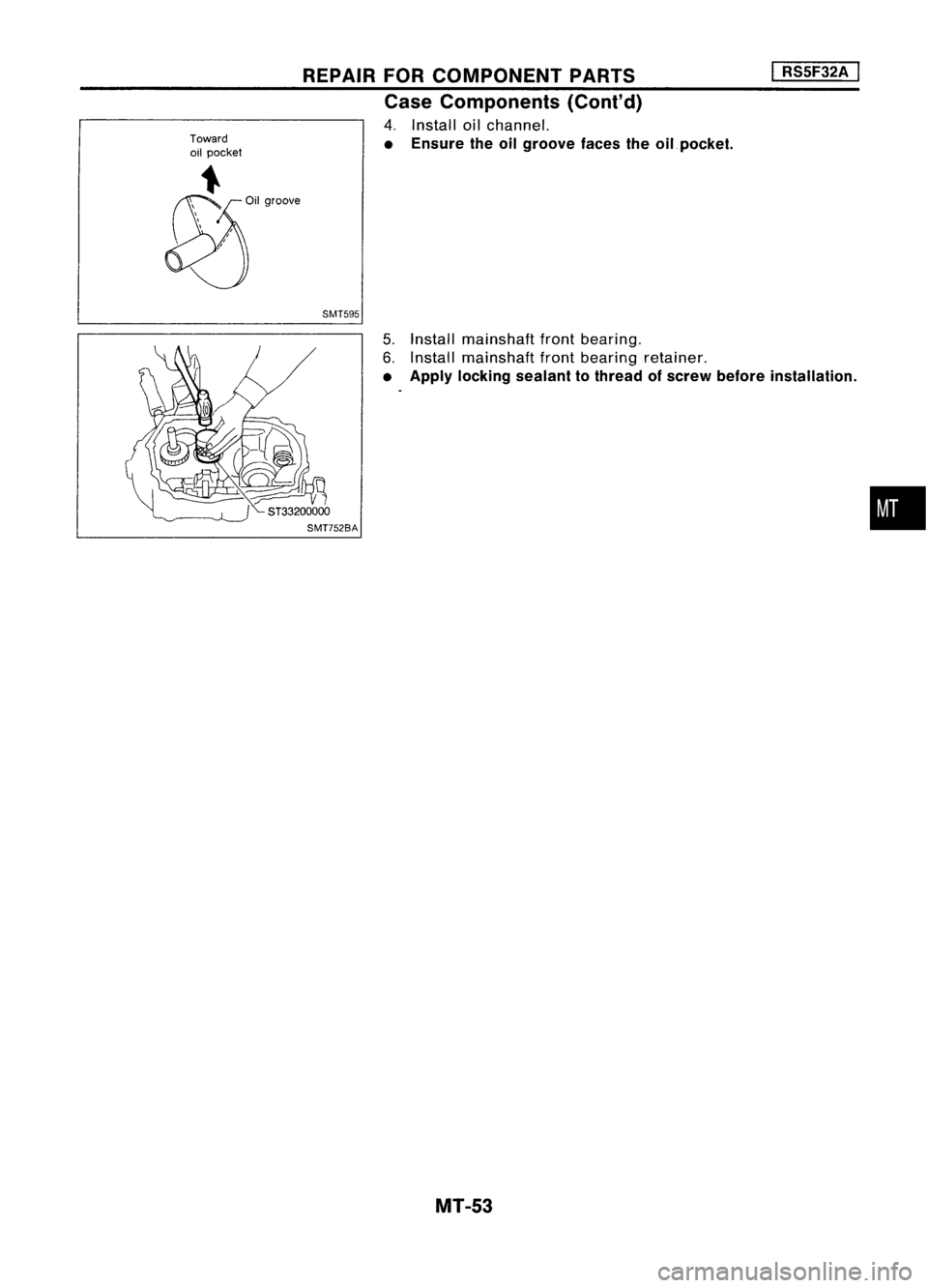

Toward

oil pocket

REPAIR

FORCOMPONENT PARTS

Case Components (Cont'd)

4. Install oilchannel.

• Ensure theoilgroove facestheoilpocket.

SMT595

I

RSSF32A

I

5. Install mainshaft frontbearing.

6. Install mainshaft frontbearing retainer.

• Apply locking sealant tothread ofscrew before installation .

MT-53

•

Page 1596 of 1701

ADJUSTMENT

I

RS5F32A

I

SMT646-A

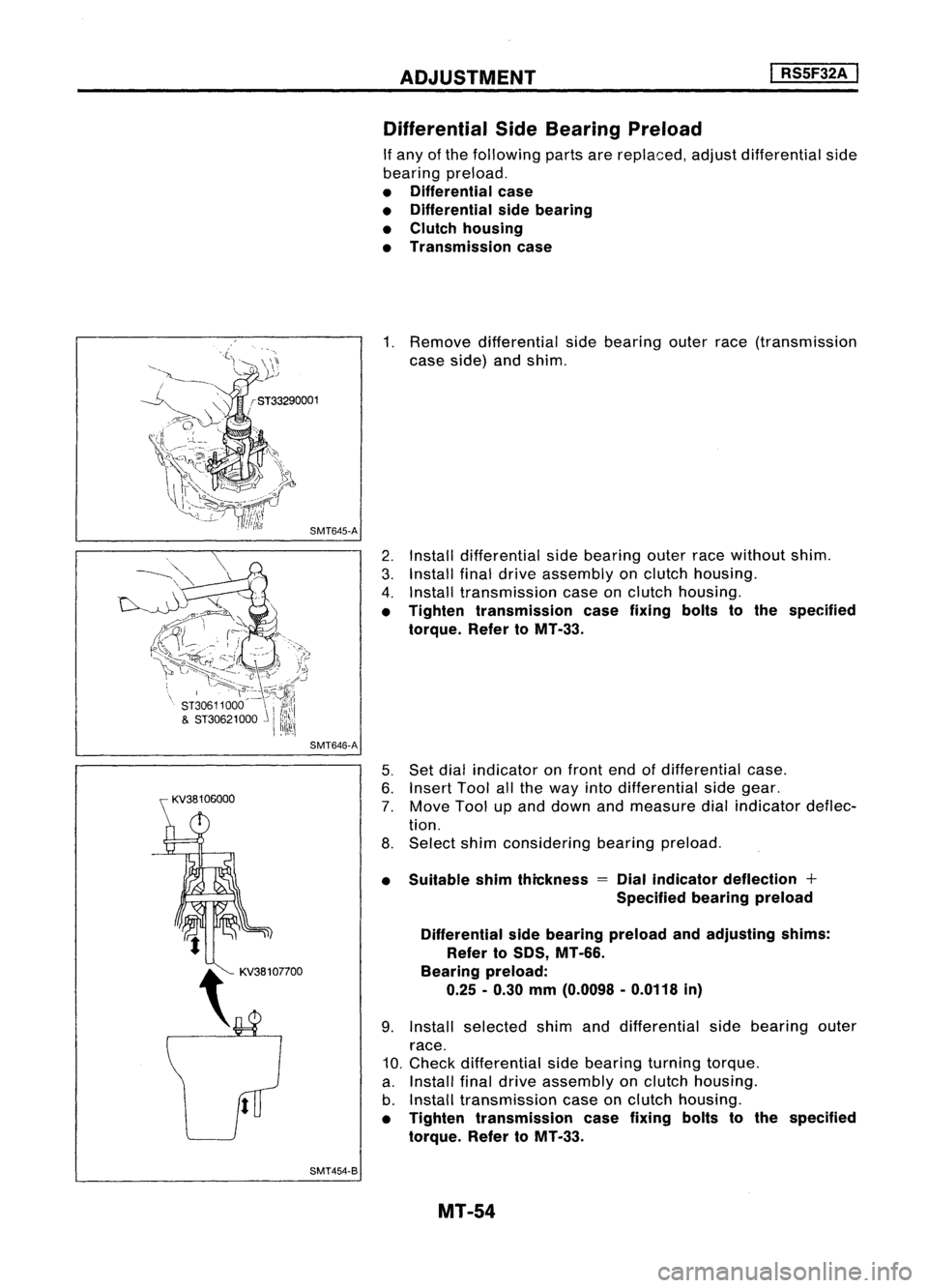

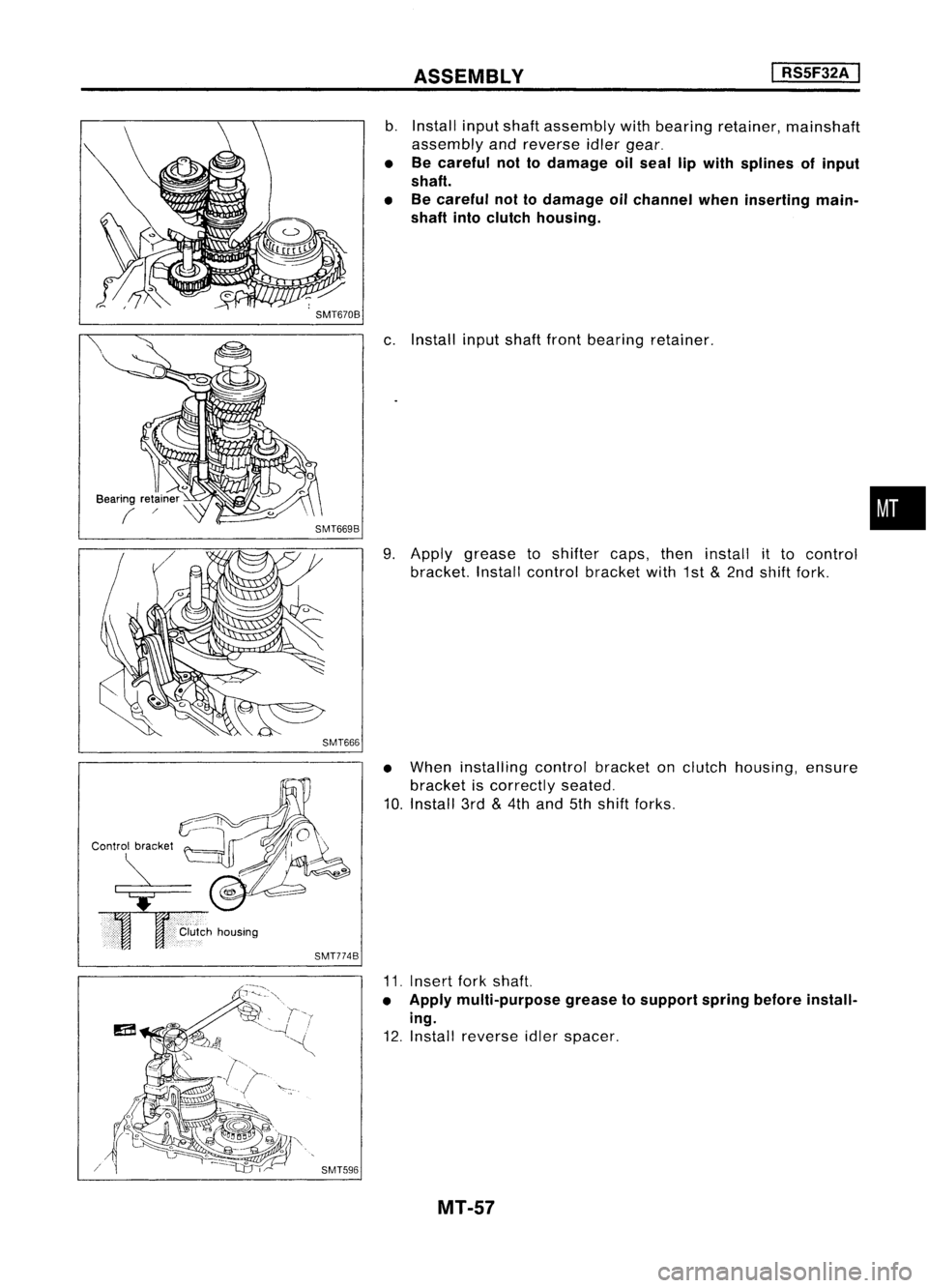

SMT454-B Differential

SideBearing Preload

If any ofthe following partsarereplaced, adjustdifferential side

bearing preload.

• Differential case

• Differential sidebearing

• Clutch housing

• Transmission case

1. Remove differential sidebearing outerrace(transmission

case side) andshim.

2. Install differential sidebearing outerracewithout shim.

3. Install finaldrive assembly onclutch housing.

4. Install transmission caseonclutch housing.

• Tighten transmission casefixing boltstothe specified

torque. RefertoMT -33.

5. Set dial indicator onfront endofdifferential case.

6. Insert Toolallthe way intodifferential sidegear.

7. Move Toolupand down andmeasure dialindicator deflec-

tion.

8. Select shimconsidering bearingpreload.

• Suitable shimthickness

=

Dial indicator deflection +

Specified bearingpreload

Differential sidebearing preload andadjusting shims:

Refer toSDS, MT-66.

Bearing preload:

0.25 -0.30 mm(0.0098 -0.0118 in)

9. Install selected shimanddifferential sidebearing outer

race.

10. Check differential sidebearing turningtorque.

a. Install finaldrive assembly onclutch housing.

b. Install transmission caseonclutch housing.

• Tighten transmission casefixing boltstothe specified

torque. RefertoMT-33.

MT-54

Page 1597 of 1701

ADJUSTMENT

I

RS5F32A

I

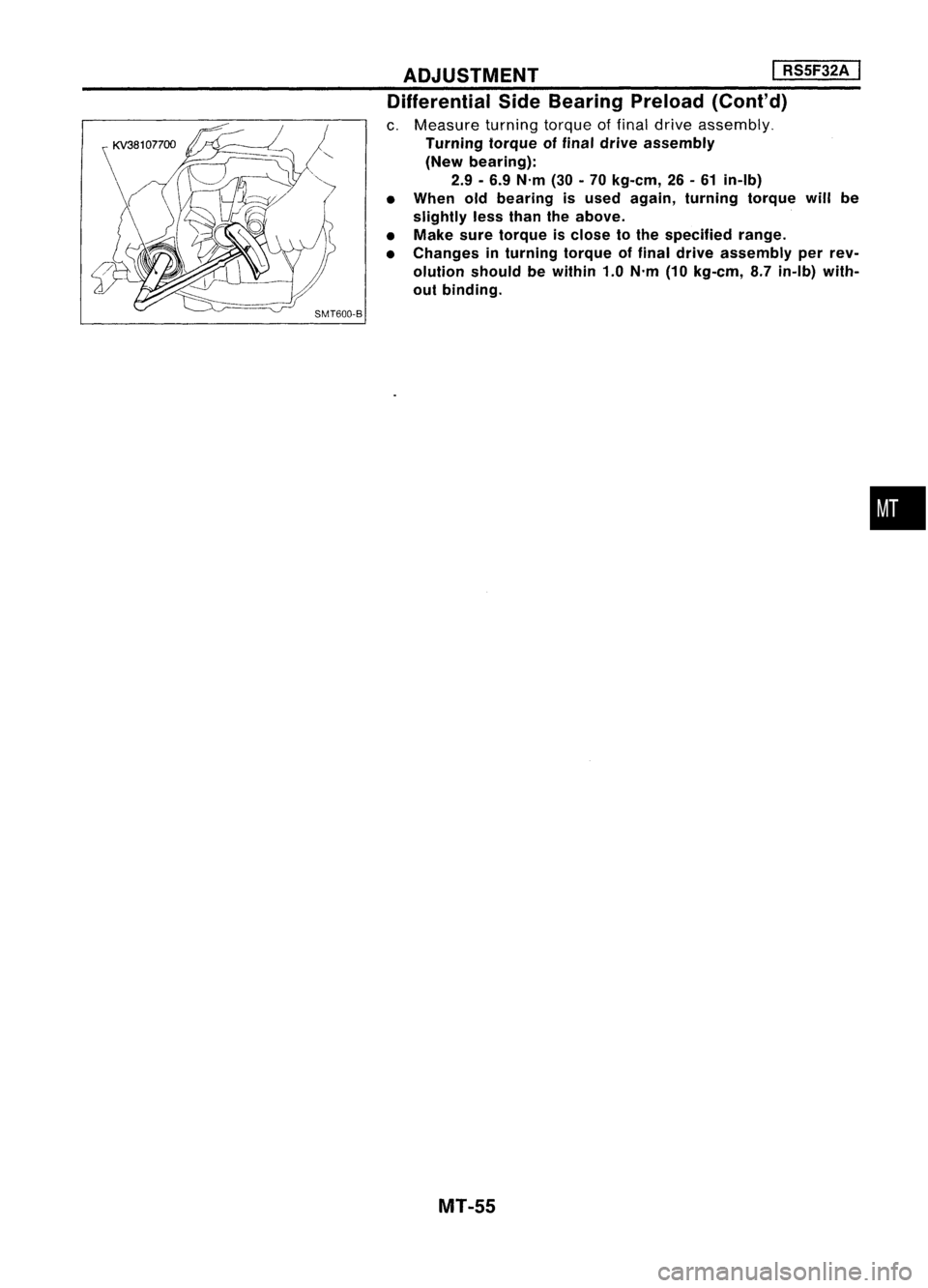

Differential SideBearing Preload(Cont'd)

c. Measure turningtorqueoffinal drive assembly.

Turning torqueoffinal drive assembly

(New bearing):

2.9 -6.9 N'm (30-70 kg-em, 26-61 in-Ib)

• When oldbearing isused again, turning torquewillbe

slightly lessthan theabove.

• Make suretorque isclose tothe specified range.

• Changes inturning torqueoffinal drive assembly perrev-

olution shouldbewithin 1.0N'm (10kg-em, 8.7in-Ib) with-

out binding.

MT-55

•

Page 1598 of 1701

ASSEMBLY

I

RS5F32A ,

J

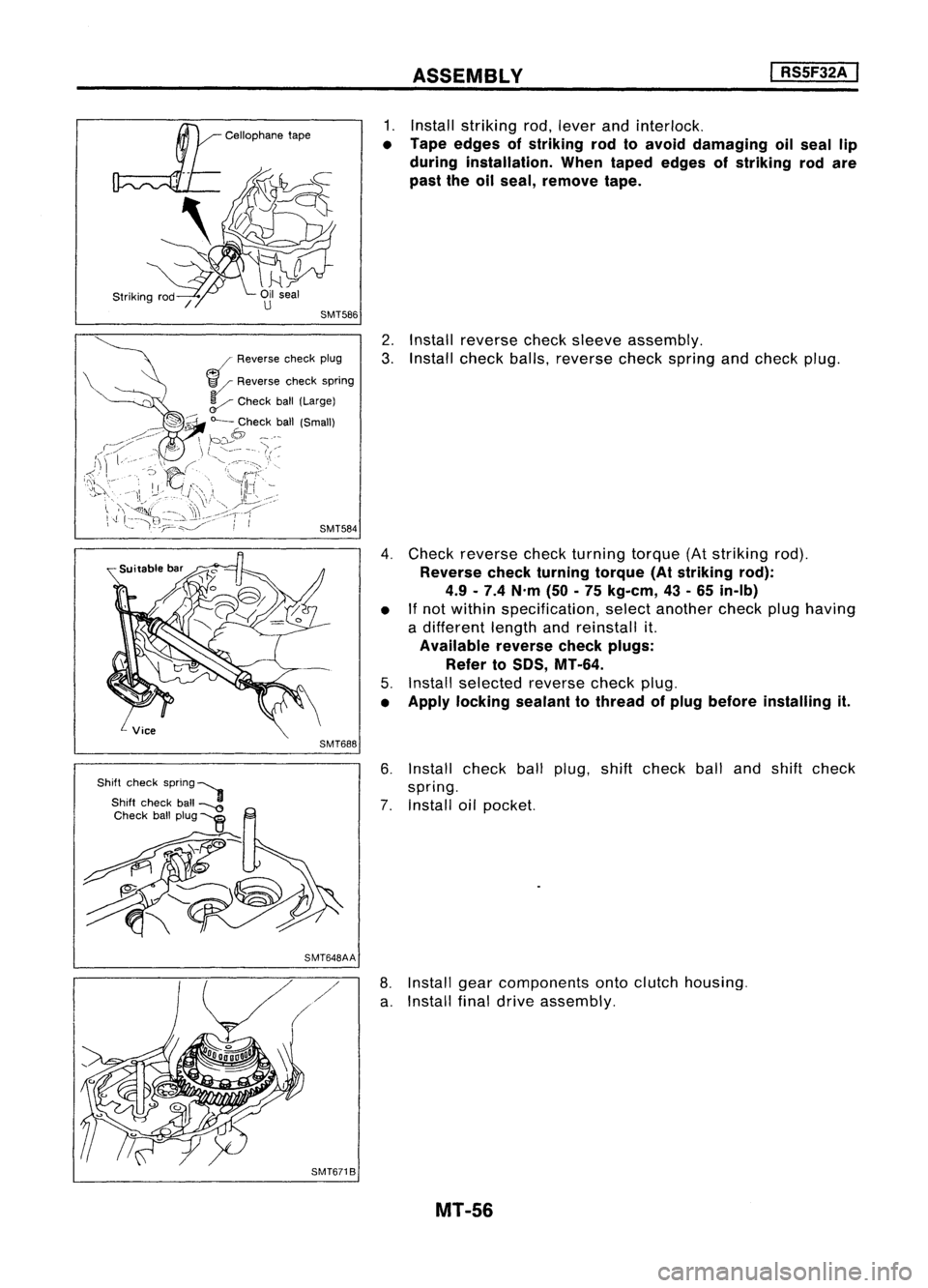

Reverse checkplug

~ Reverse checkspring

V

Check ball(Large)

"-- Check ball(Small)

b~6

,

~

l ~---- -'.

SMT584

SMT688

SMT648AA SMT671B

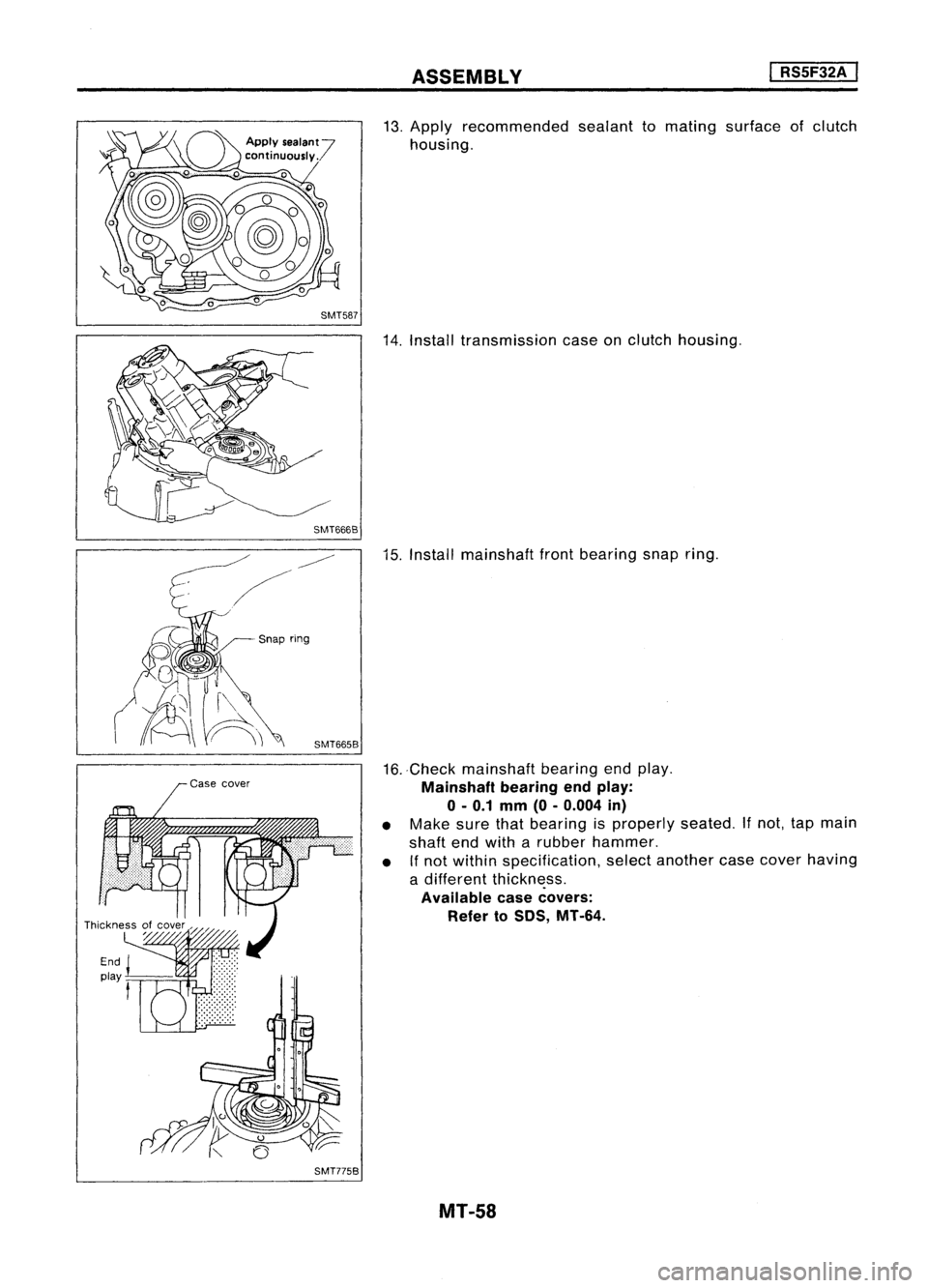

1.

Install striking rod,lever andinterlock.

• Tape edges ofstriking rodtoavoid damaging oilseal lip

during installation. Whentaped edges ofstriking rodare

past theoilseal, remove tape.

2. Install reverse checksleeve assembly.

3. Install check balls,reverse checkspring andcheck plug.

4. Check reverse checkturning torque(Atstriking rod).

Reverse checkturning torque(Atstriking rod):

4.9 -7.4 N'm (50-75 kg-em, 43-65 in-Ib)

• If

not within specification, selectanother checkplughaving

a different lengthandreinstall it.

Available reversecheckplugs:

Refer to

50S,

MT-64.

5. Install selected reversecheckplug.

• Apply locking sealanttothread ofplug before installing it.

6. Install checkballplug, shiftcheck ballandshift check

spring.

7. Install oilpocket.

8. Install gearcomponents ontoclutch housing.

a. Install finaldrive assembly.

MT-56

Page 1599 of 1701

ASSEMBLY

I

RSSF32A

I

SMT666

SMT774B

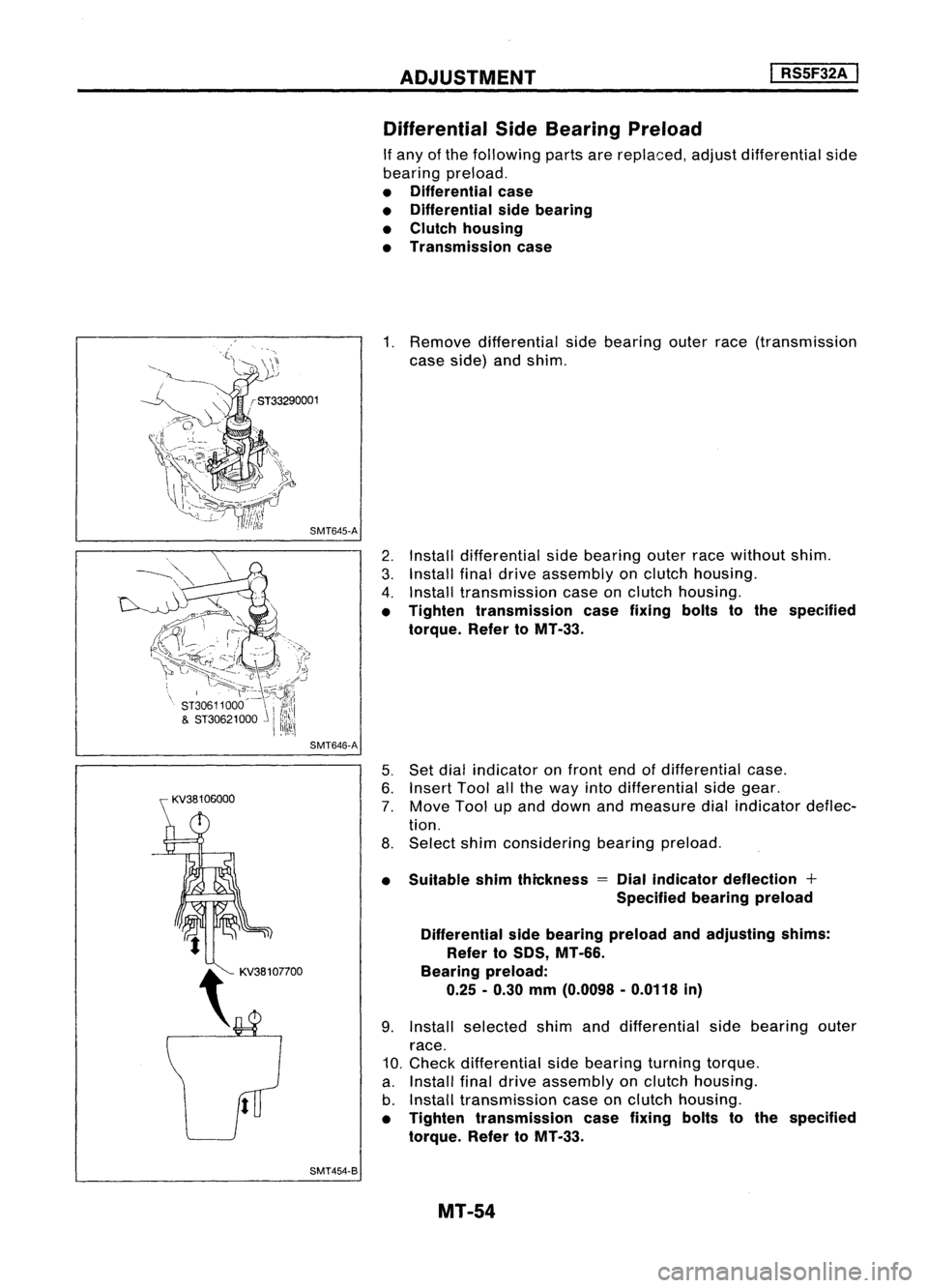

b.

Install inputshaft assembly withbearing retainer, mainshaft

assembly andreverse idlergear.

• Becareful nottodamage oilseal lipwith splines ofinput

shaft.

• Becareful nottodamage oilchannel wheninserting main-

shaft intoclutch housing.

c. Install inputshaftfrontbearing retainer.

9. Apply grease toshifter caps,theninstall itto control

bracket. Installcontrol bracket with1st

&

2nd shift fork.

• When installing controlbracket onclutch housing, ensure

bracket iscorrectly seated.

10. Install 3rd

&

4th and 5thshift forks.

•

SMT596

11.

Insert forkshaft.

• Apply multi-purpose greasetosupport springbefore install-

ing.

12. Install reverse idlerspacer.

MT-57

Page 1600 of 1701

ASSEMBLY

I

RS5F32A

I

SMT666B

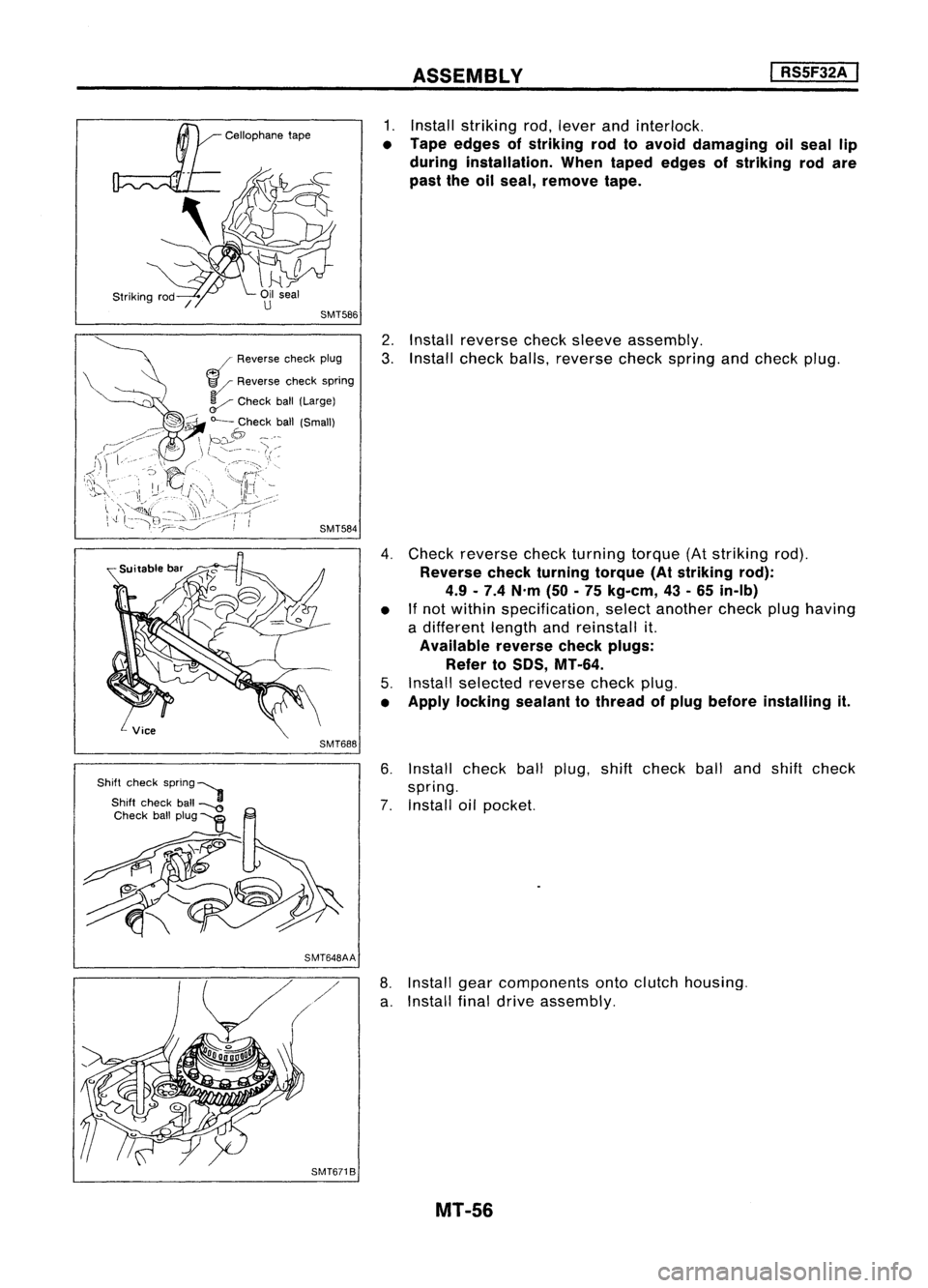

13.

Apply recommended sealanttomating surface ofclutch

housing.

14. Install transmission caseonclutch housing.

Snap ring

SMT665B

SMT775B

15.

Install mainshaft frontbearing snapring.

16. -Check mainshaft bearingendplay.

Mainshaft bearingendplay:

o -

0.1 mm (0-0.004 in)

• Make surethatbearing isproperly seated.

If

not, tapmain

shaft endwith arubber hammer.

• Ifnot within specification, selectanother casecover having

a different thickness.

Available casecovers:

Refer to50S, MT-64.

MT-58

Trending: Check light wiring, USB port, engine overheat, Instrument, trunk release, tires, spare wheel