NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1581 of 1701

REPAIRFORCOMPONENT PARTS

I

RS5F32A

I

•

Input

Shaft andGears

DISASSEMBL Y

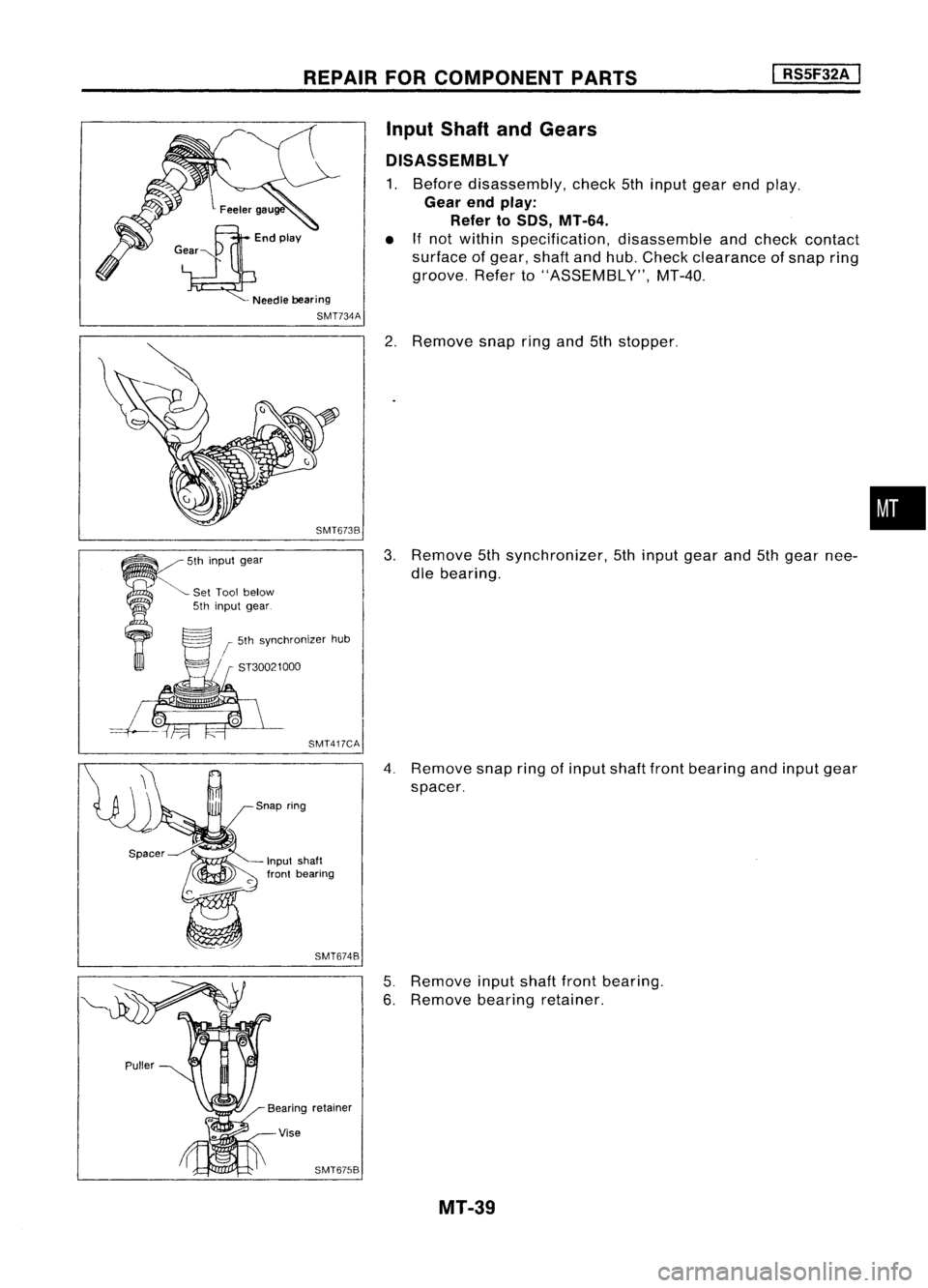

1. Before disassembly, check5thinput gearendplay.

Gear endplay:

Refer to50S, MT-64.

• Ifnot within specification, disassembleandcheck contact

surface ofgear, shaftandhub. Check clearance ofsnap ring

groove. Referto"ASSEMBLY", MT-40.

2. Remove snapringand5thstopper.

3. Remove 5thsynchronizer, 5thinput gearand5thgear nee-

dle bearing.

4. Remove snapringofinput shaftfrontbearing andinput gear

spacer.

SMT674B

SMT417CA

Input shaft

front bearing

-

r

5th synchronizer hub

/ ST30021 000

5th

input gear

~ SetTool below

5th input gear.

Spacer

5.Remove inputshaftfrontbearing.

6. Remove bearingretainer.

MT-39

Page 1582 of 1701

I

RS5F32A

I

Shifting insert

Baulkringto

gear clearance

REPAIR

FORCOMPONENT PARTS

Input Shaft andGears (Cont'd)

INSPECTION

Gear andshaft

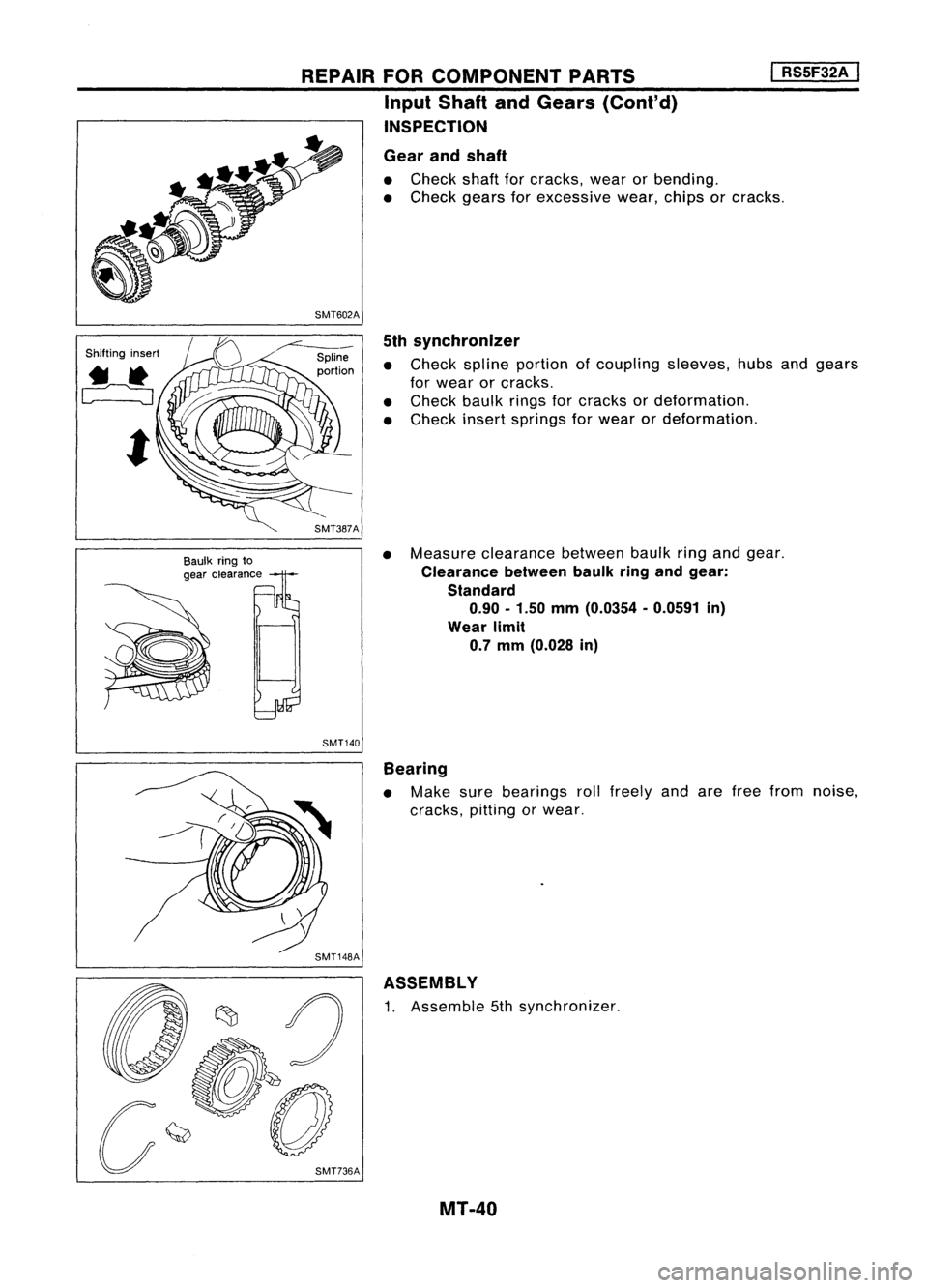

• Check shaftforcracks, wearorbending.

• Check gearsforexcessive wear,chipsorcracks.

SMT602A 5thsynchronizer

• Check splineportion ofcoupling sleeves,hubsandgears

for wear orcracks.

• Check baulkringsforcracks ordeformation.

• Check insertsprings forwear ordeformation.

SMT387A

•Measure clearance betweenbaulkringandgear.

Clearance betweenbaulkringandgear:

Standard 0.90 -1.50 mm(0.0354 -0.0591 in)

Wear limit

0.7 mm (0.028 in)

SMT140 Bearing

• Make surebearings rollfreely andarefree from noise,

cracks, pittingorwear.

ASSEMBLY

1. Assemble 5thsynchronizer.

MT-40

Page 1583 of 1701

SMT761B

REPAIR

FORCOMPONENT PARTS

I

RS5F32A

I

Input Shaft andGears (Cont'd)

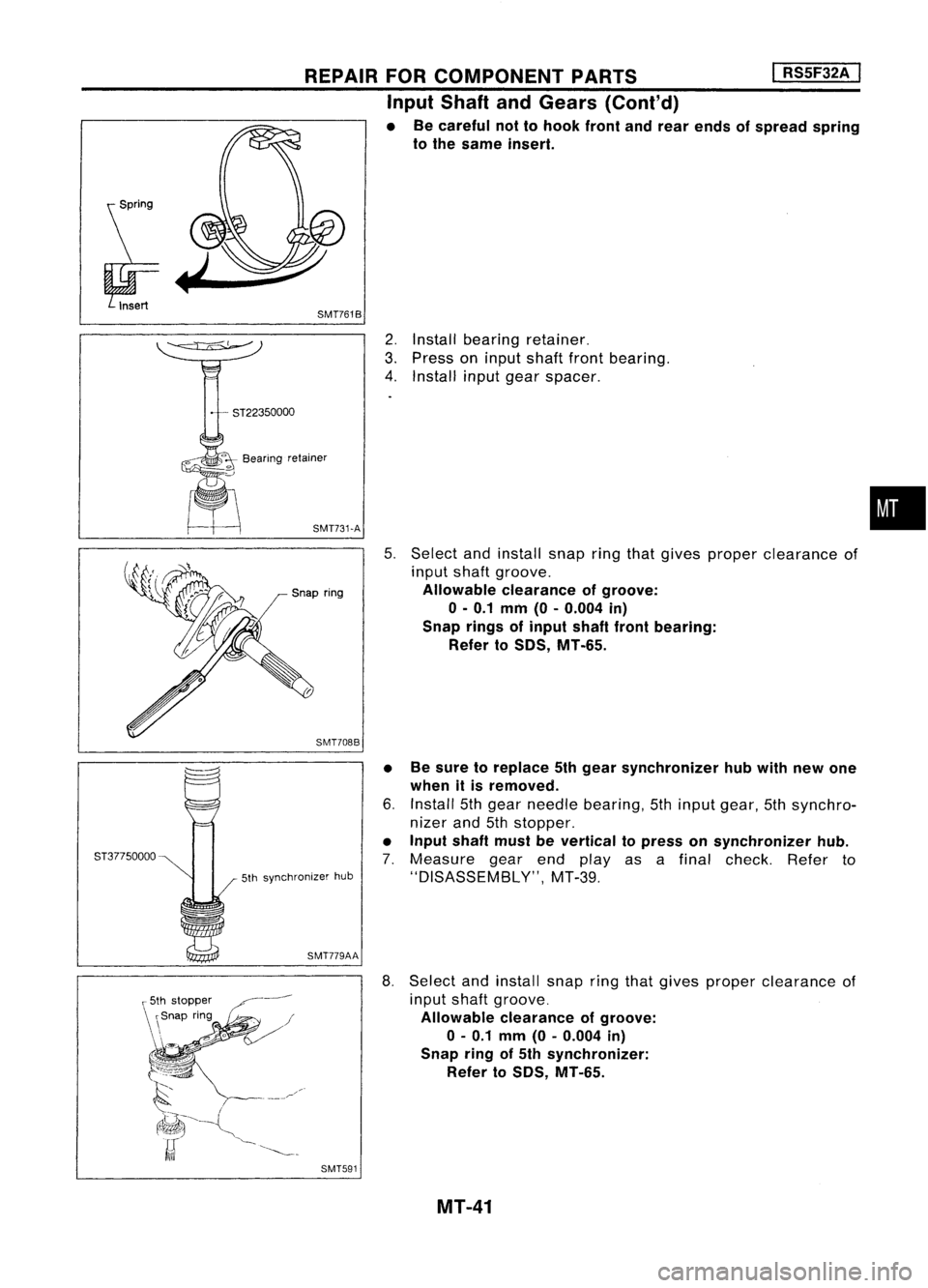

• Becareful nottohook frontandrear ends ofspread spring

to the same insert.

•

5. Select andinstall snapringthatgives proper clearance of

input shaftgroove.

Allowable clearance ofgroove:

o -

0.1 mOl (0-0.004 in)

Snap ringsofinput shaftfrontbearing:

Refer toSOS, MT-65.

2.

Install bearing retainer.

3. Press oninput shaft frontbearing.

4. Install inputgearspacer.

• Besure toreplace 5thgear synchronizer hubwith newone

when itis removed.

6. Install 5thgear needle bearing, 5thinput gear, 5thsynchro-

nizer and5thstopper.

• Input shaftmustbevertical topress onsynchronizer hub.

7. Measure gearendplayas afinal check. Referto

"DISASSEMBLY", MT-39.

8. Select andinstall snapringthatgives proper clearance of

input shaft groove.

Allowable clearance ofgroove:

o -

0.1 mm (0-0.004 in)

Snap ringof5th synchronizer:

Refer toSOS, MT-65.

SMT708B

SMT731-A

SMT779AA

Snap

ring

5th synchronizer hub

~

=

Bearing retainer

ST37750000 ~

SMT591MT-41

Page 1584 of 1701

REPAIRFORCOMPONENT PARTS

I

RS5F32A

I

Snap ring End

play

Mainshaft

andGears

DISASSEMBL Y

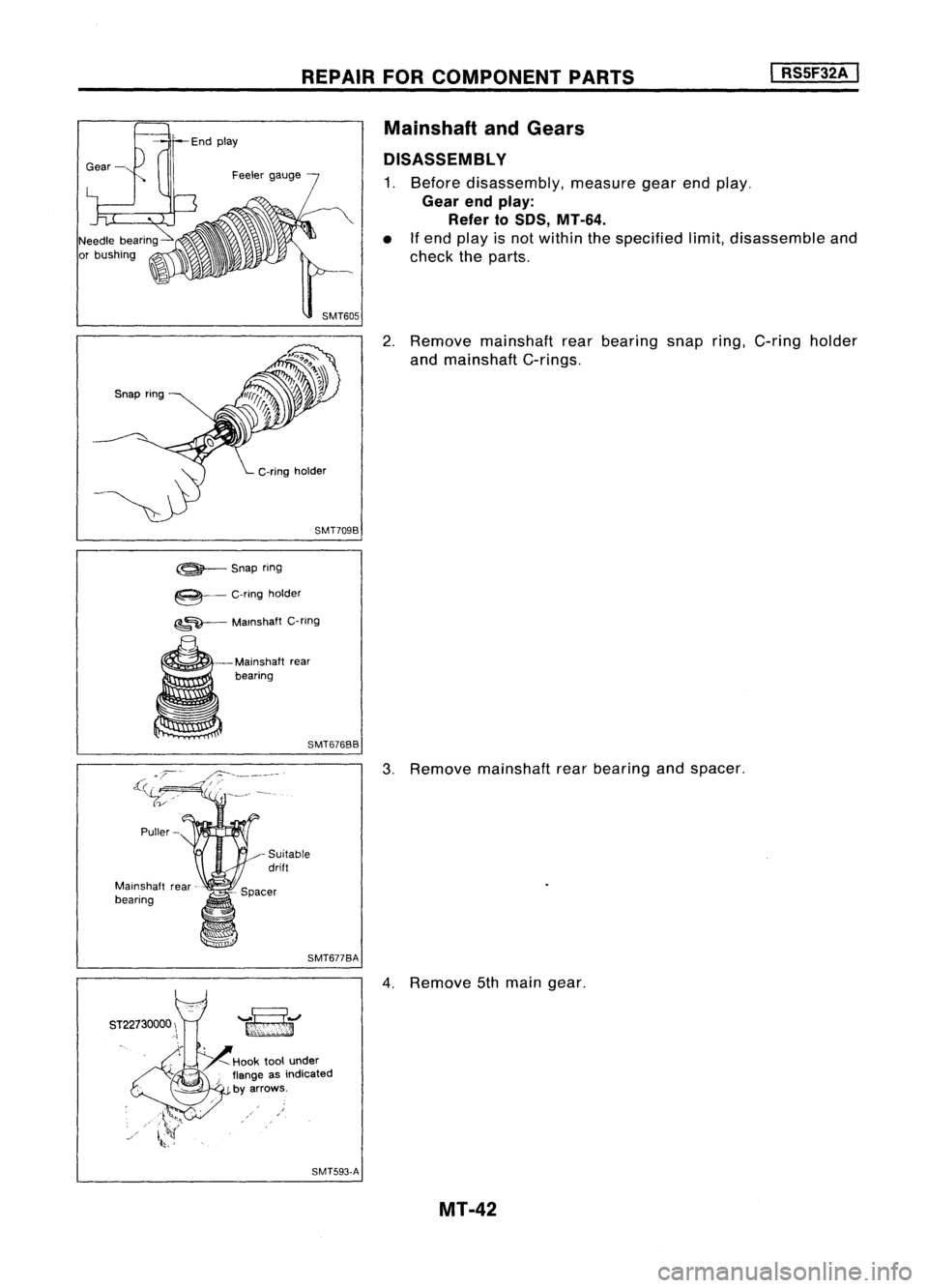

1. Before disassembly, measuregearendplay.

Gear endplay:

Refer to50S, MT-64.

• Ifend play isnot within thespecified limit,disassemble and

check theparts.

2. Remove mainshaft rearbearing snapring,Coring holder

and mainshaft C-rings.

C-ring holder

SMT709B

~Snapring

@---

C-ringholder

~~ MalnshaftC-r1ng

Puller-

Mainshaft rear

bearing -

Mainshaft rear

bearing

SMT676BB

3.Remove mainshaft rearbearing andspacer.

./- Suitable

drift

SMT677BA

4.Remove 5thmain gear.

SMT593-A MT-42

Page 1585 of 1701

2nd&3rd~

bushing -'-~)

2nd gear ~

1 st main gear REPAIR

FORCOMPONENT PARTS

I

RSSF32A

I

Mainshaft andGears (Cont'd)

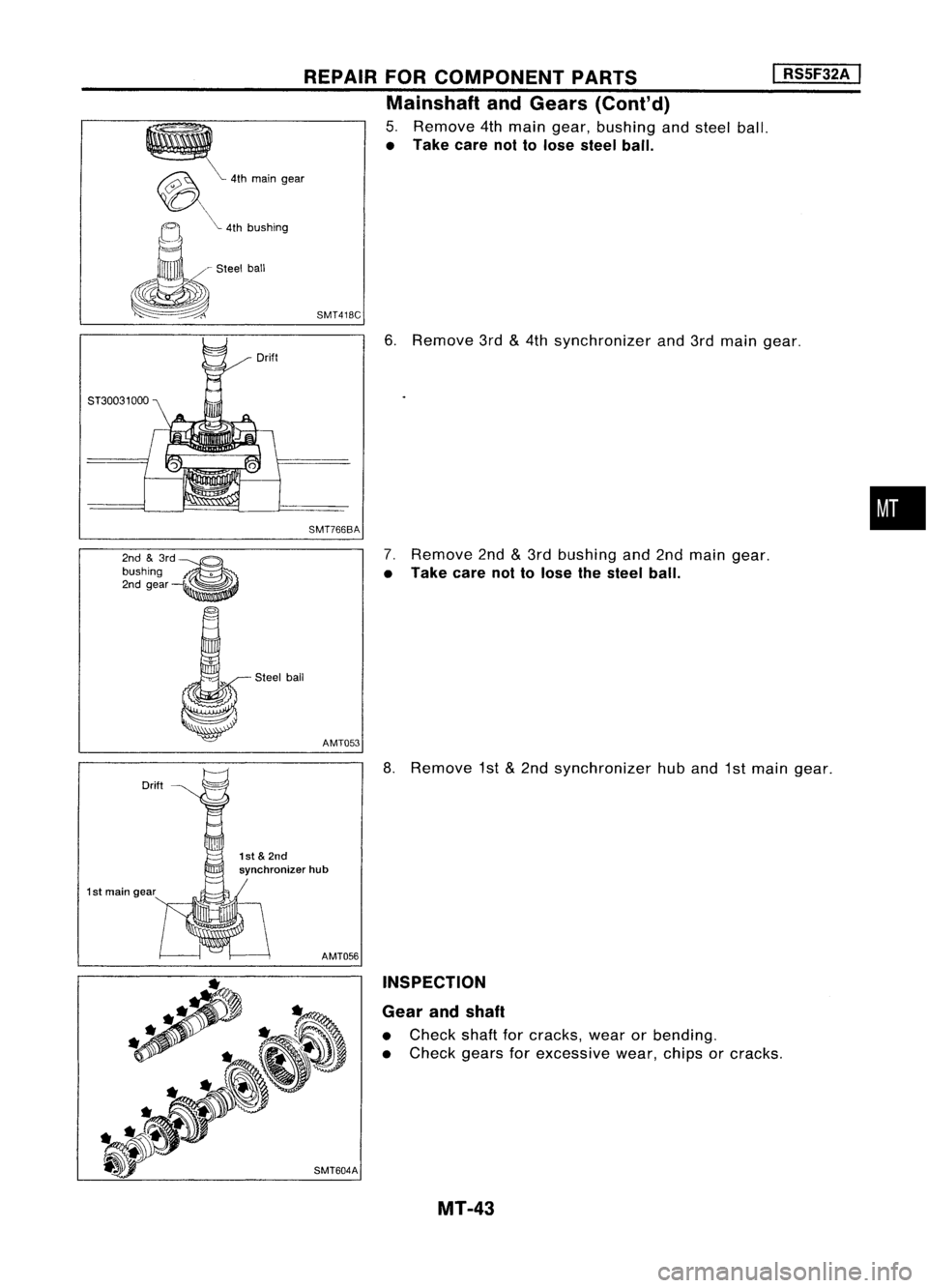

5. Remove 4thmain gear, bushing andsteel ball.

• Take carenottolose steel ball.

SMT418C

6.Remove 3rd

&

4th synchronizer and3rdmain gear.

SMT766BA

7.Remove 2nd

&

3rd bushing and2ndmain gear.

• Take carenottolose thesteel ball.

AMT053

8.Remove 1st

&

2nd synchronizer huband 1stmain gear.

AMT056 INSPECTION

Gear andshaft

• Check shaftforcracks, wearorbending.

• Check gearsforexcessive wear,chipsorcracks.

SMT604A MT-43

•

Page 1586 of 1701

t

REPAIR

FORCOMPONENT PARTS

I

RS5F32A

I

Mainshaft andGears (Cont'd)

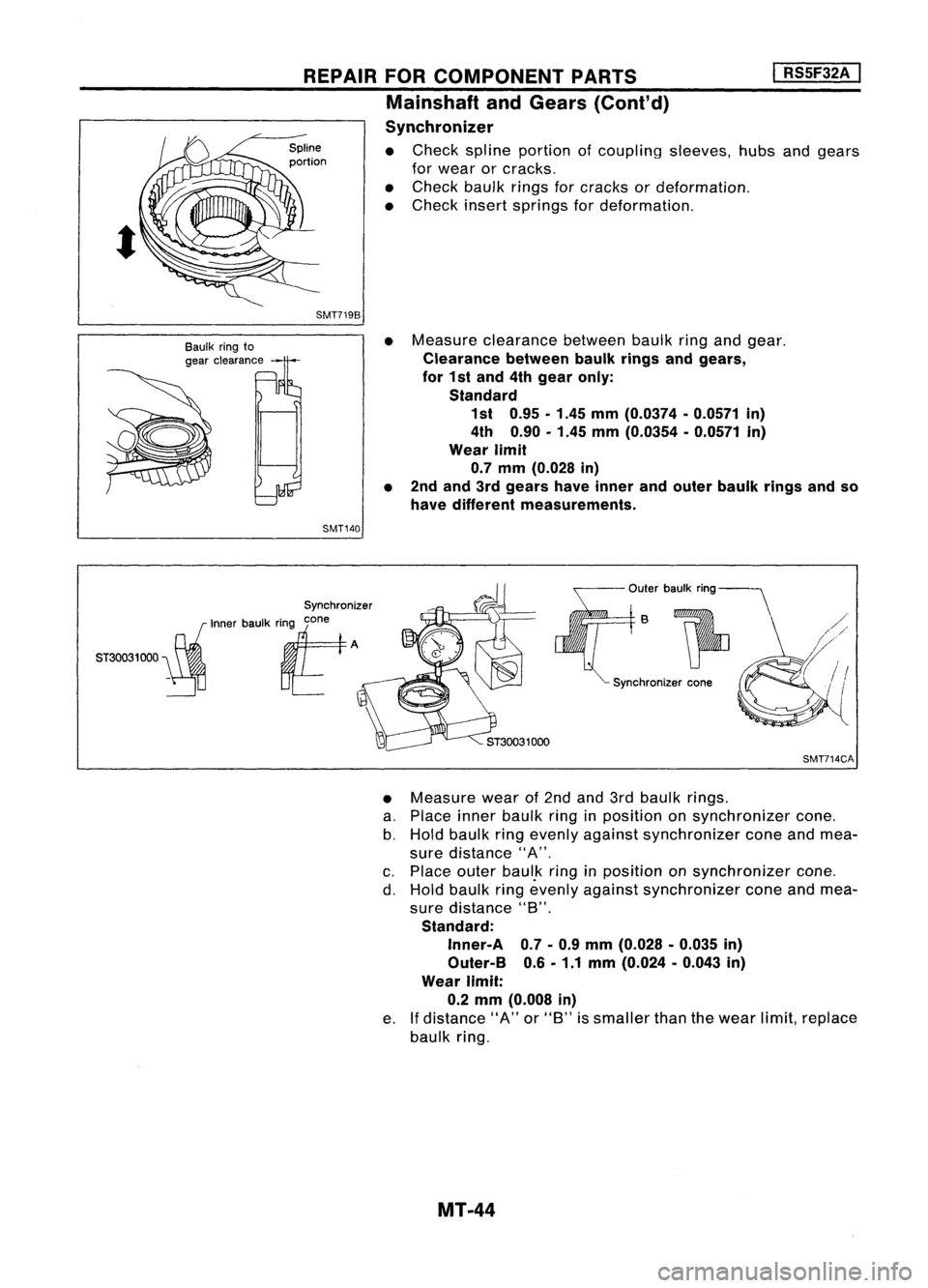

Synchronizer

• Check spline portion ofcoupling sleeves,hubsandgears

for wear orcracks.

• Check baulkringsforcracks ordeformation.

• Check insertsprings fordeformation.

SMT7198

Baulk ringto

gear clearance

SMT140

Synchronizer

, fli

10M'

baolk

'fOM FA

ST30031000 ~

•

Measure clearance betweenbaulkringandgear.

Clearance betweenbaulkringsandgears,

for 1st and 4thgear only:

Standard 1st 0.95. 1.45mm(0.0374 •0.0571 in)

4th 0.90. 1.45mm(0.0354 •0.0571 in)

Wear limit

0.7 mm (0.028 in)

• 2nd and 3rdgears haveinner andouter baulk ringsandso

have different measurements.

Outerbaulkring--\

B

SMT714CA

• Measure wearof2nd and3rdbaulk rings.

a. Place innerbaulk ringinposition onsynchronizer cone.

b. Hold baulk ringevenly against synchronizer coneandmea-

sure distance "A".

c. Place outerbaul.k ringinposition onsynchronizer cone.

d. Hold baulk ringevenly against synchronizer coneandmea-

sure distance "B".

Standard: Inner-A 0.7-0.9 mm (0.028 -0.035 in)

Outer-B 0.6-1.1 mm (0.024 -0.043 in)

Wear limit:

0.2 mm (0.008 in)

e.

If

distance "A"or"B" issmaller thanthewear limit,replace

baulk ring.

MT-44

Page 1587 of 1701

SPD715

•

I

RS5F32A

I

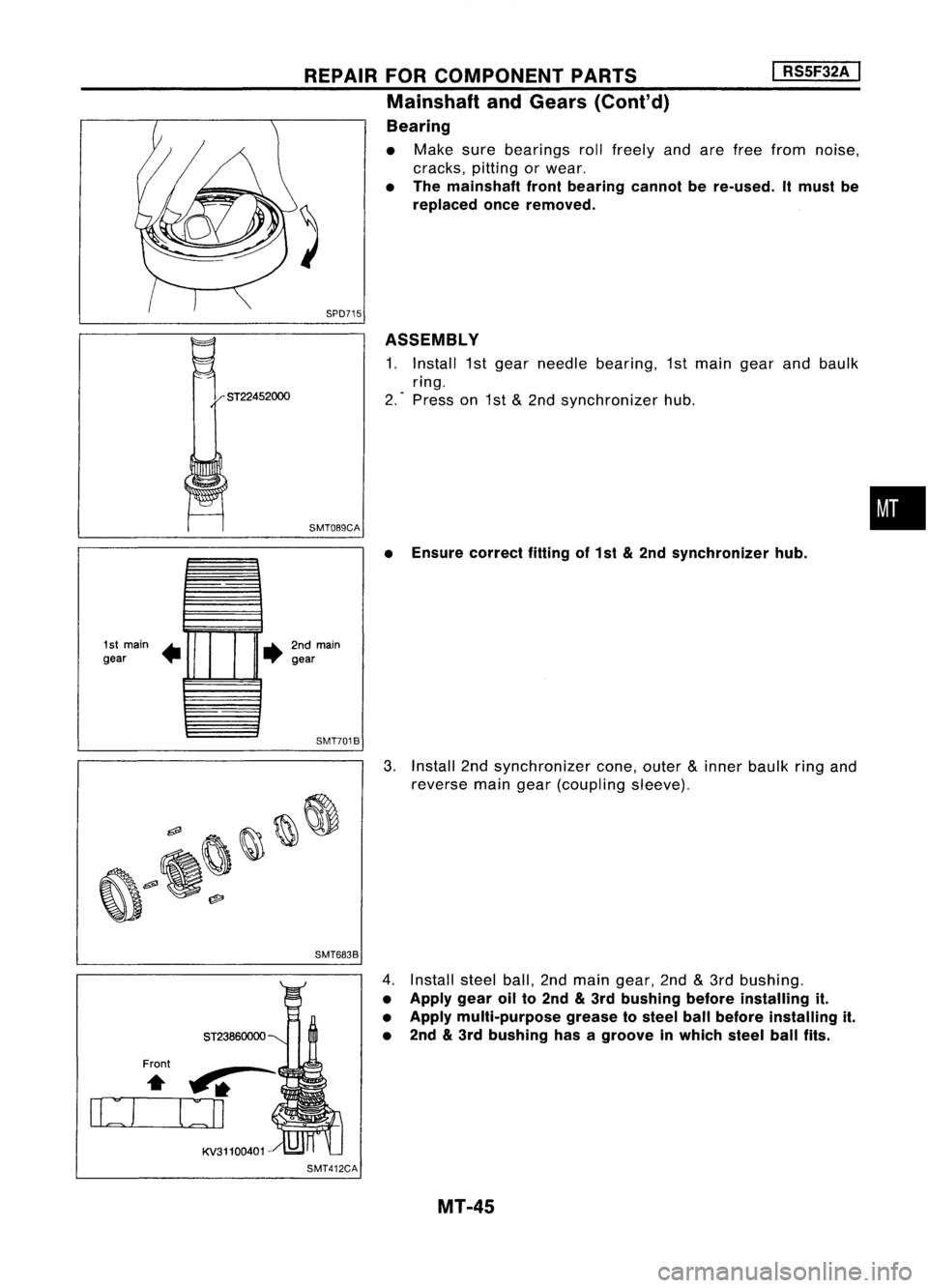

Ensure correct fittingof1st

&

2nd synchronizer hub.

ASSEMBLY

1. Install 1stgear needle bearing, 1stmain gearandbaulk

ring.

2. Press on1st

&

2nd synchronizer hub.

•

SMT089CA

REPAIR

FORCOMPONENT PARTS

Mainshaft andGears (Cont'd)

Bearing

• Make surebearings rollfreely andarefree from noise,

cracks, pittingorwear.

• The mainshaft frontbearing cannotbere-used. Itmust be

replaced onceremoved.

1st main.

gear •

2ndmain

gear

SMT7018

3.Install 2ndsynchronizer cone,outer

&

inner baulk ringand

reverse maingear(coupling sleeve).

SMT6838

ST23860000

Front

.....

rr=DJ

KV31100401-

4.

Install steelball,2ndmain gear, 2nd

&

3rd bushing.

• Apply gearoilto2nd

&

3rd bushing beforeinstalling it.

• Apply multi-purpose greasetosteel ballbefore installing it.

• 2nd

&

3rd bushing hasagroove inwhich steelballfits.

SMT412CA MT-45

Page 1588 of 1701

4thmain .....

gear ...... REPAIR

FORCOMPONENT PARTS

I

RS5F32A

I

Mainshaft andGears (Cont'd)

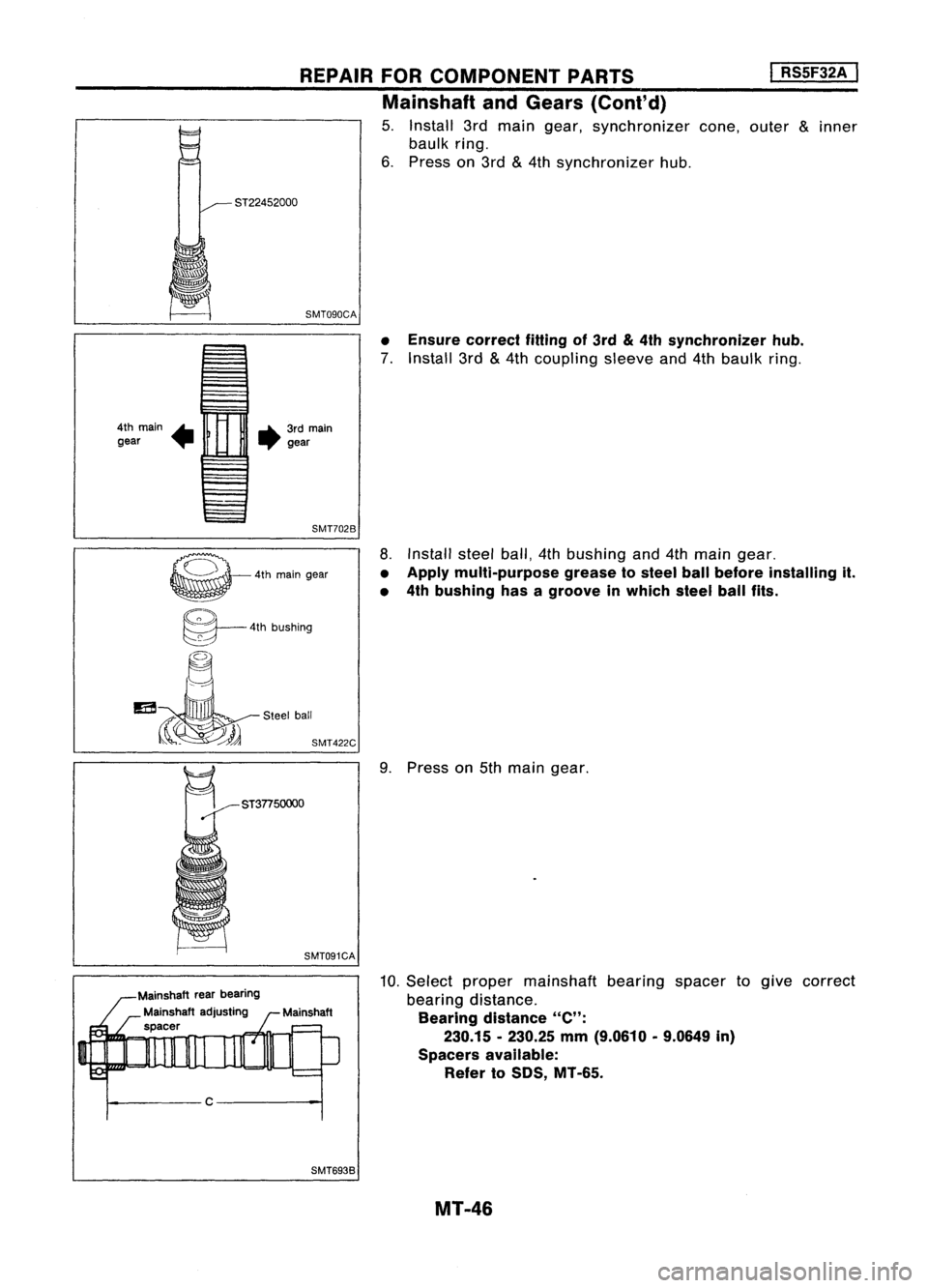

5. Install 3rdmain gear, synchronizer cone,outer

&

inner

baulk ring.

6. Press on3rd

&

4th synchronizer hub.

SMT090CA •Ensure correct fittingof3rd &4th synchronizer hub.

7. Install 3rd

&

4th coupling sleeveand4thbaulk ring.

..... 3rdmain

.".. gear

SMT7028

~ 4thm.lo

g.. '

~-

~ 4thbushing

mAr-51""'"

l(~J

SMT422C

8.

Install steelball,4thbushing and4thmain gear.

• Apply multi-purpose greasetosteel ballbefore installing it.

• 4th bushing hasagroove inwhich steelballfits.

ST3n50000

SMT091CA

9.

Press on5th main gear.

Mainshaft rearbearing

Mainshaft adjusting

spacer

c

SMT6938

10.

Select proper mainshaft bearingspacertogive correct

bearing distance.

Bearing distance

"e":

230.15 -230.25 mm(9.0610 -9.0649 in)

Spacers available:

Refer toSOS, MT-65.

MT-46

Page 1589 of 1701

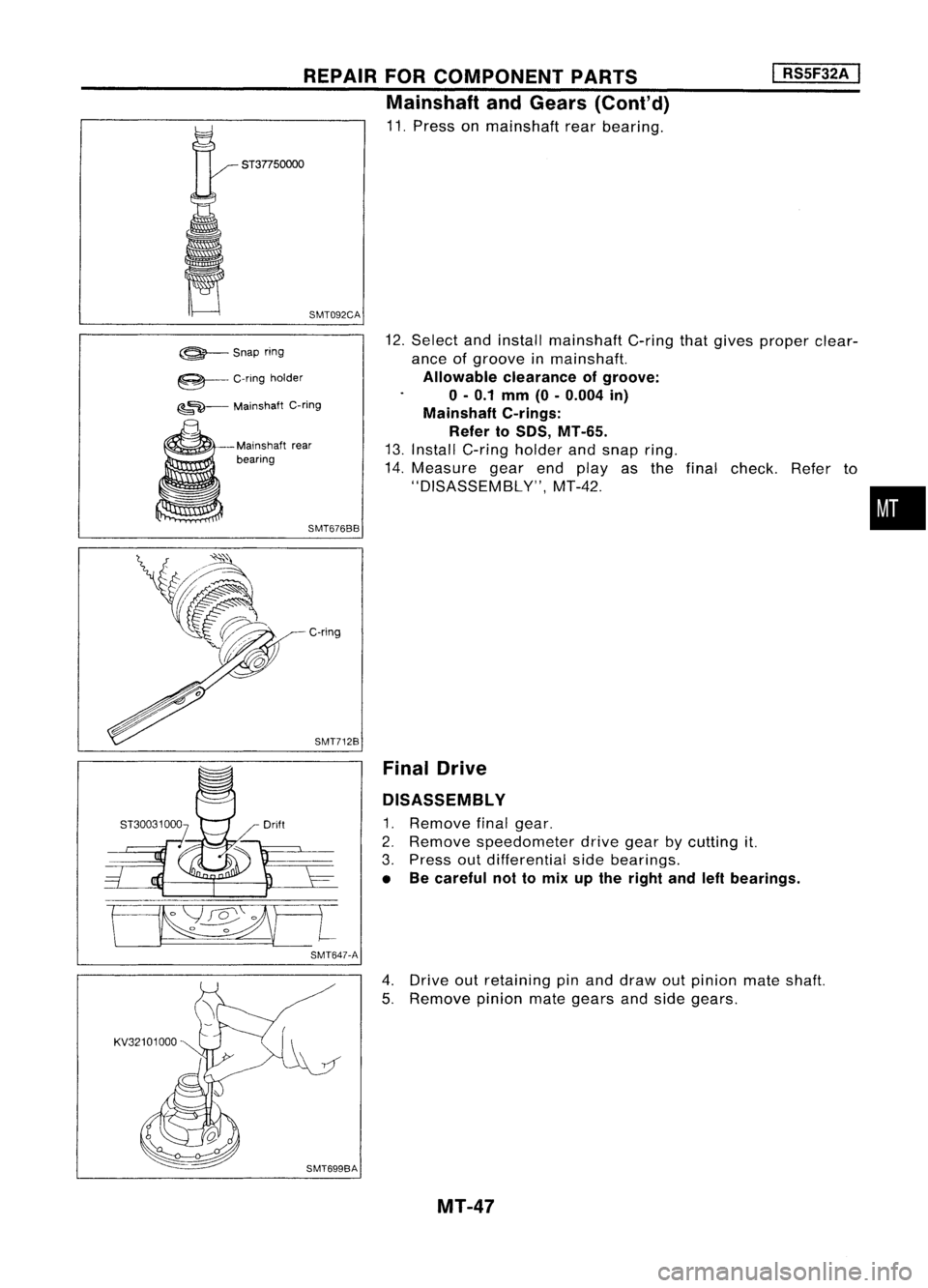

SMT092CA

REPAIR

FORCOMPONENT PARTS

Mainshaft andGears (Cont'd)

11. Press onmainshaft rearbearing.

•

I

RS5F32A

I

12. Select andinstall mainshaft C-ringthatgives proper clear-

ance ofgroove inmainshaft.

Allowable clearanceofgroove:

o -

0.1

mm

(0-0.004

in)

Mainshaft C-rings:

Refer to50S, MT-65.

13. Install C-ring holder andsnap ring.

14. Measure gearendplayas thefinal check. Referto

"DISASSEMBLY", MT-42.

ST37750000

SMT676BB

Mainshaft

rear

bearing

@-Snapring

e---

C-ringholder

~~ MainshaftC-ring

C-ring

SMT712B FinalDrive

DISASSEMBL Y

1. Remove finalgear.

2. Remove speedometer drivegearbycutting it.

3. Press outdifferential sidebearings.

• Becareful nottomix upthe right andleftbearings.

SMT647-A

4.Drive outretaining pinand draw outpinion mateshaft.

5. Remove pinionmategears andside gears.

MT-47

Page 1590 of 1701

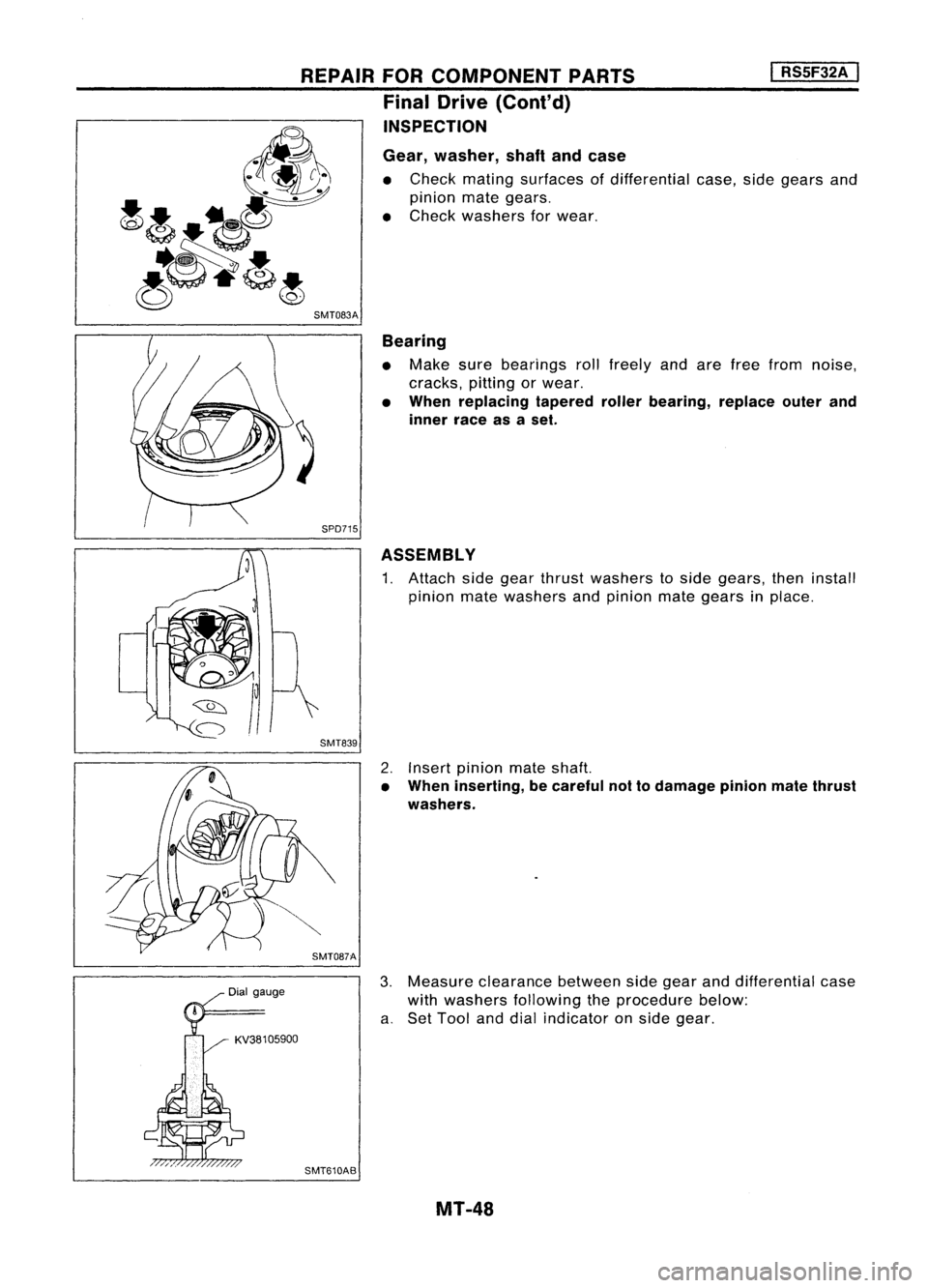

SPD715

SMT083A

ASSEMBLY

1. Attach sidegear thrust washers toside gears, theninstall

pinion matewashers andpinion mategears inplace.

I

RS5F32A

I

Gear, washer, shaftandcase

• Check mating surfaces ofdifferential case,sidegears and

pinion mategears.

• Check washers forwear.

Bearing

• Make surebearings rollfreely andarefree from noise,

cracks, pittingorwear.

• When replacing taperedrollerbearing, replaceouterand

inner raceasaset.

REPAIR

FORCOMPONENT PARTS

Final Drive (Cont'd)

INSPECTION

SMT839

KV381 05900

2.

Insert pinion mateshaft.

• When inserting, becareful nottodamage pinionmatethrust

washers.

3. Measure clearance betweensidegear anddifferential case

with washers following theprocedure below:

a. Set Tool anddial indicator onside gear.

SMT610AB MT-48