NISSAN ALMERA N15 1995 Manual PDF

ALMERA N15 1995

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57349/w960_57349-0.png

NISSAN ALMERA N15 1995 Manual PDF

Trending: Head, Idling valve, service schedule, spark plugs, heating, foldout page, engine overheat

Page 71 of 1701

REPAIRFORCOMPONENT PARTS

Oil Pump (Cont'd)

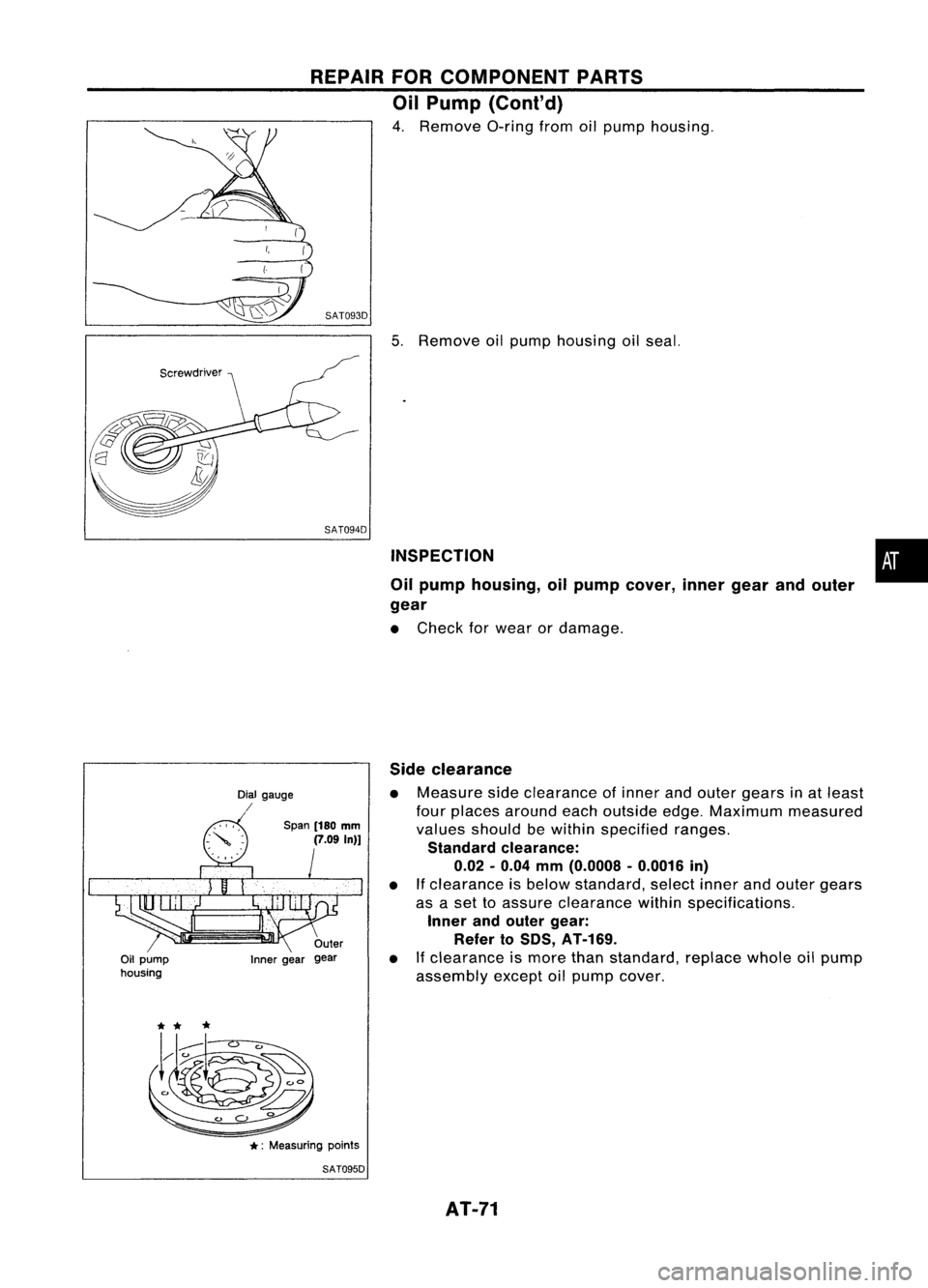

4. Remove O-ringfromoilpump housing.

(

(

~) SAT093D

5.Remove oilpump housing oilseal.

SAT094D INSPECTION

Oil pump housing, oilpump cover, innergearandouter

gear

• Check forwear ordamage.

•

Oil pump

housing Dial

gauge

/

Span(180

mm

(7.09

In)]

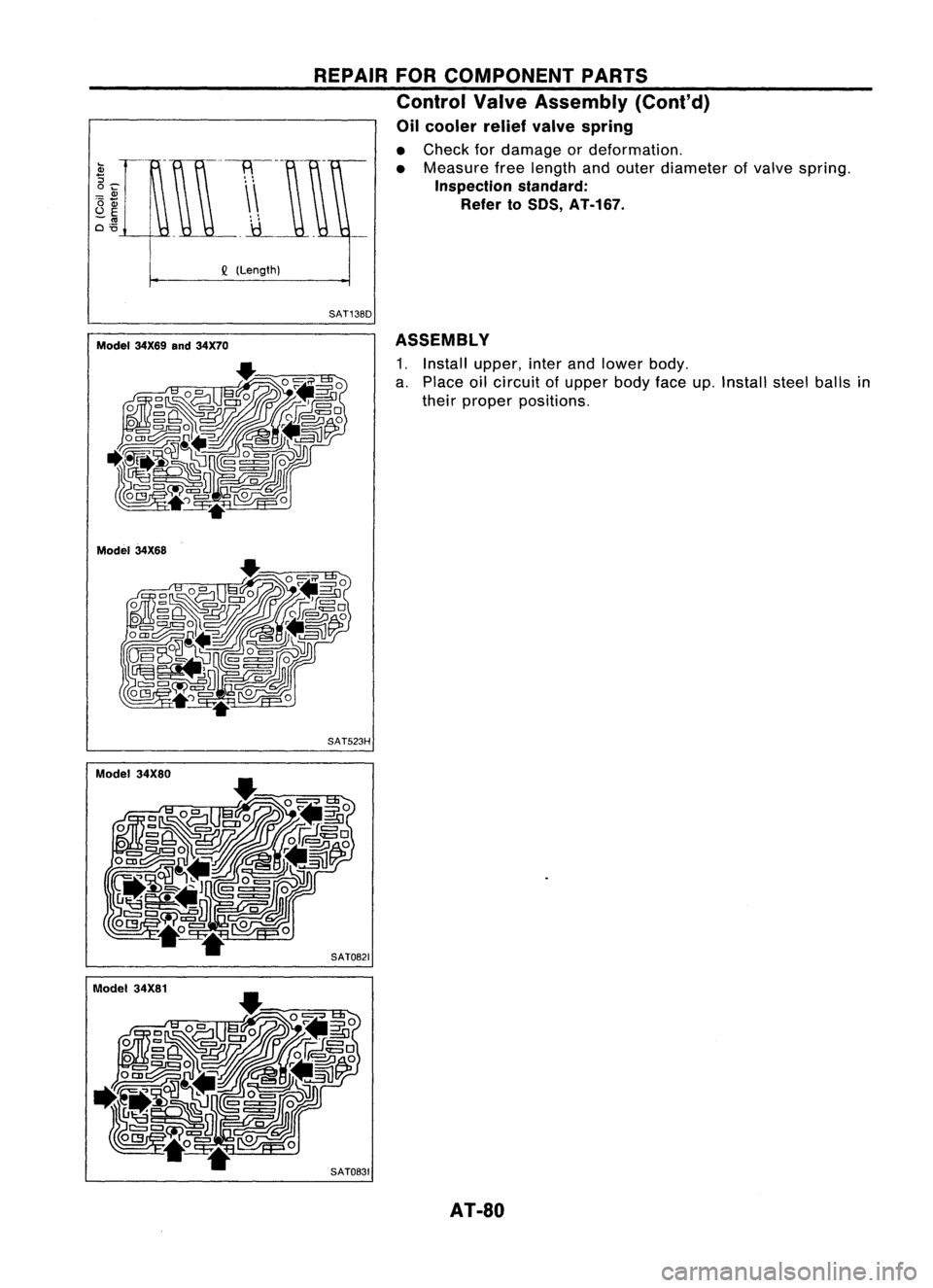

Inner gear Side

clearance

• Measure sideclearance ofinner andouter gears inat least

four places around eachoutside edge.Maximum measured

values should bewithin specified ranges.

Standard clearance:

0.02 -0.04

mm

(0.0008 -0.0016

in)

• Ifclearance isbelow standard, selectinnerandouter gears

as aset toassure clearance withinspecifications.

Inner andouter gear:

Refer toSOS, AT-169.

• Ifclearance ismore thanstandard, replacewholeoilpump

assembly exceptoilpump cover.

*:

Measuring points

SAT095D

AT-71

Page 72 of 1701

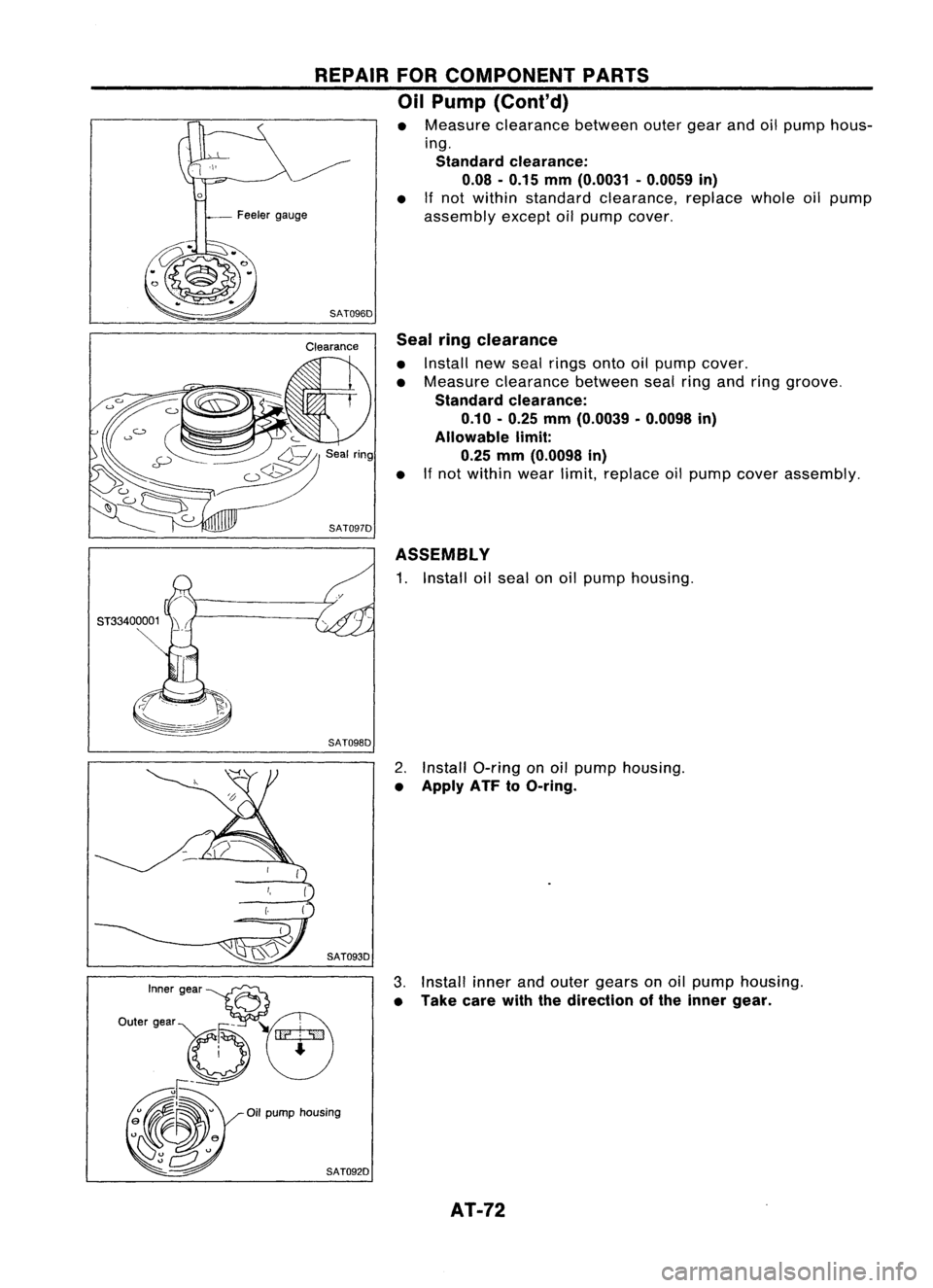

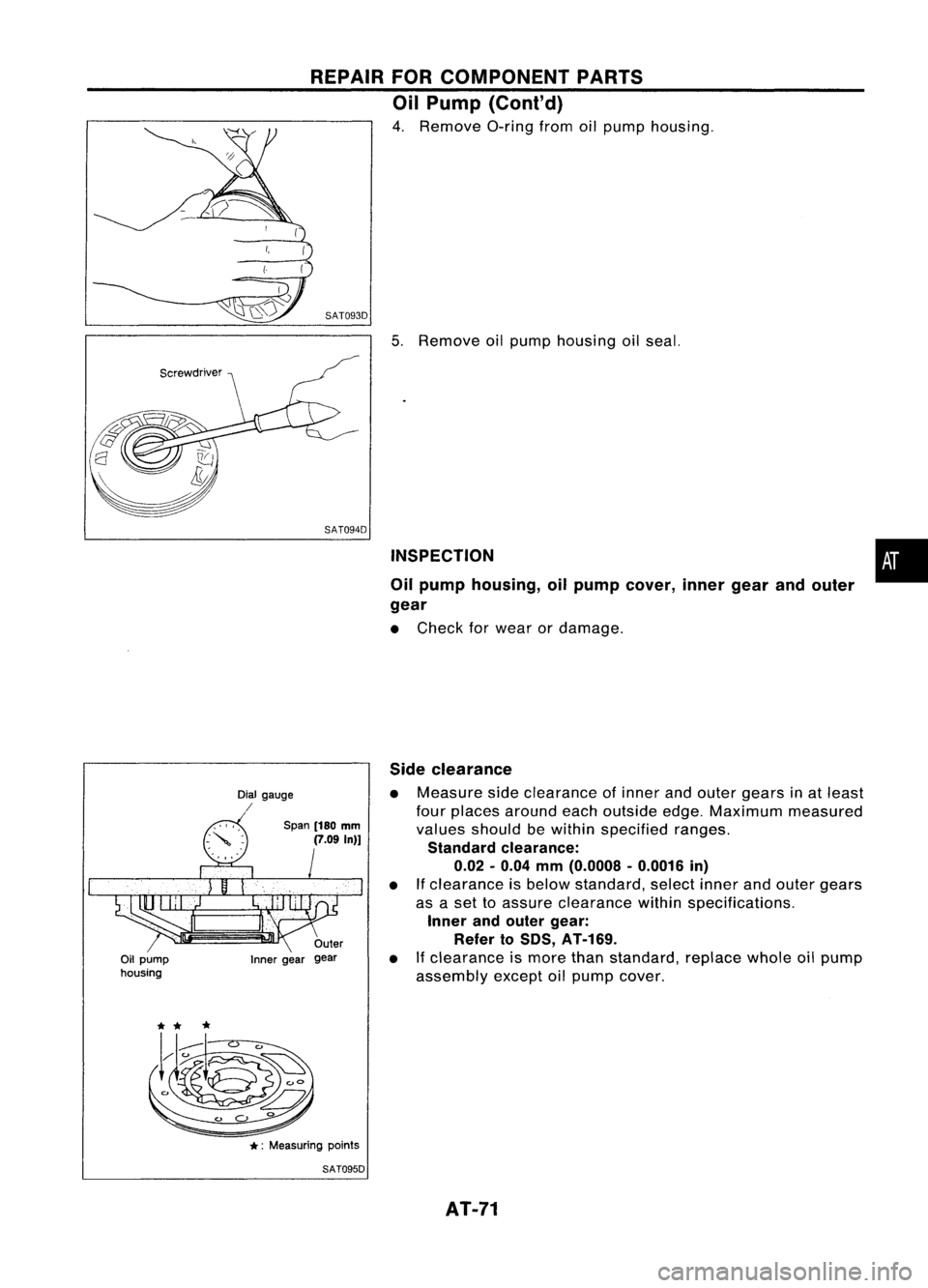

SAT0960Sealringclearance

• Install newseal rings ontooilpump cover.

• Measure clearance betweensealringandring groove.

Standard clearance:

0.10 -0.25 mm(0.0039 -0.0098 in)

Allowable limit:

0.25 mm(0.0098 in)

• Ifnot within wearlimit,replace oilpump coverassembly.

ASSEMBLY

1. Install oilseal onoil pump housing.

2. Install O-ring onoil pump housing.

• Apply ATFtoO-ring.

3. Install innerandouter gears onoil pump housing.

• Take carewiththedirection ofthe inner gear.

REPAIR

FORCOMPONENT PARTS

Oil Pump (Cont'd)

• Measure clearance betweenoutergearandoilpump hous-

ing.

Standard clearance:

0.08 -0.15 mm(0.0031 -0.0059 in)

• Ifnot within standard clearance, replacewholeoilpump

assembly exceptoilpump cover.

AT-72

Page 73 of 1701

REPAIRFORCOMPONENT PARTS

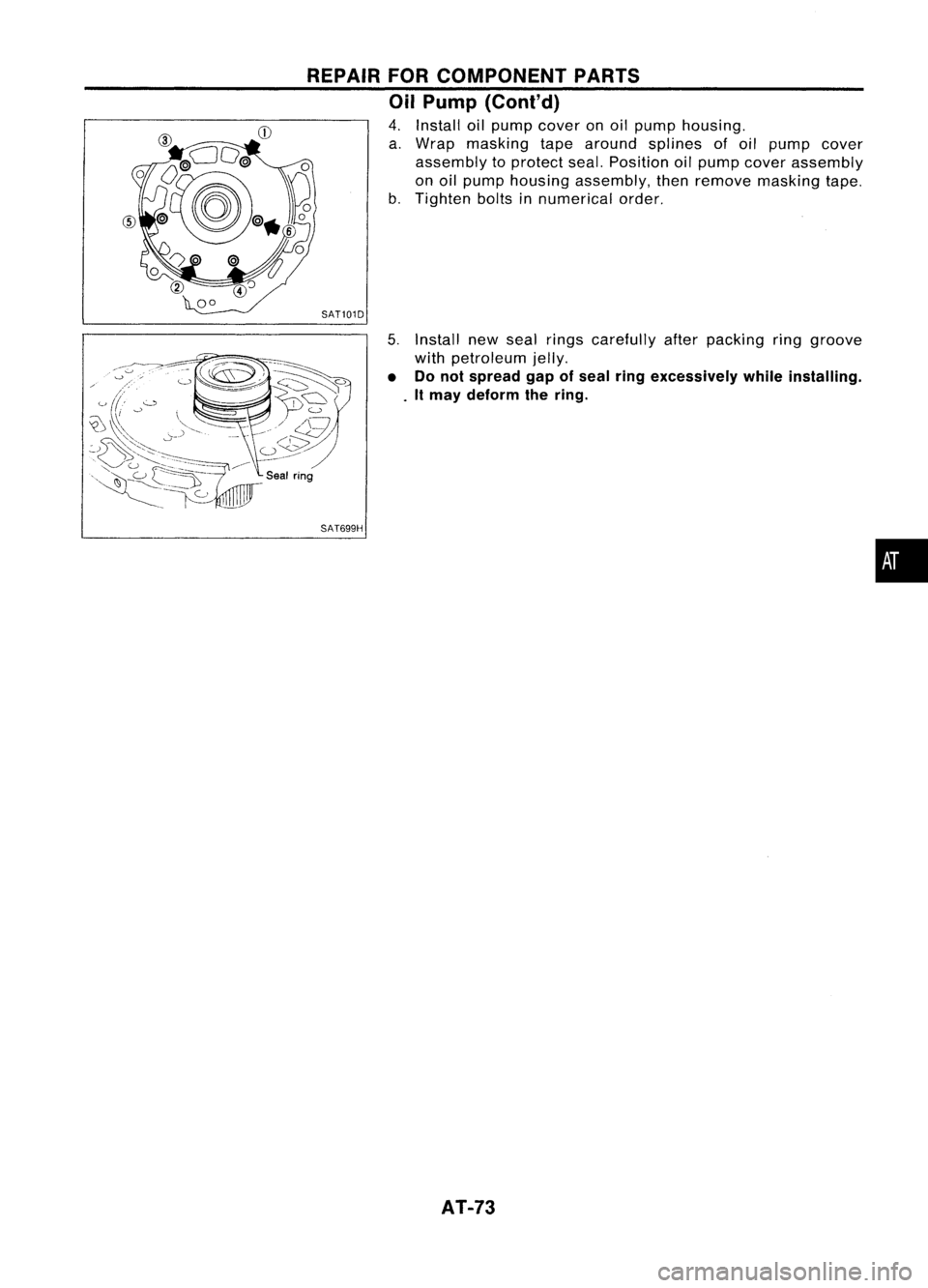

Oil Pump (Conl'd)

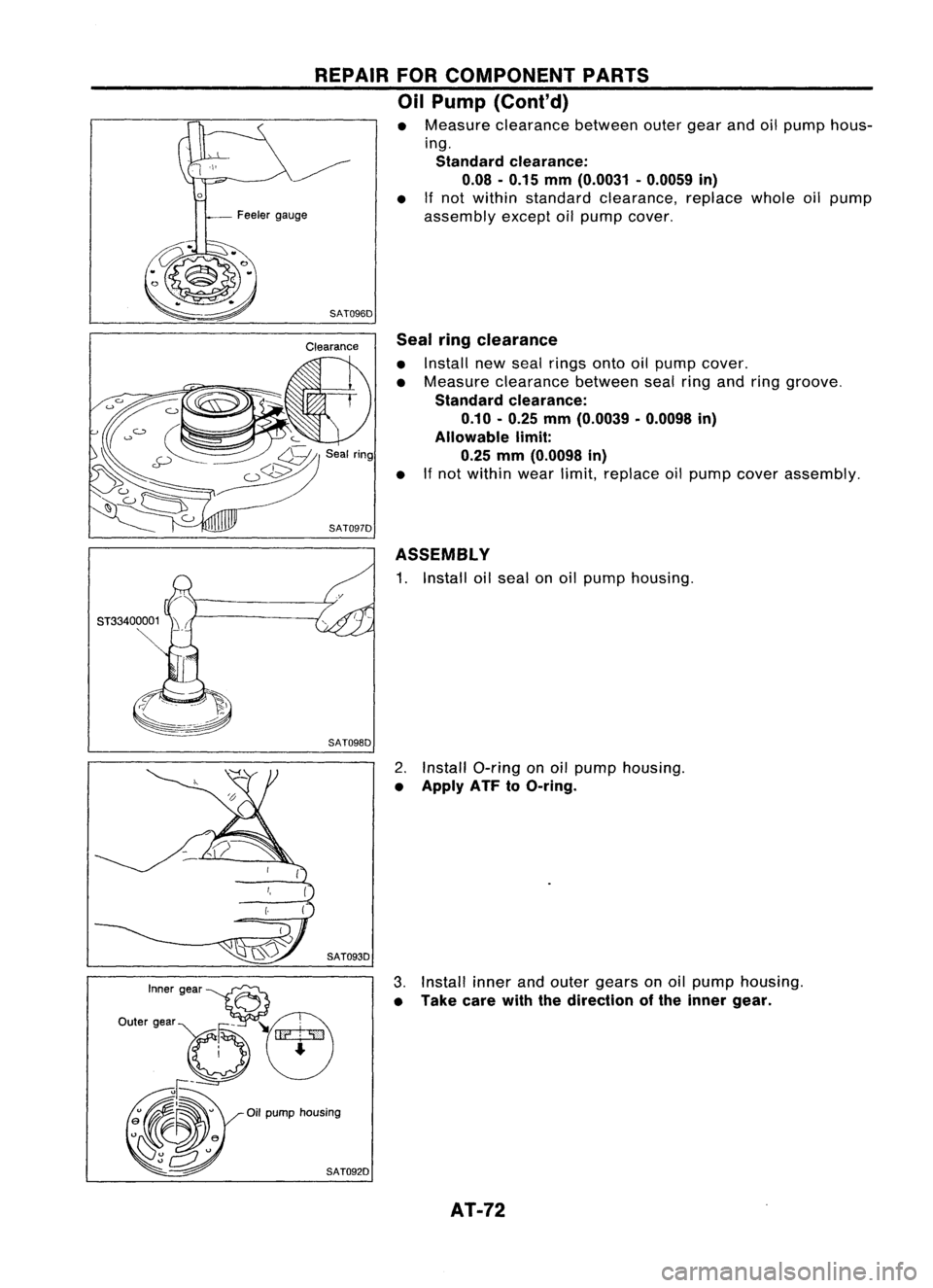

4. Install oilpump cover onoil pump housing.

a. Wrap masking tapearound splines ofoil pump cover

assembly toprotect seal.Position oilpump cover assembly

on oil pump housing assembly, thenremove masking tape.

b. Tighten boltsinnumerical order.

SAT101D

5.Install newseal rings carefully afterpacking ringgroove

with petroleum jelly.

• Donot spread gapofseal ringexcessively whileinstalling .

. It may deform thering.

SAT699H

AT-73

•

Page 74 of 1701

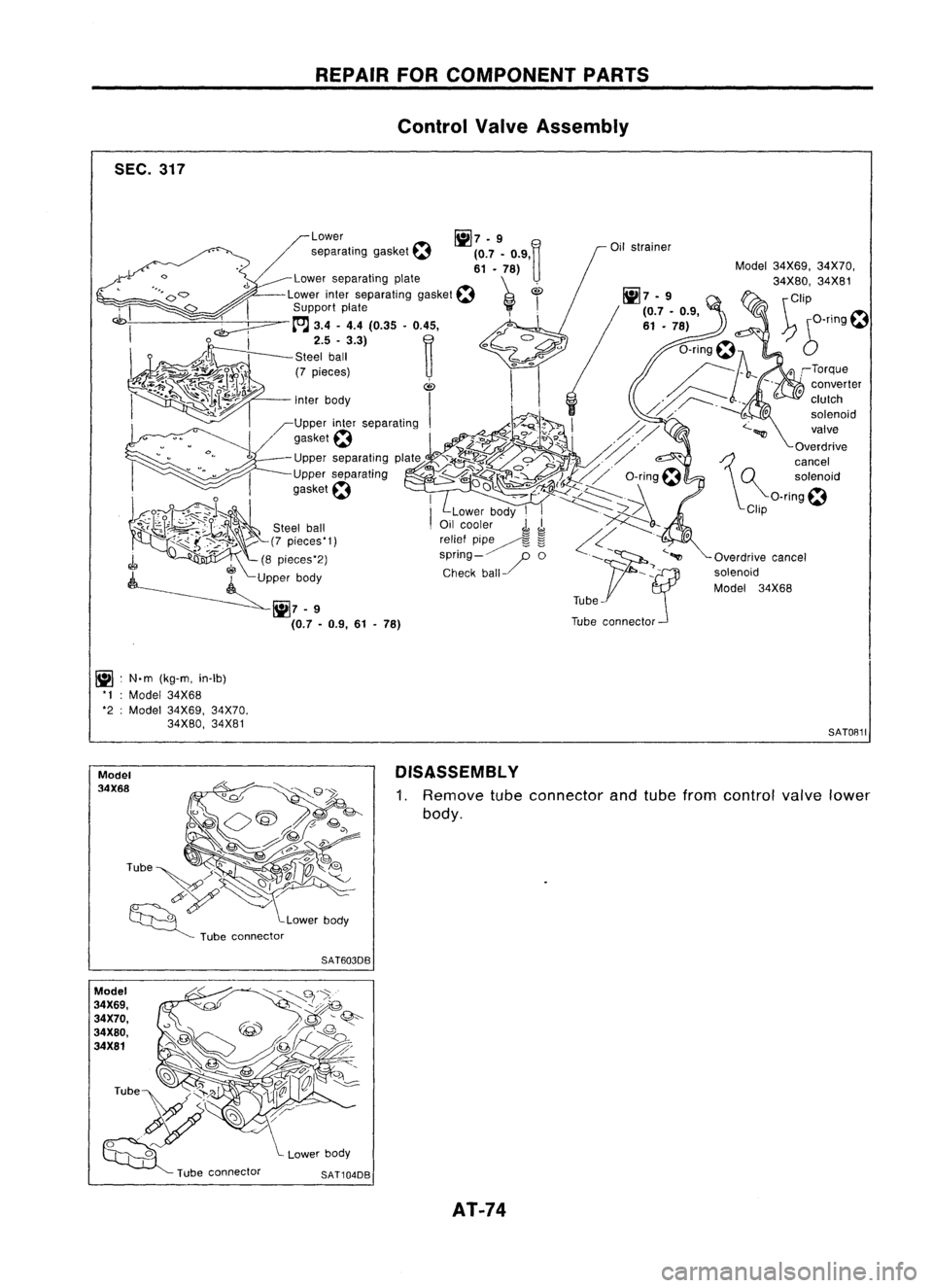

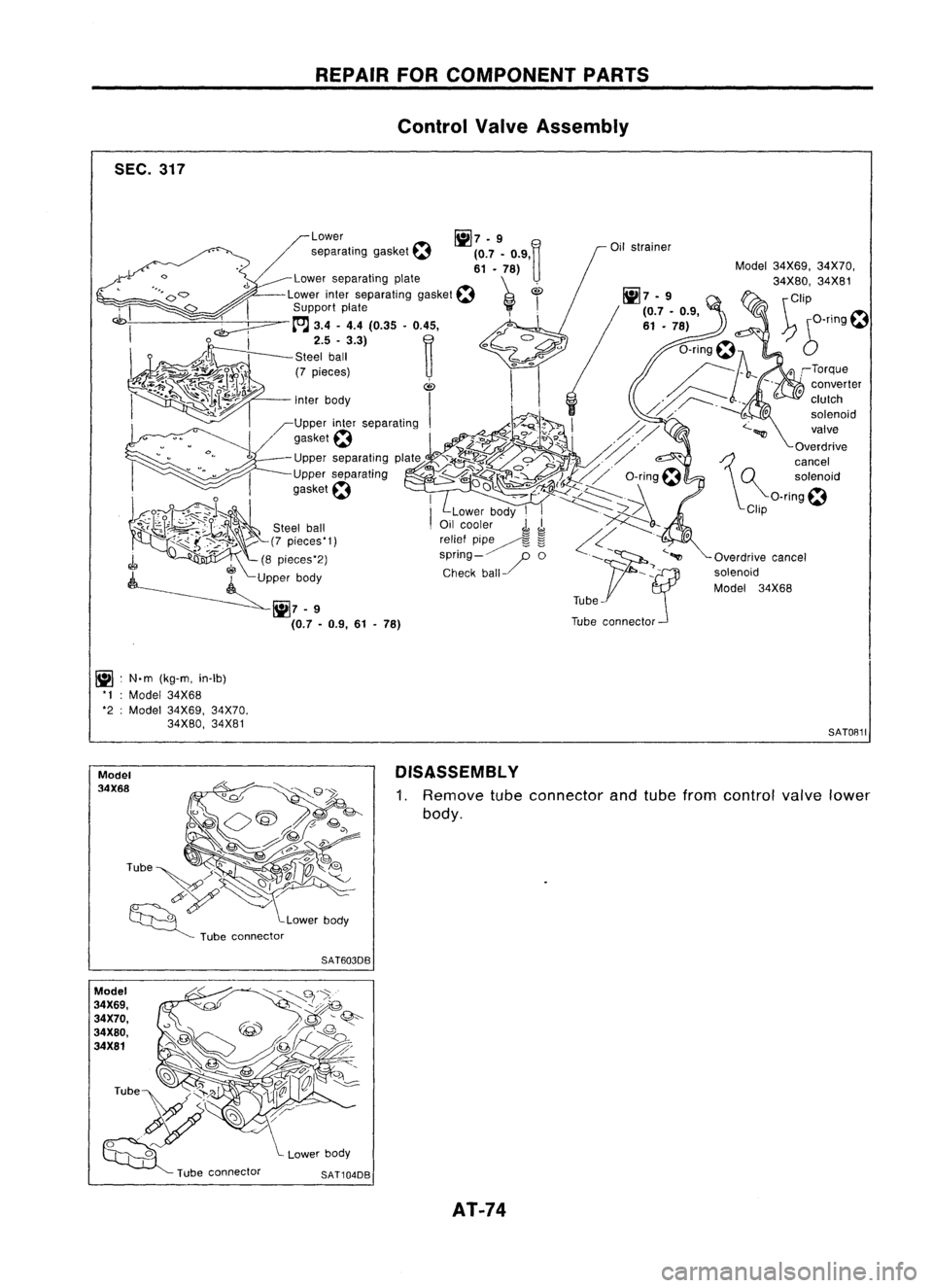

SEC.317

~ :N.m (kg-m, in-Ib)

'I :Model 34X68

'2 :Model 34X69, 34X70.

34X80, 34X81

Model

34X68

Model

34X69,

34X70.

34X80,

34X81 REPAIR

FORCOMPONENT PARTS

Control ValveAssembly

Model34X69, 34X70,

34X80, 34X81

\ Clip

~ 6-T1ng~

SATOB11

DISASSEMBL Y

1. Remove

tubeconnector andtube from control

valve

lower

body.

SAT603DB

SAT104DB AT-74

Page 75 of 1701

SAT245EB

Nut

Section Z- Z

Reamer bolt

•

Bolt

symbol

@

@ @@

CID

cD

Bolt length 'T'

13.558.0 40.0 66.033.078.0

~Qmm(in)

(0.531)

(2.283)(1.575)(2.598) (1.299)

(3.071)

Number ofbolts

4

3 611

22

Bolt symbol

@

@ @@

CID

CD

Bolt length" ("

13.558.0 40.0

66.0 33.078.0

~ (0.531)(2.283)

(1.575)(2.598) (1.299)(3.071)

>-,-1

Qmm (in)

Number ofbolts

53 611

22

With

torque converter clutchsolenoid valve

@

@

REPAIR

FORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

2. Disassemble upper,interandlower bodies usingthefollow-

ing procedures.

Bolt length, number andlocation:

Without torqueconverter clutchsolenoid valve

CD

Plain

washer

Section

y- y

Model

34X68

Section Y- Y

@Bolt~

Support plate

f

(E)BOIt~

Support plate~

(f)

Plain

washer

Nut SAT515HB

Model 34X68

a.

Remove bolts@,@and

CB

shown inthe illustration.

b. Remove oilstrainer fromcontrol valveassembly.

AT-75

Page 76 of 1701

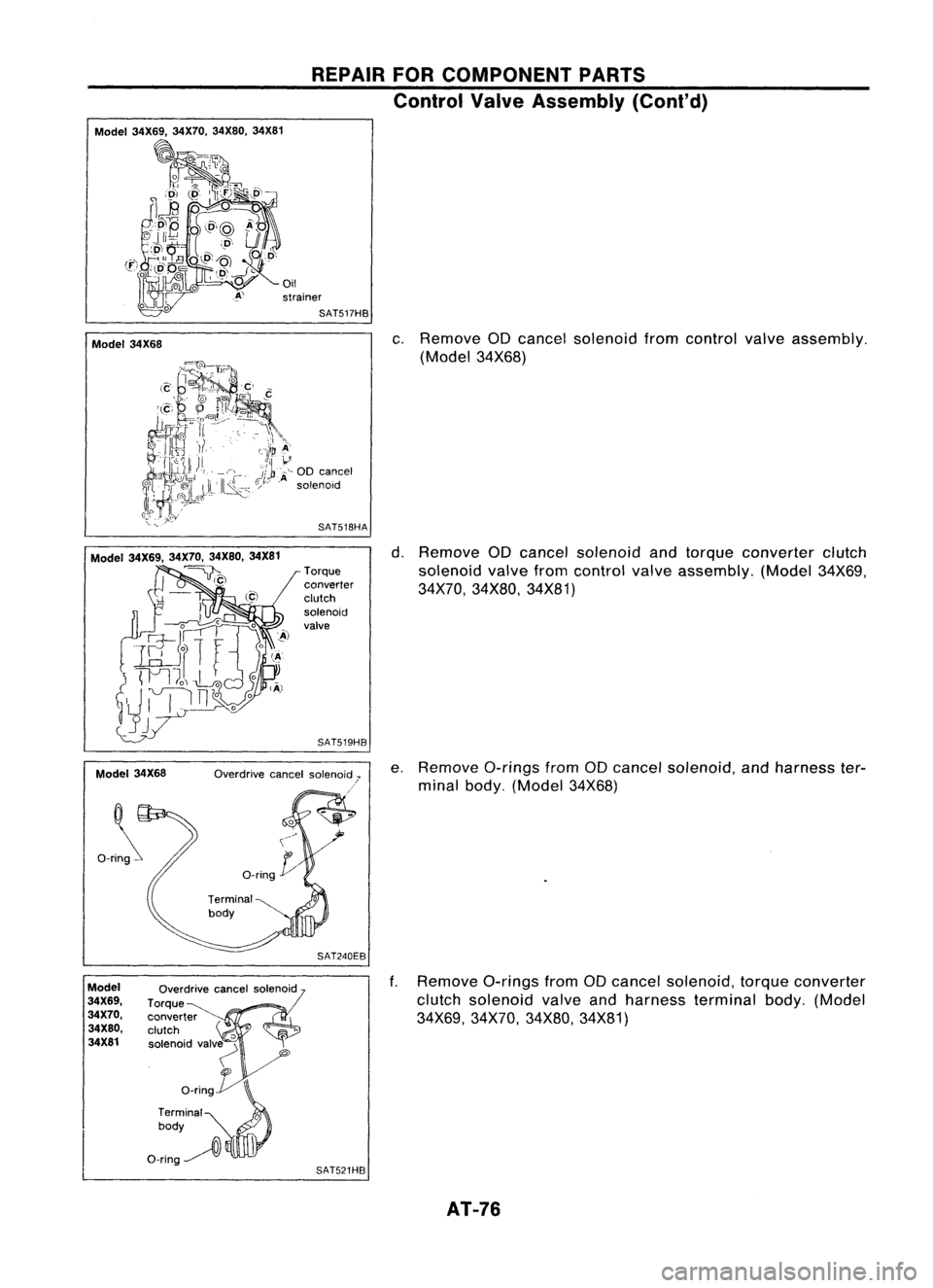

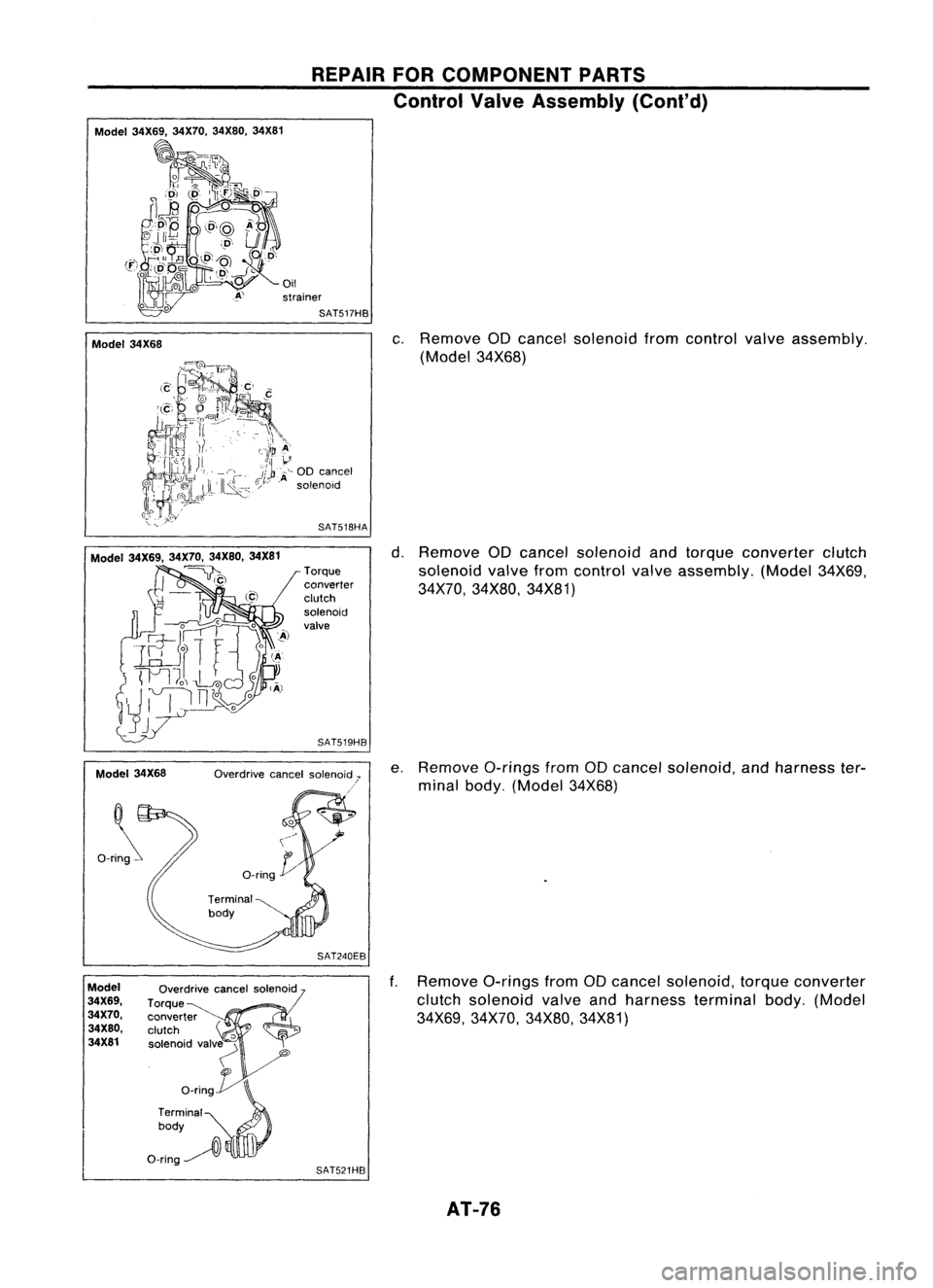

Model34X69. 34X70.34X80,34X81 REPAIR

FORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

Model 34X68

c.

Remove aDcancel solenoid fromcontrol valveassembly.

(Model 34X68)

Model 34X69. 34X70,34X80.34X81

~)

Model 34X68

Ori~

Torque

converter

clutch

solenoid

valve

SAT519HB

SAT240EB

d.

Remove aDcancel solenoid andtorque converter clutch

solenoid valvefromcontrol valveassembly. (Model34X69,

34X70, 34X80, 34X81)

e. Remove a-ringsfromaDcancel solenoid, andharness ter-

minal body. (Model 34X68)

ModeJ

34X69.

34X70.

34X80.

34X81

Overdrive

cancelsolenoid

Torque

converter

clutch

'0

solenoid valv~

"

o_rin~

Terminal

0

body

O-ring~

l\

SAT521HB

f.

Remove a-ringsfromaDcancel solenoid, torqueconverter

clutch solenoid valveandharness terminal body.(Model

34X69, 34X70, 34X80,34X81)

AT-76

Page 77 of 1701

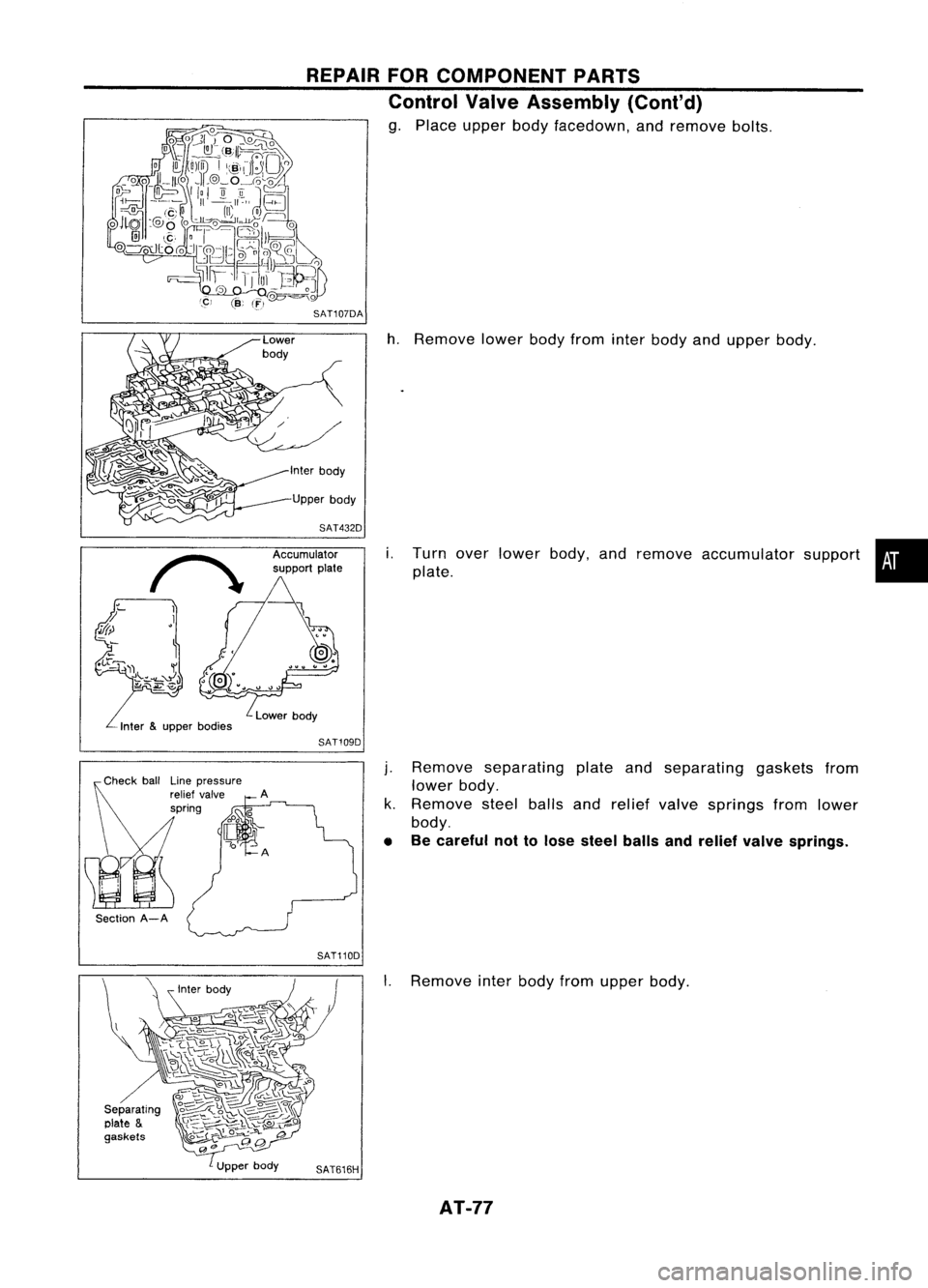

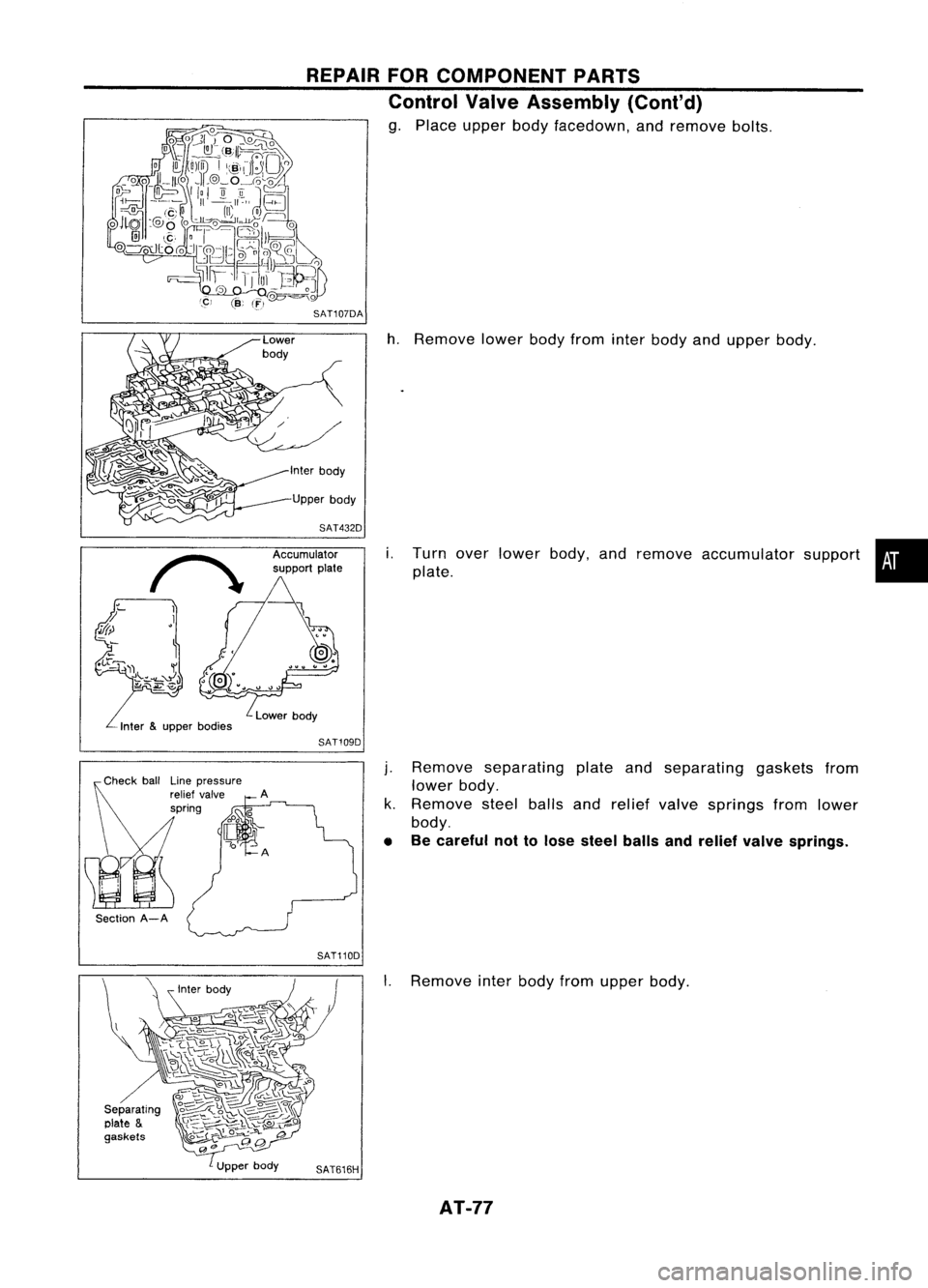

SAT107DATurnoverlower body,andremove accumulator support•

plate.

h.

Remove lowerbodyfrom interbody andupper body.

i.

REPAIR

FORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

g. Place upper bodyfacedown, andremove bolts.

Accumulator

support plate

SAT109D

Section A-ALine

pressure

relief valve

spring

j.

Remove separating plateandseparating gasketsfrom

lower body.

k. Remove steelballsandrelief valve springs fromlower

body.

• Becareful nottolose steel ballsandrelief valve springs.

SAT110D I.Remove interbody fromupper body.

AT-77

Page 78 of 1701

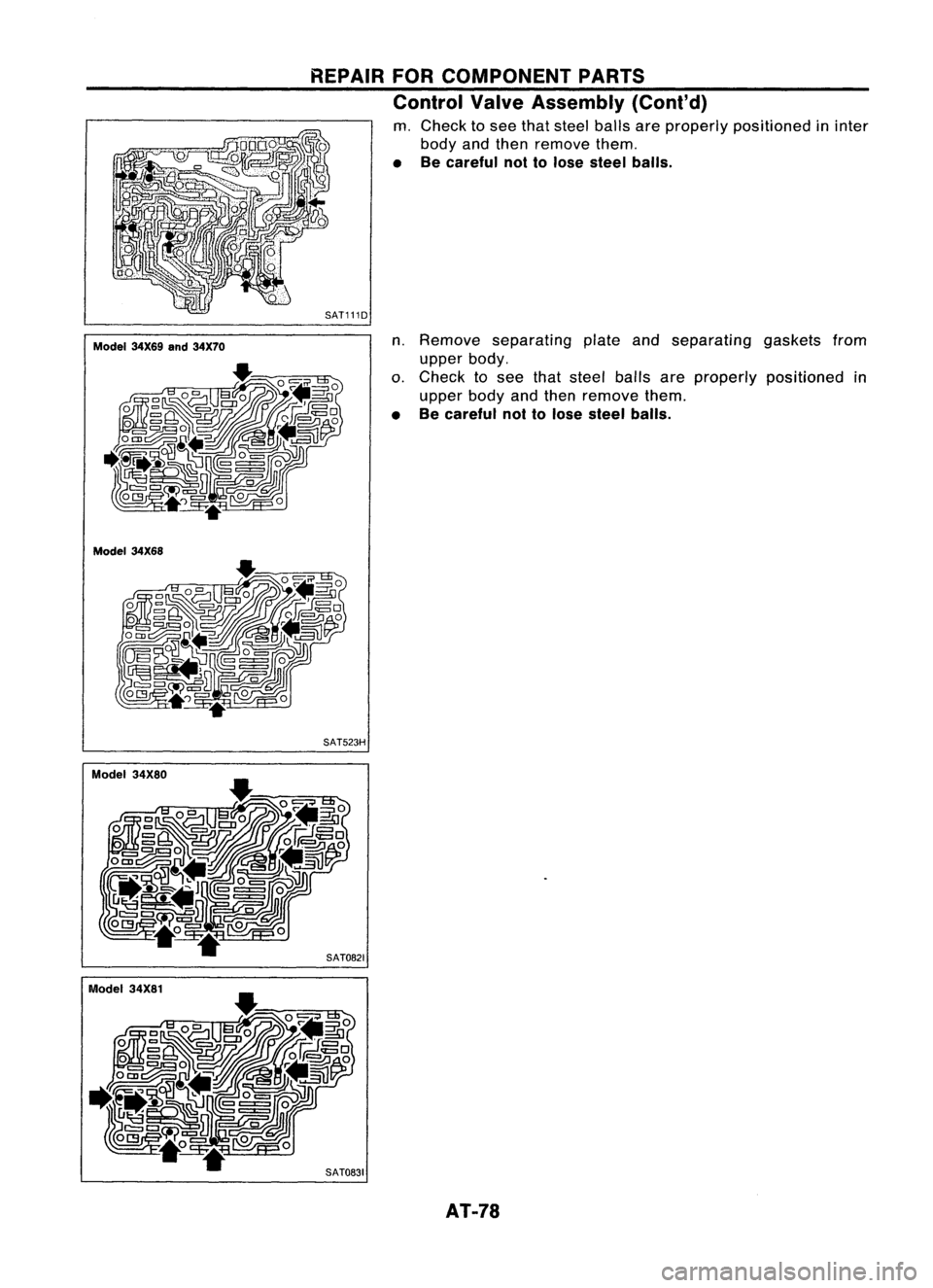

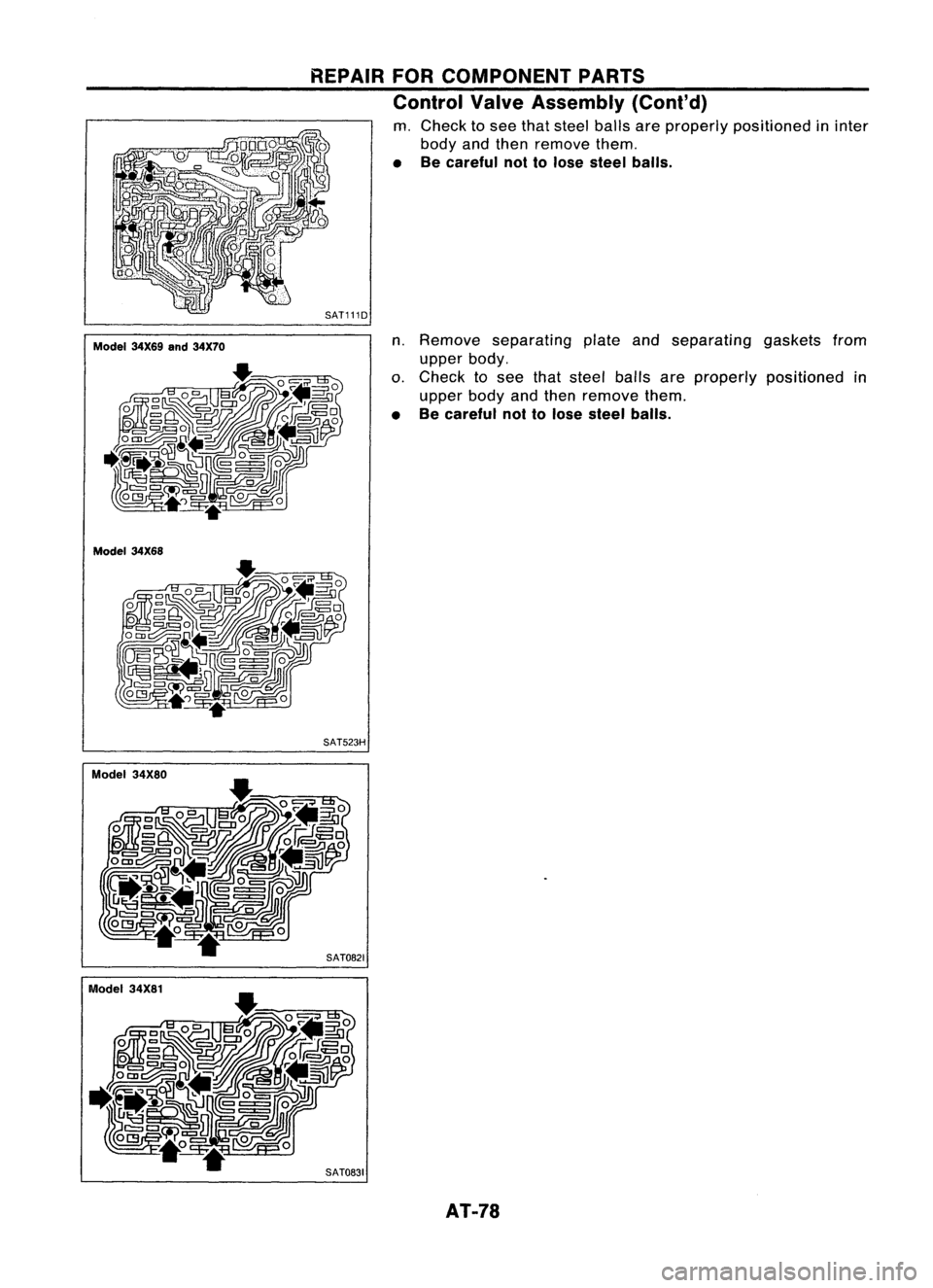

REPAIRFORCOMPONEN

Control Val TPARTS

ve Asse b

m. Check tosee that

mIy(Cont'd)

body andth steelballsar

• Becareful n~~;:ml ove them. eproperly positioned in.

ose steel b Inter

ails.

SAT111D

Model 34X69

and34X70

Model 34X68

n.

Remo

veseparatin

upper body 9plate and

o. Check tos. separatinggask

upper bodye:n~ht steelballsare elsfrom

• Becareful nollo

~en

remove themproperly positioned.

ose steel balls. .

In

Model 34X80

Model 34X81 SAT523H

SAT0831 AT-78

Page 79 of 1701

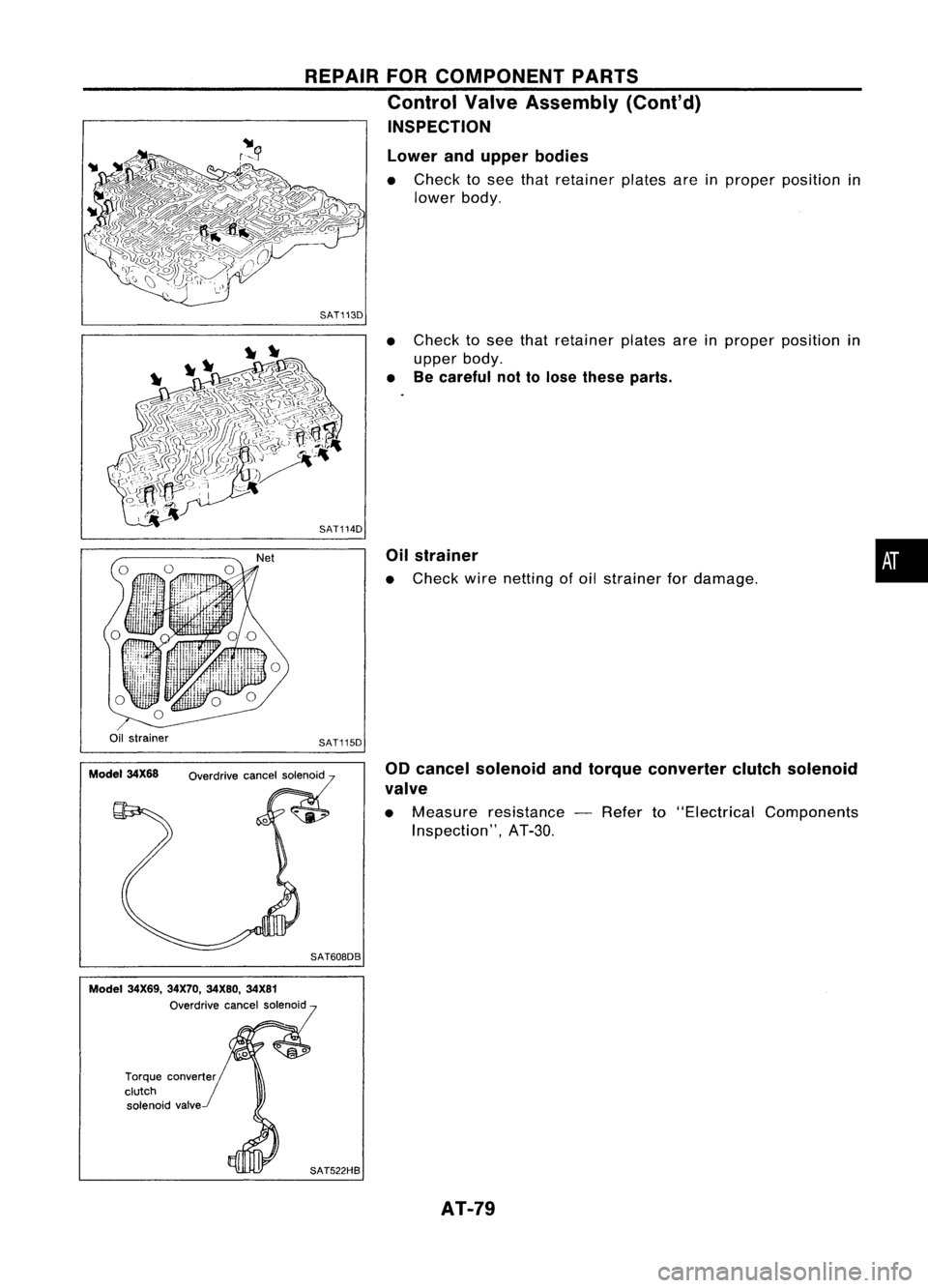

REPAIRFORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

INSPECTION

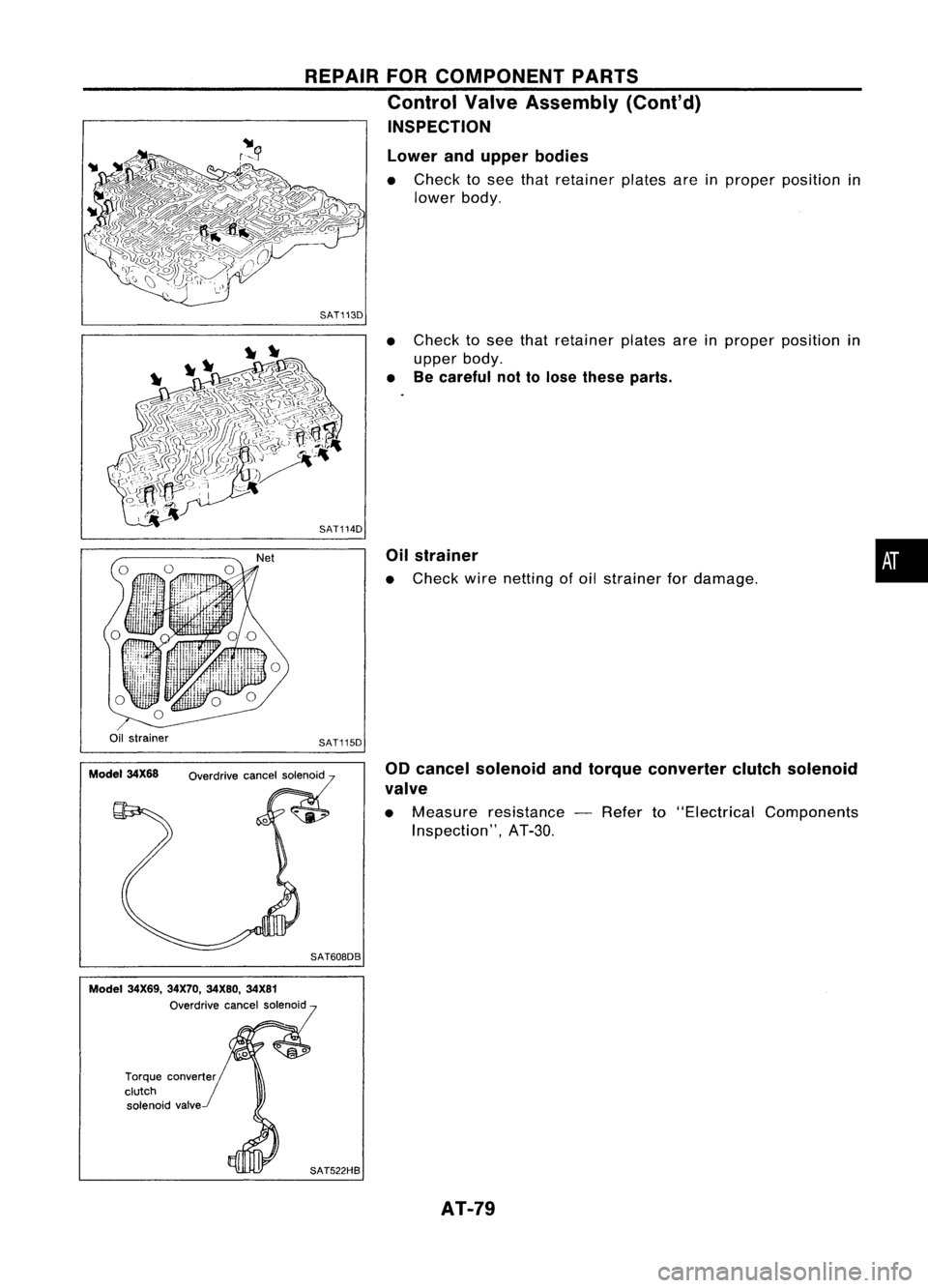

Lower andupper bodies

• Check tosee that retainer platesareinproper position in

lower body.

SAT113D

•Check tosee that retainer platesareinproper position in

upper body.

• Becareful nottolose these parts.

Oil strainer

• Check wirenetting ofoil strainer fordamage.

•

Oil strainer

Model 34X68 SAT115D

Overdrive cancelsolenoid

SAT608DB 00

cancel solenoid andtorque converter clutchsolenoid

valve

• Measure resistance -Refer to"Electrical Components

Inspection", AT-3D.

Model 34X69, 34X70,34X80, 34X81

Overdrive cancelsolenoid

Torque converter

clutch solenoid valve

SAT522HBAT-79

Page 80 of 1701

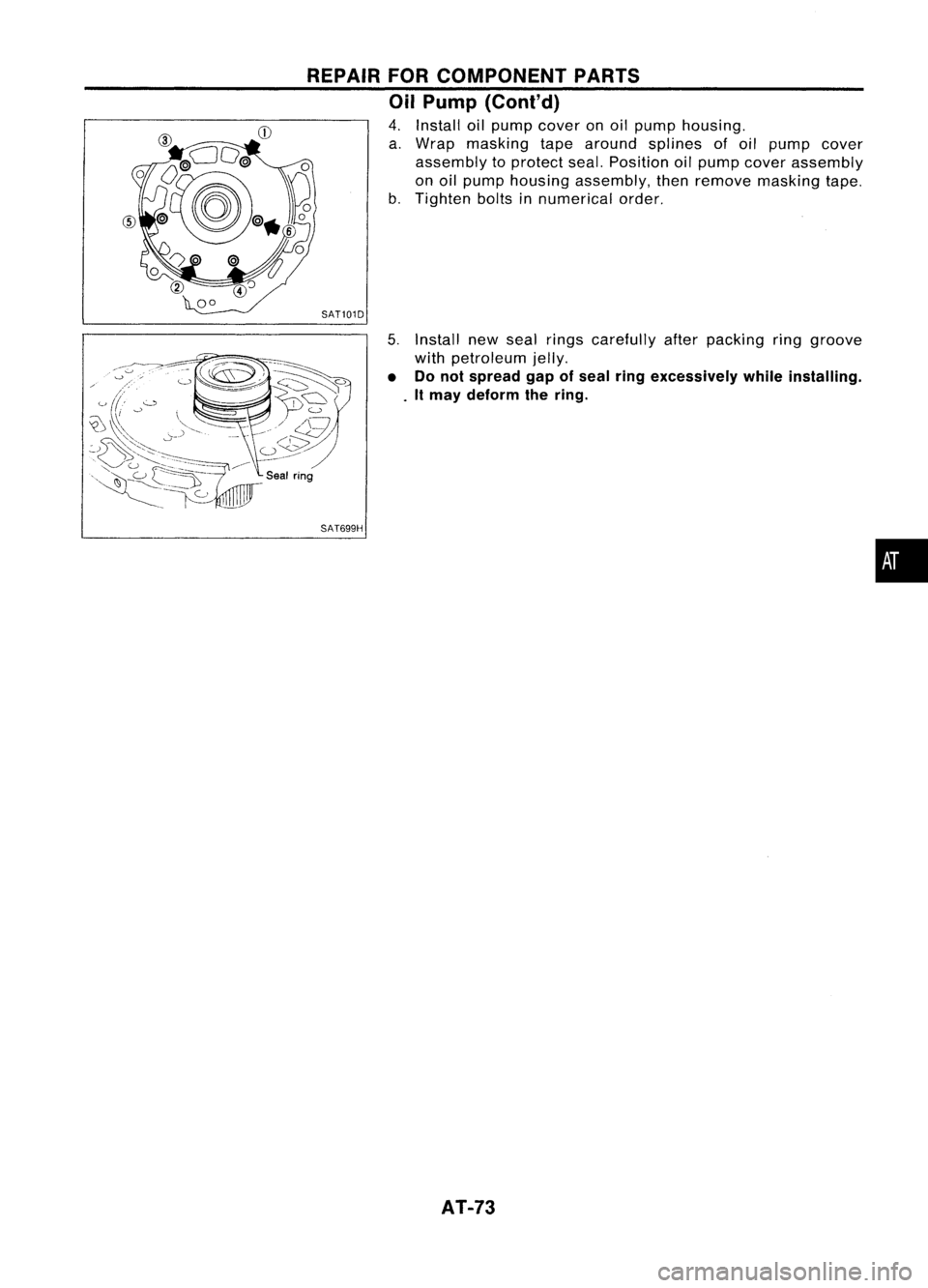

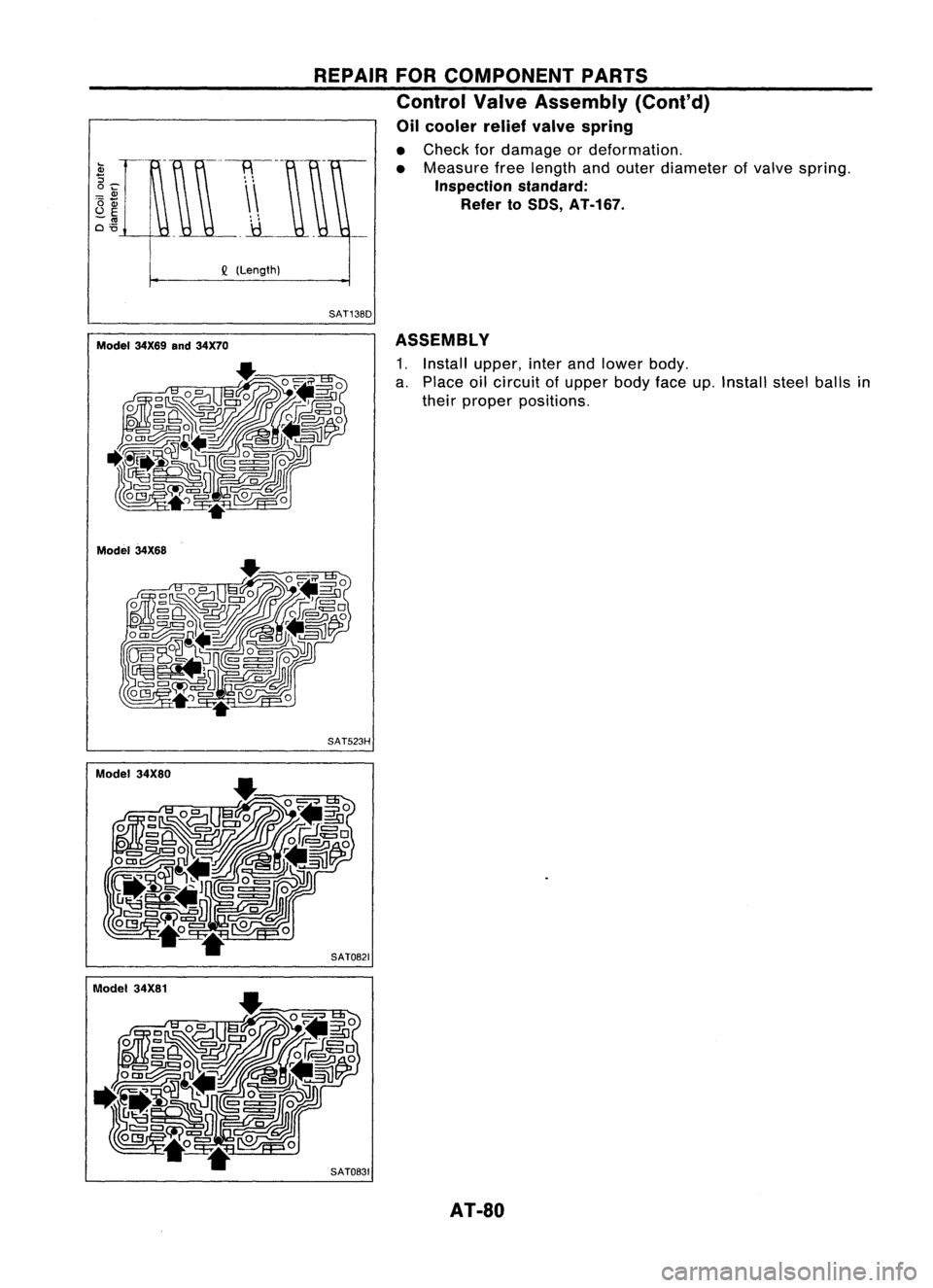

ASSEMBLY

1. Install

a PI upper, inter

. tha~e oilcircuit ofuand lower body

elr pro pperbd .

per posT

0

Yface

I

Ions. up.Install stelb'

e

ails

In

SATOB21

SATOB31

REPAIR

FOR

COMPONE

Control ValNTPARTS

0"1

veAsse b

I

cooler reli

f

mIy(Cont'd)

• Check f

evalve spring

• M ordamag

easure freeIeeor deformation

Inspection

ngthandouter d'.

R

f

standard"

Iameter

of

e er to50S AT.

valvespring

, -167. .

Q

(Length)

Model 34X69and34X70

Model 34X68

Model 34X80

AT-SO

Trending: oil capacity, automatic transmission fluid, instrument panel, headlights, fuse box diagram, fuel tank removal, ECU