NISSAN ALMERA N15 1995 Owners Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 91 of 1701

REPAIRFORCOMPONENT PARTS

Control ValveLower Body(Cont'd)

DISASSEMBL Y

1. Remove valvesatretainer plate.

For removal procedures, referto"DISASSEMBLY" in"Con-

trol Valve Upper Body", AT-B?

SAT1130 Throttle valve

o

f2- •

Remove throttlevalveatE-ring.

•

INSPECTION

Valve springs

• Check eachvalve spring fordamage ordeformation. Also

measure freelength andouter diameter.

Inspection standard:

Refer to50S, AT-167.

• Replace valvesprings ifdeformed orfatigued.

Control valves

• Check sliding surfaces ofcontrol valves, sleeves andplugs

for damage.

ASSEMBLY

Throttle valve

• Insert throttle valvetocontrol valvebodyandthen install

E-ring tothrottle valve.

SAT147D

SAT13BO

Q

(Length)

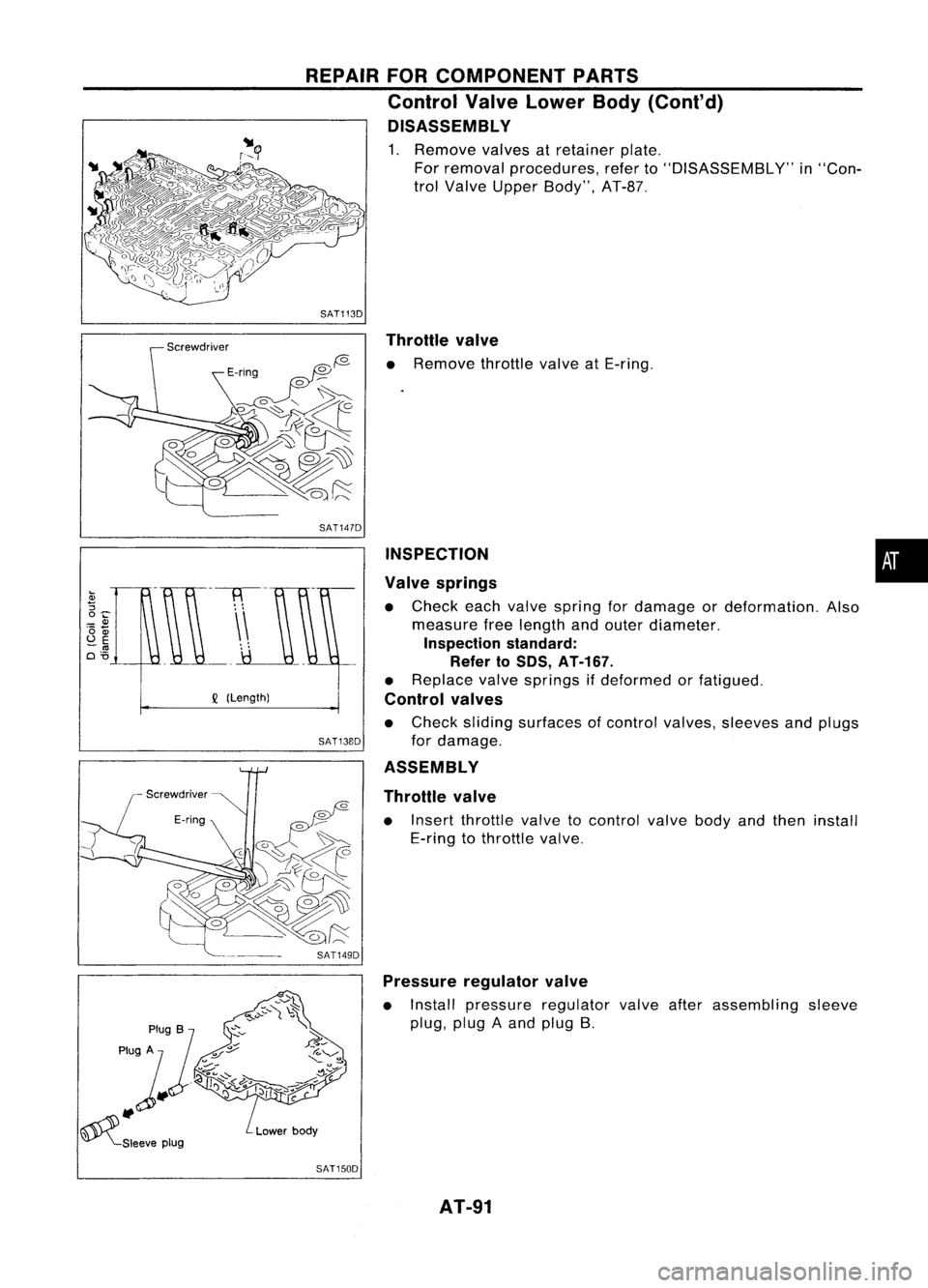

SAT1490Pressure regulator valve

• Install pressure regulator valveafterassembling sleeve

plug, plugAand plug B.

SAT1500 AT-91

Page 92 of 1701

REPAIRFORCOMPONENT PARTS

Control ValveLower Body(Cont'd)

3-4 shift valve and2-3shift valve

• Install 3-4shift valve and2-3shift valve afterfixing plugsto

retainer platesonthe opposite side.

SAT151D

•Install control valves.

For installation procedures, referto"ASSEMBLY in"Con-

trol Valve Upper Body", AT-8?

SAT113D

"A"

"B"

U

Type I

"A"

Eli

Type II

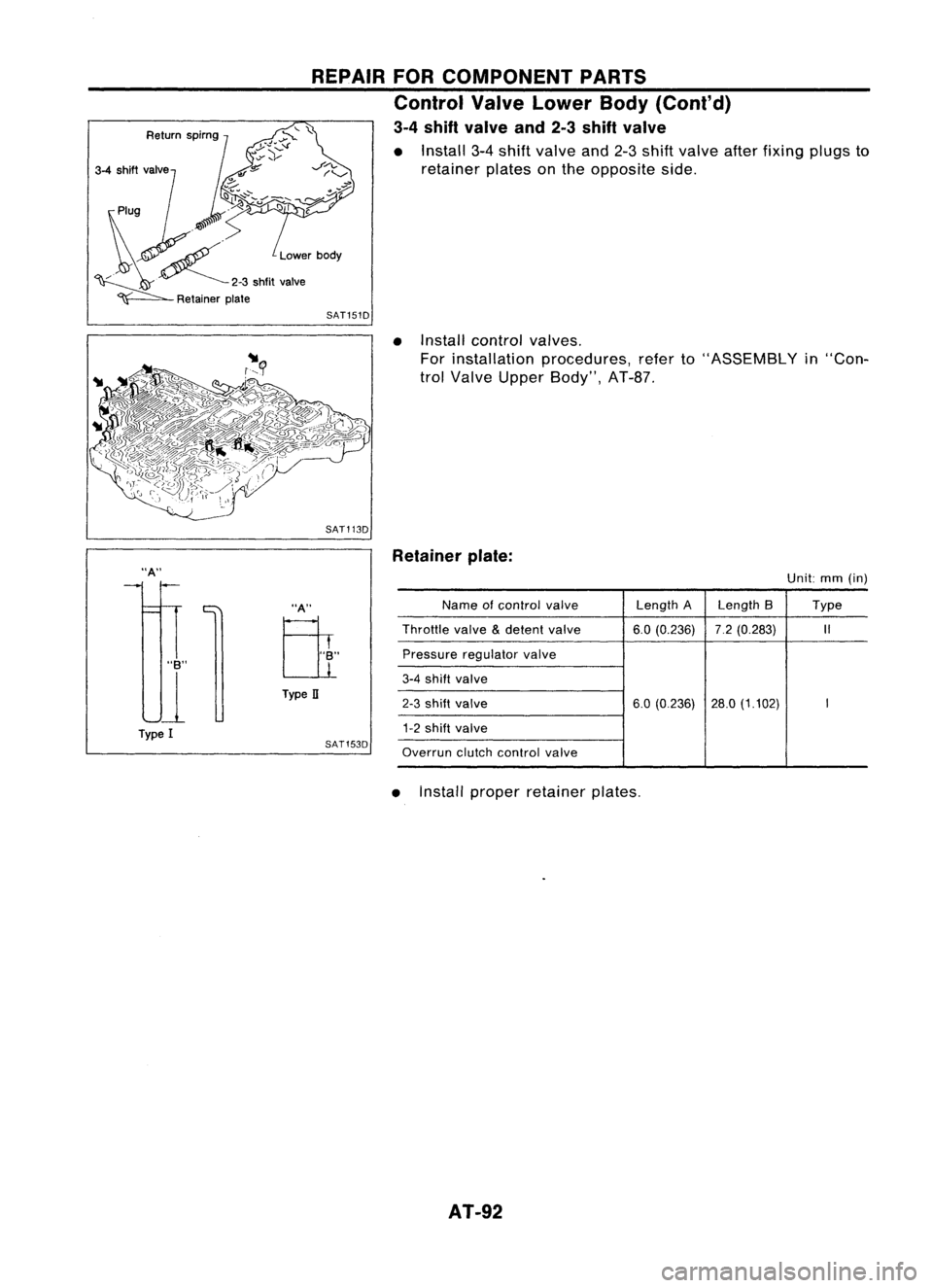

SAT153D Retainer

plate:

Unit:mm(in)

Name ofcontrol

valve

Length

ALength 8 Type

Throttle

valve

&

detent

valve 6.0(0.236) 7.2(0.283)

1/

Pressure regulator

valve

3-4

shift

valve

2-3

shift valve

6.0(0.236) 28.0(1.102)

I

1-2

shift valve

Overrun

clutchcontrol

valve

• Install proper retainer plates.

AT-92

Page 93 of 1701

REPAIRFORCOMPONENT PARTS

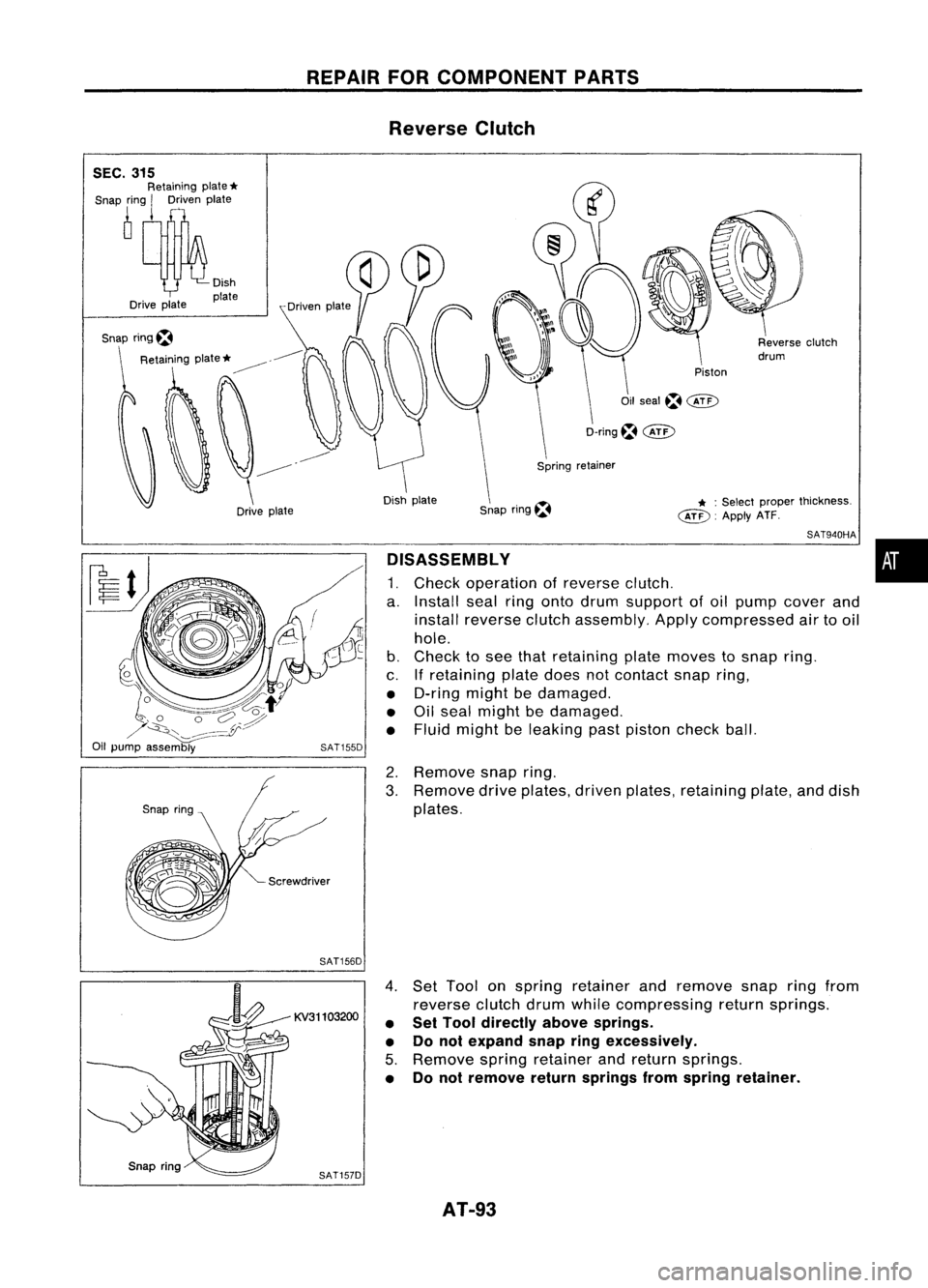

Reverse Clutch

Piston

* :

Select proper thickness.

~. ApplyATF.

Oil

seal~@D

D-ring~

@:>

Snap ring~

Dish

plate

Drive plate

SEC.

315

Retaining plate

*

Snap ring

I

Driven plate

Snap ring~

SAT940HA

DISASSEMBLY •

1. Check operation ofreverse clutch.

a. Install sealringonto drum support ofoil pump cover and

install reverse clutchassembly. Applycompressed airtooil

hole.

b. Check tosee that retaining platemoves tosnap ring.

c. Ifretaining platedoesnotcontact snapring,

• D-ring mightbedamaged.

• Oilseal might bedamaged.

• Fluid might beleaking pastpiston checkball.

2. Remove snapring.

3. Remove driveplates, drivenplates, retaining plate,anddish

plates.

SAT156D

KV31103200

SAT157D

4.

Set Tool onspring retainer andremove snapringfrom

reverse clutchdrumwhilecompressing returnsprings.

• Set Tool directly abovesprings.

• Donot expand snapringexcessively.

5. Remove springretainer andreturn springs.

• Donot remove returnsprings fromspring retainer.

AT-93

Page 94 of 1701

REPAIRFORCOMPONENT PARTS

Reverse Clutch(Cont'd)

6. Remove pistonfromreverse clutchdrumbyturning

it.

SAT159D

7.Remove O-ringandoilseal from piston.

SAT13BE INSPECTION

Reverse clutchsnapring,spring retainer andreturn

springs

• Check fordeformation, fatigueordamage.

• Replace ifnecessary.

• When replacing springretainer andreturn springs, replace

them asaset.

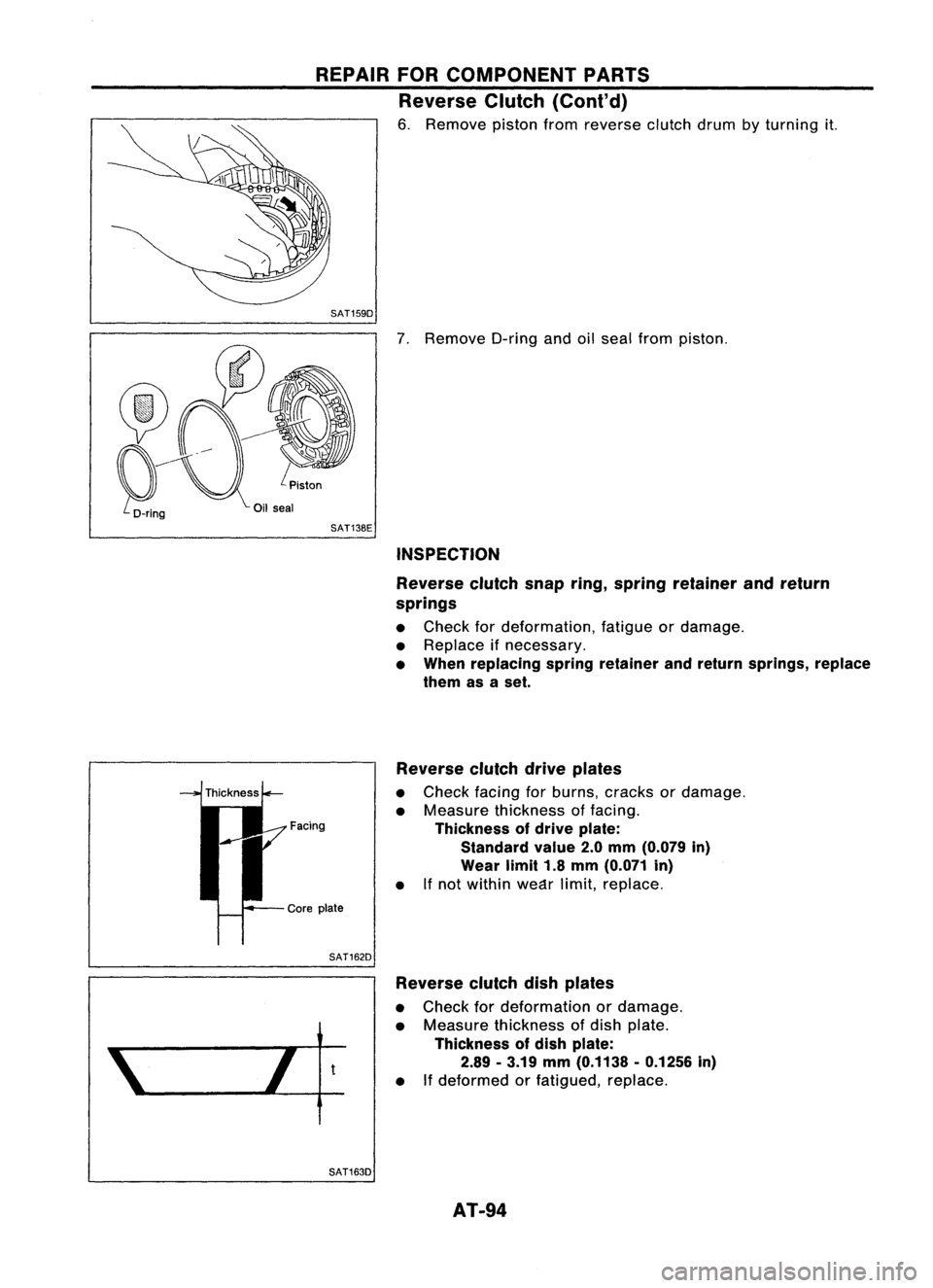

Reverse clutchdriveplates

• Check facingforburns, cracks ordamage.

• Measure thickness offacing.

Facing Thicknessofdrive plate:

Standard value2.0mm (0.079 in)

Wear limit1.8mm (0.071 in)

• Ifnot within weC1rlimit,replace.

SAT162D Reverse clutchdishplates

• Check fordeformation ordamage.

• Measure thickness ofdish plate.

Thickness ofdish plate:

2.89 -3.19 mm(0.1138 -0.1256 in)

• Ifdeformed orfatigued, replace.

SAT163D AT-94

Page 95 of 1701

Checkairdoes notflow

through ballhole.

REPAIR

FORCOMPONENT PARTS

Reverse Clutch(Cont'd)

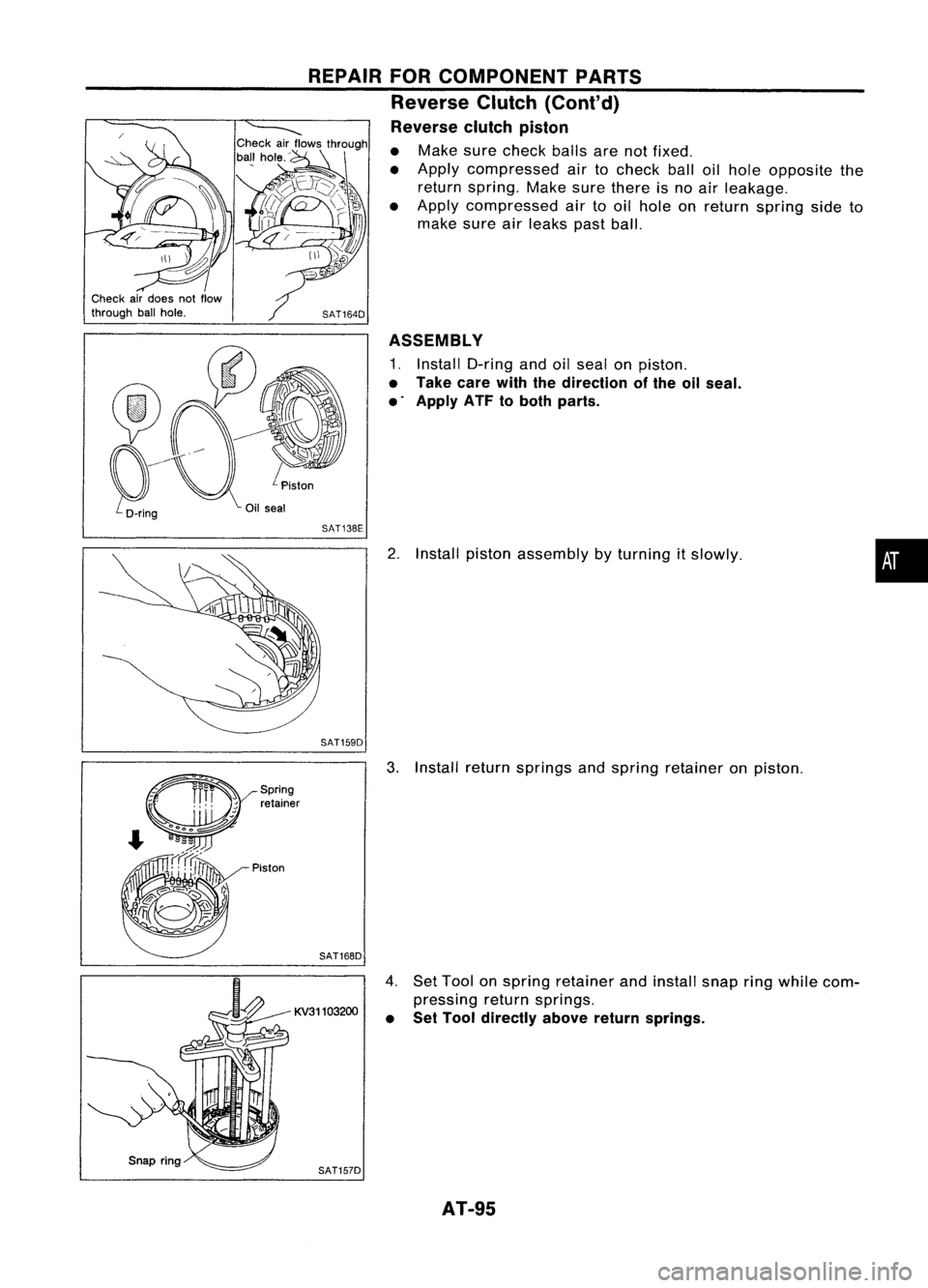

Reverse clutchpiston

• Make surecheck ballsarenotfixed.

• Apply compressed airtocheck balloilhole opposite the

return spring. Makesurethere isno air leakage.

• Apply compressed airtooil hole onreturn spring sideto

make sureairleaks pastball.

SAT164D ASSEMBLY

1. Install O-ring andoilseal onpiston.

• Take carewiththedirection ofthe oilseal.

• Apply ATFtoboth parts.

Oil seal

SAT138E

2.Install piston assembly byturning itslowly.

SAT159D

•

Piston Spring

retainer

SAT168D

KV31103200

SAT157D

3.

Install return springs andspring retainer onpiston.

4. SetTool onspring retainer andinstall snapringwhile com-

pressing returnsprings.

• Set Tool directly abovereturnsprings.

AT-95

Page 96 of 1701

REPAIRFORCOMPONENT PARTS

Reverse Clutch(Cont'd)

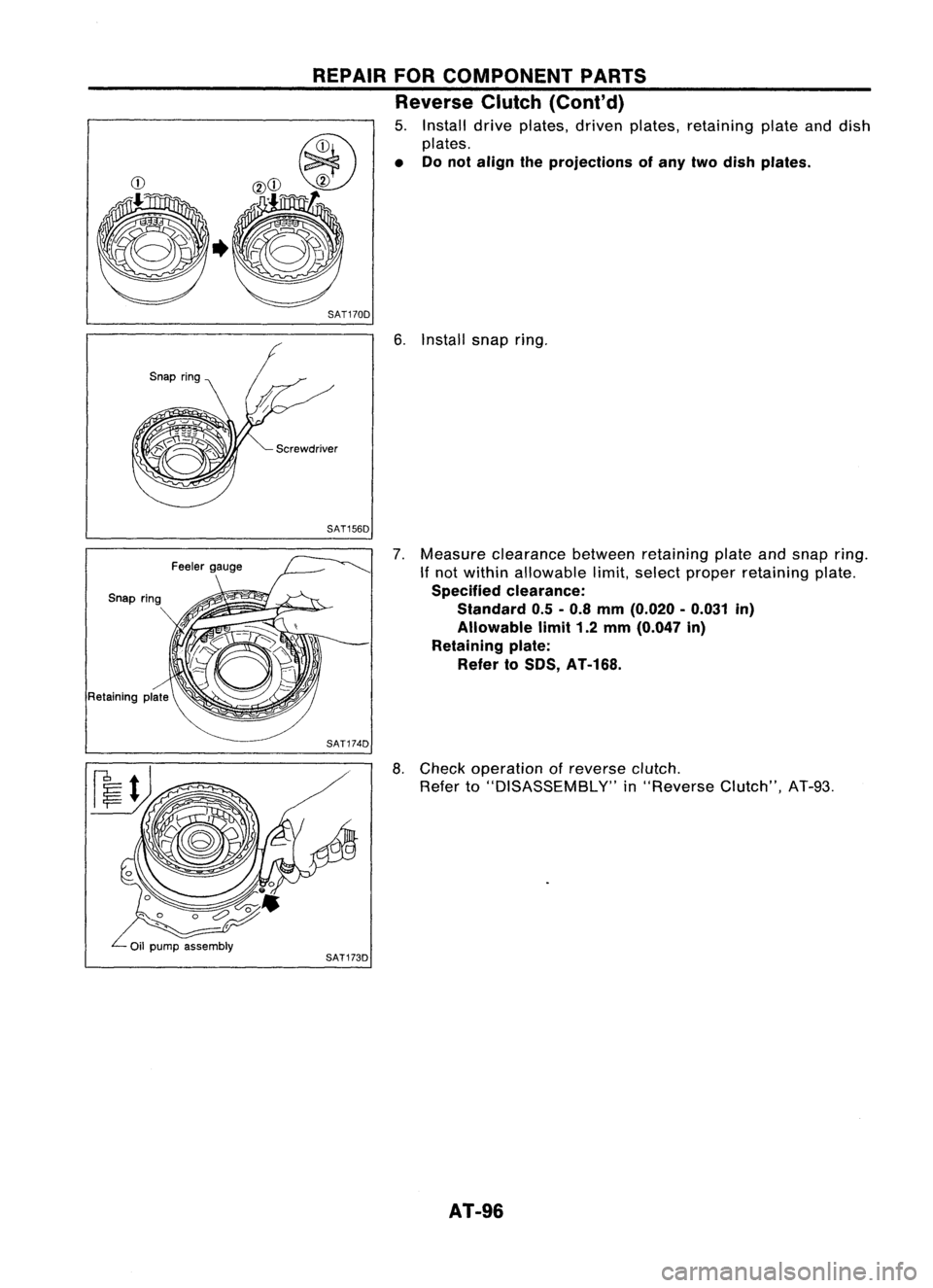

5. Install driveplates, drivenplates, retaining plateanddish

plates.

• Donot align theprojections ofany twodish plates.

~CD

evCD

?

.~

jjfu

SAT170D

6.Install snapring.

SAT156D

Retaining plate

7.

Measure clearance betweenretaining plateandsnap ring.

If

not within allowable limit,select proper retaining plate.

Specified clearance:

Standard 0.5-0.8 mm (0.020 -0.031 in)

Allowable limit1.2mm (0.047 in)

Retaining plate:

Refer toSOS, AT-168.

SAT174D

8.Check operation ofreverse clutch.

Refer to"DISASSEMBLY" in"Reverse Clutch",AT-93.

AT-96

Page 97 of 1701

REPAIRFORCOMPONENT PARTS

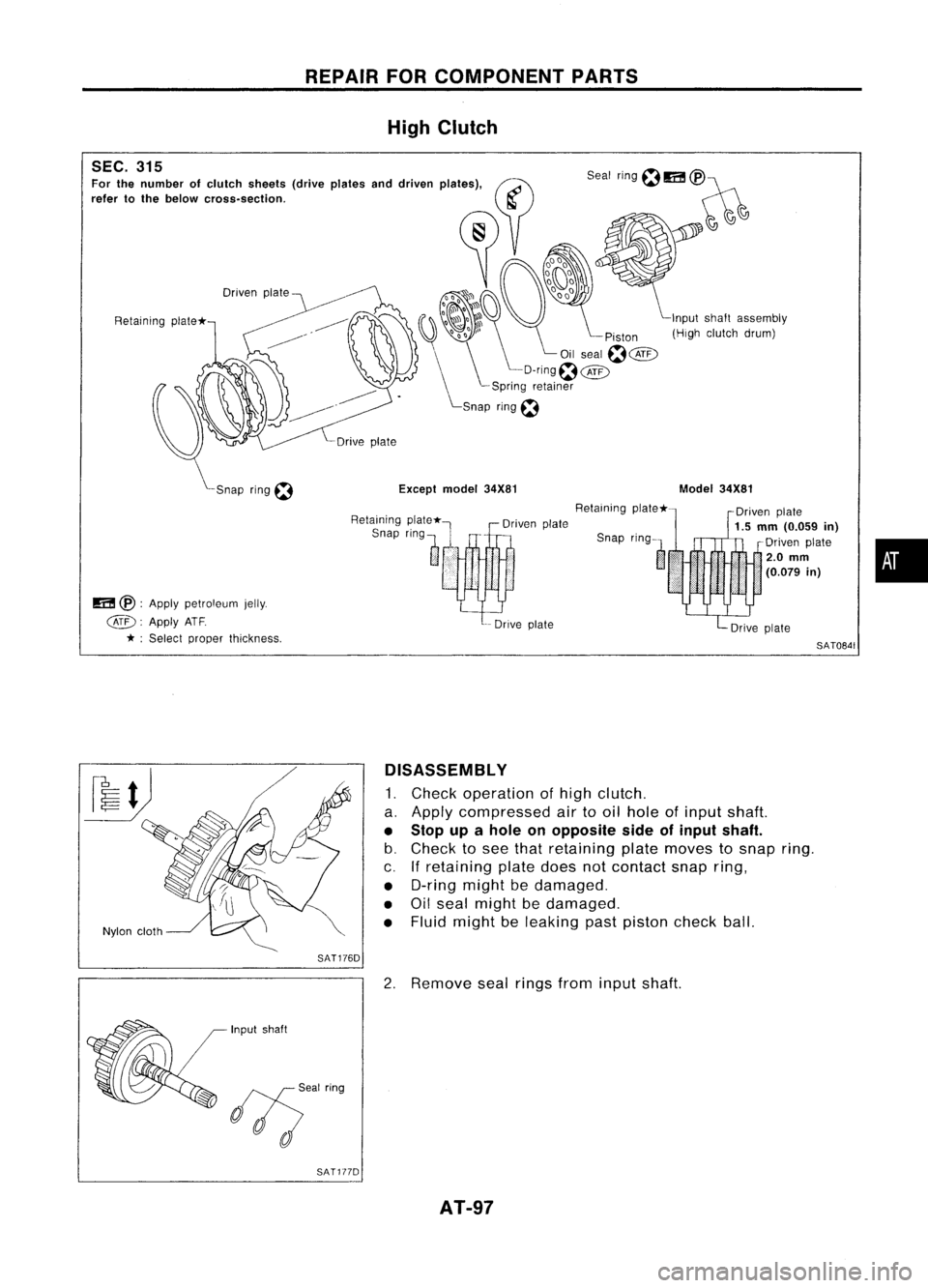

High Clutch

SEC. 315

Fa< th.oumh" of,Iuloh ,h.of. (d".,pI".... dd,I ...

PI'@(if)

,,',' to

fh'

"'ow

010.... ""00. ~)~

Driven

plate

Retaining plate* Input

shaft assembly

(High clutch drum)

Except model34X81

Snap ring

f:1

m

@•

Apply petroleum jelly.

@.

ApplyATF

* ;Select proper thickness. Retaining

Snap ring

l

Driven

plate

-- Drive plate Retaining

plate*-

Model

34X81

Driven

plate

1.5

mm

(0.059

in)

Driven plate

i

2.0

mm

•.•. (0.079

in)

SAT0841

•

Nylon cloth

SAT176D

Input shaft

1/5'"

hog

SAT177D DISASSEMBLY

1. Check operation ofhigh clutch.

a. Apply compressed airtooil hole ofinput shaft.

• Stop upahole onopposite sideofinput shaft.

b. Check tosee that retaining platemoves tosnap ring.

c. Ifretaining platedoesnotcontact snapring,

• O-ring mightbedamaged.

• Oilseal might bedamaged.

• Fluid might beleaking pastpiston checkball.

2. Remove sealrings frominput shaft.

AT-97

Page 98 of 1701

Snapring,

REPAIR

FORCOMPONENT PARTS

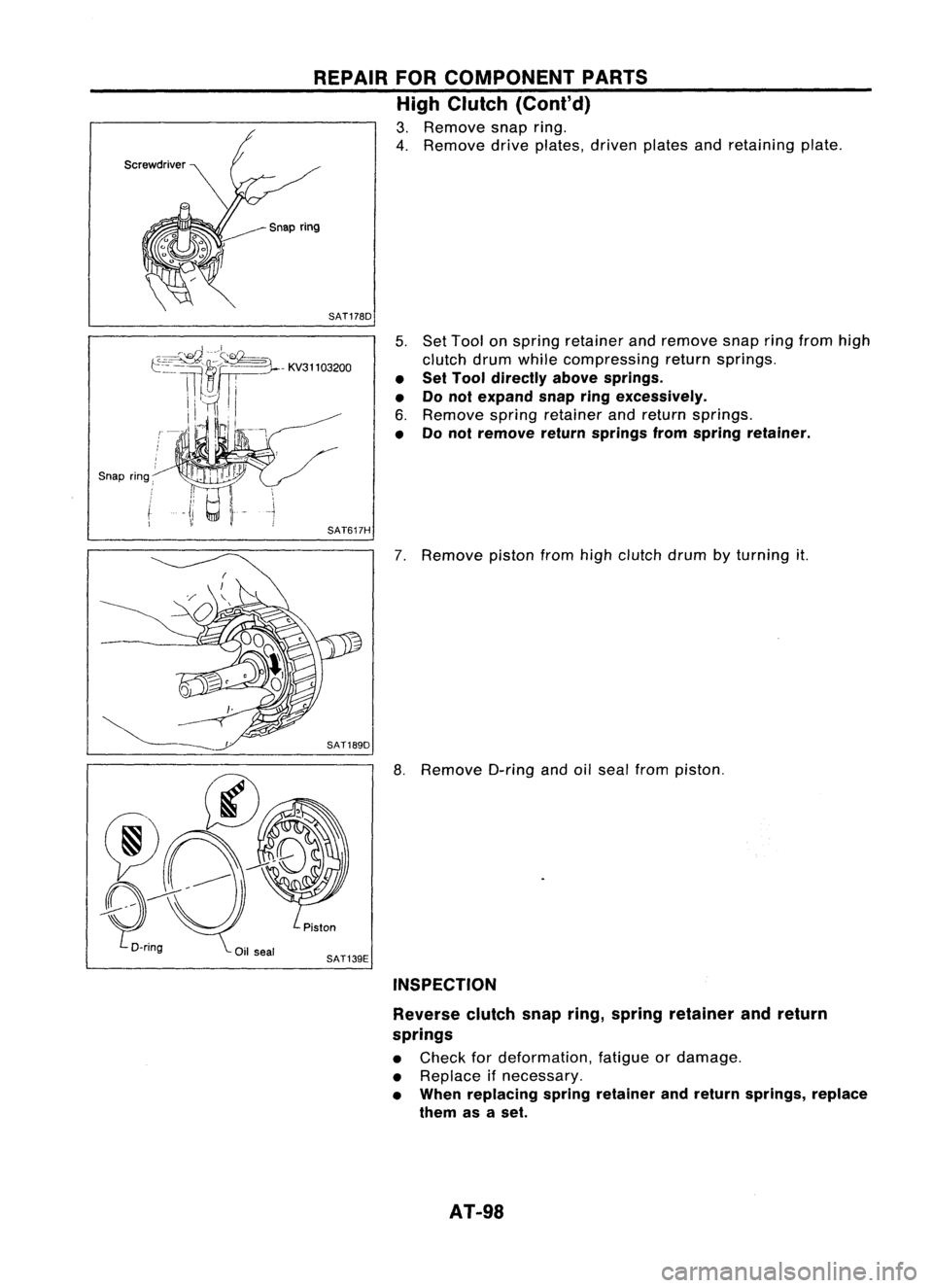

High Clutch (Cont'd)

3. Remove snapring.

4. Remove driveplates, drivenplatesandretaining plate.

SAT178D

5.Set Tool onspring retainer andremove snapringfrom high

clutch drumwhile compressing returnsprings.

• Set Tool directly abovesprings.

• Donot expand snap

ring

excessively.

6. Remove springretainer andreturn springs.

• Donot remove returnsprings fromspring retainer.

SAT617H

7.Remove pistonfromhighclutch drumbyturning it.

8. Remove O-ringandoilseal from piston.

SAT139E INSPECTION

Reverse clutchsnapring,spring retainer andreturn

springs

• Check fordeformation, fatigueordamage.

• Replace ifnecessary.

• When replacing springretainer andreturn springs, replace

them asaset.

AT-98

Page 99 of 1701

•

Seal

ringclearance

• Install newseal rings ontoinput shaft.

• Measure clearance betweensealringandring groove.

Standard clearance:

0.08 -0.23 mm(0.0031 -0.0091 in)

Allowable limit:

0.23 mm(0.0091 in)

• If

not within wearlimit,replace inputshaftassembly.

REPAIR

FORCOMPONENT PARTS

High Clutch (Cont'd)

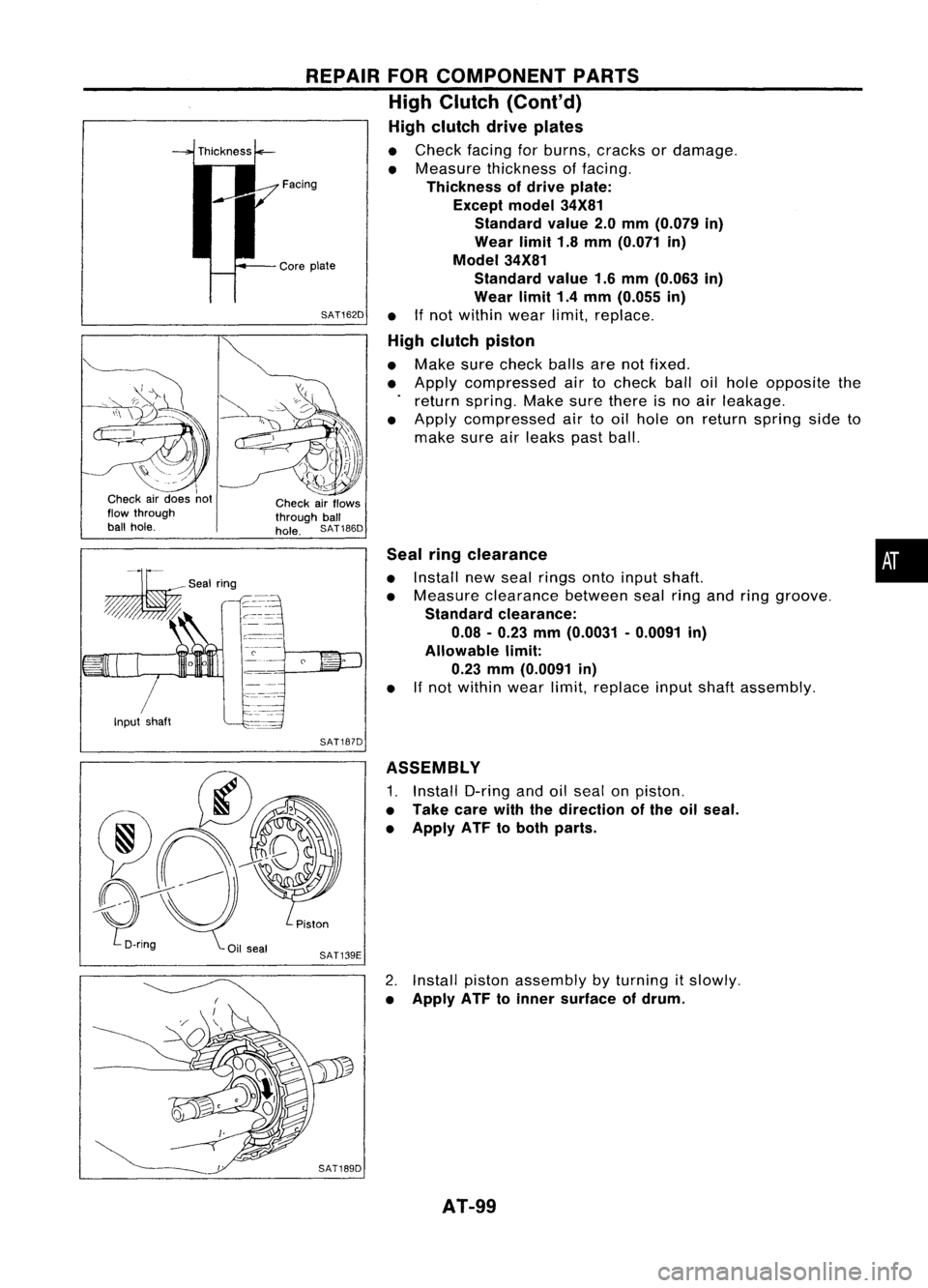

High clutch driveplates

• Check facingforburns, cracks ordamage.

• Measure thickness offacing.

Thickness ofdrive plate:

Except model34X81

Standard value2.0mm (0.079 in)

Wear limit1.8mm (0.071 in)

Model 34X81

Standard value1.6mm (0.063 in)

Wear limit1.4mm (0.055 in)

SAT162D •

Ifnot within wearlimit,replace.

High clutch piston

• Make surecheck ballsarenotfixed.

• Apply compressed airtocheck balloilhole opposite the

return spring. Makesurethere isno air leakage.

• Apply compressed airtooil hole onreturn spring sideto

make sureairleaks pastball.

Facing

Core plate

Check airflows

through ball

hole. SAT186D

Input shaft

I

I

Check airdoes not

flow through

ball hole.

SAT187D

ASSEMBLY

1. Install O-ringandoilseal onpiston.

• Take carewiththedirection ofthe oilseal.

• Apply ATFtoboth parts.

2. Install pistonassembly byturning itslowly.

• Apply ATFtoinner surface ofdrum.

AT-99

Page 100 of 1701

REPAIRFORCOMPONENT PARTS

High Clutch (Cont'd)

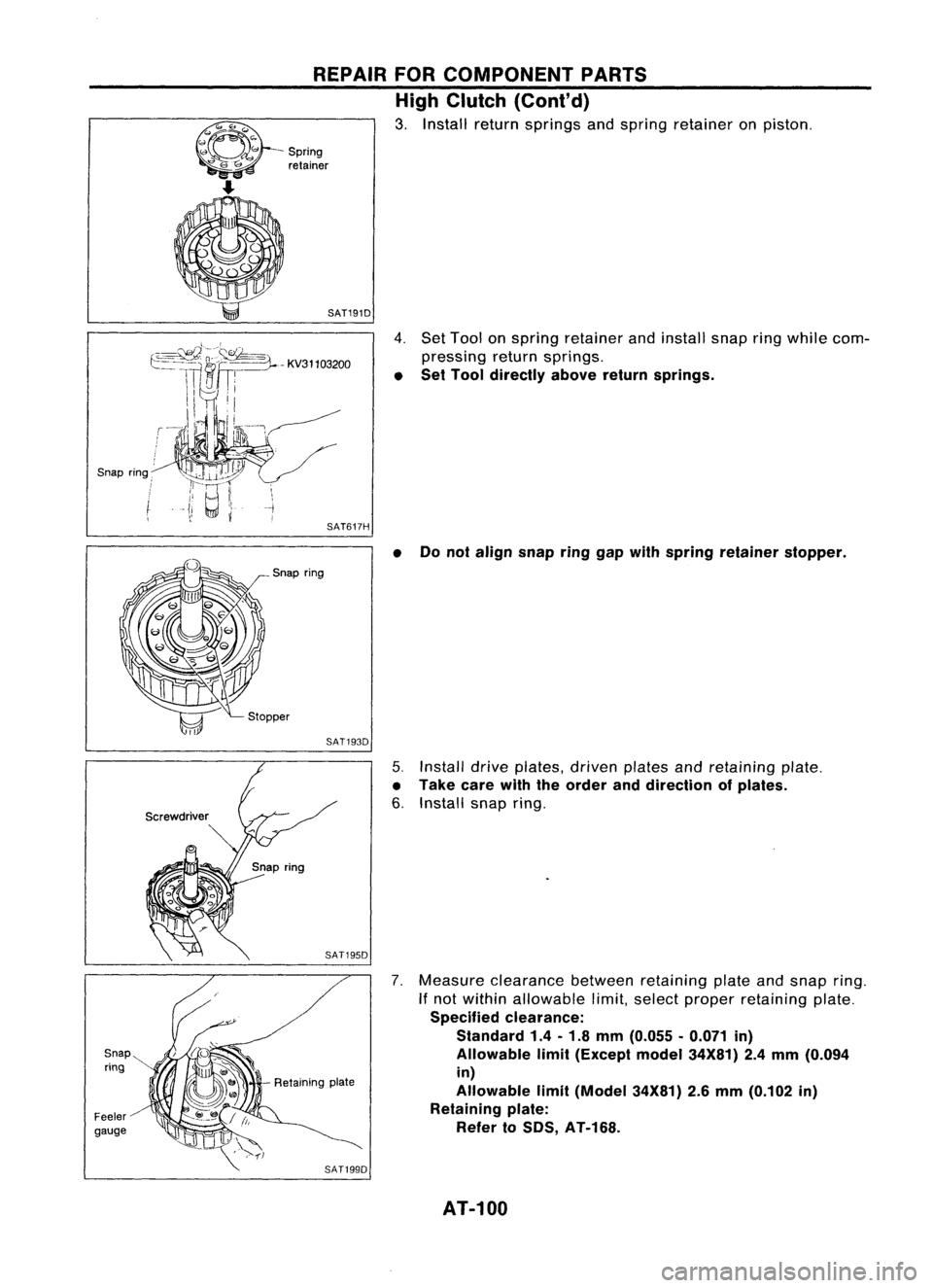

3. Install returnsprings andspring retainer onpiston.

- Spring

retainer

Snap ring:

Snap ring

Feeler

gauge

SAT191D

4.Set Toolan springretainer andinstall snapringwhile com-

pressing returnsprings.

• Set Tool directly abovereturnsprings.

--j

I

SAT617H

•Donot align snapringgapwith spring retainer stopper.

Snap ring

SAT1930

5.Install

drive

plates,

driven

platesandretaining plate.

• Take carewiththeorder anddirection ofplates.

6. Install snapring.

7. Measure clearance betweenretaining plateandsnap ring.

If not within allowable limit,select proper retaining plate.

Specified clearance:

Standard 1.4-1.8 mm {O.055 •0.071 in}

Allowable limit{Except model34X81} 2.4mm {O.094

in}

Allowable limit(Model 34X81)2.6mm (0.102 in)

Retaining plate:

Refer toSOS, AT-168.

SAT1990

AT-100