NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 111 of 1701

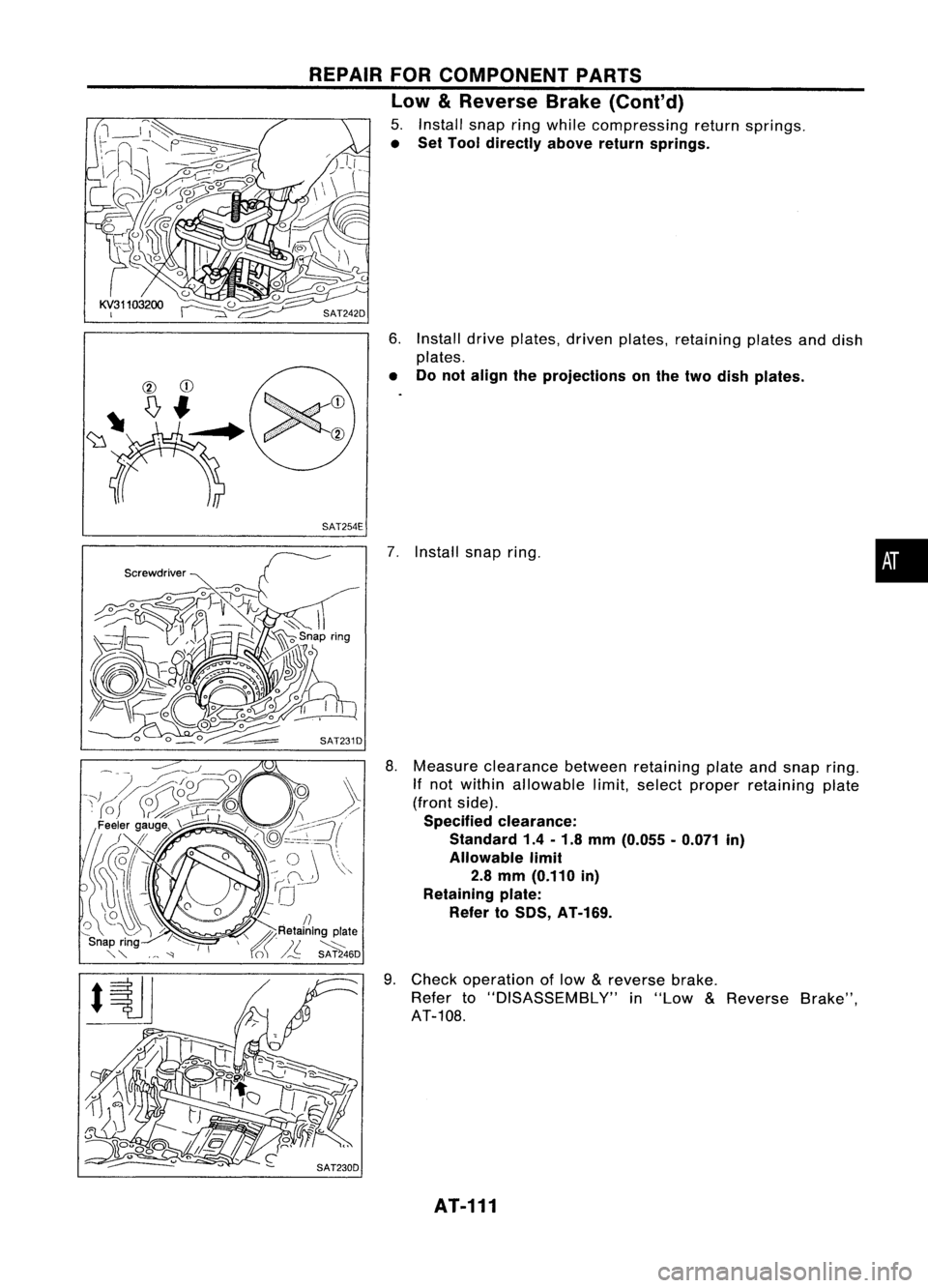

SAT254E

•

7.

Install snapring.

6.

Install driveplates, drivenplates, retaining platesanddish

plates.

• Donot align theprojections onthe two dish plates.

8. Measure clearance betweenretaining plateandsnap ring.

If not within allowable limit,select proper retaining plate

(front side).

Specified clearance:

Standard 1.4-1.8 mm (0.055 -0.071 in)

Allowable limit

2.8 mm (0.110 in)

Retaining plate:

Refer toSOS, AT-169.

9. Check operation oflow

&

reverse brake.

Refer to"DISASSEMBLY" in"Low

&

Reverse Brake",

AT-108.

REPAIR

FORCOMPONENT PARTS

Low

&

Reverse Brake(Cont'd)

5. Install snapringwhile compressing returnsprings.

• Set Tool directly abovereturnsprings.

/7

" gRetainin

g

plate

\ ~\ J/..

~6D

AT-111

Page 112 of 1701

REPAIRFORCOMPONENT PARTS

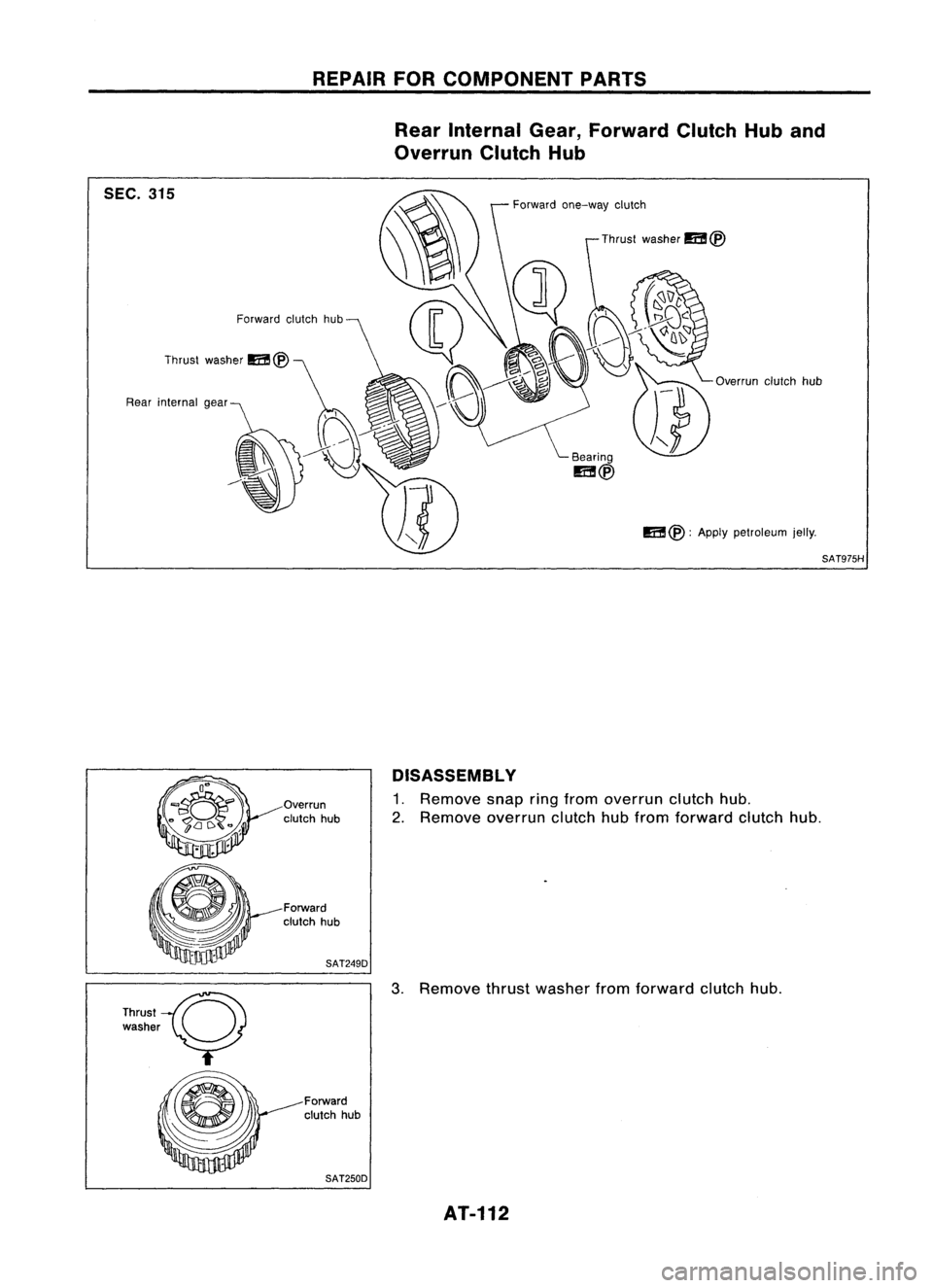

Rear Internal Gear,Forward ClutchHuband

Overrun ClutchHub

Overrunclutchhub

SEC.

315

Forwardclutchhub

Thrust washer

m@

Rear internal gear

Overrun

clutch hub

Forward

clutch hub

SAT249D

Forward

clutch hub

SAT250D Forward

one-way clutch

Thrust washer

m@

Bearing

m@

m@:

Applypetroleum jelly.

DISASSEMBL Y

1. Remove snapringfrom overrun clutchhub.

2. Remove overrunclutchhubfrom forward clutchhub.

3. Remove thrustwasher fromforward clutchhub.

AT-112 SAT975H

Page 113 of 1701

REPAIRFORCOMPONENT PARTS

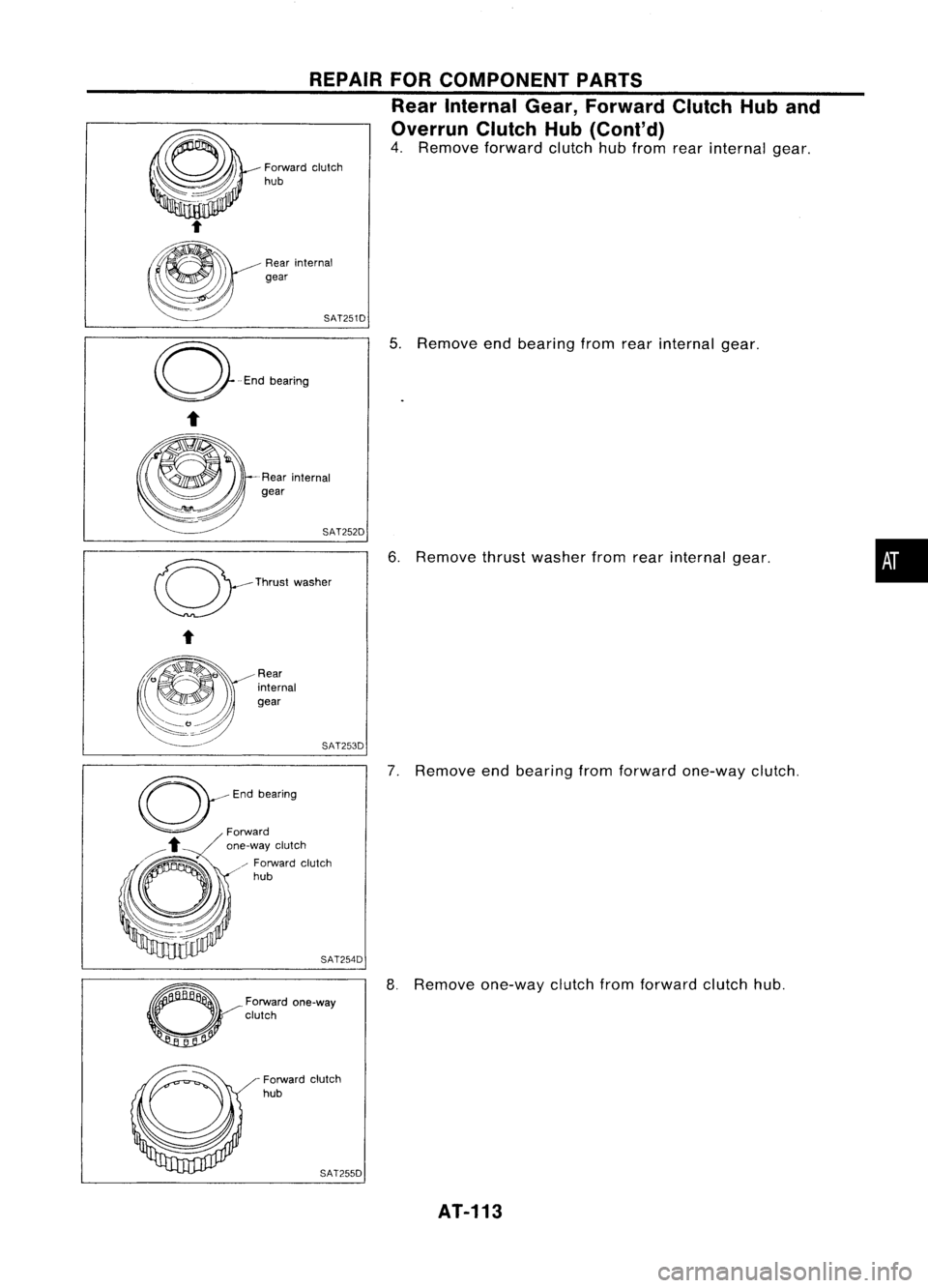

Rear Internal Gear,Forward ClutchHuband

Overrun ClutchHub(Conl'd)

4. Remove forwardclutchhubfrom rearinternal gear.

Forward clutch

hub

Rear internal

gear

SAT251D

Rear internal

gear

SAT252D

5.

Remove endbearing fromrearinternal gear.

6. Remove thrustwasher fromrearinternal gear.

•

Rear

internal

gear

SAT253D

SAT254D

O

Forwardone-way

~ clutch

[j

7.

Remove endbearing fromforward one-way clutch.

8. Remove one-way clutchfromforward clutchhub.

Forward clutch

hub

SAT255D AT-113

Page 114 of 1701

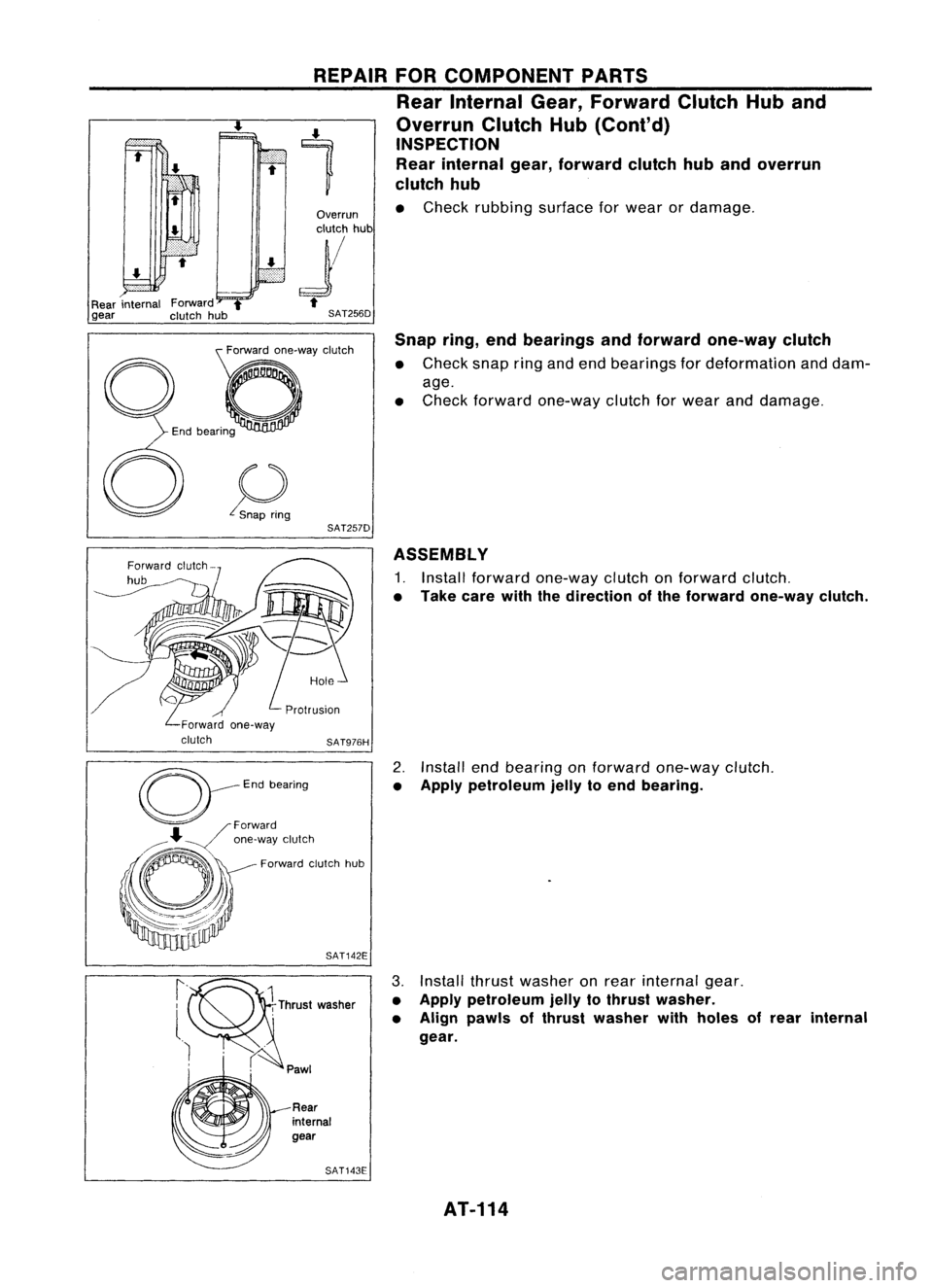

Snapring,endbearings andforward one-way clutch

• Check snapringandend bearings fordeformation anddam-

age.

• Check forward one-way clutchforwear anddamage.

SAT256D

REPAIR

FORCOMPONENT PARTS

Rear Internal Gear,Forward ClutchHuband

Overrun ClutchHub(Cont'd)

INSPECTION

Rear internal gear,forward clutchhuband overrun

clutch hub

• Check rubbing surfaceforwear ordamage.

i

SAT257D

Overrun

clutch hub

1

t

t

o

~~"'",'h

Endbeari~

Rear

Internal

gear

ASSEMBLY

1. Install forward one-way clutchonforward clutch.

• Take carewiththedirection ofthe forward one-way clutch.

2. Install endbearing onforward one-way clutch.

• Apply petroleum jellytoend bearing.

r'~l

l.

!

Thrust washer

']

.

.

, .Pawl

3.

Install thrustwasher onrear internal gear.

• Apply petroleum jellytothrust washer.

• Align pawls ofthrust washer withholes ofrear internal

gear.

Rear

internal

gear

SAT143E

AT-114

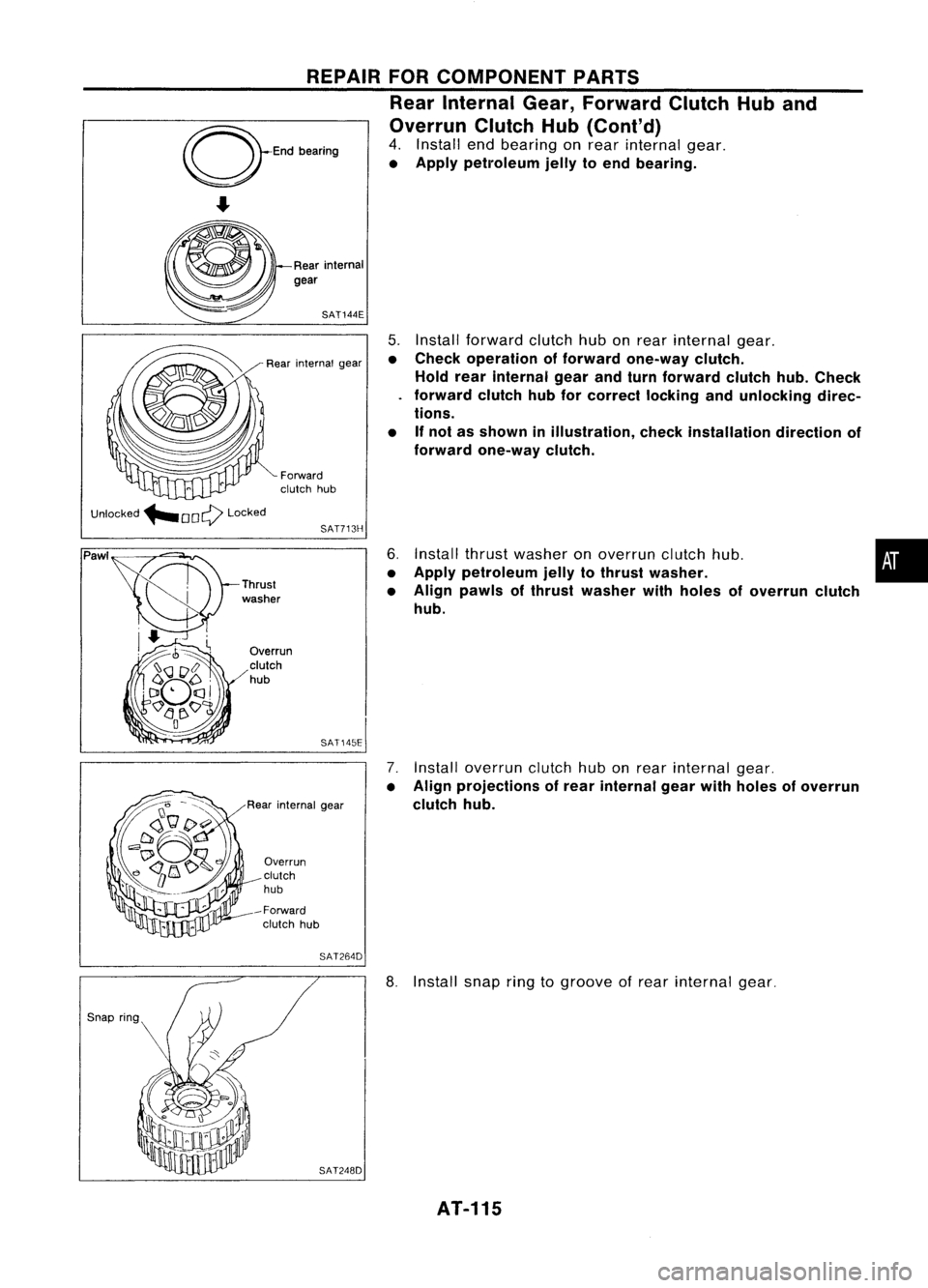

Page 115 of 1701

Rearinternal

gear

•

5.

Install forward clutchhubonrear internal gear.

• Check operation offorward one-way clutch.

Hold rearinternal gearandturn forward clutchhub.Check

forward clutchhubforcorrect lockingandunlocking direc-

tions.

• Ifnot asshown inillustration, checkinstallation directionof

forward one-way clutch.

6. Install thrustwasher onoverrun clutchhub.

• Apply petroleum jellytothrust washer.

• Align pawls ofthrust washer withholes ofoverrun clutch

hub.

7. Install overrun clutchhubonrear internal gear.

• Align projections ofrear internal gearwithholes ofoverrun

clutch hub.

SAT144E

REPAIR

FORCOMPONENT PARTS

Rear Internal Gear,Forward ClutchHuband

Overrun ClutchHub(Cont'd)

4. Install endbearing onrear internal gear.

• Apply petroleum jellytoend bearing.

SAT713H

Forward

clutch hub

Rear

internal gear

SAT145E

Overrun

clutch

hub

-Forward clutch hub

Overrun

clutch

hub

Rear internal gear

Unlocked

"'OOQ Locked

Pawl

SAT264D

SAT248D

8.

Install snapringtogroove ofrear internal gear.

AT-115

Page 116 of 1701

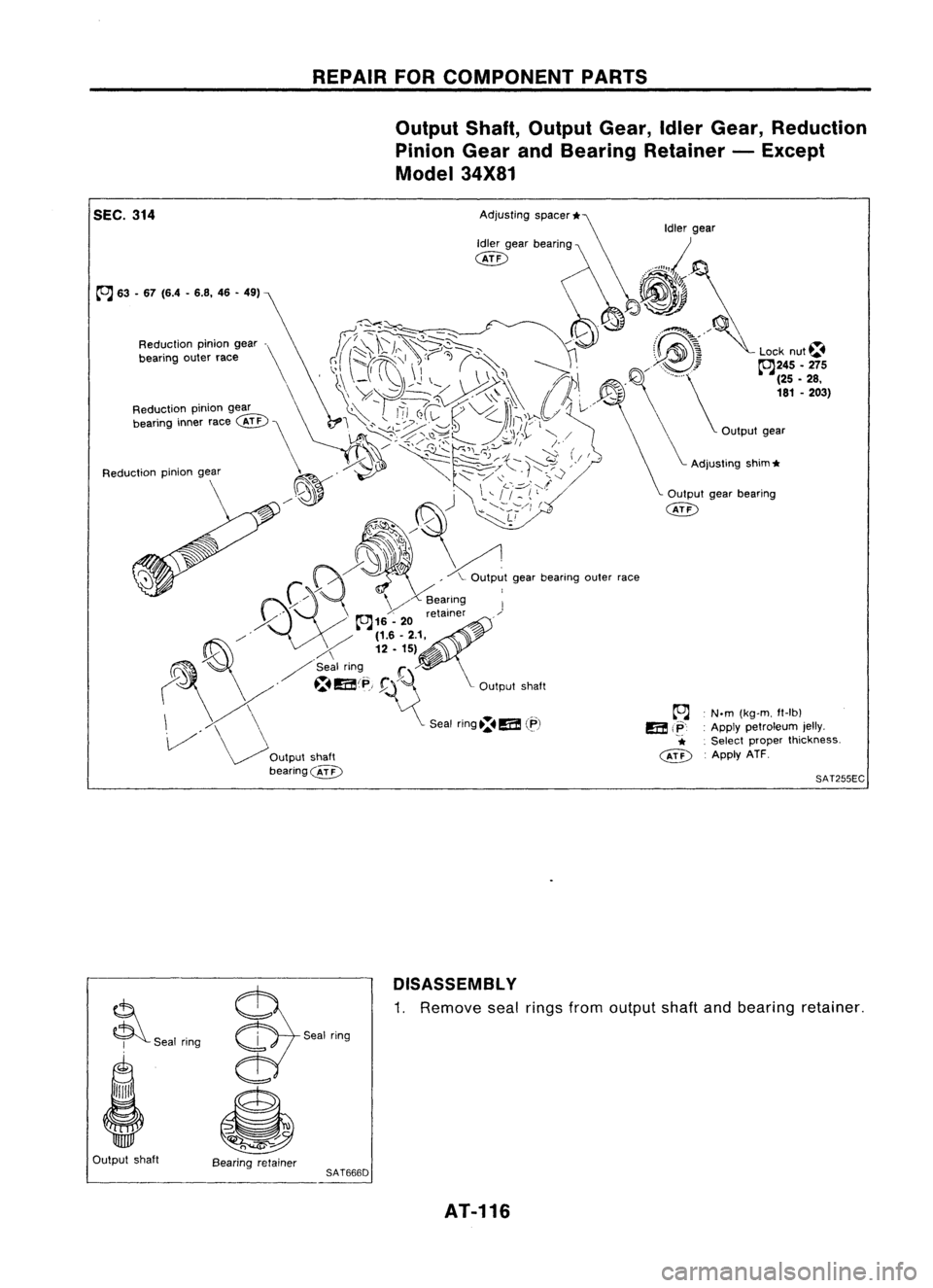

REPAIRFORCOMPONENT PARTS

Output Shaft,Output Gear,IdlerGear, Reduction

Pinion GearandBearing Retainer -Except

Model 34X81

SAT255EC

,

N.m (kg.m, tt.lb)

: Apply petroleum jelly,

, Select proper thickness,

: Apply ATF,

Idler

gear bearing

(ill)

Adjusting

spacer

*

Idlergear

""" ..,1\

~~

']I~

Reduction piniongear.

I?:(;J~~~" ,/(~)~'~~_

Locknut~

bearing outerrace \

,C~\(~~~~ljY:~ \~\

~o/p\ __

\;;~\J ~~:;.-

~5

~' \f_

2:;!_-----~~ ),

I

A .._-

181•

203)

Reduction piniongear ~

I~(l:

-:<~~)\~\.JV ~

beanng Innerrace@£)\ '\'-':" '..,-:;..?/ ,--,,~--

I-;r

l \

~~- ij",~l

-:'l")..-""/

Outputgear

...:" /"~,/ r::-,"";'--- -...,

~/I ;-

.. \: ~~ ~I':i~~/ ~((

yJ ", ---'..;-(~. ~~

/.1

,..:J

AdJustingshim

*

Reduction piniongear '-::::--_/ "

7',-.)

~ \'-.'.=;.--'--..1'

....-/ 1

o",.~)

~~;;;'~i/~

'r'.

~tgearbearing

(~i \

/l

A~\J))) .

y~,._,

R' .\..

OutP~t gearbearing outerrace

~;..-"" yX--;;earln

g;

X'

CO'.J16•

20 retainer ~/

/ "\..-/(1.6.2~"

~ /\12•15)

%l

~ ..~ /Sealring[~

(S \

V

~mp.

f{~

0"''"'

'h'"

\ Y

v \\

v\..

Sealring.~.

m

(p)

~'

\

-

..

Output shaft

bearing@£)

CO'.J

63•67 (6.4 •6.8, 46-49)

SEC.

314

$\s",

clog

-

Output

shaft

Bearingretainer Seal

ring

SAT666D DISASSEMBL

Y

1. Remove sealrings fromoutput shaftandbearing retainer.

AT-116

Page 117 of 1701

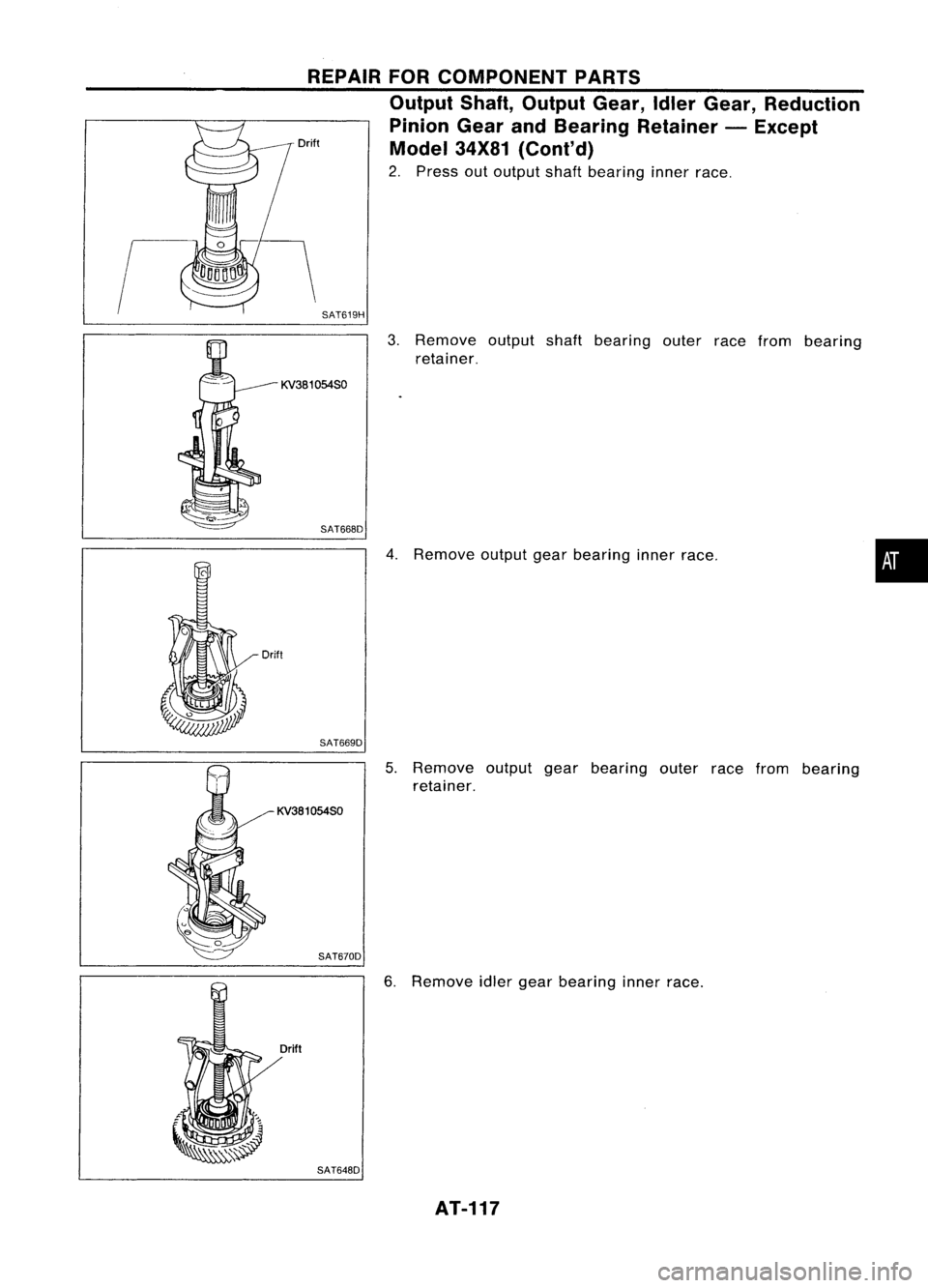

REPAIRFORCOMPONENT PARTS

Output Shaft,Output Gear,IdlerGear, Reduction

Pinion GearandBearing Retainer -Except

Model 34X81(Cont'd)

2. Press outoutput shaftbearing innerrace.

SAT619H

3.Remove outputshaftbearing outerracefrom bearing

retainer.

KV3B1054S0

SAT668D

4.Remove outputgearbearing innerrace.

Drift SAT669D

5.Remove outputgearbearing outerracefrom bearing

retainer.

KV3B1 054S0

SAT670D

6.Remove idlergear bearing innerrace.

SAT648D AT-117

•

Page 118 of 1701

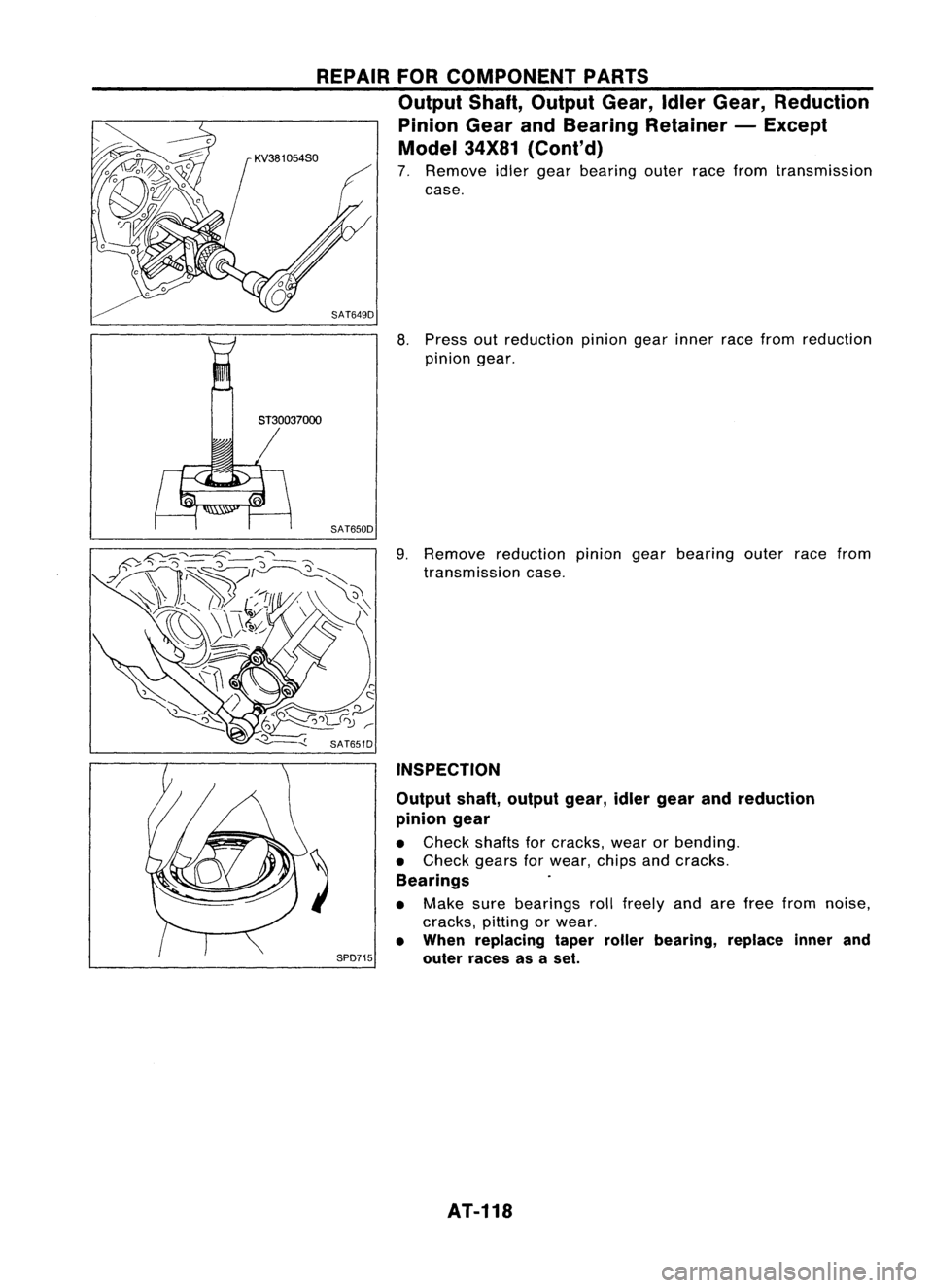

REPAIRFORCOMPONENT PARTS

Output Shaft,Output Gear,IdlerGear, Reduction

Pinion GearandBearing Retainer -Except

Model 34X81(Cont'd)

7. Remove idlergear bearing outerracefrom transmission

case.

SAT649D

8.Press outreduction piniongearinner racefrom reduction

pinion gear.

SAT650D

9.Remove reduction piniongearbearing outerracefrom

transmission case.

INSPECTION

Output shaft,output gear,idlergear andreduction

pinion gear

• Check shaftsforcracks, wearorbending.

• Check gearsforwear, chipsandcracks.

Bearings

• Make surebearings rollfreely andarefree from noise,

cracks, pittingorwear.

• When replacing taperroller bearing, replaceinnerand

SPD715

outerraces asaset.

AT-118

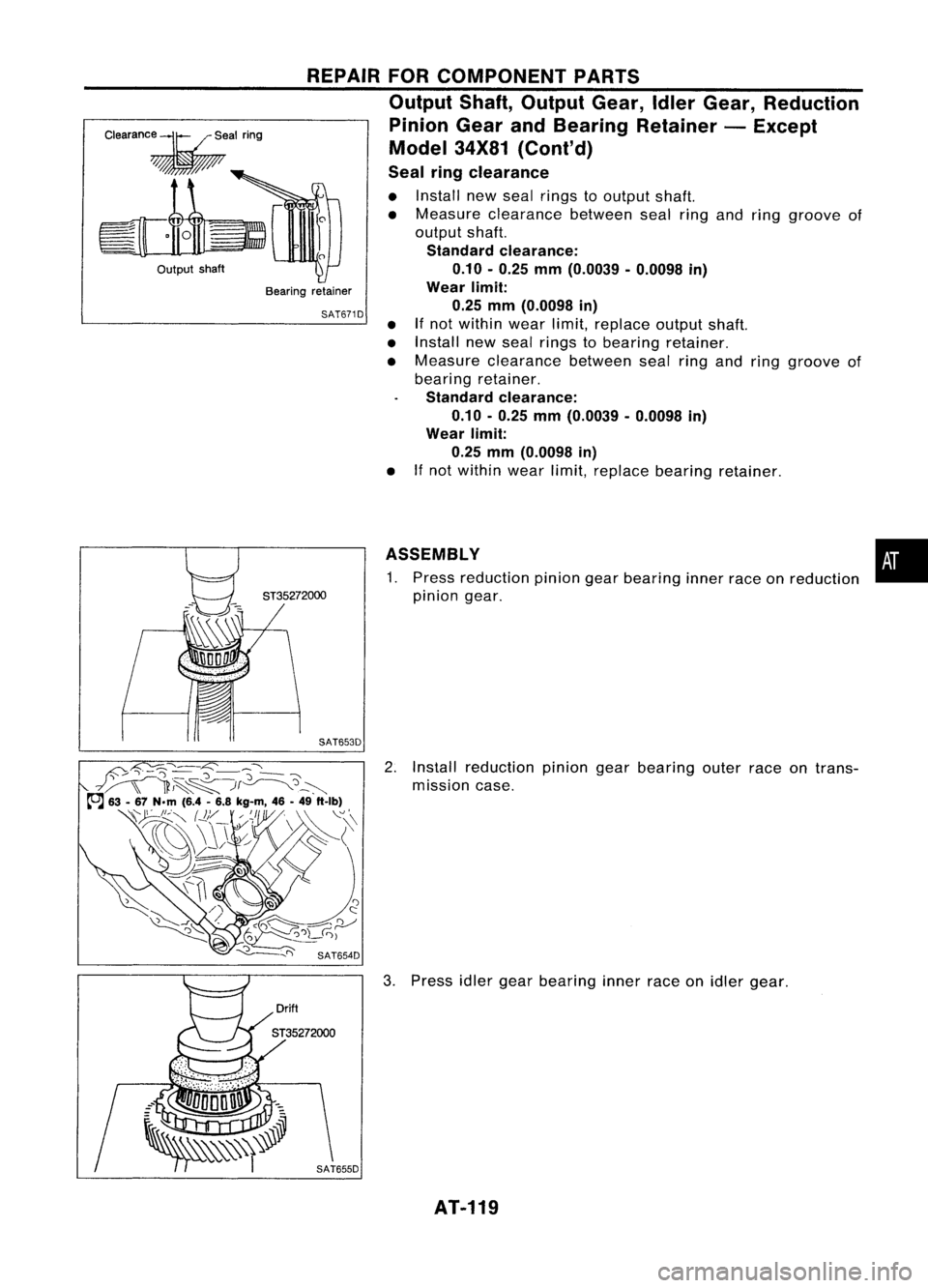

Page 119 of 1701

•

•

•

SAT6710

REPAIR

FORCOMPONENT PARTS

Output Shaft,Output Gear,IdlerGear, Reduction

Pinion GearandBearing Retainer -Except

Model 34X81(Cont'd)

Seal ringclearance

• Install newseal rings tooutput shaft.

• Measure clearance betweensealringandring groove of

output shaft.

Standard clearance:

0.10 -0.25 mm(0.0039 -0.0098 in)

Wear limit:

0.25 mm(0.0098 in)

If

not within wearlimit,replace outputshaft.

Install newseal rings tobearing retainer.

Measure clearance betweensealringandring groove of

bearing retainer.

Standard clearance:

0.10 -0.25 mm(0.0039 -0.0098 in)

Wear limit:

0.25 mm(0.0098 in)

• If

not within wearlimit,replace bearing retainer.

Bearing

retainer

Output

shaft

Clearanc.al

ring

ASSEMBLY •

1. Press reduction piniongearbearing innerraceonreduction

i

pinion gear.

2. Install reduction piniongearbearing outerraceontrans-

mission case.

3. Press idlergear bearing innerraceonidler gear.

AT-119

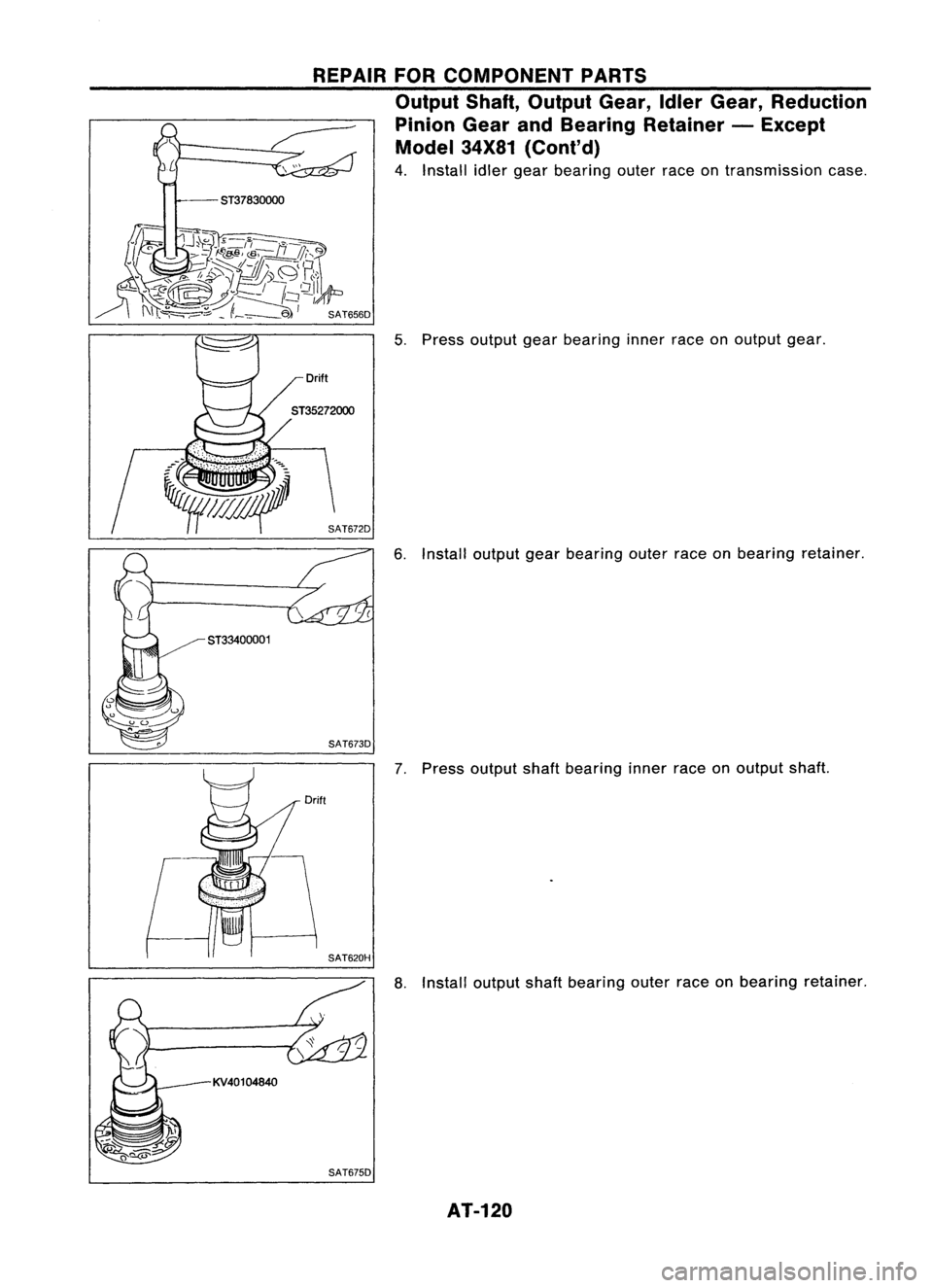

Page 120 of 1701

SAT673D

SAT620H

8.Install output shaftbearing outerraceonbearing retainer.

5.

Press output gearbearing innerraceonoutput gear.

7. Press output shaftbearing innerraceonoutput shaft.

6.

Install output gearbearing outerraceonbearing retainer.

REPAIR

FORCOMPONENT PARTS

Output Shaft,Output Gear,IdlerGear, Reduction

Pinion GearandBearing Retainer -Except

Model 34X81(Cont'd)

4. Install idlergear bearing outerraceontransmission case.

ST37830000

KV40104840

ST33400001

SAT675DAT-120