NISSAN ALMERA N15 1995 Manual Online

ALMERA N15 1995

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57349/w960_57349-0.png

NISSAN ALMERA N15 1995 Manual Online

Trending: oil dipstick, load capacity, Correct, inflation pressure, roof, Thermo, tow bar

Page 81 of 1701

REPAIRFORCOMPONENT PARTS

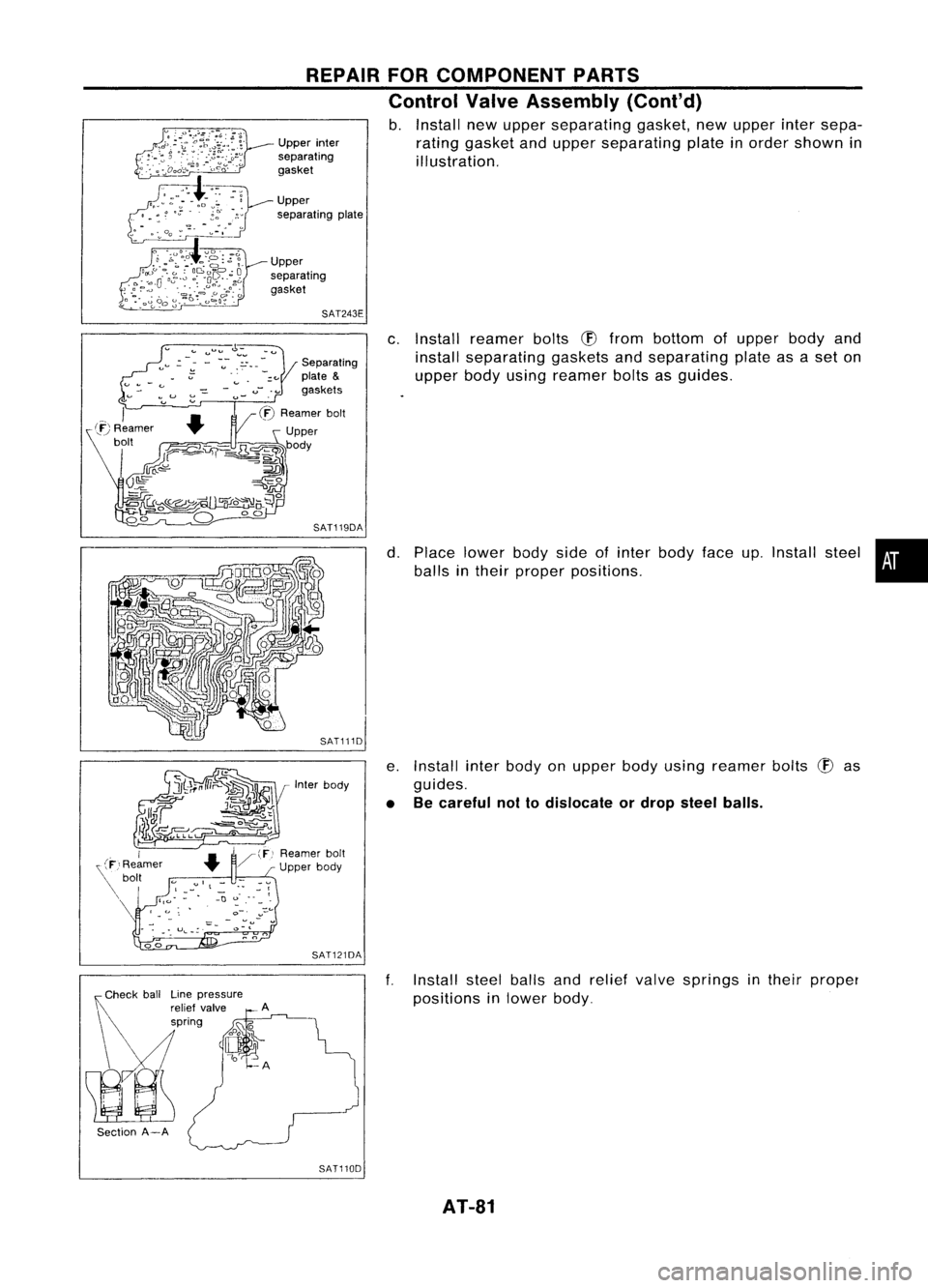

Control ValveAssembly (Cont'd)

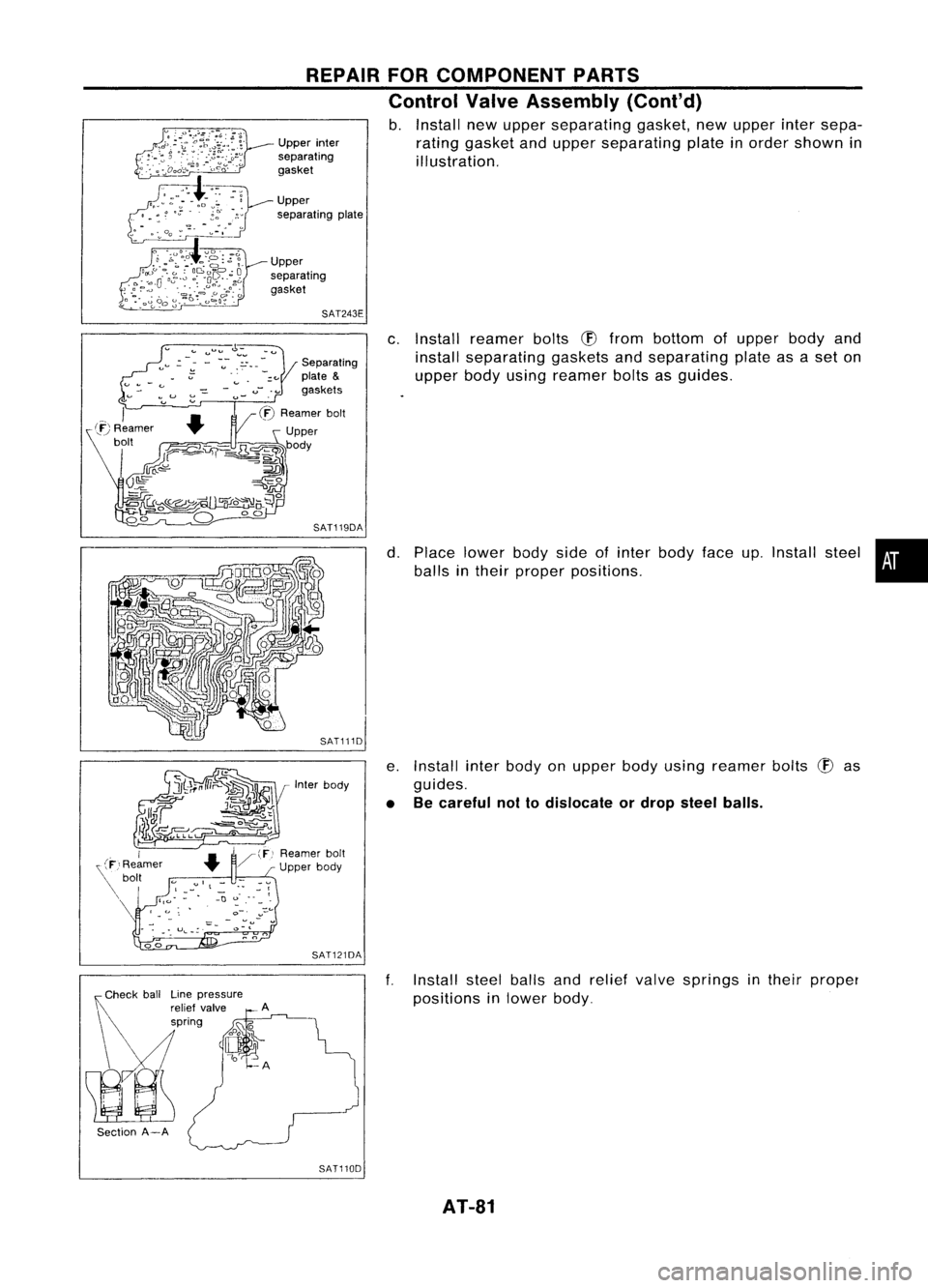

b. Install newupper separating gasket,newupper intersepa-

rating gasket andupper separating plateinorder shown in

illustration.

Upper

separating

gasket

SAT243E

Section A-ALine

pressure

relief valve

spring Separating

plate

&

gaskets

SAT119DA

Inter body

SAT121DA

SAT110D

c.

Install reamer bolts

(!)

from bottom ofupper bodyand

install separating gasketsandseparating plateasaset on

upper bodyusing reamer boltsasguides.

d. Place lower bodysideofinter body faceup.Install steel•

balls intheir proper positions.

e. Install interbody onupper bodyusing reamer bolts

(!)

as

guides.

• Becareful nottodislocate ordrop steel balls.

f. Install steelballsandrelief valve springs intheir proper

positions inlower body.

AT-81

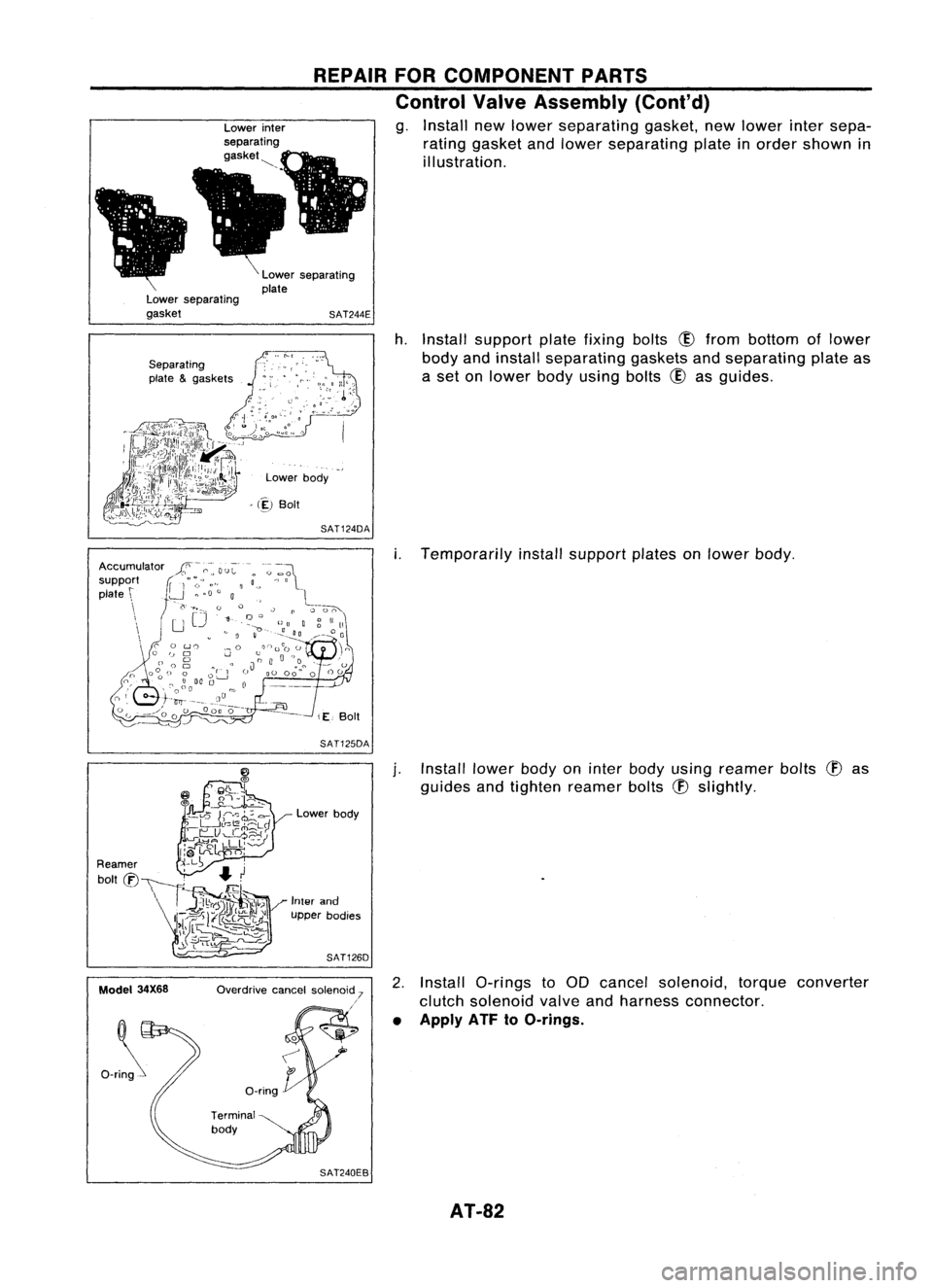

Page 82 of 1701

Lowerseparating

gasket REPAIR

FORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

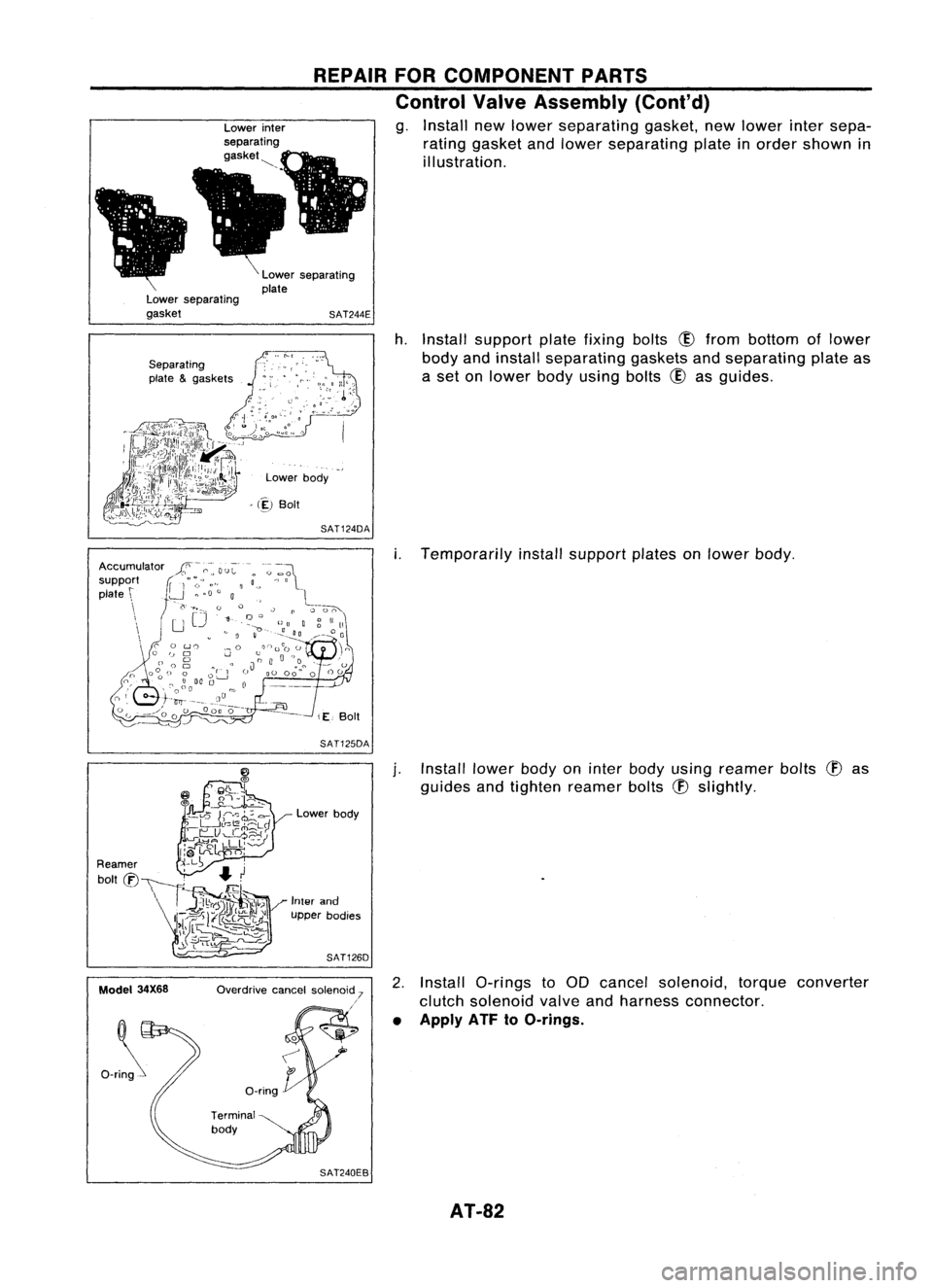

g. Install newlower separating gasket,newlower intersepa-

rating gasket andlower separating plateinorder shown in

illustration.

Lower separating

plate

SAT244E

Separating

plate &gaskets

Lowerbody

> (~)

Boit

SAT124DA

h.

Install support platefixing bolts

CID

from bottom oflower

body andinstall separating gasketsandseparating plateas

a set onlower bodyusing bolts

CID

asguides.

SAT125DA

i.

Temporarily installsupport platesonlower body.

Model 34X68 Lower

body

Inter and

upper bodies

SAT126D

Overdrive cancelsolenoid 7

.'

j.

Install lowerbodyoninter body using reamer bolts

(f)

as

guides andtighten reamer bolts

(f)

slightly.

2. Install a-rings toaD cancel solenoid, torqueconverter

clutch solenoid valveandharness connector.

• Apply ATF

toO-rings.

AT-82

Page 83 of 1701

REPAIRFORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

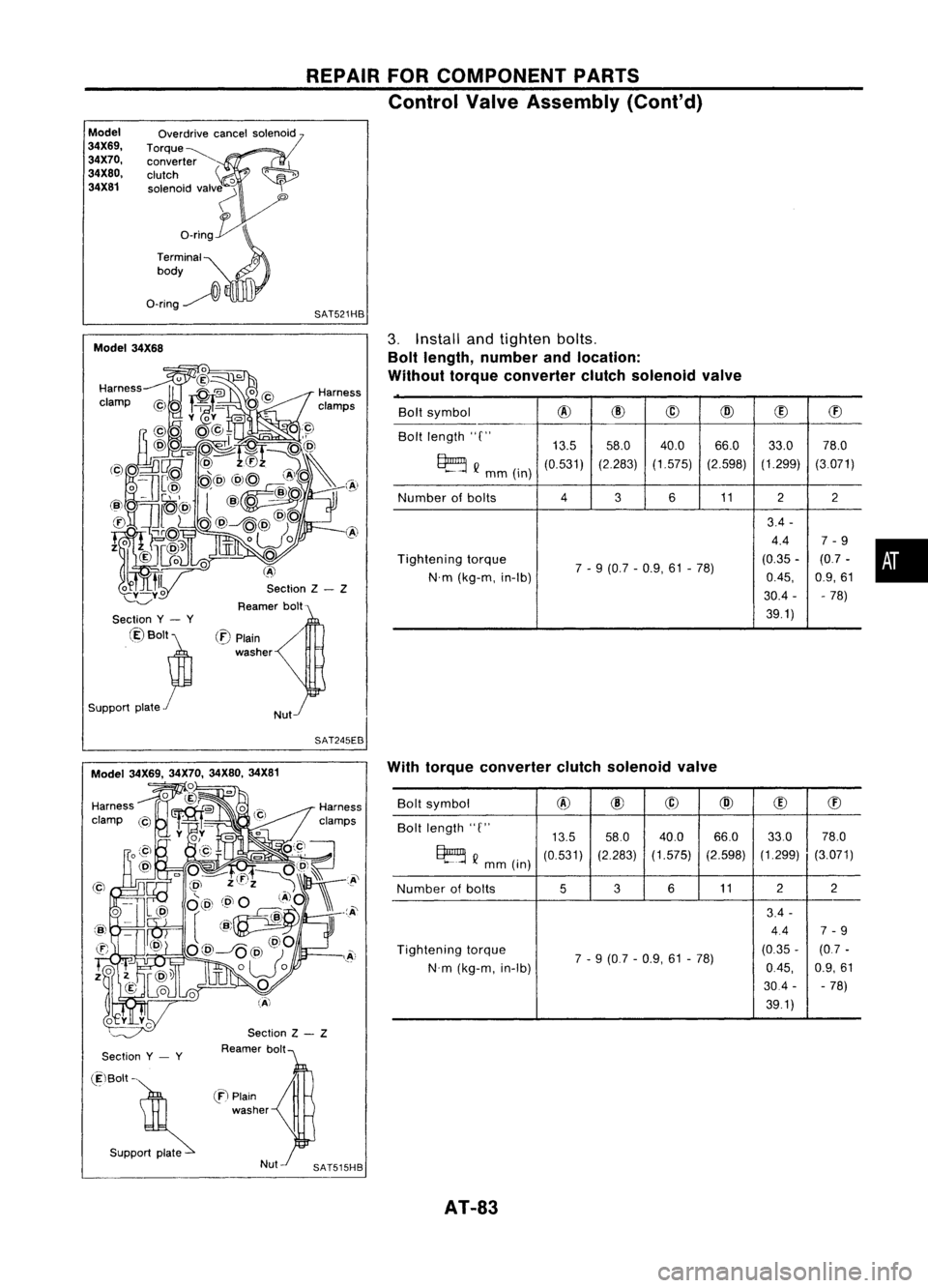

Model

34X69, 34X70,

34X80, 34X81 Overdrive

cancelsolenoid

Torque~ converter

clutch

'0

solenoid valv~

'"

o_rin~

Terminal

0

body

O-ring~

l\

SAT521HB

Section Z- Z

Reamer bolt

Model

34X68

•

Bolt

symbol

@

@

@

@

(!)

ffi

Bolt length "C"

13.558.0 40.0 66.0

33.078.0

~ Q

mm(in)

(0.531)

(2.283)(1.575) (2.598)(1.299)

(3.071)

Number ofbolts

4

3611

22

3.4 -

4.4 7-9

Tightening torque

7-9 (0.7 -0.9, 61-78) (0.35

-(0.7 -

N'm (kg-m, in-Ib)

0.45,

0.9,61

30.4 - -78)

39.1)

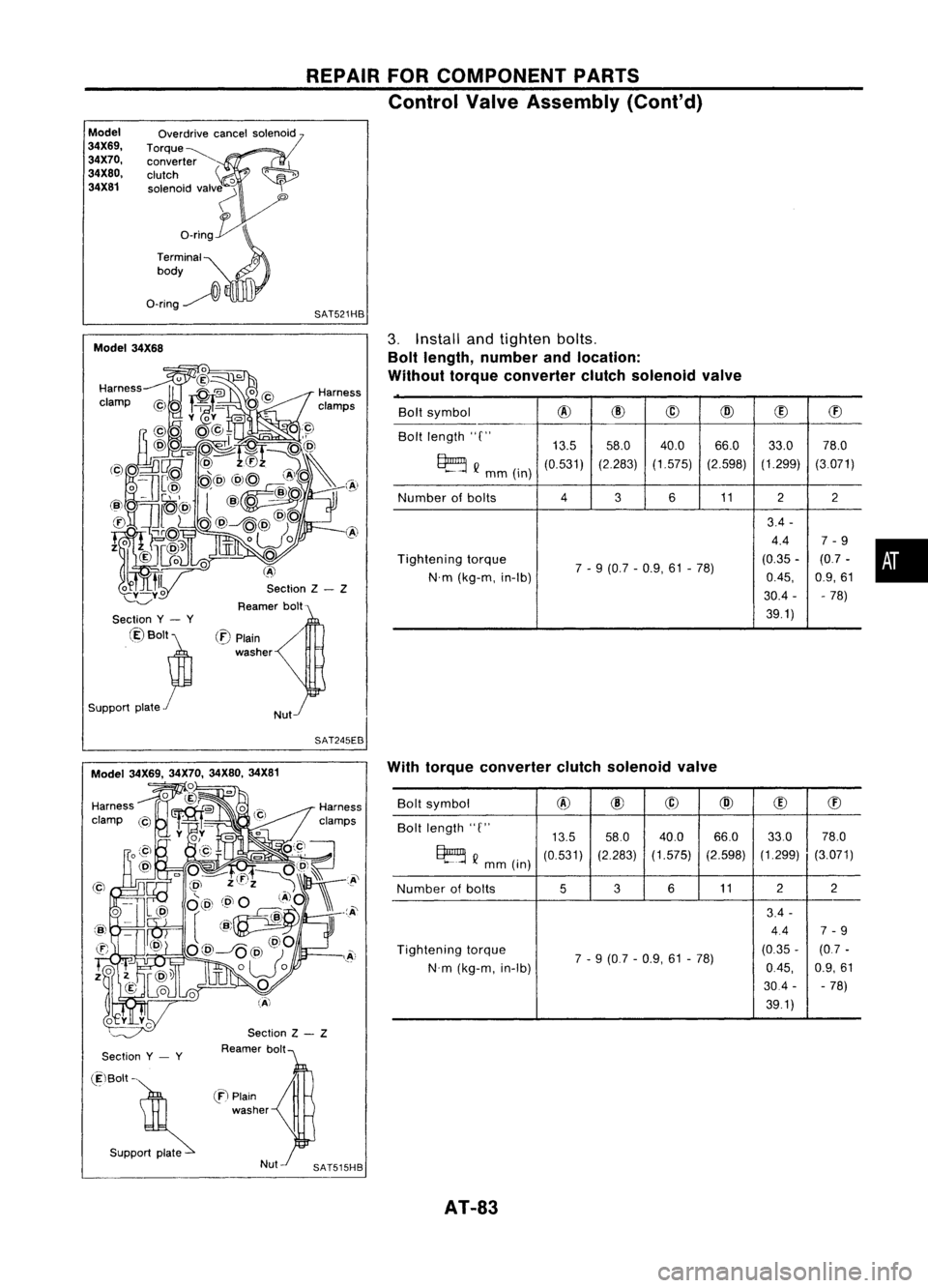

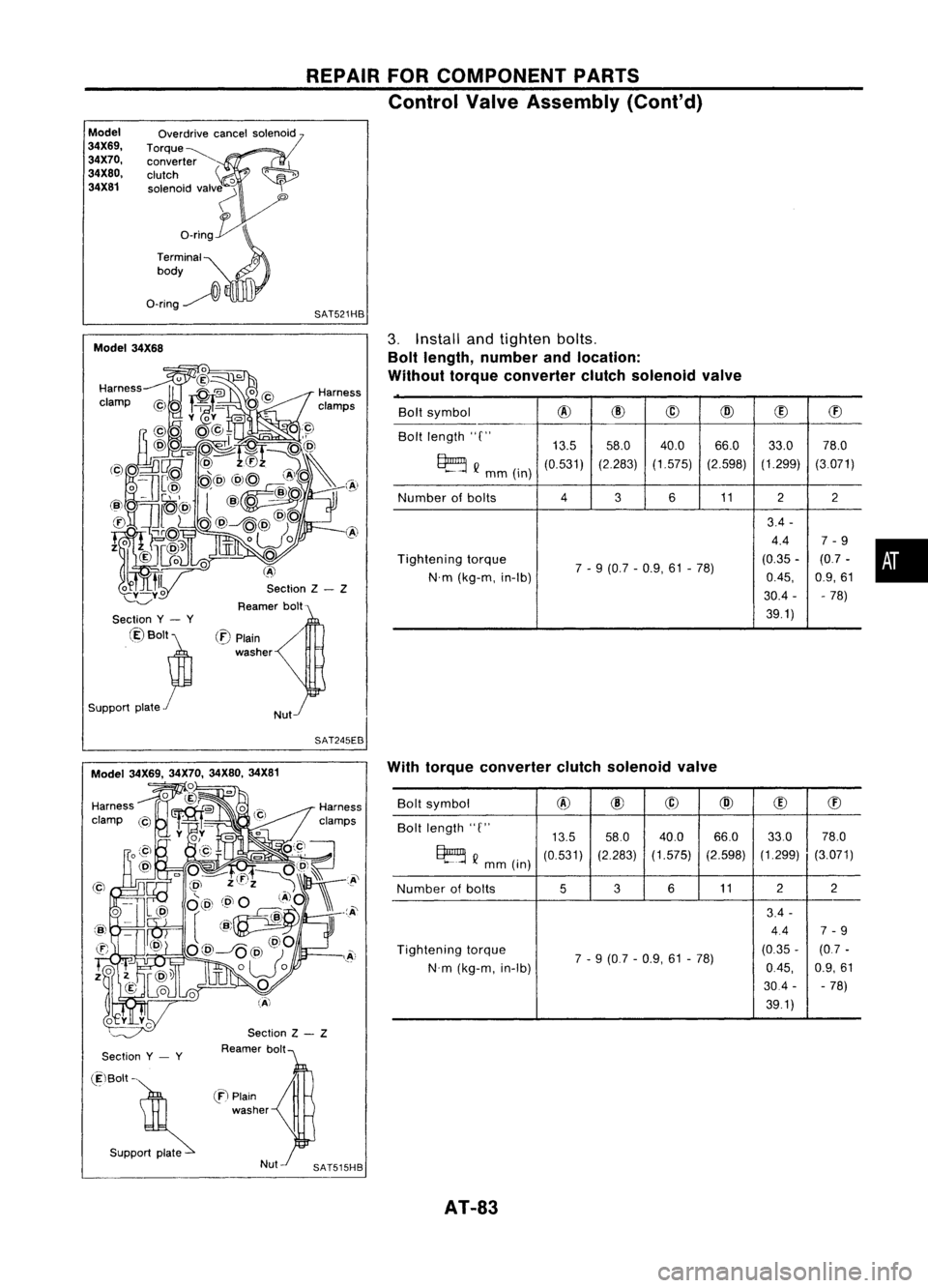

3.

Install andtighten bolts.

Bolt length, number andlocation:

Without torqueconverter clutchsolenoid valve

/

Nut

(:E)

Plain

washer

Section

y- y

@Bolt~

Support plate

r

SAT245EB

Section

y- y

Section

Z- Z

Reamer bolt With

torque converter clutchsolenoid valve

Bolt symbol

@

@

@

@

(!)

ffi

Bolt length "C"

13.558.0

40.0 66.033.0

78.0

~ Q

mm (in)

(0.531)

(2.283)

(1.575) (2.598)(1.299)

(3.071)

Number ofbolts

536

11 2

2

3.4 -

4.4 7-9

Tightening torque

7-9 (0.7 -0.9, 61-78) (0.35

-(0.7 -

N'm (kg-m, in-Ib)

0.45,

0.9,61

30.4 --

78)

39.1)

(ElBolt -

. S"PP~

en

Plain

washer

AT-83

Page 84 of 1701

REPAIRFORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

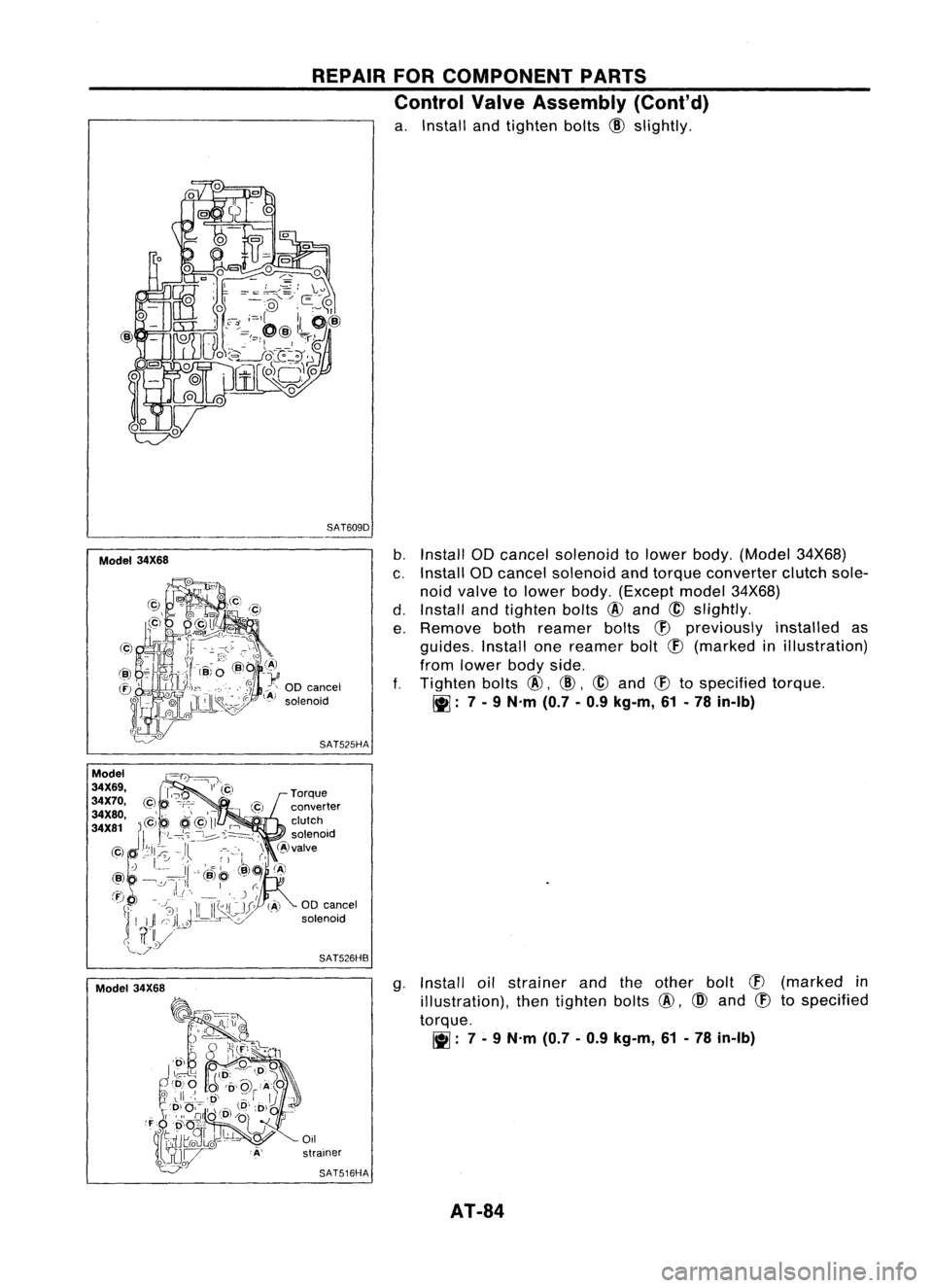

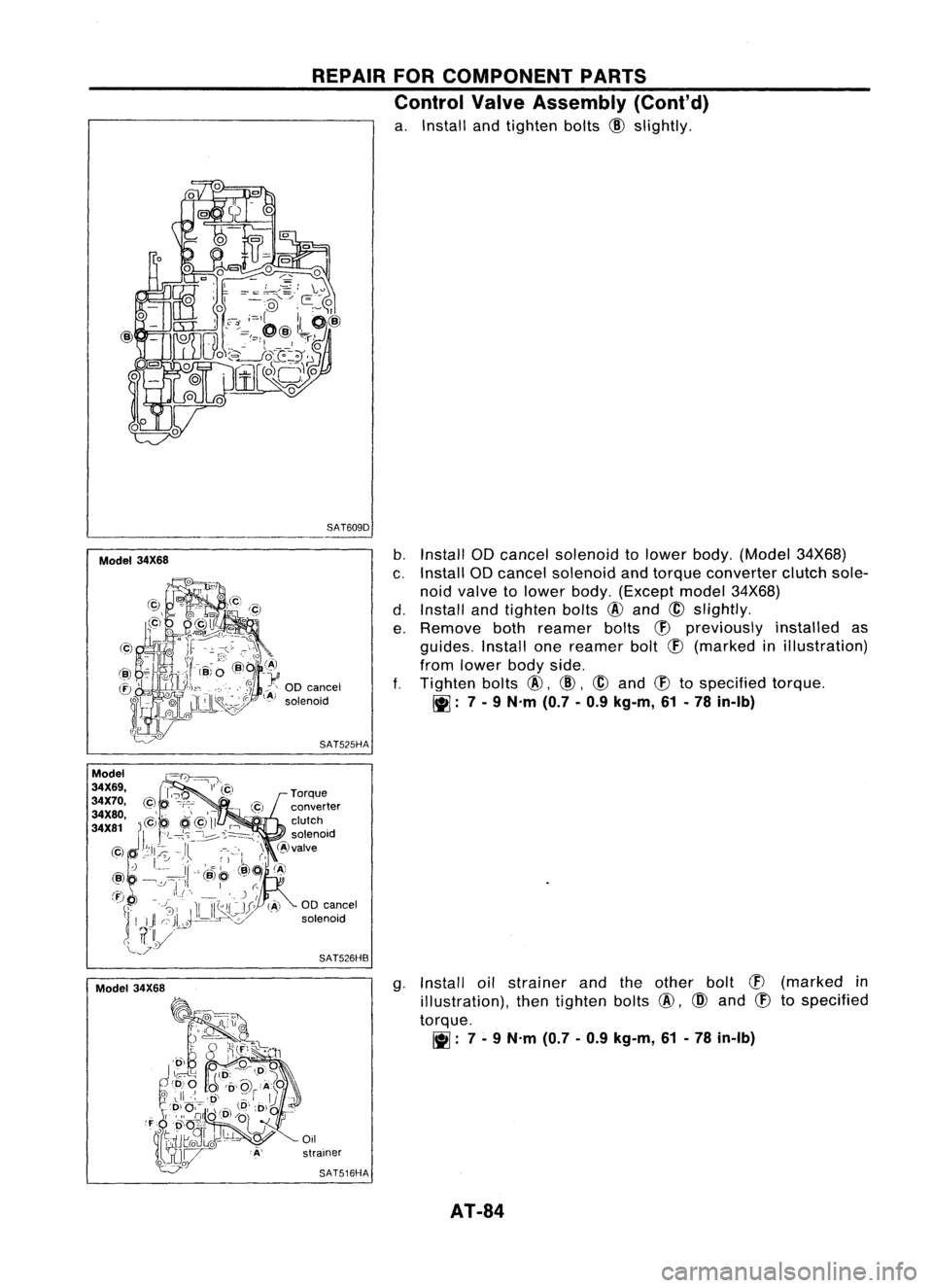

a. Install andtighten bolts

@

slightly.

SAT609D

Model 34X68

b.

Install ODcancel solenoid tolower body.(Model 34X68)

c. Install ODcancel solenoid andtorque converter clutchsole-

noid valve tolower body.(Except model34X68)

d. Install andtighten bolts

@

and

@

slightly.

e. Remove bothreamer bolts

(f)

previously installedas

guides. Installonereamer bolt

(f)

(marked inillustration)

from lower bodyside.

f.

Tighten bolts

@,

@,

@

and

(f)

tospecified torque.

~: 7-

9 N'm (0.7-0.9 kg-m, 61-78 in-Ib)

SAT525HA

00 cancel

solenoid

SAT526HB

g.Install oilstrainer andtheother bolt

CB

(marked in

illustration), thentighten bolts

@,

@

and

CB

tospecified

torque.

~: 7-

9 N'm (0.7-0.9 kg-m, 61-78 in-Ib)

Oil

strainer

SAT516HA

AT-84

Page 85 of 1701

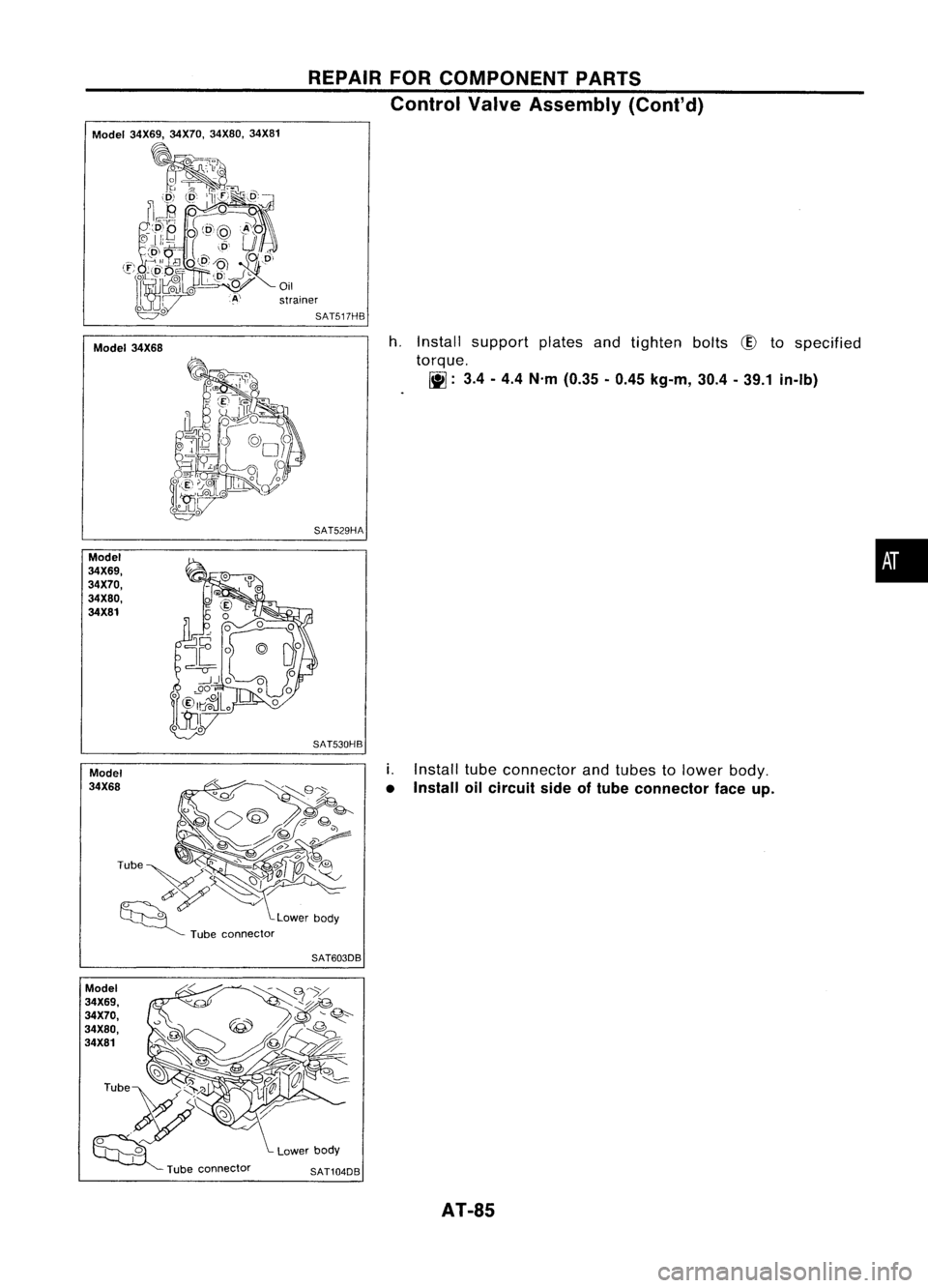

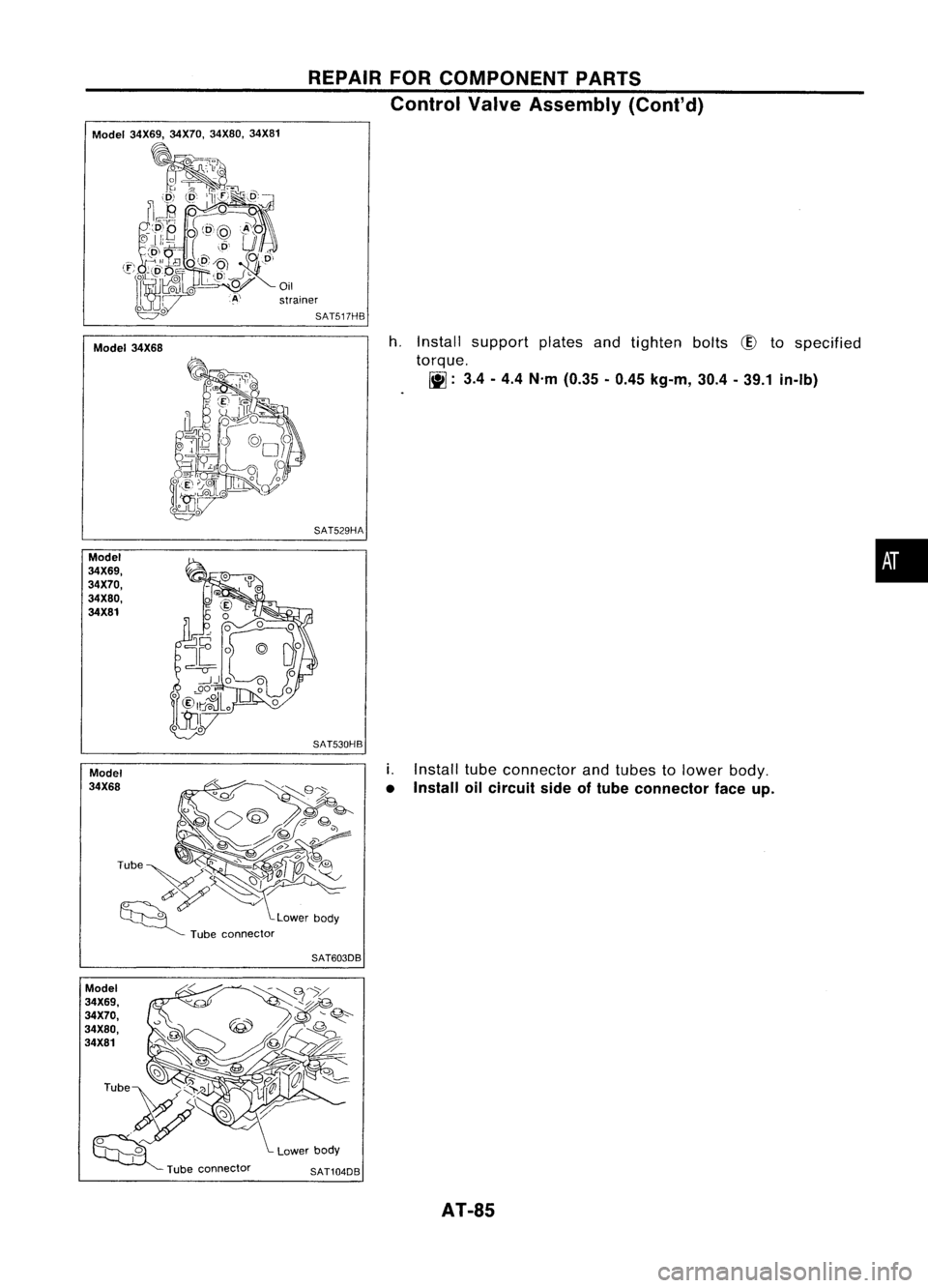

Model34X69, 34X70, 34X80,34X81 REPAIR

FORCOMPONENT PARTS

Control ValveAssembly (Cant'd)

Model 34X68

Model

34X69,

34X70,

34X80,

34X81

Model

34X68

Model

34X69,

34X70,

34X80,

34X81

h,

Install support platesandtighten bolts

CID

tospecified

torque.

[j]:

3.4-4.4 N'm (0.35 -0.45 kg-m, 30.4-39.1 in-Ib)

SAT529HA

i.

Install tubeconnector andtubes tolower body,

• Install oilcircuit sideoftube connector faceup.

SAT603DB

SAT104DB

AT-8S

•

Page 86 of 1701

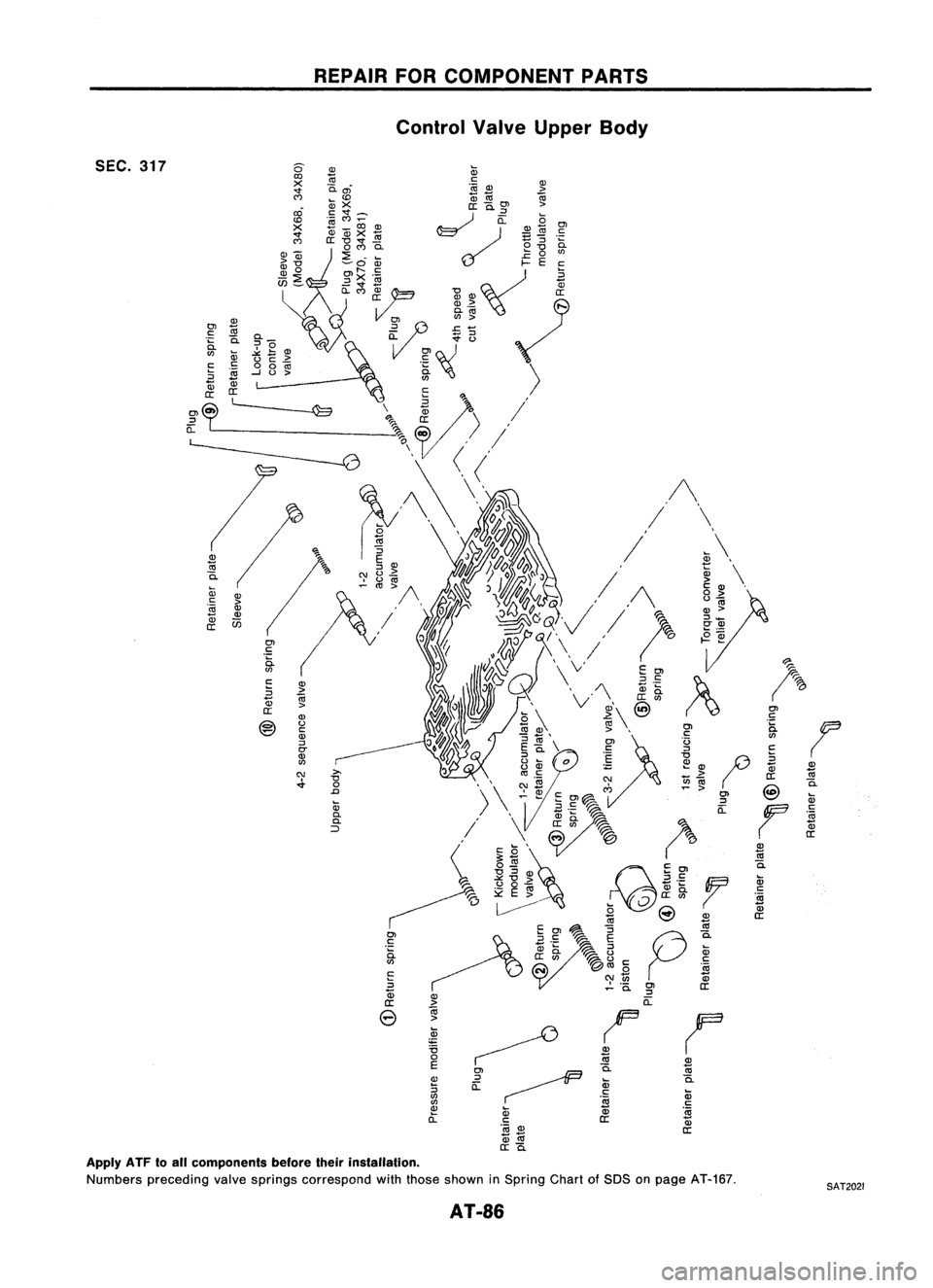

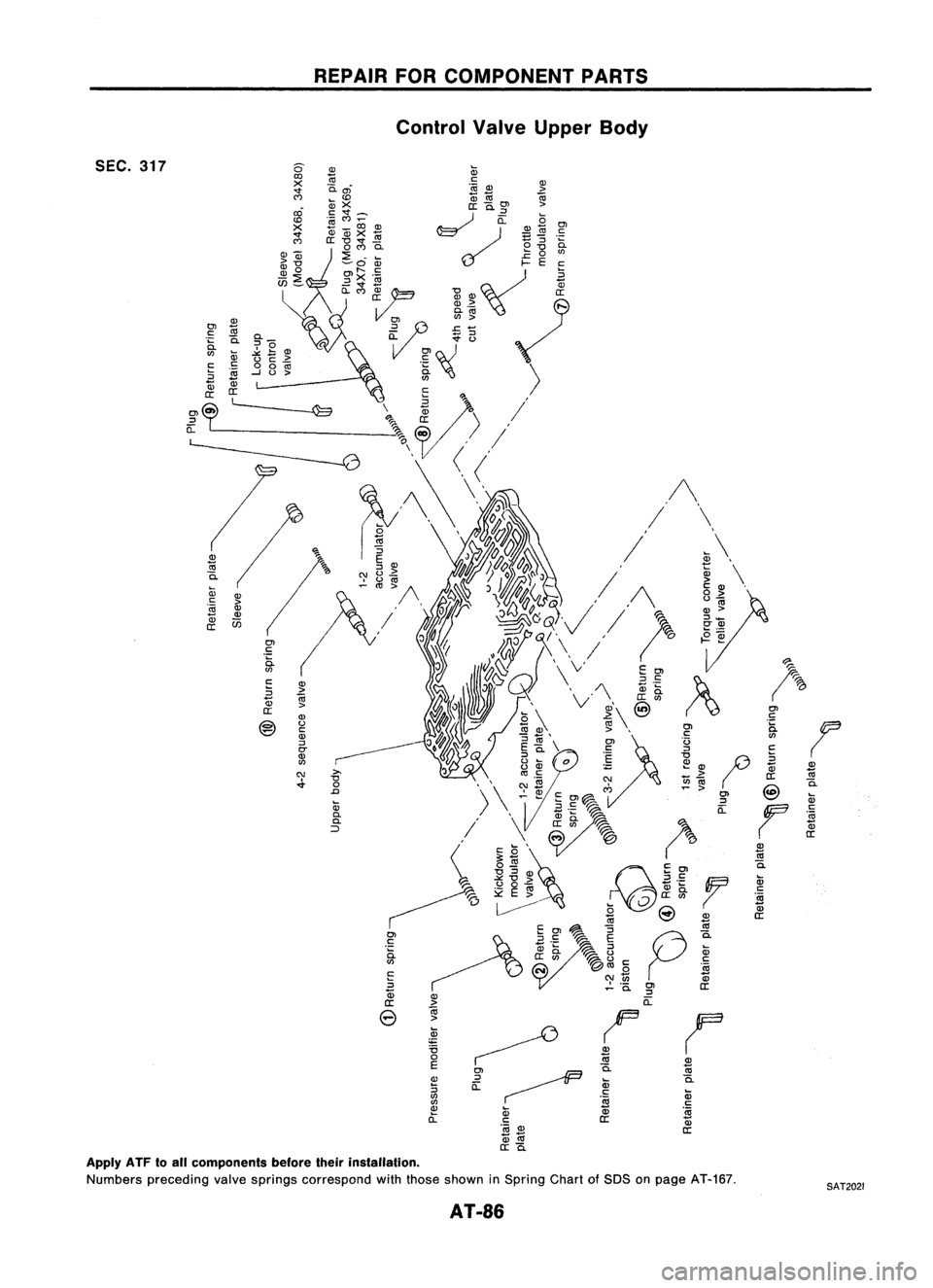

REPAIRFORCOMPONENT PARTS

Control ValveUpper Body

SEC. 317

OJ

Ql

c:

Cil

.~

c.

(J)

iii

>

u

c:

c: c:

00

Z

~

-J

u

>

Ql

c:~

5

~

>

a:

Ql

@

U

c:

Ql

::J

0-

Ql

(J)

C\I

.;.

iii

0.

0.

::>

OJ

c:

';:

iit

E

::J

~

a:

e

(I)

Cil

c.

iii

c:

'19

Ql

a:

2

co

c.

iii

c:

yg

Ql

a:

Apply ATFtoall components beforetheirinstallation.

Numbers preceding valvesprings correspond withthose shown inSpring ChartofSDS onpage AT-167,

AT-86

SAT2021

Page 87 of 1701

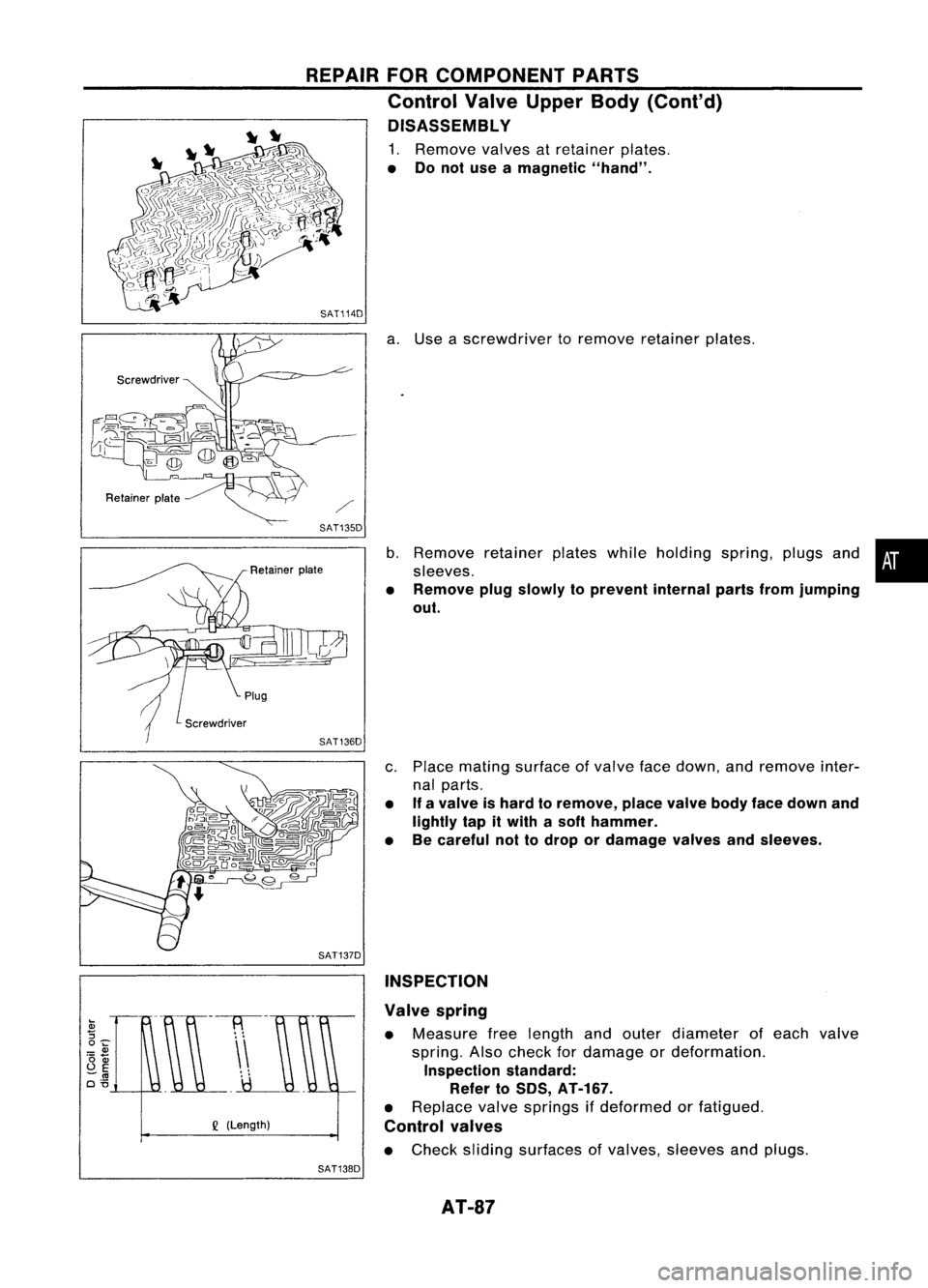

REPAIRFORCOMPONENT PARTS

Control ValveUpper Body(Cont'd)

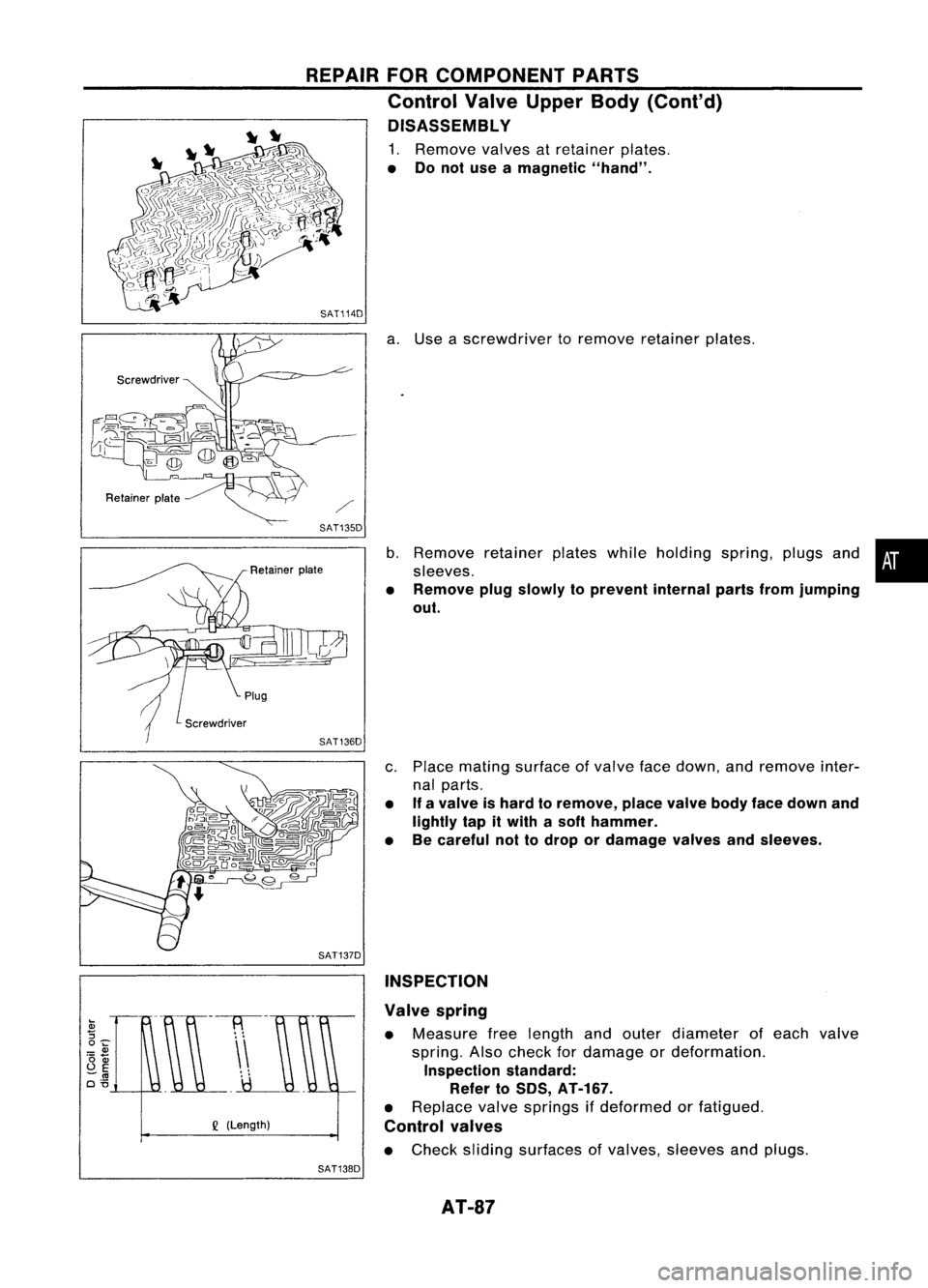

DISASSEMBL Y

1. Remove valvesatretainer plates.

• Donot use amagnetic "hand".

SAT114D

a.Use ascrewdriver toremove retainer plates.

SAT135D

b.Remove retainerplateswhileholding spring,plugsand•

sleeves.

• Remove plugslowly toprevent internalpartsfromjumping

out.

c. Place mating surface ofvalve facedown, andremove inter-

nal parts.

• If

avalve ishard toremove, placevalvebodyfacedown and

lightly tapitwith asoft hammer.

• Becareful nottodrop ordamage valvesandsleeves.

SAT137D INSPECTION

Q

(Length) Valve

spring

• Measure freelength andouter diameter ofeach valve

spring. Alsocheck fordamage ordeformation.

Inspection standard:

Refer to50S, AT-167.

• Replace valvesprings ifdeformed orfatigued.

Control valves

• Check sliding surfaces ofvalves, sleeves andplugs.

SAT138D

AT-87

Page 88 of 1701

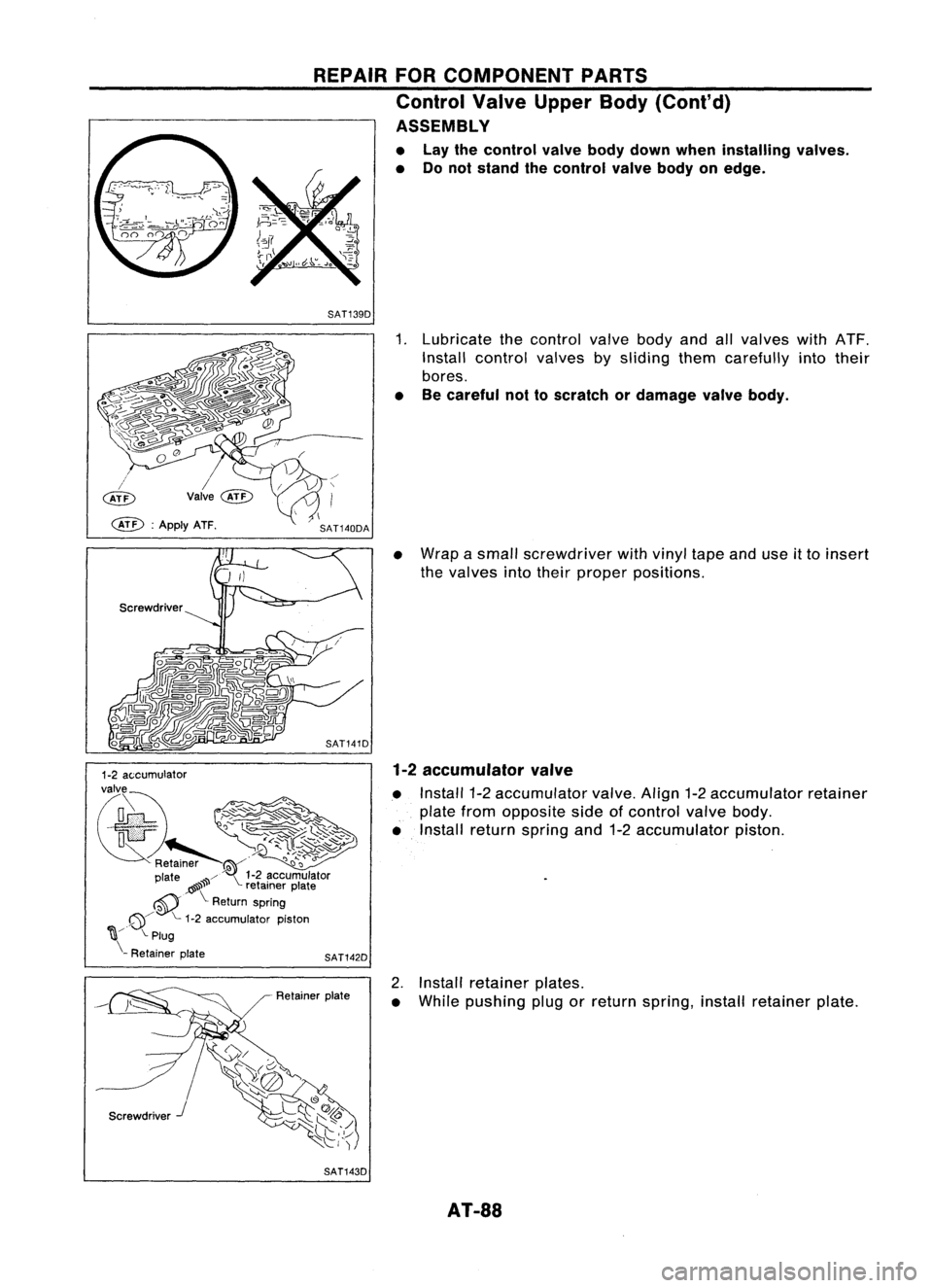

REPAIRFORCOMPONENT PARTS

Control ValveUpper Body(Cont'd)

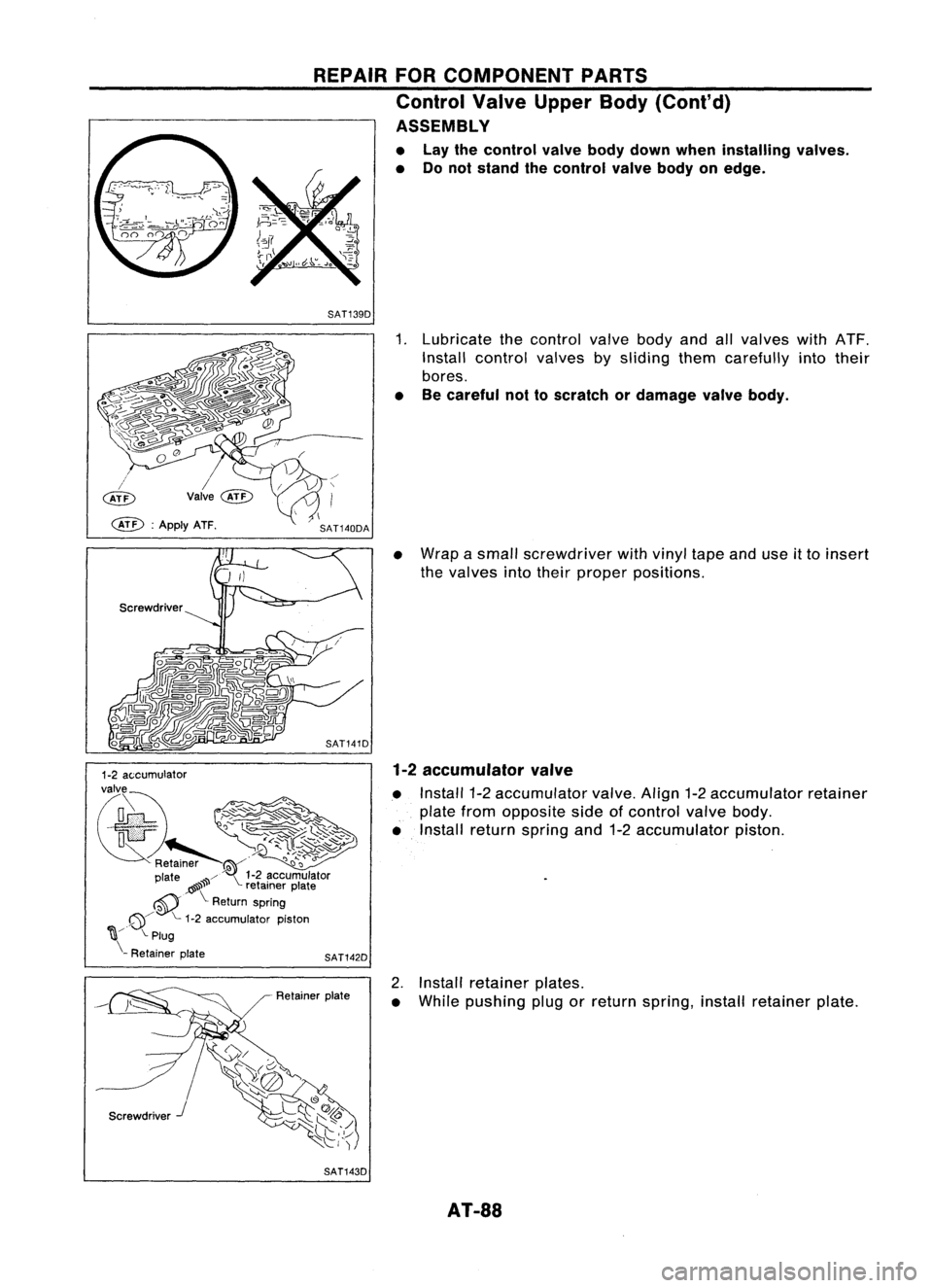

ASSEMBLY

• Lay thecontrol valvebodydown when installing valves.

• Donot stand thecontrol valvebodyonedge.

SAT139D

SAT141D

Screwdriver

Screwdriver J SAT142D

Retainer plate

SAT143D

1.

Lubricate thecontrol

valve

bodyandall

valves

withATF.

Install control valvesbysliding themcarefully intotheir

bores.

• Becareful nottoscratch ordamage valvebody.

• Wrap asmall screwdriver with

vinyl

tapeanduseitto insert

the valves intotheir proper positions.

1-2 accumulator valve

• Install 1-2accumulator

valve.

Align1-2accumulator retainer

plate fromopposite sideofcontrol

valve

body.

• Install return spring and1-2accumulator piston.

2. Install retainer plates.

• While pushing plugorreturn spring, installretainer plate.

AT-SS

Page 89 of 1701

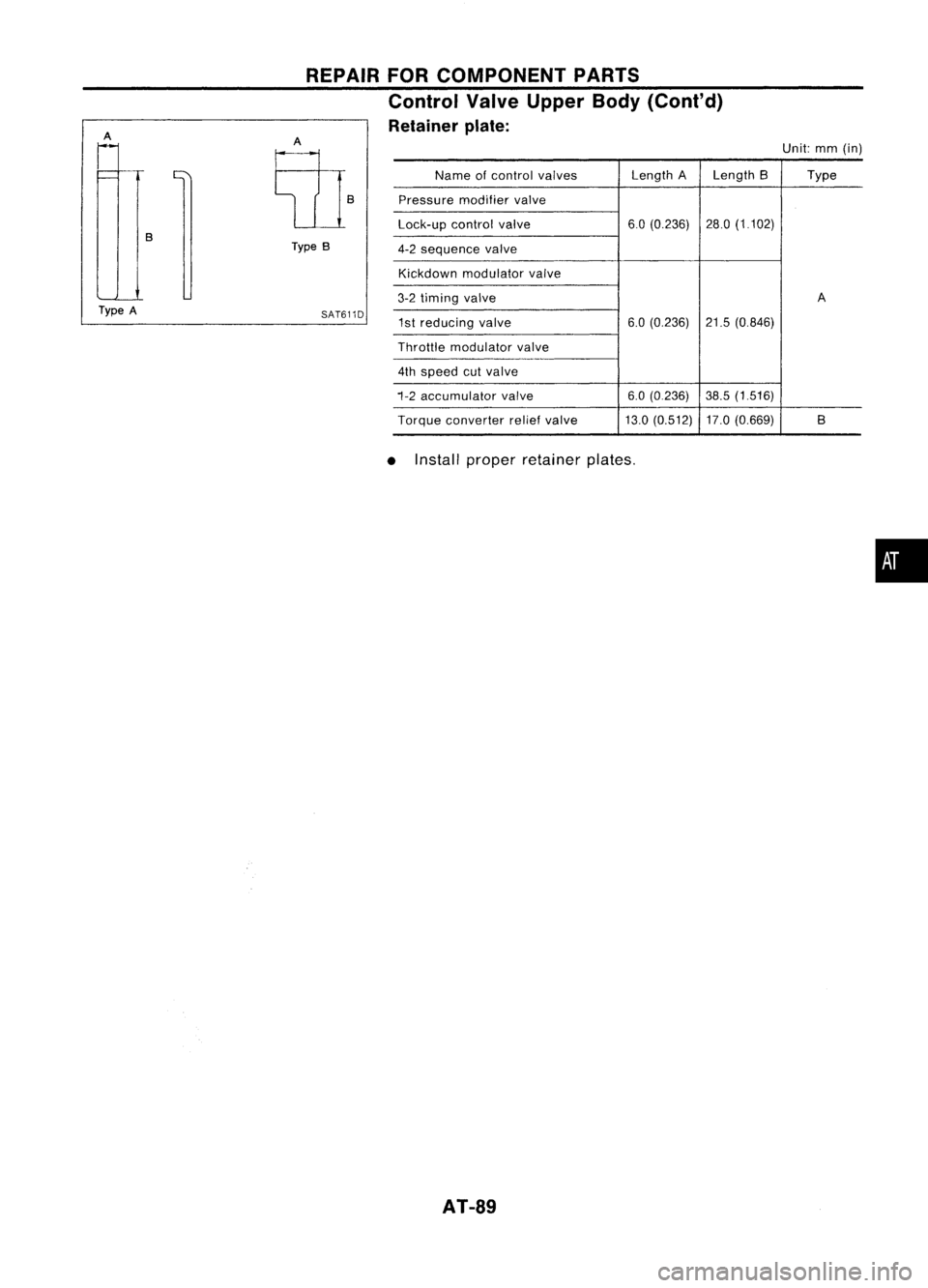

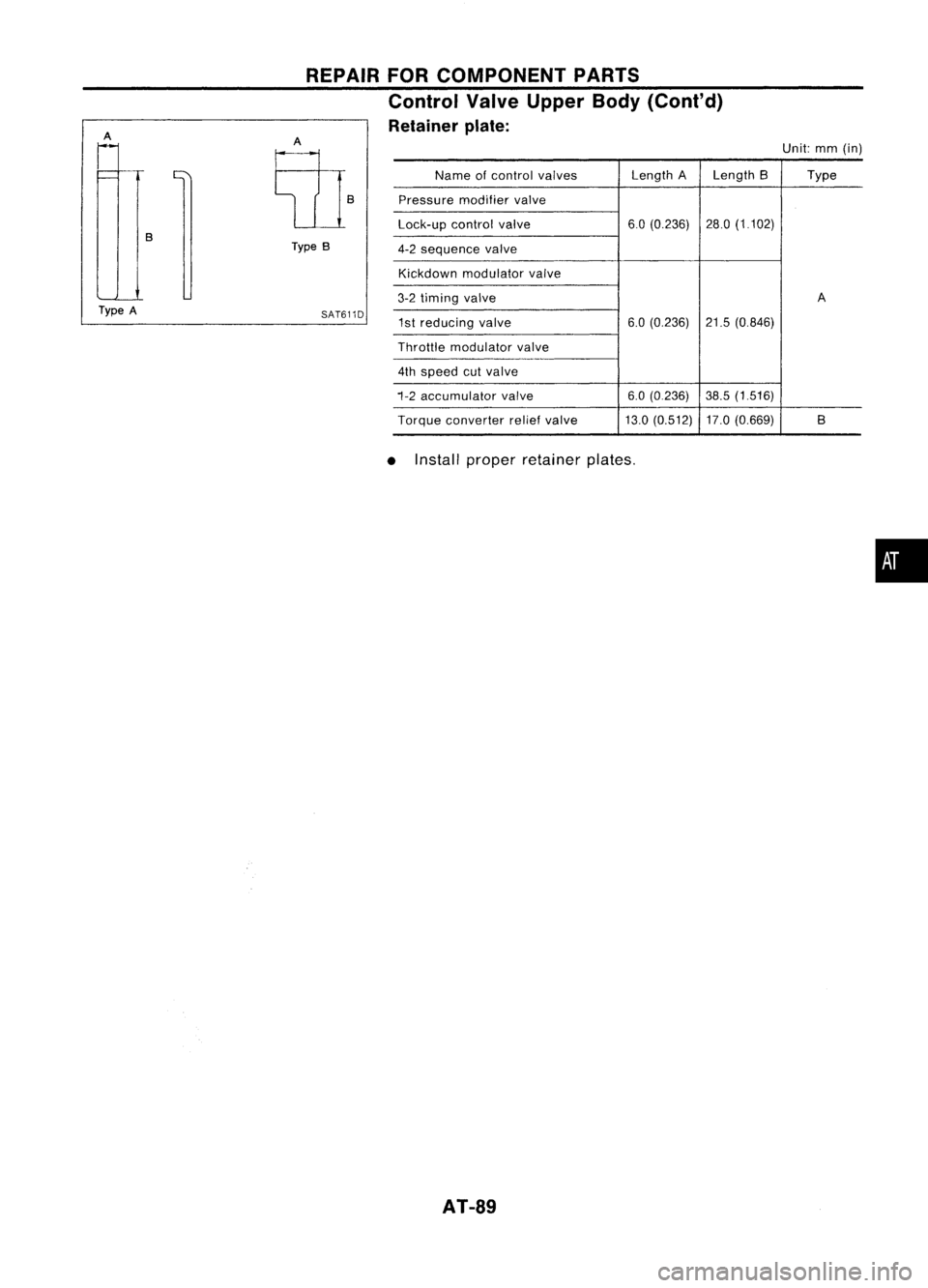

Unit:mm(in)

Name ofcontrol valves Length

ALength B Type

Pressure modifiervalve

Lock-up controlvalve 6.0

(0.236) 28.0(1.102)

4-2 sequence valve

Kickdown modulator valve

3-2 timing valve A

1st reducing valve 6.0

(0.236) 21.5(0.846)

Throttle modulator valve

4th speed cutvalve

1-2 accumulator valve 6.0

(0.236) 38.5(1516)

Torque converter reliefvalve 13.0(0.512) 17.0(0.669) B

SAT611D

REPAIR

FORCOMPONENT PARTS

Control ValveUpper Body(Cont'd)

Retainer plate:

Type B

A

E{1}

B

A

Type A

•Install proper retainer plates.

•

AT-89

Page 90 of 1701

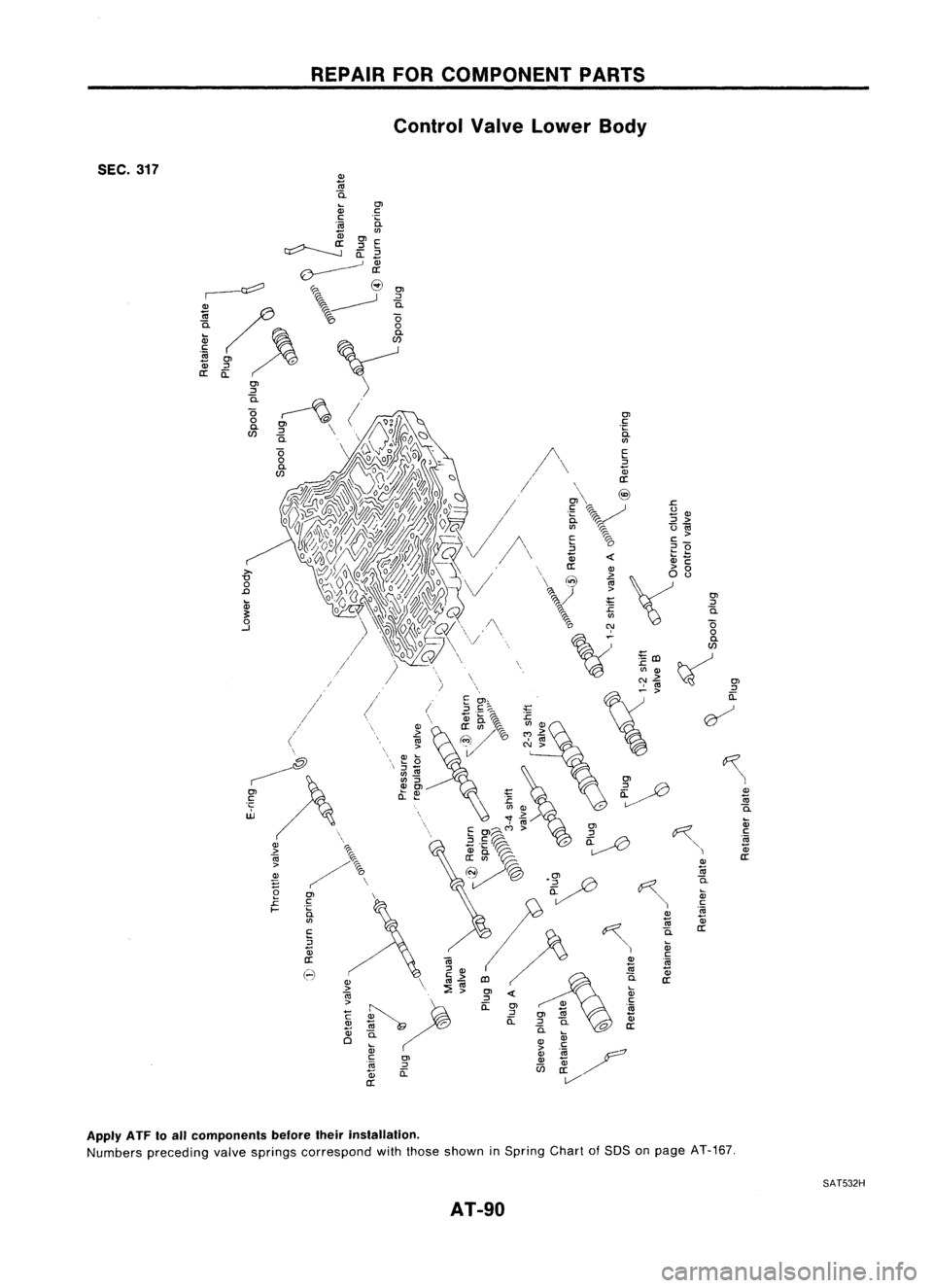

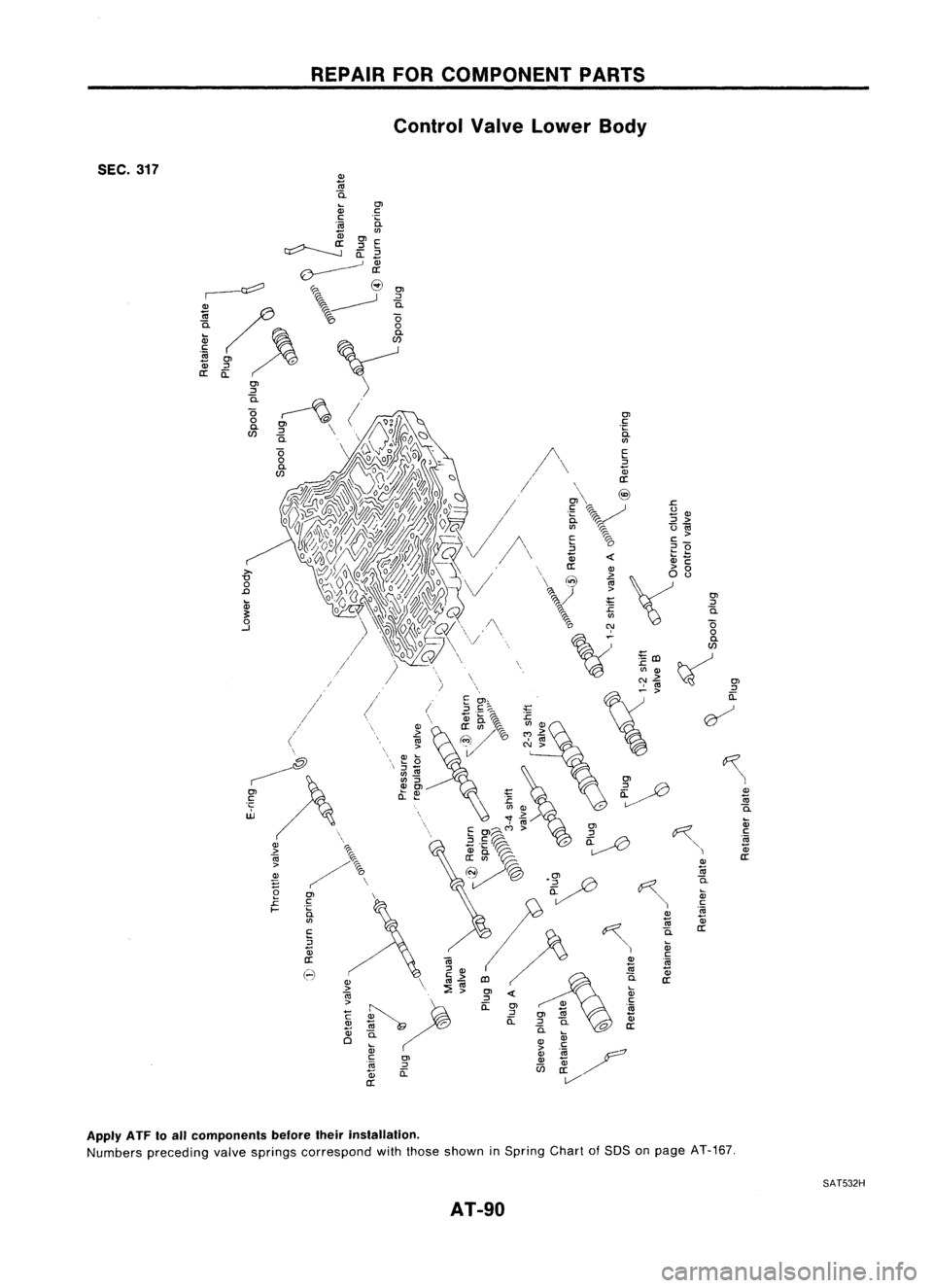

SEC.317

~

o

.0

REPAIR

FORCOMPONENT PARTS

Control ValveLower Body

Ol

::>

i5.

o

o

a.

W

~Ol

::>

a:

~

Cll

m

i5.

Q;

c

'OJ

a;

a:

Apply ATFtoall components beforetheirinstallation.

Numbers preceding valvesprings correspond withthose shown inSpring ChartofSOS onpage AT-167.

AT-gO

SAT532H

Trending: Anti lock, octane, ABS, wheel, coolant level, Lamp, wheel size