NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 981 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Cont'd)

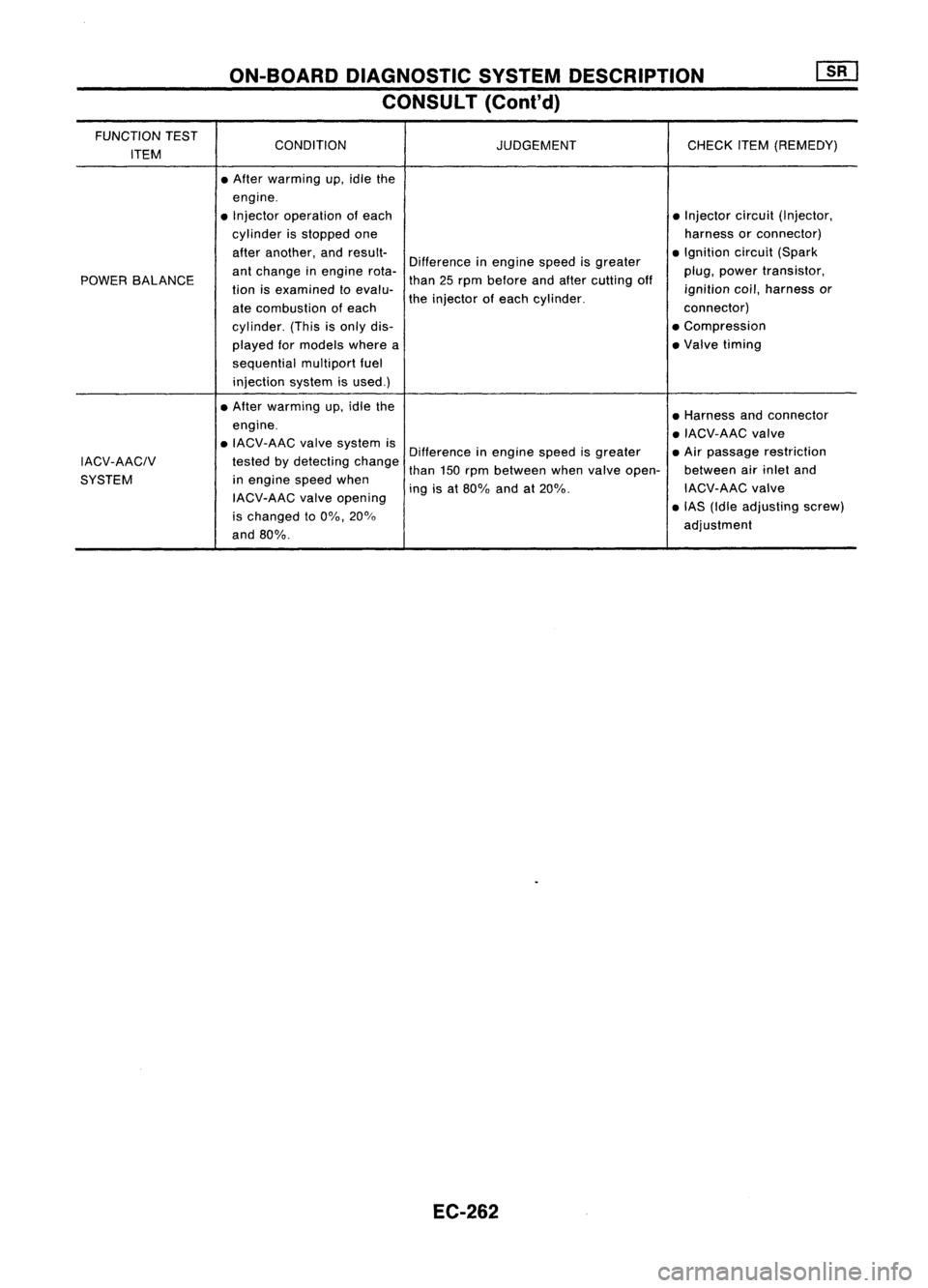

FUNCTION TEST

CONDITION JUDGEMENTCHECKITEM(REMEDY)

ITEM

•After warming up,idle the

engine.

• Injector operation ofeach •Injector circuit(Injector,

cylinder isstopped one harness

orconnector)

after another, andresult-

Difference inengine speedisgreater •

Ignition circuit(Spark

ant change inengine rota- plug,

power transistor,

POWER BALANCE

tionisexamined toevalu- than

25rpm before andafter cutting off

ignition coil,harness or

ate combustion ofeach the

injector ofeach cylinder.

connector)

cylinder. (Thisisonly dis- •

Compression

played formodels wherea •

Valve timing

sequential multiportfuel

injection systemisused.)

• After warming up,idle the

•Harness andconnector

engine. •IACV-AAC

valve

• IACV-AAC valvesystem is

Difference inengine speedisgreater •

Air passage restriction

IACV-AACIV testedbydetecting change

than150rpm between whenvalve open- between

airinlet and

SYSTEM inengine speedwhen

ingisat 80% andat20%. IACV-AAC

valve

IACV-AAC valveopening

•IAS (Idle adjusting screw)

is changed to0%,20%

adjustment

and 80%.

EC-262

Page 982 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Cont'd)

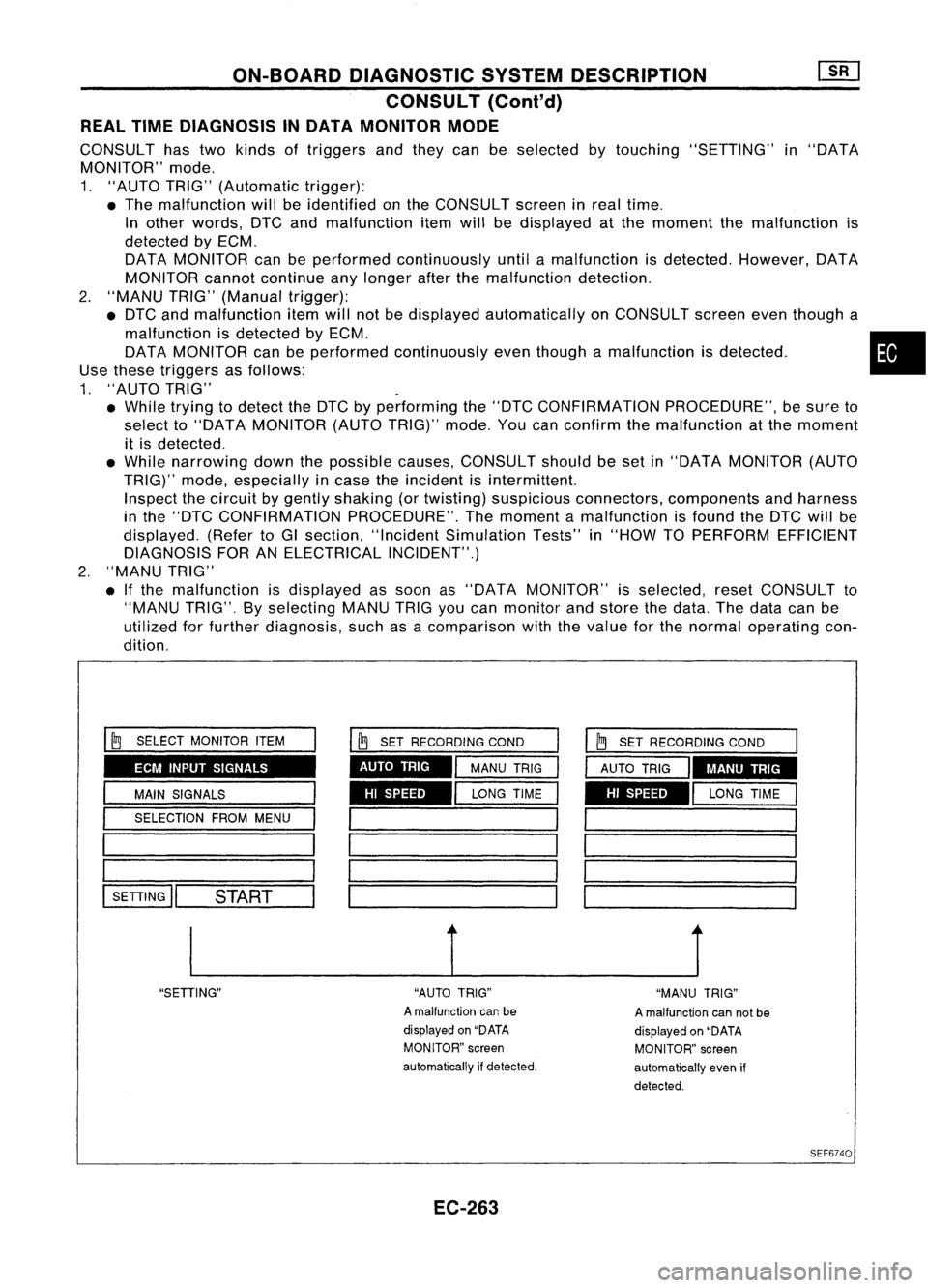

REAL TIMEDIAGNOSIS INDATA MONITOR MODE

CONSULT hastwo kinds oftriggers andthey canbeselected bytouching "SETTING" in"DATA

MONITOR" mode.

1. "AUTO TRIG"(Automatic trigger):

• The malfunction willbeidentified onthe CONSULT screeninreal time.

In other words, DTCandmalfunction itemwillbedisplayed atthe moment themalfunction is

detected byECM.

DATA MONITOR canbeperformed continuously untilamalfunction isdetected. However, DATA

MONITOR cannotcontinue anylonger afterthemalfunction detection.

2. "MANU TRIG"(Manual trigger):

• DTC andmalfunction itemwillnotbedisplayed automatically onCONSULT screeneventhough a

malfunction isdetected byECM. •

DATA MONITOR canbeperformed continuously eventhough amalfunction isdetected.

Use these triggers asfollows:

1. "AUTO TRIG"

• While trying todetect theDTC byperforming the"DTC CONFIRMATION PROCEDURE",besure to

select to"DATA MONITOR (AUTOTRIG)" mode.Youcanconfirm themalfunction atthe moment

it is detected .

• While narrowing downthepossible causes,CONSULT shouldbeset in"DATA MONITOR (AUTO

TRIG)" mode,especially incase theincident isintermittent.

Inspect thecircuit bygently shaking (ortwisting) suspicious connectors, components andharness

in the "DTC CONFIRMATION PROCEDURE".Themoment amalfunction isfound theDTC willbe

displayed. (RefertoGI section, "Incident Simulation Tests"in"HOW TOPERFORM EFFICIENT

DIAGNOSIS FORANELECTRICAL INCIDENT".)

2. "MANU TRIG"

• Ifthe malfunction isdisplayed assoon as"DATA MONITOR" isselected, resetCONSULT to

"MANU TRIG".Byselecting MANUTRIGyoucan monitor andstore thedata. Thedata canbe

utilized forfurther diagnosis, suchasacomparison withthevalue forthe normal operating con-

dition.

ECM INPUT SIGNALS

HISPEED

AUTO

TRIG

I

~

SELECT MONITOR ITEM

I

MAIN SIGNALS

I

SELECTION FROMMENU

1 _

1========

l-SE-TI-IN-G

ll--S-T.-AR-T--

I

~

SET RECORDING COND

I

MANU TRIG

I

LONG TIME HI

SPEED MANU

TRIG

__ 1__ J

"SETIING" "AUTOTRIG"

A malfunction canbe

displayed on"DATA

MONITOR" screen

automatically ifdetected.

EC-263 "MANU

TRIG"

A malfunction cannotbe

displayed on"DATA

MONITOR" screen

automatically evenif

detected.

SEF6740

Page 983 of 1701

TROUBLEDIAGNOSIS -General Description

Sensors

~ ECMActuators

~~.~ MEF036D

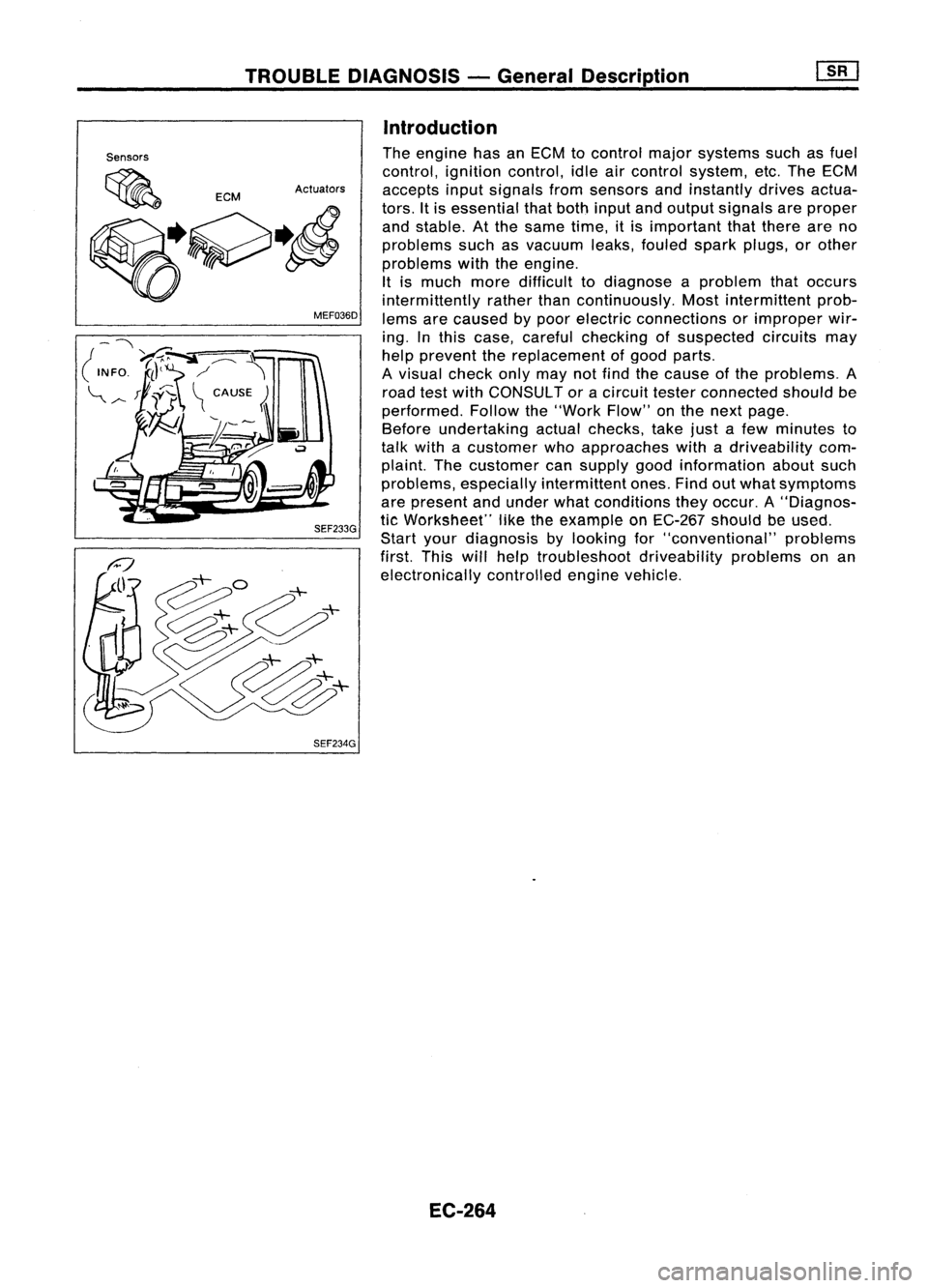

SEF234G Introduction

The engine hasanECM tocontrol majorsystems suchasfuel

control, ignitioncontrol, idleaircontrol system, etc.The ECM

accepts inputsignals fromsensors andinstantly drivesactua-

tors. Itis essential thatboth input andoutput signals areproper

and stable. Atthe same time,itis important thatthere areno

problems suchasvacuum leaks,fouled sparkplugs, orother

problems withtheengine.

It is much moredifficult todiagnose aproblem thatoccurs

intermittently ratherthancontinuously. Mostintermittent prob-

lems arecaused bypoor electric connections orimproper wir-

ing. Inthis case, careful checking ofsuspected circuitsmay

help prevent thereplacement ofgood parts.

A visual checkonlymaynotfind thecause ofthe problems. A

road testwith CONSULT oracircuit testerconnected shouldbe

performed. Followthe"Work Flow"onthe next page.

Before undertaking actualchecks, takejustafew minutes to

talk with acustomer whoapproaches withadriveability com-

plaint. Thecustomer cansupply goodinformation aboutsuch

problems, especially intermittent ones.Findoutwhat symptoms

are present andunder whatconditions theyoccur. A"Diagnos-

tic Worksheet" liketheexample onEC-267 shouldbeused.

Start yourdiagnosis bylooking for"conventional" problems

first. Thiswillhelp troubleshoot driveabilityproblemsonan

electronically controlledenginevehicle.

EC-264

Page 984 of 1701

TROUBLEDIAGNOSIS -General Description

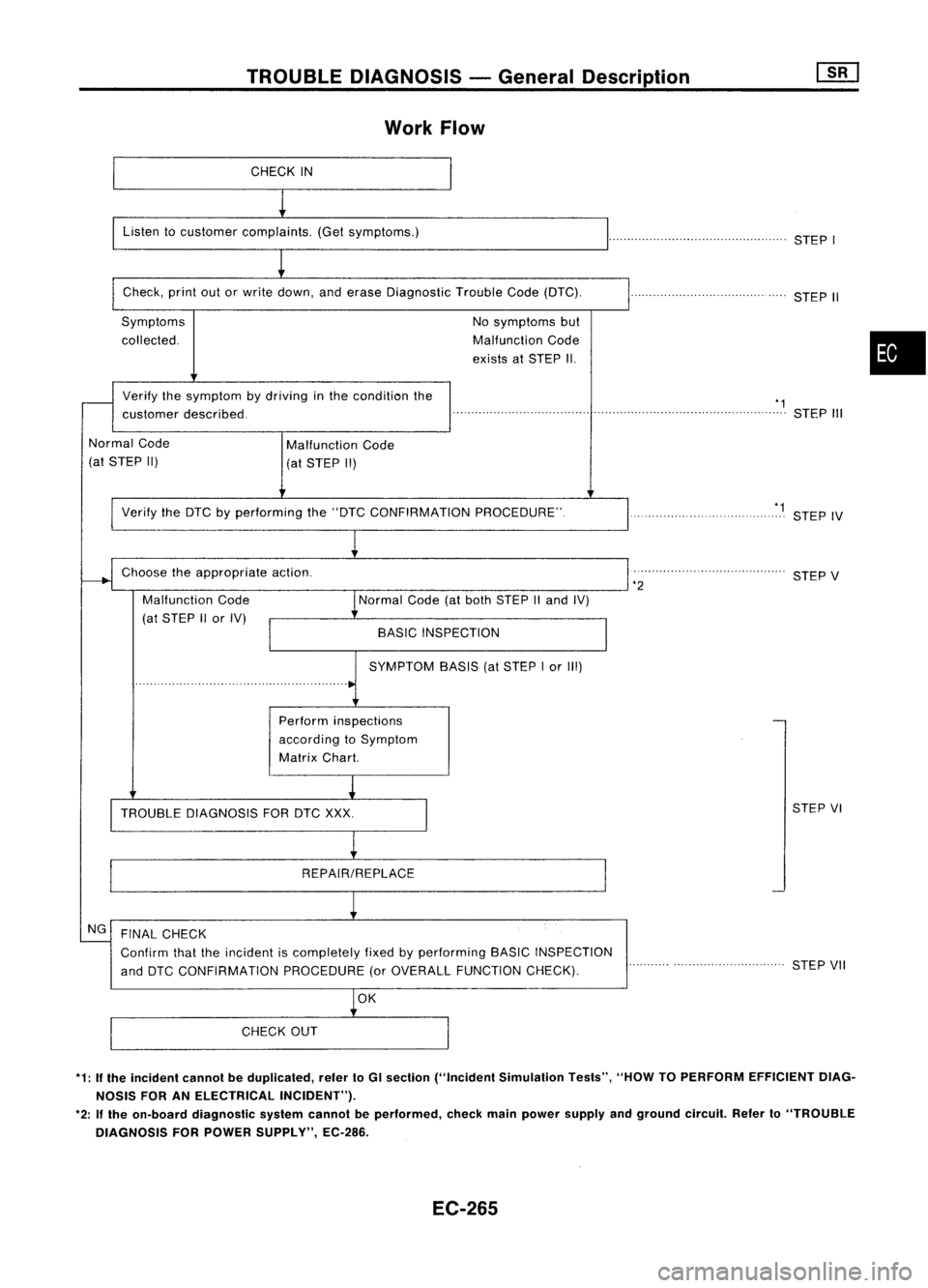

Work Flow

CHECK IN

Listen tocustomer complaints. (Getsymptoms.)

...............................................STEPI

Check, printoutorwrite down, anderase Diagnostic TroubleCode(DTC).

Symptoms

collected. No

symptoms but

Malfunction Code

exists atSTEP II. ..

STEPII

•

Verify

thesymptom bydriving inthe condition the

customer described.

'1

..................................... STEPIII

Normal Code

(at STEP II) Malfunction

Code

(at STEP II)

Verify theDTC byperforming the"DTC CONFIRMATION PROCEDURE"

'1

...... STEP IV

Choose theappropriate action.

Malfunction Code

(at STEP IIor IV) Normal

Code(atboth STEP IIand IV)

BASIC INSPECTION

SYMPTOM BASIS(atSTEP Ior III) .

STEPV

'2

Perform inspections

according toSymptom

Matrix Chart.

TROUBLE DIAGNOSIS FORDTC XXX.

REPAIR/REPLACE

NG FINAL CHECK

Confirm thattheincident iscompletely fixedbyperforming BASICINSPECTION

and DTC CONFIRMATION PROCEDURE(orOVERALL FUNCTION CHECK).

OK

CHECK OUT STEP

VI

...................................... STEPVII

*1:

If

the incident cannotbeduplicated, refer10GI section ("Incident Simulation Tesls","HOWTOPERFORM EFFICIENT DIAG-

NOSIS FORANELECTRICAL INCIDENT").

*2: If

the on-board diagnostic systemcannotbeperformed, checkmainpower supply andground circuit.Refer10"TROUBLE

DIAGNOSIS FORPOWER SUPPLY", EC-286.

EC-265

Page 985 of 1701

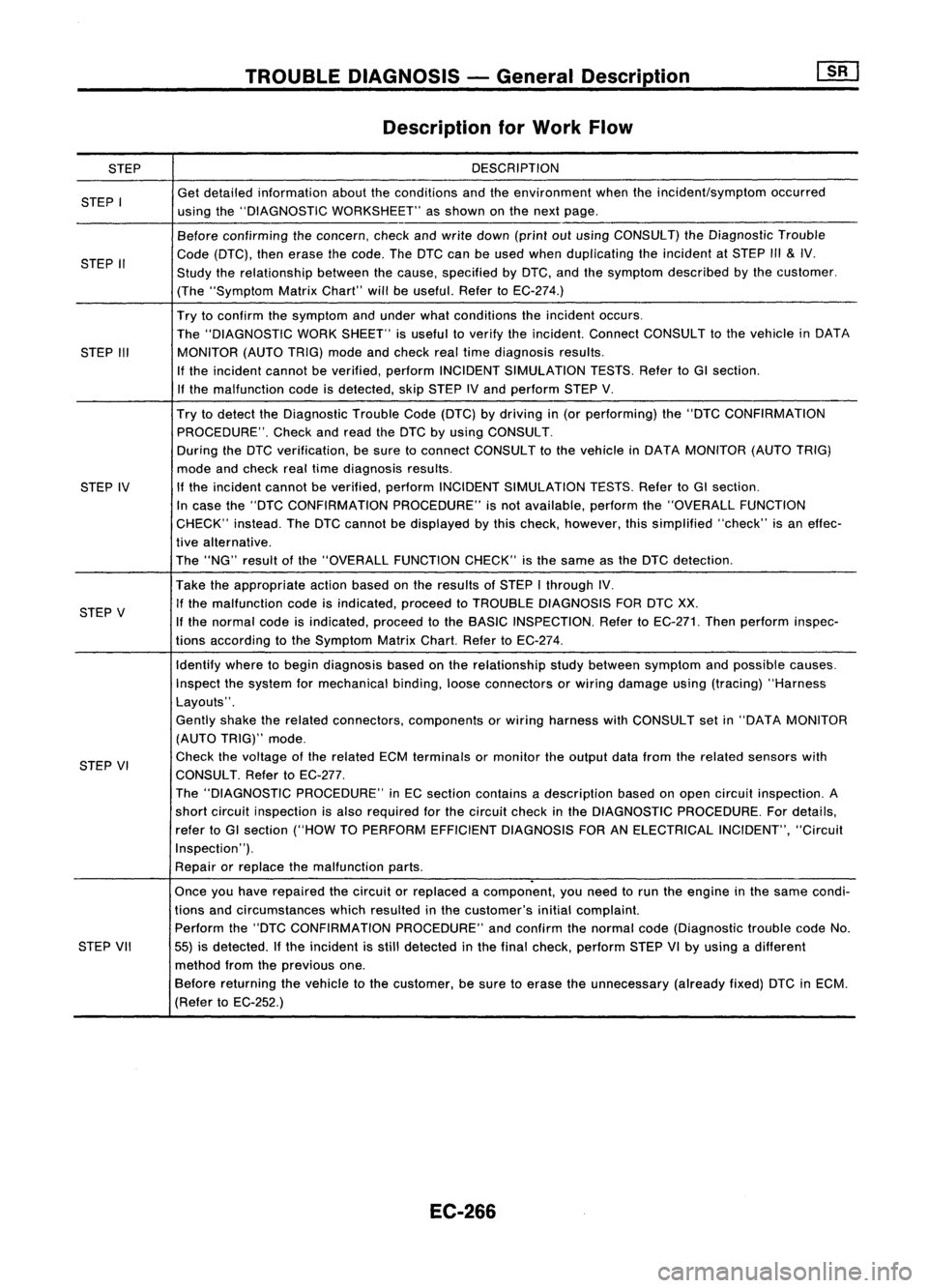

STEP

STEP I

STEP II

STEP III

STEP IV

STEP V

STEP VI

STEP VII

TROUBLE

DIAGNOSIS -General Description

Description forWork Flow

DESCRIPTION

Get detailed information abouttheconditions andtheenvironment whentheincident/symptom occurred

using the"DIAGNOSTIC WORKSHEET" asshown onthe next page.

Before confirming theconcern, checkandwrite down (printoutusing CONSULT) theDiagnostic Trouble

Code (DTC), thenerase thecode. TheDTC canbeused when duplicating theincident atSTEP

1/1

&

IV.

Study therelationship betweenthecause, specified byDTC, andthesymptom described bythe customer.

(The "Symptom MatrixChart" willbeuseful. RefertoEC-274.)

Try toconfirm thesymptom andunder whatconditions theincident occurs.

The "DIAGNOSTIC WORKSHEET" isuseful toverify theincident. ConnectCONSULT tothe vehicle inDATA

MONITOR (AUTOTRIG)modeandcheck realtime diagnosis results.

If the incident cannotbeverified, performINCIDENT SIMULATION TESTS.RefertoGI section.

If the malfunction codeisdetected, skipSTEP IVand perform STEPV.

Try todetect theDiagnostic TroubleCode(DTC) bydriving in(or performing) the"DTC CONFIRMATION

PROCEDURE". Checkandread theDTC byusing CONSULT.

During theDTC verification, besure toconnect CONSULT tothe vehicle inDATA MONITOR (AUTOTRIG)

mode andcheck realtime diagnosis results.

If the incident cannotbeverified, performINCIDENT SIMULATION TESTS.RefertoGI section.

In case the"DTC CONFIRMATION PROCEDURE"isnot available, performthe"OVERALL FUNCTION

CHECK" instead.TheDTC cannot bedisplayed bythis check, however, thissimplified "check"isan effec-

tive alternative.

The "NG" result ofthe "OVERALL FUNCTIONCHECK"isthe same asthe DTC detection.

Take theappropriate actionbasedonthe results ofSTEP Ithrough IV.

If the malfunction codeisindicated, proceedtoTROUBLE DIAGNOSIS FORDTCXX.

If the normal codeisindicated, proceedtothe BASIC INSPECTION. RefertoEC-271. Thenperform inspec-

tions according tothe Symptom MatrixChart.RefertoEC-274.

Identify wheretobegin diagnosis basedonthe relationship studybetween symptom andpossible causes.

Inspect thesystem formechanical binding,looseconnectors orwiring damage using(tracing) "Harness

Layouts".

Gently shaketherelated connectors, components orwiring harness withCONSULT setin"DATA MONITOR

(AUTO TRIG)" mode.

Check thevoltage ofthe related ECMterminals ormonitor theoutput datafrom therelated sensors with

CONSULT. RefertoEC-277.

The "DIAGNOSTIC PROCEDURE" inEC section contains adescription basedonopen circuit inspection. A

short circuit inspection isalso required forthe circuit checkinthe DIAGNOSTIC PROCEDURE. Fordetails,

refer toGI section ("HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT","Circuit

Inspection").

Repair orreplace themalfunction parts.

.

Once youhave repaired thecircuit orreplaced acomponent, youneed torun theengine inthe same condi-

tions andcircumstances whichresulted inthe customer's initialcomplaint.

Perform the"DTC CONFIRMATION PROCEDURE"andconfirm thenormal code(Diagnostic troublecodeNo.

55) isdetected. Ifthe incident isstill detected inthe final check, perform STEPVIby using adifferent

method fromtheprevious one.

Before returning thevehicle tothe customer, besure toerase theunnecessary (alreadyfixed)DTCinECM.

(Refer toEC-252.)

EC-266

Page 986 of 1701

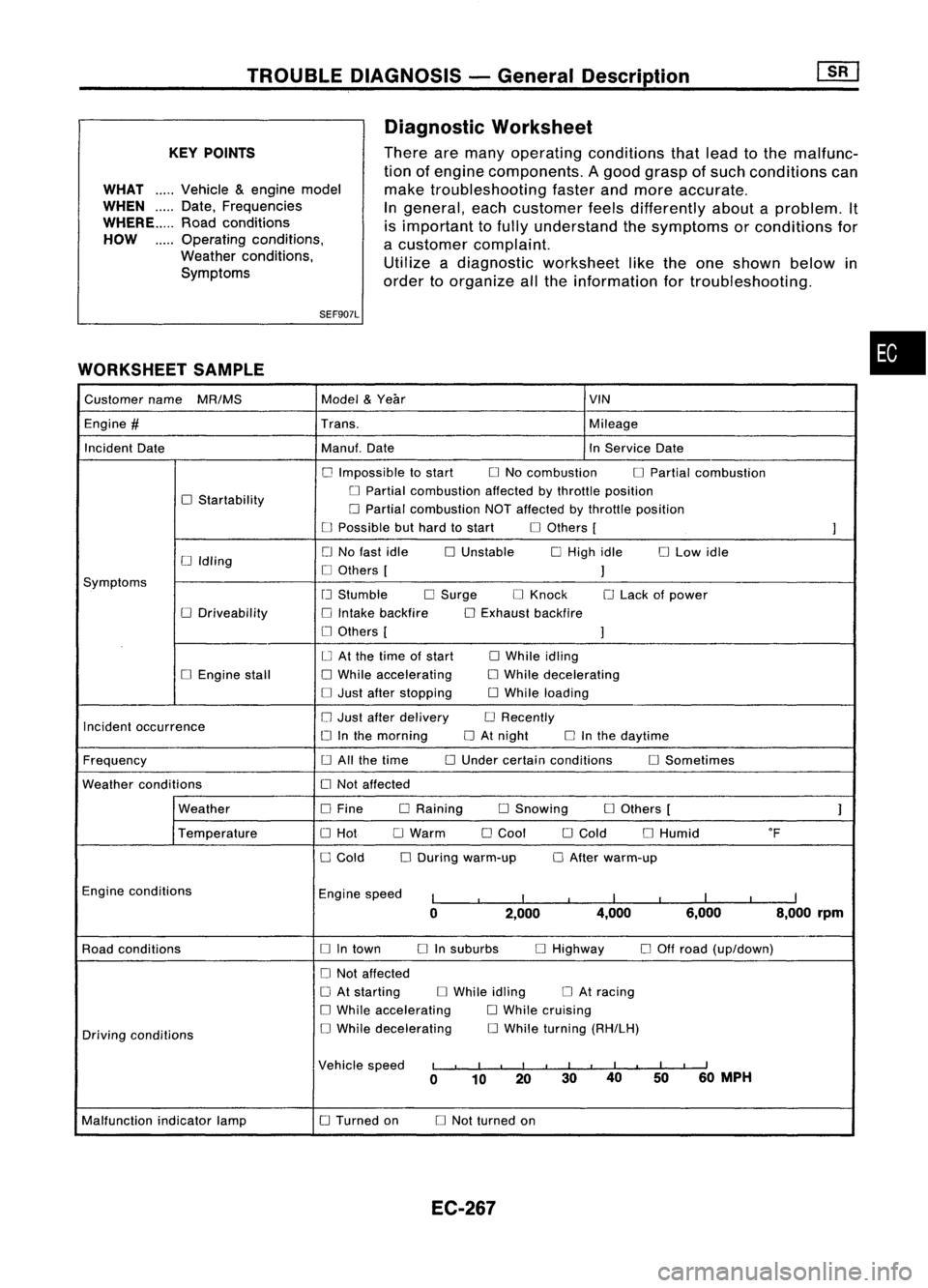

TROUBLEDIAGNOSIS -General Description

KEY POINTS

WHAT .....

Vehicle &engine model

WHEN

Date,Frequencies

WHERE Roadconditions

HOW Operatingconditions,

Weather conditions,

Symptoms

SEF907L

WORKSHEET SAMPLE Diagnostic

Worksheet

There aremany operating conditions thatlead tothe malfunc-

tion ofengine components. Agood grasp ofsuch conditions can

make troubleshooting fasterandmore accurate.

In

general, eachcustomer feelsdifferently aboutaproblem. It

is important tofully understand thesymptoms orconditions for

a customer complaint.

Utilize adiagnostic worksheet liketheone shown belowin

order toorganize allthe information fortroubleshooting.

•

Customer name

MR/MS Model

&

Year VIN

Engine

#

Trans. Mileage

Incident Date Manuf.Date InService Date

o

Impossible tostart

o

No combustion

o

Partial combustion

o

Startability

o

Partial combustion affectedbythrottle position

o

Partial combustion NOTaffected bythrottle position

o

Possible buthard tostart

o

Others [

]

o

No fast idle

o

Unstable

o

High idle

o

Low idle

[J

Idling

o

Others [

]

Symptoms

[J

Stumble

o

Surge

o

Knock

o

Lack ofpower

o

Driveability

o

Intake backfire

o

Exhaust backfire

o

Others [

]

o

At the time ofstart

o

While idling

o

Engine stall

o

While accelerating

o

While decelerating

o

Just after stopping

o

While loading

Incident occurrence

o

Just after delivery

o

Recently

o

Inthe morning

o

At night

o

Inthe daytime

Frequency

o

All the time

o

Under certain conditions

o

Sometimes

Weather conditions

o

Not affected

Weather

o

Fine DRaining

o

Snowing

o

Others [

]

Temperature

o

Hot

o

Warm

o

Cool

o

Cold

o

Humid

of

o

Cold

o

During warm-up

o

After warm-up

Engine conditions

Enginespeed

I

I

I

I

I

I

I

I

I

0 2,000 4,000

6,000 8,000rpm

Road conditions

o

Intown

o

Insuburbs

o

Highway

o

Off road (up/down)

o

Not affected

o

At starting

o

While idling

o

At racing

o

While accelerating

o

While cruising

Driving conditions

o

While decelerating

o

While turning (RH/LH)

Vehicle speed

I

I

I

I

I

I

II

I

I

I

II

0 10 20 3040

5060

MPH

Malfunction indicatorlamp

o

Turned on

o

Not turned on

EC-267

Page 987 of 1701

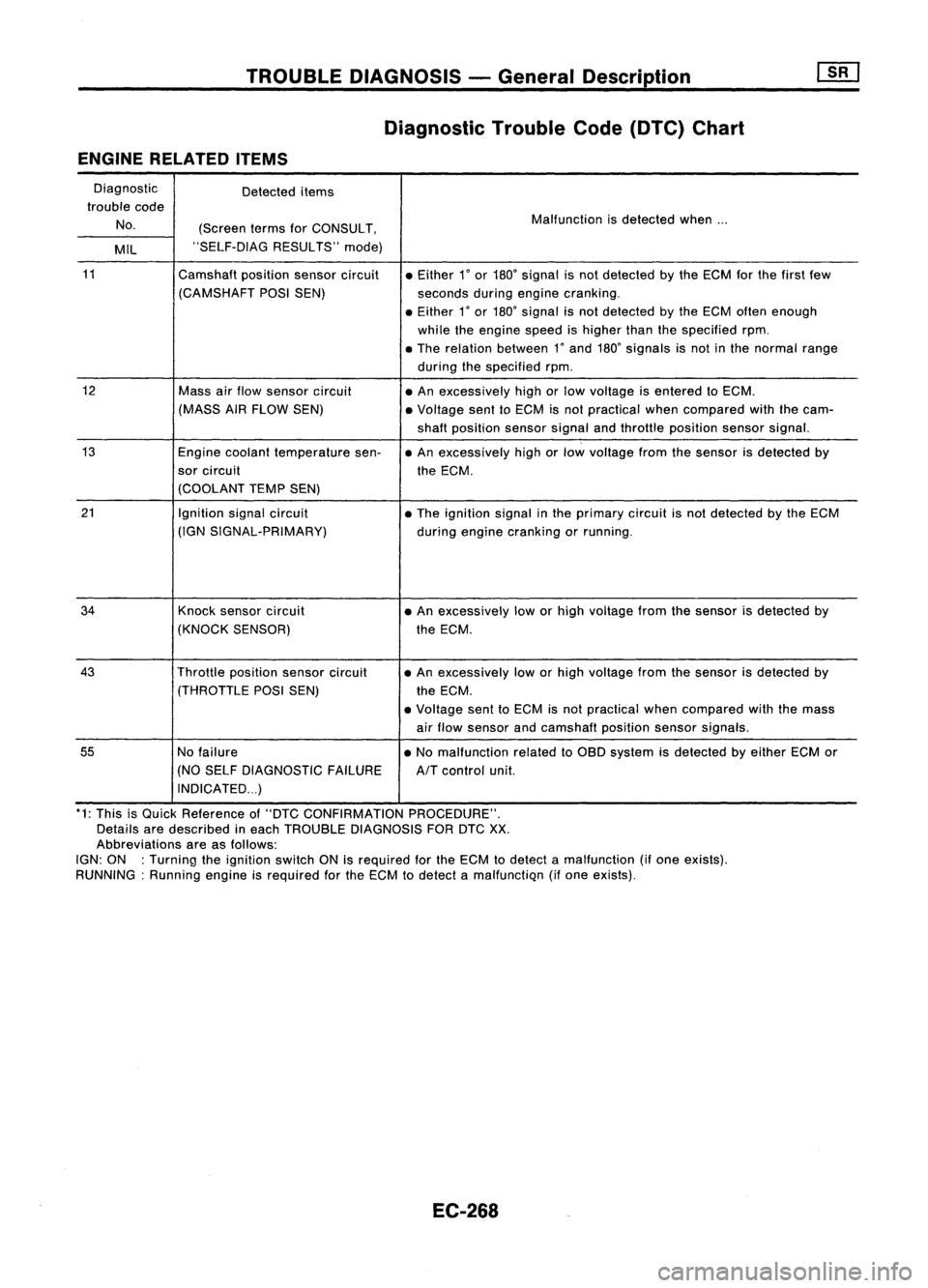

TROUBLEDIAGNOSIS -General Description

Diagnostic TroubleCode(DTC) Chart

ENGINE RELATED ITEMS

Diagnostic Detecteditems

trouble code

No. (ScreentermsforCONSULT, Malfunction

isdetected when...

MIL "SELF-DIAG

RESULTS"mode)

11

Camshaftpositionsensorcircuit •Either

1

0

or

180

0

signal isnot detected bythe ECM forthe first few

(CAMSHAFT POSISEN) secondsduringengine cranking .

• Either

1

0

or

180

0

signal isnot detected bythe ECM often enough

while theengine speedishigher thanthespecified rpm.

• The relation between

1"

and

180"

signals isnot inthe normal range

during thespecified rpm.

12

Massairflow sensor circuit

•An excessively highorlow voltage isentered toECM.

(MASS AIRFLOW SEN) •Voltage senttoECM isnot practical whencompared withthecam-

shaft position sensorsignalandthrottle position sensorsignal.

13

Enginecoolant temperature sen-•An excessively highorlow voltage fromthesensor isdetected by

sor circuit theECM.

(COOLANT TEMPSEN)

21

Ignitionsignalcircuit

•The ignition signalinthe primary circuitisnot detected bythe ECM

(IGN SIGNAL-PRIMARY)

duringengine cranking orrunning.

34

Knocksensor circuit •An excessively loworhigh voltage fromthesensor isdetected by

(KNOCK SENSOR) theECM .

43

Throttlepositionsensorcircuit •

An excessively loworhigh voltage fromthesensor isdetected by

(THROTTLE POSISEN)

theECM.

• Voltage senttoECM isnot practical whencompared withthemass

air flow sensor andcamshaft positionsensorsignals.

55

Nofailure •No malfunction relatedtoOBD system isdetected byeither ECMor

(NO SELF DIAGNOSTIC FAILURE

AIT

control unit.

INDICATED ...)

*1: This isQuick Reference of"DTC CONFIRMATION PROCEDURE".

Details aredescribed ineach TROUBLE DIAGNOSIS FORDTC

XX.

Abbreviations areasfollows:

IGN: ON :Turning theignition switchONisrequired forthe ECM todetect amalfunction (ifone exists).

RUNNING: Runningengineisrequired forthe ECM todetect amalfunctiQn (ifone eXists).

EC-268

Page 988 of 1701

![NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSIS -General Description

ill]

Diagnostic TroubleCode(DTC) Chart(Cont'd)

x:

Applicable

-: Not applicable

"DTC *1

*2

Check Items CONFIRMATION

"OVERALLFUNC-

Fail ReferencePag NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSIS -General Description

ill]

Diagnostic TroubleCode(DTC) Chart(Cont'd)

x:

Applicable

-: Not applicable

"DTC *1

*2

Check Items CONFIRMATION

"OVERALLFUNC-

Fail ReferencePag](/img/5/57349/w960_57349-987.png)

TROUBLEDIAGNOSIS -General Description

ill]

Diagnostic TroubleCode(DTC) Chart(Cont'd)

x:

Applicable

-: Not applicable

"DTC *1

*2

Check Items CONFIRMATION

"OVERALLFUNC-

Fail ReferencePage

(Possible Cause) PROCEDURE"

TIONCHECK"

Safe

Quick Ref. QuickRef. System

• Harness orconnectors

(The sensor circuitisopen orshorted.)

• Camshaft positionsensor

RUNNING

--

EC-289

• Starter motor

• Starting systemcircuit(ELsection)

• Dead (Weak) battery

• Harness orconnectors

-

(The sensor circuitisopen orshorted.) RUNNING

RUNNING

X

EC-293

• Mass airflow sensor

• Harness orconnectors

(The sensor circuitisopen orshorted.) IGN:

ON

-

X

EC-297

• Engine coolant temperature sensor

• Harness orconnectors

(The ignition primary circuitisopen orshorted.)

• Power transistor unit RUNNING

--

EC-301

• Camshaft positionsensor

• Camshaft positionsensorcircuit

• Harness orconnectors

(The sensor circuitisopen orshorted.) RUNNING

--

EC-306

• Knock sensor

• Harness orconnectors

(The sensor circuitisopen orshorted.)

-

IGN:

ON

X

EC-309

• Throttle position sensor

• No failure

--

-

-

*2: •The "OVERALL FUNCTIONCHECK"isasimplified andeffective waytoinspect acomponent orcircuit.

In some cases, the"OVERALL FUNCTIONCHECK"isused rather thana"DIAGNOSTIC TROUBLECODECONFIRMA-

TION PROCEDURE".

When noDTC CONFIRMATION PROCEDUREisavailable, the"NG" result ofthe OVERALL FUNCTION CHECKcanbe

considered tomean thesame asaDTC detection .

• During an"NG" OVERALL FUNCTION CHECK,theDTC might notbeconfirmed.

EC-269

•

Page 989 of 1701

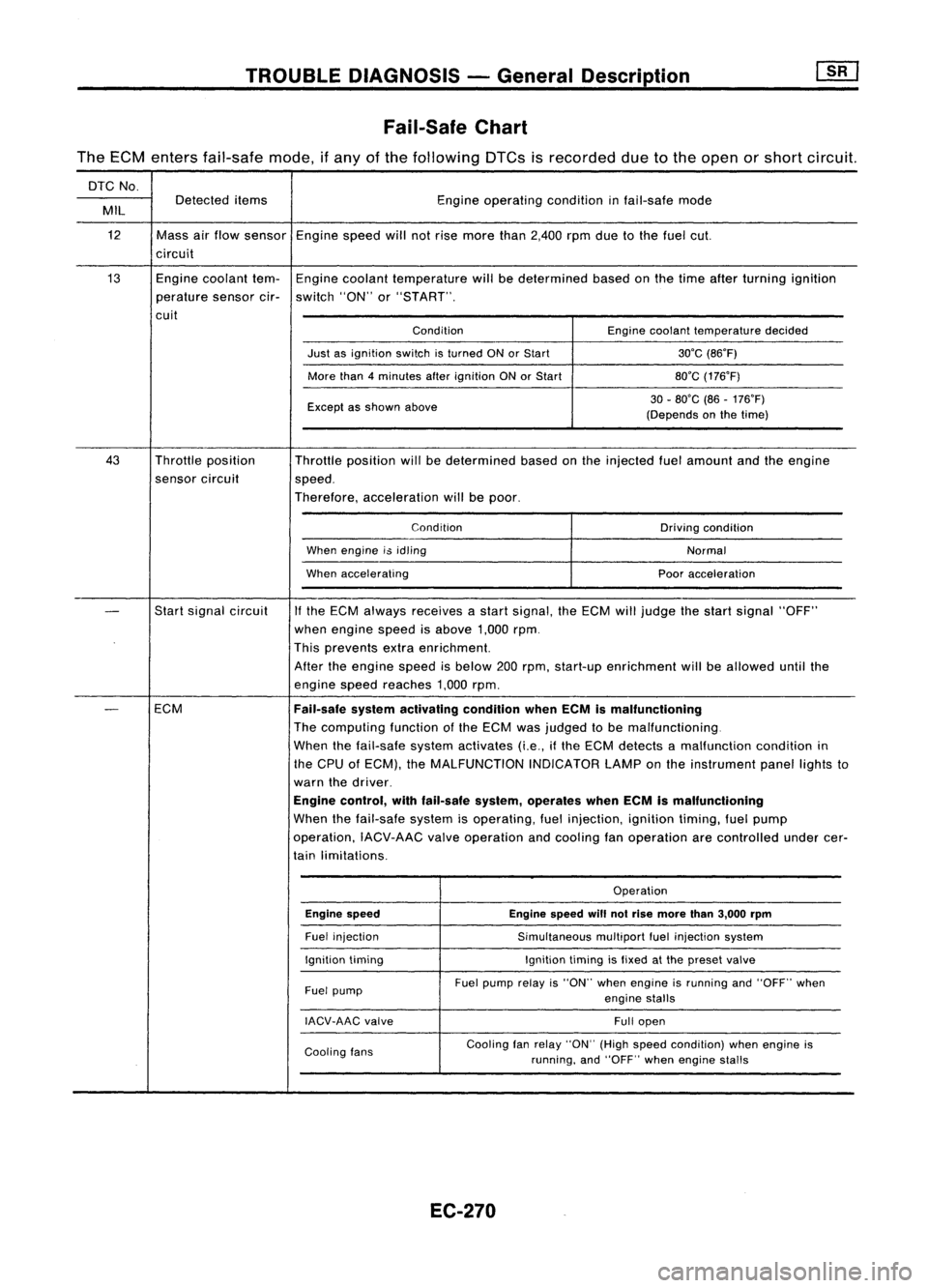

TROUBLEDIAGNOSIS -General Description

Fail-Safe Chart

The ECM enters fail-safe mode,ifany ofthe following DTCsisrecorded duetothe open orshort circuit.

DTC No.

Detected items Engineoperating conditioninfail-safe mode

MIL

12 Massairflow sensor Enginespeedwillnotrise more than2,400 rpmduetothe fuel cut.

circuit

13 Enginecoolant tem-Engine coolant temperature willbedetermined basedonthe time after turning ignition

perature sensorcir-switch "ON"or"START".

cuit ConditionEnginecoolant temperature decided

Just asignition switchisturned ONorStart 30'C(86'F)

More than4minutes afterignition ONorStart 80'C(176'F)

Except asshown above 30

-80'C (86-176'F)

(Depends onthe time)

43 Throttle position

Throttleposition willbedetermined basedonthe injected fuelamount andtheengine

sensor circuit

speed.

Therefore, acceleration willbepoor.

Condition Drivingcondition

When engine i$idling

Normal

When accelerating Pooracceleration

-

Start

signal circuit

If

the ECM always receives astart signal, theECM willjudge thestart signal "OFF"

when engine speedisabove 1,000rpm.

This prevents extraenrichment.

After theengine speedisbelow 200rpm, start-up enrichment willbeallowed untilthe

engine speedreaches 1,000rpm.

-

ECM

Fail-safesystemactivating conditionwhenECMismalfunctioning

The computing functionofthe ECM wasjudged tobe malfunctioning.

When thefail-safe systemactivates (i.e.,ifthe ECM detects amalfunction conditionin

the CPU ofECM), theMALFUNCTION INDICATORLAMPonthe instrument panellightsto

warn thedriver.

Engine control, withfail-safe system,operates whenECMismalfunctioning

When thefail-safe systemisoperating, fuelinjection, ignitiontiming,fuelpump

operation, IACV-AACvalveoperation andcooling fanoperation arecontrolled undercer-

tain limitations.

Operation

Engine speed Enginespeedwillnotrise more than3,000 rpm

Fuel injection

Simultaneousmultiportfuelinjection system

Ignition timing Ignitiontimingisfixed atthe preset valve

Fuel pump Fuel

pump relayis"ON" whenengine isrunning and"OFF" when

engine stalls

IACV-AAC valve

Fullopen

Cooling fans Cooling

fanrelay "ON" (Highspeed condition) whenengine is

running, and"OFF" whenengine stalls

EC-270

Page 990 of 1701

TROUBLEDIAGNOSIS -General Descrip_ti_on

1S_R_'

Basic Inspection

Precaution:

Perform BasicInspection withoutelectrical ormechanical loads

applied;

• Headlamp switchisOFF,

• Air conditioner switchisOFF,

• Rear defogger switchisOFF,

• Steering wheelisinthe straight-ahead position,etc.

m

BEFORE STARTING

1. Check service records forany recent •

repairs thatmay indicate arelated

problem, orthe current needfor

scheduled maintenance.

2. Open engine hoodandcheck thefol-

lowing:

• Harness connectors forimproper con-

nections

• Vacuum hosesforsplits, kinks,or

improper connections

• Wiring forimproper connections,

pinches, orcuts

Goto

(I.

No

CONNECT

CONSULTTOTHE VEHICLE.

Connect "CONSULT" tothe data link

connector forCONSULT andselect

"ENGINE" fromthemenu. Referto

EC-254.

DOES ENGINE START?

\\

~

~ SEF1421

START

•

IGN TIMING ADJ.

0

IGNITION TIMINGFEEDBACK

CONTROL WILLBEHELD BY

TOUCHING START

AFTER DOING SO,ADJUST

IGNITION TIMINGWITHA

TIMING LIGHTBYTURNING

THE CAMSHAFT POSITION

SENSOR.

SEF555N

Yes

CHECK IGNITION TIMING.

(ij\

1.Warm upengine sufficiently.

~ 2.Select "IGNTIMING ADJ"in

"WORK SUPPORT" mode.

3. Touch "START".

4. Check ignition timingatidle

using timing light.

Ignition timing:

15°::f:2° BTDC

~ 1Warm upengine sufficiently.

~ 2:

Stop engine anddisconnect

throttle position sensorhar-

ness connector.

3. Start engine.

4. Check ignition timingatidle

using timing light.

Ignition timing:

15°::f:2° BTDC

OK

(Go to

@

onnext page.) Adjust

ignition timingby

turning distributor.

EC-271