NISSAN ALMERA N16 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2261 of 3189

Service NoticeNJBT0001When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to oil

or damage them.

Apply sealing compound where necessary when installing parts.

When applying sealing compound, be careful that the sealing compound doesnot protrude from parts.

When replacing any metal parts (for example body outer panel, members, etc.),besuretotakerustpre-

vention measures.

Supplemental Restraint System (SRS) “AIR

BAG” and “SEAT BELT PRE-TENSIONER”

NJBT0002The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER” used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removalofSpiralCableandAir

Bag Module, see the RS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow or/and orange harness connec-

tor.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

HA

SC

EL

IDX

PRECAUTIONS

Service Notice

BT-3

Page 2262 of 3189

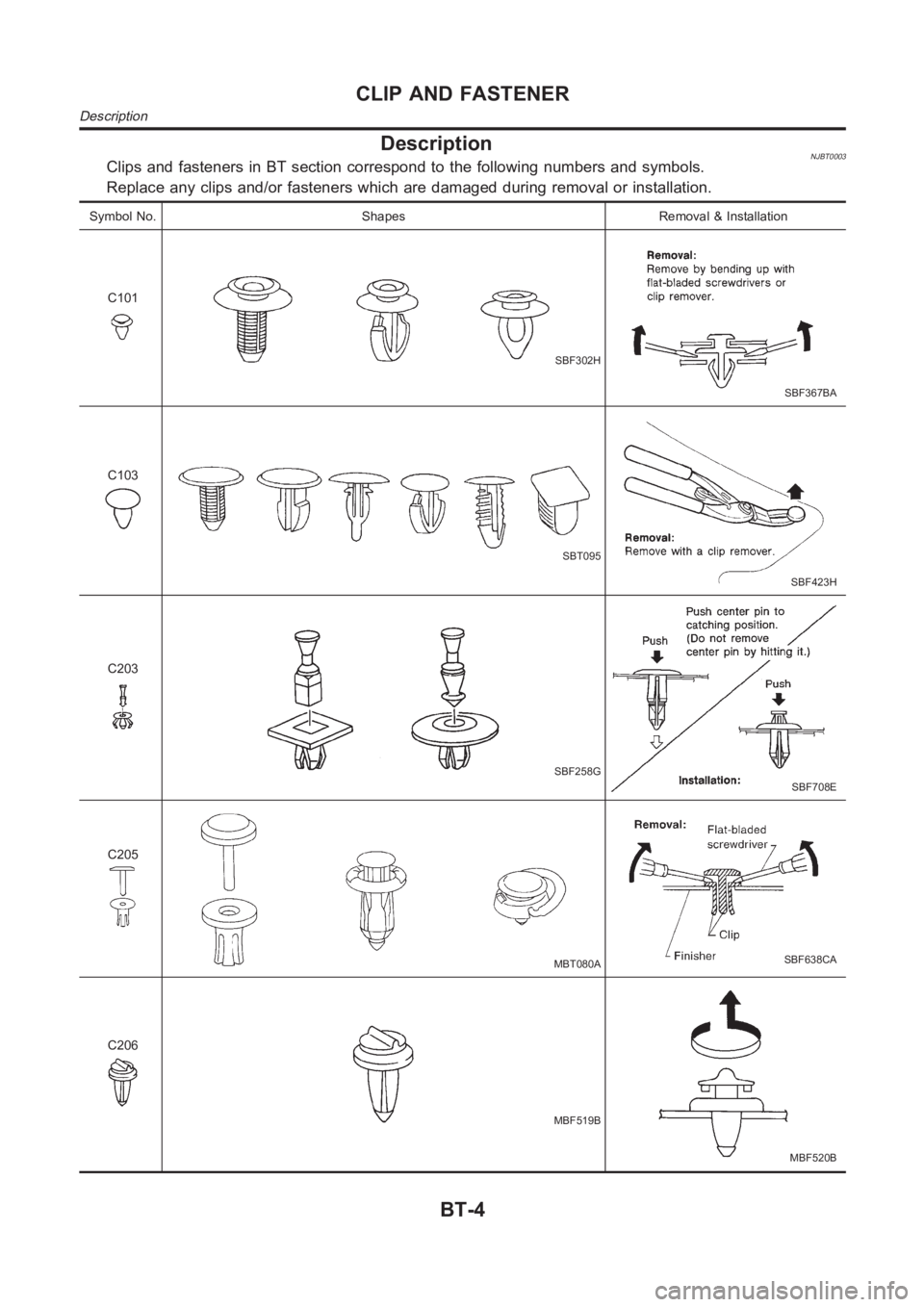

DescriptionNJBT0003Clips and fasteners in BT section correspond to the following numbers and symbols.

Replace any clips and/or fasteners which are damaged during removal or installation.

Symbol No. Shapes Removal & Installation

C101

SBF302H

SBF367BA

C103

SBT095

SBF423H

C203

SBF258G

SBF708E

C205

MBT080ASBF638CA

C206

MBF519B

MBF520B

CLIP AND FASTENER

Description

BT-4

Page 2263 of 3189

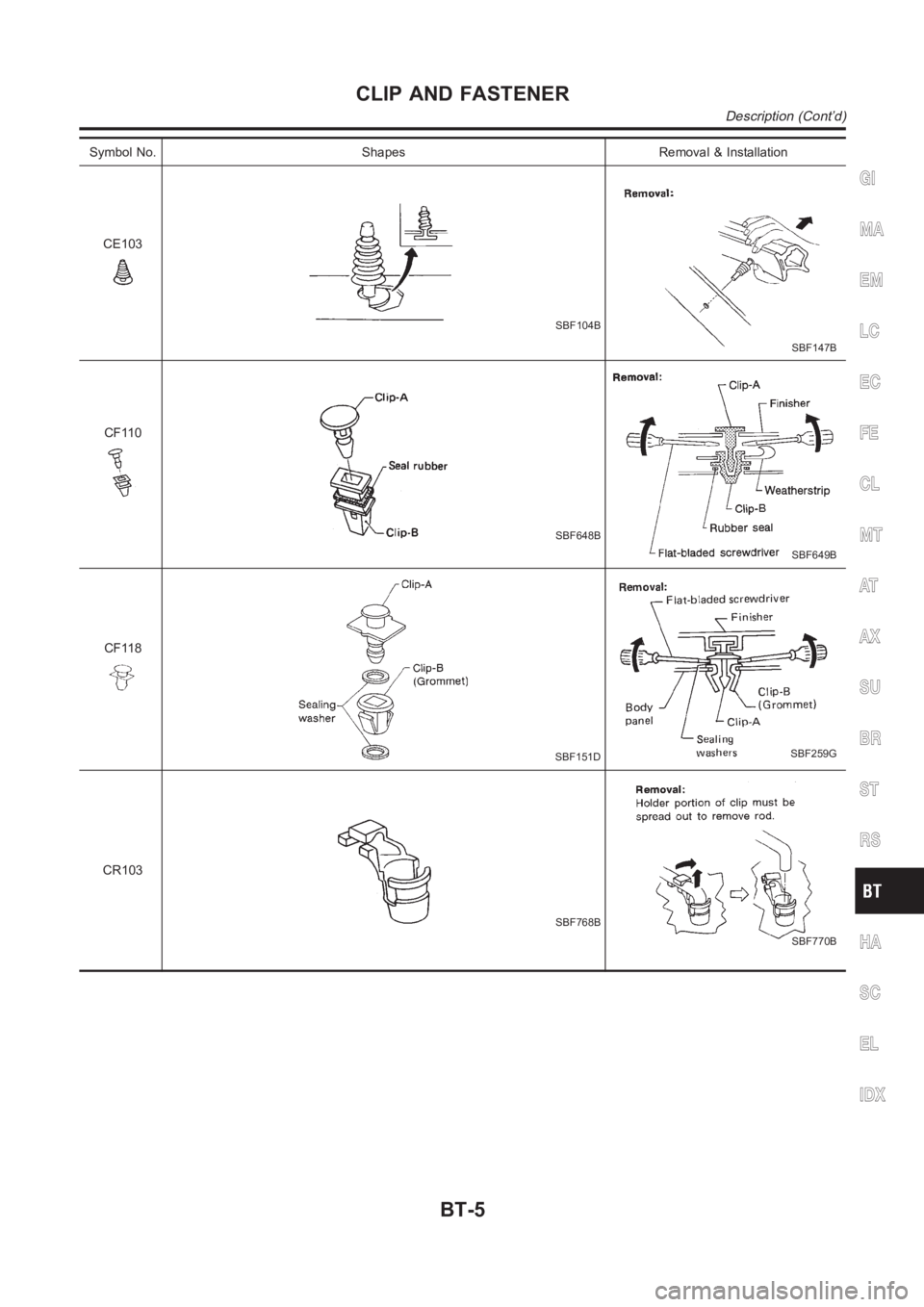

Symbol No. Shapes Removal & Installation

CE103

SBF104B

SBF147B

CF110

SBF648B

SBF649B

CF118

SBF151DSBF259G

CR103

SBF768B

SBF770B

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

HA

SC

EL

IDX

CLIP AND FASTENER

Description (Cont’d)

BT-5

Page 2264 of 3189

Checking Body CorrosionNJBT0033Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Trunk lid opening, sunroof opening, fender wheelarch flange, fuel fillerlid flange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

Checking Body Corrosion

BT-6

Page 2265 of 3189

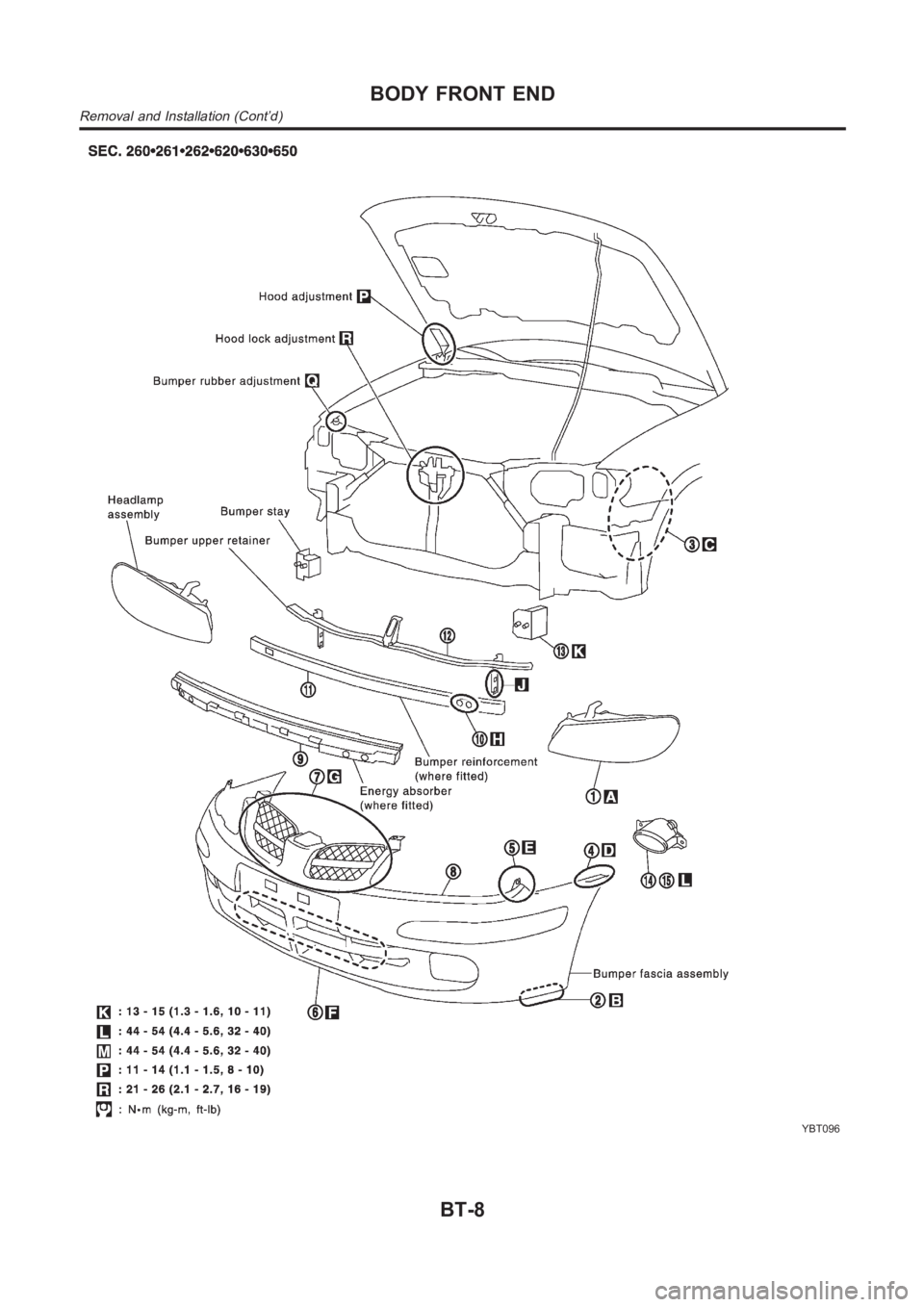

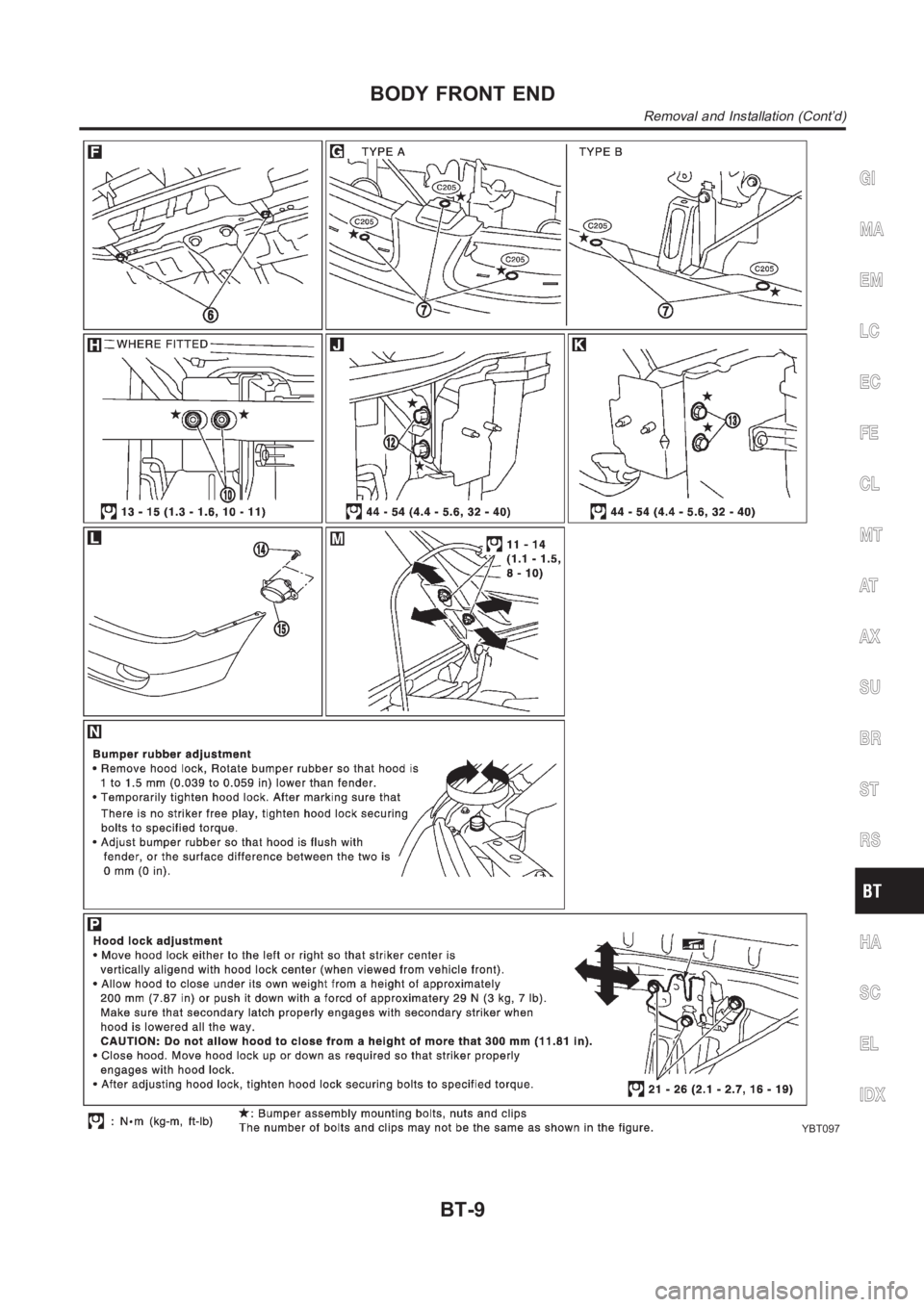

Removal and InstallationNJBT0004When removing or installing hood, place a cloth or other padding on hood. This prevents vehicle body from

being scratched.

Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

Hood adjustment: Adjust at hinge portion.

Hood lock adjustment: After adjusting, check hood lock control operation. Apply a coat of grease to hood

locks engaging mechanism.

Hood opener: Do not attempt to bend cable forcibly. Doing so increases effort required to unlock hood.

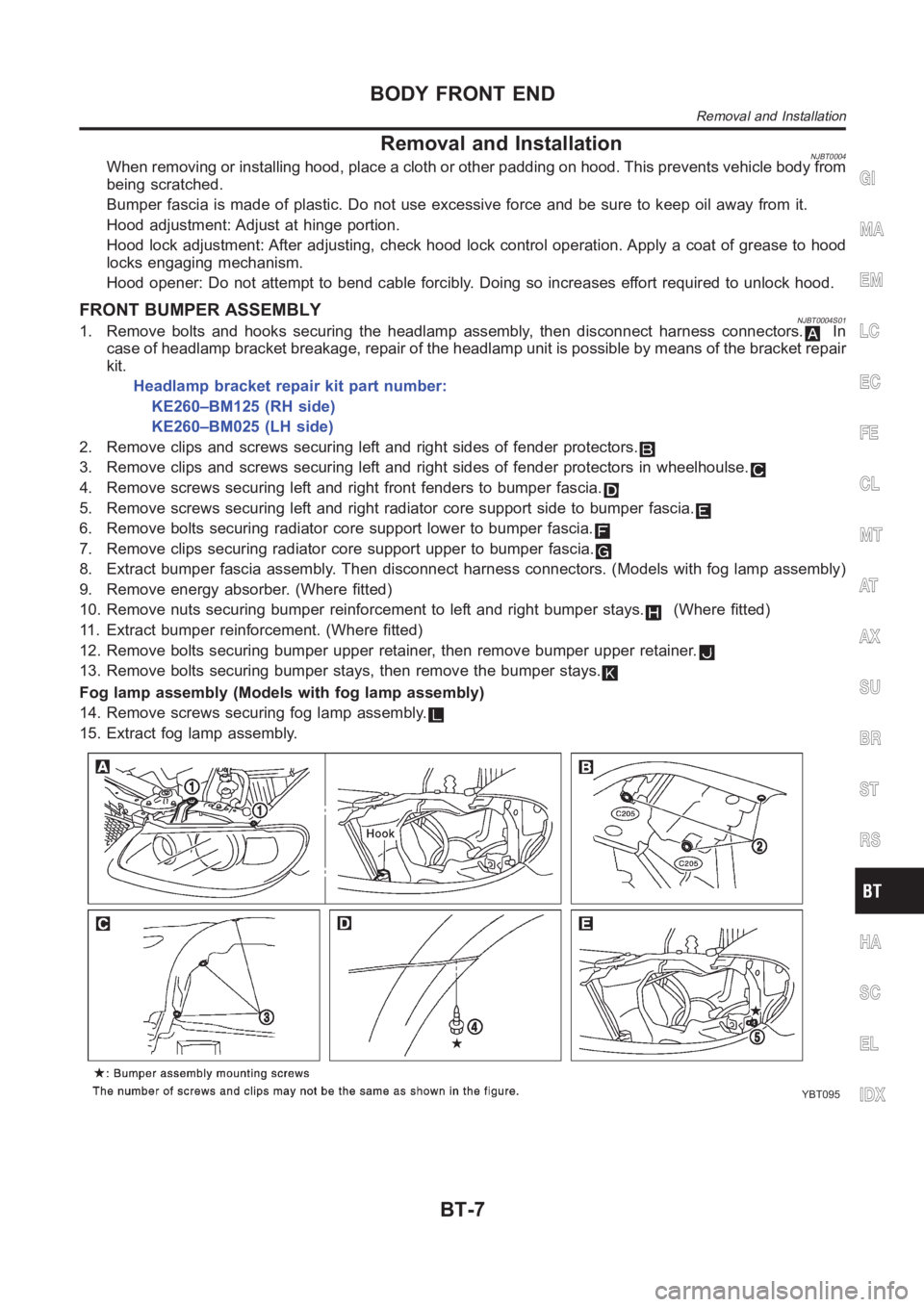

FRONT BUMPER ASSEMBLYNJBT0004S011. Remove bolts and hooks securing the headlamp assembly, then disconnectharness connectors.In

case of headlamp bracket breakage, repair of the headlamp unit is possibleby means of the bracket repair

kit.

Headlamp bracket repair kit part number:

KE260–BM125 (RH side)

KE260–BM025 (LH side)

2. Remove clips and screws securing left and right sides of fender protectors.

3. Remove clips and screws securing left and right sides of fender protectors in wheelhoulse.

4. Remove screws securing left and right front fenders to bumper fascia.

5. Remove screws securing left and right radiator core support side to bumper fascia.

6. Remove bolts securing radiator core support lower to bumper fascia.

7. Remove clips securing radiator core support upper to bumper fascia.

8. Extract bumper fascia assembly. Then disconnect harness connectors. (Models with fog lamp assembly)

9. Remove energy absorber. (Where fitted)

10. Remove nuts securing bumper reinforcement to left and right bumper stays.

(Where fitted)

11. Extract bumper reinforcement. (Where fitted)

12. Remove bolts securing bumper upper retainer, then remove bumper upperretainer.

13. Remove bolts securing bumper stays, then remove the bumper stays.

Fog lamp assembly (Models with fog lamp assembly)

14. Remove screws securing fog lamp assembly.

15. Extract fog lamp assembly.

YBT095

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

HA

SC

EL

IDX

BODY FRONT END

Removal and Installation

BT-7

Page 2266 of 3189

YBT096

BODY FRONT END

Removal and Installation (Cont’d)

BT-8

Page 2267 of 3189

YBT097

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

HA

SC

EL

IDX

BODY FRONT END

Removal and Installation (Cont’d)

BT-9

Page 2268 of 3189

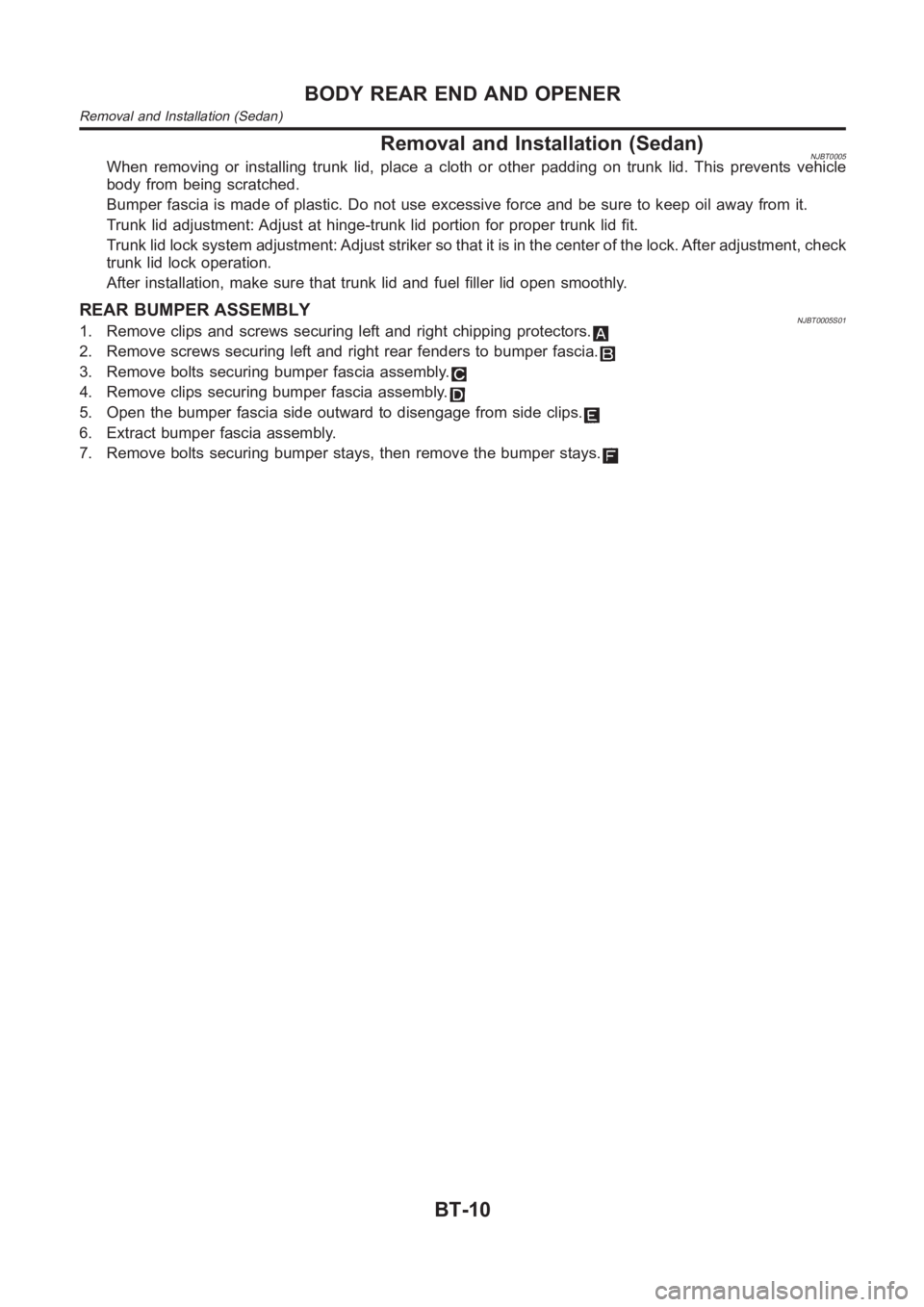

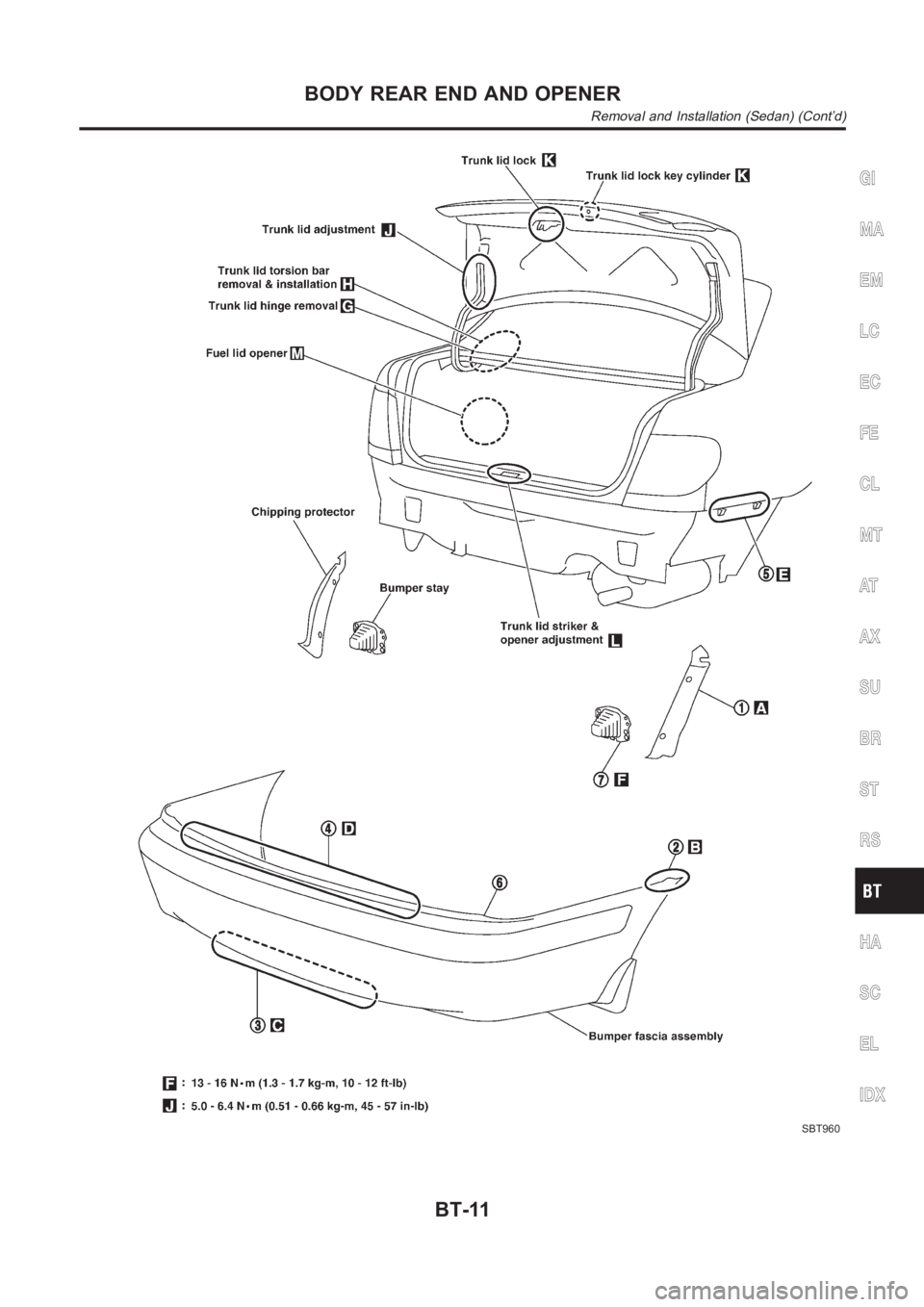

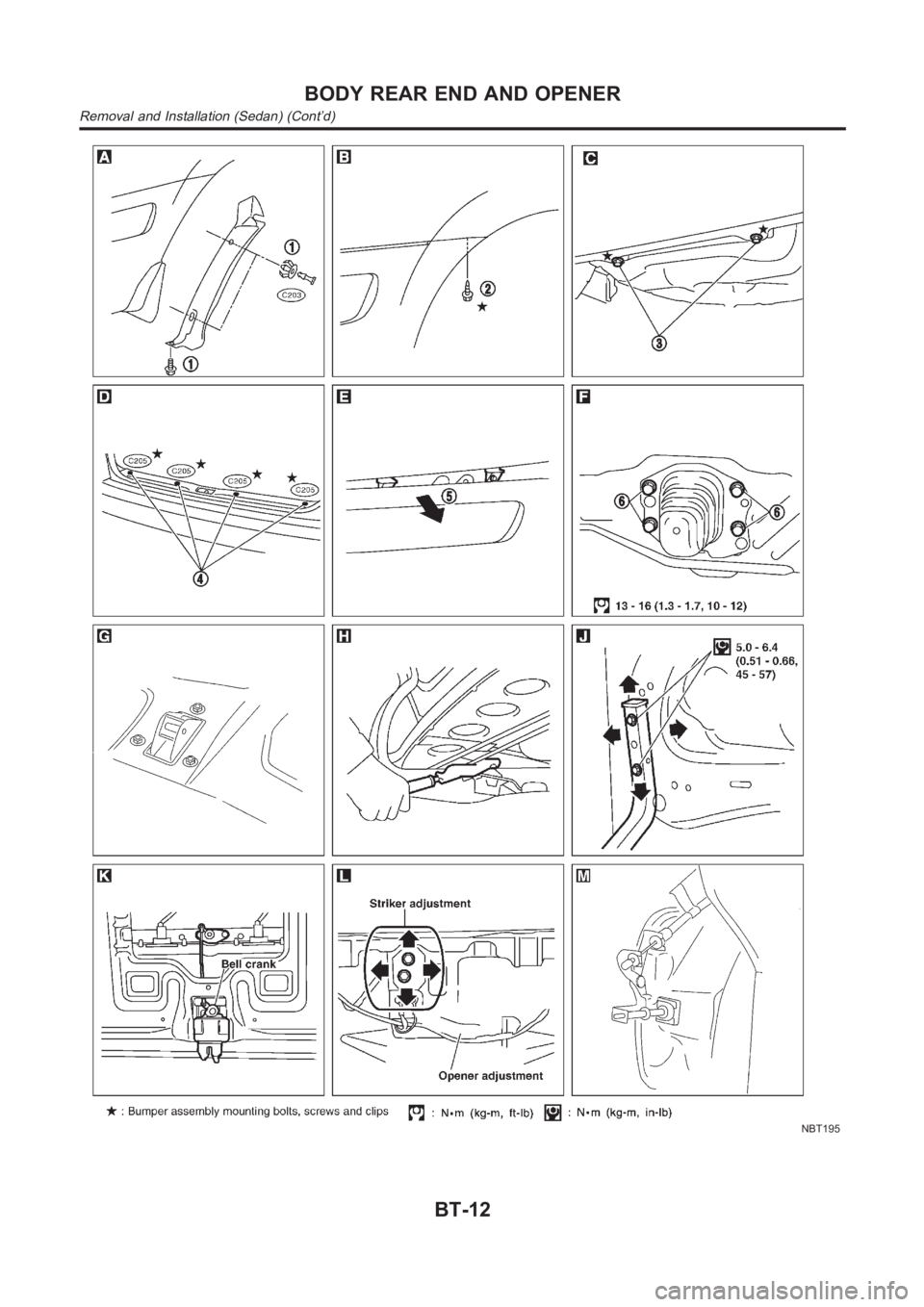

Removal and Installation (Sedan)NJBT0005When removing or installing trunk lid, place a cloth or other padding on trunk lid. This prevents vehicle

body from being scratched.

Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

Trunk lid adjustment: Adjust at hinge-trunk lid portion for proper trunk lid fit.

Trunk lid lock system adjustment: Adjust striker so that it is in the centerof the lock. After adjustment, check

trunk lid lock operation.

After installation, make sure that trunk lid and fuel filler lid open smoothly.

REAR BUMPER ASSEMBLYNJBT0005S011. Remove clips and screws securing left and right chipping protectors.

2. Remove screws securing left and right rear fenders to bumper fascia.

3. Remove bolts securing bumper fascia assembly.

4. Remove clips securing bumper fascia assembly.

5. Open the bumper fascia side outward to disengage from side clips.

6. Extract bumper fascia assembly.

7. Remove bolts securing bumper stays, then remove the bumper stays.

BODY REAR END AND OPENER

Removal and Installation (Sedan)

BT-10

Page 2269 of 3189

SBT960

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

HA

SC

EL

IDX

BODY REAR END AND OPENER

Removal and Installation (Sedan) (Cont’d)

BT-11

Page 2270 of 3189

NBT195

BODY REAR END AND OPENER

Removal and Installation (Sedan) (Cont’d)

BT-12