NISSAN ALMERA N16 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 231 of 3189

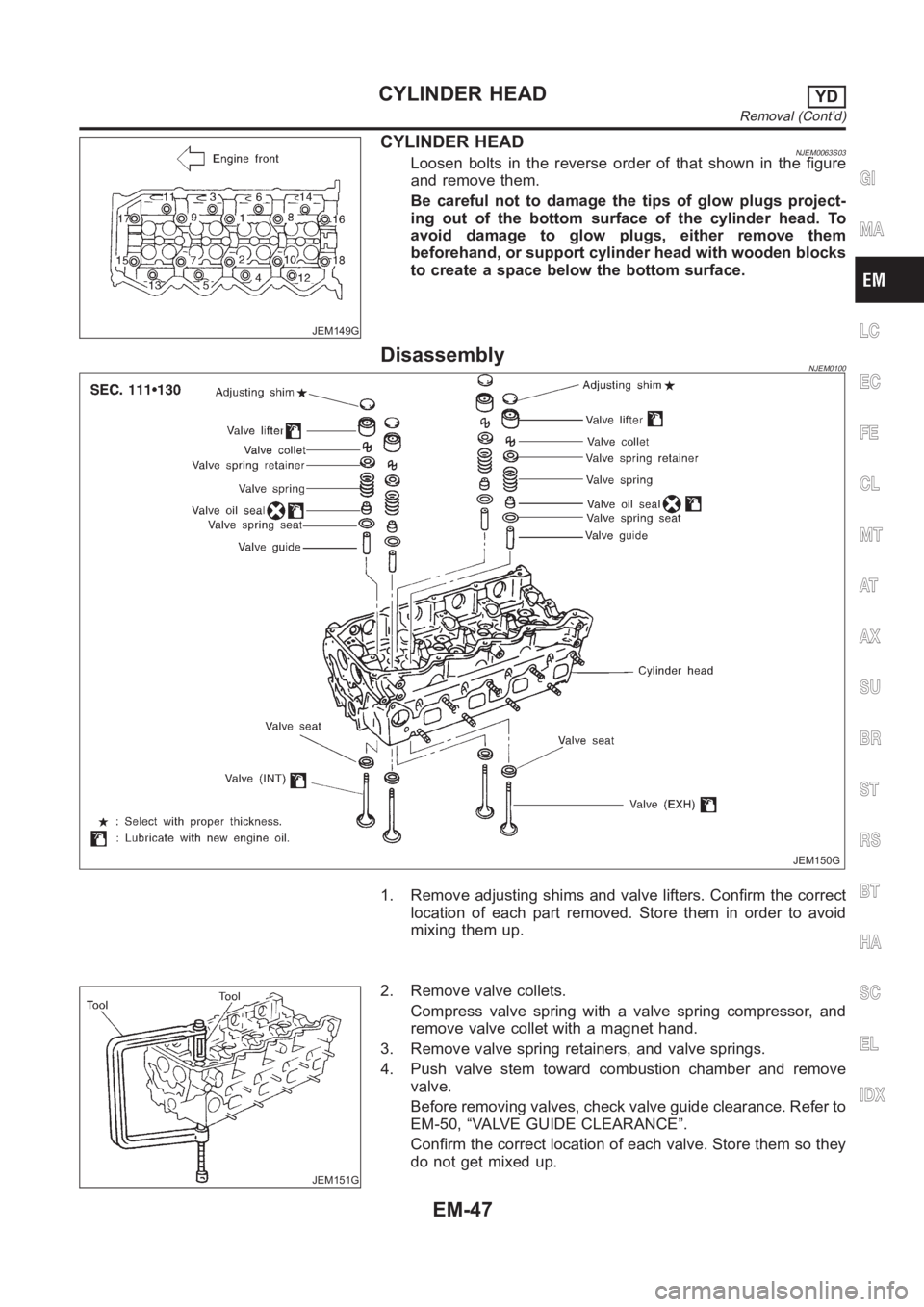

JEM149G

CYLINDER HEADNJEM0063S03Loosen bolts in the reverse order of that shown in the figure

and remove them.

Be careful not to damage the tips of glow plugs project-

ing out of the bottom surface of the cylinder head. To

avoid damage to glow plugs, either remove them

beforehand, or support cylinder head with wooden blocks

to create a space below the bottom surface.

DisassemblyNJEM0100

JEM150G

1. Remove adjusting shims and valve lifters. Confirm the correct

location of each part removed. Store them in order to avoid

mixing them up.

JEM151G

2. Remove valve collets.

Compress valve spring with a valve spring compressor, and

remove valve collet with a magnet hand.

3. Remove valve spring retainers, and valve springs.

4. Push valve stem toward combustion chamber and remove

valve.

Before removing valves, check valve guide clearance. Refer to

EM-50, “VALVE GUIDE CLEARANCE”.

Confirm the correct location of each valve. Store them so they

do not get mixed up.

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CYLINDER HEADYD

Removal (Cont’d)

EM-47

Page 232 of 3189

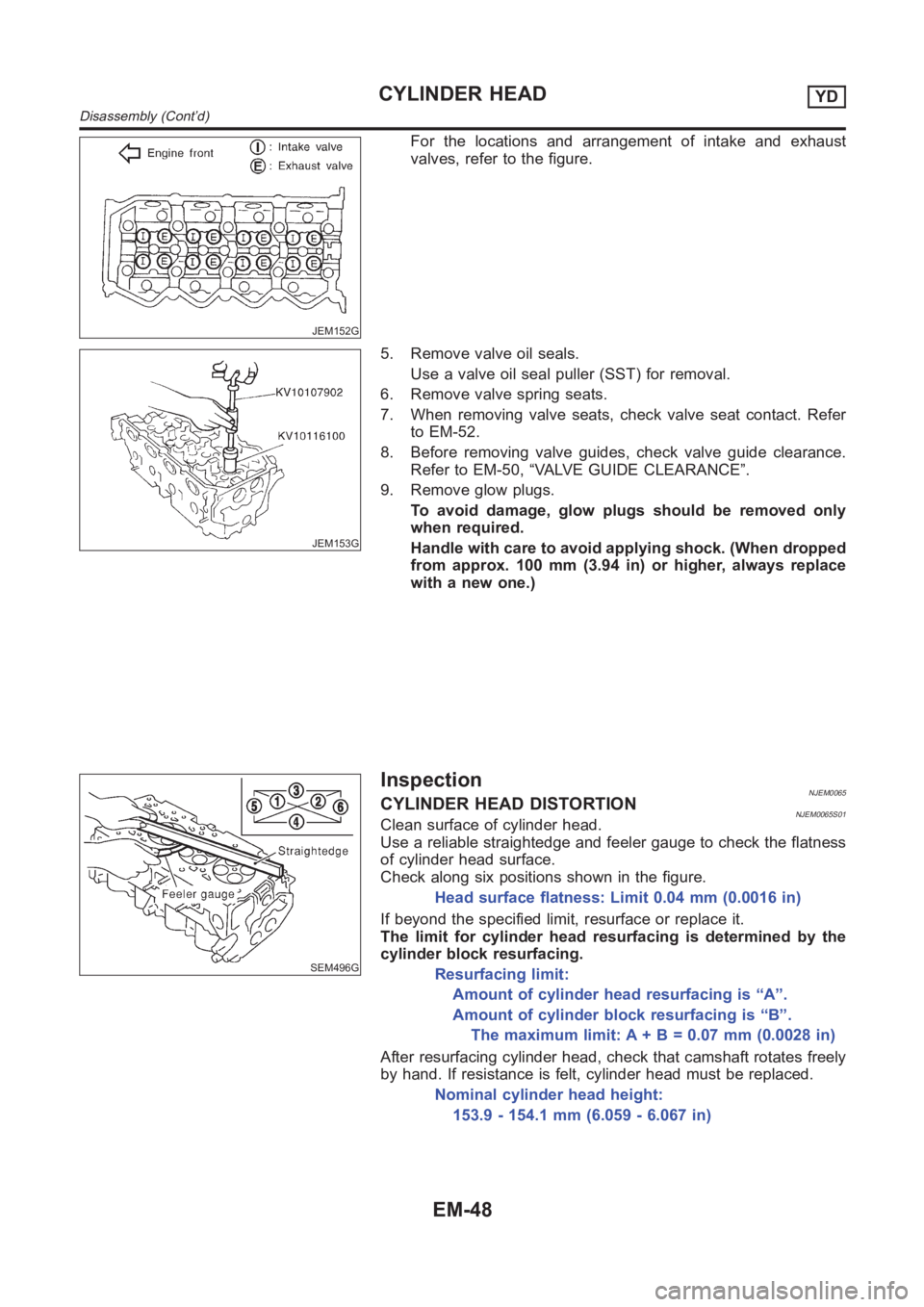

JEM152G

For the locations and arrangement of intake and exhaust

valves, refer to the figure.

JEM153G

5. Remove valve oil seals.

Use a valve oil seal puller (SST) for removal.

6. Remove valve spring seats.

7. When removing valve seats, check valve seat contact. Refer

to EM-52.

8. Before removing valve guides, check valve guide clearance.

Refer to EM-50, “VALVE GUIDE CLEARANCE”.

9. Remove glow plugs.

To avoid damage, glow plugs should be removed only

when required.

Handle with care to avoid applying shock. (When dropped

from approx. 100 mm (3.94 in) or higher, always replace

with a new one.)

SEM496G

InspectionNJEM0065CYLINDER HEAD DISTORTIONNJEM0065S01Clean surface of cylinder head.

Use a reliable straightedge and feeler gauge to check the flatness

of cylinder head surface.

Check along six positions shown in the figure.

Head surface flatness: Limit 0.04 mm (0.0016 in)

If beyond the specified limit, resurface or replace it.

The limit for cylinder head resurfacing is determined by the

cylinder block resurfacing.

Resurfacing limit:

Amount of cylinder head resurfacing is “A”.

Amount of cylinder block resurfacing is “B”.

The maximum limit: A + B = 0.07 mm (0.0028 in)

After resurfacing cylinder head, check that camshaft rotates freely

by hand. If resistance is felt, cylinder head must be replaced.

Nominal cylinder head height:

153.9 - 154.1 mm (6.059 - 6.067 in)

CYLINDER HEADYD

Disassembly (Cont’d)

EM-48

Page 233 of 3189

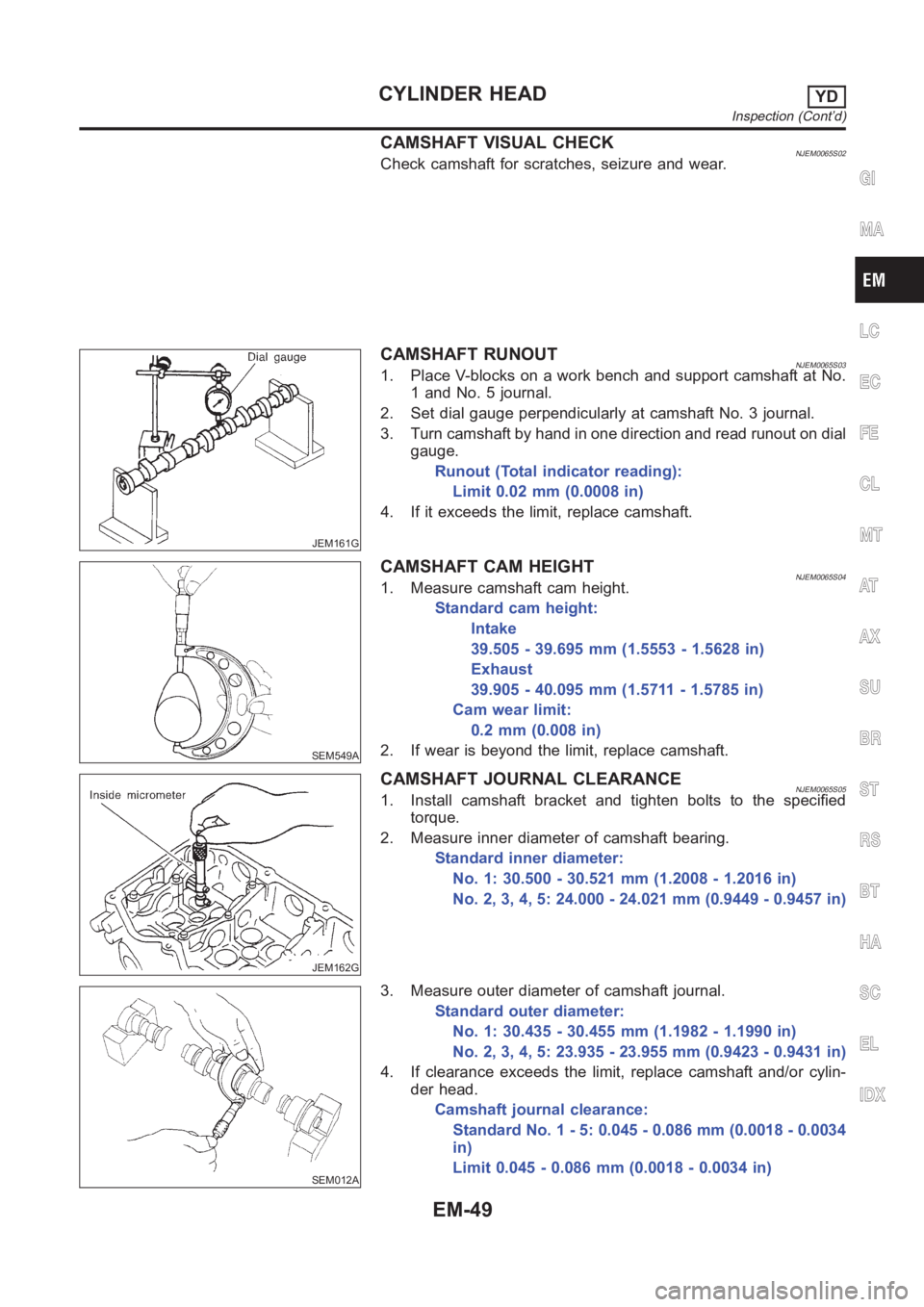

CAMSHAFT VISUAL CHECKNJEM0065S02Check camshaft for scratches, seizure and wear.

JEM161G

CAMSHAFT RUNOUTNJEM0065S031. Place V-blocks on a work bench and support camshaft at No.

1 and No. 5 journal.

2. Set dial gauge perpendicularly at camshaft No. 3 journal.

3. Turn camshaft by hand in one direction and read runout on dial

gauge.

Runout (Total indicator reading):

Limit 0.02 mm (0.0008 in)

4. If it exceeds the limit, replace camshaft.

SEM549A

CAMSHAFT CAM HEIGHTNJEM0065S041. Measure camshaft cam height.

Standard cam height:

Intake

39.505 - 39.695 mm (1.5553 - 1.5628 in)

Exhaust

39.905 - 40.095 mm (1.5711 - 1.5785 in)

Cam wear limit:

0.2mm(0.008in)

2. If wear is beyond the limit, replace camshaft.

JEM162G

CAMSHAFT JOURNAL CLEARANCENJEM0065S051. Install camshaft bracket and tighten bolts to the specified

torque.

2. Measure inner diameter of camshaft bearing.

Standard inner diameter:

No. 1: 30.500 - 30.521 mm (1.2008 - 1.2016 in)

No. 2, 3, 4, 5: 24.000 - 24.021 mm (0.9449 - 0.9457 in)

SEM012A

3. Measure outer diameter of camshaft journal.

Standard outer diameter:

No. 1: 30.435 - 30.455 mm (1.1982 - 1.1990 in)

No. 2, 3, 4, 5: 23.935 - 23.955 mm (0.9423 - 0.9431 in)

4. If clearance exceeds the limit, replace camshaft and/or cylin-

der head.

Camshaft journal clearance:

Standard No. 1 - 5: 0.045 - 0.086 mm (0.0018 - 0.0034

in)

Limit 0.045 - 0.086 mm (0.0018 - 0.0034 in)

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CYLINDER HEADYD

Inspection (Cont’d)

EM-49

Page 234 of 3189

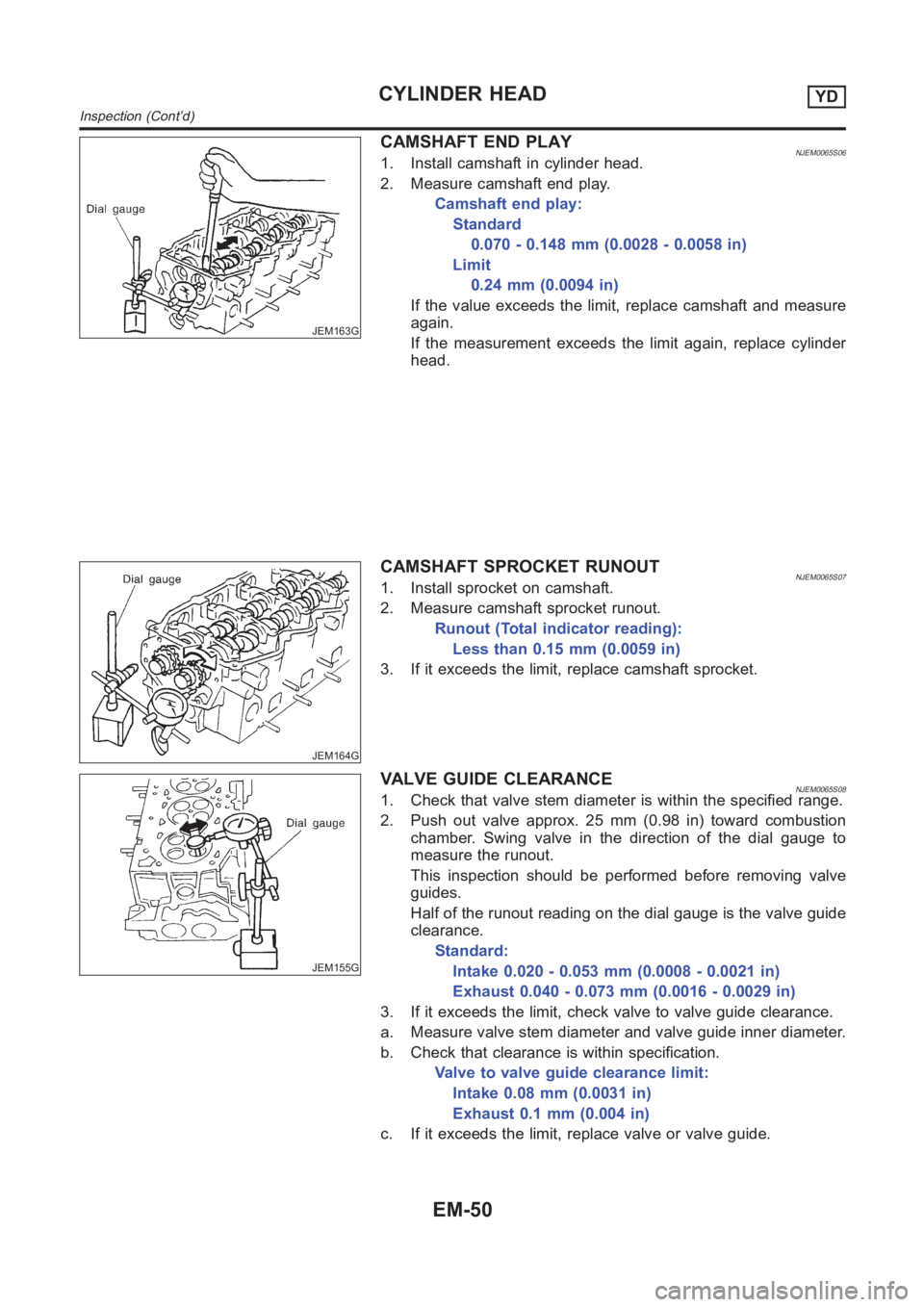

JEM163G

CAMSHAFT END PLAYNJEM0065S061. Install camshaft in cylinder head.

2. Measure camshaft end play.

Camshaft end play:

Standard

0.070 - 0.148 mm (0.0028 - 0.0058 in)

Limit

0.24 mm (0.0094 in)

If the value exceeds the limit, replace camshaft and measure

again.

If the measurement exceeds the limit again, replace cylinder

head.

JEM164G

CAMSHAFT SPROCKET RUNOUTNJEM0065S071. Install sprocket on camshaft.

2. Measure camshaft sprocket runout.

Runout (Total indicator reading):

Less than 0.15 mm (0.0059 in)

3. If it exceeds the limit, replace camshaft sprocket.

JEM155G

VALVE GUIDE CLEARANCENJEM0065S081. Check that valve stem diameter is within the specified range.

2. Push out valve approx. 25 mm (0.98 in) toward combustion

chamber. Swing valve in the direction of the dial gauge to

measure the runout.

This inspection should be performed before removing valve

guides.

Half of the runout reading on the dial gauge is the valve guide

clearance.

Standard:

Intake 0.020 - 0.053 mm (0.0008 - 0.0021 in)

Exhaust 0.040 - 0.073 mm (0.0016 - 0.0029 in)

3. If it exceeds the limit, check valve to valve guide clearance.

a. Measure valve stem diameter and valve guide inner diameter.

b. Check that clearance is within specification.

Valve to valve guide clearance limit:

Intake 0.08 mm (0.0031 in)

Exhaust 0.1 mm (0.004 in)

c. If it exceeds the limit, replace valve or valve guide.

CYLINDER HEADYD

Inspection (Cont’d)

EM-50

Page 235 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual SEM008A

VALVE GUIDE REPLACEMENTNJEM0065S09When a valve guide is removed, replace with an oversized [0.2

mm (0.008 in)] valve guide.

1. To remove valve guide, heat cylinder head to 110 to 130°C

(230 t NISSAN ALMERA N16 2003 Electronic Repair Manual SEM008A

VALVE GUIDE REPLACEMENTNJEM0065S09When a valve guide is removed, replace with an oversized [0.2

mm (0.008 in)] valve guide.

1. To remove valve guide, heat cylinder head to 110 to 130°C

(230 t](/img/5/57350/w960_57350-234.png)

SEM008A

VALVE GUIDE REPLACEMENTNJEM0065S09When a valve guide is removed, replace with an oversized [0.2

mm (0.008 in)] valve guide.

1. To remove valve guide, heat cylinder head to 110 to 130°C

(230 to 266°F) by soaking in heated oil.

SEM931C

2. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2

US ton, 2.0 Imp ton) pressure] or hammer and suitable tool.

SEM932C

3. Ream cylinder head valve guide hole.

Valve guide hole diameter (for service parts):

10.175 - 10.196 mm (0.4006 - 0.4014 in)

JEM156G

4. Heat cylinder head to 110 to 130°C (230 to 266°F) and press

service valve guide onto cylinder head.

Projection “L”:

10.4 - 10.6 mm (0.409 - 0.417 in)

5. Ream valve guide.

Finished size:

6.000 - 6.018 mm (0.2362 - 0.2369 in)

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CYLINDER HEADYD

Inspection (Cont’d)

EM-51

Page 236 of 3189

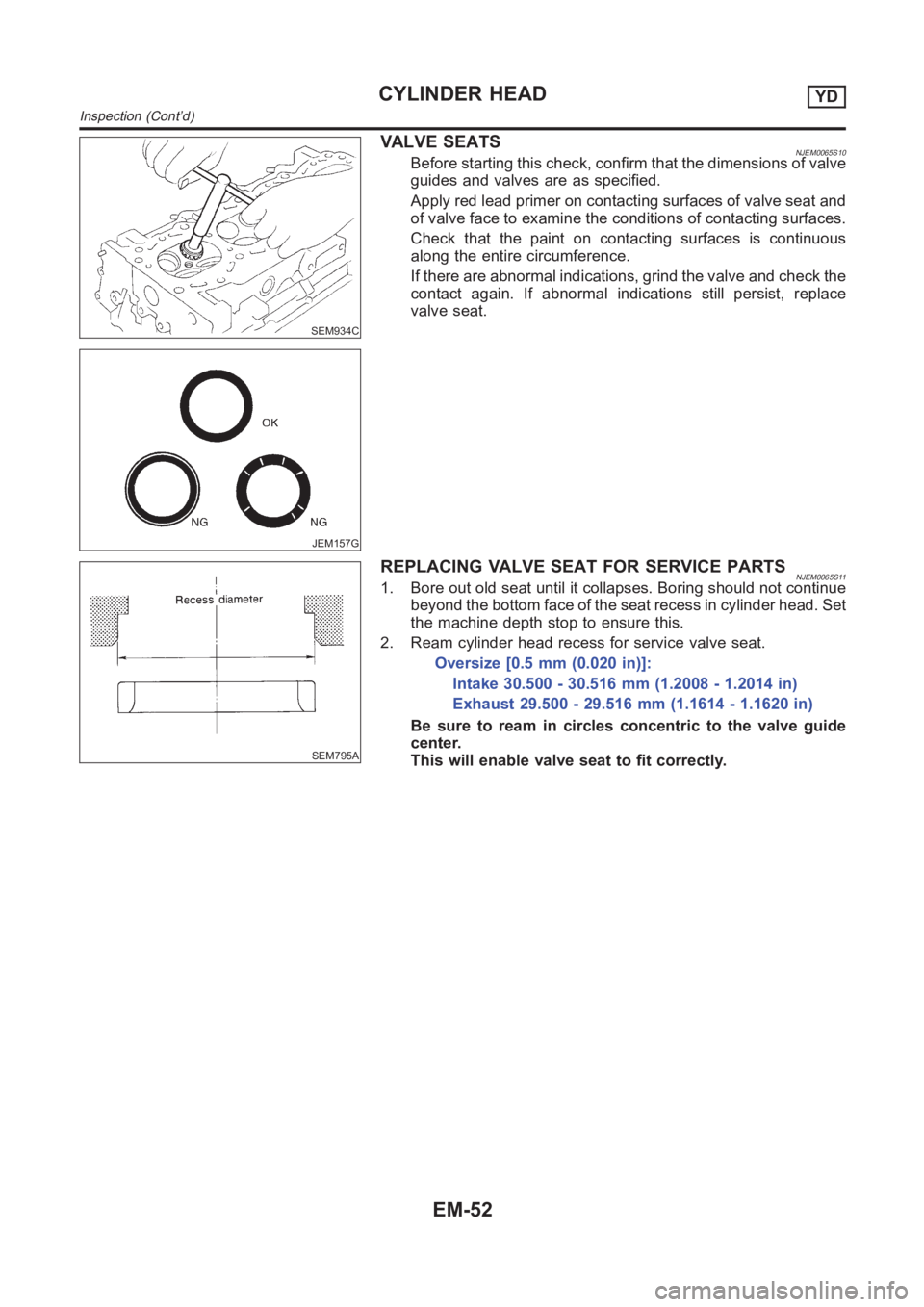

SEM934C

JEM157G

VALVE SEATSNJEM0065S10Before starting this check, confirm that the dimensions of valve

guides and valves are as specified.

Apply red lead primer on contacting surfaces of valve seat and

of valve face to examine the conditions of contacting surfaces.

Check that the paint on contacting surfaces is continuous

along the entire circumference.

If there are abnormal indications, grind the valve and check the

contact again. If abnormal indications still persist, replace

valve seat.

SEM795A

REPLACING VALVE SEAT FOR SERVICE PARTSNJEM0065S111. Bore out old seat until it collapses. Boring should not continue

beyond the bottom face of the seat recess in cylinder head. Set

the machine depth stop to ensure this.

2. Ream cylinder head recess for service valve seat.

Oversize [0.5 mm (0.020 in)]:

Intake 30.500 - 30.516 mm (1.2008 - 1.2014 in)

Exhaust 29.500 - 29.516 mm (1.1614 - 1.1620 in)

Be sure to ream in circles concentric to the valve guide

center.

This will enable valve seat to fit correctly.

CYLINDER HEADYD

Inspection (Cont’d)

EM-52

Page 237 of 3189

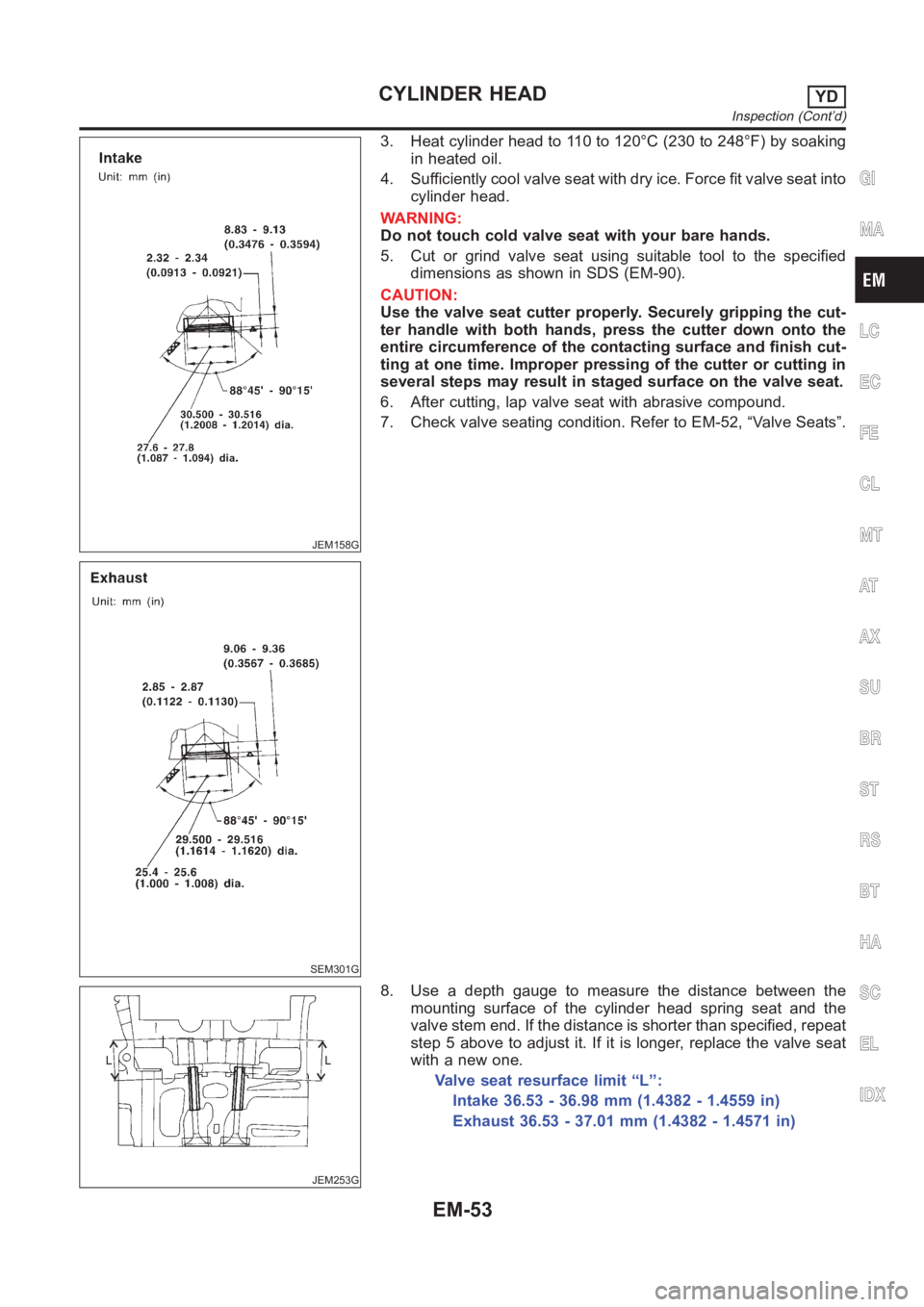

JEM158G

SEM301G

3. Heat cylinder head to 110 to 120°C (230 to 248°F) by soaking

in heated oil.

4. Sufficiently cool valve seat with dry ice. Force fit valve seat into

cylinder head.

WARNING:

Do not touch cold valve seat with your bare hands.

5. Cut or grind valve seat using suitable tool to the specified

dimensions as shown in SDS (EM-90).

CAUTION:

Use the valve seat cutter properly. Securely gripping the cut-

ter handle with both hands, press the cutter down onto the

entire circumference of the contacting surface and finish cut-

ting at one time. Improper pressing of the cutter or cutting in

several steps may result in staged surface on the valve seat.

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition. Refer to EM-52, “Valve Seats”.

JEM253G

8. Use a depth gauge to measure the distance between the

mounting surface of the cylinder head spring seat and the

valve stem end. If the distance is shorter than specified, repeat

step 5 above to adjust it. If it is longer, replace the valve seat

with a new one.

Valve seat resurface limit “L”:

Intake 36.53 - 36.98 mm (1.4382 - 1.4559 in)

Exhaust 36.53 - 37.01 mm (1.4382 - 1.4571 in)

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CYLINDER HEADYD

Inspection (Cont’d)

EM-53

Page 238 of 3189

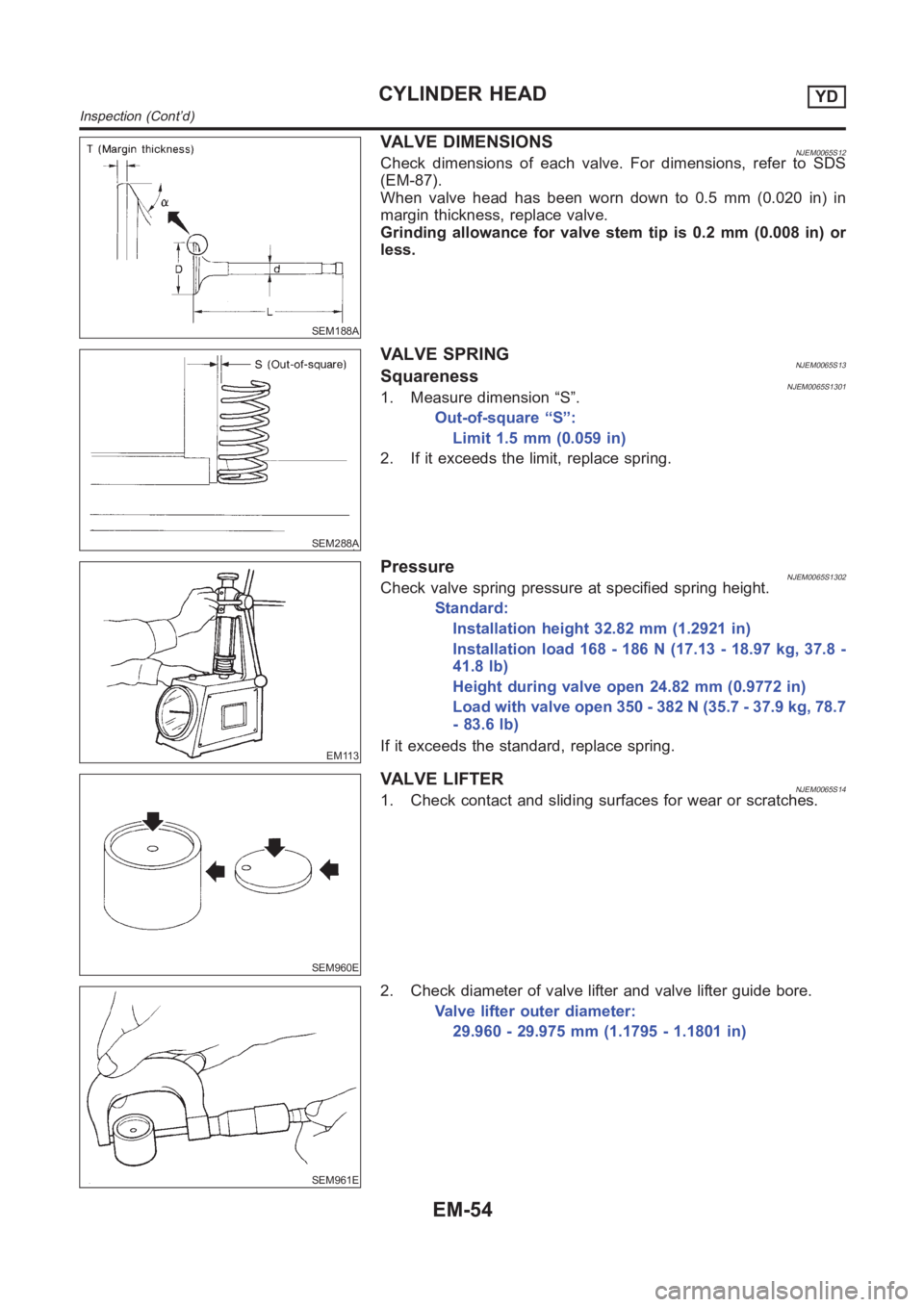

SEM188A

VALVE DIMENSIONSNJEM0065S12Check dimensions of each valve. For dimensions, refer to SDS

(EM-87).

When valve head has been worn down to 0.5 mm (0.020 in) in

margin thickness, replace valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

SEM288A

VALVE SPRINGNJEM0065S13SquarenessNJEM0065S13011. Measure dimension “S”.

Out-of-square “S”:

Limit 1.5 mm (0.059 in)

2. If it exceeds the limit, replace spring.

EM113

PressureNJEM0065S1302Check valve spring pressure at specified spring height.

Standard:

Installation height 32.82 mm (1.2921 in)

Installation load 168 - 186 N (17.13 - 18.97 kg, 37.8 -

41.8 lb)

Height during valve open 24.82 mm (0.9772 in)

Load with valve open 350 - 382 N (35.7 - 37.9 kg, 78.7

- 83.6 lb)

If it exceeds the standard, replace spring.

SEM960E

VALVE LIFTERNJEM0065S141. Check contact and sliding surfaces for wear or scratches.

SEM961E

2. Check diameter of valve lifter and valve lifter guide bore.

Valve lifter outer diameter:

29.960 - 29.975 mm (1.1795 - 1.1801 in)

CYLINDER HEADYD

Inspection (Cont’d)

EM-54

Page 239 of 3189

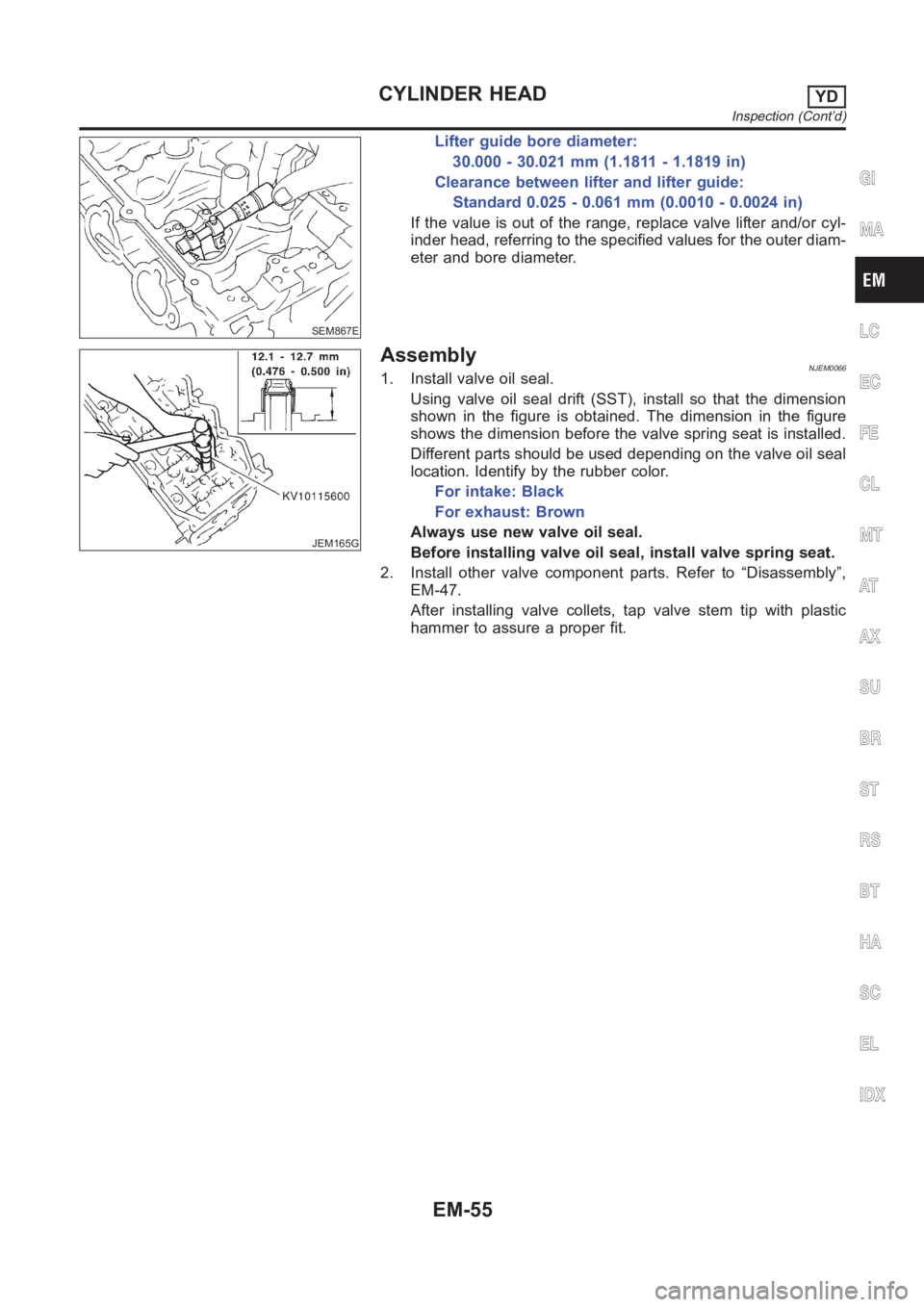

SEM867E

Lifter guide bore diameter:

30.000 - 30.021 mm (1.1811 - 1.1819 in)

Clearance between lifter and lifter guide:

Standard 0.025 - 0.061 mm (0.0010 - 0.0024 in)

If the value is out of the range, replace valve lifter and/or cyl-

inder head, referring to the specified values for the outer diam-

eter and bore diameter.

JEM165G

AssemblyNJEM00661. Install valve oil seal.

Using valve oil seal drift (SST), install so that the dimension

shown in the figure is obtained. The dimension in the figure

shows the dimension before the valve spring seat is installed.

Different parts should be used depending on the valve oil seal

location. Identify by the rubber color.

For intake: Black

For exhaust: Brown

Always use new valve oil seal.

Before installing valve oil seal, install valve spring seat.

2. Install other valve component parts. Refer to “Disassembly”,

EM-47.

After installing valve collets, tap valve stem tip with plastic

hammer to assure a proper fit.

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CYLINDER HEADYD

Inspection (Cont’d)

EM-55

Page 240 of 3189

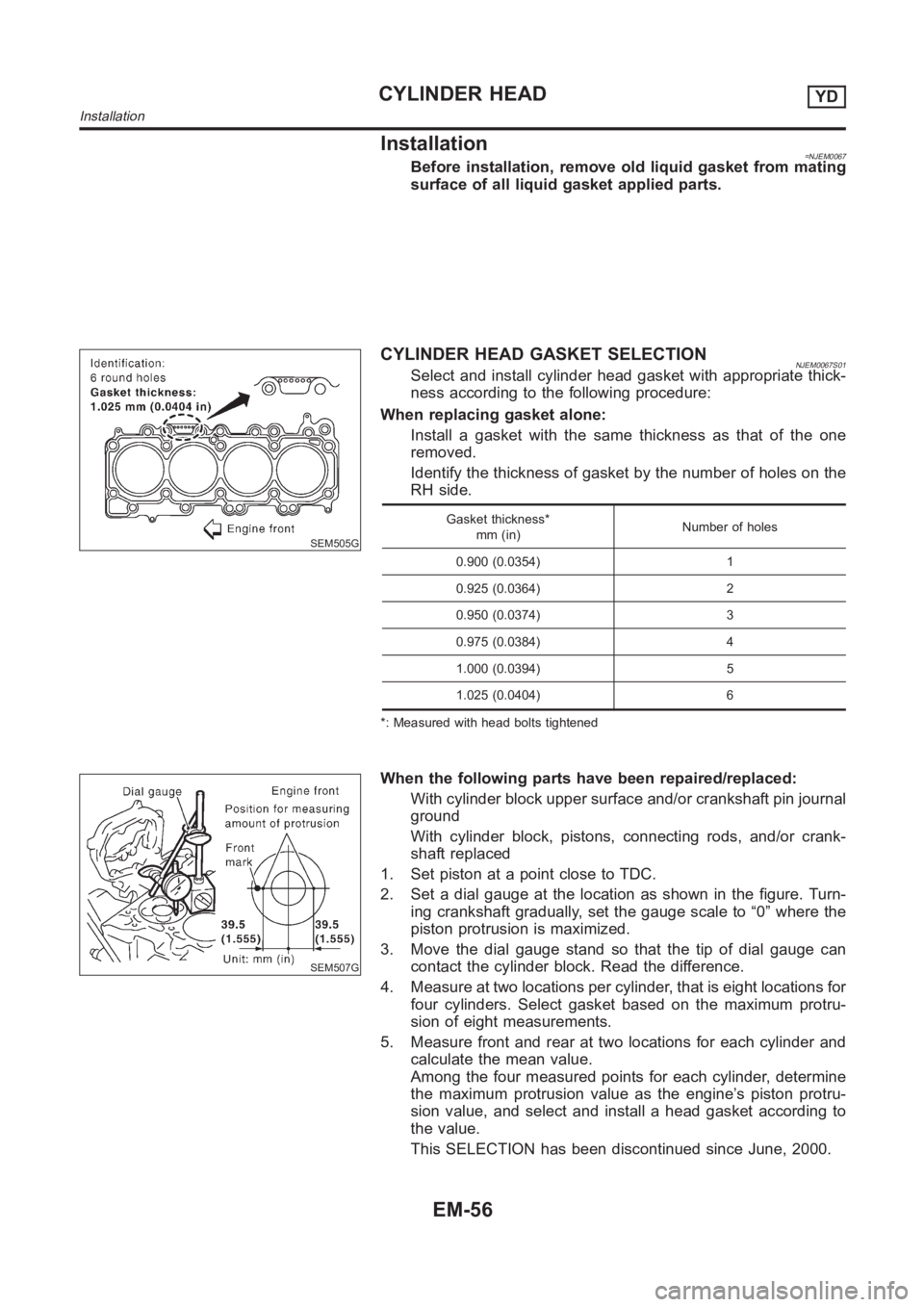

Installation=NJEM0067Before installation, remove old liquid gasket from mating

surface of all liquid gasket applied parts.

SEM505G

CYLINDER HEAD GASKET SELECTIONNJEM0067S01Select and install cylinder head gasket with appropriate thick-

ness according to the following procedure:

When replacing gasket alone:

Install a gasket with the same thickness as that of the one

removed.

Identify the thickness of gasket by the number of holes on the

RH side.

Gasket thickness*

mm (in)Number of holes

0.900 (0.0354) 1

0.925 (0.0364) 2

0.950 (0.0374) 3

0.975 (0.0384) 4

1.000 (0.0394) 5

1.025 (0.0404) 6

*: Measured with head bolts tightened

SEM507G

When the following parts have been repaired/replaced:

With cylinder block upper surface and/or crankshaft pin journal

ground

With cylinder block, pistons, connecting rods, and/or crank-

shaft replaced

1. Set piston at a point close to TDC.

2. Set a dial gauge at the location as shown in the figure. Turn-

ing crankshaft gradually, set the gauge scale to “0” where the

piston protrusion is maximized.

3. Move the dial gauge stand so that the tip of dial gauge can

contact the cylinder block. Read the difference.

4. Measure at two locations per cylinder, that is eight locations for

four cylinders. Select gasket based on the maximum protru-

sion of eight measurements.

5. Measure front and rear at two locations for each cylinder and

calculate the mean value.

Among the four measured points for each cylinder, determine

the maximum protrusion value as the engine’s piston protru-

sion value, and select and install a head gasket according to

the value.

This SELECTION has been discontinued since June, 2000.

CYLINDER HEADYD

Installation

EM-56