NISSAN ALMERA N16 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 211 of 3189

JEM134G

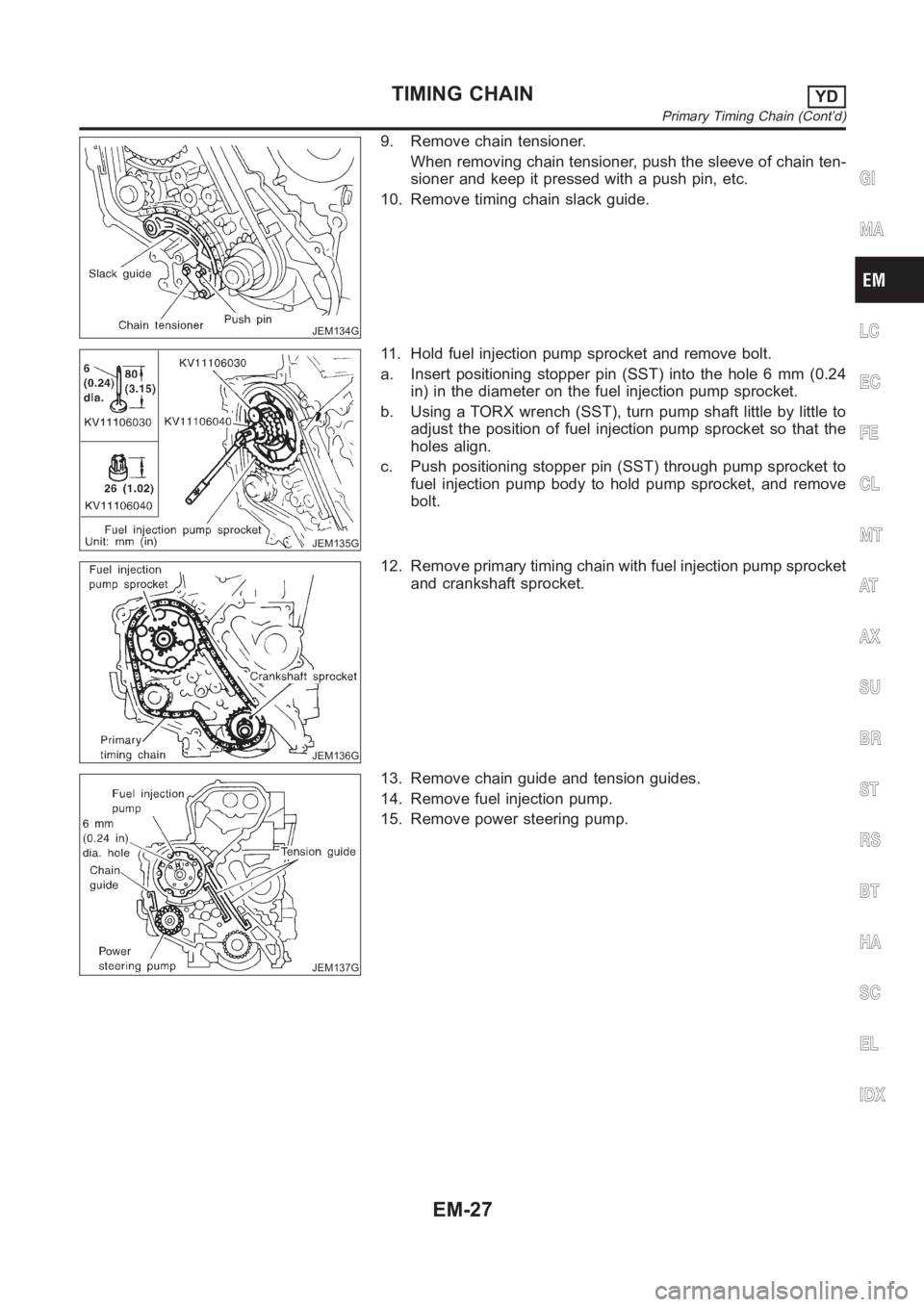

9. Remove chain tensioner.

When removing chain tensioner, push the sleeve of chain ten-

sioner and keep it pressed with a push pin, etc.

10. Remove timing chain slack guide.

JEM135G

11. Hold fuel injection pump sprocket and remove bolt.

a. Insert positioning stopper pin (SST) into the hole 6 mm (0.24

in) in the diameter on the fuel injection pump sprocket.

b. Using a TORX wrench (SST), turn pump shaft little by little to

adjust the position of fuel injection pump sprocket so that the

holes align.

c. Push positioning stopper pin (SST) through pump sprocket to

fuel injection pump body to hold pump sprocket, and remove

bolt.

JEM136G

12. Remove primary timing chain with fuel injection pump sprocket

and crankshaft sprocket.

JEM137G

13. Remove chain guide and tension guides.

14. Remove fuel injection pump.

15. Remove power steering pump.

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAINYD

Primary Timing Chain (Cont’d)

EM-27

Page 212 of 3189

JEM138G

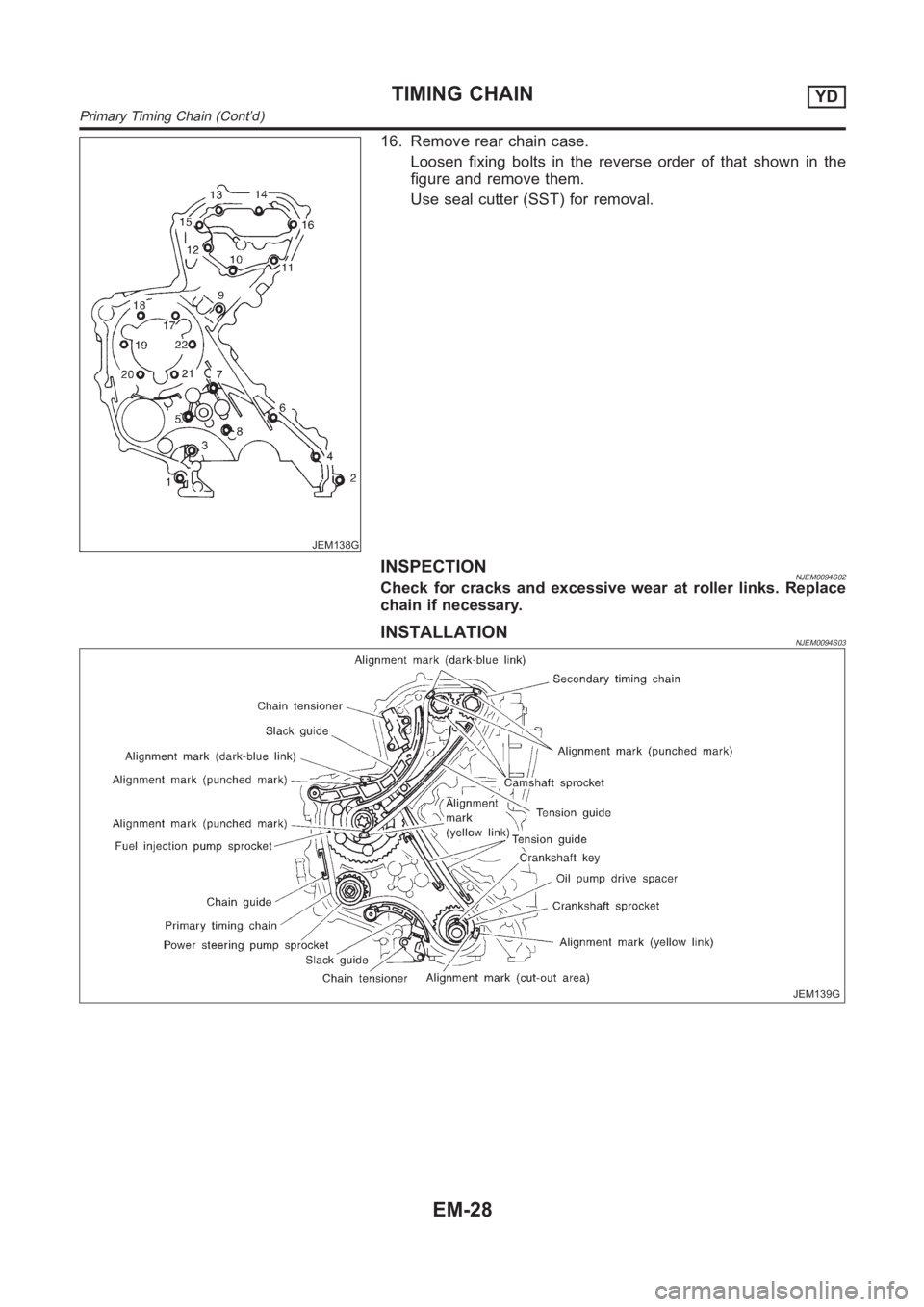

16. Remove rear chain case.

Loosen fixing bolts in the reverse order of that shown in the

figure and remove them.

Use seal cutter (SST) for removal.

INSPECTIONNJEM0094S02Check for cracks and excessive wear at roller links. Replace

chain if necessary.

INSTALLATIONNJEM0094S03

JEM139G

TIMING CHAINYD

Primary Timing Chain (Cont’d)

EM-28

Page 213 of 3189

JEM140G

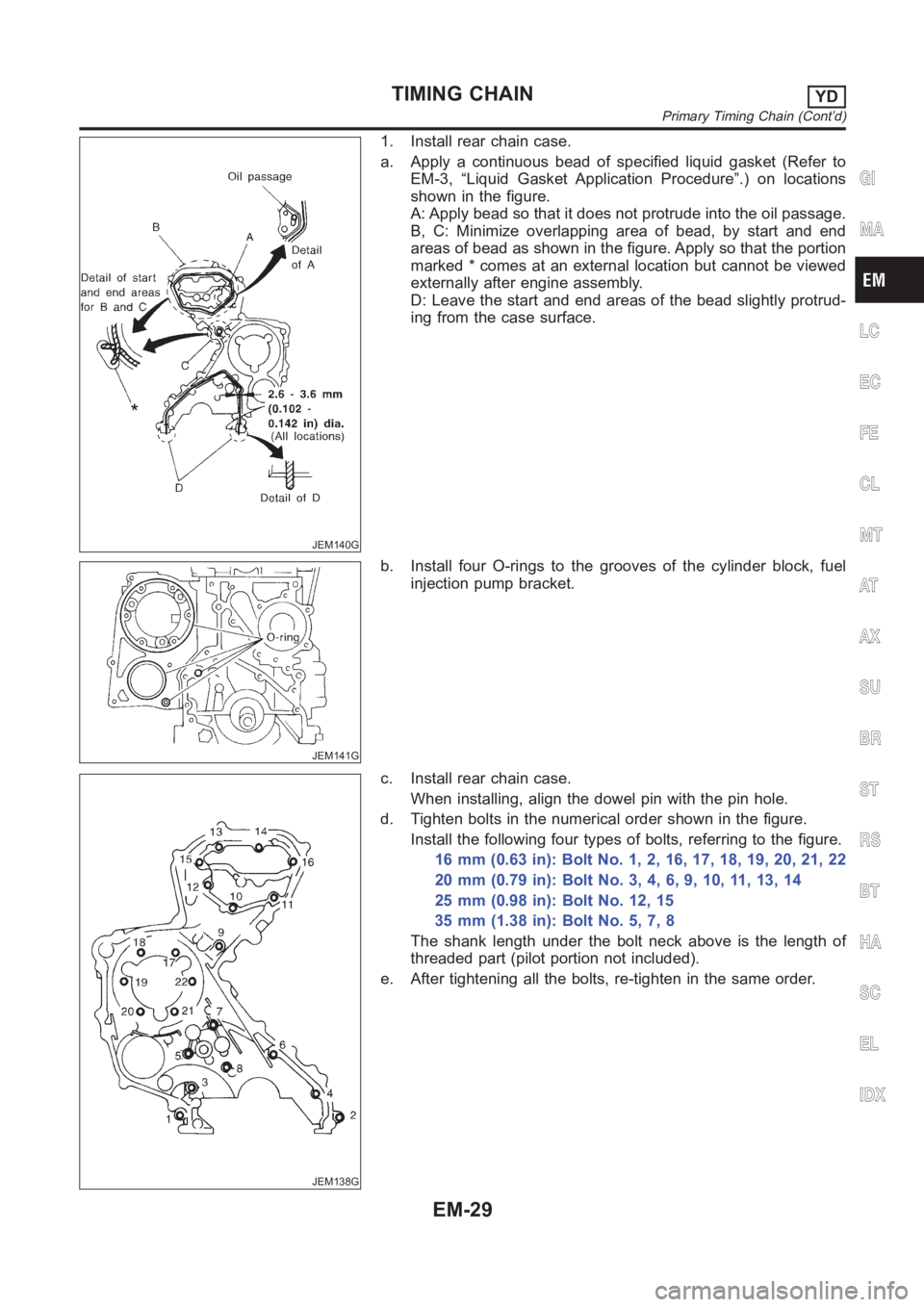

1. Install rear chain case.

a. Apply a continuous bead of specified liquid gasket (Refer to

EM-3, “Liquid Gasket Application Procedure”.) on locations

shown in the figure.

A: Apply bead so that it does not protrude into the oil passage.

B, C: Minimize overlapping area of bead, by start and end

areas of bead as shown in the figure. Apply so that the portion

marked * comes at an external location but cannot be viewed

externally after engine assembly.

D: Leave the start and end areas of the bead slightly protrud-

ing from the case surface.

JEM141G

b. Install four O-rings to the grooves of the cylinder block, fuel

injection pump bracket.

JEM138G

c. Install rear chain case.

When installing, align the dowel pin with the pin hole.

d. Tighten bolts in the numerical order shown in the figure.

Install the following four types of bolts, referring to the figure.

16 mm (0.63 in): Bolt No. 1, 2, 16, 17, 18, 19, 20, 21, 22

20mm(0.79in):BoltNo.3,4,6,9,10,11,13,14

25 mm (0.98 in): Bolt No. 12, 15

35 mm (1.38 in): Bolt No. 5, 7, 8

The shank length under the bolt neck above is the length of

threaded part (pilot portion not included).

e. After tightening all the bolts, re-tighten in the same order.

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAINYD

Primary Timing Chain (Cont’d)

EM-29

Page 214 of 3189

JEM137G

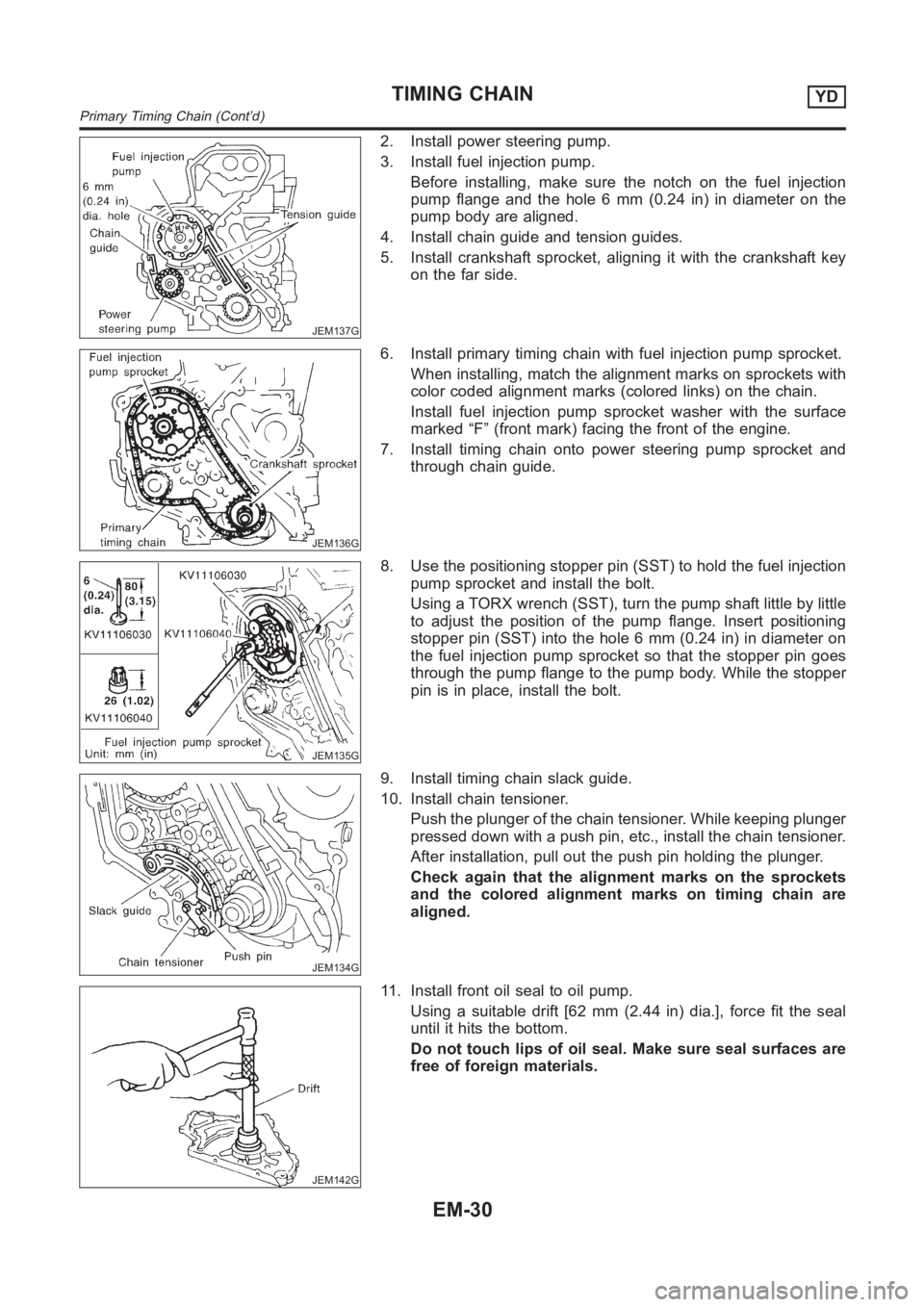

2. Install power steering pump.

3. Install fuel injection pump.

Before installing, make sure the notch on the fuel injection

pump flange and the hole 6 mm (0.24 in) in diameter on the

pump body are aligned.

4. Install chain guide and tension guides.

5. Install crankshaft sprocket, aligning it with the crankshaft key

on the far side.

JEM136G

6. Install primary timing chain with fuel injection pump sprocket.

When installing, match the alignment marks on sprockets with

color coded alignment marks (colored links) on the chain.

Install fuel injection pump sprocket washer with the surface

marked “F” (front mark) facing the front of the engine.

7. Install timing chain onto power steering pump sprocket and

through chain guide.

JEM135G

8. Use the positioning stopper pin (SST) to hold the fuel injection

pump sprocket and install the bolt.

Using a TORX wrench (SST), turn the pump shaft little by little

to adjust the position of the pump flange. Insert positioning

stopper pin (SST) into the hole 6 mm (0.24 in) in diameter on

the fuel injection pump sprocket so that the stopper pin goes

through the pump flange to the pump body. While the stopper

pin is in place, install the bolt.

JEM134G

9. Install timing chain slack guide.

10. Install chain tensioner.

Push the plunger of the chain tensioner. While keeping plunger

pressed down with a push pin, etc., install the chain tensioner.

After installation, pull out the push pin holding the plunger.

Check again that the alignment marks on the sprockets

and the colored alignment marks on timing chain are

aligned.

JEM142G

11. Install front oil seal to oil pump.

Using a suitable drift [62 mm (2.44 in) dia.], force fit the seal

until it hits the bottom.

Do not touch lips of oil seal. Make sure seal surfaces are

free of foreign materials.

TIMING CHAINYD

Primary Timing Chain (Cont’d)

EM-30

Page 215 of 3189

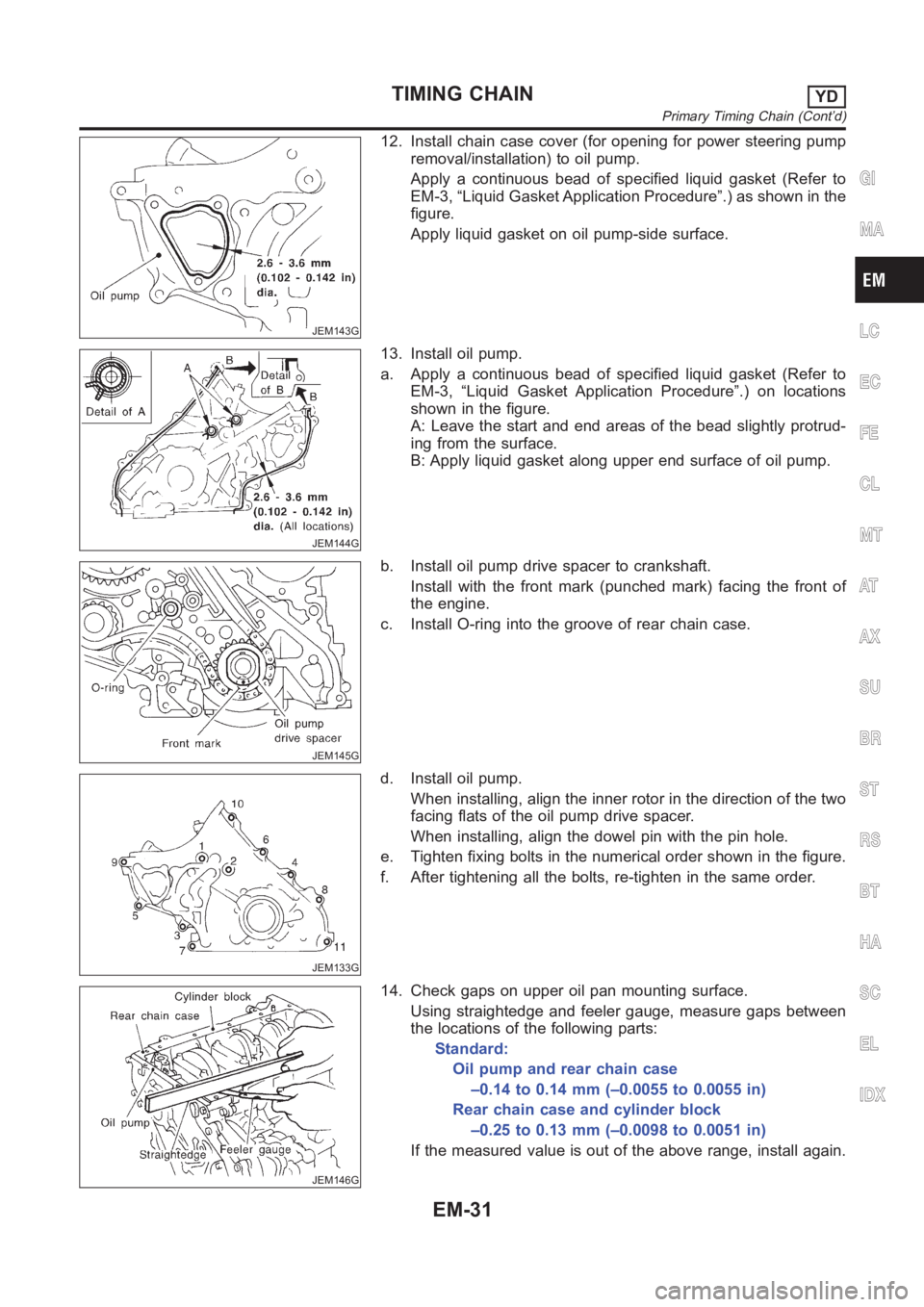

JEM143G

12. Install chain case cover (for opening for power steering pump

removal/installation) to oil pump.

Apply a continuous bead of specified liquid gasket (Refer to

EM-3, “Liquid Gasket Application Procedure”.) as shown in the

figure.

Apply liquid gasket on oil pump-side surface.

JEM144G

13. Install oil pump.

a. Apply a continuous bead of specified liquid gasket (Refer to

EM-3, “Liquid Gasket Application Procedure”.) on locations

shown in the figure.

A: Leave the start and end areas of the bead slightly protrud-

ing from the surface.

B: Apply liquid gasket along upper end surface of oil pump.

JEM145G

b. Install oil pump drive spacer to crankshaft.

Install with the front mark (punched mark) facing the front of

the engine.

c. Install O-ring into the groove of rear chain case.

JEM133G

d. Install oil pump.

When installing, align the inner rotor in the direction of the two

facing flats of the oil pump drive spacer.

When installing, align the dowel pin with the pin hole.

e. Tighten fixing bolts in the numerical order shown in the figure.

f. After tightening all the bolts, re-tighten in the same order.

JEM146G

14. Check gaps on upper oil pan mounting surface.

Using straightedge and feeler gauge, measure gaps between

the locations of the following parts:

Standard:

Oil pump and rear chain case

–0.14 to 0.14 mm (–0.0055 to 0.0055 in)

Rear chain case and cylinder block

–0.25 to 0.13 mm (–0.0098 to 0.0051 in)

If the measured value is out of the above range, install again.

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAINYD

Primary Timing Chain (Cont’d)

EM-31

Page 216 of 3189

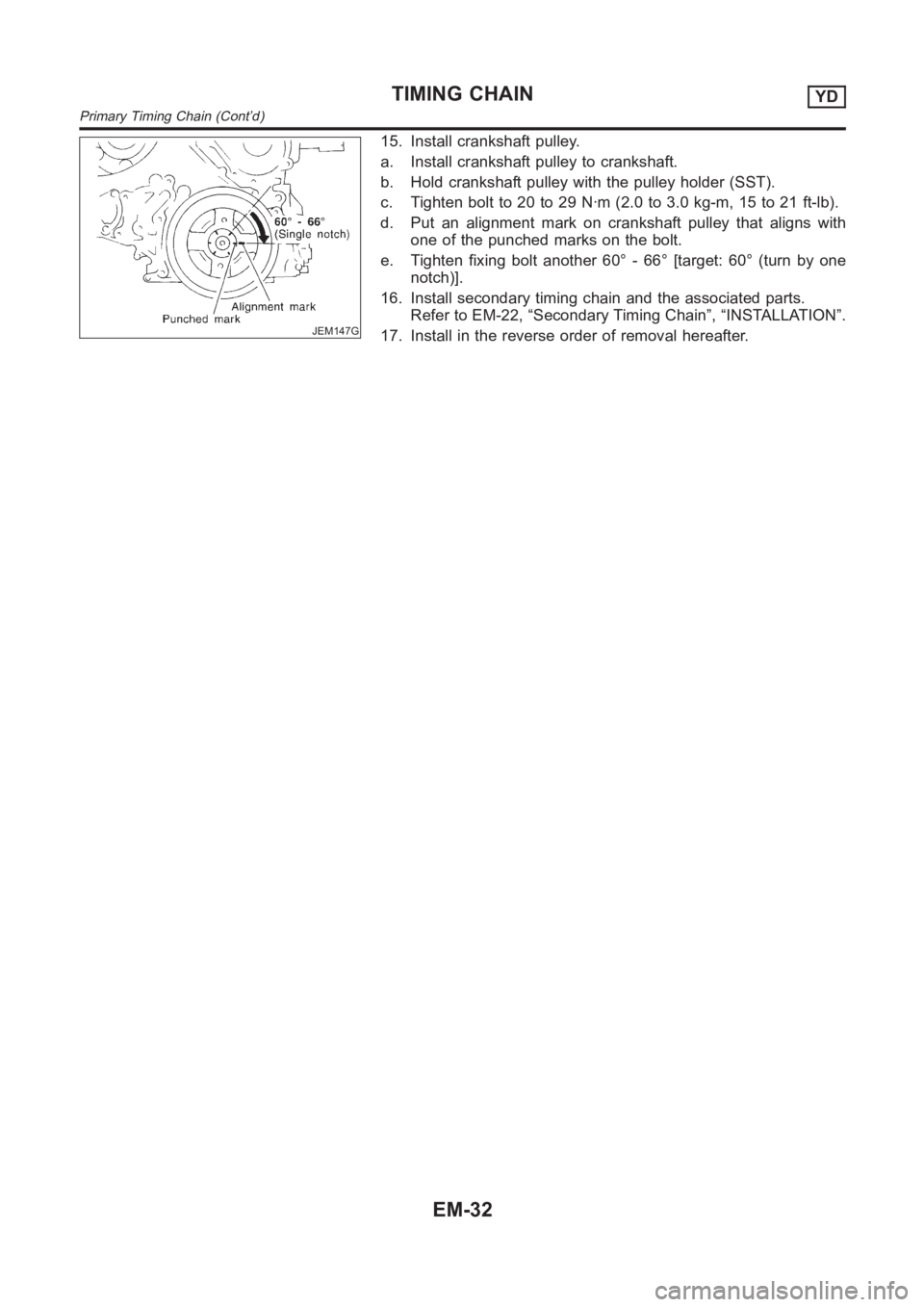

JEM147G

15. Install crankshaft pulley.

a. Install crankshaft pulley to crankshaft.

b. Hold crankshaft pulley with the pulley holder (SST).

c. Tighten bolt to 20 to 29 N·m (2.0 to 3.0 kg-m, 15 to 21 ft-lb).

d. Put an alignment mark on crankshaft pulley that aligns with

one of the punched marks on the bolt.

e. Tighten fixing bolt another 60° - 66° [target: 60° (turn by one

notch)].

16. Install secondary timing chain and the associated parts.

Refer to EM-22, “Secondary Timing Chain”, “INSTALLATION”.

17. Install in the reverse order of removal hereafter.

TIMING CHAINYD

Primary Timing Chain (Cont’d)

EM-32

Page 217 of 3189

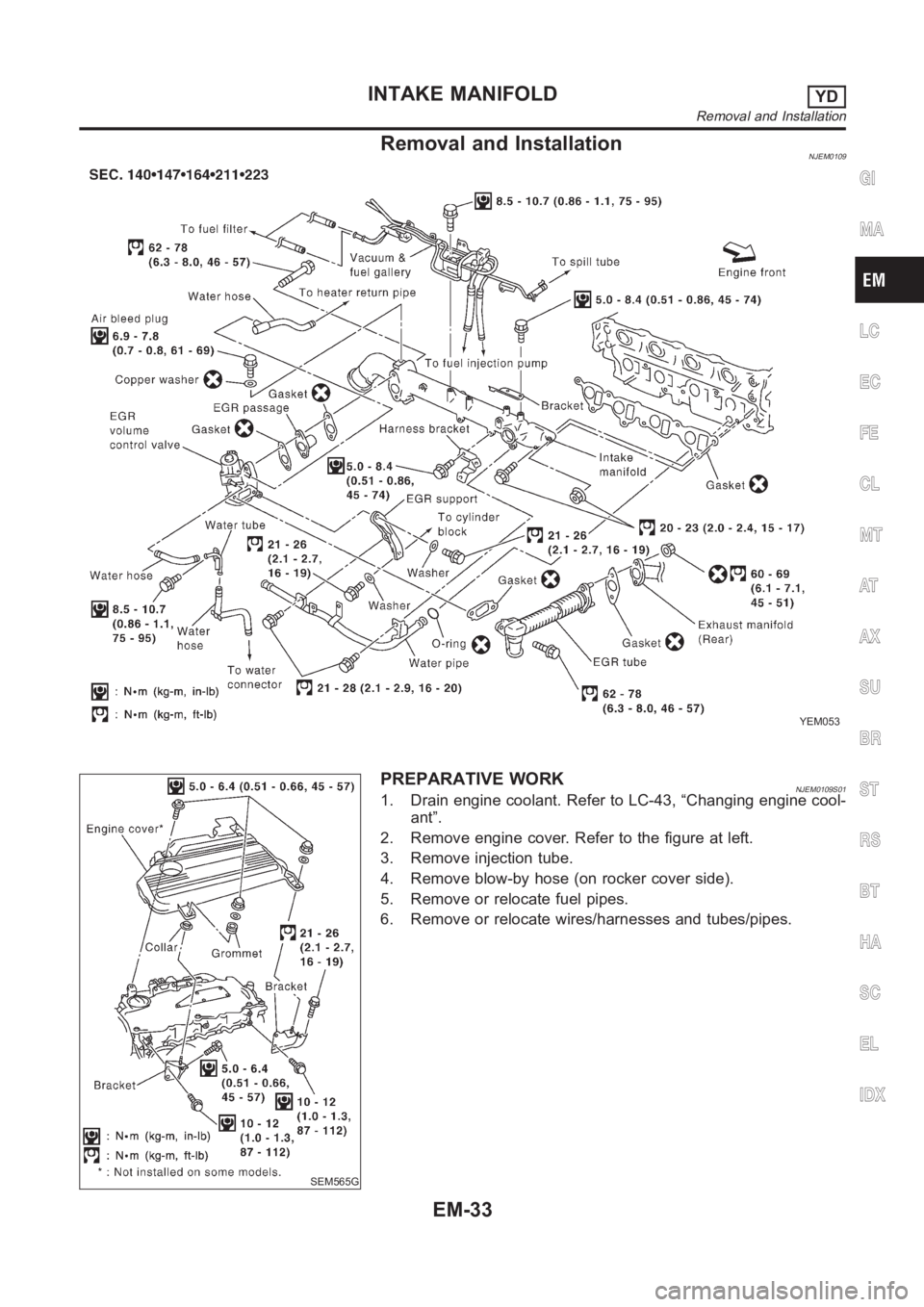

Removal and InstallationNJEM0109

YEM053

SEM565G

PREPARATIVE WORKNJEM0109S011. Drain engine coolant. Refer to LC-43, “Changing engine cool-

ant”.

2. Remove engine cover. Refer to the figure at left.

3. Remove injection tube.

4. Remove blow-by hose (on rocker cover side).

5. Remove or relocate fuel pipes.

6. Remove or relocate wires/harnesses and tubes/pipes.

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

INTAKE MANIFOLDYD

Removal and Installation

EM-33

Page 218 of 3189

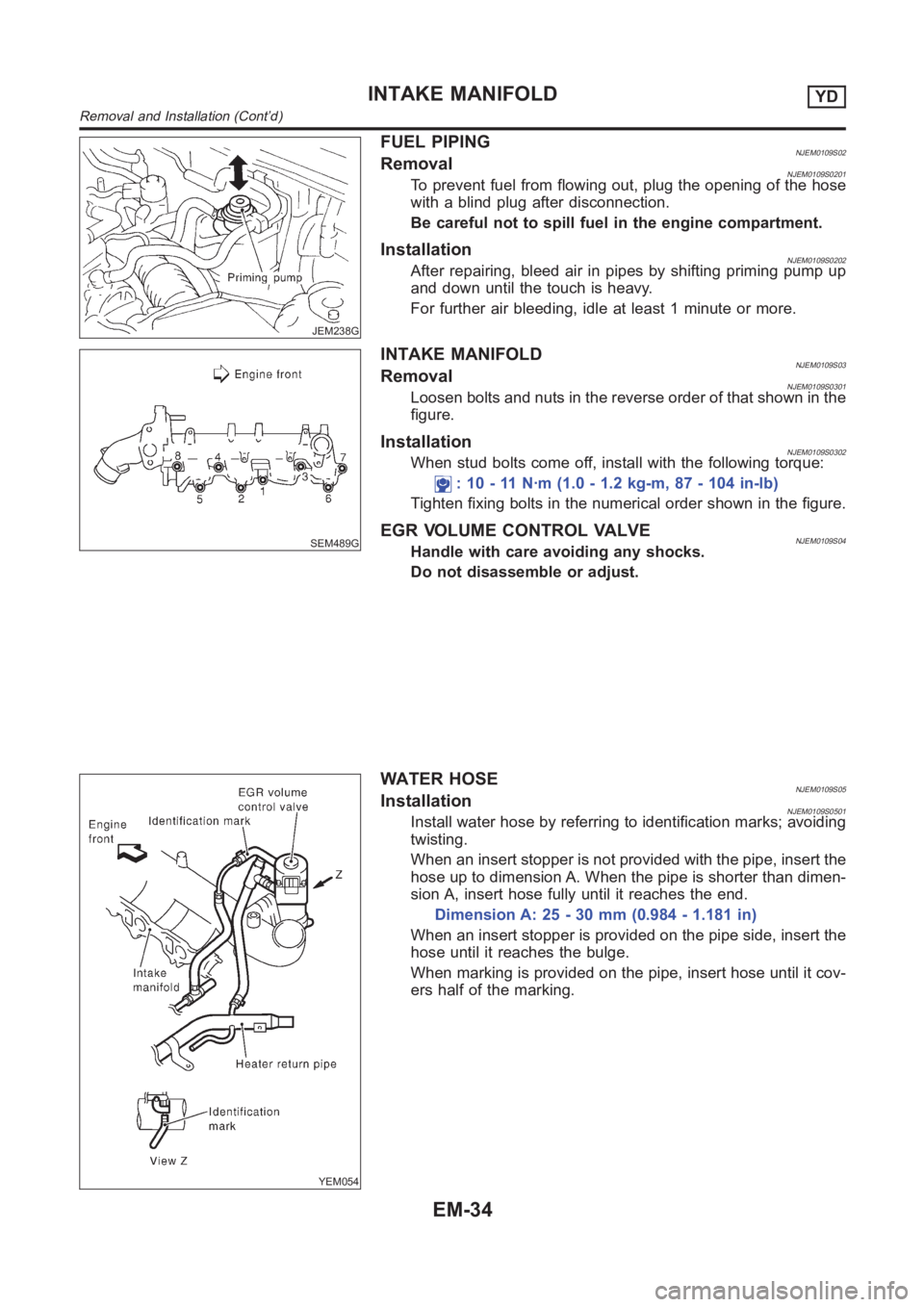

JEM238G

FUEL PIPINGNJEM0109S02RemovalNJEM0109S0201To prevent fuel from flowing out, plug the opening of the hose

with a blind plug after disconnection.

Be careful not to spill fuel in the engine compartment.

InstallationNJEM0109S0202After repairing, bleed air in pipes by shifting priming pump up

and down until the touch is heavy.

For further air bleeding, idle at least 1 minute or more.

SEM489G

INTAKE MANIFOLDNJEM0109S03RemovalNJEM0109S0301Loosen bolts and nuts in the reverse order of that shown in the

figure.

InstallationNJEM0109S0302When stud bolts come off, install with the following torque:

: 10 - 11 N·m (1.0 - 1.2 kg-m, 87 - 104 in-lb)

Tighten fixing bolts in the numerical order shown in the figure.

EGR VOLUME CONTROL VALVENJEM0109S04Handle with care avoiding any shocks.

Do not disassemble or adjust.

YEM054

WATER HOSENJEM0109S05InstallationNJEM0109S0501Install water hose by referring to identification marks; avoiding

twisting.

When an insert stopper is not provided with the pipe, insert the

hose up to dimension A. When the pipe is shorter than dimen-

sion A, insert hose fully until it reaches the end.

Dimension A: 25 - 30 mm (0.984 - 1.181 in)

When an insert stopper is provided on the pipe side, insert the

hose until it reaches the bulge.

When marking is provided on the pipe, insert hose until it cov-

ers half of the marking.

INTAKE MANIFOLDYD

Removal and Installation (Cont’d)

EM-34

Page 219 of 3189

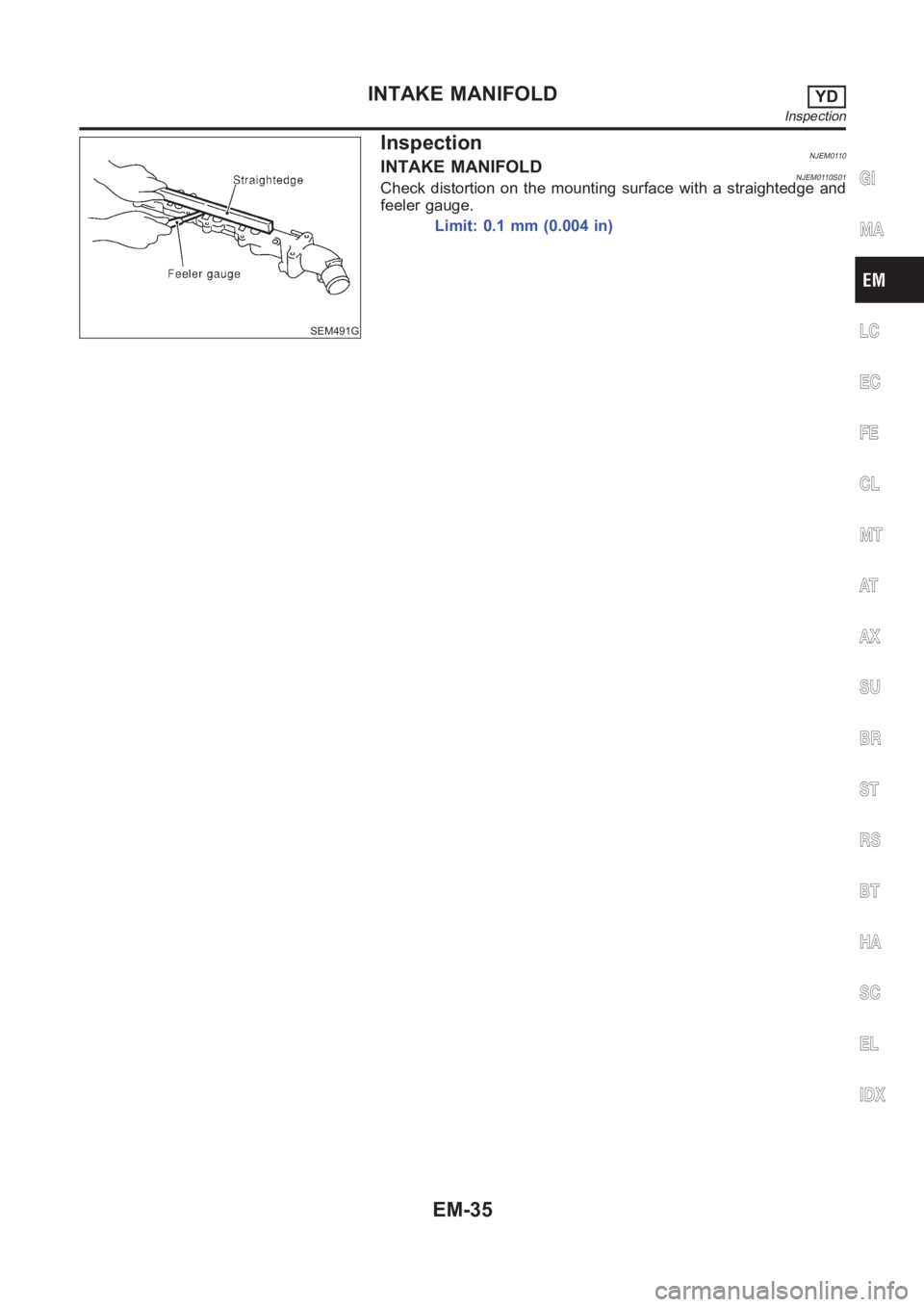

SEM491G

InspectionNJEM0110INTAKE MANIFOLDNJEM0110S01Check distortion on the mounting surface with a straightedge and

feeler gauge.

Limit: 0.1 mm (0.004 in)

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

INTAKE MANIFOLDYD

Inspection

EM-35

Page 220 of 3189

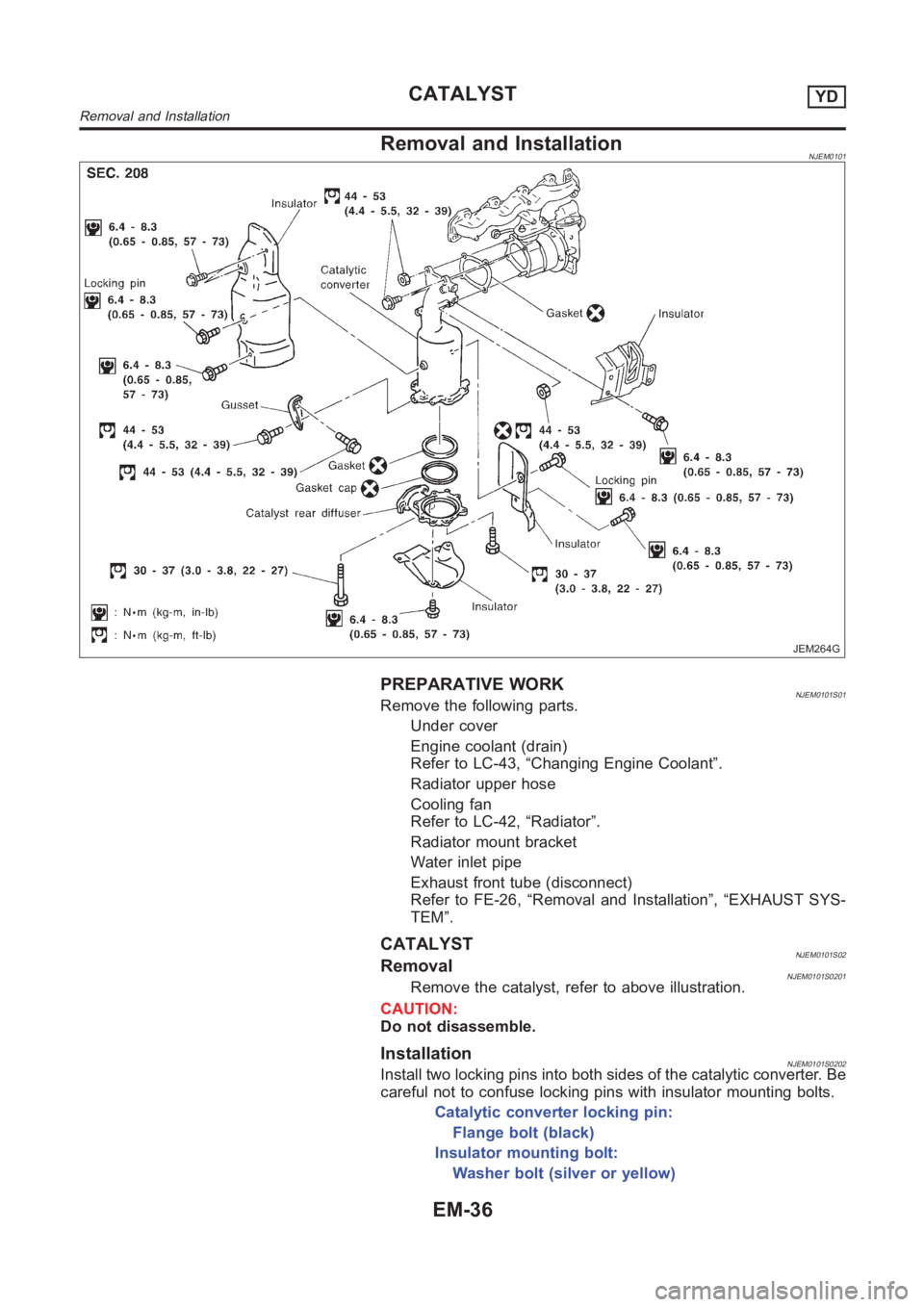

Removal and InstallationNJEM0101

JEM264G

PREPARATIVE WORKNJEM0101S01Remove the following parts.

Under cover

Engine coolant (drain)

Refer to LC-43, “Changing Engine Coolant”.

Radiator upper hose

Cooling fan

Refer to LC-42, “Radiator”.

Radiator mount bracket

Water inlet pipe

Exhaust front tube (disconnect)

Refer to FE-26, “Removal and Installation”, “EXHAUST SYS-

TEM”.

CATALYSTNJEM0101S02RemovalNJEM0101S0201Remove the catalyst, refer to above illustration.

CAUTION:

Do not disassemble.

InstallationNJEM0101S0202Install two locking pins into both sides of the catalytic converter. Be

careful not to confuse locking pins with insulator mounting bolts.

Catalytic converter locking pin:

Flange bolt (black)

Insulator mounting bolt:

Washer bolt (silver or yellow)

CATALYSTYD

Removal and Installation

EM-36