NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 101 of 3171

DTC U1000 CAN COMMUNICATION LINE

AT-93

D

E

F

G

H

I

J

K

L

MA

B

AT

Data are reference value and are measured between each terminal and ground.

Diagnostic ProcedureECS00FXH

1.CHECK CAN COMMUNICATION CIRCUIT

With CONSULT-II

1. Turn ignition switch ON and start engine.

2. Select “SELF-DIAG RESULTS” mode for “A/T” with CONSULT-

II.

Is any malfunction of the

“U1000 CAN COMM CIRCUIT”indicated?

YES >> Print out CONSULT-II screen, GO TO LAN section.

Refer toLAN-3, "

Precautions When Using CONSULT-II"

.

NO >>INSPECTION END

Terminal Wire color Item Condition Data (Approx.)

3 L CAN-H – –

8 P CAN-L – –

PCIA0061E

Page 102 of 3171

AT-94

DTC P0615 START SIGNAL CIRCUIT

DTC P0615 START SIGNAL CIRCUIT

PFP:25230

DescriptionECS00FXI

TCM prohibits cranking other than at “P” or “N” position.

CONSULT-II Reference ValueECS00FXJ

On Board Diagnosis LogicECS00FXK

Diagnostic trouble code “P0615 STARTER RELAY/CIRC” with CONSULT-II or 14th judgement flicker without

CONSULT-II is detected when starter relay is switched ON other than at “P” or “N” position. (Or when switched

OFF at “P” or “N” position).

Possible CauseECS00FXL

lHarness or connectors

(starter relay and TCM circuit is open or shorted.)

lstarter relay

DTC Confirmation ProcedureECS00FXM

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode

for “A/T” with CONSULT-II and check monitor “STARTER

RELAY” ON/OFF.

3. Start engine.

4. Drive vehicle for at least 2 consecutive seconds.

5. If DTC is detected, go toAT-96, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine.

2. Drive vehicle for at least 2 consecutive seconds.

3. Perform self-diagnosis. Refer toAT-89, "

Diagnostic Procedure Without CONSULT-II".

4. If DTC is detected, go toAT-96, "

Diagnostic Procedure".

Item name Condition Display value

STARTER RELAYSelector lever in “N” or “P” position. ON

Selector lever in other positions. OFF

BCIA0031E

Page 103 of 3171

DTC P0615 START SIGNAL CIRCUIT

AT-95

D

E

F

G

H

I

J

K

L

MA

B

AT

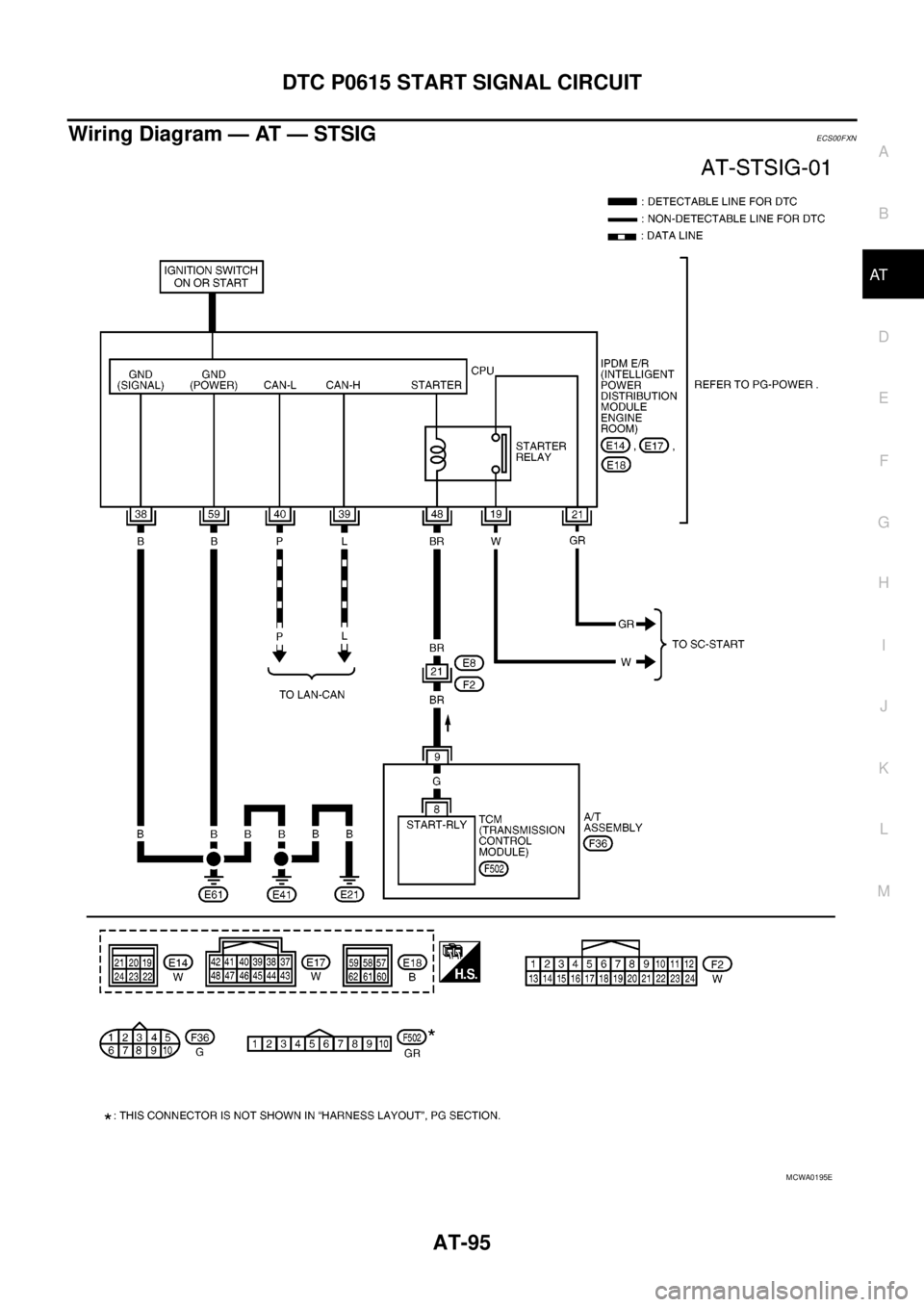

Wiring Diagram — AT — STSIGECS00FXN

MCWA0195E

Page 104 of 3171

AT-96

DTC P0615 START SIGNAL CIRCUIT

Data are reference value and are measured between each terminal and ground.

Diagnostic ProcedureECS00FXO

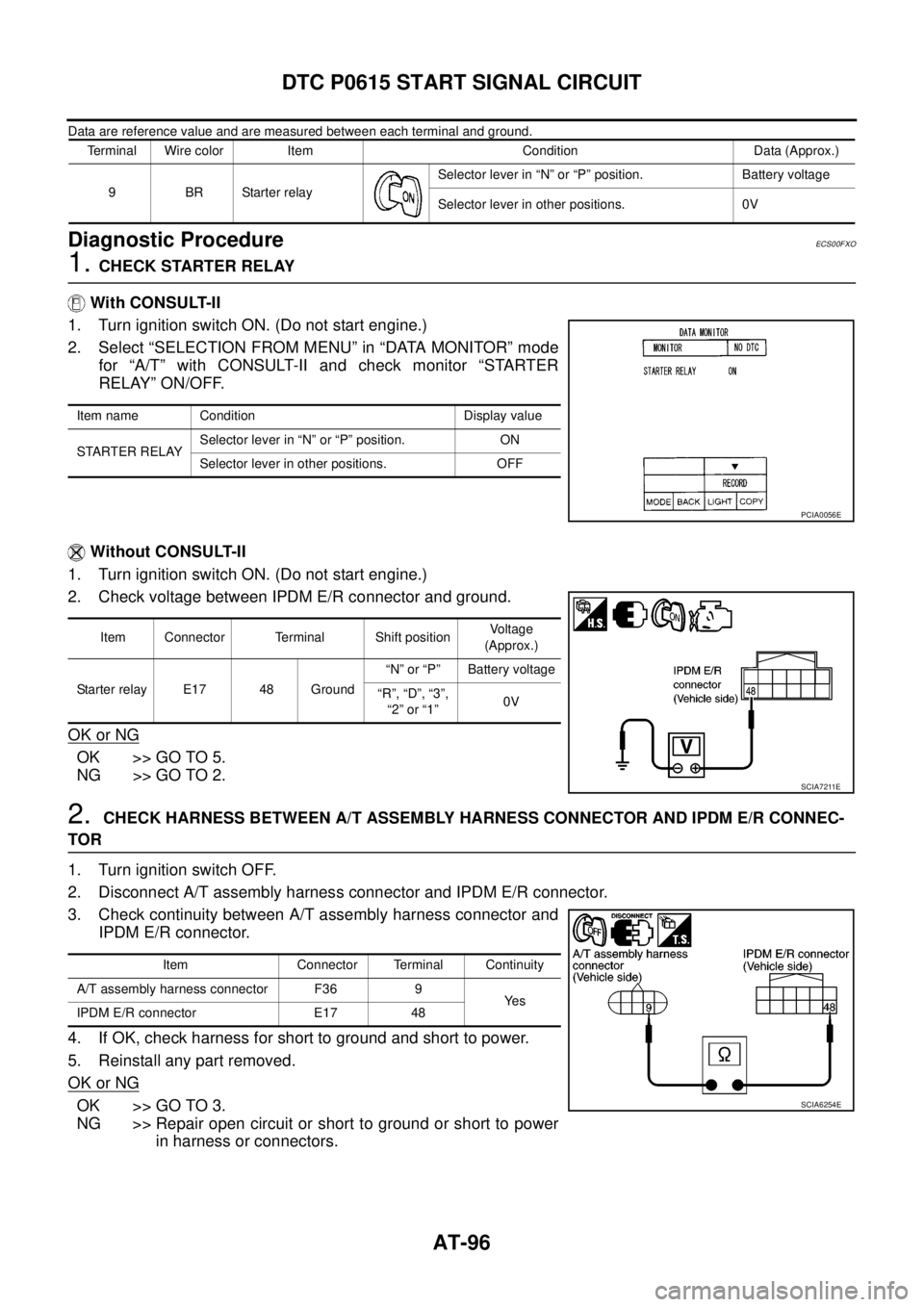

1.CHECK STARTER RELAY

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode

for “A/T” with CONSULT-II and check monitor “STARTER

RELAY” ON/OFF.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between IPDM E/R connector and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK HARNESS BETWEEN A/T ASSEMBLY HARNESS CONNECTOR AND IPDM E/R CONNEC-

TOR

1. Turn ignition switch OFF.

2. Disconnect A/T assembly harness connector and IPDM E/R connector.

3. Check continuity between A/T assembly harness connector and

IPDM E/R connector.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

Terminal Wire color Item Condition Data (Approx.)

9BRStarterrelaySelector lever in “N” or “P” position. Battery voltage

Selector lever in other positions. 0V

Item name Condition Display value

STARTER RELAYSelector lever in “N” or “P” position. ON

Selector lever in other positions. OFF

PCIA0056E

Item Connector Terminal Shift positionVoltage

(Approx.)

Starter relay E17 48 Ground“N” or “P” Battery voltage

“R”, “D”, “3”,

“2”or“1”0V

SCIA7211E

Item Connector Terminal Continuity

A/T assembly harness connector F36 9

Ye s

IPDM E/R connector E17 48

SCIA6254E

Page 105 of 3171

DTC P0615 START SIGNAL CIRCUIT

AT-97

D

E

F

G

H

I

J

K

L

MA

B

AT

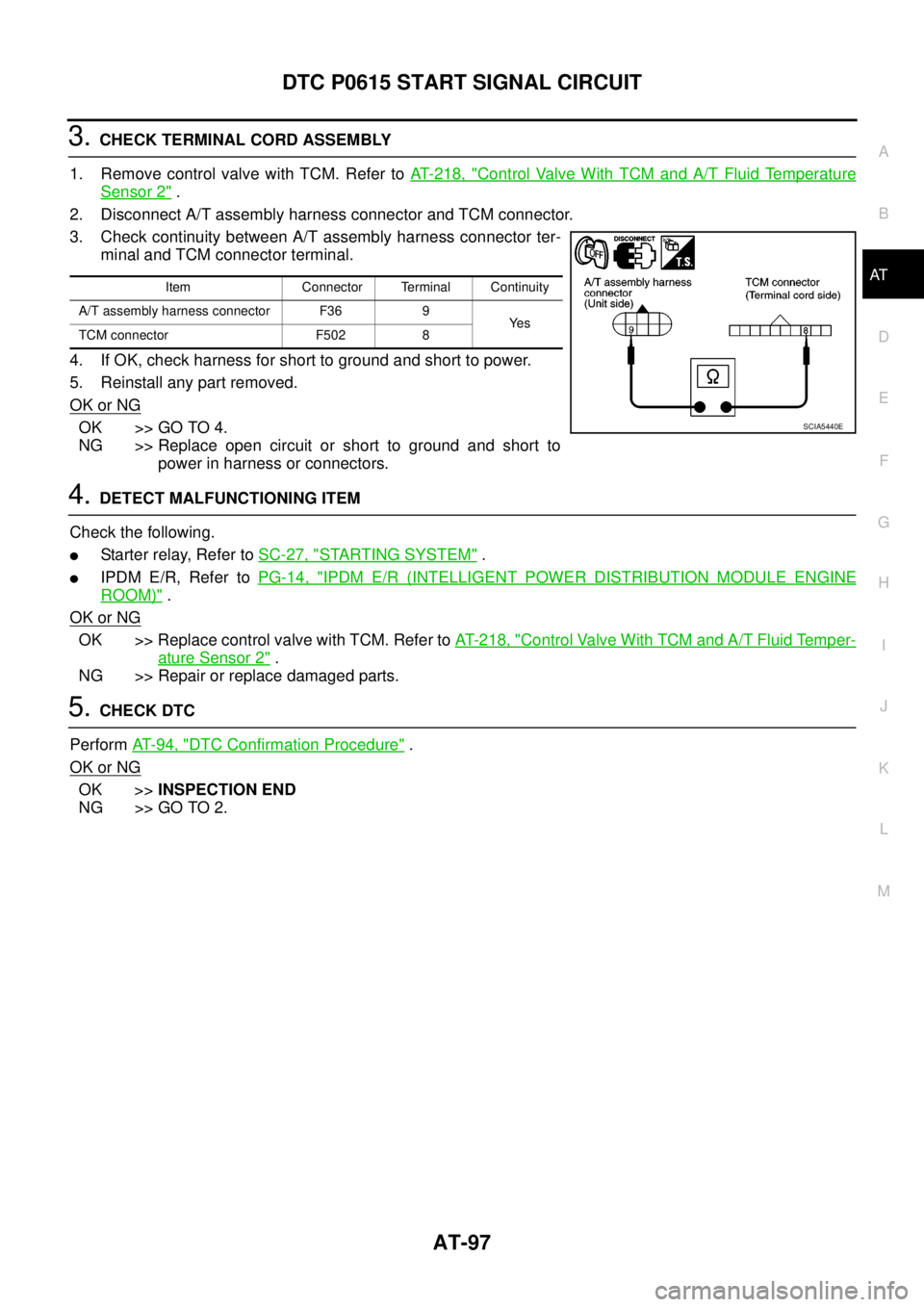

3.CHECK TERMINAL CORD ASSEMBLY

1. Remove control valve with TCM. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature

Sensor 2".

2. Disconnect A/T assembly harness connector and TCM connector.

3. Check continuity between A/T assembly harness connector ter-

minal and TCM connector terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 4.

NG >> Replace open circuit or short to ground and short to

power in harness or connectors.

4.DETECT MALFUNCTIONING ITEM

Check the following.

lStarter relay, Refer toSC-27, "STARTING SYSTEM".

lIPDM E/R, Refer toPG-14, "IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)".

OK or NG

OK >> Replace control valve with TCM. Refer toAT- 2 1 8 , "Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

NG >> Repair or replace damaged parts.

5.CHECK DTC

PerformAT-94, "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item Connector Terminal Continuity

A/T assembly harness connector F36 9

Ye s

TCM connector F502 8

SCIA5440E

Page 106 of 3171

AT-98

DTC P0700 TCM

DTC P0700 TCM

PFP:31036

DescriptionECS00FXP

TCM consists of a microcomputer and connectors for signal input and output and for power supply. TCM con-

trols A/T.

On Board Diagnosis LogicECS00FXQ

Diagnostic trouble code “P0700 TCM” with CONSULT-II is detected when TCM is malfunctioning.

Possible CauseECS00FXR

TCM

DTC Confirmation ProcedureECS00FXS

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” or “MAIN SIGNALS” in “DATA

MONITOR” mode for “A/T” with CONSULT-II.

3. Start engine.

4. Run engine for at least 2 consecutive seconds at idle speed.

5. If DTC is detected, go toAT-98, "

Diagnostic Procedure".

Diagnostic ProcedureECS00FXT

1.CHECK DTC

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELF DIAG RESULTS” mode for “A/T” with CONSULT-II.

3. Touch “ERASE”.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. PerformAT- 9 8 , "

DTC Confirmation Procedure".

Is the

“P0700 TCM”displayed again?

YES >> Replace control valve with TCM. Refer toAT- 2 1 8 , "Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

NO >>INSPECTION END

BCIA0031E

Page 107 of 3171

DTC P0705 PARK/NEUTRAL POSITION SWITCH

AT-99

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC P0705 PARK/NEUTRAL POSITION SWITCHPFP:32006

DescriptionECS00FXU

lPNP switch includes a transmission range switch.

lThe transmission range switch detects the selector lever position and sends a signal to TCM.

CONSULT-II Reference ValueECS00FXV

On Board Diagnosis LogicECS00FXW

Diagnostic trouble code “P0705 PNP SW/CIRC” with CONSULT-II or 9th judgement flicker without CONSULT-

II is detected under the following conditions.

lWhen TCM does not receive the correct voltage signal from PNP switches 1, 2, 3 and 4 based on the gear

position.

lWhen no other positions but “P” position is detected from “N” position.

Possible CauseECS00FXX

lHarness or connectors

PNP switches 1, 2, 3 and 4 and TCM circuit is open or shorted.

lPNPswitches1,2,3and4

DTC Confirmation ProcedureECS00FXY

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” or “MAIN SIGNALS” in “DATA

MONITOR” mode for “A/T” with CONSULT-II.

3. Touch “START”.

4. Start engine.

5. Drive vehicle and maintain the following conditions for at least 2

consecutive seconds.

ACCELE POSI: More than 1.0/8

6. If DTC is detected, go toAT- 1 0 1 , "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine.

2. Drive vehicle and maintain the following conditions for at least 2 consecutive seconds.

Accelerator opening: More than 1.0/8

3. Perform self-diagnosis. Refer toAT-89, "

Diagnostic Procedure Without CONSULT-II".

4. If DTC is detected, go toAT- 1 0 1 , "

Diagnostic Procedure".

Item name Condition Display value

SLCTLVR POSISelector lever in “N” or “P” position. N/P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “3” position. 3

Selector lever in “2” position. 2

Selector lever in “1” position. 1

BCIA0031E

Page 108 of 3171

AT-100

DTC P0705 PARK/NEUTRAL POSITION SWITCH

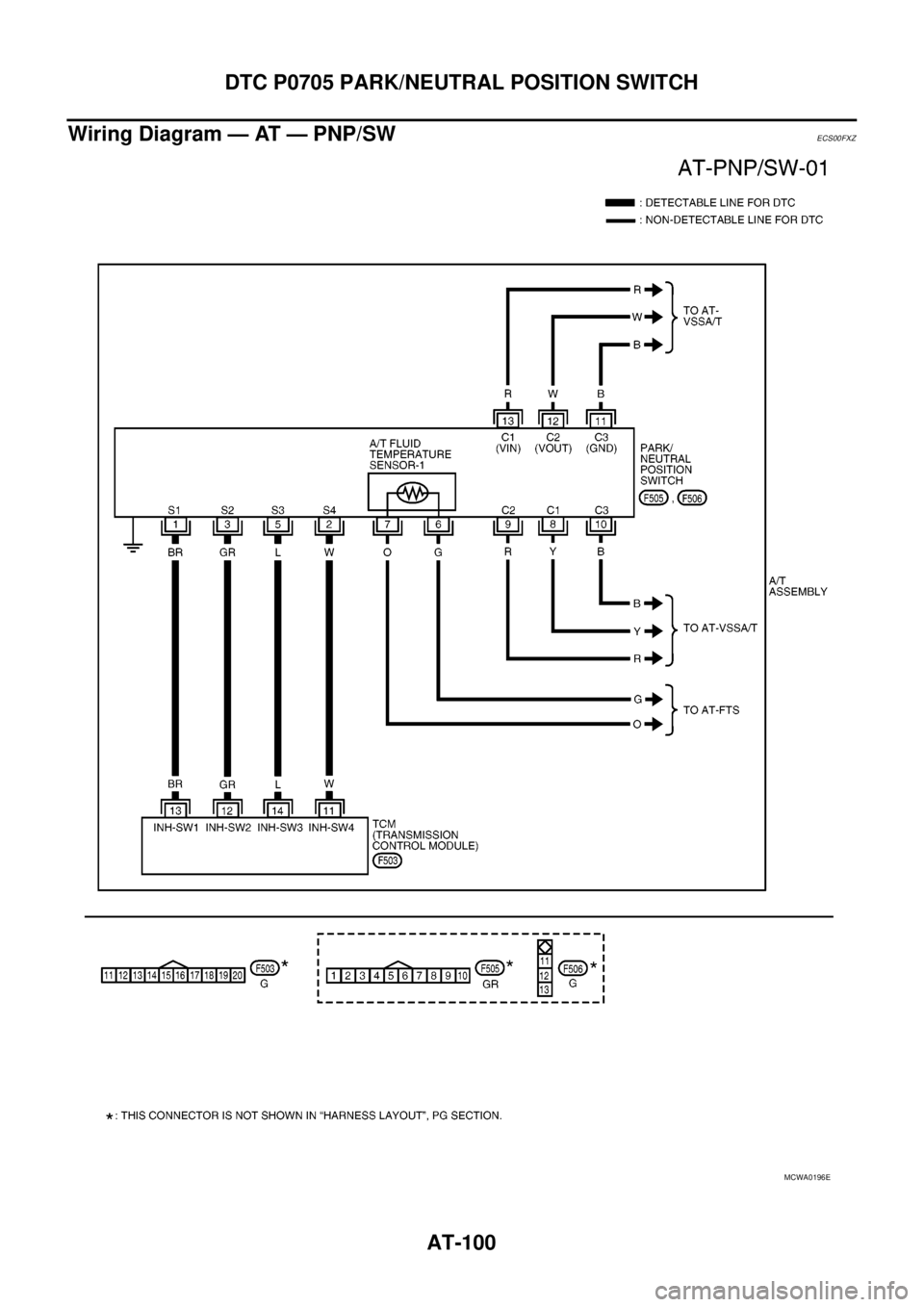

Wiring Diagram — AT — PNP/SW

ECS00FXZ

MCWA0196E

Page 109 of 3171

DTC P0705 PARK/NEUTRAL POSITION SWITCH

AT-101

D

E

F

G

H

I

J

K

L

MA

B

AT

Diagnostic ProcedureECS00FY0

1.CHECK PNP SW CIRCUIT

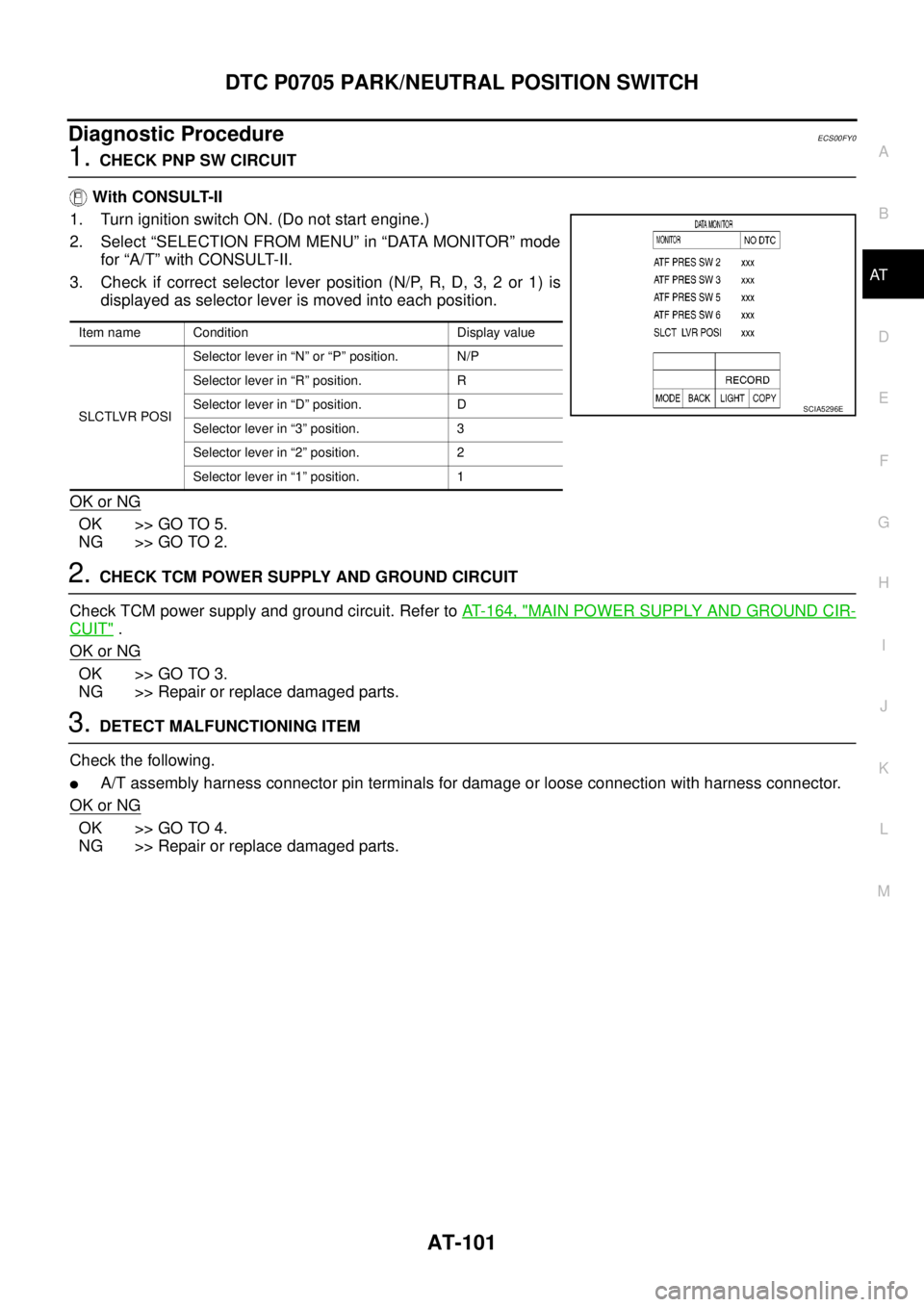

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode

for “A/T” with CONSULT-II.

3. Check if correct selector lever position (N/P, R, D, 3, 2 or 1) is

displayed as selector lever is moved into each position.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer toAT- 1 6 4 , "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.DETECT MALFUNCTIONING ITEM

Check the following.

lA/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

Item name Condition Display value

SLCTLVR POSISelector lever in “N” or “P” position. N/P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “3” position. 3

Selector lever in “2” position. 2

Selector lever in “1” position. 1

SCIA5296E

Page 110 of 3171

AT-102

DTC P0705 PARK/NEUTRAL POSITION SWITCH

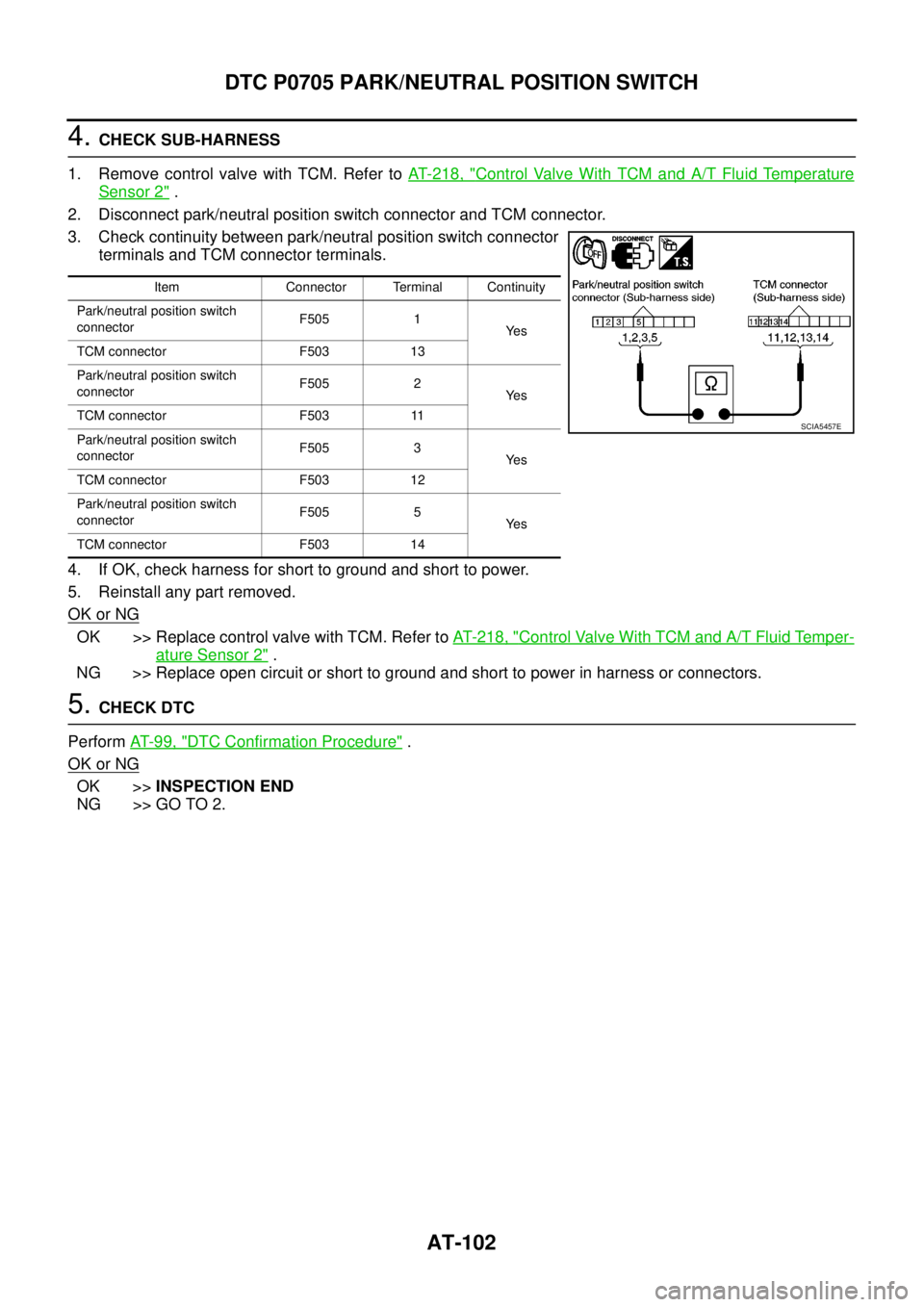

4.CHECK SUB-HARNESS

1. Remove control valve with TCM. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature

Sensor 2".

2. Disconnect park/neutral position switch connector and TCM connector.

3. Check continuity between park/neutral position switch connector

terminals and TCM connector terminals.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> Replace control valve with TCM. Refer toAT- 2 1 8 , "Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

NG >> Replace open circuit or short to ground and short to power in harness or connectors.

5.CHECK DTC

PerformAT-99, "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item Connector Terminal Continuity

Park/neutral position switch

connectorF505 1

Ye s

TCM connector F503 13

Park/neutral position switch

connectorF505 2

Ye s

TCM connector F503 11

Park/neutral position switch

connectorF505 3

Ye s

TCM connector F503 12

Park/neutral position switch

connectorF505 5

Ye s

TCM connector F503 14

SCIA5457E