4WD NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1607 of 3171

ON-VEHICLE SERVICE

FSU-7

C

D

F

G

H

I

J

K

L

MA

B

FSU

ON-VEHICLE SERVICEPFP:00000

Front Suspension PartsEES002KM

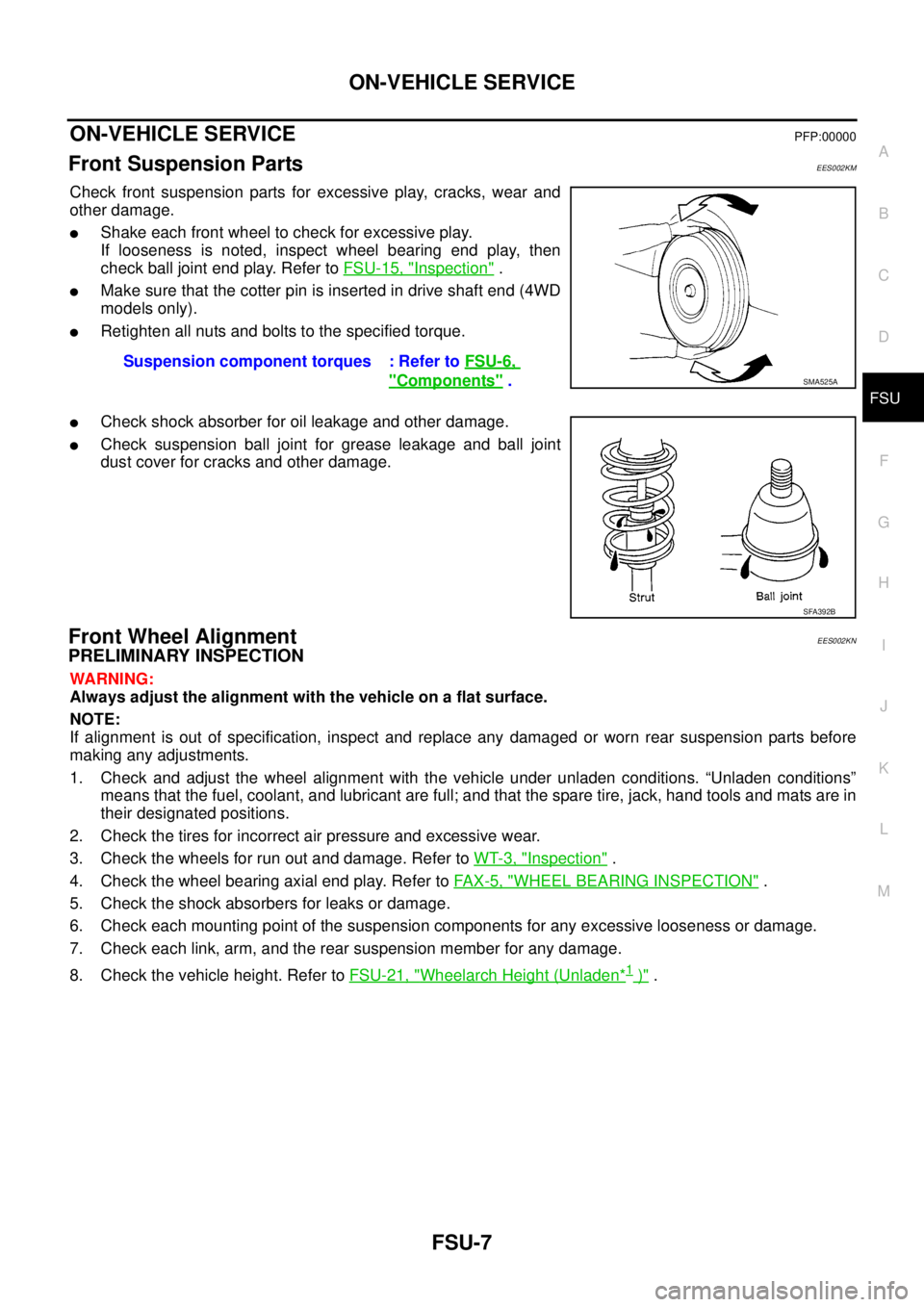

Check front suspension parts for excessive play, cracks, wear and

other damage.

lShake each front wheel to check for excessive play.

If looseness is noted, inspect wheel bearing end play, then

check ball joint end play. Refer toFSU-15, "

Inspection".

lMake sure that the cotter pin is inserted in drive shaft end (4WD

models only).

lRetighten all nuts and bolts to the specified torque.

lCheck shock absorber for oil leakage and other damage.

lCheck suspension ball joint for grease leakage and ball joint

dust cover for cracks and other damage.

Front Wheel AlignmentEES002KN

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer toWT-3, "

Inspection".

4. Check the wheel bearing axial end play. Refer toFA X - 5 , "

WHEEL BEARING INSPECTION".

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer toFSU-21, "

Wheelarch Height (Unladen*1)". Suspension component torques : Refer toFSU-6,

"Components".SMA525A

SFA392B

Page 1616 of 3171

FSU-16

KNUCKLE

KNUCKLE

PFP:40014

On-Vehicle Inspection and ServiceEES002KV

Make sure the mounting conditions (looseness, backlash) of each component and component status (wear,

damage) are within specifications. Refer toFSU-20, "

Ball Joint".

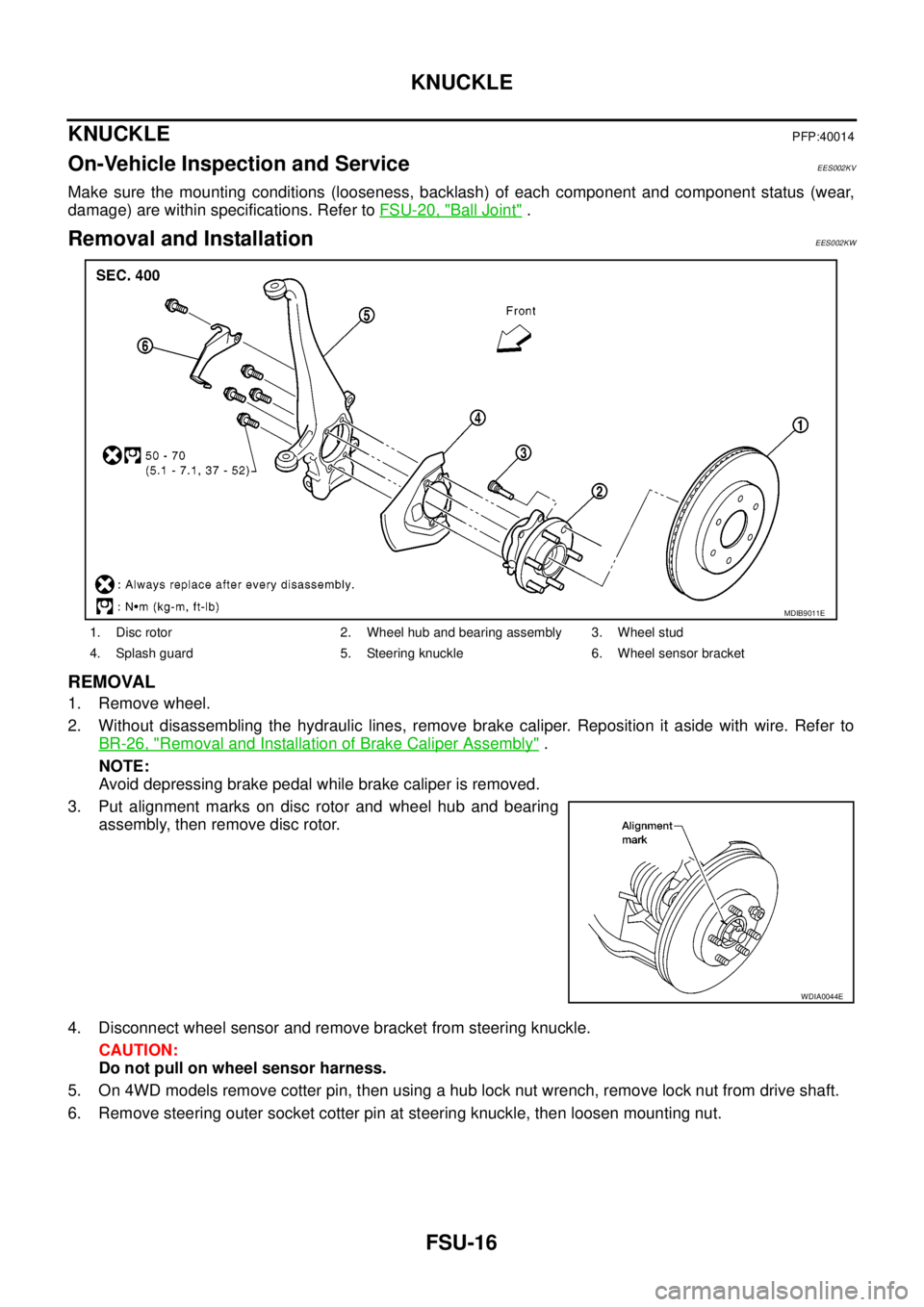

Removal and InstallationEES002KW

REMOVAL

1. Remove wheel.

2. Without disassembling the hydraulic lines, remove brake caliper. Reposition it aside with wire. Refer to

BR-26, "

Removal and Installation of Brake Caliper Assembly".

NOTE:

Avoid depressing brake pedal while brake caliper is removed.

3. Put alignment marks on disc rotor and wheel hub and bearing

assembly, then remove disc rotor.

4. Disconnect wheel sensor and remove bracket from steering knuckle.

CAUTION:

Do not pull on wheel sensor harness.

5. On 4WD models remove cotter pin, then using a hub lock nut wrench, remove lock nut from drive shaft.

6. Remove steering outer socket cotter pin at steering knuckle, then loosen mounting nut.

1. Disc rotor 2. Wheel hub and bearing assembly 3. Wheel stud

4. Splash guard 5. Steering knuckle 6. Wheel sensor bracket

MDIB9011E

WDIA0044E

Page 1617 of 3171

KNUCKLE

FSU-17

C

D

F

G

H

I

J

K

L

MA

B

FSU

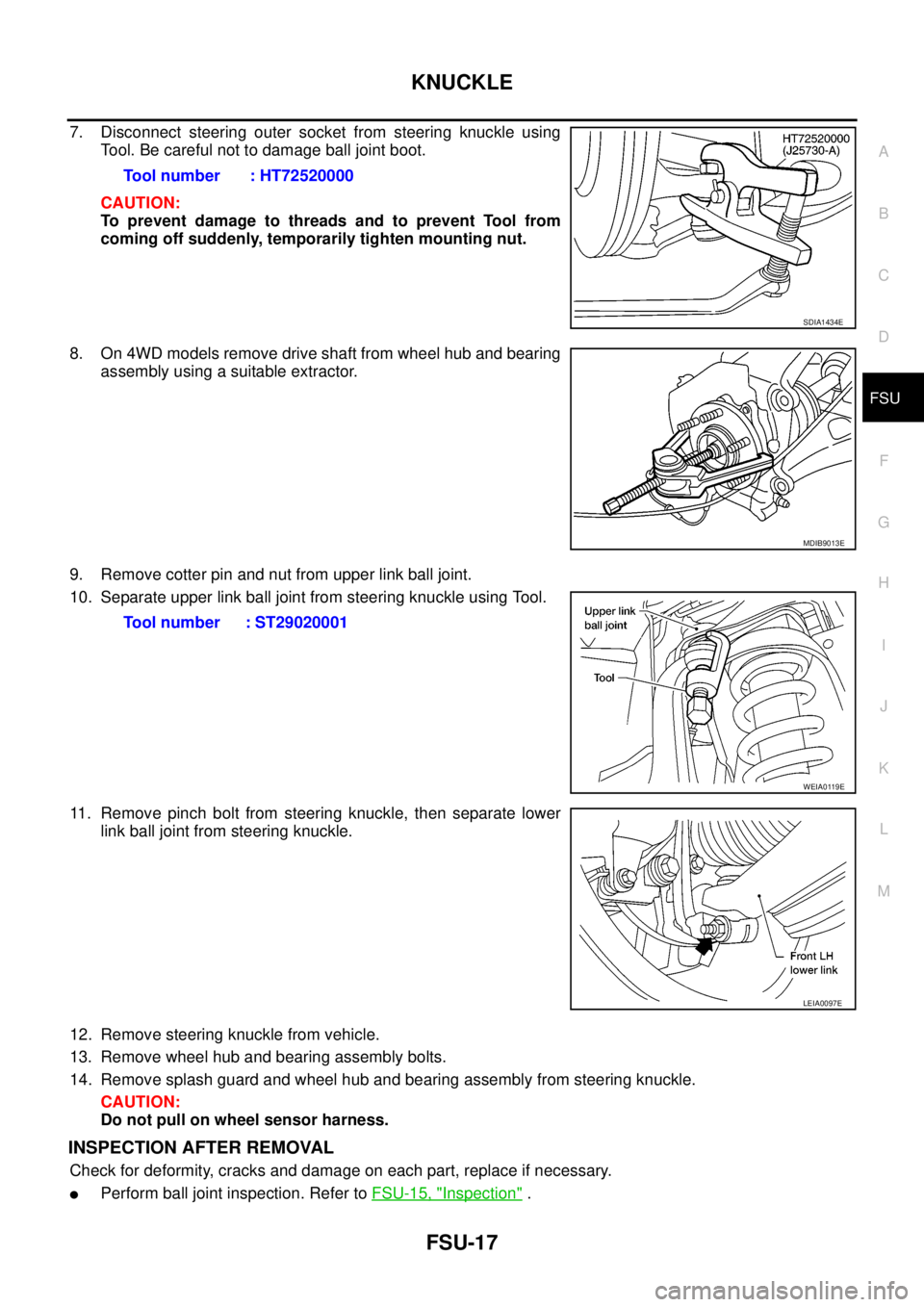

7. Disconnect steering outer socket from steering knuckle using

Tool. Be careful not to damage ball joint boot.

CAUTION:

To prevent damage to threads and to prevent Tool from

coming off suddenly, temporarily tighten mounting nut.

8. On 4WD models remove drive shaft from wheel hub and bearing

assembly using a suitable extractor.

9. Remove cotter pin and nut from upper link ball joint.

10. Separate upper link ball joint from steering knuckle using Tool.

11. Remove pinch bolt from steering knuckle, then separate lower

link ball joint from steering knuckle.

12. Remove steering knuckle from vehicle.

13. Remove wheel hub and bearing assembly bolts.

14. Remove splash guard and wheel hub and bearing assembly from steering knuckle.

CAUTION:

Do not pull on wheel sensor harness.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part, replace if necessary.

lPerform ball joint inspection. Refer toFSU-15, "Inspection". Tool number : HT72520000

SDIA1434E

MDIB9013E

Tool number : ST29020001

WEIA0119E

LEIA0097E

Page 1619 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

FSU-19

C

D

F

G

H

I

J

K

L

MA

B

FSU

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

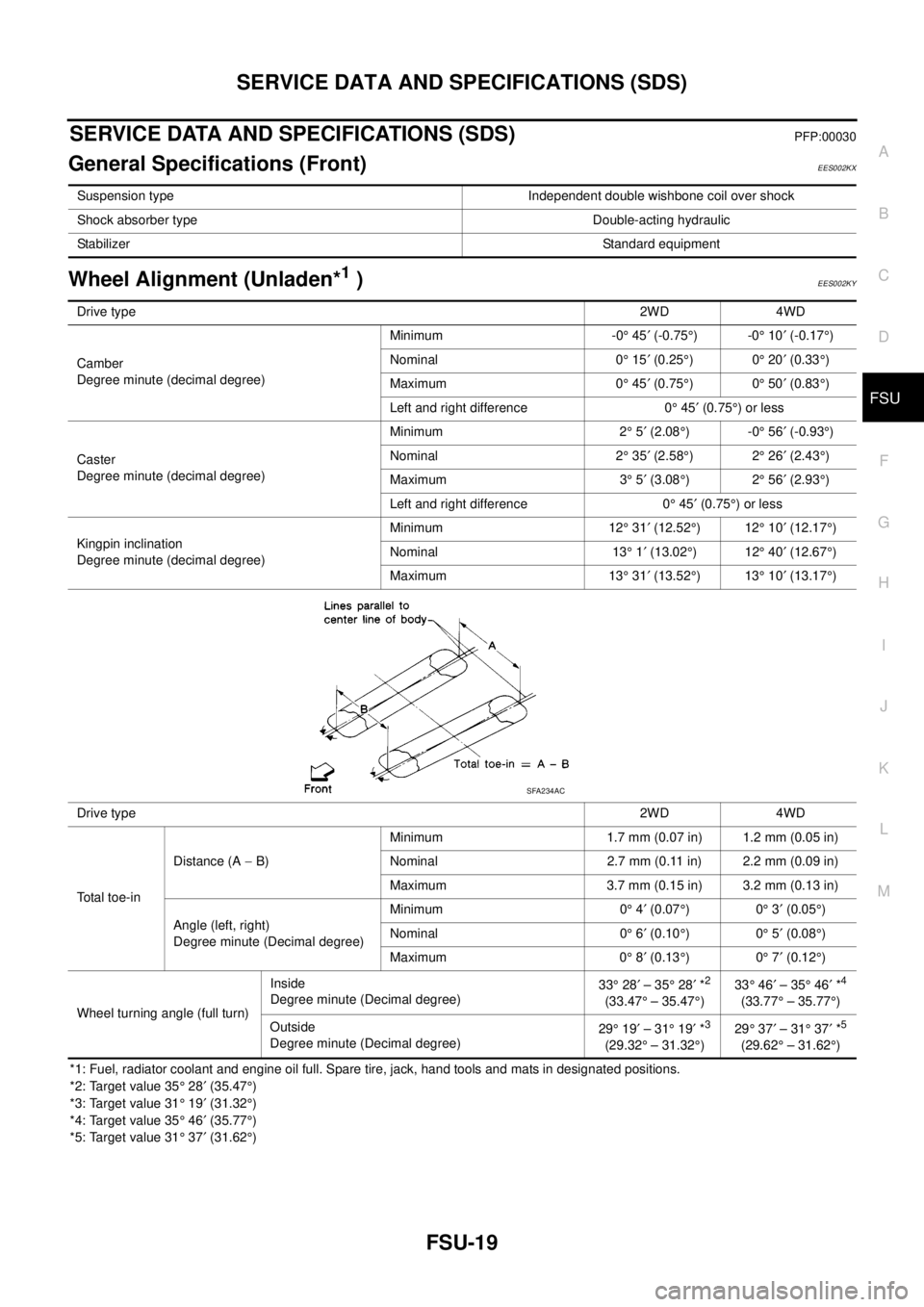

General Specifications (Front)EES002KX

Wheel Alignment (Unladen*1)EES002KY

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Target value 35°28¢(35.47°)

*3: Target value 31°19¢(31.32°)

*4: Target value 35°46¢(35.77°)

*5: Target value 31°37¢(31.62°) Suspension type Independent double wishbone coil over shock

Shock absorber type Double-acting hydraulic

StabilizerStandard equipment

Drive type2WD 4WD

Camber

Degree minute (decimal degree)Minimum -0°45¢(-0.75°)-0°10¢(-0.17°)

Nominal 0°15¢(0.25°)0°20¢(0.33°)

Maximum 0°45¢(0.75°)0°50¢(0.83°)

Left and right difference 0°45¢(0.75°)orless

Caster

Degree minute (decimal degree)Minimum 2°5¢(2.08°)-0°56¢(-0.93°)

Nominal 2°35¢(2.58°)2°26¢(2.43°)

Maximum 3°5¢(3.08°)2°56¢(2.93°)

Left and right difference 0°45¢(0.75°)orless

Kingpin inclination

Degree minute (decimal degree)Minimum 12°31¢(12.52°)12°10¢(12.17°)

Nominal 13°1¢(13.02°)12°40¢(12.67°)

Maximum 13°31¢(13.52°)13°10¢(13.17°)

Drive type2WD 4WD

Total toe-inDistance (A-B)Minimum 1.7 mm (0.07 in) 1.2 mm (0.05 in)

Nominal 2.7 mm (0.11 in) 2.2 mm (0.09 in)

Maximum 3.7 mm (0.15 in) 3.2 mm (0.13 in)

Angle (left, right)

Degree minute (Decimal degree)Minimum 0°4¢(0.07°)0°3¢(0.05°)

Nominal 0°6¢(0.10°)0°5¢(0.08°)

Maximum 0°8¢(0.13°)0°7¢(0.12°)

Wheel turning angle (full turn)Inside

Degree minute (Decimal degree)33°28¢–35°28¢*

2

(33.47°– 35.47°)33°46¢–35°46¢*

4

(33.77°– 35.77°)

Outside

Degree minute (Decimal degree)29°19¢–31°19¢*

3

(29.32°– 31.32°)29°37¢–31°37¢*

5

(29.62°– 31.62°)

SFA234AC

Page 1621 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

FSU-21

C

D

F

G

H

I

J

K

L

MA

B

FSU

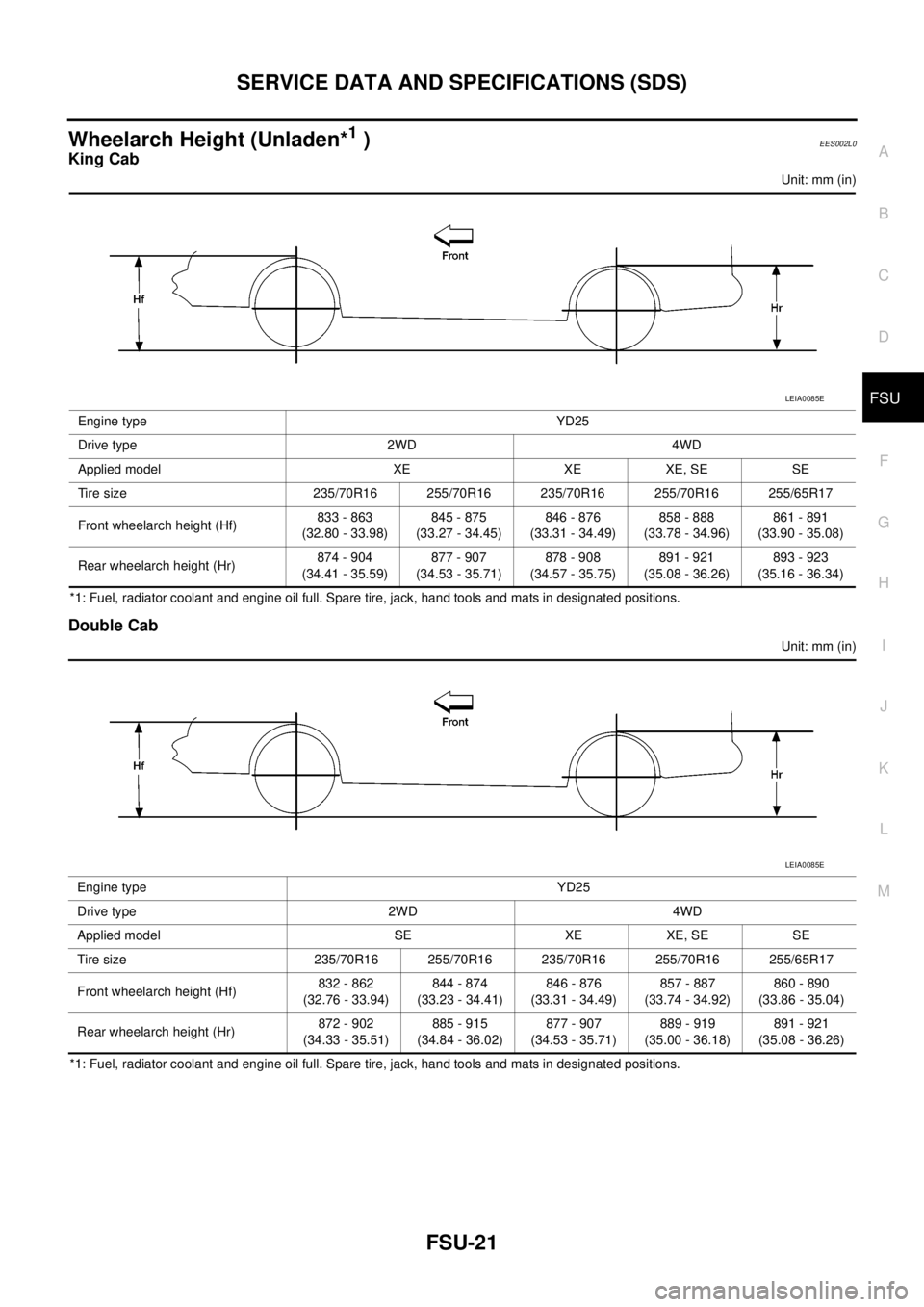

Wheelarch Height (Unladen*1)EES002L0

King Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Double Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Engine type YD25

Drive type 2WD 4WD

Applied model XE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)833 - 863

(32.80 - 33.98)845 - 875

(33.27 - 34.45)846 - 876

(33.31 - 34.49)858 - 888

(33.78 - 34.96)861 - 891

(33.90 - 35.08)

Rear wheelarch height (Hr)874 - 904

(34.41 - 35.59)877 - 907

(34.53 - 35.71)878 - 908

(34.57 - 35.75)891 - 921

(35.08 - 36.26)893 - 923

(35.16 - 36.34)

LEIA0085E

Engine type YD25

Drive type 2WD 4WD

Applied model SE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)832 - 862

(32.76 - 33.94)844 - 874

(33.23 - 34.41)846 - 876

(33.31 - 34.49)857 - 887

(33.74 - 34.92)860 - 890

(33.86 - 35.04)

Rear wheelarch height (Hr)872 - 902

(34.33 - 35.51)885 - 915

(34.84 - 36.02)877 - 907

(34.53 - 35.71)889 - 919

(35.00 - 36.18)891 - 921

(35.08 - 36.26)

LEIA0085E

Page 1669 of 3171

CONSULT-II CHECKING SYSTEM

GI-47

C

D

E

F

G

H

I

J

K

L

MB

GI

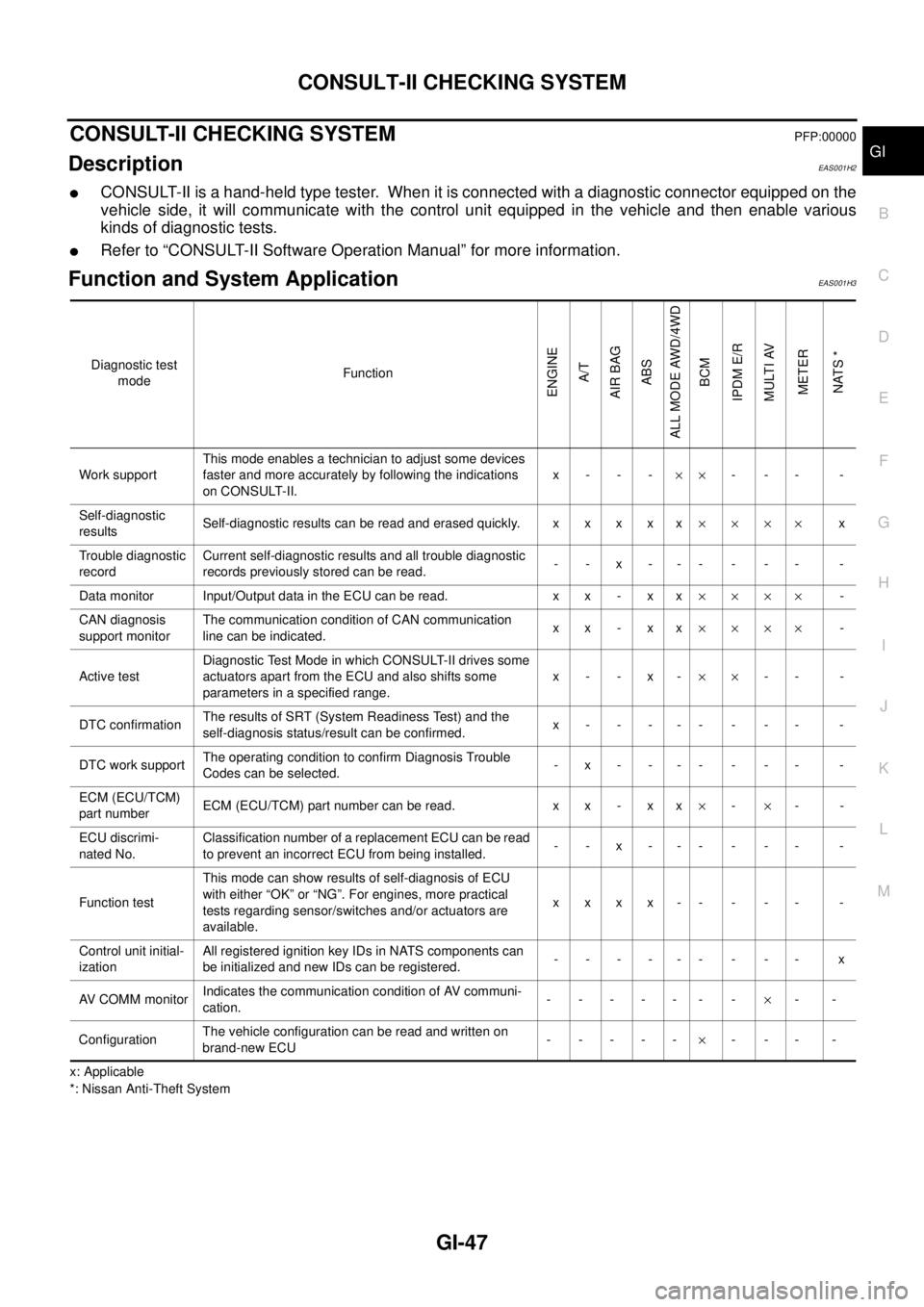

CONSULT-II CHECKING SYSTEMPFP:00000

DescriptionEAS001H2

lCONSULT-II is a hand-held type tester. When it is connected with a diagnostic connector equipped on the

vehicle side, it will communicate with the control unit equipped in the vehicle and then enable various

kinds of diagnostic tests.

lRefer to “CONSULT-II Software Operation Manual” for more information.

Function and System ApplicationEAS001H3

x: Applicable

*: Nissan Anti-Theft SystemDiagnostic test

modeFunction

ENGINE

A/T

AIR BAG

ABS

ALL MODE AWD/4WD

BCM

IPDM E/R

MULTI AV

METER

NATS *

Work supportThis mode enables a technician to adjust some devices

faster and more accurately by following the indications

on CONSULT-II.x---´´--- -

Self-diagnostic

resultsSelf-diagnostic results can be read and erased quickly. x x x x x´´´´x

Trouble diagnostic

recordCurrent self-diagnostic results and all trouble diagnostic

records previously stored can be read.--x------ -

Data monitor Input/Output data in the ECU can be read. x x - x x´´´´-

CAN diagnosis

support monitorThe communication condition of CAN communication

line can be indicated.xx - xx´´´´-

Active testDiagnostic Test Mode in which CONSULT-II drives some

actuators apart from the ECU and also shifts some

parameters in a specified range.x- -x-´´-- -

DTC confirmationThe results of SRT (System Readiness Test) and the

self-diagnosis status/result can be confirmed.x----- - -- -

DTC work supportThe operating condition to confirm Diagnosis Trouble

Codes can be selected.-x------- -

ECM (ECU/TCM)

part numberECM (ECU/TCM) part number can be read. x x - x x´-´--

ECU discrimi-

nated No.Classification number of a replacement ECU can be read

to prevent an incorrect ECU from being installed.--x------ -

Function testThis mode can show results of self-diagnosis of ECU

with either “OK” or “NG”. For engines, more practical

tests regarding sensor/switches and/or actuators are

available.xxxx-- - - - -

Control unit initial-

izationAll registered ignition key IDs in NATS components can

be initialized and new IDs can be registered.------ - -- x

AV C O M M m o n i t o rIndicates the communication condition of AV communi-

cation.- ----- -´--

ConfigurationThe vehicle configuration can be read and written on

brand-new ECU- ----´--- -

Page 1678 of 3171

GI-56

IDENTIFICATION INFORMATION

IDENTIFICATION INFORMATION

PFP:00010

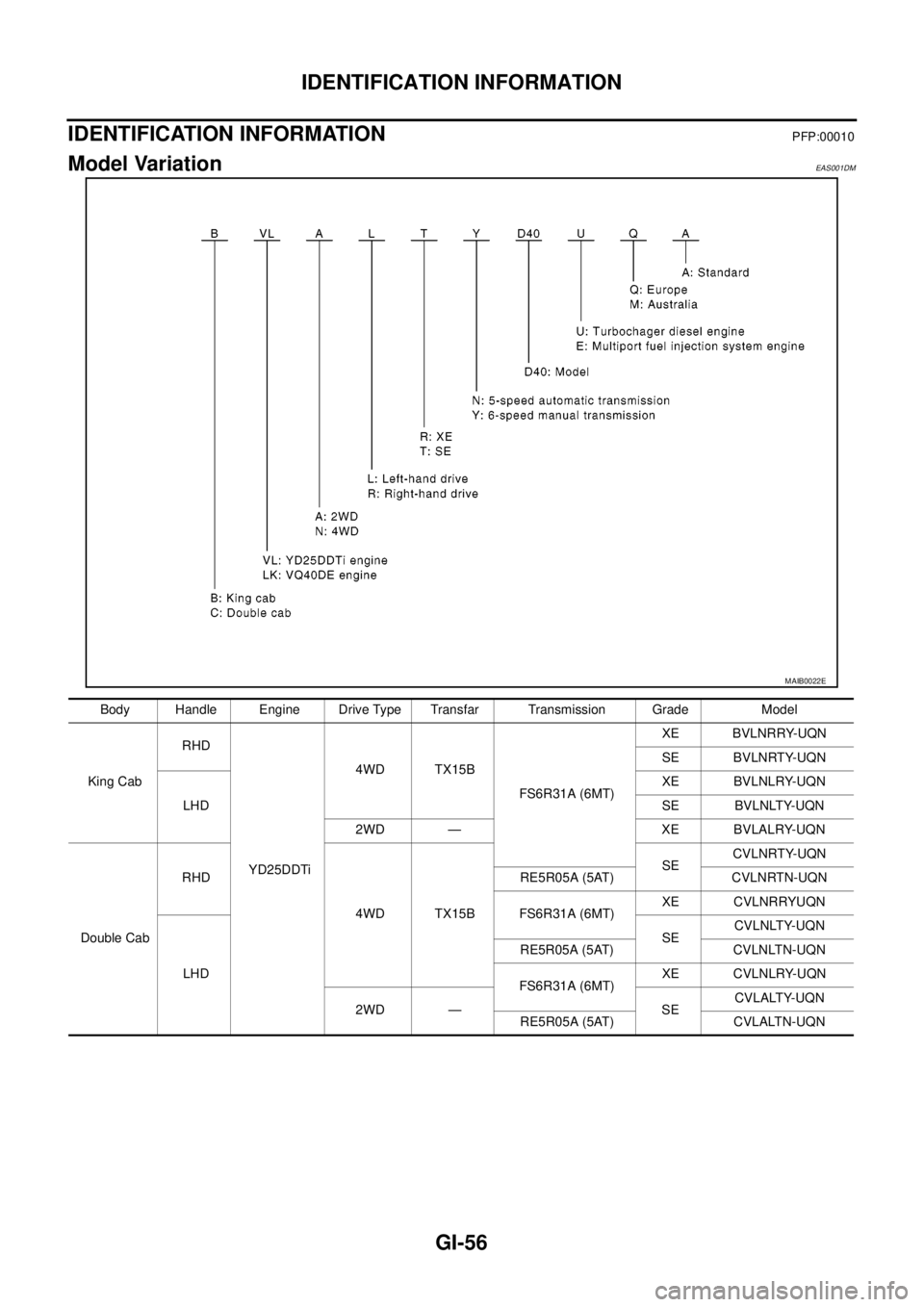

Model VariationEAS001DM

MAIB0022E

Body Handle Engine Drive Type Transfar Transmission Grade Model

King CabRHD

YD25DDTi4WD TX15B

FS6R31A (6MT)XE BVLNRRY-UQN

SE BVLNRTY-UQN

LHDXE BVLNLRY-UQN

SE BVLNLTY-UQN

2WD — XE BVLALRY-UQN

Double CabRHD

4WD TX15BSECVLNRTY-UQN

RE5R05A (5AT) CVLNRTN-UQN

FS6R31A (6MT)XE CVLNRRYUQN

LHDSECVLNLTY-UQN

RE5R05A (5AT) CVLNLTN-UQN

FS6R31A (6MT)XE CVLNLRY-UQN

2WD — SECVLALTY-UQN

RE5R05A (5AT) CVLALTN-UQN

Page 1682 of 3171

GI-60

IDENTIFICATION INFORMATION

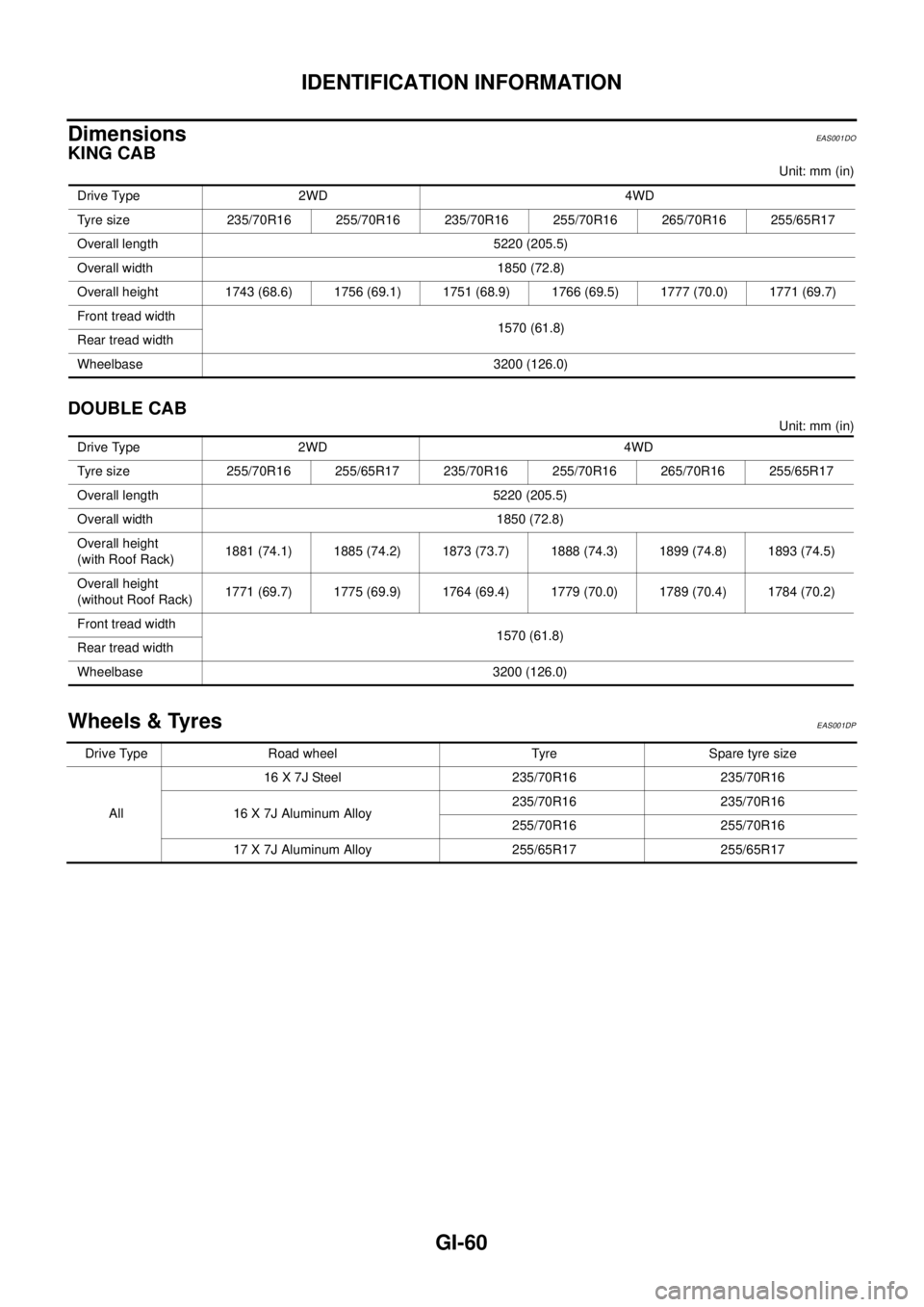

Dimensions

EAS001DO

KING CAB

Unit: mm (in)

DOUBLE CAB

Unit: mm (in)

Wheels & TyresEAS001DP

Drive Type 2WD 4WD

Tyre size 235/70R16 255/70R16 235/70R16 255/70R16 265/70R16 255/65R17

Overall length 5220 (205.5)

Overall width 1850 (72.8)

Overall height 1743 (68.6) 1756 (69.1) 1751 (68.9) 1766 (69.5) 1777 (70.0) 1771 (69.7)

Front tread width

1570 (61.8)

Rear tread width

Wheelbase 3200 (126.0)

Drive Type 2WD 4WD

Tyre size 255/70R16 255/65R17 235/70R16 255/70R16 265/70R16 255/65R17

Overall length 5220 (205.5)

Overall width 1850 (72.8)

Overall height

(with Roof Rack)1881 (74.1) 1885 (74.2) 1873 (73.7) 1888 (74.3) 1899 (74.8) 1893 (74.5)

Overall height

(without Roof Rack)1771 (69.7) 1775 (69.9) 1764 (69.4) 1779 (70.0) 1789 (70.4) 1784 (70.2)

Front tread width

1570 (61.8)

Rear tread width

Wheelbase 3200 (126.0)

Drive Type Road wheel Tyre Spare tyre size

All16 X 7J Steel 235/70R16 235/70R16

16 X 7J Aluminum Alloy235/70R16 235/70R16

255/70R16 255/70R16

17 X 7J Aluminum Alloy 255/65R17 255/65R17

Page 1754 of 3171

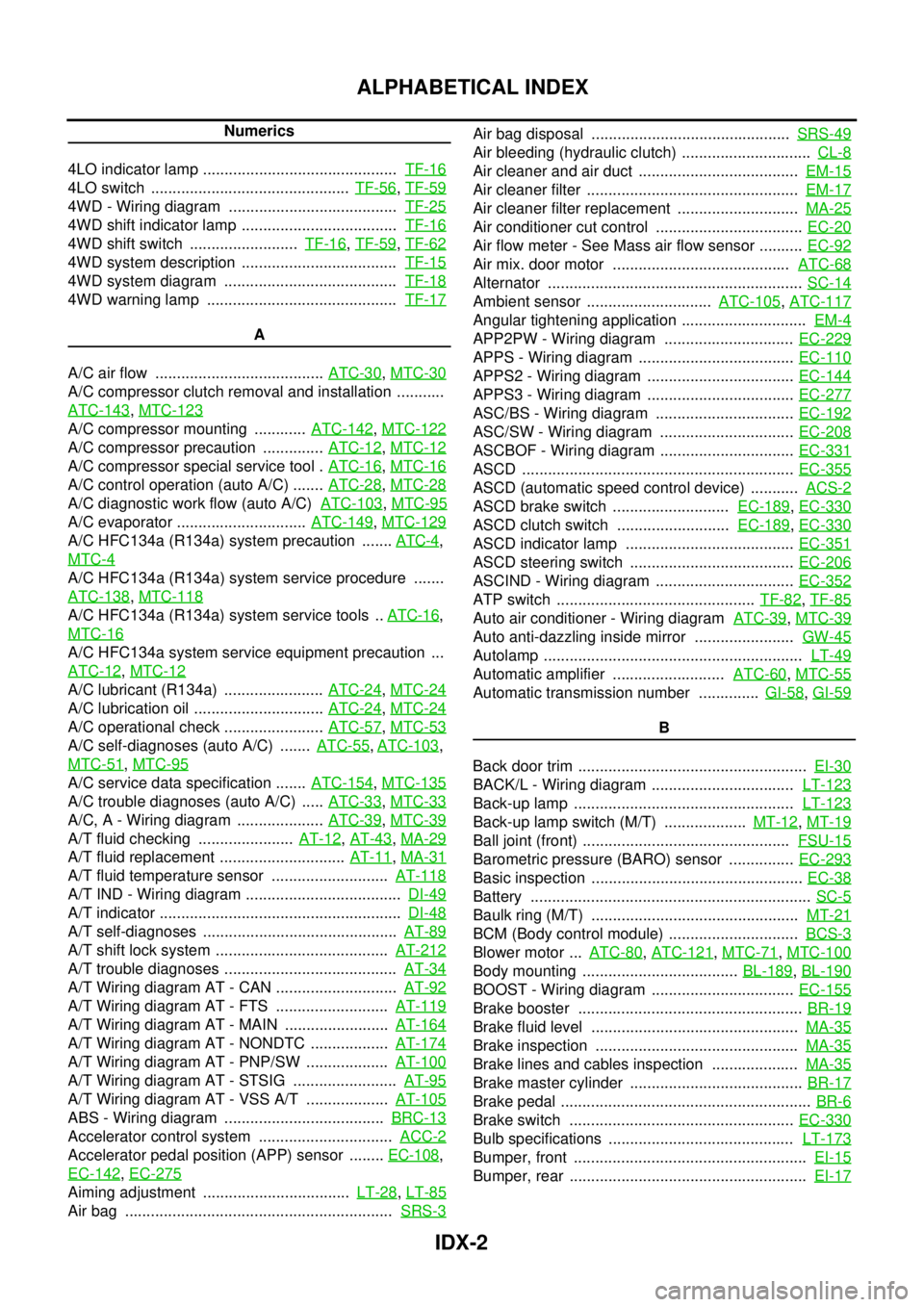

IDX-2

ALPHABETICAL INDEX

Numerics

4LO indicator lamp .............................................TF-16

4LO switch ..............................................TF-56,TF-59

4WD - Wiring diagram .......................................TF-25

4WD shift indicator lamp ....................................TF-16

4WD shift switch .........................TF-16,TF-59,TF-62

4WD system description ....................................TF-15

4WD system diagram ........................................TF-18

4WD warning lamp ............................................TF-17

A

A/C air flow .......................................ATC-30

,MTC-30

A/C compressor clutch removal and installation ...........

ATC-143

,MTC-123

A/C compressor mounting ............ATC-142,MTC-122

A/C compressor precaution ..............ATC-12,MTC-12

A/C compressor special service tool .ATC-16,MTC-16

A/C control operation (auto A/C) .......ATC-28,MTC-28

A/C diagnostic work flow (auto A/C)ATC-103,MTC-95

A/C evaporator ..............................ATC-149,MTC-129

A/C HFC134a (R134a) system precaution .......ATC-4,

MTC-4

A/C HFC134a (R134a) system service procedure .......

ATC-138

,MTC-118

A/C HFC134a (R134a) system service tools ..ATC-16,

MTC-16

A/C HFC134a system service equipment precaution ...

ATC-12

,MTC-12

A/C lubricant (R134a) .......................ATC-24,MTC-24

A/C lubrication oil ..............................ATC-24,MTC-24

A/C operational check .......................ATC-57,MTC-53

A/C self-diagnoses (auto A/C) .......ATC-55,ATC-103,

MTC-51

,MTC-95

A/C service data specification .......ATC-154,MTC-135

A/C trouble diagnoses (auto A/C) .....ATC-33,MTC-33

A/C, A - Wiring diagram ....................ATC-39,MTC-39

A/T fluid checking ......................AT-12,AT-43,MA-29

A/T fluid replacement .............................AT-11,MA-31

A/T fluid temperature sensor ...........................AT-118

A/T IND - Wiring diagram ....................................DI-49

A/T indicator ........................................................DI-48

A/T self-diagnoses .............................................AT-89

A/T shift lock system ........................................AT-212

A/T trouble diagnoses ........................................AT-34

A/T Wiring diagram AT - CAN ............................AT-92

A/T Wiring diagram AT - FTS ..........................AT-119

A/T Wiring diagram AT - MAIN ........................AT-164

A/T Wiring diagram AT - NONDTC ..................AT-174

A/T Wiring diagram AT - PNP/SW ...................AT-100

A/T Wiring diagram AT - STSIG ........................AT-95

A/T Wiring diagram AT - VSS A/T ...................AT-105

ABS - Wiring diagram .....................................BRC-13

Accelerator control system ...............................ACC-2

Accelerator pedal position (APP) sensor ........EC-108,

EC-142

,EC-275

Aiming adjustment ..................................LT-28,LT-85

Air bag ..............................................................SRS-3

Air bag disposal ..............................................SRS-49

Air bleeding (hydraulic clutch) ..............................CL-8

Air cleaner and air duct .....................................EM-15

Air cleaner filter .................................................EM-17

Air cleaner filter replacement ............................MA-25

Air conditioner cut control ..................................EC-20

Air flow meter - See Mass air flow sensor ..........EC-92

Air mix. door motor .........................................ATC-68

Alternator ...........................................................SC-14

Ambient sensor .............................ATC-105,ATC-117

Angular tightening application .............................EM-4

APP2PW - Wiring diagram ..............................EC-229

APPS - Wiring diagram ....................................EC-110

APPS2 - Wiring diagram ..................................EC-144

APPS3 - Wiring diagram ..................................EC-277

ASC/BS - Wiring diagram ................................EC-192

ASC/SW - Wiring diagram ...............................EC-208

ASCBOF - Wiring diagram ...............................EC-331

ASCD ...............................................................EC-355

ASCD (automatic speed control device) ...........ACS-2

ASCD brake switch ...........................EC-189,EC-330

ASCD clutch switch ..........................EC-189,EC-330

ASCD indicator lamp .......................................EC-351

ASCD steering switch ......................................EC-206

ASCIND - Wiring diagram ................................EC-352

ATP switch ..............................................TF-82,TF-85

Auto air conditioner - Wiring diagramATC-39,MTC-39

Auto anti-dazzling inside mirror .......................GW-45

Autolamp ............................................................LT-49

Automatic amplifier ..........................ATC-60,MTC-55

Automatic transmission number ..............GI-58,GI-59

B

Back door trim .....................................................EI-30

BACK/L - Wiring diagram .................................LT-123

Back-up lamp ...................................................LT-123

Back-up lamp switch (M/T) ...................MT-12,MT-19

Ball joint (front) ................................................FSU-15

Barometric pressure (BARO) sensor ...............EC-293

Basic inspection .................................................EC-38

Battery .................................................................SC-5

Baulk ring (M/T) ................................................MT-21

BCM (Body control module) ..............................BCS-3

Blower motor ...ATC-80,ATC-121,MTC-71,MTC-100

Body mounting ....................................BL-189,BL-190

BOOST - Wiring diagram .................................EC-155

Brake booster ....................................................BR-19

Brake fluid level ................................................MA-35

Brake inspection ...............................................MA-35

Brake lines and cables inspection ....................MA-35

Brake master cylinder ........................................BR-17

Brake pedal ..........................................................BR-6

Brake switch ....................................................EC-330

Bulb specifications ...........................................LT-173

Bumper, front ......................................................EI-15

Bumper, rear .......................................................EI-17

Page 1755 of 3171

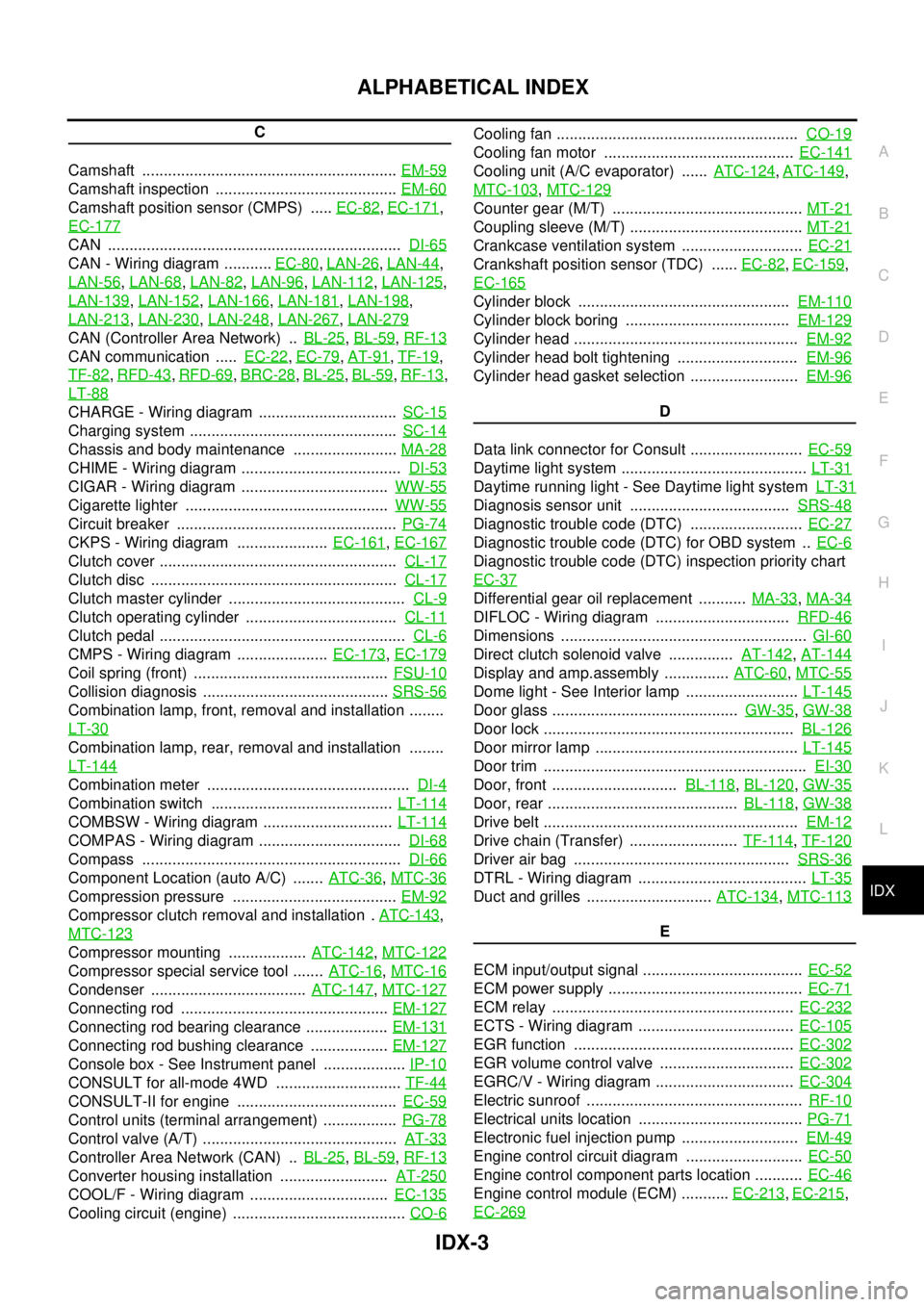

IDX-3

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

C

Camshaft ...........................................................EM-59

Camshaft inspection ..........................................EM-60

Camshaft position sensor (CMPS) .....EC-82,EC-171,

EC-177

CAN ....................................................................DI-65

CAN - Wiring diagram ...........EC-80,LAN-26,LAN-44,

LAN-56

,LAN-68,LAN-82,LAN-96,LAN-112,LAN-125,

LAN-139

,LAN-152,LAN-166,LAN-181,LAN-198,

LAN-213

,LAN-230,LAN-248,LAN-267,LAN-279

CAN (Controller Area Network) ..BL-25,BL-59,RF-13

CAN communication .....EC-22,EC-79,AT-91,TF-19,

TF-82

,RFD-43,RFD-69,BRC-28,BL-25,BL-59,RF-13,

LT-88

CHARGE - Wiring diagram ................................SC-15

Charging system ................................................SC-14

Chassis and body maintenance ........................MA-28

CHIME - Wiring diagram .....................................DI-53

CIGAR - Wiring diagram ..................................WW-55

Cigarette lighter ...............................................WW-55

Circuit breaker ...................................................PG-74

CKPS - Wiring diagram .....................EC-161,EC-167

Clutch cover .......................................................CL-17

Clutch disc .........................................................CL-17

Clutch master cylinder .........................................CL-9

Clutch operating cylinder ...................................CL-11

Clutch pedal .........................................................CL-6

CMPS - Wiring diagram .....................EC-173,EC-179

Coil spring (front) .............................................FSU-10

Collision diagnosis ...........................................SRS-56

Combination lamp, front, removal and installation ........

LT-30

Combination lamp, rear, removal and installation ........

LT-144

Combination meter ...............................................DI-4

Combination switch ..........................................LT-114

COMBSW - Wiring diagram ..............................LT-114

COMPAS - Wiring diagram .................................DI-68

Compass ............................................................DI-66

Component Location (auto A/C) .......ATC-36,MTC-36

Compression pressure ......................................EM-92

Compressor clutch removal and installation .ATC-143,

MTC-123

Compressor mounting ..................ATC-142,MTC-122

Compressor special service tool .......ATC-16,MTC-16

Condenser ....................................ATC-147,MTC-127

Connecting rod ................................................EM-127

Connecting rod bearing clearance ...................EM-131

Connecting rod bushing clearance ..................EM-127

Console box - See Instrument panel ...................IP-10

CONSULT for all-mode 4WD .............................TF-44

CONSULT-II for engine .....................................EC-59

Control units (terminal arrangement) .................PG-78

Control valve (A/T) .............................................AT-33

Controller Area Network (CAN) ..BL-25,BL-59,RF-13

Converter housing installation .........................AT-250

COOL/F - Wiring diagram ................................EC-135

Cooling circuit (engine) ........................................CO-6

Cooling fan ........................................................CO-19

Cooling fan motor ............................................EC-141

Cooling unit (A/C evaporator) ......ATC-124,ATC-149,

MTC-103

,MTC-129

Counter gear (M/T) ............................................MT-21

Coupling sleeve (M/T) ........................................MT-21

Crankcase ventilation system ............................EC-21

Crankshaft position sensor (TDC) ......EC-82,EC-159,

EC-165

Cylinder block .................................................EM-110

Cylinder block boring ......................................EM-129

Cylinder head ....................................................EM-92

Cylinder head bolt tightening ............................EM-96

Cylinder head gasket selection .........................EM-96

D

Data link connector for Consult ..........................EC-59

Daytime light system ...........................................LT-31

Daytime running light - See Daytime light systemLT-31

Diagnosis sensor unit .....................................SRS-48

Diagnostic trouble code (DTC) ..........................EC-27

Diagnostic trouble code (DTC) for OBD system ..EC-6

Diagnostic trouble code (DTC) inspection priority chart

EC-37

Differential gear oil replacement ...........MA-33,MA-34

DIFLOC - Wiring diagram ...............................RFD-46

Dimensions .........................................................GI-60

Direct clutch solenoid valve ...............AT-142,AT-144

Display and amp.assembly ...............ATC-60,MTC-55

Dome light - See Interior lamp ..........................LT-145

Door glass ...........................................GW-35,GW-38

Door lock ..........................................................BL-126

Door mirror lamp ...............................................LT-145

Door trim .............................................................EI-30

Door, front .............................BL-118,BL-120,GW-35

Door, rear ............................................BL-118,GW-38

Drive belt ...........................................................EM-12

Drive chain (Transfer) .........................TF-114,TF-120

Driver air bag ..................................................SRS-36

DTRL - Wiring diagram .......................................LT-35

Duct and grilles .............................ATC-134,MTC-113

E

ECM input/output signal .....................................EC-52

ECM power supply .............................................EC-71

ECM relay ........................................................EC-232

ECTS - Wiring diagram ....................................EC-105

EGR function ...................................................EC-302

EGR volume control valve ...............................EC-302

EGRC/V - Wiring diagram ................................EC-304

Electric sunroof ..................................................RF-10

Electrical units location ......................................PG-71

Electronic fuel injection pump ...........................EM-49

Engine control circuit diagram ...........................EC-50

Engine control component parts location ...........EC-46

Engine control module (ECM) ...........EC-213,EC-215,

EC-269