NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1301 of 3171

HEAT UP SWITCH

EC-321

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KME

1.CHECK OVERALL FUNCTION-I

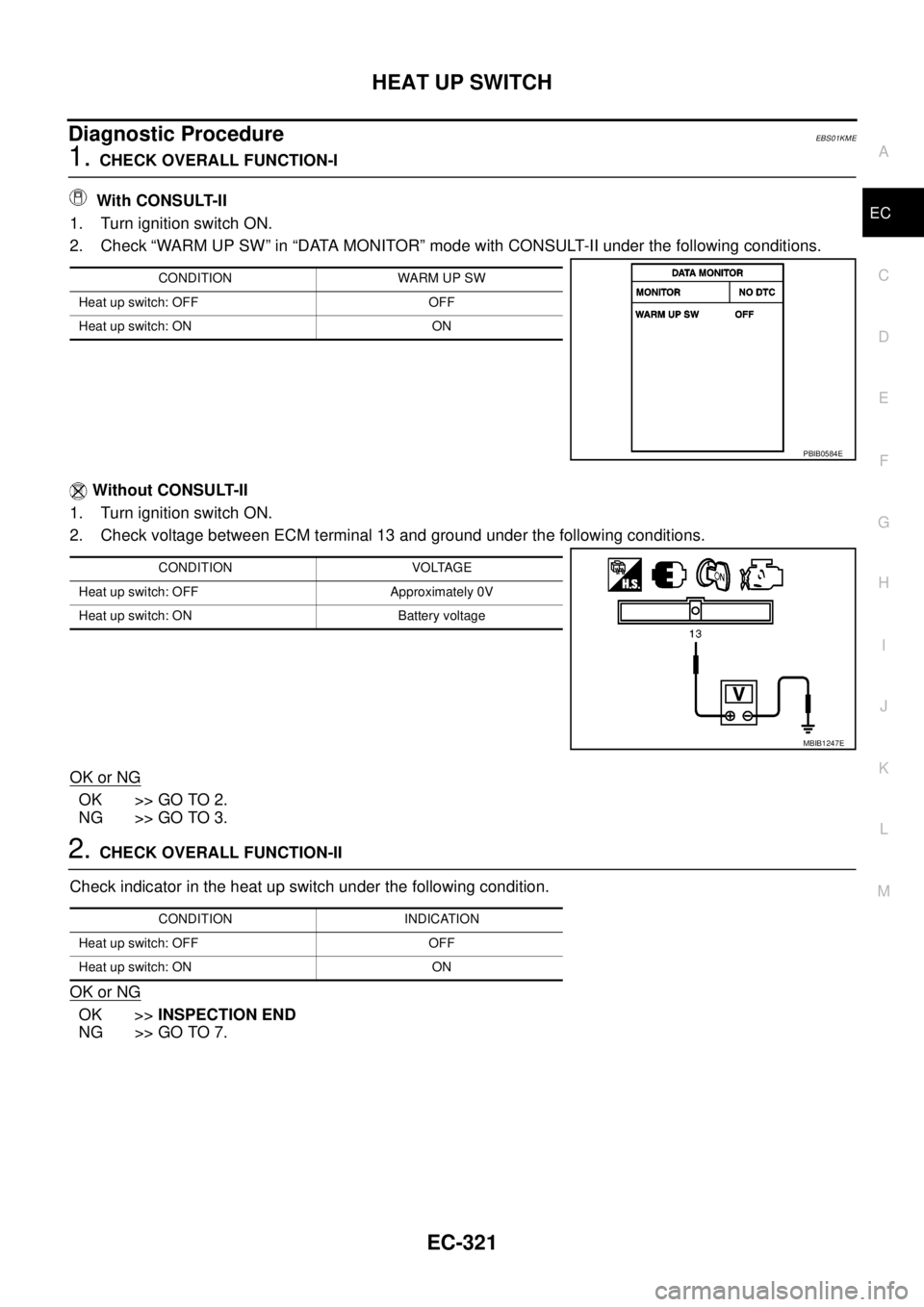

With CONSULT-II

1. Turn ignition switch ON.

2. Check “WARM UP SW” in “DATA MONITOR” mode with CONSULT-II under the following conditions.

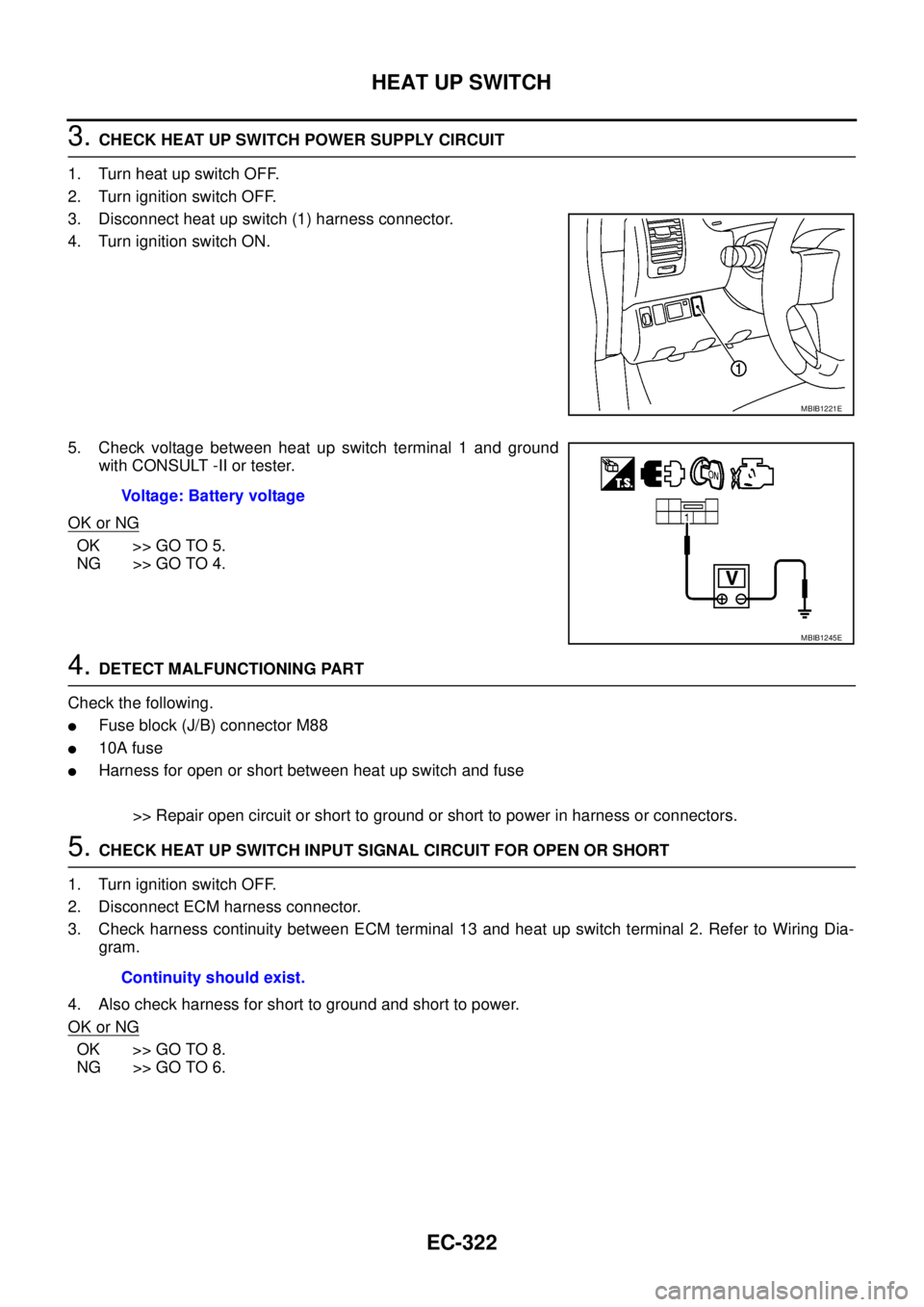

Without CONSULT-II

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 13 and ground under the following conditions.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK OVERALL FUNCTION-II

Check indicator in the heat up switch under the following condition.

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

CONDITION WARM UP SW

Heat up switch: OFF OFF

Heat up switch: ON ON

PBIB0584E

CONDITION VOLTAGE

Heat up switch: OFF Approximately 0V

Heat up switch: ON Battery voltage

MBIB1247E

CONDITION INDICATION

Heat up switch: OFF OFF

Heat up switch: ON ON

Page 1302 of 3171

EC-322

HEAT UP SWITCH

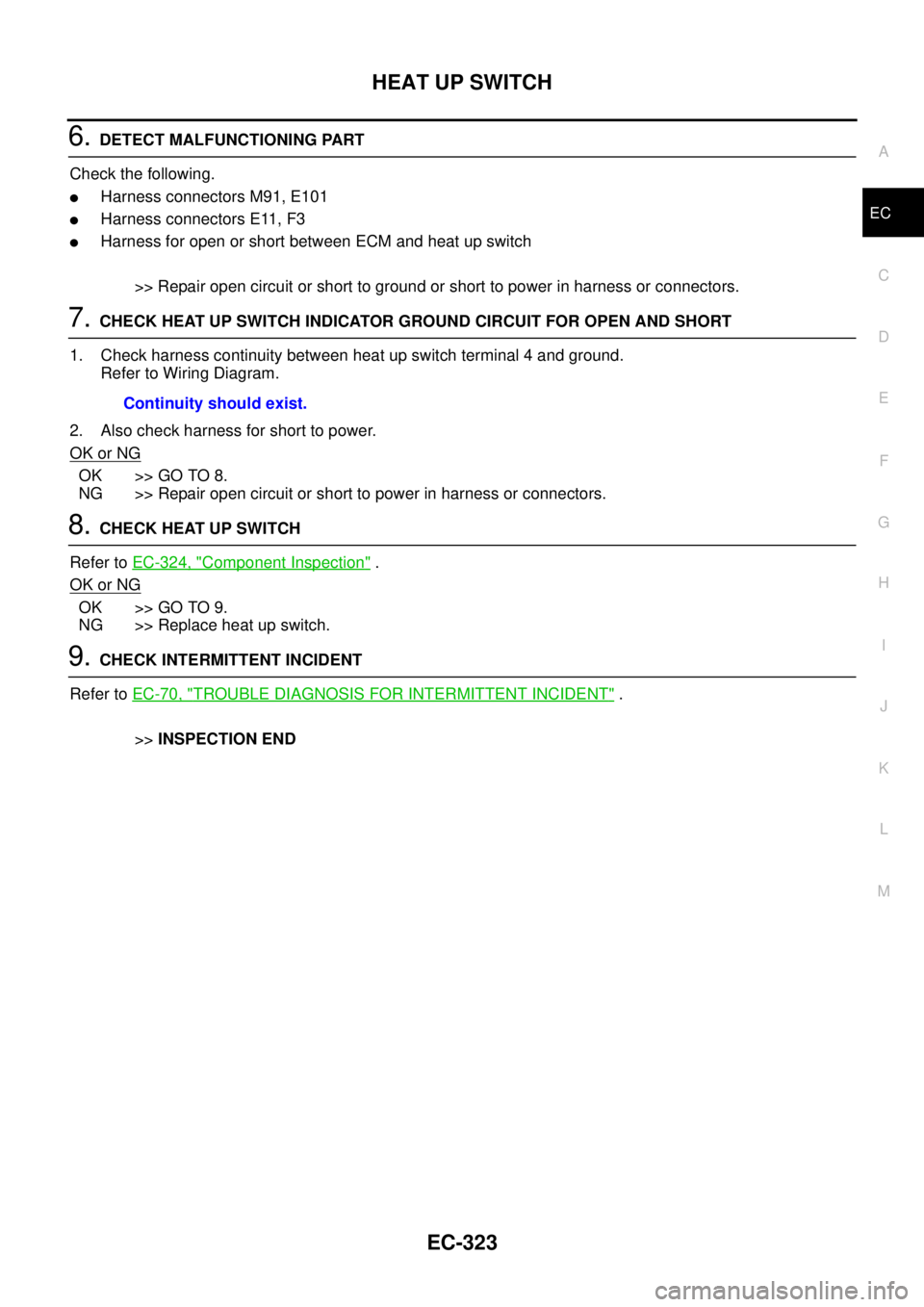

3.CHECK HEAT UP SWITCH POWER SUPPLY CIRCUIT

1. Turn heat up switch OFF.

2. Turn ignition switch OFF.

3. Disconnect heat up switch (1) harness connector.

4. Turn ignition switch ON.

5. Check voltage between heat up switch terminal 1 and ground

with CONSULT -II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

lFuse block (J/B) connector M88

l10A fuse

lHarness for open or short between heat up switch and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK HEAT UP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN OR SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 13 and heat up switch terminal 2. Refer to Wiring Dia-

gram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> GO TO 6.

MBIB1221E

Voltage: Battery voltage

MBIB1245E

Continuity should exist.

Page 1303 of 3171

HEAT UP SWITCH

EC-323

C

D

E

F

G

H

I

J

K

L

MA

EC

6.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors M91, E101

lHarness connectors E11, F3

lHarness for open or short between ECM and heat up switch

>> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK HEAT UP SWITCH INDICATOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between heat up switch terminal 4 and ground.

Refer to Wiring Diagram.

2. Also check harness for short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair open circuit or short to power in harness or connectors.

8.CHECK HEAT UP SWITCH

Refer toEC-324, "

Component Inspection".

OK or NG

OK >> GO TO 9.

NG >> Replace heat up switch.

9.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END Continuity should exist.

Page 1304 of 3171

EC-324

HEAT UP SWITCH

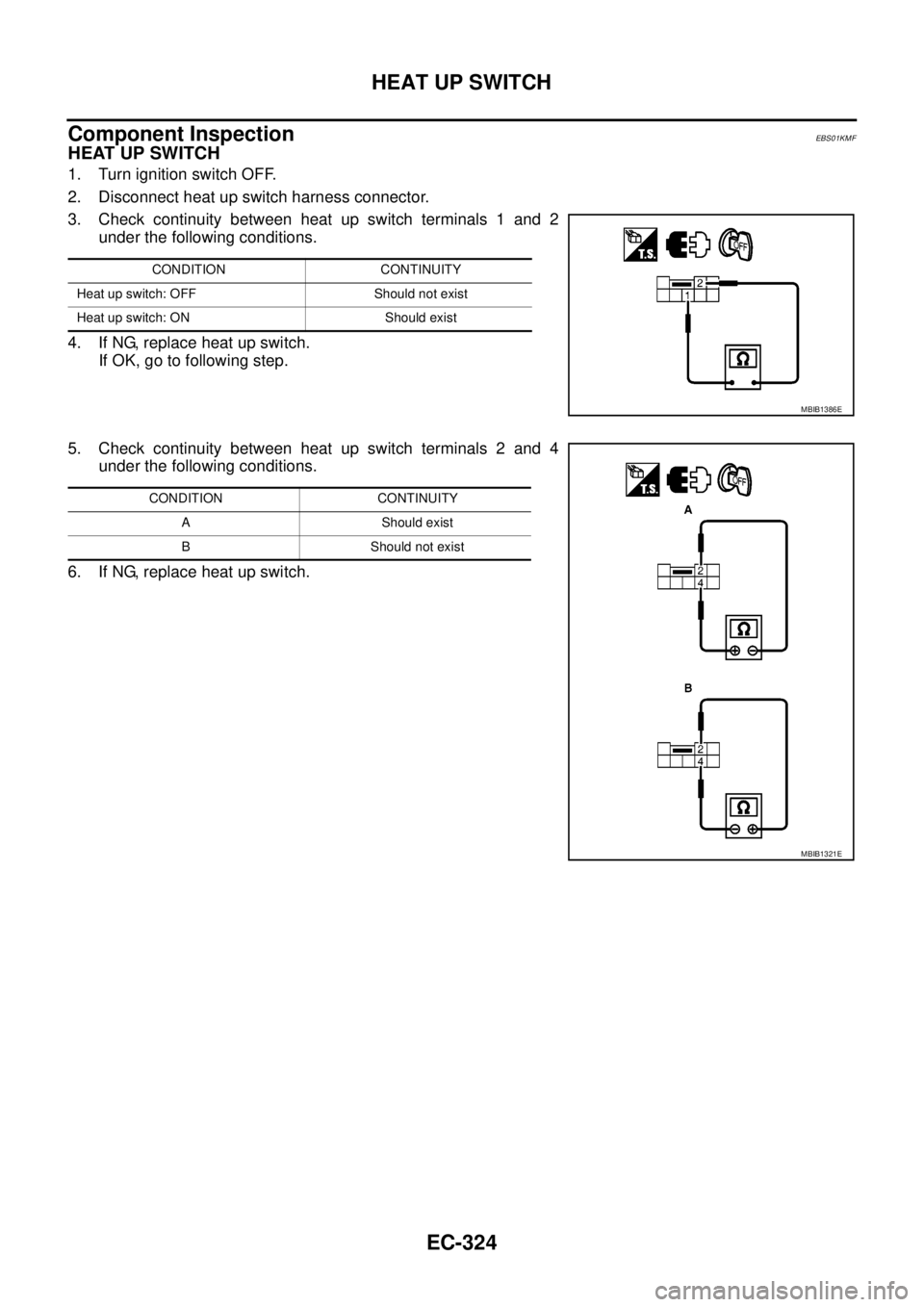

Component Inspection

EBS01KMF

HEAT UP SWITCH

1. Turn ignition switch OFF.

2. Disconnect heat up switch harness connector.

3. Check continuity between heat up switch terminals 1 and 2

under the following conditions.

4. If NG, replace heat up switch.

If OK, go to following step.

5. Check continuity between heat up switch terminals 2 and 4

under the following conditions.

6. If NG, replace heat up switch.

CONDITION CONTINUITY

Heat up switch: OFF Should not exist

Heat up switch: ON Should exist

MBIB1386E

CONDITION CONTINUITY

A Should exist

B Should not exist

MBIB1321E

Page 1305 of 3171

REFRIGERANT PRESSURE SENSOR

EC-325

C

D

E

F

G

H

I

J

K

L

MA

EC

REFRIGERANT PRESSURE SENSORPFP:92136

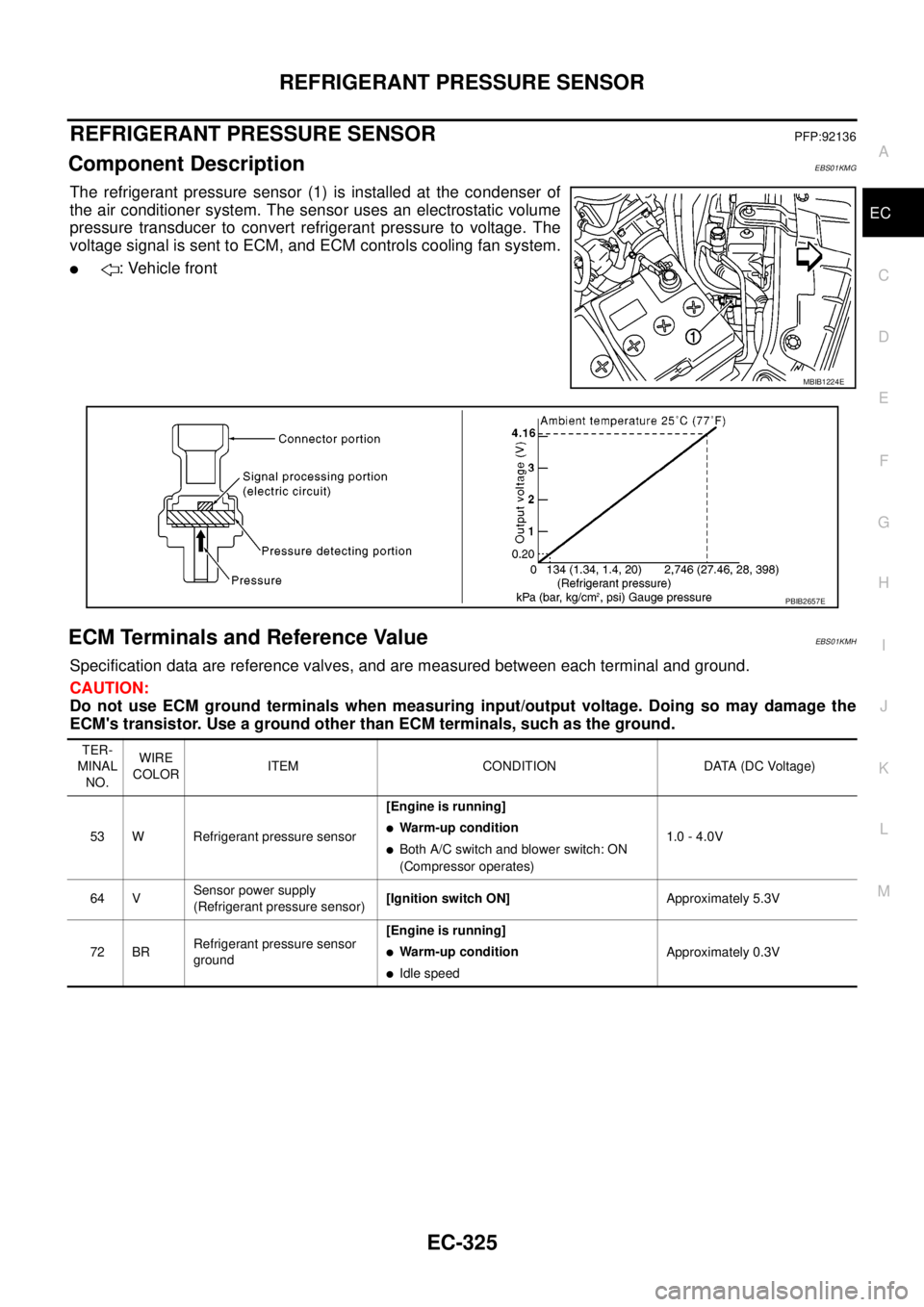

Component DescriptionEBS01KMG

The refrigerant pressure sensor (1) is installed at the condenser of

the air conditioner system. The sensor uses an electrostatic volume

pressure transducer to convert refrigerant pressure to voltage. The

voltage signal is sent to ECM, and ECM controls cooling fan system.

l: Vehicle front

ECM Terminals and Reference ValueEBS01KMH

Specification data are reference valves, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

MBIB1224E

PBIB2657E

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

53 W Refrigerant pressure sensor[Engine is running]

lWarm-up condition

lBoth A/C switch and blower switch: ON

(Compressor operates)1.0 - 4.0V

64 VSensor power supply

(Refrigerant pressure sensor)[Ignition switch ON]Approximately 5.3V

72 BRRefrigerant pressure sensor

ground[Engine is running]

lWarm-up condition

lIdle speedApproximately 0.3V

Page 1306 of 3171

EC-326

REFRIGERANT PRESSURE SENSOR

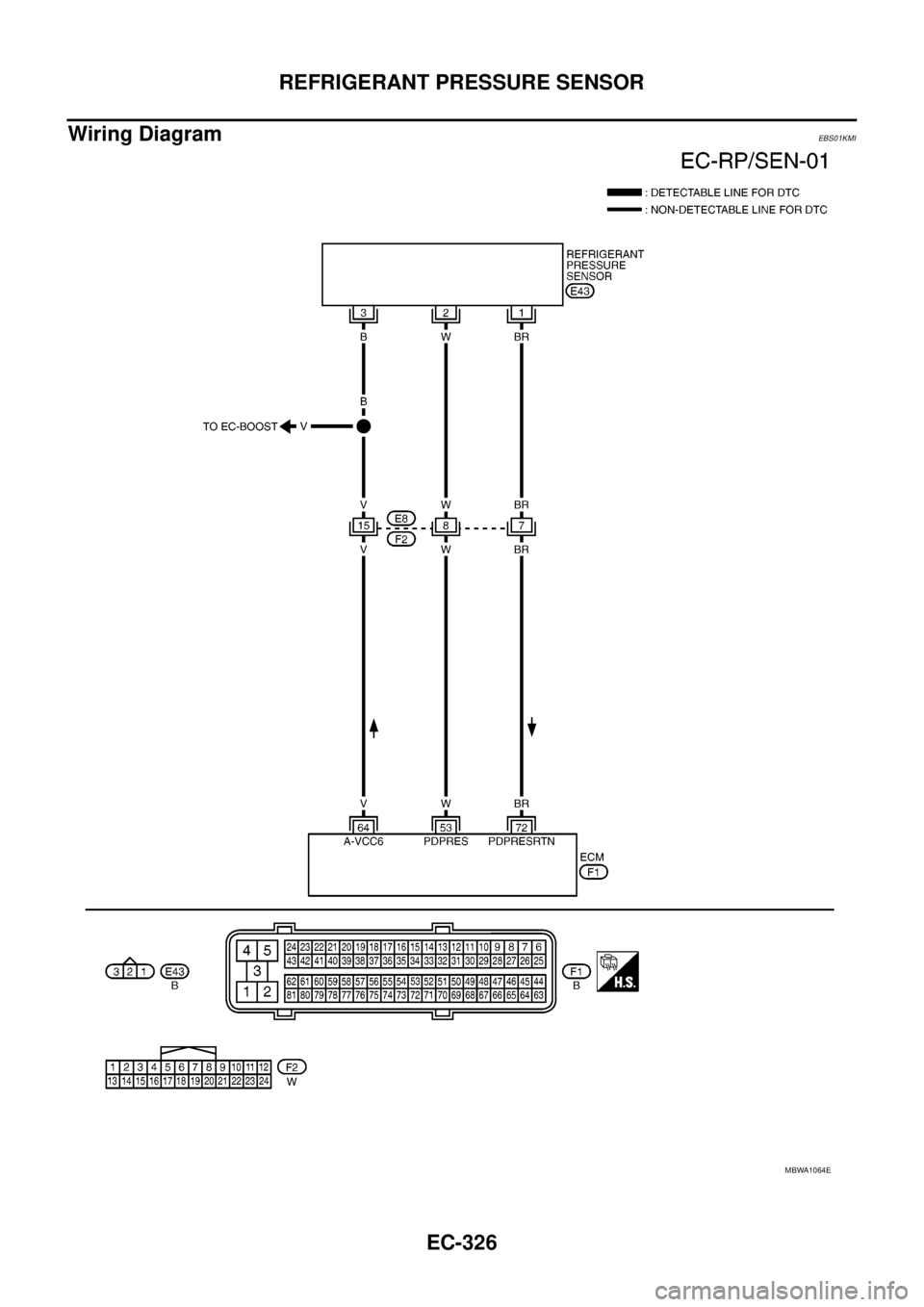

Wiring Diagram

EBS01KMI

MBWA1064E

Page 1307 of 3171

REFRIGERANT PRESSURE SENSOR

EC-327

C

D

E

F

G

H

I

J

K

L

MA

EC

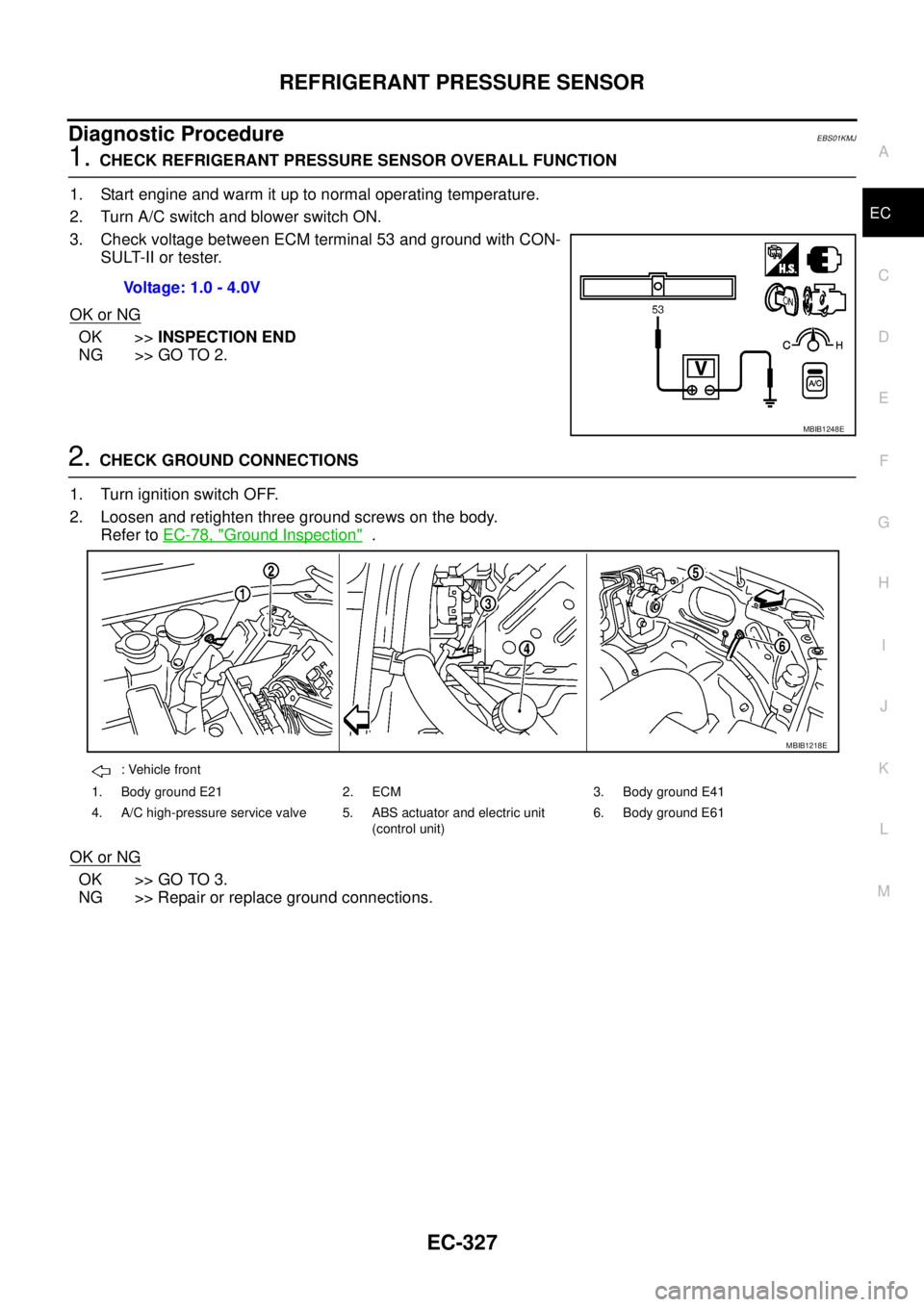

Diagnostic ProcedureEBS01KMJ

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower switch ON.

3. Check voltage between ECM terminal 53 and ground with CON-

SULT-II or tester.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.Voltage: 1.0 - 4.0V

MBIB1248E

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

Page 1308 of 3171

EC-328

REFRIGERANT PRESSURE SENSOR

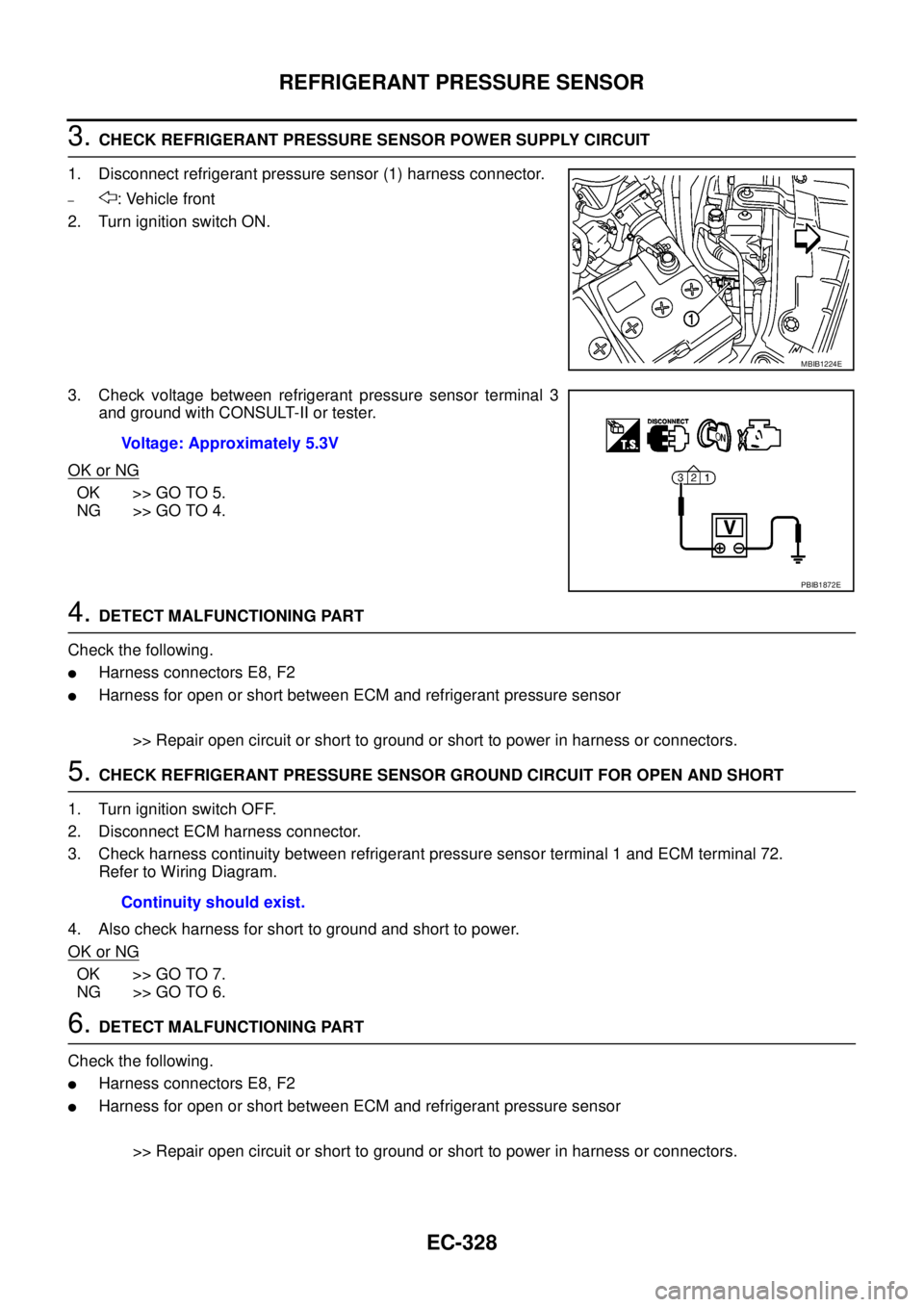

3.CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Disconnect refrigerant pressure sensor (1) harness connector.

–: Vehicle front

2. Turn ignition switch ON.

3. Check voltage between refrigerant pressure sensor terminal 3

and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E8, F2

lHarness for open or short between ECM and refrigerant pressure sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK REFRIGERANT PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between refrigerant pressure sensor terminal 1 and ECM terminal 72.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E8, F2

lHarness for open or short between ECM and refrigerant pressure sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

MBIB1224E

Voltage: Approximately 5.3V

PBIB1872E

Continuity should exist.

Page 1309 of 3171

REFRIGERANT PRESSURE SENSOR

EC-329

C

D

E

F

G

H

I

J

K

L

MA

EC

7.CHECK REFRIGERANT PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 53 and refrigerant pressure sensor terminal 2.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 9.

NG >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E8, F2

lHarness for open or short between ECM and refrigerant pressure sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

OK or NG

OK >> Replace refrigerant pressure sensor.

NG >> Repair or replace.

Removal and InstallationEBS01KMK

REFRIGERANT PRESSURE SENSOR

Refer toMTC-127, "Removal and Installation for Refrigerant Pressure Sensor". Continuity should exist.

Page 1310 of 3171

EC-330

BRAKE SWITCH

BRAKE SWITCH

PFP:25230

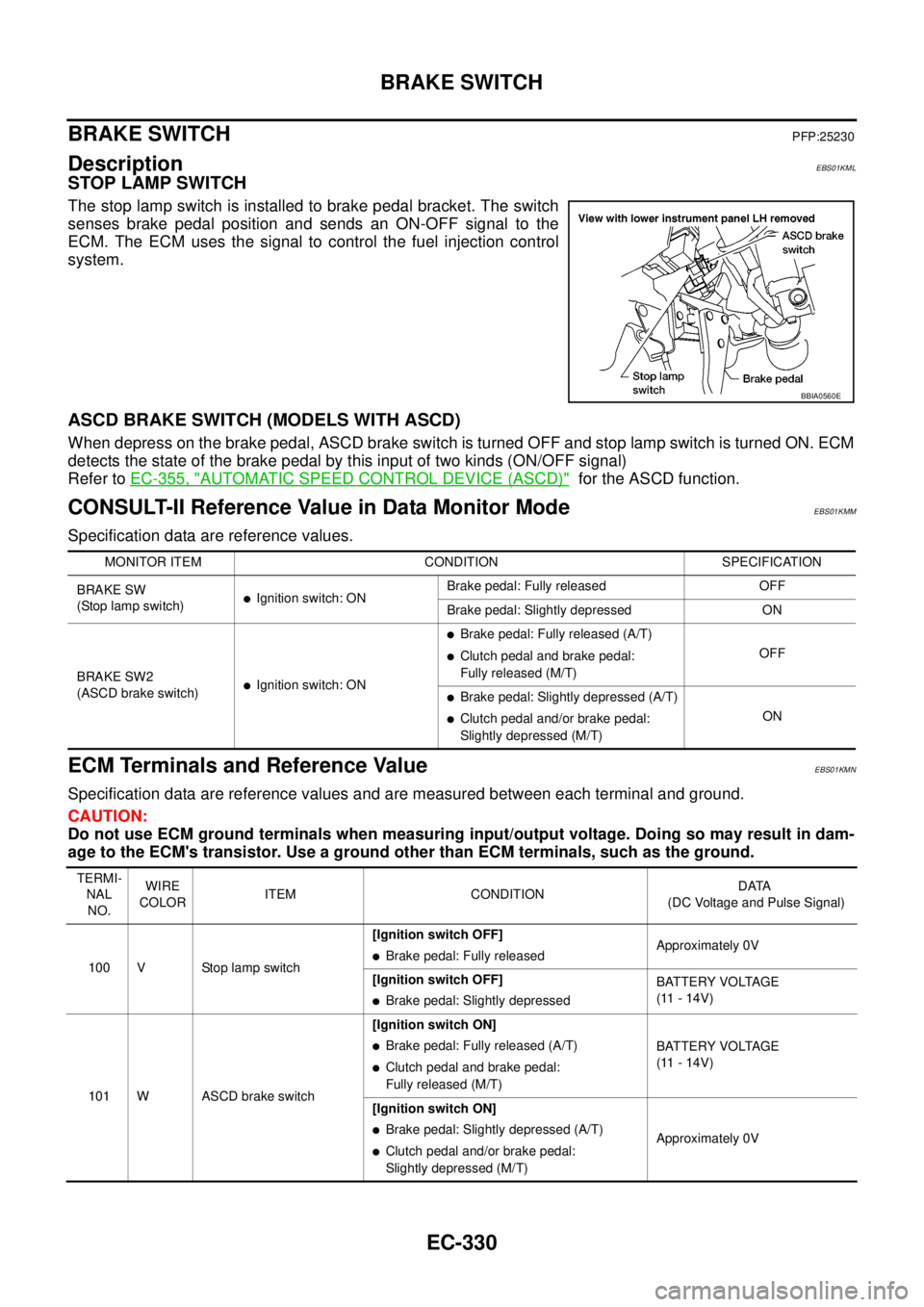

DescriptionEBS01KML

STOP LAMP SWITCH

The stop lamp switch is installed to brake pedal bracket. The switch

senses brake pedal position and sends an ON-OFF signal to the

ECM. The ECM uses the signal to control the fuel injection control

system.

ASCD BRAKE SWITCH (MODELS WITH ASCD)

When depress on the brake pedal, ASCD brake switch is turned OFF and stop lamp switch is turned ON. ECM

detects the state of the brake pedal by this input of two kinds (ON/OFF signal)

Refer toEC-355, "

AUTOMATIC SPEED CONTROL DEVICE (ASCD)"for the ASCD function.

CONSULT-II Reference Value in Data Monitor ModeEBS01KMM

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KMN

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

BBIA0560E

MONITOR ITEM CONDITION SPECIFICATION

BRAKE SW

(Stoplampswitch)

lIgnition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

BRAKE SW2

(ASCD brake switch)

lIgnition switch: ON

lBrake pedal: Fully released (A/T)

lClutch pedal and brake pedal:

Fully released (M/T)OFF

lBrake pedal: Slightly depressed (A/T)

lClutch pedal and/or brake pedal:

Slightly depressed (M/T)ON

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

100 V Stop lamp switch[Ignition switch OFF]

lBrake pedal: Fully releasedApproximately 0V

[Ignition switch OFF]

lBrake pedal: Slightly depressedBATTERY VOLTAGE

(11 - 14V)

101 W ASCD brake switch[Ignition switch ON]

lBrake pedal: Fully released (A/T)

lClutch pedal and brake pedal:

Fully released (M/T)BATTERY VOLTAGE

(11 - 14V)

[Ignition switch ON]

lBrake pedal: Slightly depressed (A/T)

lClutch pedal and/or brake pedal:

Slightly depressed (M/T)Approximately 0V