NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1331 of 3171

ASCD INDICATOR

EC-351

C

D

E

F

G

H

I

J

K

L

MA

EC

ASCD INDICATORPFP:24814

Component DescriptionEBS01KMY

ASCD indicator lamp illuminates to indicate ASCD operation status. Lamp has two indicators, CRUISE and

SET, and is integrated in combination meter.

CRUISE indicator illuminates when MAIN switch on ASCD steering switch is turned ON to indicated that

ASCD system is ready for operation.

SET indicator illuminates when following conditions are met.

lCRUISE indicator is illuminated.

lSET/COAST switch on ASCD steering switch is turned ON while vehicle speed is within the range of

ASCD setting.

SET indicator remains lit during ASCD control.

Refer toEC-355, "

AUTOMATIC SPEED CONTROL DEVICE (ASCD)"for the ASCD function.

Page 1332 of 3171

EC-352

ASCD INDICATOR

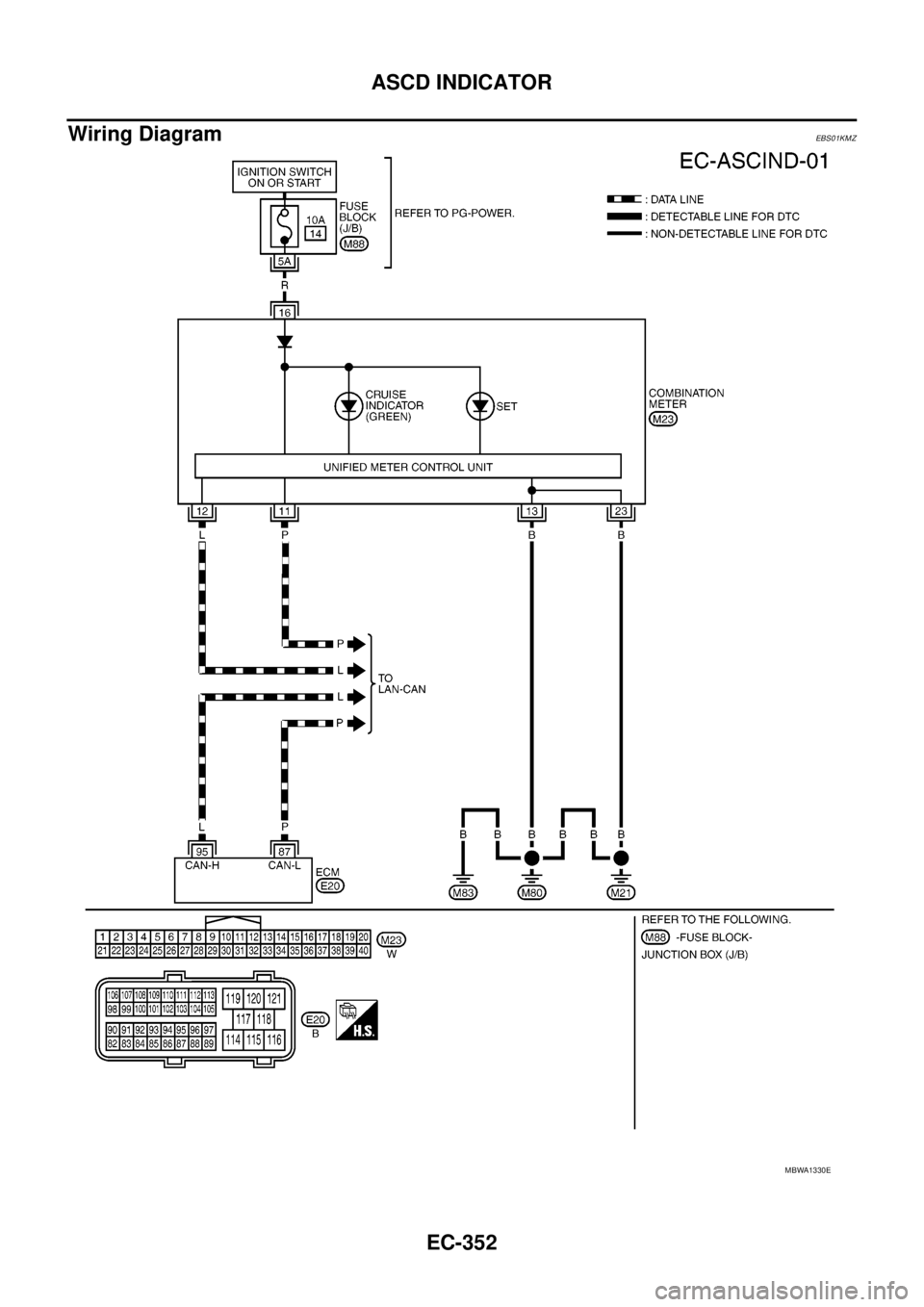

Wiring Diagram

EBS01KMZ

MBWA1330E

Page 1333 of 3171

ASCD INDICATOR

EC-353

C

D

E

F

G

H

I

J

K

L

MA

EC

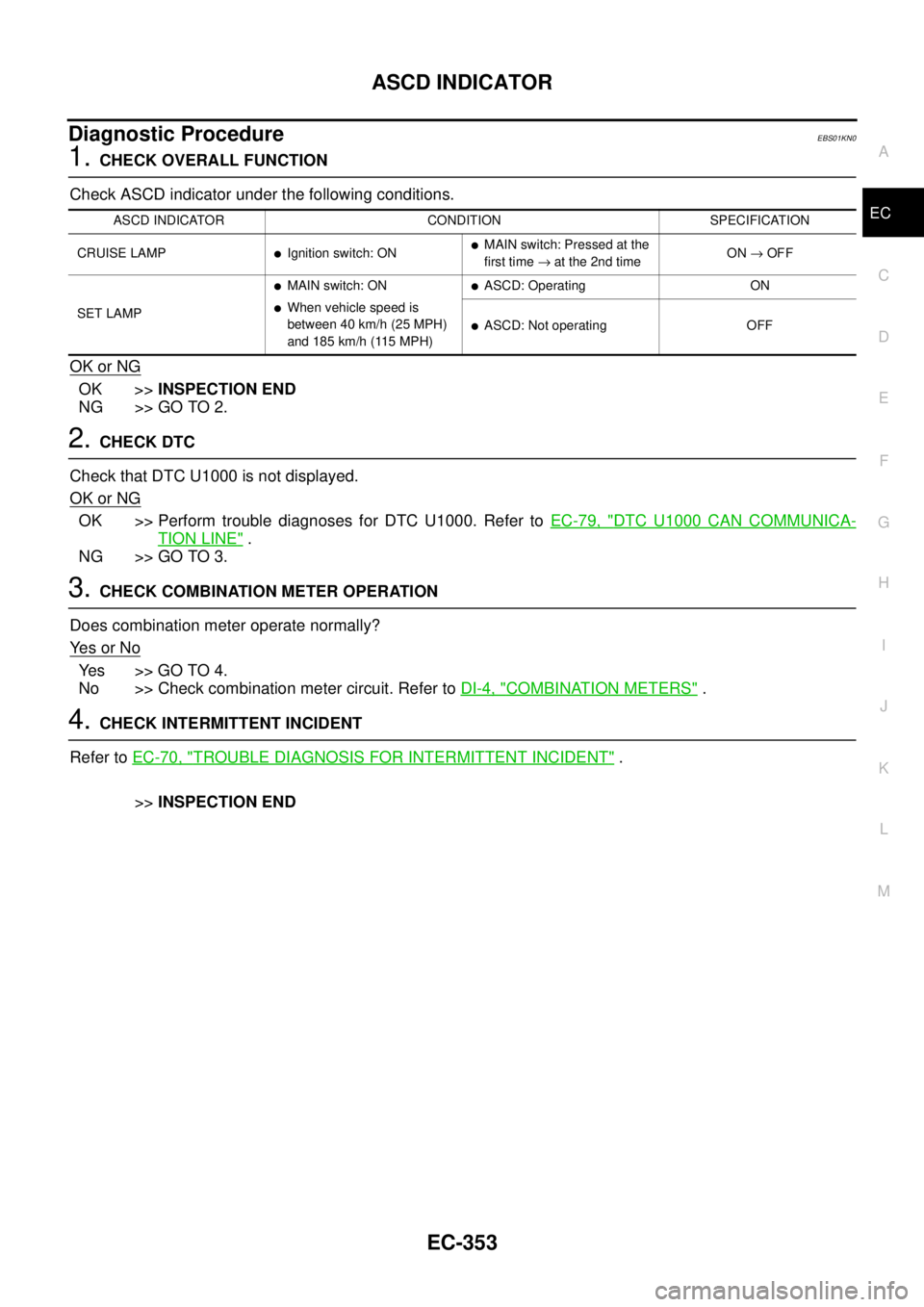

Diagnostic ProcedureEBS01KN0

1.CHECK OVERALL FUNCTION

Check ASCD indicator under the following conditions.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK DTC

Check that DTC U1000 is not displayed.

OK or NG

OK >> Perform trouble diagnoses for DTC U1000. Refer toEC-79, "DTC U1000 CAN COMMUNICA-

TION LINE".

NG >> GO TO 3.

3.CHECK COMBINATION METER OPERATION

Does combination meter operate normally?

Ye s o r N o

Ye s > > G O T O 4 .

No >> Check combination meter circuit. Refer toDI-4, "

COMBINATION METERS".

4.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

ASCD INDICATOR CONDITION SPECIFICATION

CRUISE LAMP

lIgnition switch: ONlMAIN switch: Pressed at the

first time®at the 2nd timeON®OFF

SET LAMP

lMAIN switch: ON

lWhen vehicle speed is

between 40 km/h (25 MPH)

and185km/h(115MPH)

lASCD: Operating ON

lASCD: Not operating OFF

Page 1334 of 3171

EC-354

MI & DATA LINK CONNECTORS

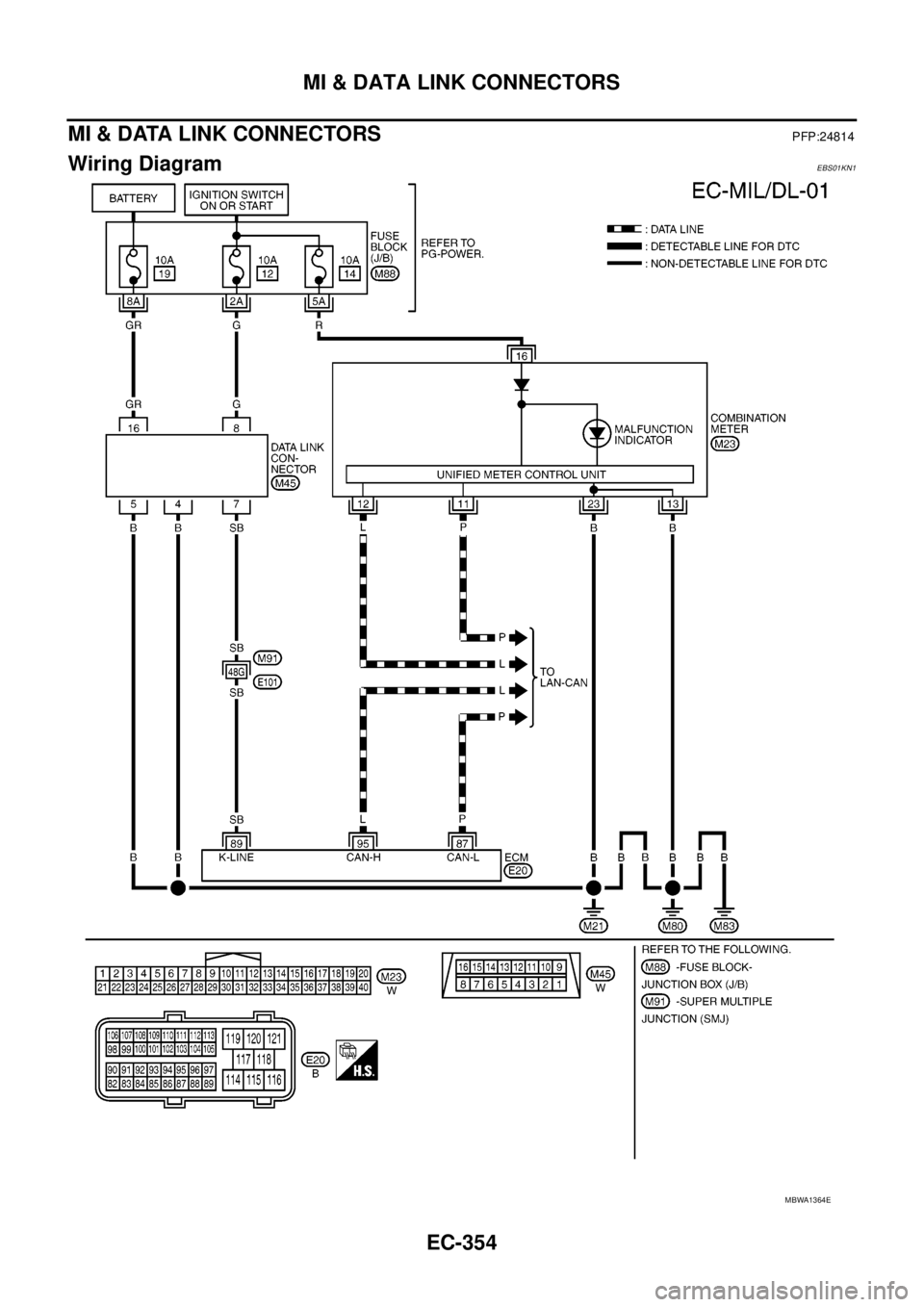

MI&DATALINKCONNECTORS

PFP:24814

Wiring DiagramEBS01KN1

MBWA1364E

Page 1335 of 3171

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

EC-355

C

D

E

F

G

H

I

J

K

L

MA

EC

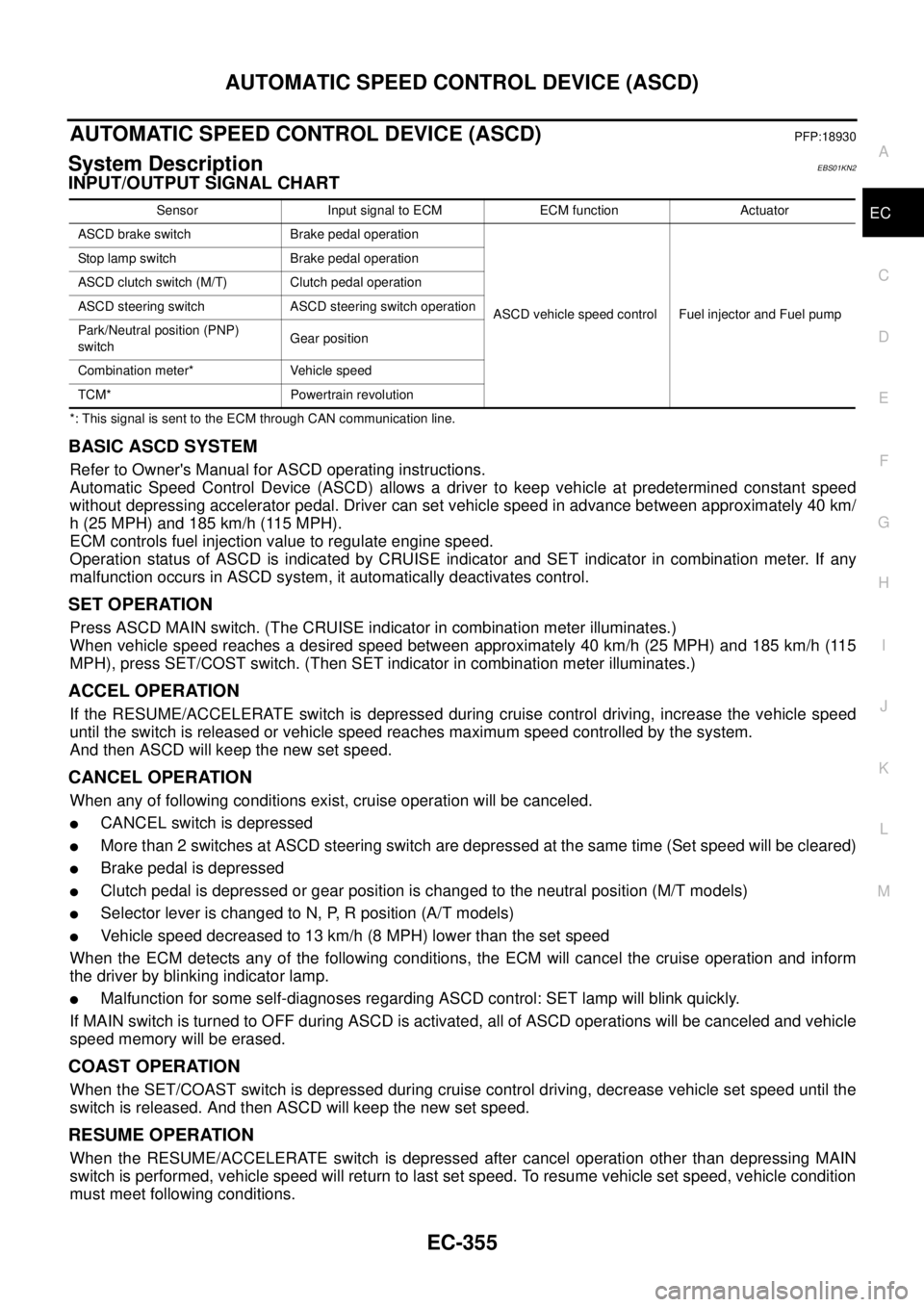

AUTOMATIC SPEED CONTROL DEVICE (ASCD)PFP:18930

System DescriptionEBS01KN2

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line.

BASIC ASCD SYSTEM

Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) allows a driver to keep vehicle at predetermined constant speed

without depressing accelerator pedal. Driver can set vehicle speed in advance between approximately 40 km/

h(25MPH)and185km/h(115MPH).

ECM controls fuel injection value to regulate engine speed.

Operation status of ASCD is indicated by CRUISE indicator and SET indicator in combination meter. If any

malfunction occurs in ASCD system, it automatically deactivates control.

SET OPERATION

Press ASCD MAIN switch. (The CRUISE indicator in combination meter illuminates.)

When vehicle speed reaches a desired speed between approximately 40 km/h (25 MPH) and 185 km/h (115

MPH), press SET/COST switch. (Then SET indicator in combination meter illuminates.)

ACCEL OPERATION

If the RESUME/ACCELERATE switch is depressed during cruise control driving, increase the vehicle speed

until the switch is released or vehicle speed reaches maximum speed controlled by the system.

And then ASCD will keep the new set speed.

CANCEL OPERATION

When any of following conditions exist, cruise operation will be canceled.

lCANCEL switch is depressed

lMore than 2 switches at ASCD steering switch are depressed at the same time (Set speed will be cleared)

lBrake pedal is depressed

lClutch pedal is depressed or gear position is changed to the neutral position (M/T models)

lSelector lever is changed to N, P, R position (A/T models)

lVehicle speed decreased to 13 km/h (8 MPH) lower than the set speed

When the ECM detects any of the following conditions, the ECM will cancel the cruise operation and inform

the driver by blinking indicator lamp.

lMalfunction for some self-diagnoses regarding ASCD control: SET lamp will blink quickly.

If MAIN switch is turned to OFF during ASCD is activated, all of ASCD operations will be canceled and vehicle

speed memory will be erased.

COAST OPERATION

When the SET/COAST switch is depressed during cruise control driving, decrease vehicle set speed until the

switch is released. And then ASCD will keep the new set speed.

RESUME OPERATION

When the RESUME/ACCELERATE switch is depressed after cancel operation other than depressing MAIN

switch is performed, vehicle speed will return to last set speed. To resume vehicle set speed, vehicle condition

must meet following conditions.

Sensor Input signal to ECM ECM function Actuator

ASCD brake switch Brake pedal operation

ASCD vehicle speed control Fuel injector and Fuel pump Stop lamp switch Brake pedal operation

ASCD clutch switch (M/T) Clutch pedal operation

ASCD steering switch ASCD steering switch operation

Park/Neutral position (PNP)

switchGear position

Combination meter* Vehicle speed

TCM* Powertrain revolution

Page 1336 of 3171

EC-356

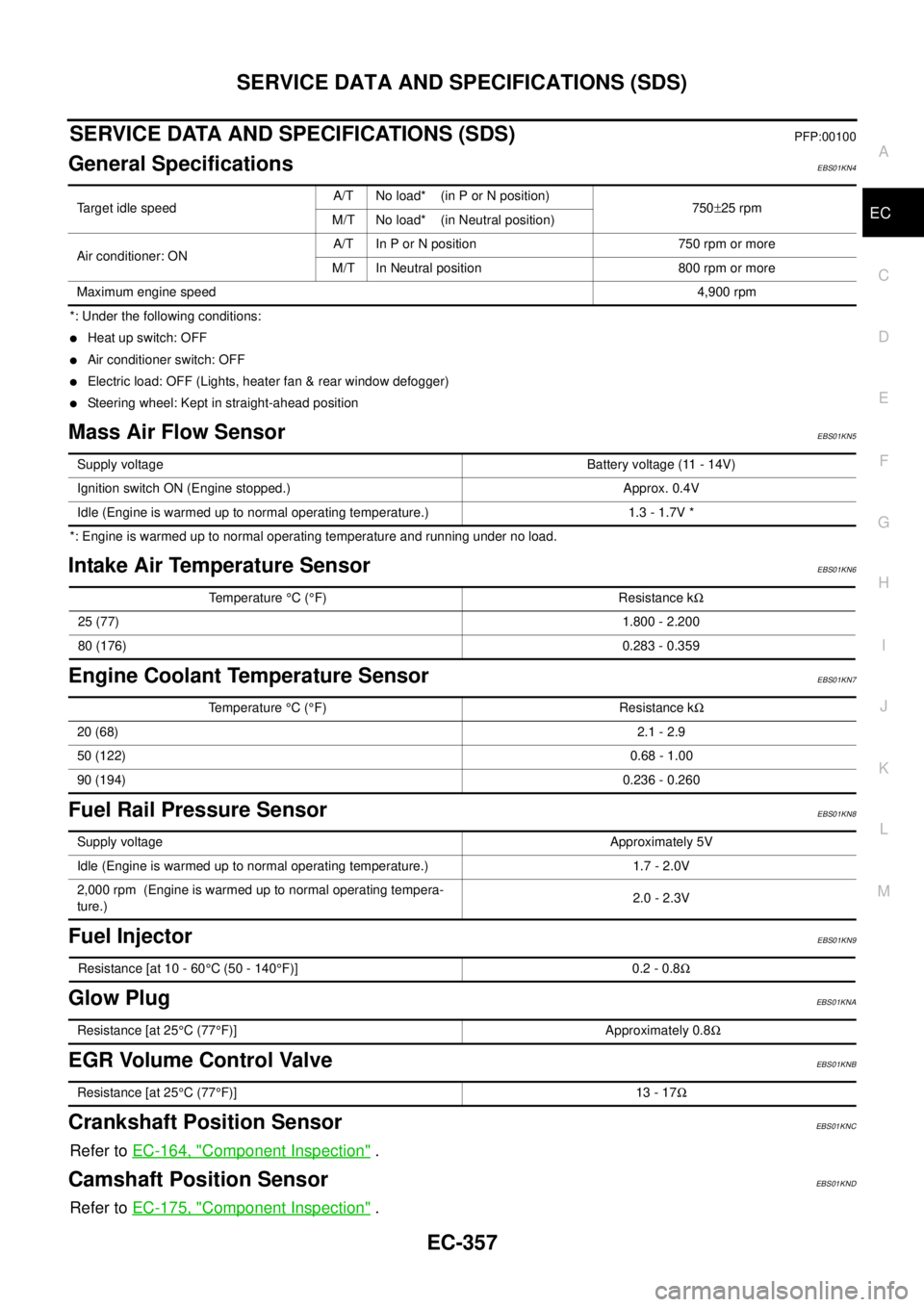

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

lBrake pedal is released

lClutch pedal is released (M/T models)

lSelector lever is in other than P and N positions (A/T models)

lVehicle speed is greater than 40 km/h (25 MPH) and less than 185 km/h (115 MPH)

Component DescriptionEBS01KN3

ASCD STEERING SWITCH

Refer toEC-206.

ASCD BRAKE SWITCH

Refer toEC-189andEC-330.

ASCD CLUTCH SWITCH

Refer toEC-189andEC-330.

STOP LAMP SWITCH

Refer toEC-189andEC-330.

ASCD INDICATOR

Refer toEC-351.

Page 1337 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

EC-357

C

D

E

F

G

H

I

J

K

L

MA

EC

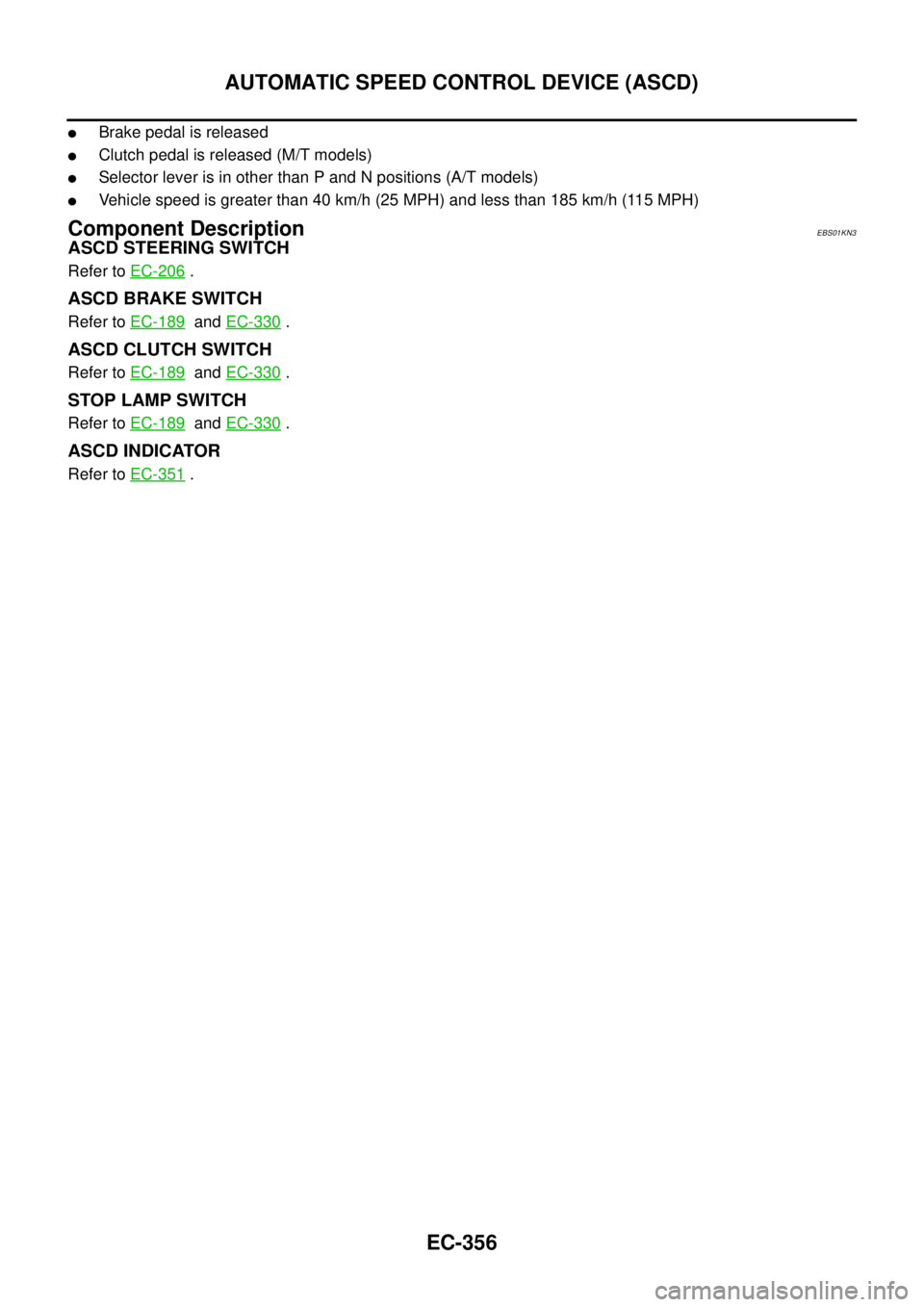

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00100

General SpecificationsEBS01KN4

*: Under the following conditions:

lHeat up switch: OFF

lAir conditioner switch: OFF

lElectric load: OFF (Lights, heater fan & rear window defogger)

lSteering wheel: Kept in straight-ahead position

Mass Air Flow SensorEBS01KN5

*: Engine is warmed up to normal operating temperature and running under no load.

Intake Air Temperature SensorEBS01KN6

Engine Coolant Temperature SensorEBS01KN7

Fuel Rail Pressure SensorEBS01KN8

Fuel InjectorEBS01KN9

Glow PlugEBS01KNA

EGR Volume Control ValveEBS01KNB

Crankshaft Position SensorEBS01KNC

Refer toEC-164, "Component Inspection".

Camshaft Position SensorEBS01KND

Refer toEC-175, "Component Inspection".

Target idle speedA/T No load* (in P or N position)

750±25 rpm

M/T No load* (in Neutral position)

Air conditioner: ONA/T In P or N position 750 rpm or more

M/T In Neutral position 800 rpm or more

Maximum engine speed4,900 rpm

Supply voltageBattery voltage (11 - 14V)

Ignition switch ON (Engine stopped.) Approx. 0.4V

Idle (Engine is warmed up to normal operating temperature.) 1.3 - 1.7V *

Temperature°C(°F) Resistance kW

25 (77)1.800 - 2.200

80 (176)0.283 - 0.359

Temperature°C(°F) Resistance kW

20 (68)2.1 - 2.9

50 (122)0.68 - 1.00

90 (194)0.236 - 0.260

Supply voltageApproximately 5V

Idle (Engine is warmed up to normal operating temperature.) 1.7 - 2.0V

2,000 rpm (Engine is warmed up to normal operating tempera-

ture.)2.0 - 2.3V

Resistance [at 10 - 60°C (50 - 140°F)] 0.2 - 0.8W

Resistance [at 25°C(77°F)] Approximately 0.8W

Resistance [at 25°C(77°F)] 13 - 17W

Page 1338 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual EC-358

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel Pump

EBS01KNE

Resistance [at 10 - 60°C (50 - 140°F)] 1.5 - 3.0W NISSAN NAVARA 2005 Repair Workshop Manual EC-358

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel Pump

EBS01KNE

Resistance [at 10 - 60°C (50 - 140°F)] 1.5 - 3.0W](/img/5/57362/w960_57362-1337.png)

EC-358

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel Pump

EBS01KNE

Resistance [at 10 - 60°C (50 - 140°F)] 1.5 - 3.0W

Page 1339 of 3171

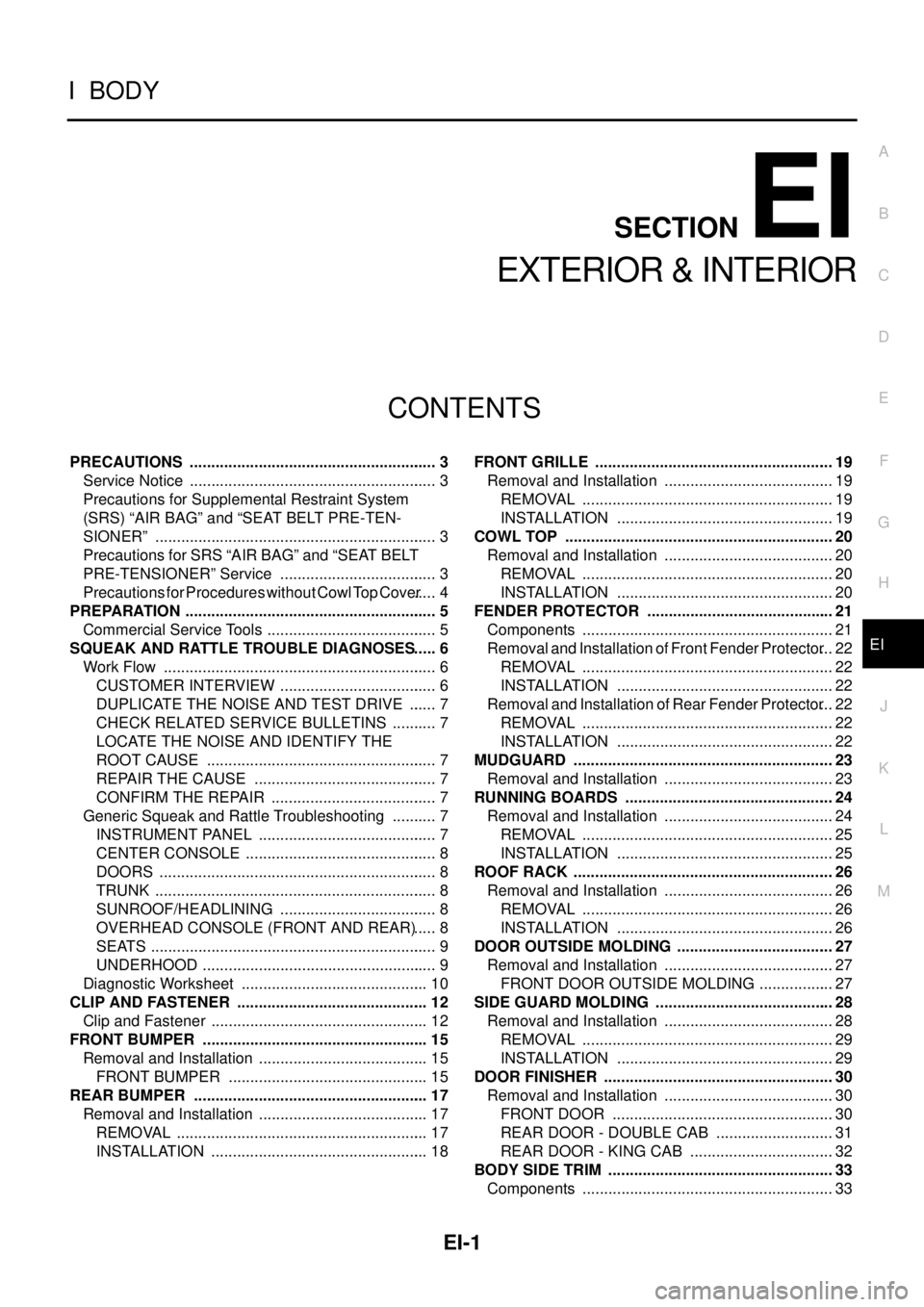

EI-1

EXTERIOR & INTERIOR

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONEI

A

B

EI

EXTERIOR & INTERIOR

PRECAUTIONS .......................................................... 3

Service Notice .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for SRS “AIR BAG” and “SEAT BELT

PRE-TENSIONER” Service ..................................... 3

Precautions for Procedures without Cowl Top Cover..... 4

PREPARATION ........................................................... 5

Commercial Service Tools ........................................ 5

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 6

Work Flow ................................................................ 6

CUSTOMER INTERVIEW ..................................... 6

DUPLICATE THE NOISE AND TEST DRIVE ....... 7

CHECK RELATED SERVICE BULLETINS ........... 7

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 7

REPAIR THE CAUSE ........................................... 7

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 8

DOORS ................................................................. 8

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

OVERHEAD CONSOLE (FRONT AND REAR)..... 8

SEATS ................................................................... 9

UNDERHOOD ....................................................... 9

Diagnostic Worksheet ............................................ 10

CLIP AND FASTENER ............................................. 12

Clip and Fastener ................................................... 12

FRONT BUMPER ..................................................... 15

Removal and Installation ........................................ 15

FRONT BUMPER ............................................... 15

REAR BUMPER ....................................................... 17

Removal and Installation ........................................ 17

REMOVAL ........................................................... 17

INSTALLATION ................................................... 18FRONT GRILLE ........................................................ 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSTALLATION ................................................... 19

COWL TOP ............................................................... 20

Removal and Installation ........................................ 20

REMOVAL ........................................................... 20

INSTALLATION ................................................... 20

FENDER PROTECTOR ............................................ 21

Components ........................................................... 21

Removal and Installation of Front Fender Protector... 22

REMOVAL ........................................................... 22

INSTALLATION ................................................... 22

Removal and Installation of Rear Fender Protector... 22

REMOVAL ........................................................... 22

INSTALLATION ................................................... 22

MUDGUARD ............................................................. 23

Removal and Installation ........................................ 23

RUNNING BOARDS ................................................. 24

Removal and Installation ........................................ 24

REMOVAL ........................................................... 25

INSTALLATION ................................................... 25

ROOF RACK ............................................................. 26

Removal and Installation ........................................ 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 26

DOOR OUTSIDE MOLDING ..................................... 27

Removal and Installation ........................................ 27

FRONT DOOR OUTSIDE MOLDING .................. 27

SIDE GUARD MOLDING .......................................... 28

Removal and Installation ........................................ 28

REMOVAL ........................................................... 29

INSTALLATION ................................................... 29

DOOR FINISHER ...................................................... 30

Removal and Installation ........................................ 30

FRONT DOOR .................................................... 30

REAR DOOR - DOUBLE CAB ............................ 31

REAR DOOR - KING CAB .................................. 32

BODY SIDE TRIM ..................................................... 33

Components ........................................................... 33

Page 1340 of 3171

EI-2

DOUBLE CAB ..................................................... 33

KING CAB ........................................................... 34

Removal and installation ......................................... 34

LOWER DASH SIDE FINISHER ......................... 34

CENTER PILLAR LOWER FINISHER ................ 35

CENTER PILLAR UPPER FINISHER ................. 35

FRONT PILLAR UPPER FINISHER .................... 35

FRONT PILLAR LOWER FINISHER ................... 35

KICK PLATES ...................................................... 35

REAR ................................................................... 36

FLOOR TRIM ............................................................ 38

Removal and Installation ........................................ 38

REMOVAL ........................................................... 39

INSTALLATION .................................................... 39HEADLINING ............................................................. 40

Removal and Installation ......................................... 40

REMOVAL ............................................................ 41

INSTALLATION .................................................... 41

BED RAILS AND TRIM ............................................. 42

Removal and Installation ......................................... 42

REMOVAL ............................................................ 43

INSTALLATION .................................................... 43

TAIL GATE FINISHER ............................................... 44

Removal and Installation ......................................... 44

REMOVAL ............................................................ 44

INSTALLATION .................................................... 44