NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1321 of 3171

BRAKE SWITCH

EC-341

C

D

E

F

G

H

I

J

K

L

MA

EC

Component InspectionEBS01KMQ

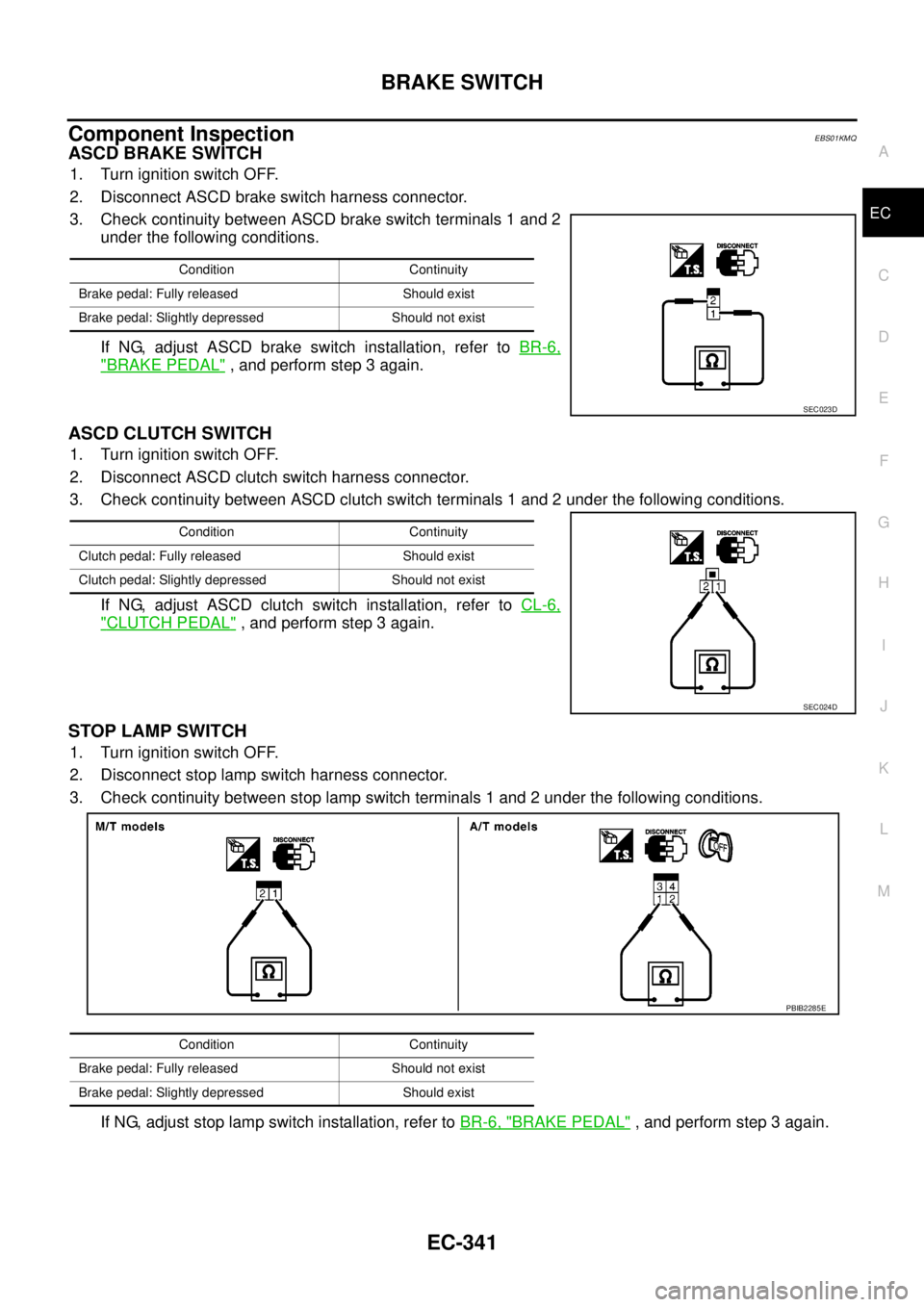

ASCD BRAKE SWITCH

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Check continuity between ASCD brake switch terminals 1 and 2

under the following conditions.

If NG, adjust ASCD brake switch installation, refer toBR-6,

"BRAKE PEDAL", and perform step 3 again.

ASCD CLUTCH SWITCH

1. Turn ignition switch OFF.

2. Disconnect ASCD clutch switch harness connector.

3. Check continuity between ASCD clutch switch terminals 1 and 2 under the following conditions.

If NG, adjust ASCD clutch switch installation, refer toCL-6,

"CLUTCH PEDAL", and perform step 3 again.

STOP LAMP SWITCH

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check continuity between stop lamp switch terminals 1 and 2 under the following conditions.

If NG, adjust stop lamp switch installation, refer toBR-6, "

BRAKE PEDAL", and perform step 3 again.

Condition Continuity

Brake pedal: Fully released Should exist

Brake pedal: Slightly depressed Should not exist

SEC023D

Condition Continuity

Clutch pedal: Fully released Should exist

Clutch pedal: Slightly depressed Should not exist

SEC024D

Condition Continuity

Brake pedal: Fully released Should not exist

Brake pedal: Slightly depressed Should exist

PBIB2285E

Page 1322 of 3171

EC-342

PNP SWITCH

PNP SWITCH

PFP:32006

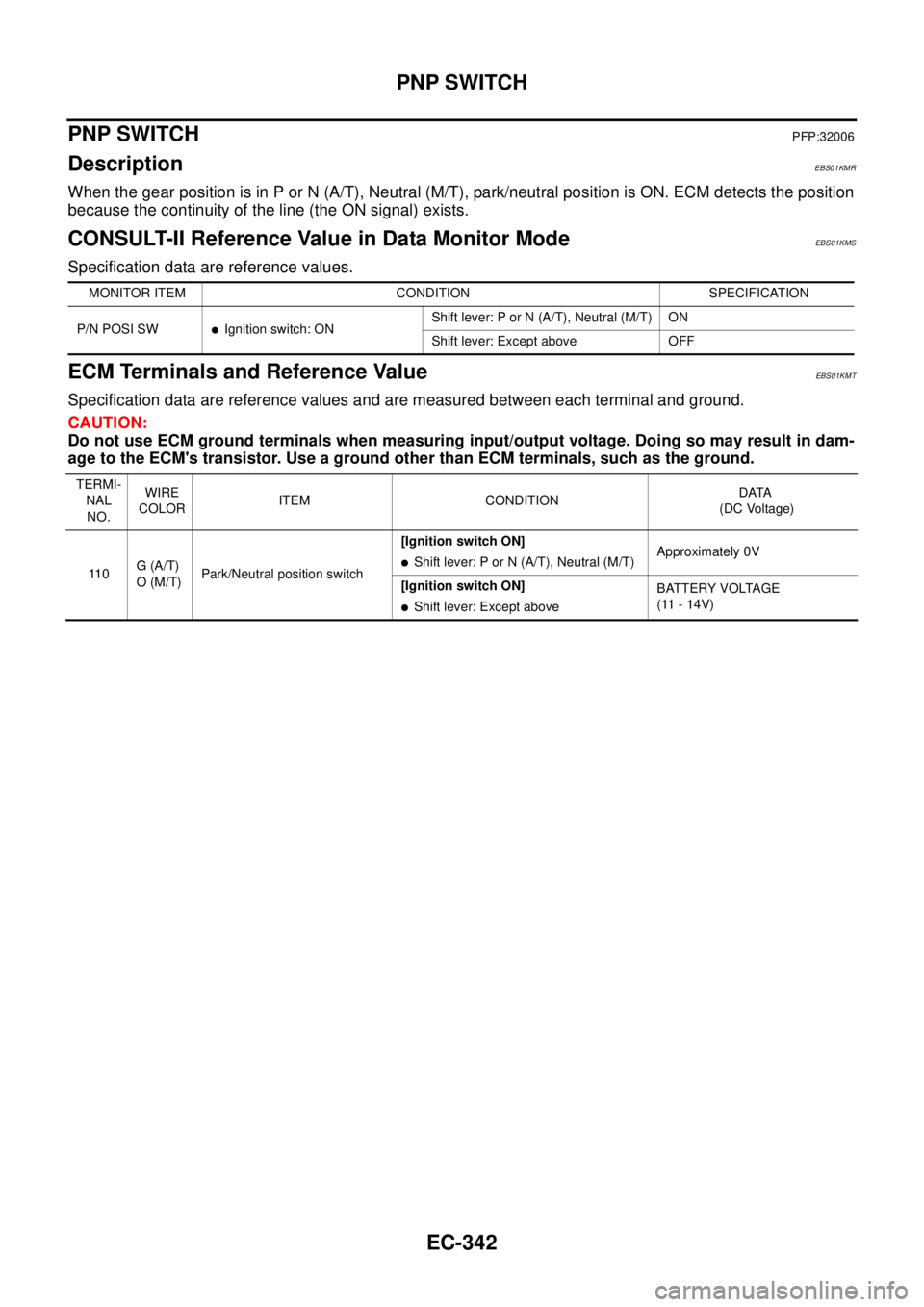

DescriptionEBS01KMR

When the gear position is in P or N (A/T), Neutral (M/T), park/neutral position is ON. ECM detects the position

because the continuity of the line (the ON signal) exists.

CONSULT-II Reference Value in Data Monitor ModeEBS01KMS

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KMT

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SW

lIgnition switch: ONShift lever: P or N (A/T), Neutral (M/T) ON

Shift lever: Except above OFF

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

11 0G(A/T)

O(M/T)Park/Neutral position switch[Ignition switch ON]

lShift lever: P or N (A/T), Neutral (M/T)Approximately 0V

[Ignition switch ON]

lShift lever: Except aboveBATTERY VOLTAGE

(11 - 14V)

Page 1323 of 3171

PNP SWITCH

EC-343

C

D

E

F

G

H

I

J

K

L

MA

EC

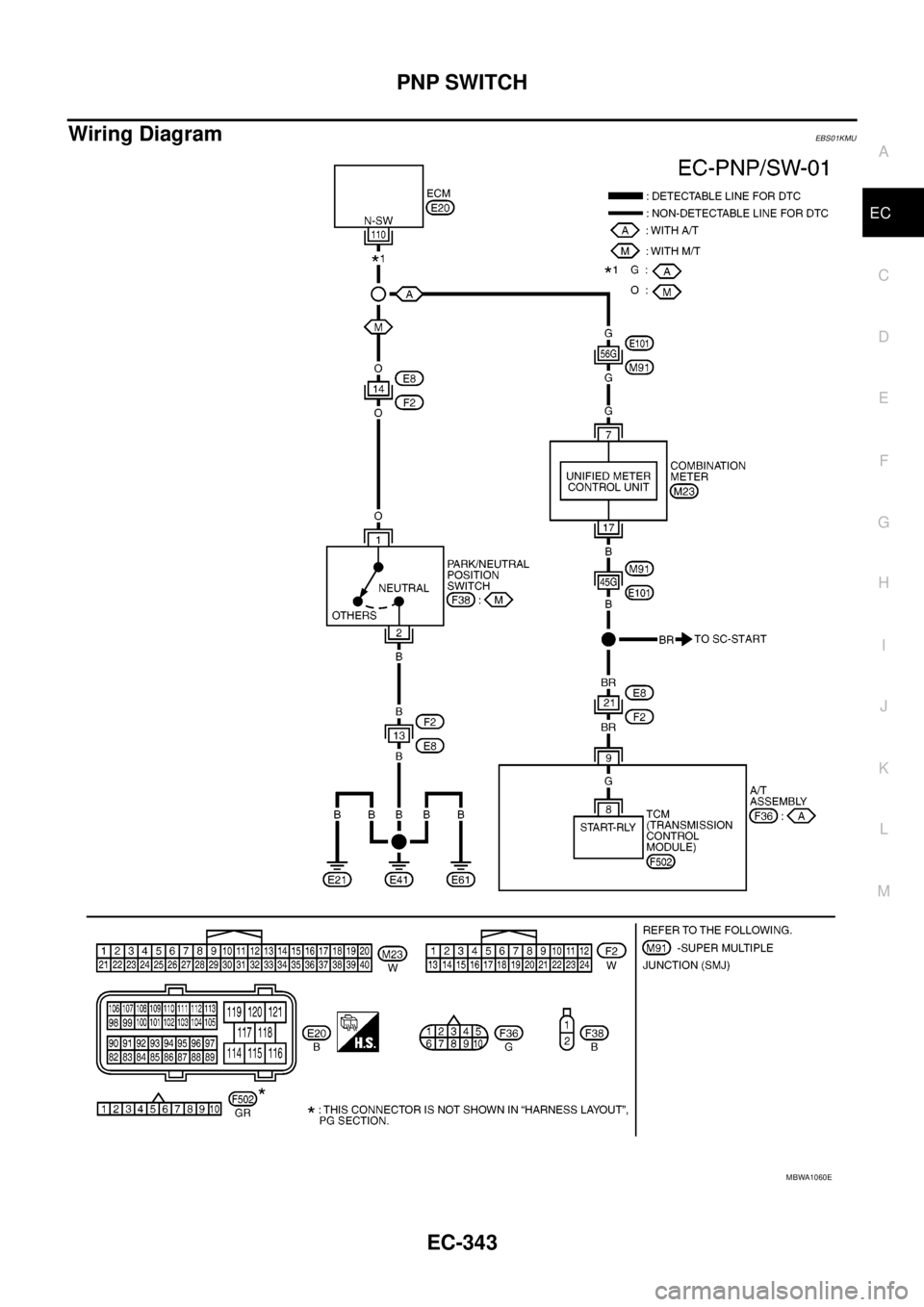

Wiring DiagramEBS01KMU

MBWA1060E

Page 1324 of 3171

EC-344

PNP SWITCH

Diagnostic Procedure

EBS01KMV

A/T MODELS

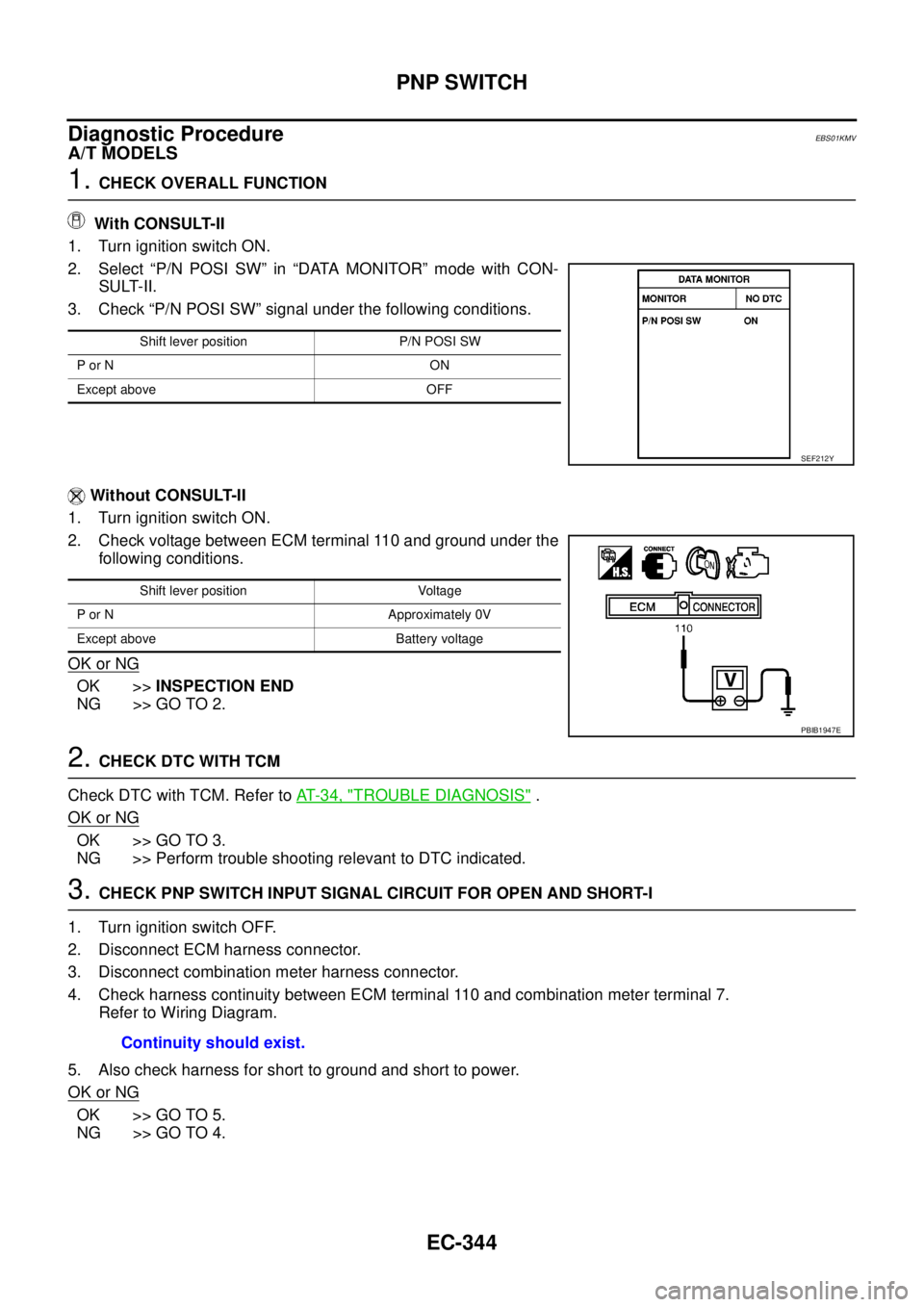

1.CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ON.

2. Select “P/N POSI SW” in “DATA MONITOR” mode with CON-

SULT-II.

3. Check “P/N POSI SW” signal under the following conditions.

Without CONSULT-II

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 110 and ground under the

following conditions.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK DTC WITH TCM

Check DTC with TCM. Refer toAT-34, "

TROUBLE DIAGNOSIS".

OK or NG

OK >> GO TO 3.

NG >> Perform trouble shooting relevant to DTC indicated.

3.CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Disconnect combination meter harness connector.

4. Check harness continuity between ECM terminal 110 and combination meter terminal 7.

Refer to Wiring Diagram.

5. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

Shift lever position P/N POSI SW

PorN ON

Except above OFF

SEF212Y

Shift lever position Voltage

P or N Approximately 0V

Except above Battery voltage

PBIB1947E

Continuity should exist.

Page 1325 of 3171

PNP SWITCH

EC-345

C

D

E

F

G

H

I

J

K

L

MA

EC

4.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E101, M91

lHarness for open or short between ECM and combination meter

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT-II

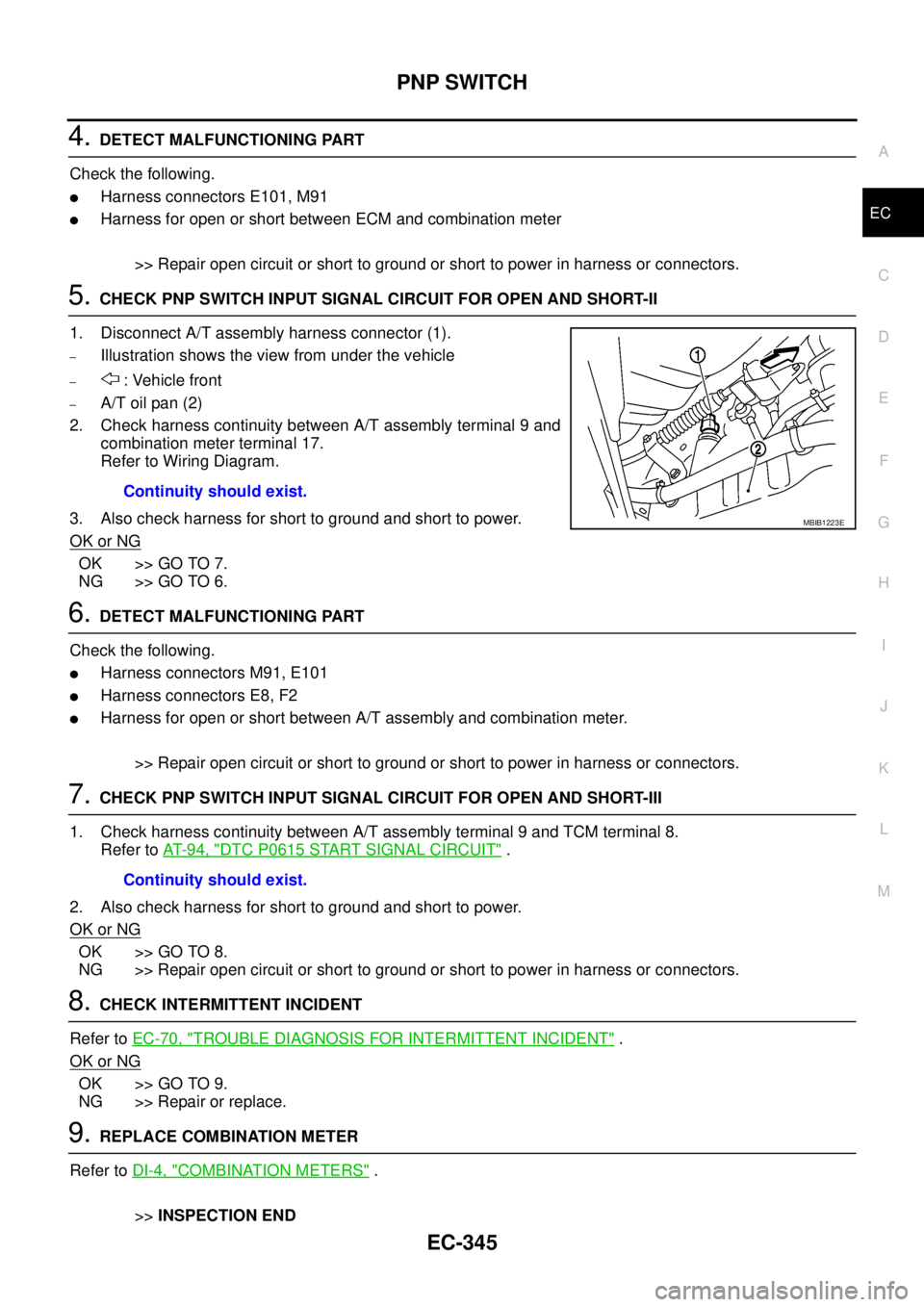

1. Disconnect A/T assembly harness connector (1).

–Illustration shows the view from under the vehicle

–: Vehicle front

–A/T oil pan (2)

2. Check harness continuity between A/T assembly terminal 9 and

combination meter terminal 17.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors M91, E101

lHarness connectors E8, F2

lHarness for open or short between A/T assembly and combination meter.

>> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT-III

1. Check harness continuity between A/T assembly terminal 9 and TCM terminal 8.

Refer toAT-94, "

DTC P0615 START SIGNAL CIRCUIT".

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

OK or NG

OK >> GO TO 9.

NG >> Repair or replace.

9.REPLACE COMBINATION METER

Refer toDI-4, "

COMBINATION METERS".

>>INSPECTION END Continuity should exist.

MBIB1223E

Continuity should exist.

Page 1326 of 3171

EC-346

PNP SWITCH

M/T MODELS

1.CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ON.

2. Select “P/N POSI SW” in “DATA MONITOR” mode with CON-

SULT-II.

3. Check “P/N POSI SW” signal under the following conditions.

Without CONSULT-II

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 110 and ground under the

following conditions.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

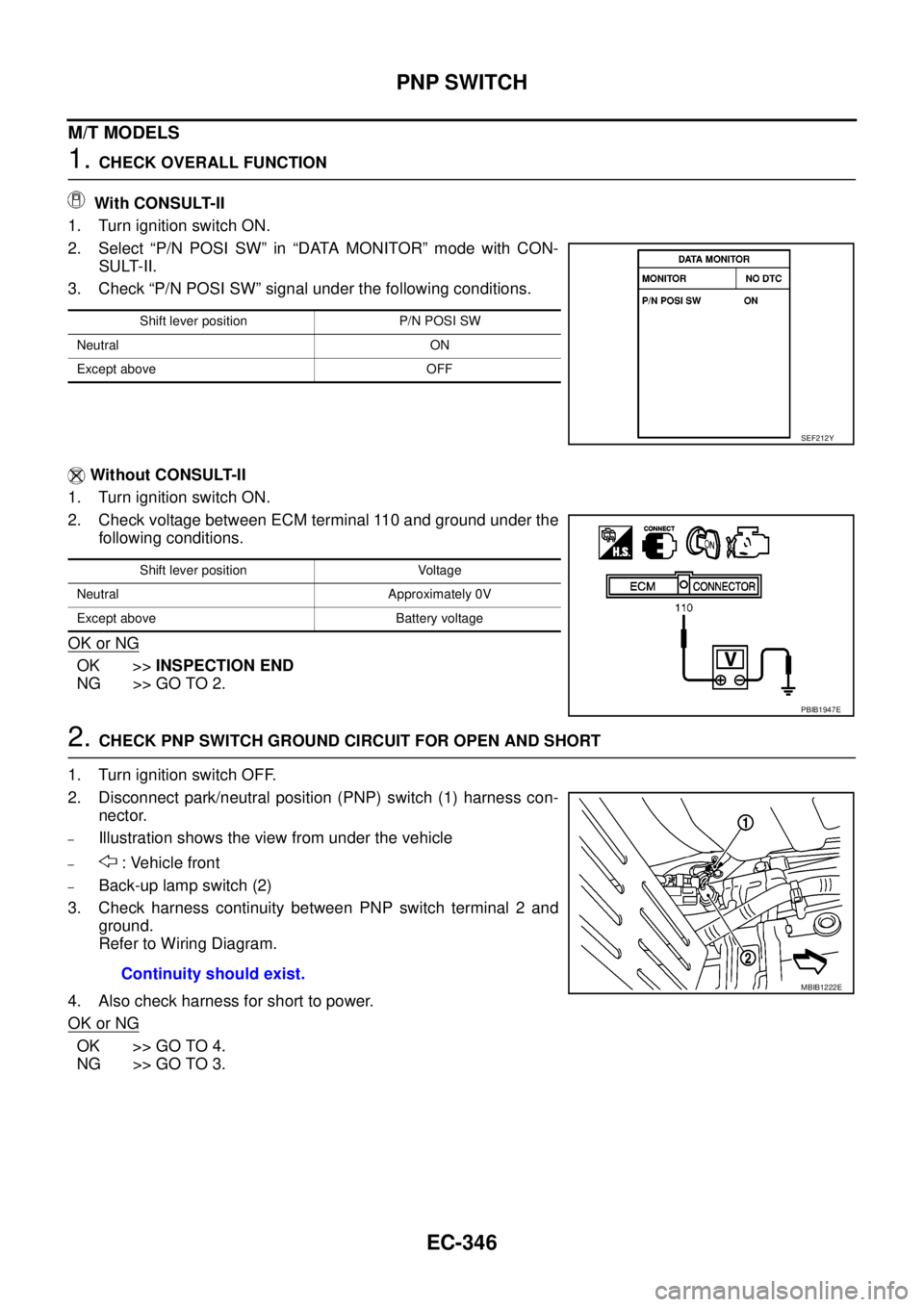

2.CHECK PNP SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect park/neutral position (PNP) switch (1) harness con-

nector.

–Illustration shows the view from under the vehicle

–: Vehicle front

–Back-up lamp switch (2)

3. Check harness continuity between PNP switch terminal 2 and

ground.

Refer to Wiring Diagram.

4. Also check harness for short to power.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

Shift lever position P/N POSI SW

Neutral ON

Except above OFF

SEF212Y

Shift lever position Voltage

Neutral Approximately 0V

Except above Battery voltage

PBIB1947E

Continuity should exist.MBIB1222E

Page 1327 of 3171

PNP SWITCH

EC-347

C

D

E

F

G

H

I

J

K

L

MA

EC

3.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E8, F2

lHarness for open or short between ECM and PNP switch

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 110 and PNP switch terminal 1.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E8, F2

lHarness for open or short between ECM and PNP switch

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK PARK/NEUTRAL POSITION SWITCH

Refer toMT-12, "

POSITION SWITCH".

OK or NG

OK >> GO TO 7.

NG >> Replace park/neutral position switch.

7.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END Continuity should exist.

Page 1328 of 3171

EC-348

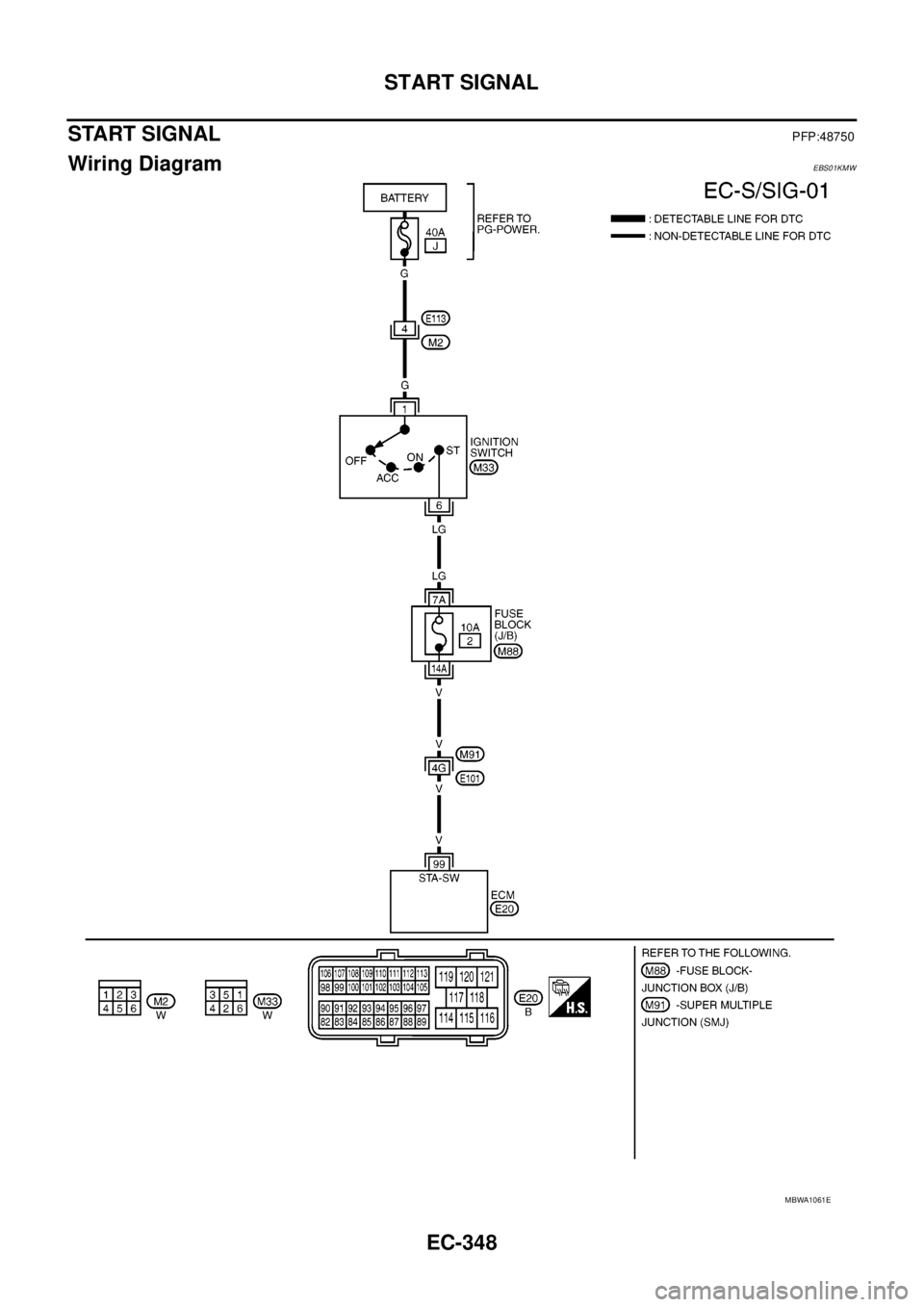

START SIGNAL

START SIGNAL

PFP:48750

Wiring DiagramEBS01KMW

MBWA1061E

Page 1329 of 3171

START SIGNAL

EC-349

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KMX

1.CHECK START SIGNAL OVERALL FUNCTION

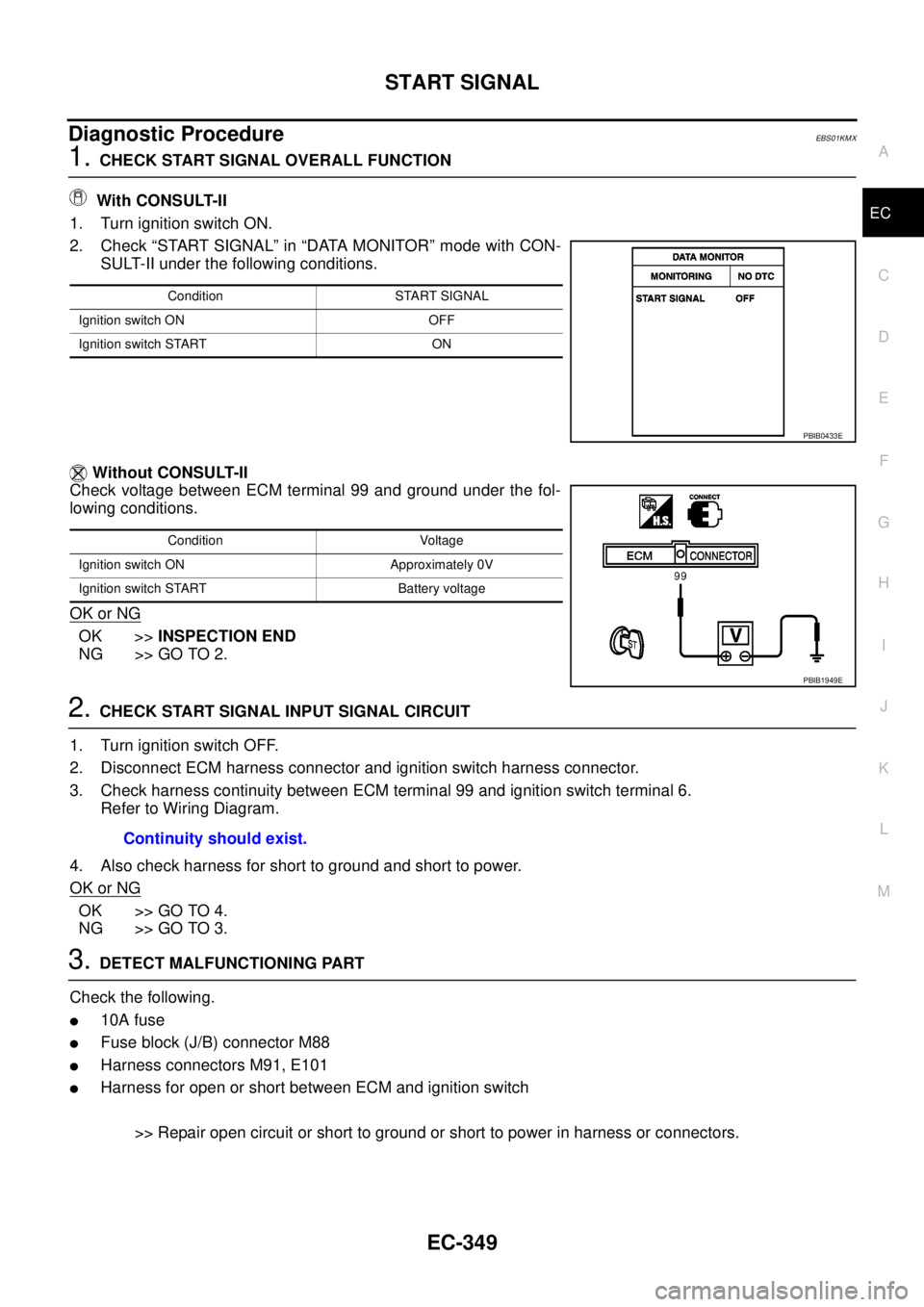

With CONSULT-II

1. Turn ignition switch ON.

2. Check “START SIGNAL” in “DATA MONITOR” mode with CON-

SULT-II under the following conditions.

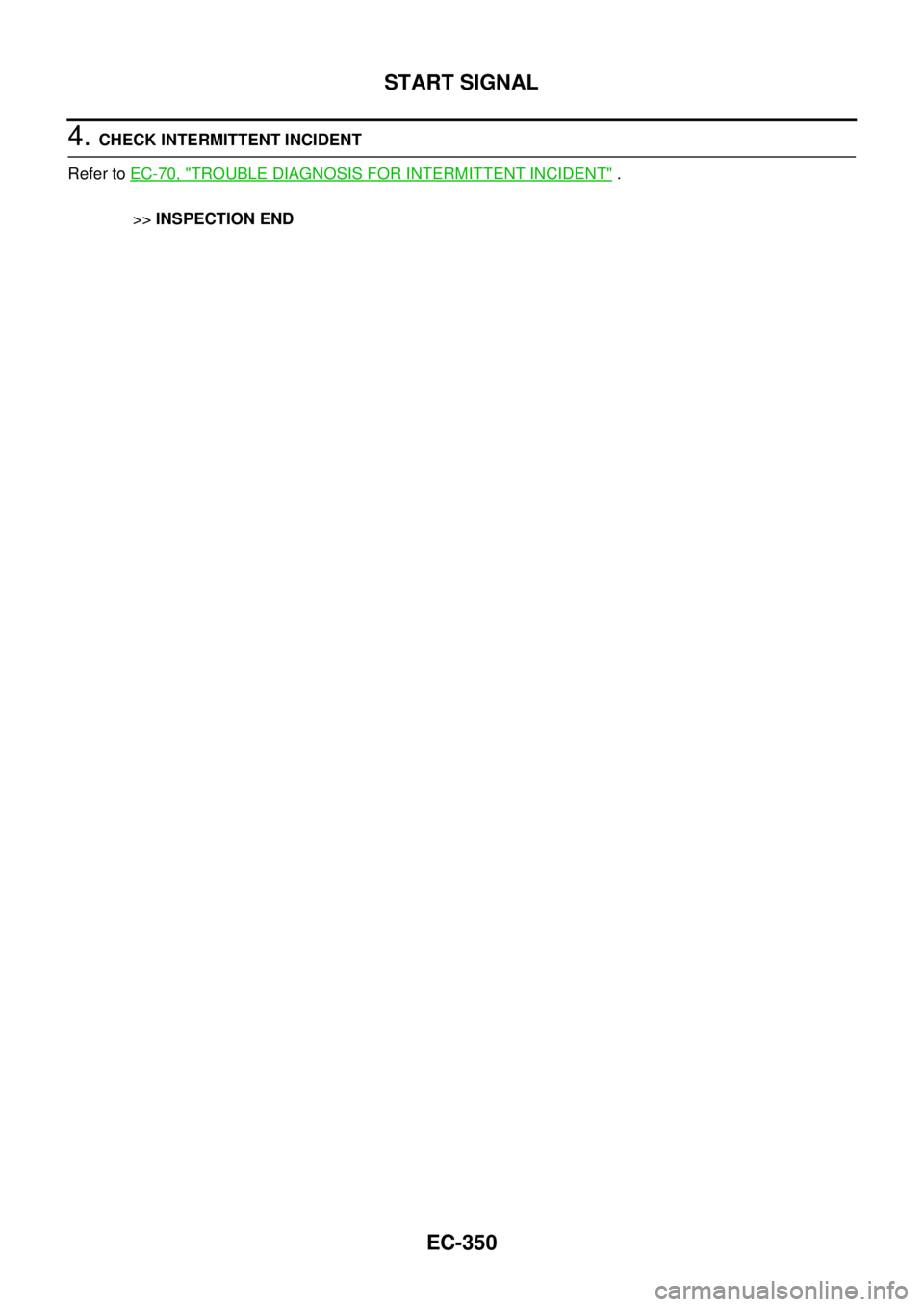

Without CONSULT-II

Check voltage between ECM terminal 99 and ground under the fol-

lowing conditions.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK START SIGNAL INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector and ignition switch harness connector.

3. Check harness continuity between ECM terminal 99 and ignition switch terminal 6.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

l10A fuse

lFuse block (J/B) connector M88

lHarness connectors M91, E101

lHarness for open or short between ECM and ignition switch

>> Repair open circuit or short to ground or short to power in harness or connectors.

Condition START SIGNAL

Ignition switch ON OFF

Ignition switch START ON

PBIB0433E

Condition Voltage

Ignition switch ON Approximately 0V

Ignition switch START Battery voltage

PBIB1949E

Continuity should exist.

Page 1330 of 3171

EC-350

START SIGNAL

4.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END