NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 211 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-203

D

E

F

G

H

I

J

K

L

MA

B

AT

7.CHECK TCM

1. Check TCM input/output signals. Refer toAT-76, "

TCM Input/Output Signal Reference Values".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

8.DETECT MALFUNCTIONING ITEM

Check malfunction items. If any items are damaged, repair or replace damaged parts. Refer toAT-53, "

Symp-

tom Chart"(Symptom No.15).

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

A/T Does Not Shift: 3rd Gear®2nd GearECS00G2T

SYMPTOM:

When shifted from 33to 22position, does not downshift from 3rd to 2nd gear.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer toAT-80, "SELF-DIAGNOSTIC RESULT MODE",AT- 9 0 ,

"Judgement Self-diagnosis Code".

NO >> GO TO 2.

2.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer toAT-12, "

Checking A/T Fluid".

OK or NG

OK >> GO TO 3.

NG >> Refill ATF.

3.CHECK CONTROL CABLE

Check control cable. Refer toAT- 2 11 , "

Checking of A/T Position".

OK or NG

OK >> GO TO 4.

NG >> Adjust control cable. Refer toAT- 2 11 , "

Adjustment of A/T Position".

4.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer toAT-43, "

A/T Fluid Condition Check".

OK or NG

OK >> GO TO 5.

NG >> GO TO 8.

Page 212 of 3171

AT-204

TROUBLE DIAGNOSIS FOR SYMPTOMS

5.DETECT MALFUNCTIONING ITEM

Check malfunction items. If any items are damaged, repair or replace damaged parts. Refer toAT-53, "

Symp-

tom Chart"(Symptom No.16).

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK SYMPTOM

Check again. Refer toAT-51, "

Cruise Test - Part 3".

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

7.CHECK TCM

1. Check TCM input/output signals. Refer toAT-76, "

TCM Input/Output Signal Reference Values".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

8.DETECT MALFUNCTIONING ITEM

Check malfunction items. If any items are damaged, repair or replace damaged parts. Refer toAT-53, "

Symp-

tom Chart"(Symptom No.16).

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

A/T Does Not Shift: 2nd Gear®1st GearECS00G81

SYMPTOM:

When shifted from 22to 11position, does not downshift from 2nd to 1st gear.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II"

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer toAT-80, "SELF-DIAGNOSTIC RESULT MODE",AT- 9 0 ,

"Judgement Self-diagnosis Code".

NO >> GO TO 2.

2.CHECK 1ST POSITION SWITCH CIRCUIT

Check 1st position switch circuit. Refer toAT- 1 7 0 , "

1ST POSITION SWITCH".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

Page 213 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-205

D

E

F

G

H

I

J

K

L

MA

B

AT

3.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer toAT-12, "

Checking A/T Fluid".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK CONTROL CABLE

Check control cable. Refer toAT- 2 11 , "

Checking of A/T Position".

OK or NG

OK >> GO TO 5.

NG >> Adjust control cable. Refer toAT- 2 11 , "

Adjustment of A/T Position".

5.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer toAT-43, "

A/T Fluid Condition Check".

OK or NG

OK >> GO TO 6.

NG >> GO TO 9.

6.DETECT MALFUNCTIONING ITEM

Check malfunction items. If any items are damaged, repair or replace damaged parts. Refer toAT-53, "

Symp-

tom Chart"(Symptom No.17).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again. Refer toAT-51, "

Cruise Test - Part 3".

OK or NG

OK >>INSPECTION END

NG >> GO TO 8.

8.CHECK TCM

1. Check TCM input/output signals. Refer toAT-76, "

TCM Input/Output Signal Reference Values".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

9.DETECT MALFUNCTIONING ITEM

Check malfunction items. If any items are damaged, repair or replace damaged parts. Refer toAT-53, "

Symp-

tom Chart"(Symptom No.17).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

Page 214 of 3171

AT-206

TROUBLE DIAGNOSIS FOR SYMPTOMS

Vehicle Does Not Decelerate by Engine Brake

ECS00G82

SYMPTOM:

No engine brake is applied when the gear is shifted from the 22to 11gear.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II"

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer toAT-80, "SELF-DIAGNOSTIC RESULT MODE",AT- 9 0 ,

"Judgement Self-diagnosis Code".

NO >> GO TO 2.

2.CHECK 1ST POSITION SWITCH CIRCUIT

Check 1st position switch circuit. Refer toAT- 1 7 0 , "

1ST POSITION SWITCH".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer toAT-12, "

Checking A/T Fluid".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK CONTROL CABLE

Check control cable. Refer toAT- 2 11 , "

Checking of A/T Position".

OK or NG

OK >> GO TO 5.

NG >> Adjust control cable. Refer toAT- 2 11 , "

Adjustment of A/T Position".

5.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer toAT-43, "

A/T Fluid Condition Check".

OK or NG

OK >> GO TO 6.

NG >> GO TO 9.

6.DETECT MALFUNCTIONING ITEM

Check malfunction items. If any items are damaged, repair or replace damaged parts. Refer toAT-53, "

Symp-

tom Chart"(Symptom No.53).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again. Refer toAT-51, "

Cruise Test - Part 3".

OK or NG

OK >>INSPECTION END

NG >> GO TO 8.

Page 215 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-207

D

E

F

G

H

I

J

K

L

MA

B

AT

8.CHECK TCM

1. Check TCM input/output signals. Refer toAT-76, "

TCM Input/Output Signal Reference Values".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

9.DETECT MALFUNCTIONING ITEM

Check malfunction items. If any items are damaged, repair or replace damaged parts. Refer toAT-53, "

Symp-

tom Chart"(Symptom No.53).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

Page 216 of 3171

AT-208

SHIFT CONTROL SYSTEM

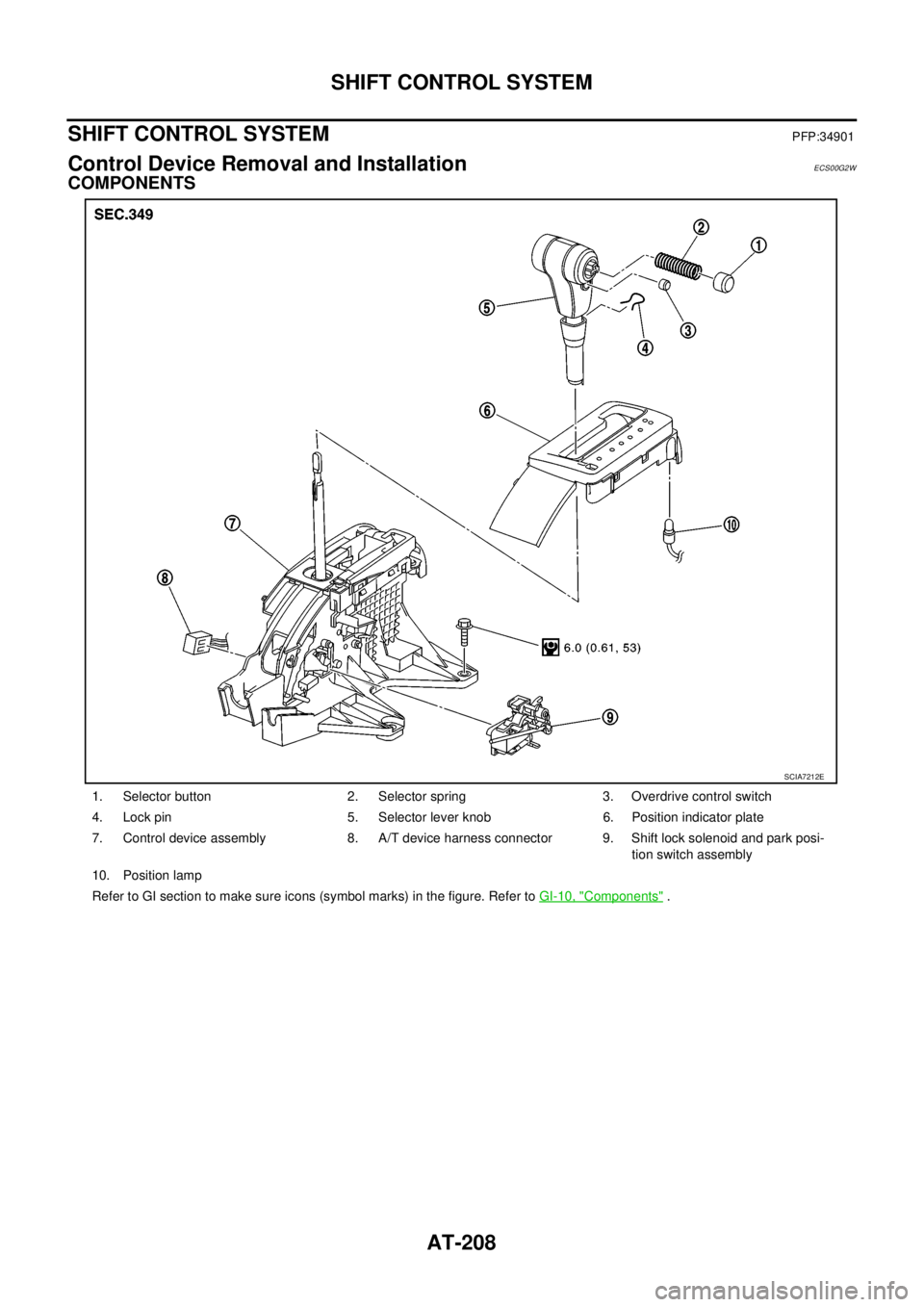

SHIFT CONTROL SYSTEM

PFP:34901

Control Device Removal and InstallationECS00G2W

COMPONENTS

1. Selector button 2. Selector spring 3. Overdrive control switch

4. Lock pin 5. Selector lever knob 6. Position indicator plate

7. Control device assembly 8. A/T device harness connector 9. Shift lock solenoid and park posi-

tion switch assembly

10. Position lamp

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

SCIA7212E

Page 217 of 3171

SHIFT CONTROL SYSTEM

AT-209

D

E

F

G

H

I

J

K

L

MA

B

AT

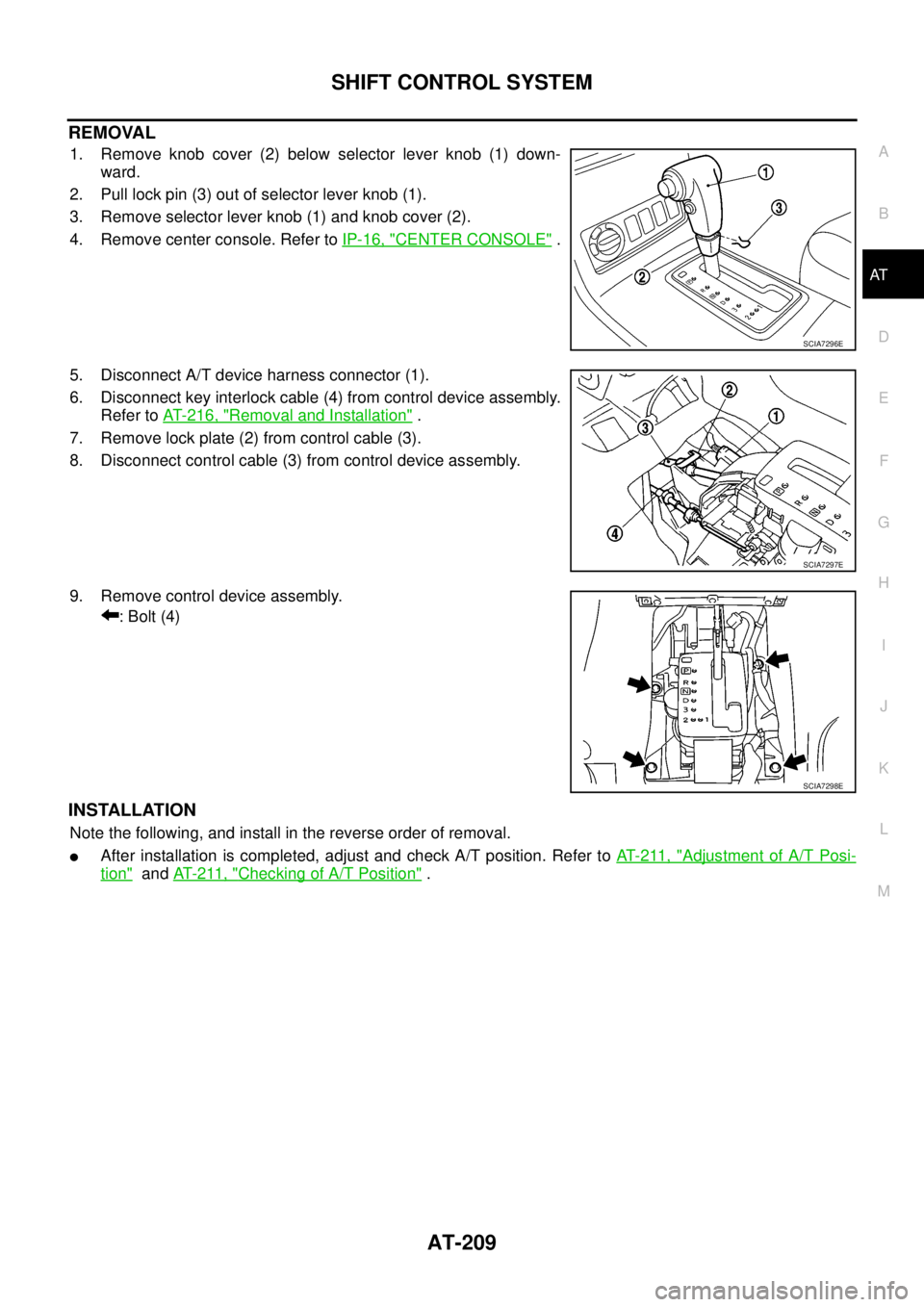

REMOVAL

1. Remove knob cover (2) below selector lever knob (1) down-

ward.

2. Pull lock pin (3) out of selector lever knob (1).

3. Remove selector lever knob (1) and knob cover (2).

4. Remove center console. Refer toIP-16, "

CENTER CONSOLE".

5. Disconnect A/T device harness connector (1).

6. Disconnect key interlock cable (4) from control device assembly.

Refer toAT- 2 1 6 , "

Removal and Installation".

7. Remove lock plate (2) from control cable (3).

8. Disconnect control cable (3) from control device assembly.

9. Remove control device assembly.

: Bolt (4)

INSTALLATION

Note the following, and install in the reverse order of removal.

lAfter installation is completed, adjust and check A/T position. Refer toAT- 2 11 , "Adjustment of A/T Posi-

tion"andAT- 2 11 , "Checking of A/T Position".

SCIA7296E

SCIA7297E

SCIA7298E

Page 218 of 3171

AT-210

SHIFT CONTROL SYSTEM

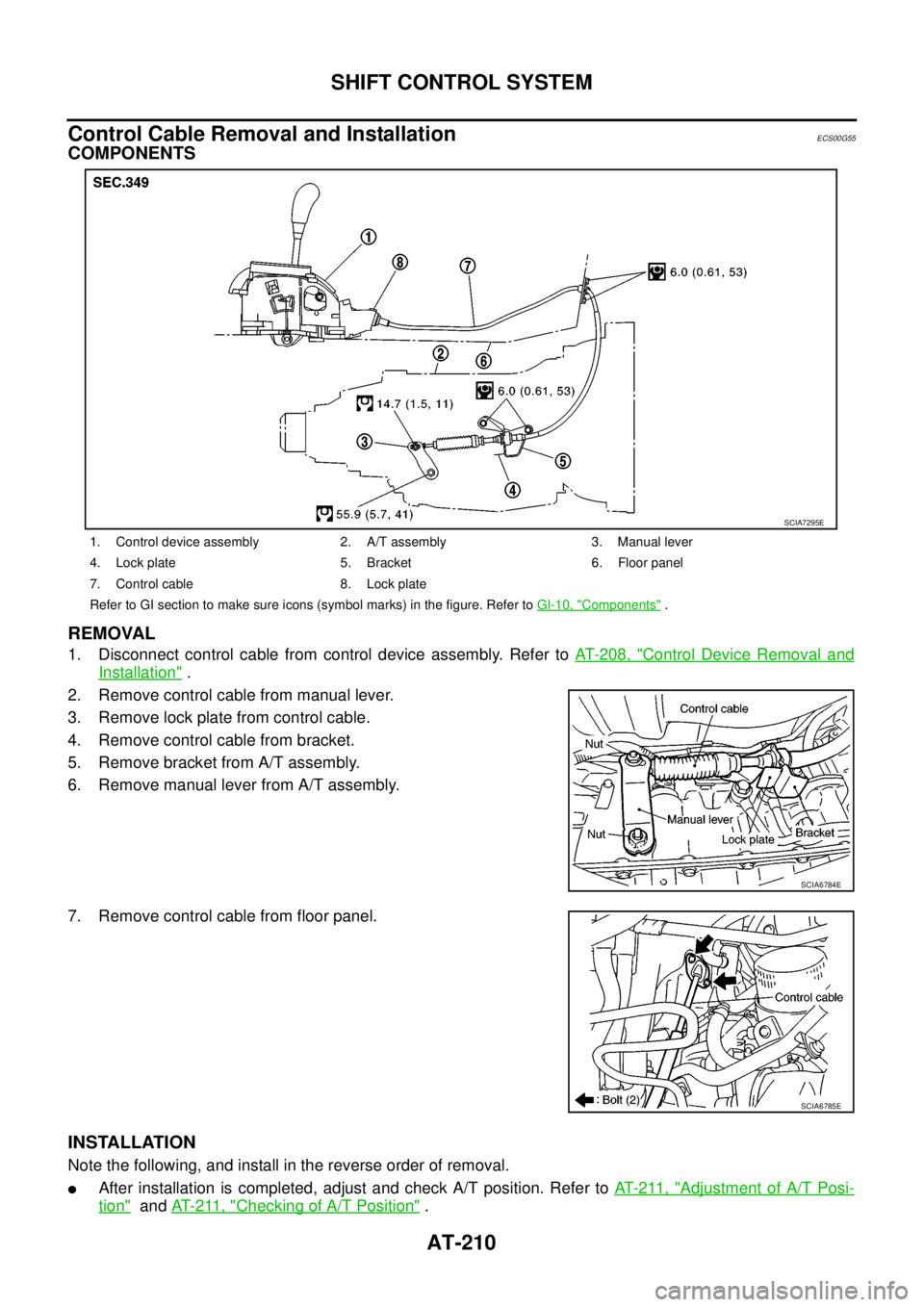

Control Cable Removal and Installation

ECS00G55

COMPONENTS

REMOVAL

1. Disconnect control cable from control device assembly. Refer toAT- 2 0 8 , "Control Device Removal and

Installation".

2. Remove control cable from manual lever.

3. Remove lock plate from control cable.

4. Remove control cable from bracket.

5. Remove bracket from A/T assembly.

6. Remove manual lever from A/T assembly.

7. Remove control cable from floor panel.

INSTALLATION

Note the following, and install in the reverse order of removal.

lAfter installation is completed, adjust and check A/T position. Refer toAT- 2 11 , "Adjustment of A/T Posi-

tion"andAT- 2 11 , "Checking of A/T Position".

1. Control device assembly 2. A/T assembly 3. Manual lever

4. Lock plate 5. Bracket 6. Floor panel

7. Control cable 8. Lock plate

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

SCIA7295E

SCIA6784E

SCIA6785E

Page 219 of 3171

SHIFT CONTROL SYSTEM

AT-211

D

E

F

G

H

I

J

K

L

MA

B

AT

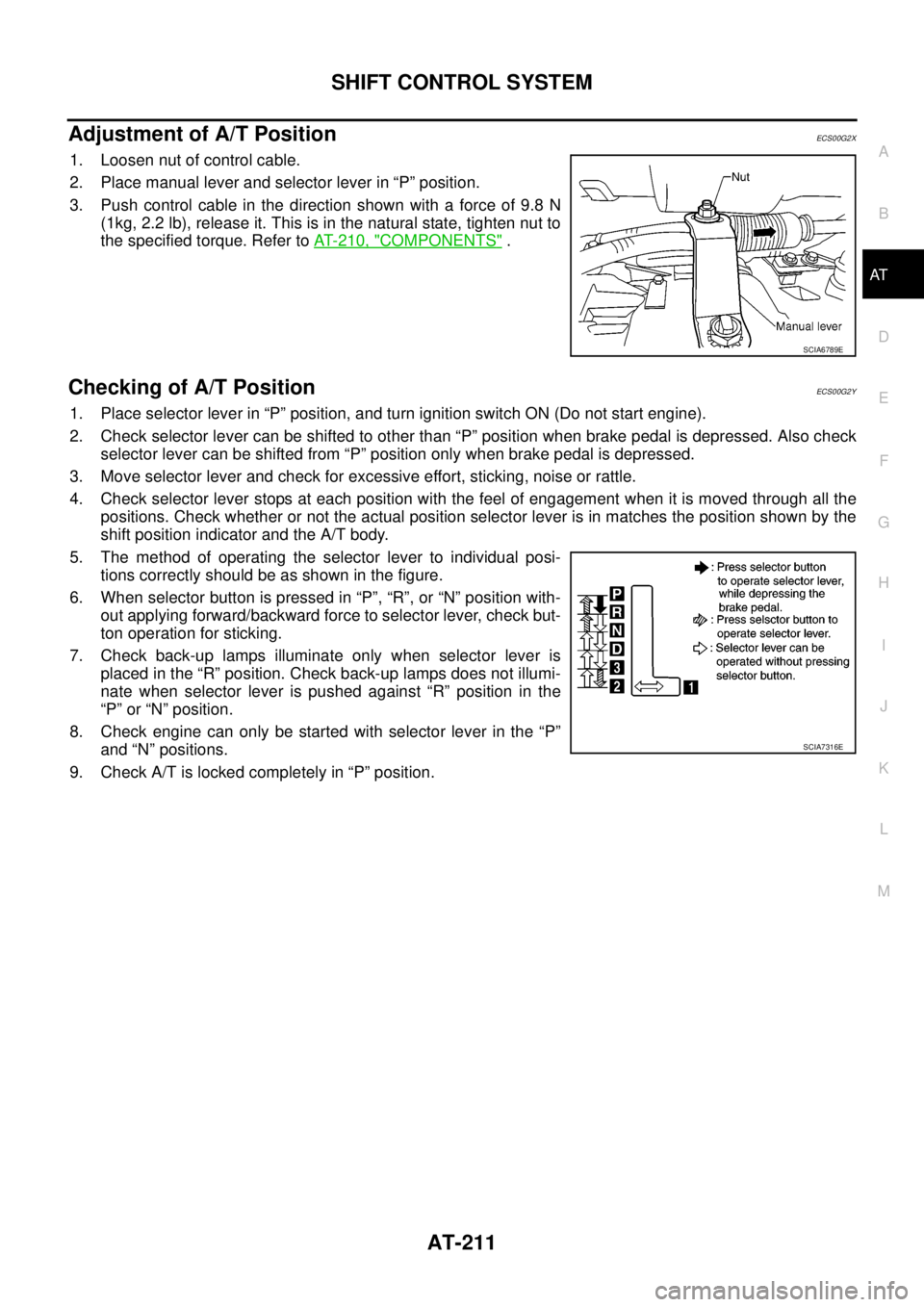

Adjustment of A/T PositionECS00G2X

1. Loosen nut of control cable.

2. Place manual lever and selector lever in “P” position.

3. Push control cable in the direction shown with a force of 9.8 N

(1kg, 2.2 lb), release it. This is in the natural state, tighten nut to

the specified torque. Refer toAT- 2 1 0 , "

COMPONENTS".

Checking of A/T PositionECS00G2Y

1. Place selector lever in “P” position, and turn ignition switch ON (Do not start engine).

2. Check selector lever can be shifted to other than “P” position when brake pedal is depressed. Also check

selector lever can be shifted from “P” position only when brake pedal is depressed.

3. Move selector lever and check for excessive effort, sticking, noise or rattle.

4. Check selector lever stops at each position with the feel of engagement when it is moved through all the

positions. Check whether or not the actual position selector lever is in matches the position shown by the

shift position indicator and the A/T body.

5. The method of operating the selector lever to individual posi-

tions correctly should be as shown in the figure.

6. When selector button is pressed in “P”, “R”, or “N” position with-

out applying forward/backward force to selector lever, check but-

ton operation for sticking.

7. Check back-up lamps illuminate only when selector lever is

placed in the “R” position. Check back-up lamps does not illumi-

nate when selector lever is pushed against “R” position in the

“P” or “N” position.

8. Check engine can only be started with selector lever in the “P”

and “N” positions.

9. Check A/T is locked completely in “P” position.

SCIA6789E

SCIA7316E

Page 220 of 3171

AT-212

A/T SHIFT LOCK SYSTEM

A/T SHIFT LOCK SYSTEM

PFP:34950

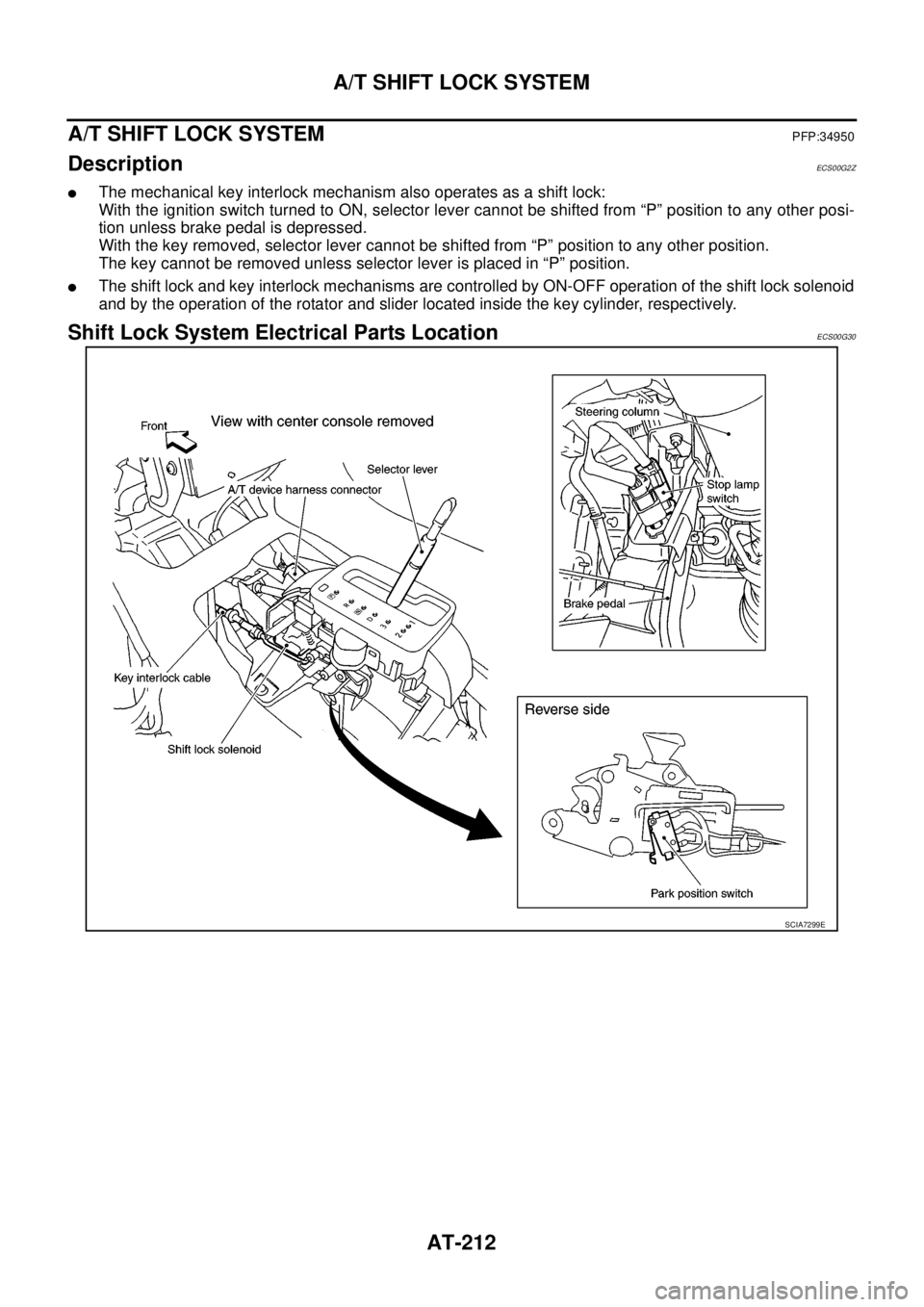

DescriptionECS00G2Z

lThe mechanical key interlock mechanism also operates as a shift lock:

With the ignition switch turned to ON, selector lever cannot be shifted from “P” position to any other posi-

tion unless brake pedal is depressed.

With the key removed, selector lever cannot be shifted from “P” position to any other position.

The key cannot be removed unless selector lever is placed in “P” position.

lThe shift lock and key interlock mechanisms are controlled by ON-OFF operation of the shift lock solenoid

and by the operation of the rotator and slider located inside the key cylinder, respectively.

Shift Lock System Electrical Parts LocationECS00G30

SCIA7299E