NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 251 of 3171

AIR BREATHER HOSE

AT-243

D

E

F

G

H

I

J

K

L

MA

B

AT

AIR BREATHER HOSEPFP:31098

Removal and InstallationECS00GVO

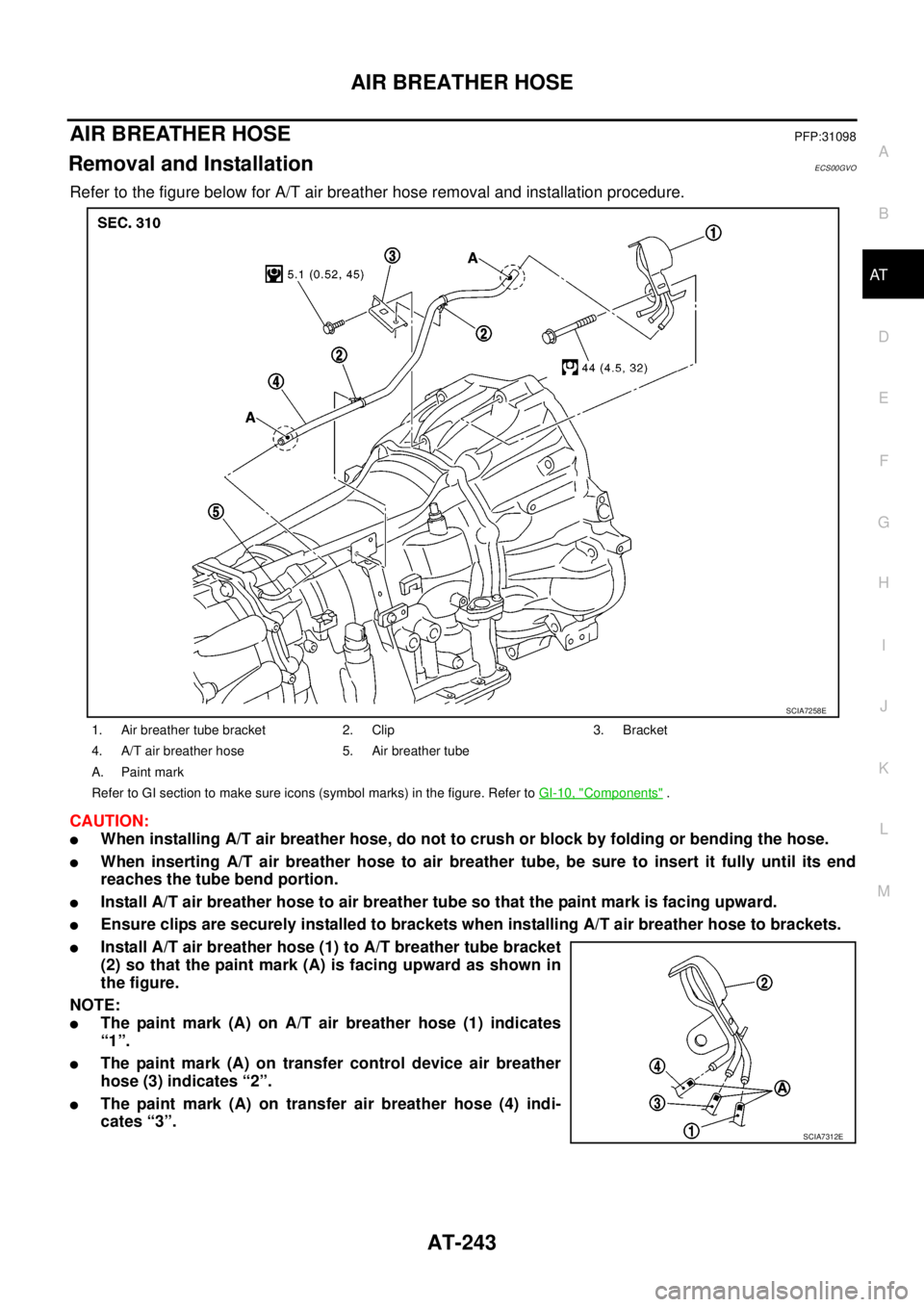

Refer to the figure below for A/T air breather hose removal and installation procedure.

CAUTION:

lWhen installing A/T air breather hose, do not to crush or block by folding or bending the hose.

lWhen inserting A/T air breather hose to air breather tube, be sure to insert it fully until its end

reaches the tube bend portion.

lInstall A/T air breather hose to air breather tube so that the paint mark is facing upward.

lEnsure clips are securely installed to brackets when installing A/T air breather hose to brackets.

lInstall A/T air breather hose (1) to A/T breather tube bracket

(2) so that the paint mark (A) is facing upward as shown in

the figure.

NOTE:

lThe paint mark (A) on A/T air breather hose (1) indicates

“1”.

lThe paint mark (A) on transfer control device air breather

hose (3) indicates “2”.

lThe paint mark (A) on transfer air breather hose (4) indi-

cates “3”.

1. Air breather tube bracket 2. Clip 3. Bracket

4. A/T air breather hose 5. Air breather tube

A. Paint mark

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

SCIA7258E

SCIA7312E

Page 252 of 3171

AT-244

A/T FLUID COOLER

A/T FLUID COOLER

PFP:21600

Removal and InstallationECS00G56

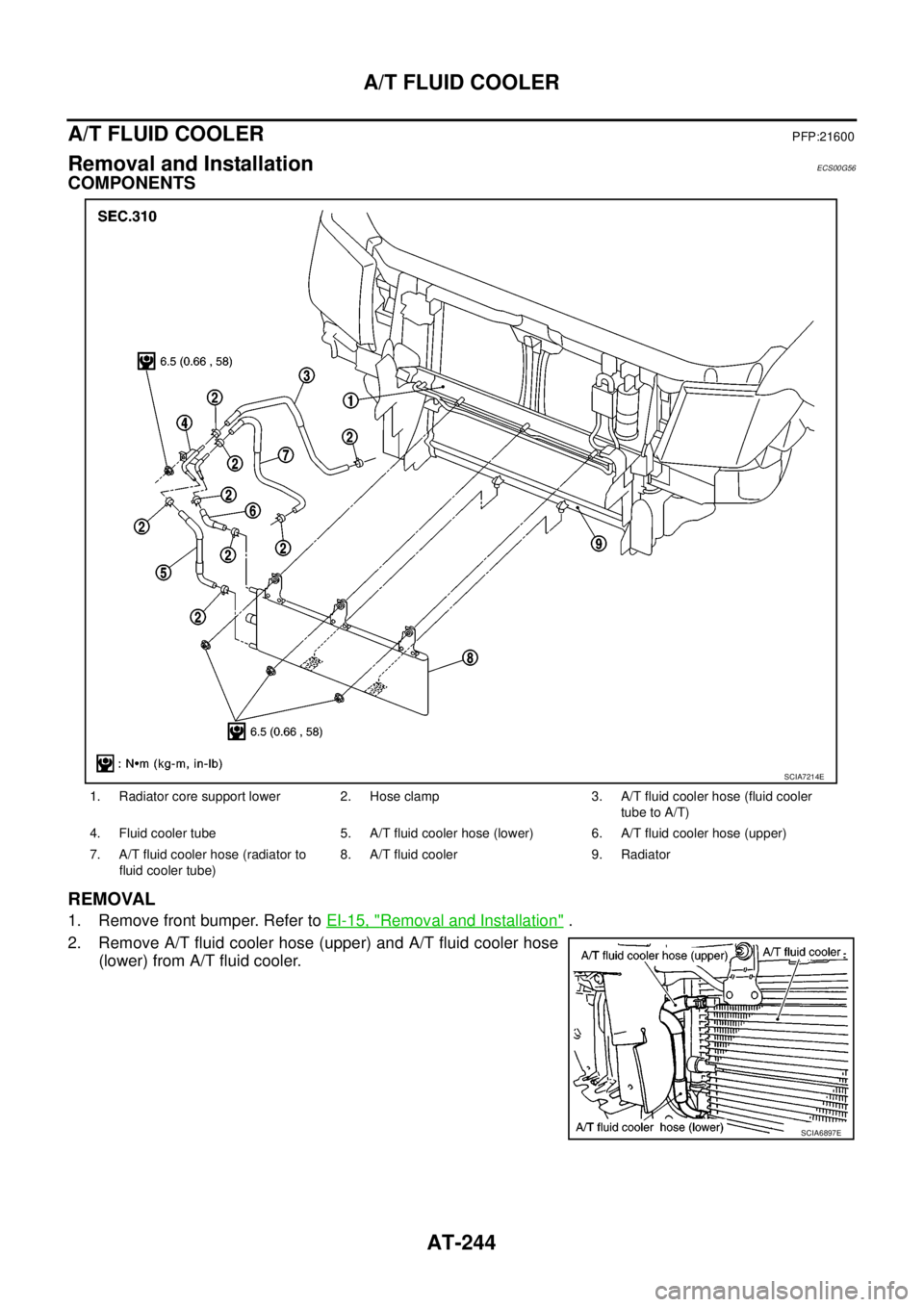

COMPONENTS

REMOVAL

1. Remove front bumper. Refer toEI-15, "Removal and Installation".

2. Remove A/T fluid cooler hose (upper) and A/T fluid cooler hose

(lower) from A/T fluid cooler.

1. Radiator core support lower 2. Hose clamp 3. A/T fluid cooler hose (fluid cooler

tube to A/T)

4. Fluid cooler tube 5. A/T fluid cooler hose (lower) 6. A/T fluid cooler hose (upper)

7. A/T fluid cooler hose (radiator to

fluid cooler tube)8. A/T fluid cooler 9. Radiator

SCIA7214E

SCIA6897E

Page 253 of 3171

A/T FLUID COOLER

AT-245

D

E

F

G

H

I

J

K

L

MA

B

AT

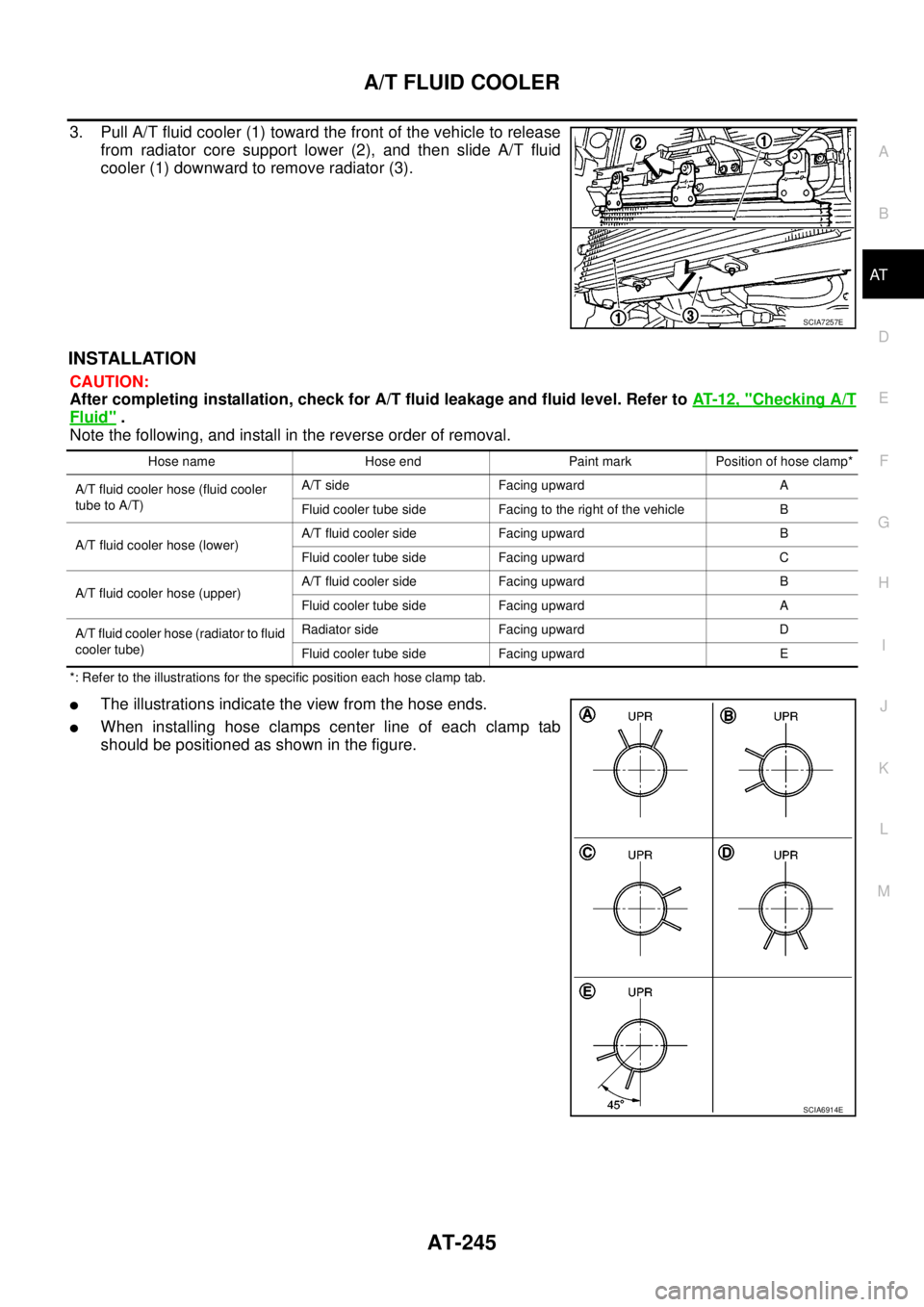

3. Pull A/T fluid cooler (1) toward the front of the vehicle to release

from radiator core support lower (2), and then slide A/T fluid

cooler (1) downward to remove radiator (3).

INSTALLATION

CAUTION:

After completing installation, check for A/T fluid leakage and fluid level. Refer toAT-12, "

Checking A/T

Fluid".

Note the following, and install in the reverse order of removal.

*: Refer to the illustrations for the specific position each hose clamp tab.

lThe illustrations indicate the view from the hose ends.

lWhen installing hose clamps center line of each clamp tab

should be positioned as shown in the figure.

SCIA7257E

Hose name Hose end Paint mark Position of hose clamp*

A/T fluid cooler hose (fluid cooler

tube to A/T)A/T side Facing upward A

Fluid cooler tube side Facing to the right of the vehicle B

A/T fluid cooler hose (lower)A/T fluid cooler side Facing upward B

Fluid cooler tube side Facing upward C

A/T fluid cooler hose (upper)A/T fluid cooler side Facing upward B

Fluid cooler tube side Facing upward A

A/T fluid cooler hose (radiator to fluid

cooler tube)Radiator side Facing upward D

Fluid cooler tube side Facing upward E

SCIA6914E

Page 254 of 3171

AT-246

A/T FLUID COOLER

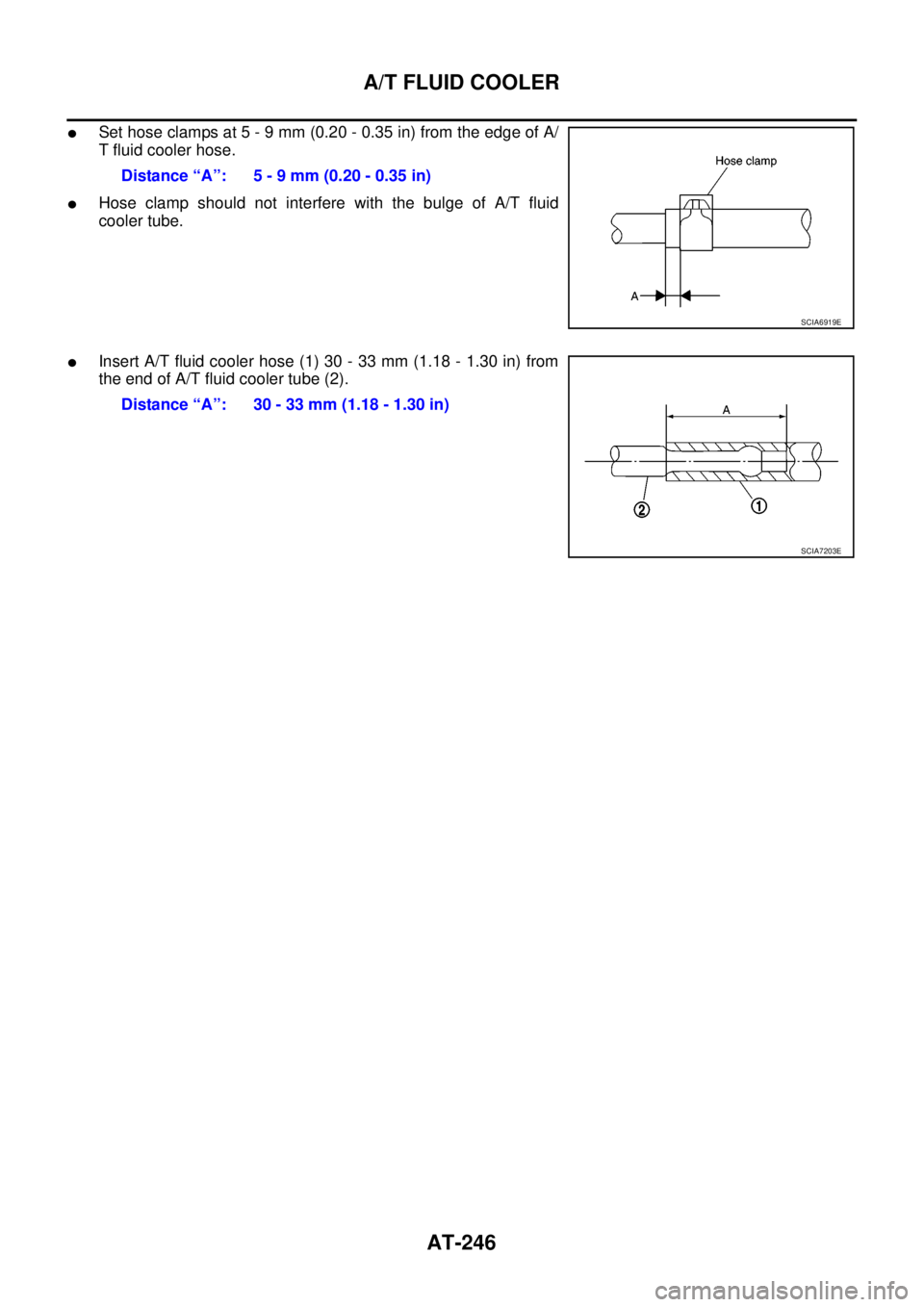

lSet hose clamps at 5 - 9 mm (0.20 - 0.35 in) from the edge of A/

T fluid cooler hose.

lHose clamp should not interfere with the bulge of A/T fluid

cooler tube.

lInsert A/T fluid cooler hose (1) 30 - 33 mm (1.18 - 1.30 in) from

the end of A/T fluid cooler tube (2).Distance “A”: 5 - 9 mm (0.20 - 0.35 in)

SCIA6919E

Distance “A”: 30 - 33 mm (1.18 - 1.30 in)

SCIA7203E

Page 255 of 3171

TRANSMISSION ASSEMBLY

AT-247

D

E

F

G

H

I

J

K

L

MA

B

AT

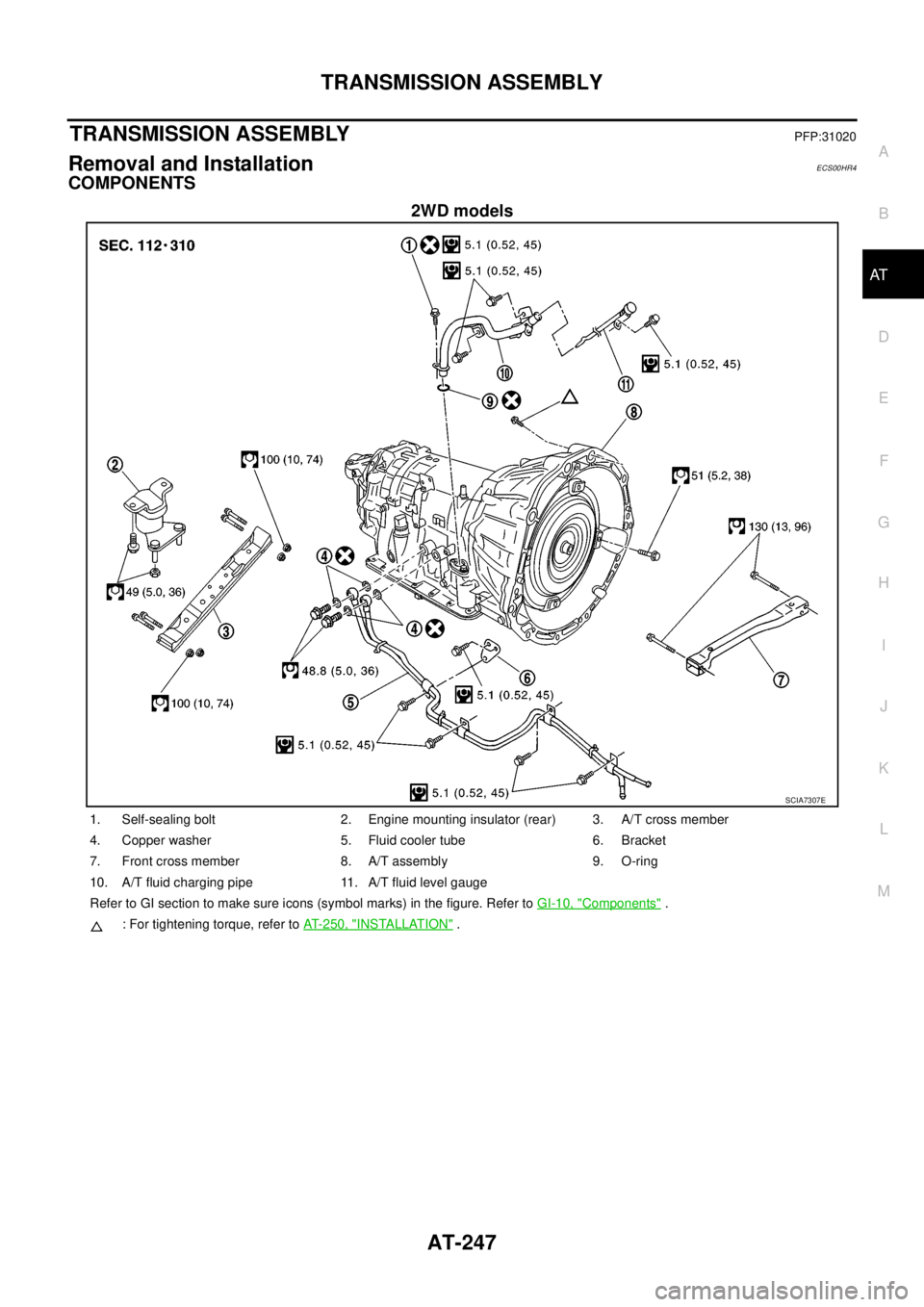

TRANSMISSION ASSEMBLYPFP:31020

Removal and InstallationECS00HR4

COMPONENTS

2WD models

SCIA7307E

1. Self-sealing bolt 2. Engine mounting insulator (rear) 3. A/T cross member

4. Copper washer 5. Fluid cooler tube 6. Bracket

7. Front cross member 8. A/T assembly 9. O-ring

10. A/T fluid charging pipe 11. A/T fluid level gauge

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

: For tightening torque, refer toAT- 2 5 0 , "

INSTALLATION".

Page 256 of 3171

AT-248

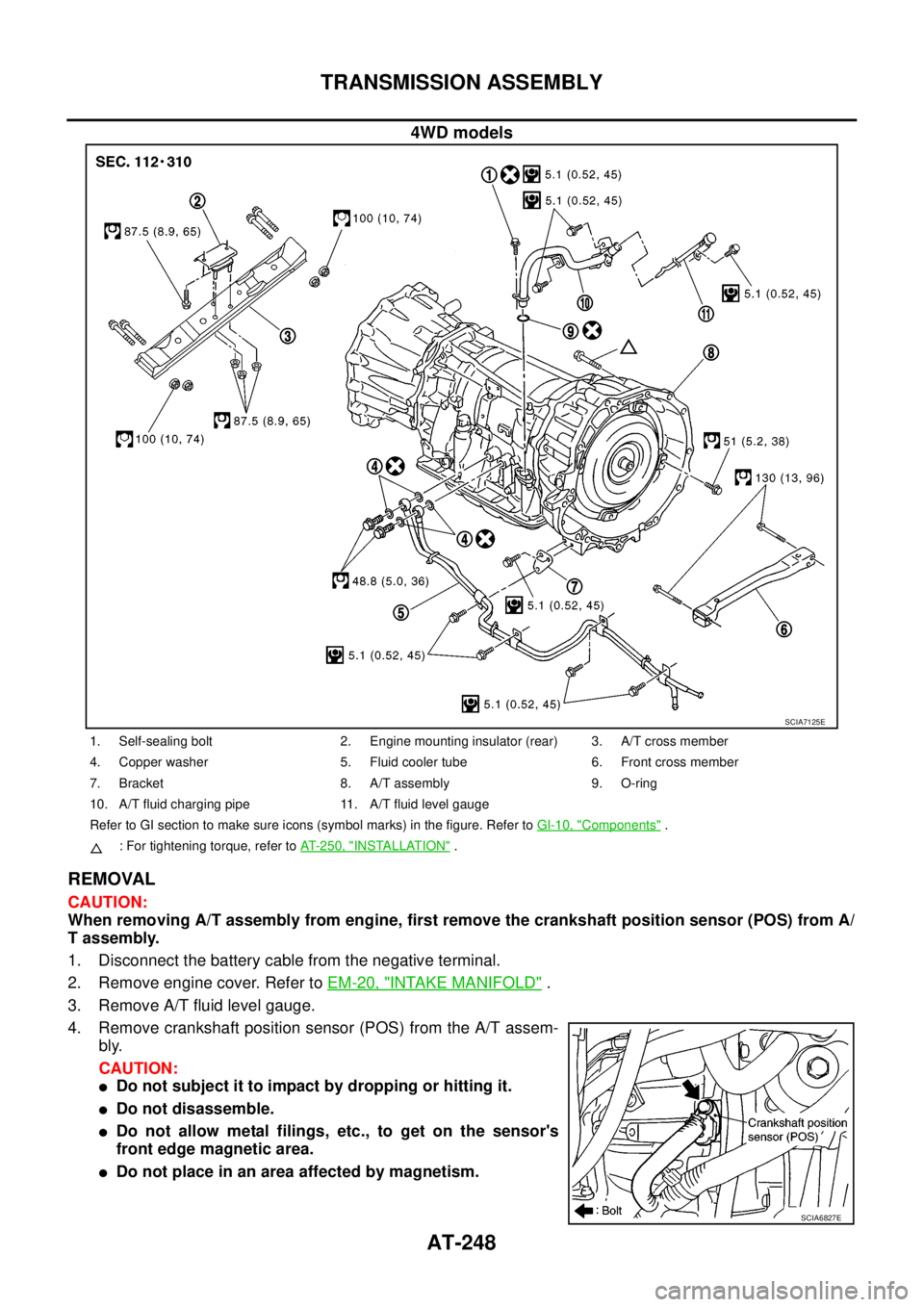

TRANSMISSION ASSEMBLY

4WD models

REMOVAL

CAUTION:

When removing A/T assembly from engine, first remove the crankshaft position sensor (POS) from A/

T assembly.

1. Disconnect the battery cable from the negative terminal.

2. Remove engine cover. Refer toEM-20, "

INTAKE MANIFOLD".

3. Remove A/T fluid level gauge.

4. Remove crankshaft position sensor (POS) from the A/T assem-

bly.

CAUTION:

lDo not subject it to impact by dropping or hitting it.

lDo not disassemble.

lDo not allow metal filings, etc., to get on the sensor's

front edge magnetic area.

lDo not place in an area affected by magnetism.

SCIA7125E

1. Self-sealing bolt 2. Engine mounting insulator (rear) 3. A/T cross member

4. Copper washer 5. Fluid cooler tube 6. Front cross member

7. Bracket 8. A/T assembly 9. O-ring

10. A/T fluid charging pipe 11. A/T fluid level gauge

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

: For tightening torque, refer toAT-250, "

INSTALLATION".

SCIA6827E

Page 257 of 3171

TRANSMISSION ASSEMBLY

AT-249

D

E

F

G

H

I

J

K

L

MA

B

AT

5. Remove front valance center, engine undercover front, engine under cover middle and engine under

coverrear.RefertoEI-15, "

FRONT BUMPER".

6. Remove front cross member.

7. Remove main muffler. Refer toEX-2, "

EXHAUST SYSTEM".

8. Remove rear propeller shaft. Refer toPR-8, "

Removal and Installation".

9. Remove front propeller shaft. Refer toPR-4, "

Removal and Installation".

10. Remove starter motor. Refer toSC-31, "

Removal and Installation".

11. Remove control cable and bracket. Refer toAT- 2 1 0 , "

Control Cable Removal and Installation".

12. Disconnect fluid cooler tube.

13. Remove A/T fluid charging pipe from A/T assembly.

14. Remove O-ring from A/T fluid charging pipe.

15. Plug up openings such as A/T fluid charging pipe hole, etc.

16. Remove rear plate cover from rear plate.

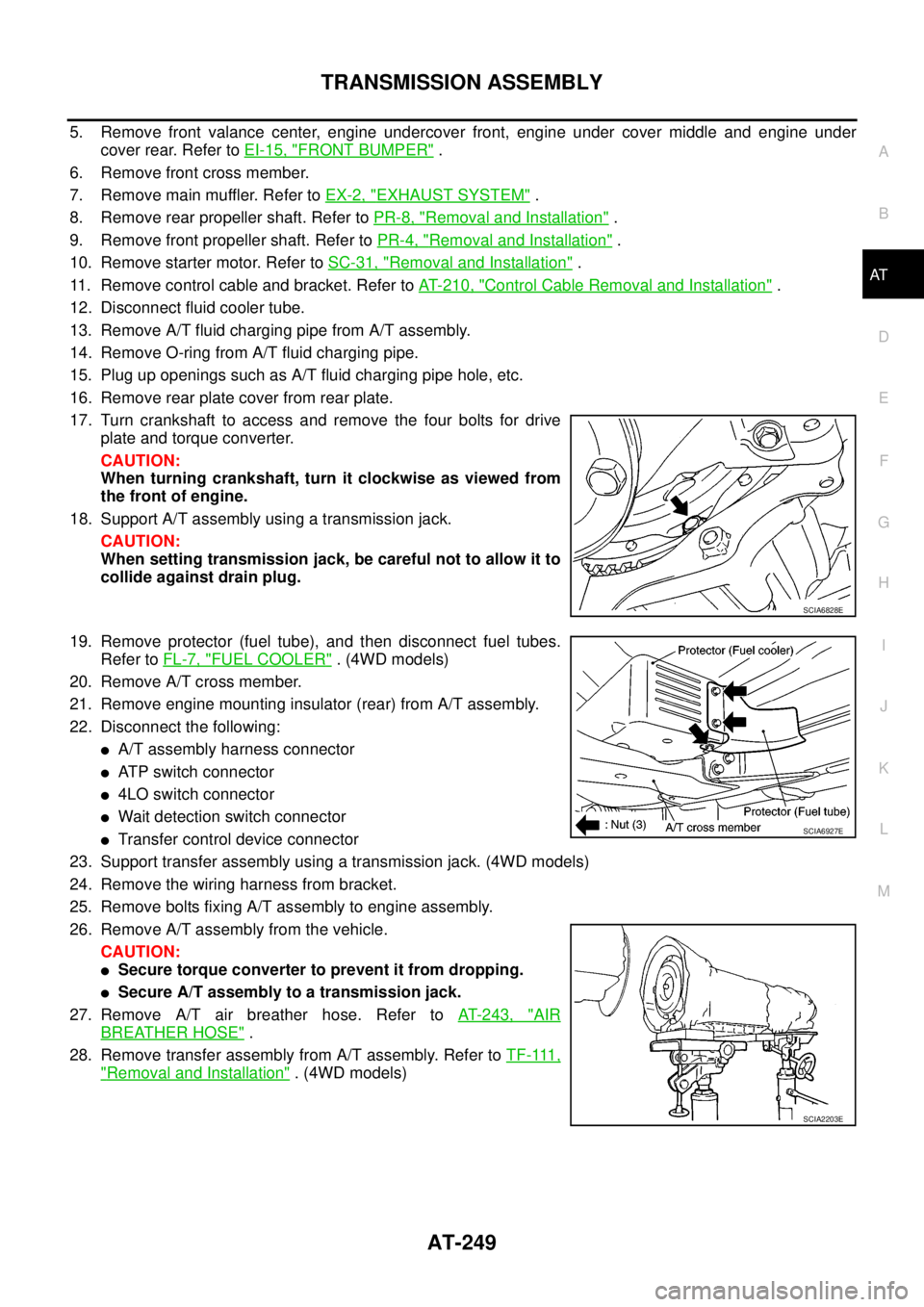

17. Turn crankshaft to access and remove the four bolts for drive

plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of engine.

18. Support A/T assembly using a transmission jack.

CAUTION:

When setting transmission jack, be careful not to allow it to

collide against drain plug.

19. Remove protector (fuel tube), and then disconnect fuel tubes.

Refer toFL-7, "

FUEL COOLER". (4WD models)

20. Remove A/T cross member.

21. Remove engine mounting insulator (rear) from A/T assembly.

22. Disconnect the following:

lA/T assembly harness connector

lATP switch connector

l4LO switch connector

lWait detection switch connector

lTransfer control device connector

23. Support transfer assembly using a transmission jack. (4WD models)

24. Remove the wiring harness from bracket.

25. Remove bolts fixing A/T assembly to engine assembly.

26. Remove A/T assembly from the vehicle.

CAUTION:

lSecure torque converter to prevent it from dropping.

lSecure A/T assembly to a transmission jack.

27. Remove A/T air breather hose. Refer toAT- 2 4 3 , "

AIR

BREATHER HOSE".

28. Remove transfer assembly from A/T assembly. Refer toT F - 111 ,

"Removal and Installation". (4WD models)

SCIA6828E

SCIA6927E

SCIA2203E

Page 258 of 3171

AT-250

TRANSMISSION ASSEMBLY

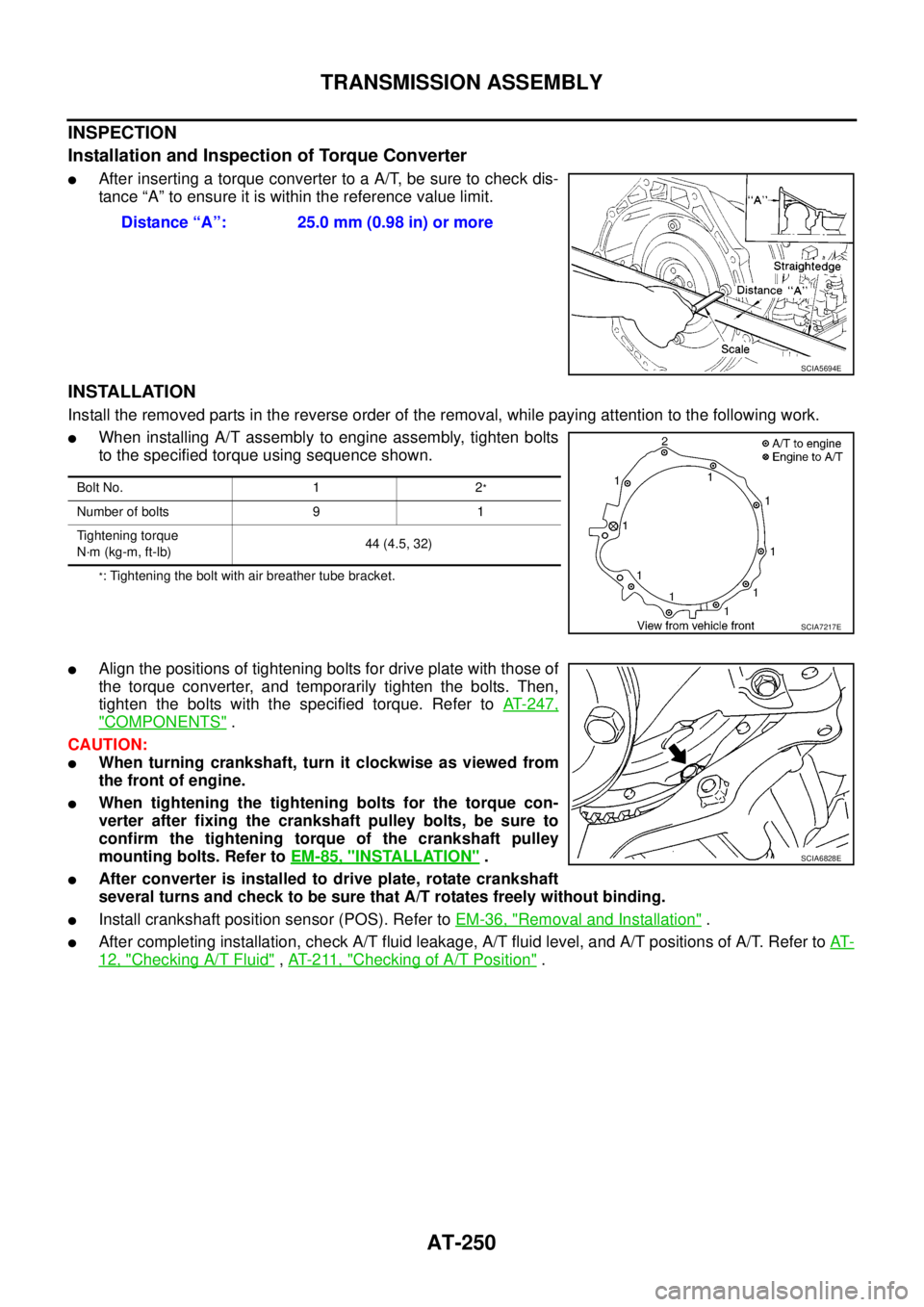

INSPECTION

Installation and Inspection of Torque Converter

lAfter inserting a torque converter to a A/T, be sure to check dis-

tance “A” to ensure it is within the reference value limit.

INSTALLATION

Install the removed parts in the reverse order of the removal, while paying attention to the following work.

lWhen installing A/T assembly to engine assembly, tighten bolts

to the specified torque using sequence shown.

*: Tightening the bolt with air breather tube bracket.

lAlign the positions of tightening bolts for drive plate with those of

the torque converter, and temporarily tighten the bolts. Then,

tighten the bolts with the specified torque. Refer toAT-247,

"COMPONENTS".

CAUTION:

lWhen turning crankshaft, turn it clockwise as viewed from

the front of engine.

lWhen tightening the tightening bolts for the torque con-

verter after fixing the crankshaft pulley bolts, be sure to

confirm the tightening torque of the crankshaft pulley

mounting bolts. Refer toEM-85, "

INSTALLATION".

lAfter converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that A/T rotates freely without binding.

lInstall crankshaft position sensor (POS). Refer toEM-36, "Removal and Installation".

lAfter completing installation, check A/T fluid leakage, A/T fluid level, and A/T positions of A/T. Refer toAT-

12, "Checking A/T Fluid",AT- 2 11 , "Checking of A/T Position". Distance “A”: 25.0 mm (0.98 in) or more

SCIA5694E

Bolt No. 1 2*

Number of bolts 9 1

Tightening torque

N·m (kg-m, ft-lb)44 (4.5, 32)

SCIA7217E

SCIA6828E

Page 259 of 3171

OVERHAUL

AT-251

D

E

F

G

H

I

J

K

L

MA

B

AT

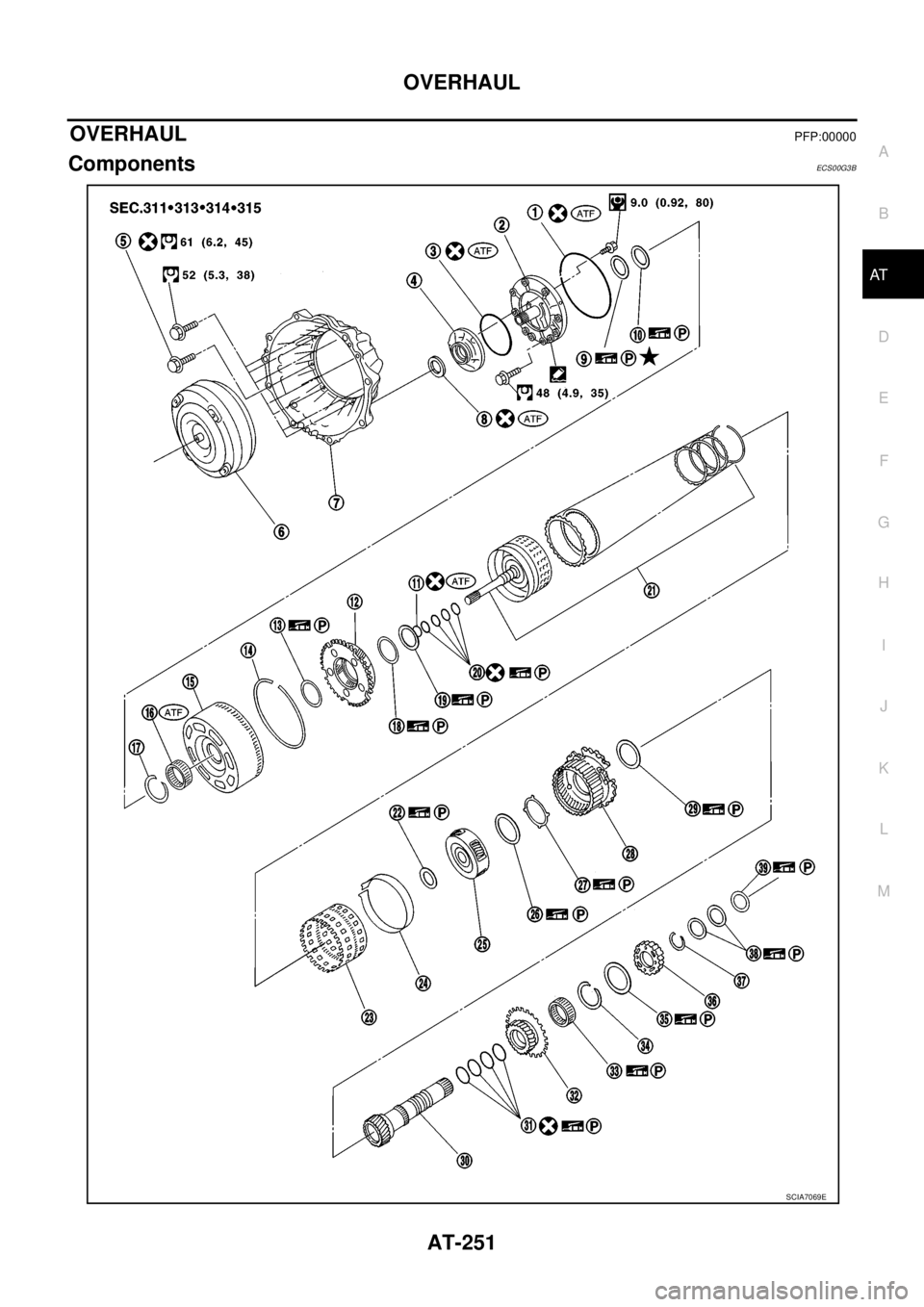

OVERHAULPFP:00000

ComponentsECS00G3B

SCIA7069E

Page 260 of 3171

AT-252

OVERHAUL

1. O-ring 2. Oil pump cover 3. O-ring

4. Oil pump housing 5. Self-sealing bolt 6. Torque converter

7. Converter housing 8. Oil pump housing oil seal 9. Bearing race

10. Needle bearing 11. O-ring 12. Front carrier assembly

13. Needle bearing 14. Snap ring 15. Front sun gear

16. 3rd one-way clutch 17. Snap ring 18. Bearing race

19. Needle bearing 20. Seal ring 21. Input clutch assembly

22. Needle bearing 23. Rear internal gear 24. Brake band

25. Mid carrier assembly 26. Needle bearing 27. Bearing race

28. Rear carrier assembly 29. Needle bearing 30. Mid sun gear

31. Seal ring 32. Rear sun gear 33. 1st one-way clutch

34. Snap ring 35. Needle bearing 36. High and low reverse clutch hub

37. Snap ring 38. Bearing race 39. Needle bearing

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

However, refer to the following symbols for others.

:Apply Liquid Gasket (Three Bond 1215) or equivalent.