NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 221 of 3171

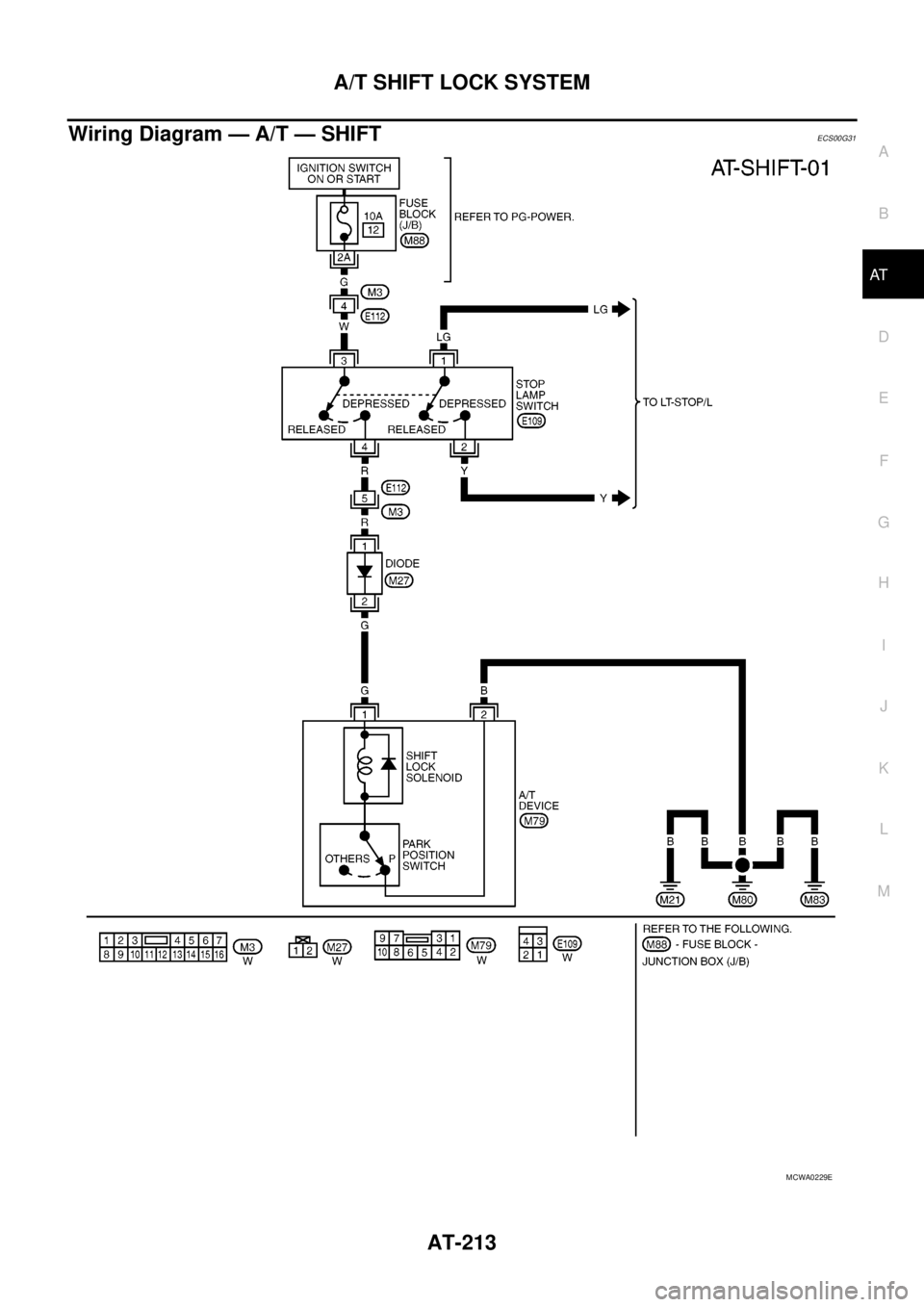

A/T SHIFT LOCK SYSTEM

AT-213

D

E

F

G

H

I

J

K

L

MA

B

AT

Wiring Diagram — A/T — SHIFTECS00G31

MCWA0229E

Page 222 of 3171

AT-214

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

ECS00G32

SYMPTOM 1:

lSelector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

lSelector lever can be moved from “P” position with key in ON position and brake pedal released.

lSelector lever can be moved from “P” position when key is removed from key cylinder.

SYMPTOM 2:

lIgnition key cannot be removed when selector lever is set to “P” position.

lIgnition key can be removed when selector lever is set to any position except “P” position.

1.CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace key interlock cable. Refer toAT- 2 1 6 , "

Removal and Installation".

2.CHECK SELECTOR LEVER POSITION

Check selector lever position for damage. Refer toAT- 2 11 , "

Checking of A/T Position"

OK or NG

OK >> GO TO 3.

NG >> Adjust control cable. Refer toAT- 2 11 , "

Adjustment of A/T Position".

3.CHECK SHIFT LOCK SOLENOID AND PARK POSITION SWITCH

1. Connect A/T device harness connector.

2. Turn ignition switch ON. (Do not start engine.)

3. Selector lever is set in “P” position.

4. Check operation.

OK or NG

OK >>INSPECTION END

NG >> GO TO 4.

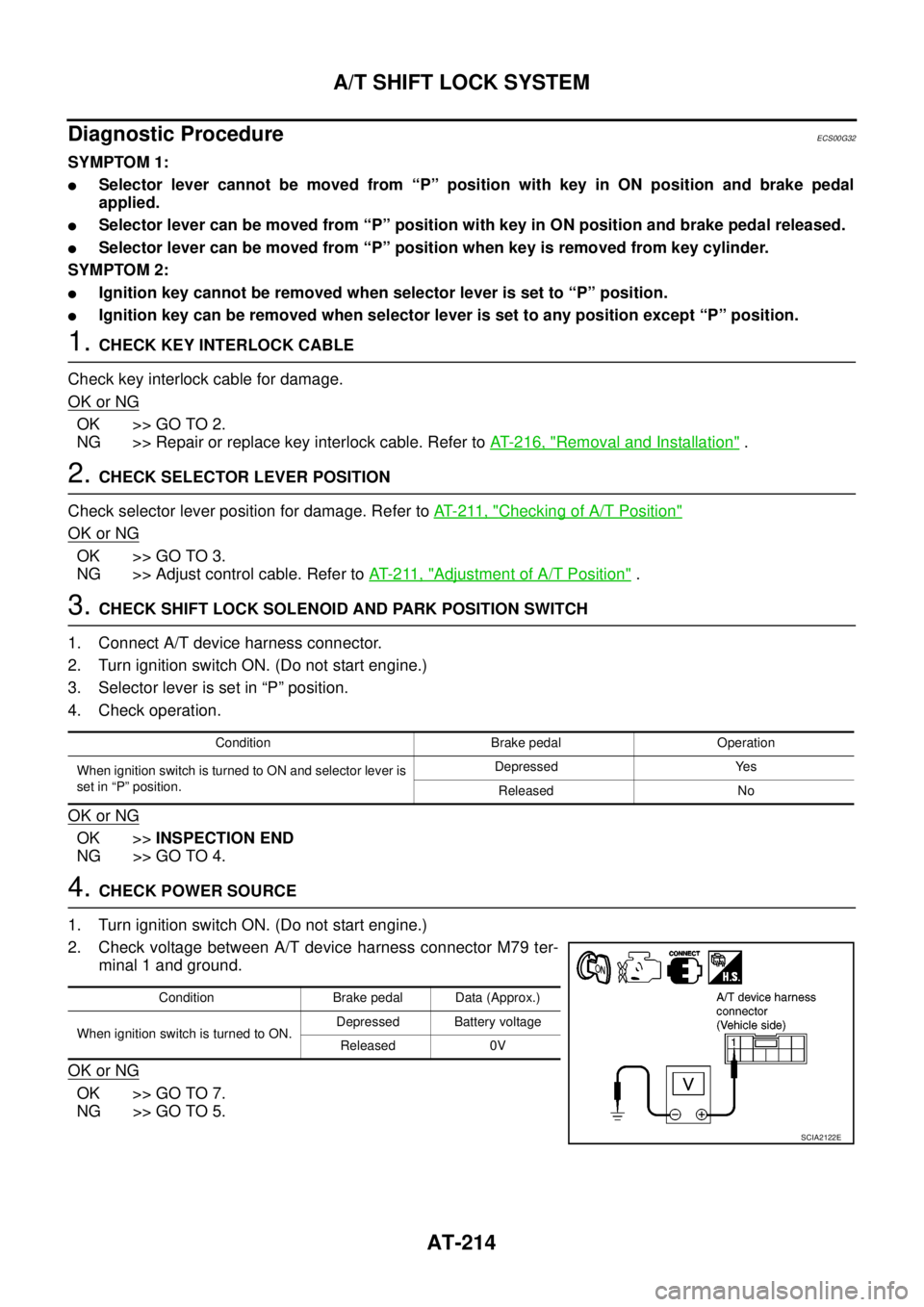

4.CHECK POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between A/T device harness connector M79 ter-

minal 1 and ground.

OK or NG

OK >> GO TO 7.

NG >> GO TO 5.

Condition Brake pedal Operation

When ignition switch is turned to ON and selector lever is

set in “P” position.Depressed Yes

Released No

Condition Brake pedal Data (Approx.)

When ignition switch is turned to ON.Depressed Battery voltage

Released 0V

SCIA2122E

Page 223 of 3171

A/T SHIFT LOCK SYSTEM

AT-215

D

E

F

G

H

I

J

K

L

MA

B

AT

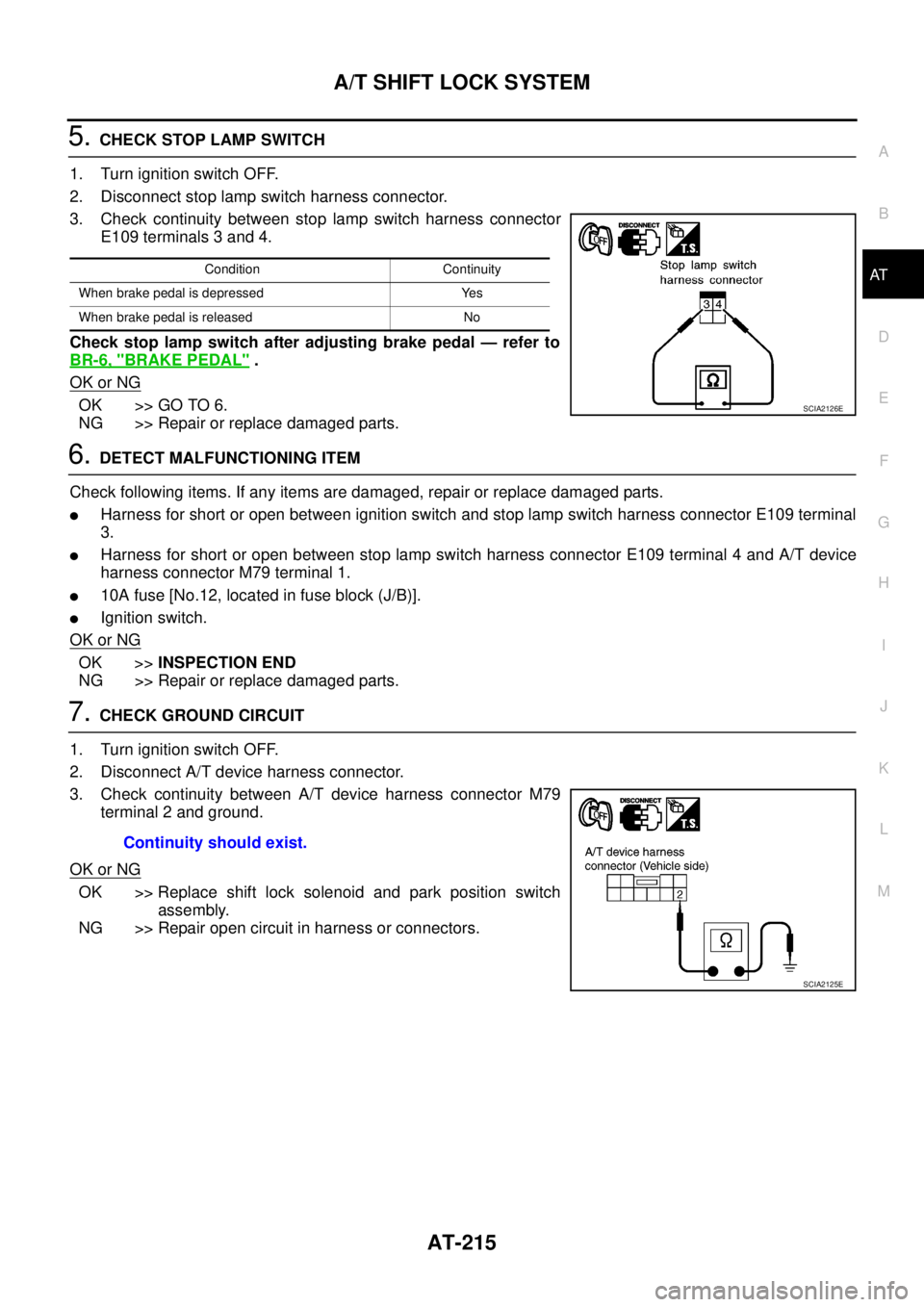

5.CHECK STOP LAMP SWITCH

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check continuity between stop lamp switch harness connector

E109 terminals 3 and 4.

Check stop lamp switch after adjusting brake pedal — refer to

BR-6, "

BRAKE PEDAL".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

Check following items. If any items are damaged, repair or replace damaged parts.

lHarness for short or open between ignition switch and stop lamp switch harness connector E109 terminal

3.

lHarness for short or open between stop lamp switch harness connector E109 terminal 4 and A/T device

harness connector M79 terminal 1.

l10A fuse [No.12, located in fuse block (J/B)].

lIgnition switch.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

7.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness connector M79

terminal 2 and ground.

OK or NG

OK >> Replace shift lock solenoid and park position switch

assembly.

NG >> Repair open circuit in harness or connectors.

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

SCIA2126E

Continuity should exist.

SCIA2125E

Page 224 of 3171

AT-216

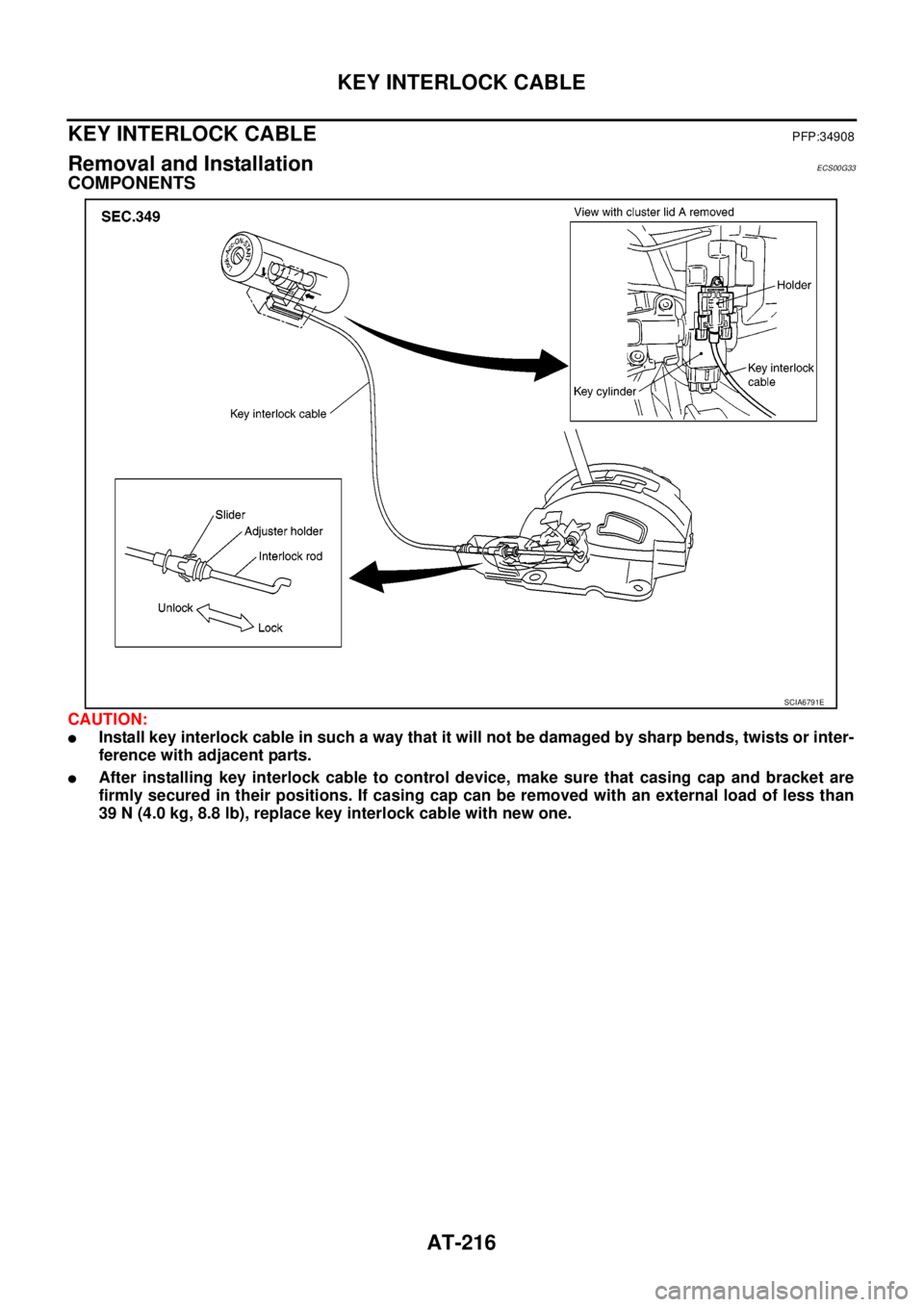

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

Removal and InstallationECS00G33

COMPONENTS

CAUTION:

lInstall key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

ference with adjacent parts.

lAfter installing key interlock cable to control device, make sure that casing cap and bracket are

firmly secured in their positions. If casing cap can be removed with an external load of less than

39 N (4.0 kg, 8.8 lb), replace key interlock cable with new one.

SCIA6791E

Page 225 of 3171

KEY INTERLOCK CABLE

AT-217

D

E

F

G

H

I

J

K

L

MA

B

AT

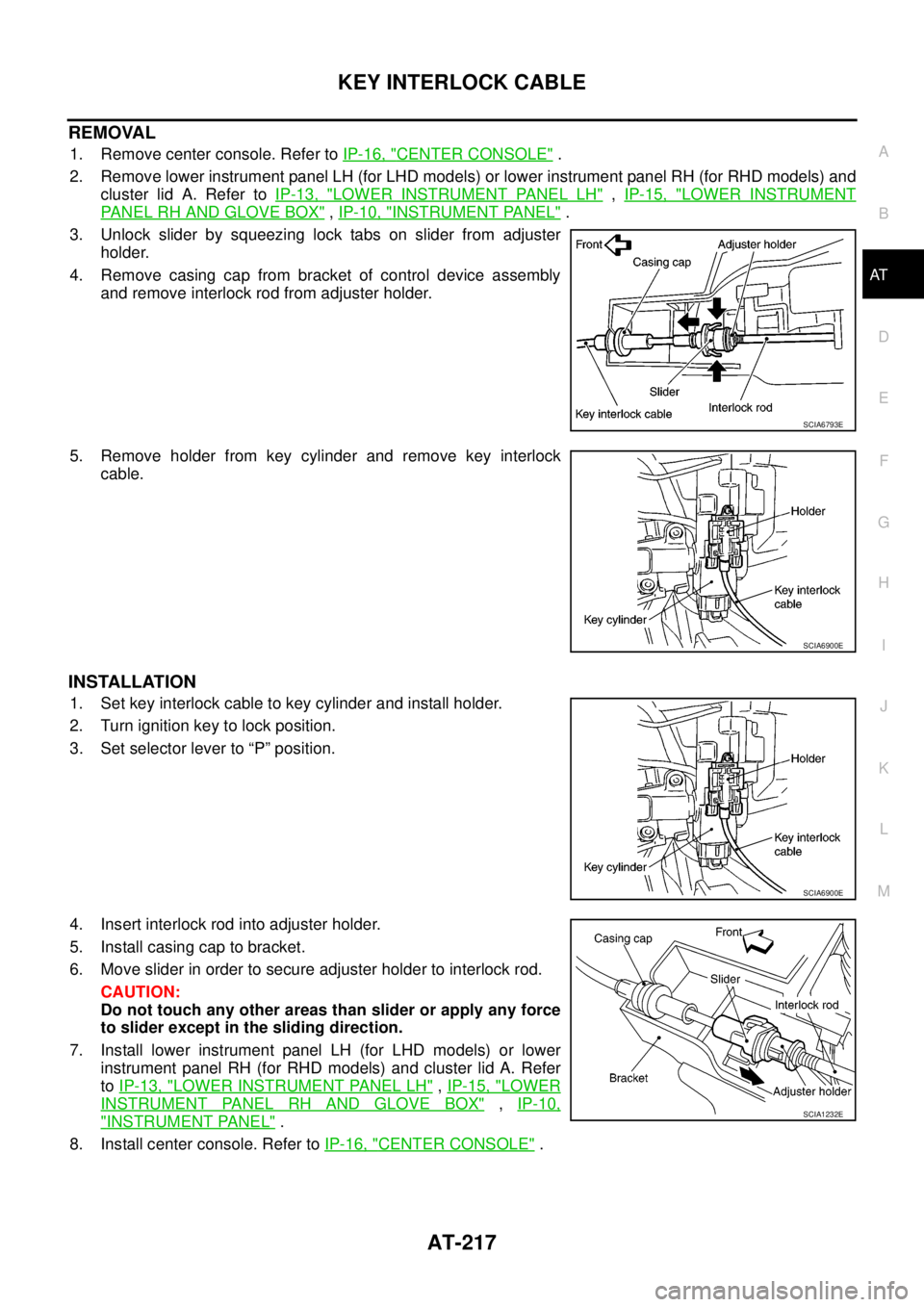

REMOVAL

1. Remove center console. Refer toIP-16, "CENTER CONSOLE".

2. Remove lower instrument panel LH (for LHD models) or lower instrument panel RH (for RHD models) and

cluster lid A. Refer toIP-13, "

LOWER INSTRUMENT PANEL LH",IP-15, "LOWER INSTRUMENT

PANEL RH AND GLOVE BOX",IP-10, "INSTRUMENT PANEL".

3. Unlock slider by squeezing lock tabs on slider from adjuster

holder.

4. Remove casing cap from bracket of control device assembly

and remove interlock rod from adjuster holder.

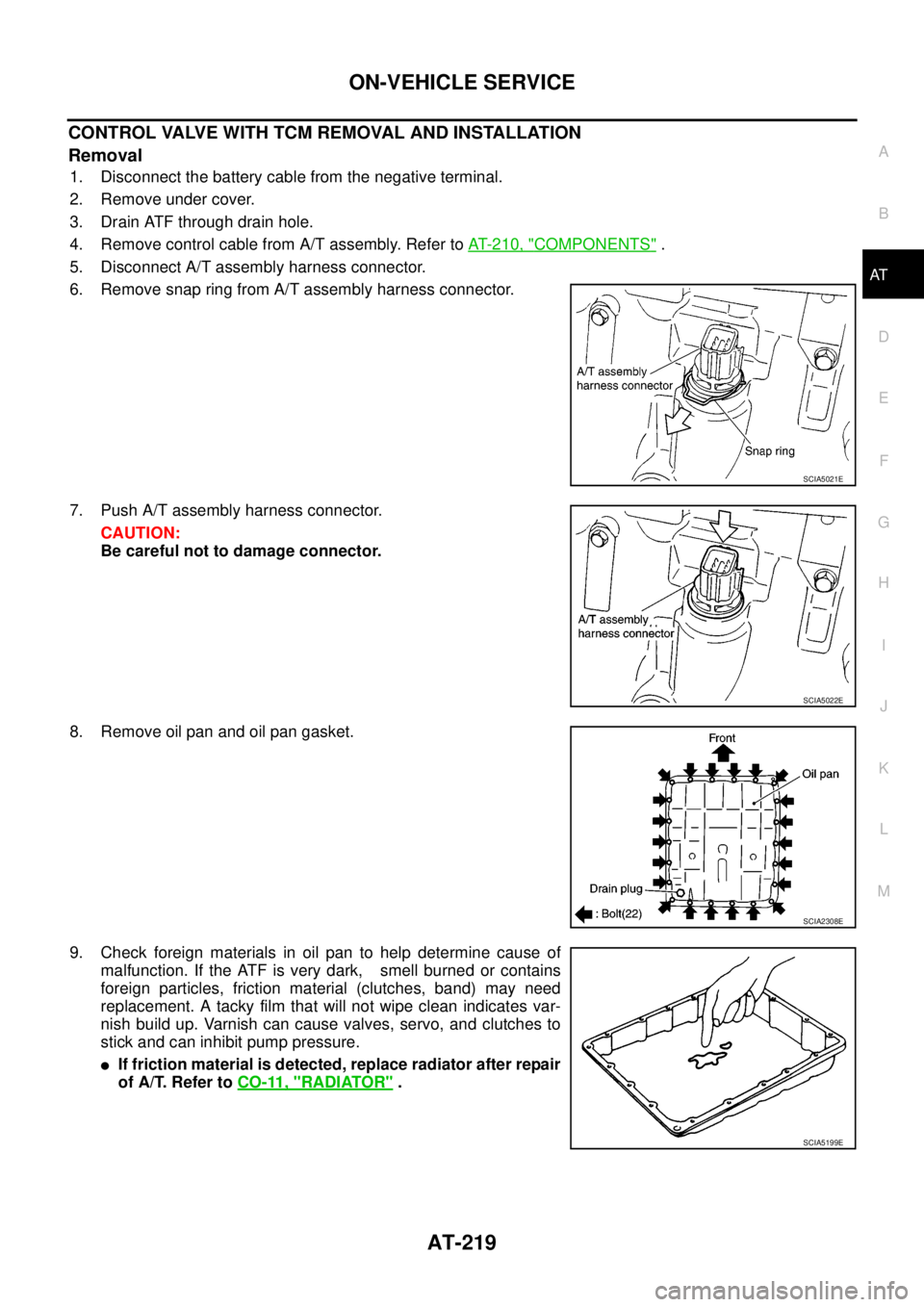

5. Remove holder from key cylinder and remove key interlock

cable.

INSTALLATION

1. Set key interlock cable to key cylinder and install holder.

2. Turn ignition key to lock position.

3. Set selector lever to “P” position.

4. Insert interlock rod into adjuster holder.

5. Install casing cap to bracket.

6. Move slider in order to secure adjuster holder to interlock rod.

CAUTION:

Do not touch any other areas than slider or apply any force

to slider except in the sliding direction.

7. Install lower instrument panel LH (for LHD models) or lower

instrument panel RH (for RHD models) and cluster lid A. Refer

toIP-13, "

LOWER INSTRUMENT PANEL LH",IP-15, "LOWER

INSTRUMENT PANEL RH AND GLOVE BOX",IP-10,

"INSTRUMENT PANEL".

8. Install center console. Refer toIP-16, "

CENTER CONSOLE".

SCIA6793E

SCIA6900E

SCIA6900E

SCIA1232E

Page 226 of 3171

AT-218

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

PFP:00000

Control Valve With TCM and A/T Fluid Temperature Sensor 2ECS00G36

COMPONENTS

1. A/T 2. Snap ring 3. Sub-harness

4. Control valve with TCM 5. Bracket 6. A/T fluid temperature sensor 2

7. Oil pan gasket 8. Oil pan 9. Magnet

10. Drain plug 11. Drain plug gasket 12. Oil pan mounting bolt

13. Terminal cord assembly 14. O-ring

SCIA5478E

Page 227 of 3171

ON-VEHICLE SERVICE

AT-219

D

E

F

G

H

I

J

K

L

MA

B

AT

CONTROL VALVE WITH TCM REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery cable from the negative terminal.

2. Remove under cover.

3. Drain ATF through drain hole.

4. Remove control cable from A/T assembly. Refer toAT- 2 1 0 , "

COMPONENTS".

5. Disconnect A/T assembly harness connector.

6. Remove snap ring from A/T assembly harness connector.

7. Push A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

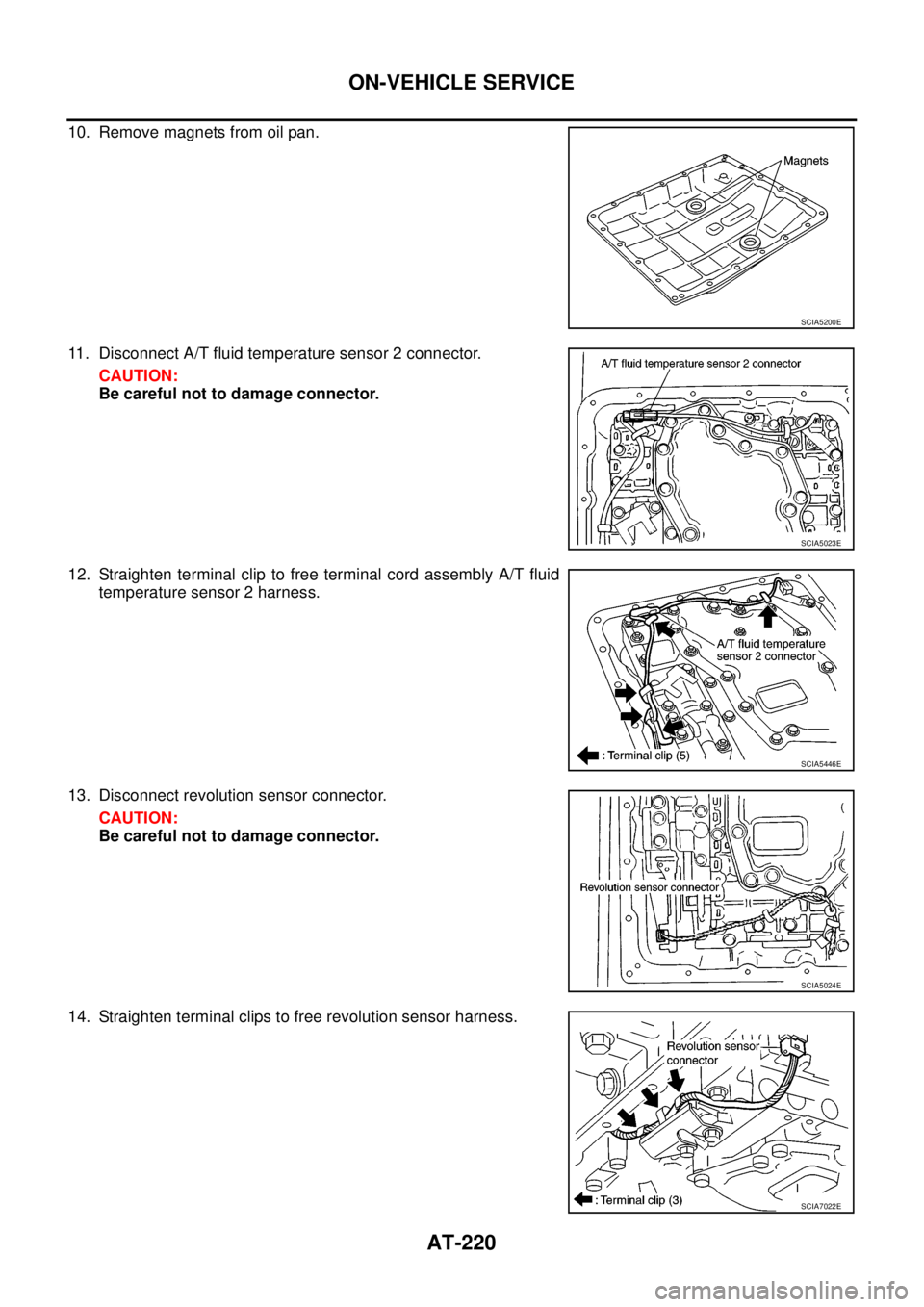

8. Remove oil pan and oil pan gasket.

9. Check foreign materials in oil pan to help determine cause of

malfunction. If the ATF is very dark, smell burned or contains

foreign particles, friction material (clutches, band) may need

replacement. A tacky film that will not wipe clean indicates var-

nish build up. Varnish can cause valves, servo, and clutches to

stick and can inhibit pump pressure.

lIf friction material is detected, replace radiator after repair

of A/T. Refer toCO-11, "

RADIATOR".

SCIA5021E

SCIA5022E

SCIA2308E

SCIA5199E

Page 228 of 3171

AT-220

ON-VEHICLE SERVICE

10. Remove magnets from oil pan.

11. Disconnect A/T fluid temperature sensor 2 connector.

CAUTION:

Be careful not to damage connector.

12. Straighten terminal clip to free terminal cord assembly A/T fluid

temperature sensor 2 harness.

13. Disconnect revolution sensor connector.

CAUTION:

Be careful not to damage connector.

14. Straighten terminal clips to free revolution sensor harness.

SCIA5200E

SCIA5023E

SCIA5446E

SCIA5024E

SCIA7022E

Page 229 of 3171

ON-VEHICLE SERVICE

AT-221

D

E

F

G

H

I

J

K

L

MA

B

AT

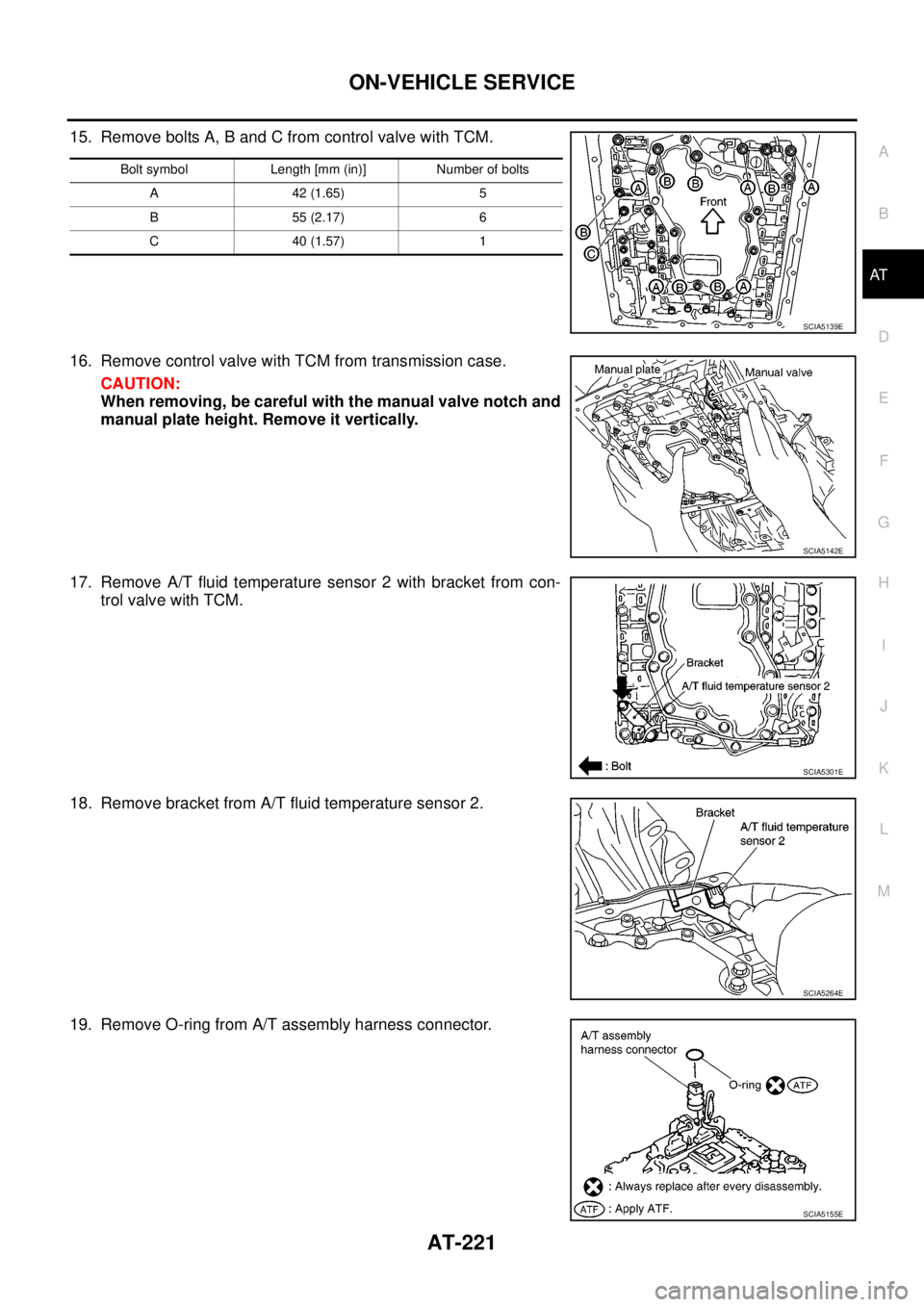

15. Remove bolts A, B and C from control valve with TCM.

16. Remove control valve with TCM from transmission case.

CAUTION:

When removing, be careful with the manual valve notch and

manual plate height. Remove it vertically.

17. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

18. Remove bracket from A/T fluid temperature sensor 2.

19. Remove O-ring from A/T assembly harness connector.

Bolt symbol Length [mm (in)] Number of bolts

A42(1.65) 5

B55(2.17) 6

C40(1.57) 1

SCIA5139E

SCIA5142E

SCIA5301E

SCIA5264E

SCIA5155E

Page 230 of 3171

AT-222

ON-VEHICLE SERVICE

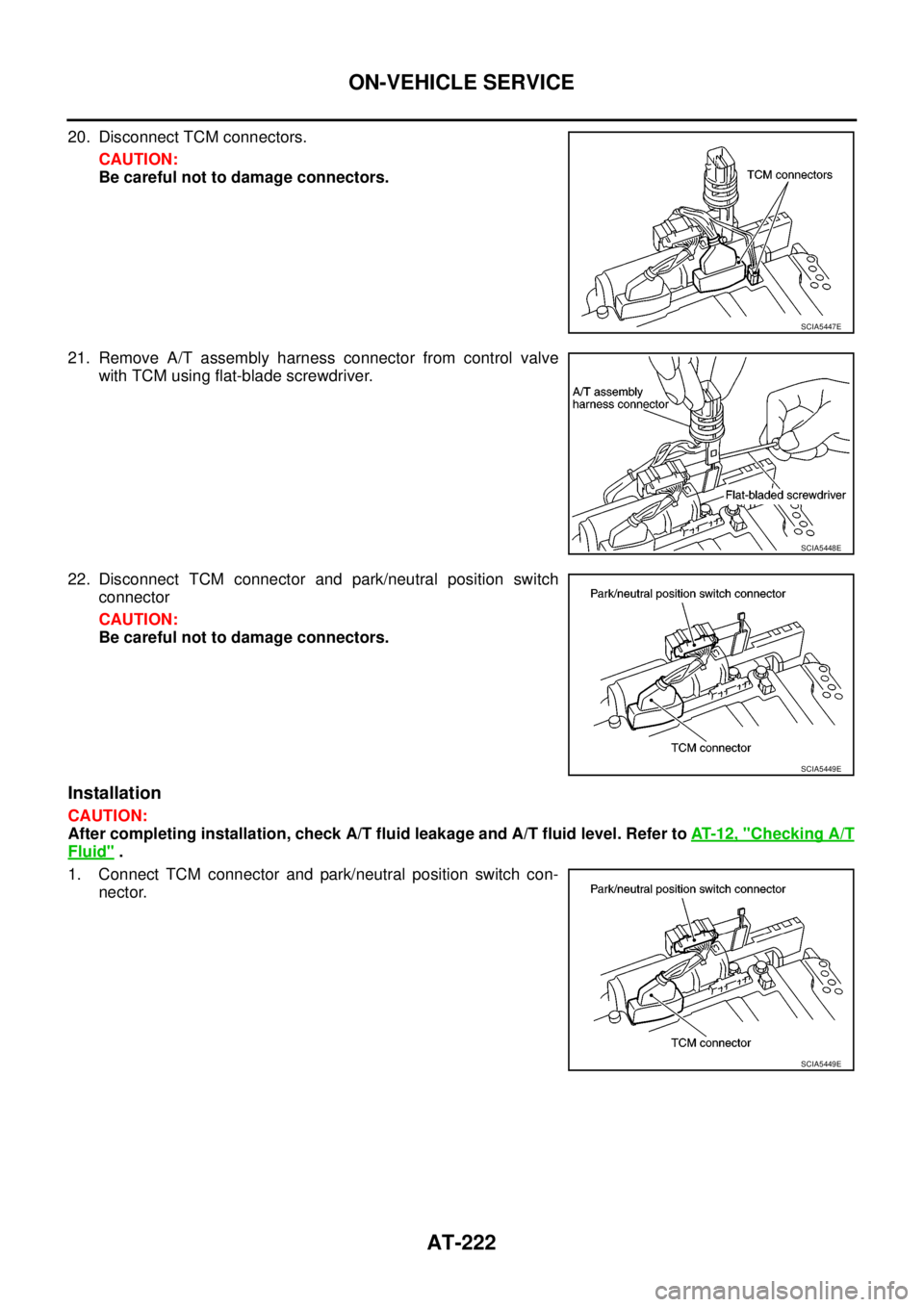

20. Disconnect TCM connectors.

CAUTION:

Be careful not to damage connectors.

21. Remove A/T assembly harness connector from control valve

with TCM using flat-blade screwdriver.

22. Disconnect TCM connector and park/neutral position switch

connector

CAUTION:

Be careful not to damage connectors.

Installation

CAUTION:

After completing installation, check A/T fluid leakage and A/T fluid level. Refer toAT-12, "

Checking A/T

Fluid".

1. Connect TCM connector and park/neutral position switch con-

nector.

SCIA5447E

SCIA5448E

SCIA5449E

SCIA5449E