NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2311 of 3171

MA-36

CHASSIS AND BODY MAINTENANCE

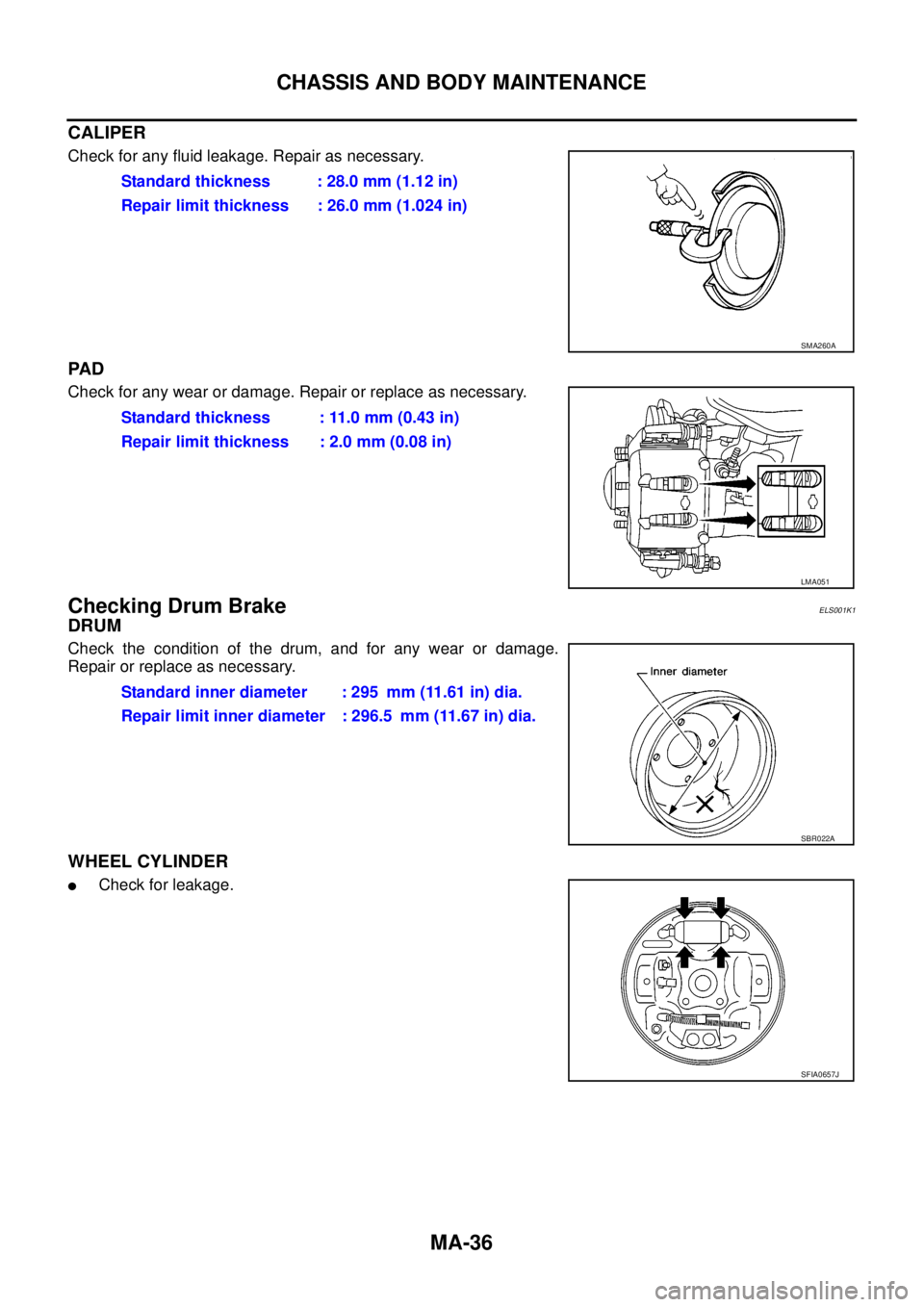

CALIPER

Check for any fluid leakage. Repair as necessary.

PA D

Check for any wear or damage. Repair or replace as necessary.

Checking Drum BrakeELS001K1

DRUM

Check the condition of the drum, and for any wear or damage.

Repair or replace as necessary.

WHEEL CYLINDER

lCheck for leakage.Standard thickness : 28.0 mm (1.12 in)

Repair limit thickness : 26.0 mm (1.024 in)

SMA260A

Standard thickness : 11.0 mm (0.43 in)

Repair limit thickness : 2.0 mm (0.08 in)

LMA051

Standard inner diameter : 295 mm (11.61 in) dia.

Repair limit inner diameter : 296.5 mm (11.67 in) dia.

SBR022A

SFIA0657J

Page 2312 of 3171

CHASSIS AND BODY MAINTENANCE

MA-37

C

D

E

F

G

H

I

J

K

MA

B

MA

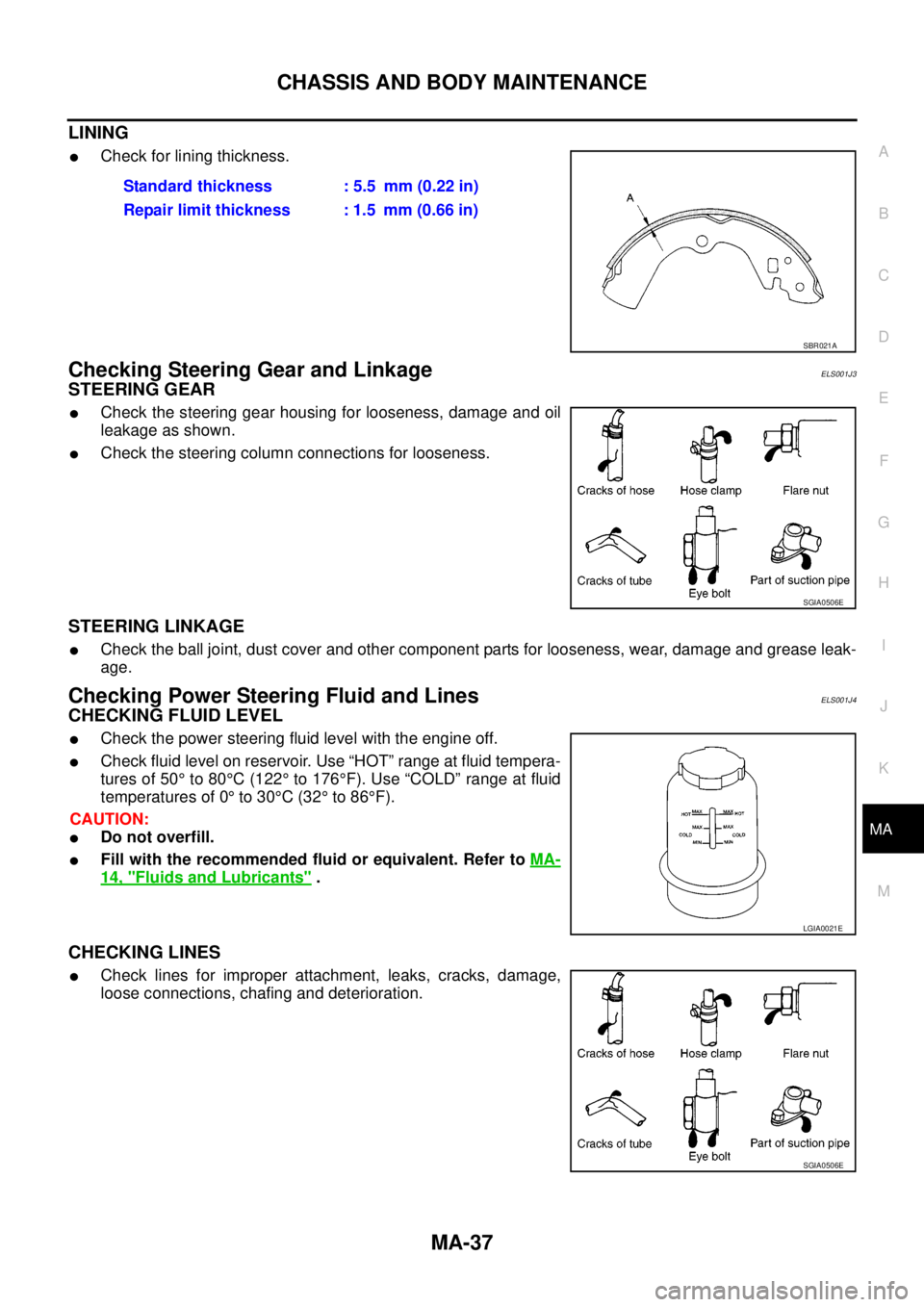

LINING

lCheck for lining thickness.

Checking Steering Gear and LinkageELS001J3

STEERING GEAR

lCheck the steering gear housing for looseness, damage and oil

leakage as shown.

lCheck the steering column connections for looseness.

STEERING LINKAGE

lCheck the ball joint, dust cover and other component parts for looseness, wear, damage and grease leak-

age.

Checking Power Steering Fluid and LinesELS001J4

CHECKING FLUID LEVEL

lCheck the power steering fluid level with the engine off.

lCheck fluid level on reservoir. Use “HOT” range at fluid tempera-

tures of 50°to 80°C(122°to 176°F). Use “COLD” range at fluid

temperatures of 0°to 30°C(32°to 86°F).

CAUTION:

lDo not overfill.

lFill with the recommended fluid or equivalent. Refer toMA-

14, "Fluids and Lubricants".

CHECKING LINES

lCheck lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.Standard thickness : 5.5 mm (0.22 in)

Repair limit thickness : 1.5 mm (0.66 in)

SBR021A

SGIA0506E

LGIA0021E

SGIA0506E

Page 2313 of 3171

MA-38

CHASSIS AND BODY MAINTENANCE

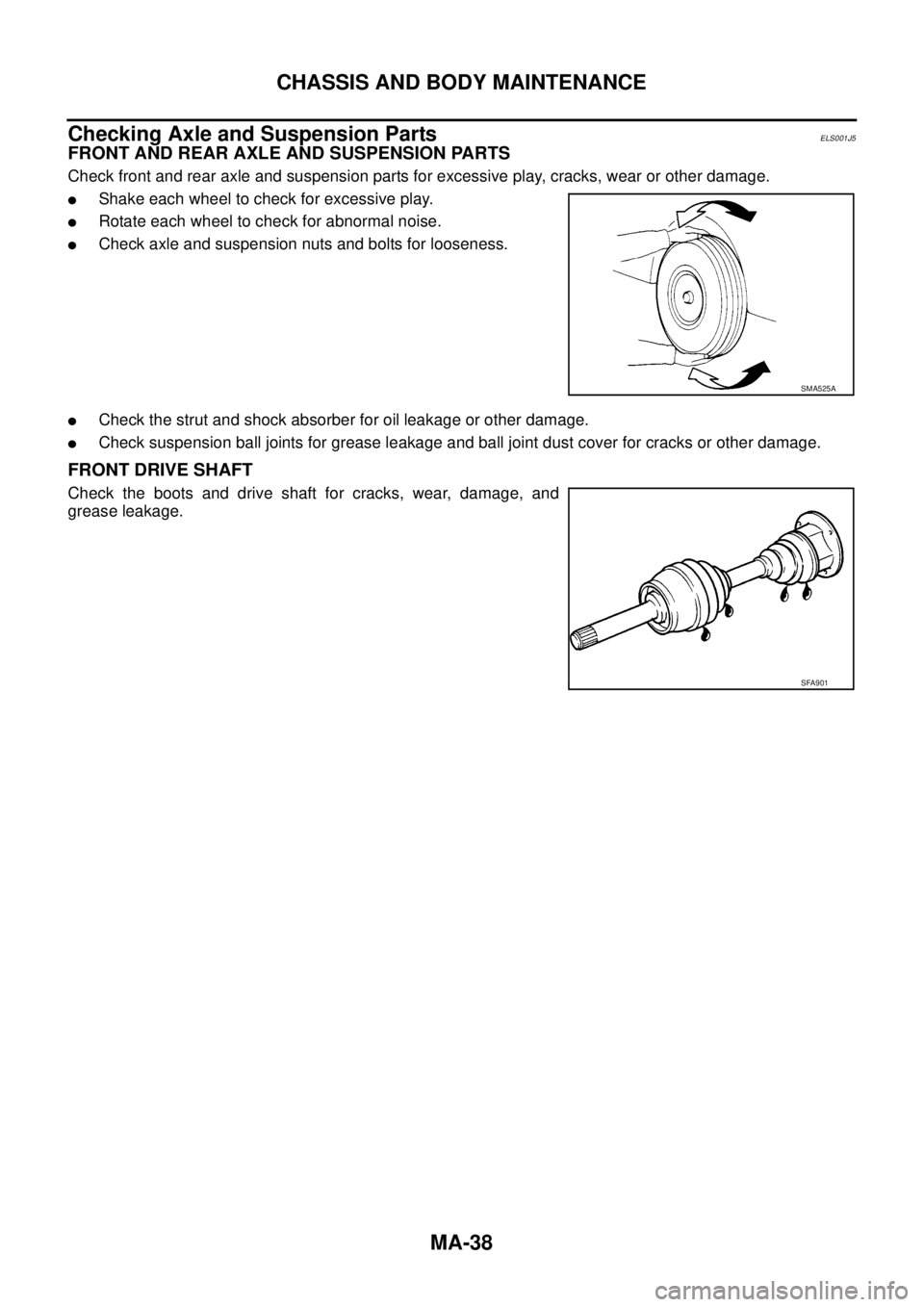

Checking Axle and Suspension Parts

ELS001J5

FRONT AND REAR AXLE AND SUSPENSION PARTS

Check front and rear axle and suspension parts for excessive play, cracks, wear or other damage.

lShake each wheel to check for excessive play.

lRotate each wheel to check for abnormal noise.

lCheck axle and suspension nuts and bolts for looseness.

lCheck the strut and shock absorber for oil leakage or other damage.

lCheck suspension ball joints for grease leakage and ball joint dust cover for cracks or other damage.

FRONT DRIVE SHAFT

Check the boots and drive shaft for cracks, wear, damage, and

grease leakage.

SMA525A

SFA901

Page 2314 of 3171

CHASSIS AND BODY MAINTENANCE

MA-39

C

D

E

F

G

H

I

J

K

MA

B

MA

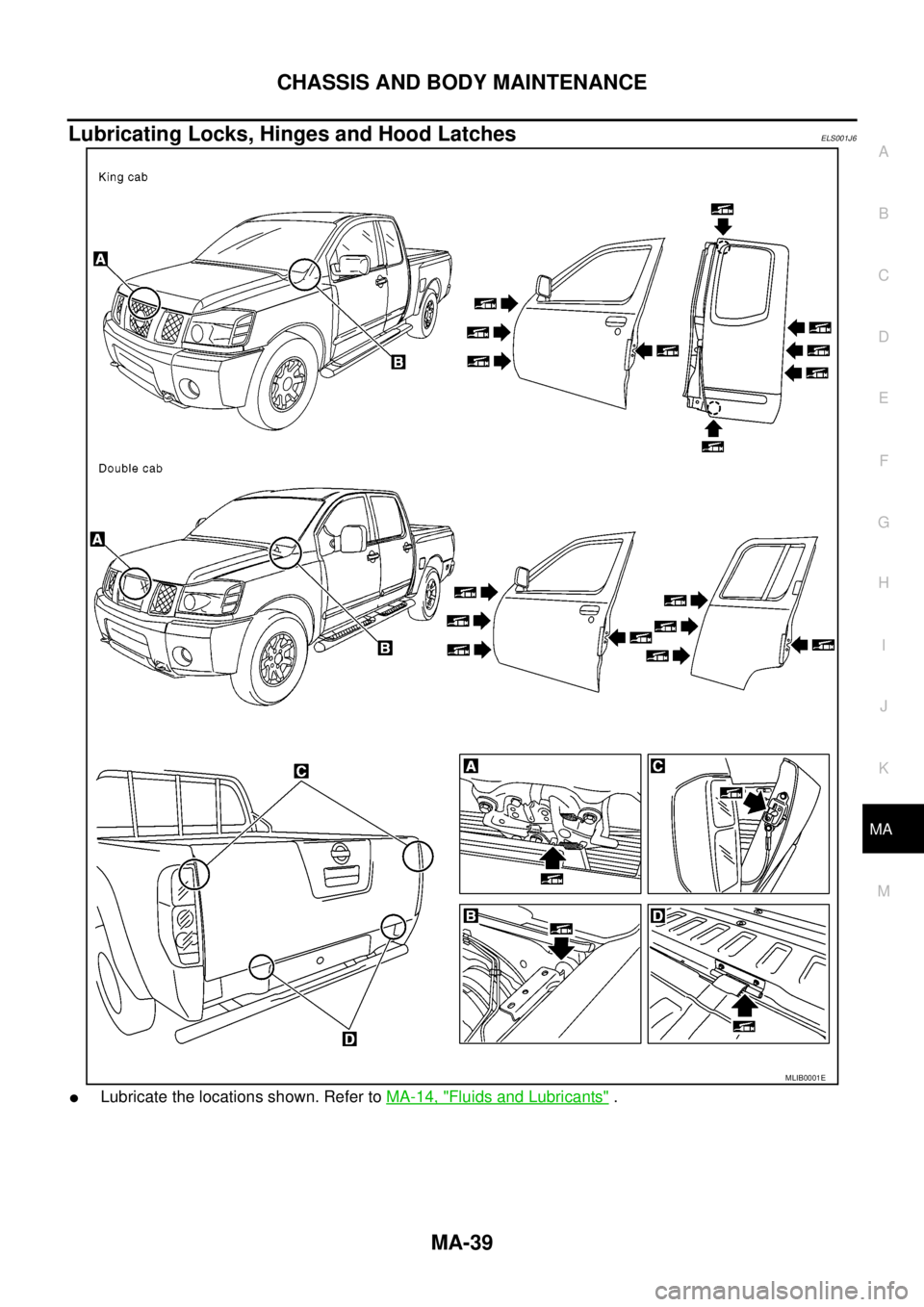

Lubricating Locks, Hinges and Hood LatchesELS001J6

lLubricate the locations shown. Refer toMA-14, "Fluids and Lubricants".

MLIB0001E

Page 2315 of 3171

MA-40

CHASSIS AND BODY MAINTENANCE

Checking Seat Belts, Buckles, Retractors, Anchors and Adjusters

ELS001J7

Check the seat belt buckles, webbing, retractors, anchors and adjusters. Replace any seat belt assembly as

necessary. Refer toSB-11, "

Seat Belt Inspection".

lCheck the seat belt anchors for loose mounting bolts, damage, or excessive wear.

lCheck the seat belt webbing for any damage, cuts, fraying, or excessive wear.

lCheck the retractor for smooth operation.

lCheck the function of the buckles by inserting the seat belt tongue and checking for proper engagement of

the buckle and press the button on the buckle to check for proper release of the seat belt tongue.

CAUTION:

lAfter any collision, inspect all seat belt assemblies, including retractors and other attached com-

ponents, such as the guide rail set. NISSAN recommends replacing all seat belt assemblies in use

during a collision, unless they are not damaged and are inspected to confirm they are operating

properly after a minor collision.

Also inspect all seat belt assemblies that are not in use during a collision, and replace any compo-

nents if damaged or not operating properly. The seat belt pre-tensioner should be replaced even if

the seat belts are not in use during a frontal collision where the driver and passenger air bags

have been deployed.

lIf any component of the seat belt assembly is suspected of being damaged or not operating prop-

erly, do not repair the component. Replace the components as an assembly.

lIf the seat belt webbing is cut, frayed, or damaged then replace the seat belt assembly.

lNever lubricate the seat belt buckle or tongue.

lWhen replacing any seat belt assembly always use a Genuine NISSAN seat belt assembly.

Checking Body CorrosionELS001K3

Visually check body panels for collision damage (scratches, chipping, rubbing, etc.) or damage to the anti-cor-

rosion materials. In particular, check the following locations.

HEMMED PANELS

Hood front end, door lower end, trunk lid rear end, etc.

PANEL JOINT

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine com-

partment, etc.

PANEL EDGE

Trunk lid opening, sunroof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel, etc.

PARTS CONTACT

Waist moulding, windshield moulding, bumper, etc.

PROTECTORS

Damage or condition of mudguard, fender protector, chipping protector, etc.

ANTI-CORROSION MATERIALS

Damage or separation of anti-corrosion materials under the body.

DRAIN HOLES

Condition of drain holes at door and side sill. When repairing corroded areas, refer to the Corrosion Repair

Manual.

Page 2316 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-41

C

D

E

F

G

H

I

J

K

MA

B

MA

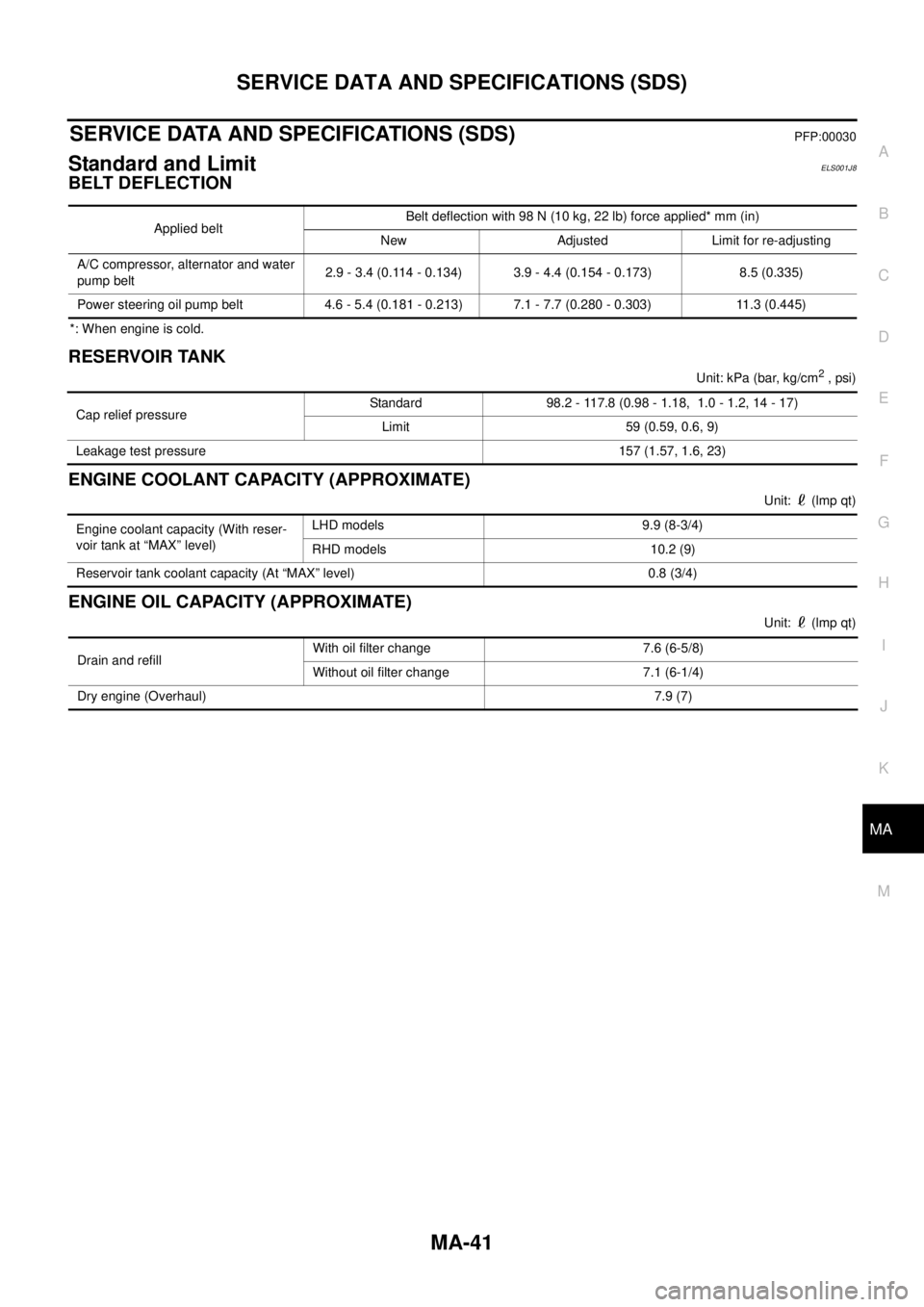

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitELS001J8

BELT DEFLECTION

*: When engine is cold.

RESERVOIR TANK

Unit:kPa(bar,kg/cm2, psi)

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (lmp qt)

ENGINE OIL CAPACITY (APPROXIMATE)

Unit: (lmp qt) Applied beltBelt deflection with 98 N (10 kg, 22 lb) force applied* mm (in)

New Adjusted Limit for re-adjusting

A/C compressor, alternator and water

pump belt2.9 - 3.4 (0.114 - 0.134) 3.9 - 4.4 (0.154 - 0.173) 8.5 (0.335)

Power steering oil pump belt 4.6 - 5.4 (0.181 - 0.213) 7.1 - 7.7 (0.280 - 0.303) 11.3 (0.445)

Cap relief pressureStandard 98.2 - 117.8 (0.98 - 1.18, 1.0 - 1.2, 14 - 17)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Engine coolant capacity (With reser-

voir tank at “MAX” level)LHD models 9.9 (8-3/4)

RHD models 10.2 (9)

Reservoir tank coolant capacity (At “MAX” level) 0.8 (3/4)

Drain and refillWith oil filter change 7.6 (6-5/8)

Without oil filter change 7.1 (6-1/4)

Dry engine (Overhaul)7.9 (7)

Page 2317 of 3171

MA-42

SERVICE DATA AND SPECIFICATIONS (SDS)

Page 2318 of 3171

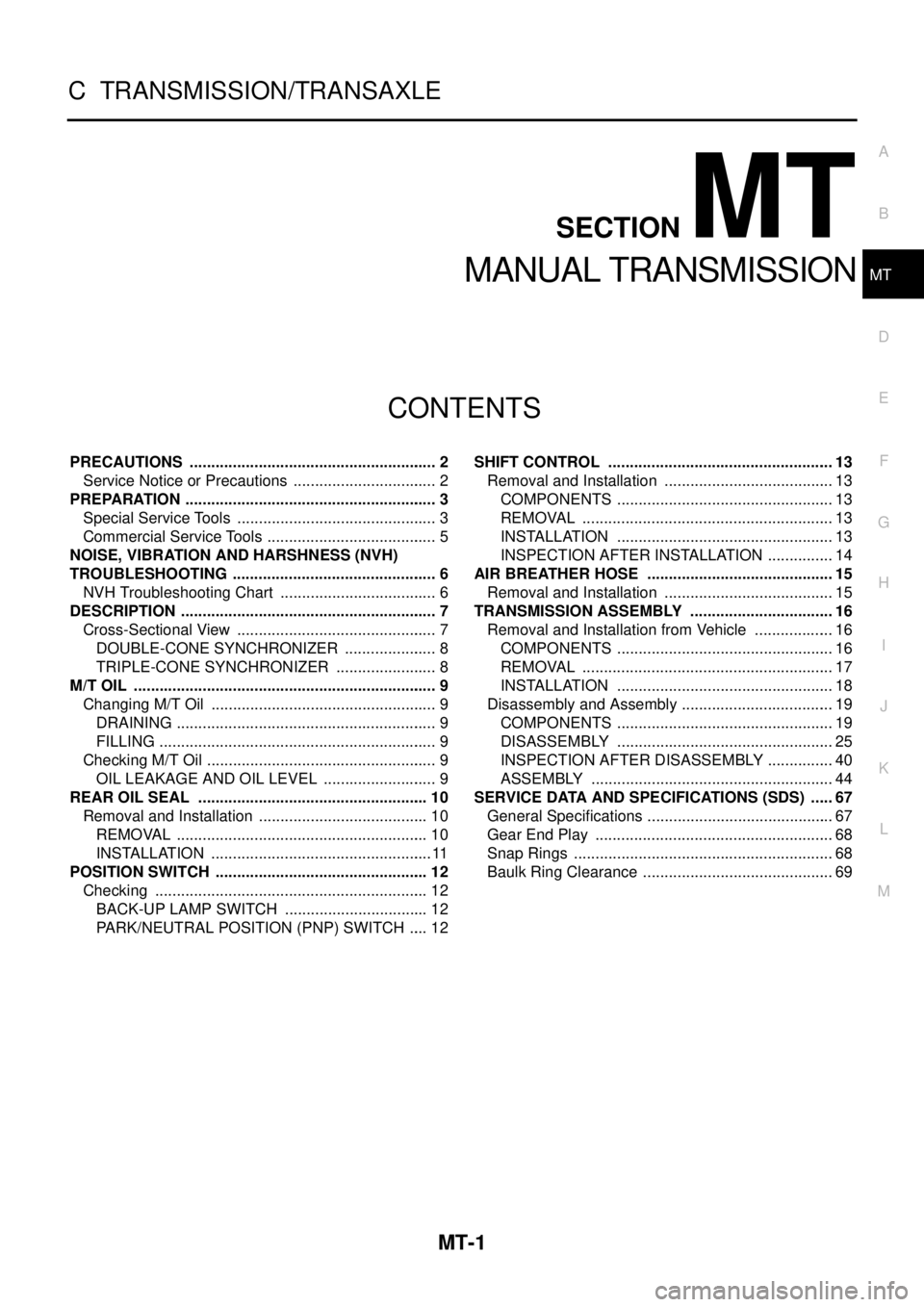

MT-1

MANUAL TRANSMISSION

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTIONMT

A

B

MT

MANUAL TRANSMISSION

PRECAUTIONS .......................................................... 2

Service Notice or Precautions .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 5

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 6

NVH Troubleshooting Chart ..................................... 6

DESCRIPTION ............................................................ 7

Cross-Sectional View ............................................... 7

DOUBLE-CONE SYNCHRONIZER ...................... 8

TRIPLE-CONE SYNCHRONIZER ........................ 8

M/T OIL ....................................................................... 9

Changing M/T Oil ..................................................... 9

DRAINING ............................................................. 9

FILLING ................................................................. 9

Checking M/T Oil ...................................................... 9

OIL LEAKAGE AND OIL LEVEL ........................... 9

REAR OIL SEAL ...................................................... 10

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION .................................................... 11

POSITION SWITCH .................................................. 12

Checking ................................................................ 12

BACK-UP LAMP SWITCH .................................. 12

PARK/NEUTRAL POSITION (PNP) SWITCH ..... 12SHIFT CONTROL ..................................................... 13

Removal and Installation ........................................ 13

COMPONENTS ................................................... 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13

INSPECTION AFTER INSTALLATION ................ 14

AIR BREATHER HOSE ............................................ 15

Removal and Installation ........................................ 15

TRANSMISSION ASSEMBLY .................................. 16

Removal and Installation from Vehicle ................... 16

COMPONENTS ................................................... 16

REMOVAL ........................................................... 17

INSTALLATION ................................................... 18

Disassembly and Assembly .................................... 19

COMPONENTS ................................................... 19

DISASSEMBLY ................................................... 25

INSPECTION AFTER DISASSEMBLY ................ 40

ASSEMBLY ......................................................... 44

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 67

General Specifications ............................................ 67

Gear End Play ........................................................ 68

Snap Rings ............................................................. 68

Baulk Ring Clearance ............................................. 69

Page 2319 of 3171

MT-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

ServiceNoticeorPrecautionsECS00ICY

lDo not reuse transmission oil, once it has been drained.

lCheck oil level or replace oil with vehicle on level surface.

lDuring removal or installation, keep inside of transmission clear of dust or dirt.

lCheck for the correct installation status prior to removal or disassembly. If matching mark are required, be

certain they do not interfere with the function of the parts they are applied.

lIn principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, use it.

lBe careful not to damage sliding surfaces and mating surfaces.

Page 2320 of 3171

PREPARATION

MT-3

D

E

F

G

H

I

J

K

L

MA

B

MT

PREPARATIONPFP:00002

Special Service ToolsECS00ICZ

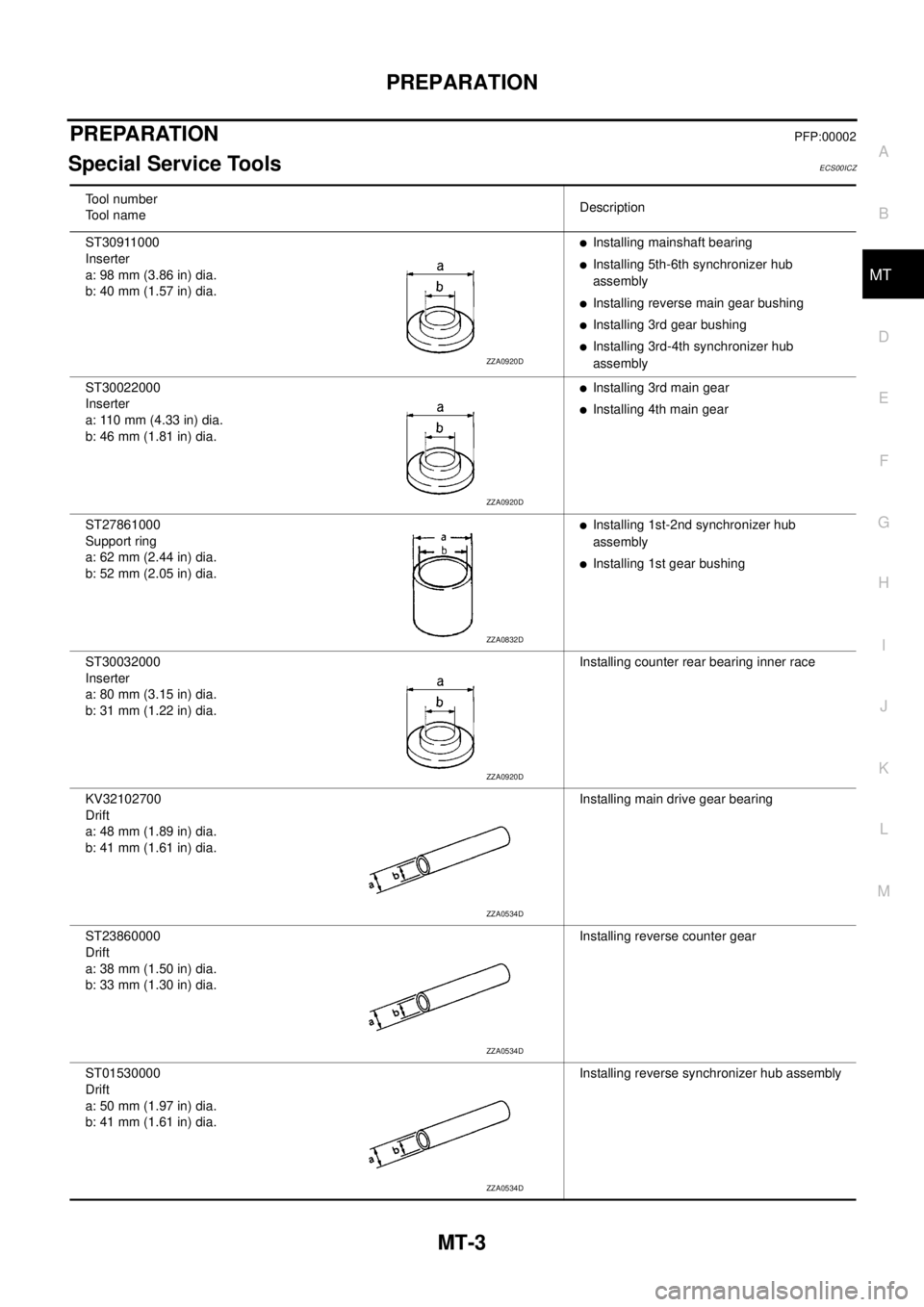

Tool number

Tool nameDescription

ST30911000

Inserter

a: 98 mm (3.86 in) dia.

b: 40 mm (1.57 in) dia.

lInstalling mainshaft bearing

lInstalling 5th-6th synchronizer hub

assembly

lInstalling reverse main gear bushing

lInstalling 3rd gear bushing

lInstalling 3rd-4th synchronizer hub

assembly

ST30022000

Inserter

a: 110 mm (4.33 in) dia.

b: 46 mm (1.81 in) dia.

lInstalling 3rd main gear

lInstalling 4th main gear

ST27861000

Support ring

a: 62 mm (2.44 in) dia.

b: 52 mm (2.05 in) dia.

lInstalling 1st-2nd synchronizer hub

assembly

lInstalling 1st gear bushing

ST30032000

Inserter

a: 80 mm (3.15 in) dia.

b: 31 mm (1.22 in) dia.Installing counter rear bearing inner race

KV32102700

Drift

a: 48 mm (1.89 in) dia.

b: 41 mm (1.61 in) dia.Installing main drive gear bearing

ST23860000

Drift

a: 38 mm (1.50 in) dia.

b: 33 mm (1.30 in) dia.Installing reverse counter gear

ST01530000

Drift

a: 50 mm (1.97 in) dia.

b: 41 mm (1.61 in) dia.Installing reverse synchronizer hub assembly

ZZA0920D

ZZA0920D

ZZA0832D

ZZA0920D

ZZA0534D

ZZA0534D

ZZA0534D