NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2521 of 3171

MTC-134

REFRIGERANT LINES

11. Discharge A/C system using approved refrigerant recovery equipment. Repair the leaking fitting or com-

ponent as necessary.

12. Evacuate and recharge A/C system and perform the leak test to confirm no refrigerant leaks.

13. Perform A/C performance test to ensure system works properly.

Page 2522 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MTC-135

C

D

E

F

G

H

I

K

L

MA

B

MTC

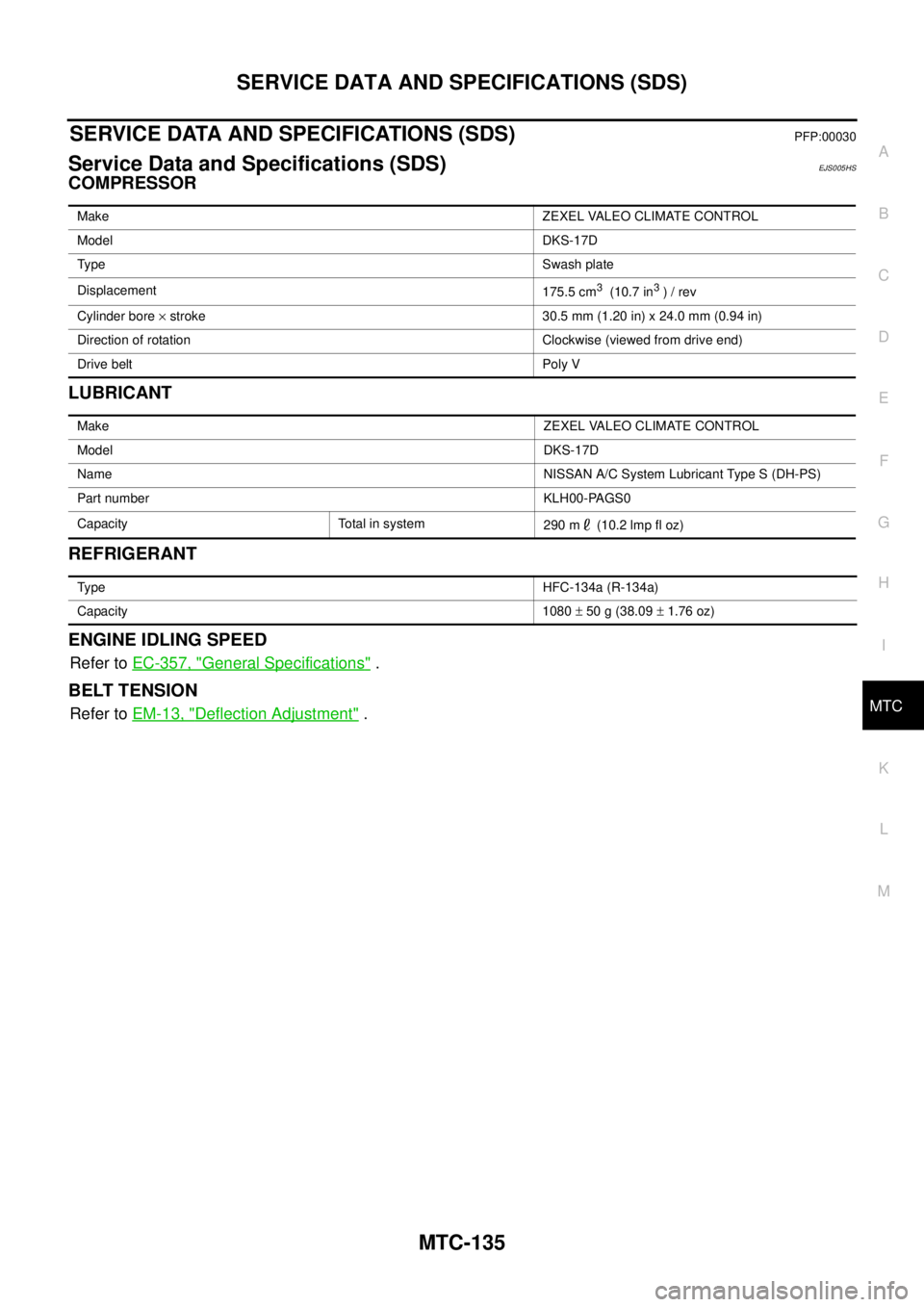

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Service Data and Specifications (SDS)EJS005HS

COMPRESSOR

LUBRICANT

REFRIGERANT

ENGINE IDLING SPEED

Refer toEC-357, "General Specifications".

BELT TENSION

Refer toEM-13, "Deflection Adjustment".

MakeZEXEL VALEO CLIMATE CONTROL

ModelDKS-17D

Ty p eSwash plate

Displacement

175.5 cm

3(10.7 in3)/rev

Cylinder bore´stroke 30.5 mm (1.20 in) x 24.0 mm (0.94 in)

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly V

MakeZEXEL VALEO CLIMATE CONTROL

ModelDKS-17D

NameNISSAN A/C System Lubricant Type S (DH-PS)

Part number KLH00-PAGS0

Capacity Total in system

290m (10.2lmpfloz)

Ty p eHFC-134a (R-134a)

Capacity 1080±50g(38.09±1.76 oz)

Page 2523 of 3171

MTC-136

SERVICE DATA AND SPECIFICATIONS (SDS)

Page 2524 of 3171

PB-1

PARKING BRAKE SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTIONPB

A

B

PB

PARKING BRAKE SYSTEM

PARKING BRAKE CONTROL ................................... 2

On-Vehicle Service ................................................... 2

INSPECTION ........................................................ 2

COMPONENTS INSPECTION ............................. 2

ADJUSTMENT ...................................................... 2Components ............................................................. 3

Removal and Installation .......................................... 4

REMOVAL ............................................................. 4

INSTALLATION ..................................................... 5

SERVICE DATA AND SPECIFICATIONS (SDS) ........ 6

Parking Brake Control .............................................. 6

Page 2525 of 3171

PB-2

PARKING BRAKE CONTROL

PARKING BRAKE CONTROL

PFP:36010

On-Vehicle ServiceEFS006AJ

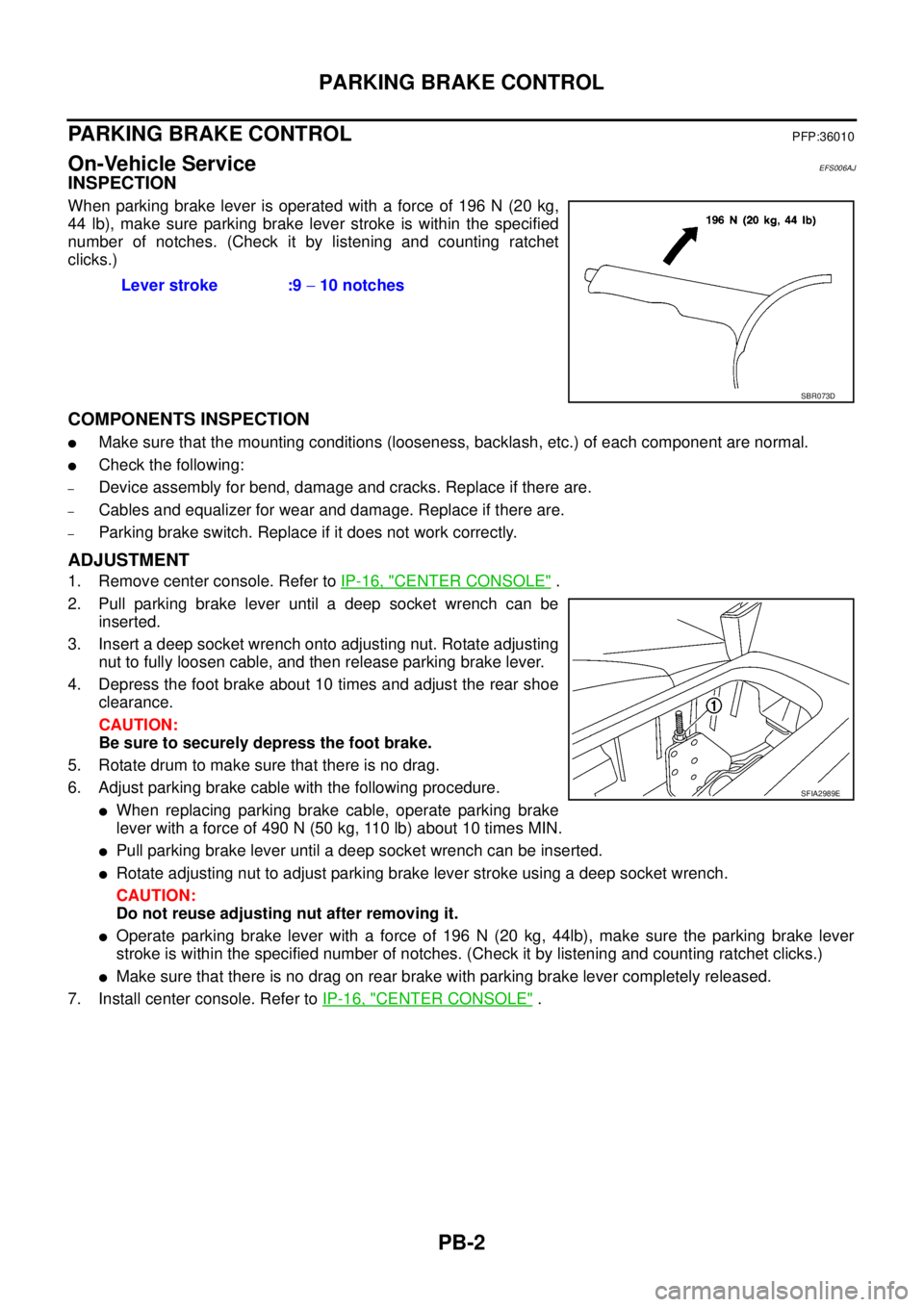

INSPECTION

When parking brake lever is operated with a force of 196 N (20 kg,

44 lb), make sure parking brake lever stroke is within the specified

number of notches. (Check it by listening and counting ratchet

clicks.)

COMPONENTS INSPECTION

lMake sure that the mounting conditions (looseness, backlash, etc.) of each component are normal.

lCheck the following:

–Device assembly for bend, damage and cracks. Replace if there are.

–Cables and equalizer for wear and damage. Replace if there are.

–Parking brake switch. Replace if it does not work correctly.

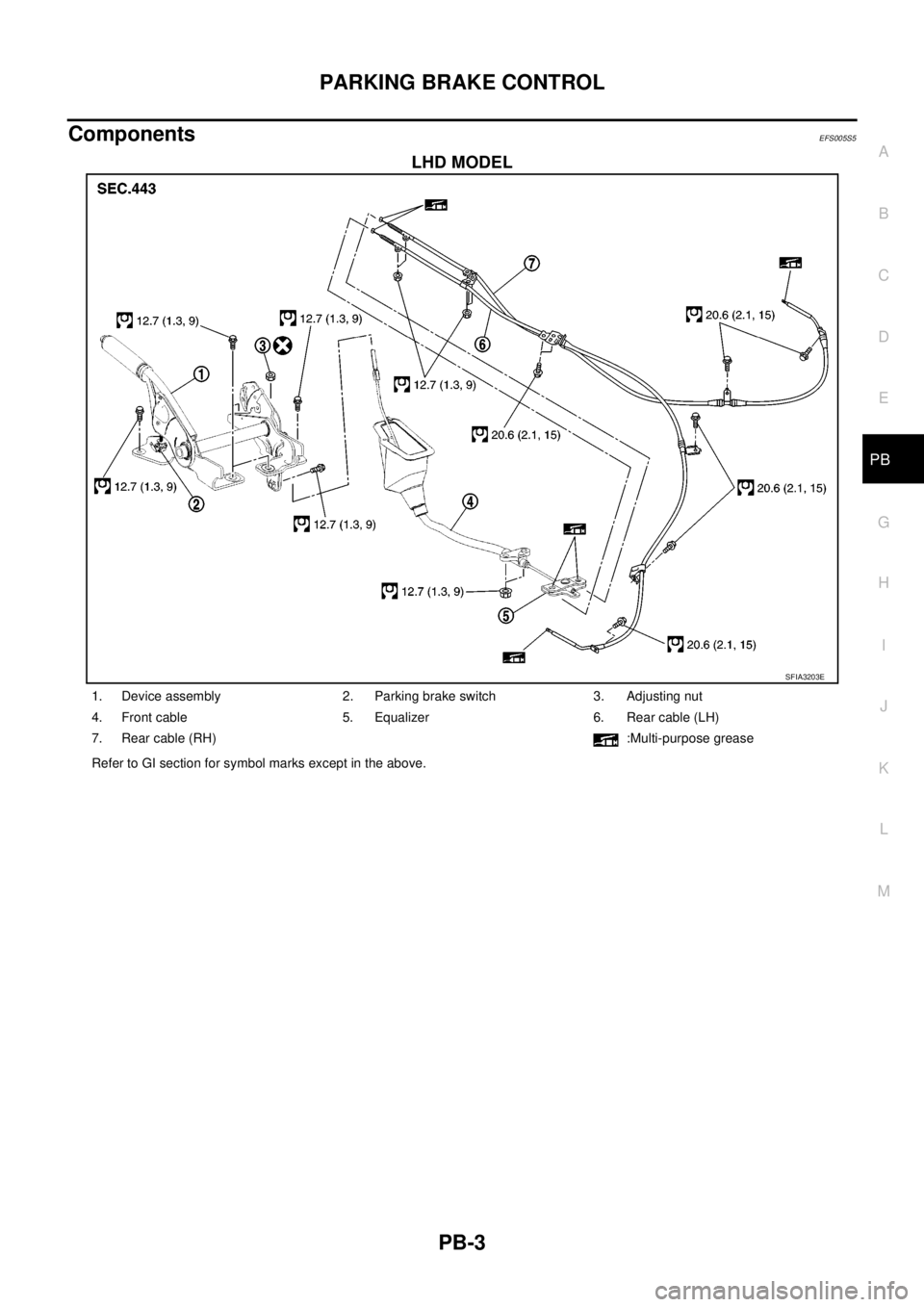

ADJUSTMENT

1. Remove center console. Refer toIP-16, "CENTER CONSOLE".

2. Pull parking brake lever until a deep socket wrench can be

inserted.

3. Insert a deep socket wrench onto adjusting nut. Rotate adjusting

nut to fully loosen cable, and then release parking brake lever.

4. Depress the foot brake about 10 times and adjust the rear shoe

clearance.

CAUTION:

Be sure to securely depress the foot brake.

5. Rotate drum to make sure that there is no drag.

6. Adjust parking brake cable with the following procedure.

lWhen replacing parking brake cable, operate parking brake

leverwithaforceof490N(50kg,110lb)about10timesMIN.

lPull parking brake lever until a deep socket wrench can be inserted.

lRotate adjusting nut to adjust parking brake lever stroke using a deep socket wrench.

CAUTION:

Do not reuse adjusting nut after removing it.

lOperate parking brake lever with a force of 196 N (20 kg, 44lb), make sure the parking brake lever

stroke is within the specified number of notches. (Check it by listening and counting ratchet clicks.)

lMake sure that there is no drag on rear brake with parking brake lever completely released.

7. Install center console. Refer toIP-16, "

CENTER CONSOLE". Lever stroke :9-10 notches

SBR073D

SFIA2989E

Page 2526 of 3171

PARKING BRAKE CONTROL

PB-3

C

D

E

G

H

I

J

K

L

MA

B

PB

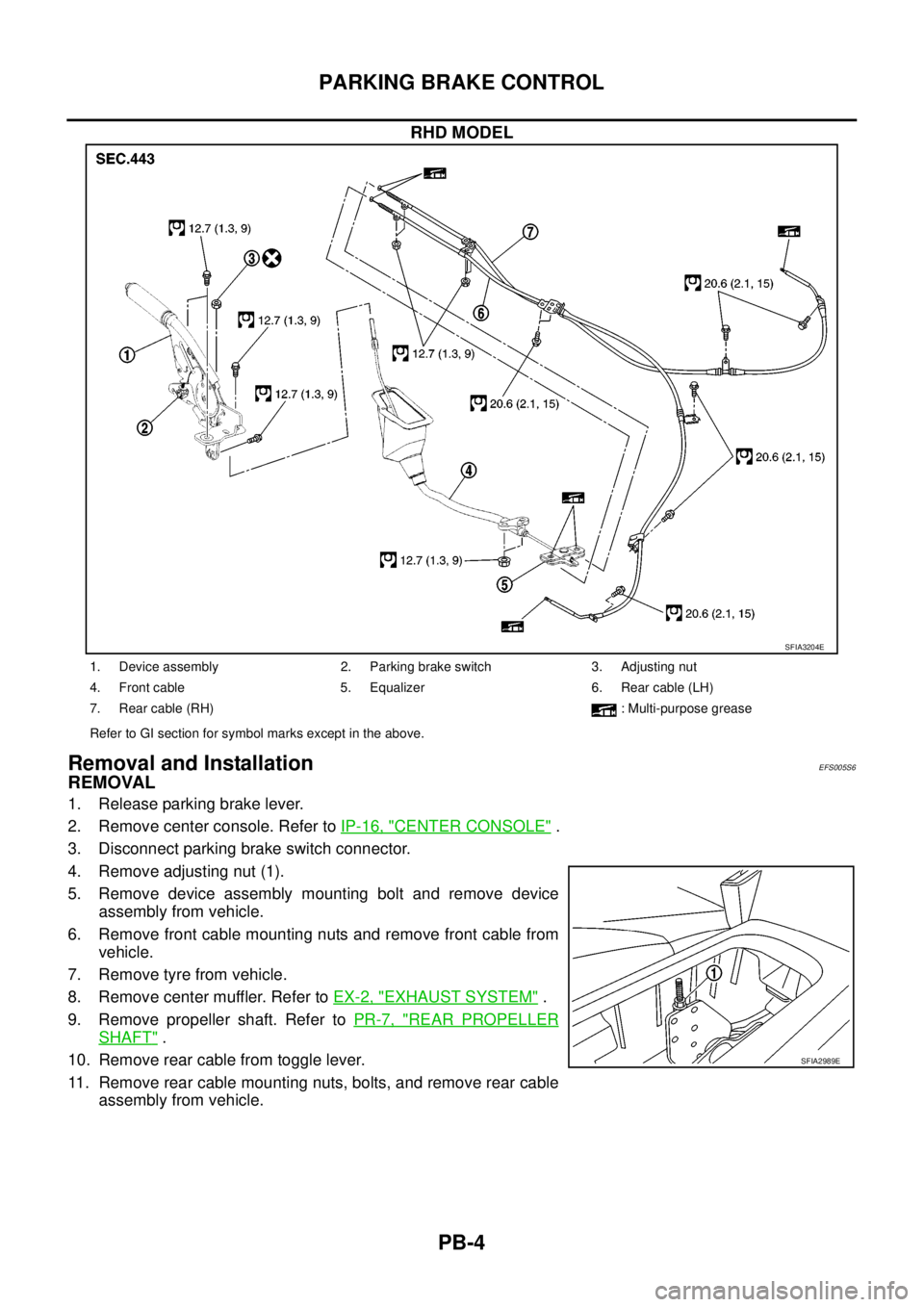

ComponentsEFS005S5

LHD MODEL

SFIA3203E

1. Device assembly 2. Parking brake switch 3. Adjusting nut

4. Front cable 5. Equalizer 6. Rear cable (LH)

7. Rear cable (RH) :Multi-purpose grease

Refer to GI section for symbol marks except in the above.

Page 2527 of 3171

PB-4

PARKING BRAKE CONTROL

RHD MODEL

Removal and InstallationEFS005S6

REMOVAL

1. Release parking brake lever.

2. Remove center console. Refer toIP-16, "

CENTER CONSOLE".

3. Disconnect parking brake switch connector.

4. Remove adjusting nut (1).

5. Remove device assembly mounting bolt and remove device

assembly from vehicle.

6. Remove front cable mounting nuts and remove front cable from

vehicle.

7. Remove tyre from vehicle.

8. Remove center muffler. Refer toEX-2, "

EXHAUST SYSTEM".

9. Remove propeller shaft. Refer toPR-7, "

REAR PROPELLER

SHAFT".

10. Remove rear cable from toggle lever.

11. Remove rear cable mounting nuts, bolts, and remove rear cable

assembly from vehicle.

SFIA3204E

1. Device assembly 2. Parking brake switch 3. Adjusting nut

4. Front cable 5. Equalizer 6. Rear cable (LH)

7. Rear cable (RH) : Multi-purpose grease

Refer to GI section for symbol marks except in the above.

SFIA2989E

Page 2528 of 3171

PARKING BRAKE CONTROL

PB-5

C

D

E

G

H

I

J

K

L

MA

B

PB

INSTALLATION

1. Installation is in the reverse order of the removal. Refer toPB-3, "Components"for tightening torque.

2. Adjust parking brake. Refer toPB-2, "

ADJUSTMENT".

Page 2529 of 3171

PB-6

SERVICE DATA AND SPECIFICATIONS (SDS)

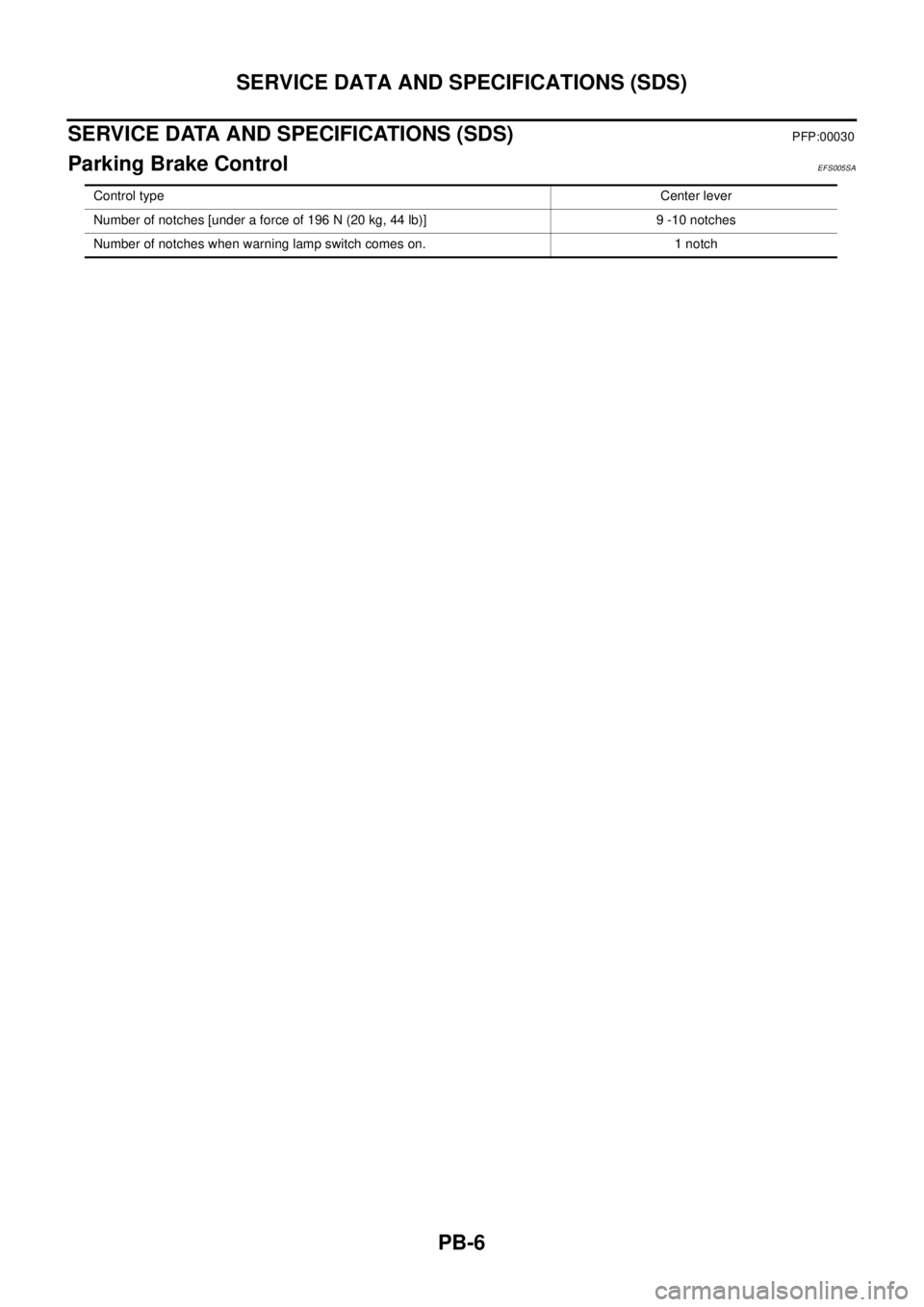

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Parking Brake ControlEFS005SA

Control typeCenter lever

Number of notches [under a force of 196 N (20 kg, 44 lb)] 9 -10 notches

Number of notches when warning lamp switch comes on. 1 notch

Page 2530 of 3171

PG-1

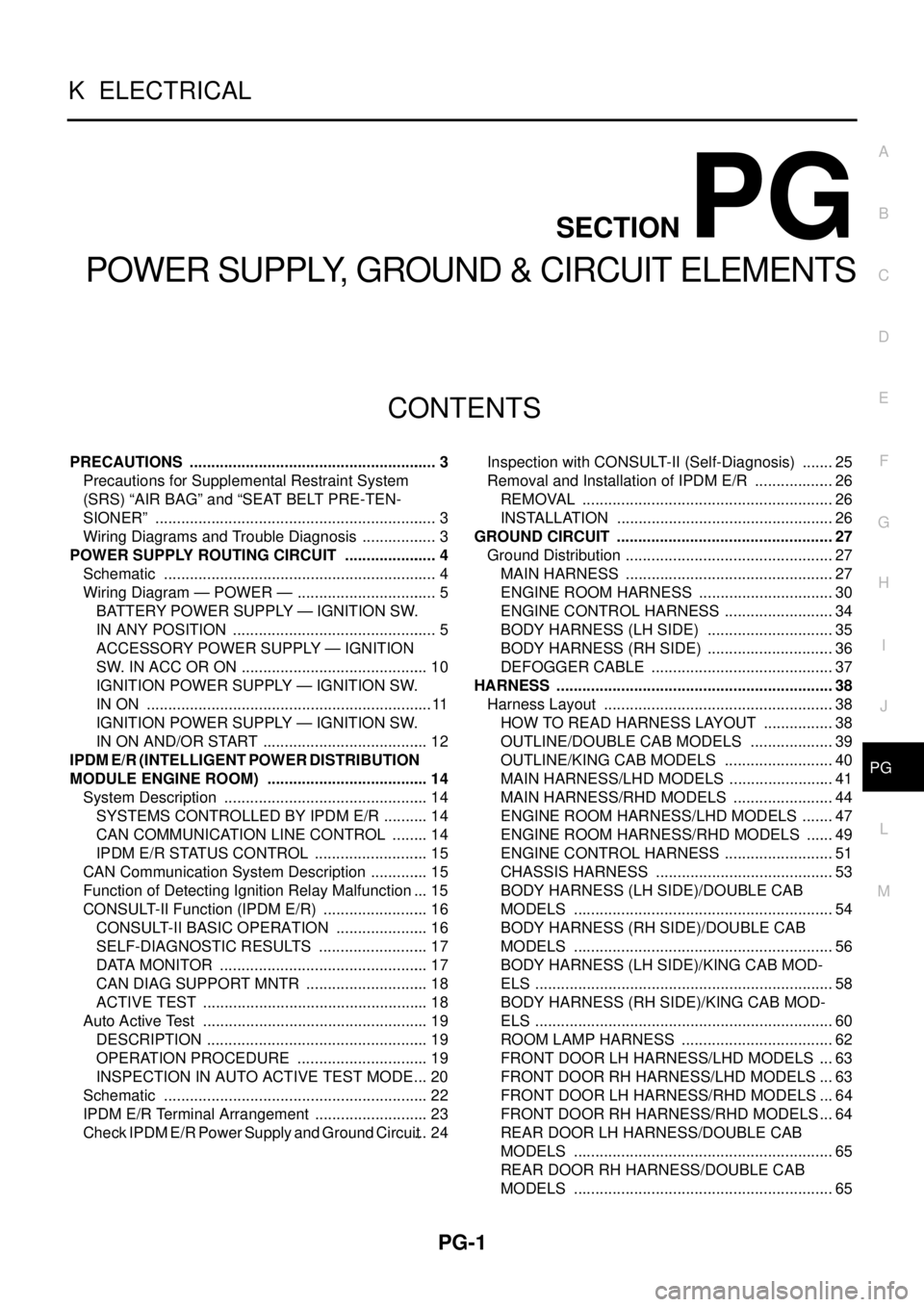

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONPG

A

B

PG

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

POWER SUPPLY ROUTING CIRCUIT ...................... 4

Schematic ................................................................ 4

Wiring Diagram — POWER — ................................. 5

BATTERY POWER SUPPLY — IGNITION SW.

IN ANY POSITION ................................................ 5

ACCESSORY POWER SUPPLY — IGNITION

SW. IN ACC OR ON ............................................ 10

IGNITION POWER SUPPLY — IGNITION SW.

IN ON ................................................................... 11

IGNITION POWER SUPPLY — IGNITION SW.

IN ON AND/OR START ....................................... 12

IPDM E/R (INTELLIGENT POWER DISTRIBUTION

MODULE ENGINE ROOM) ...................................... 14

System Description ................................................ 14

SYSTEMS CONTROLLED BY IPDM E/R ........... 14

CAN COMMUNICATION LINE CONTROL ......... 14

IPDM E/R STATUS CONTROL ........................... 15

CAN Communication System Description .............. 15

Function of Detecting Ignition Relay Malfunction ... 15

CONSULT-II Function (IPDM E/R) ......................... 16

CONSULT-II BASIC OPERATION ...................... 16

SELF-DIAGNOSTIC RESULTS .......................... 17

DATA MONITOR ................................................. 17

CAN DIAG SUPPORT MNTR ............................. 18

ACTIVE TEST ..................................................... 18

Auto Active Test ..................................................... 19

DESCRIPTION .................................................... 19

OPERATION PROCEDURE ............................... 19

INSPECTION IN AUTO ACTIVE TEST MODE... 20

Schematic .............................................................. 22

IPDM E/R Terminal Arrangement ........................... 23

Check IPDM E/R Power Supply and Ground Circuit... 24Inspection with CONSULT-II (Self-Diagnosis) ........ 25

Removal and Installation of IPDM E/R ................... 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 26

GROUND CIRCUIT ................................................... 27

Ground Distribution ................................................. 27

MAIN HARNESS ................................................. 27

ENGINE ROOM HARNESS ................................ 30

ENGINE CONTROL HARNESS .......................... 34

BODY HARNESS (LH SIDE) .............................. 35

BODY HARNESS (RH SIDE) .............................. 36

DEFOGGER CABLE ........................................... 37

HARNESS ................................................................. 38

Harness Layout ...................................................... 38

HOW TO READ HARNESS LAYOUT ................. 38

OUTLINE/DOUBLE CAB MODELS .................... 39

OUTLINE/KING CAB MODELS .......................... 40

MAIN HARNESS/LHD MODELS ......................... 41

MAIN HARNESS/RHD MODELS ........................ 44

ENGINE ROOM HARNESS/LHD MODELS ........ 47

ENGINE ROOM HARNESS/RHD MODELS ....... 49

ENGINE CONTROL HARNESS .......................... 51

CHASSIS HARNESS .......................................... 53

BODY HARNESS (LH SIDE)/DOUBLE CAB

MODELS ............................................................. 54

BODY HARNESS (RH SIDE)/DOUBLE CAB

MODELS ............................................................. 56

BODY HARNESS (LH SIDE)/KING CAB MOD-

ELS ...................................................................... 58

BODY HARNESS (RH SIDE)/KING CAB MOD-

ELS ...................................................................... 60

ROOM LAMP HARNESS .................................... 62

FRONT DOOR LH HARNESS/LHD MODELS .... 63

FRONT DOOR RH HARNESS/LHD MODELS ... 63

FRONT DOOR LH HARNESS/RHD MODELS ... 64

FRONT DOOR RH HARNESS/RHD MODELS ... 64

REAR DOOR LH HARNESS/DOUBLE CAB

MODELS ............................................................. 65

REAR DOOR RH HARNESS/DOUBLE CAB

MODELS ............................................................. 65