NISSAN NAVARA 2005 Repair Workshop Manual

NAVARA 2005

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57362/w960_57362-0.png

NISSAN NAVARA 2005 Repair Workshop Manual

Trending: oil capacity, service interval, recommended oil, jacking points, Coolant leak, Em-49, EI-15

Page 2611 of 3171

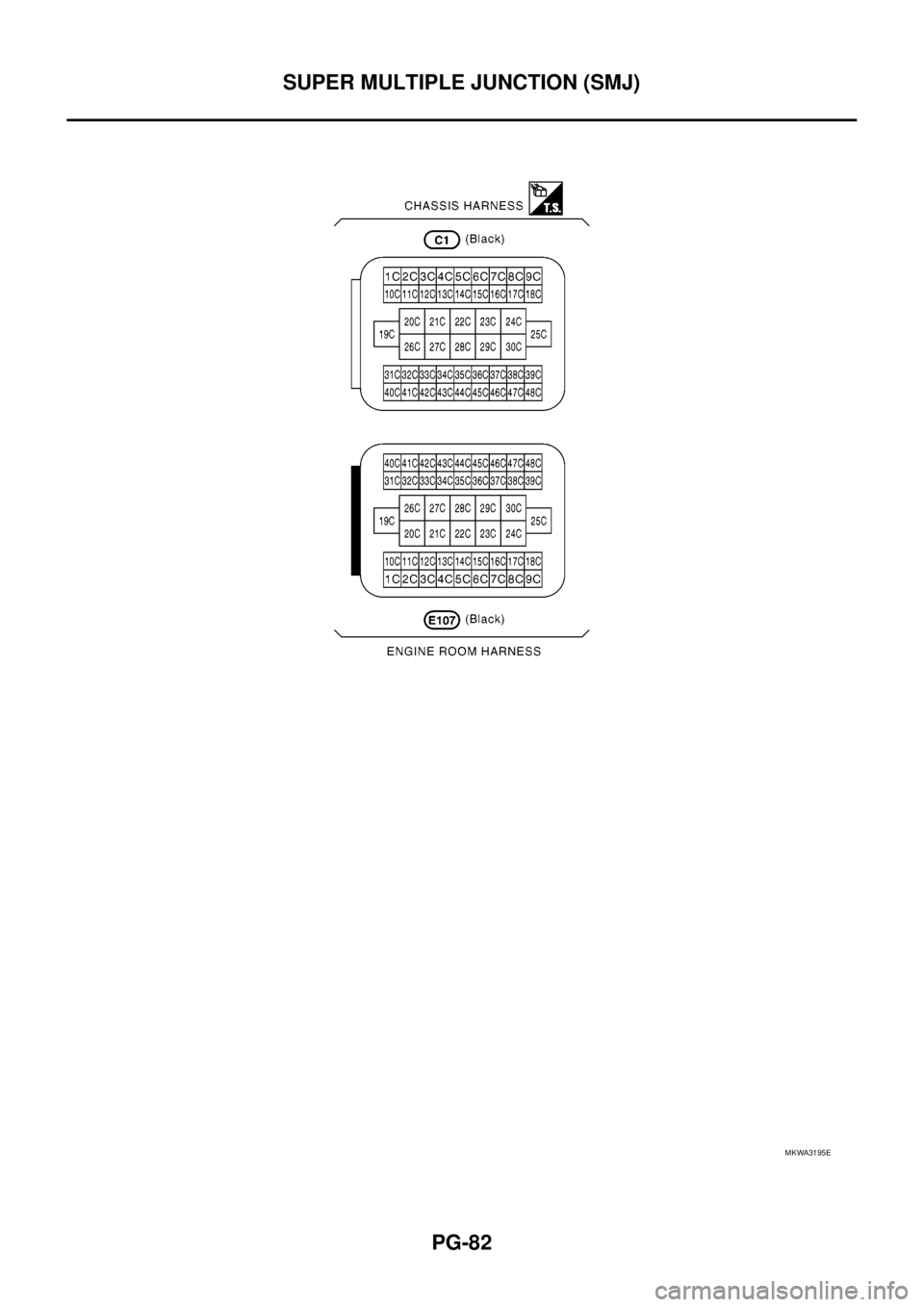

PG-82

SUPER MULTIPLE JUNCTION (SMJ)

MKWA3195E

Page 2612 of 3171

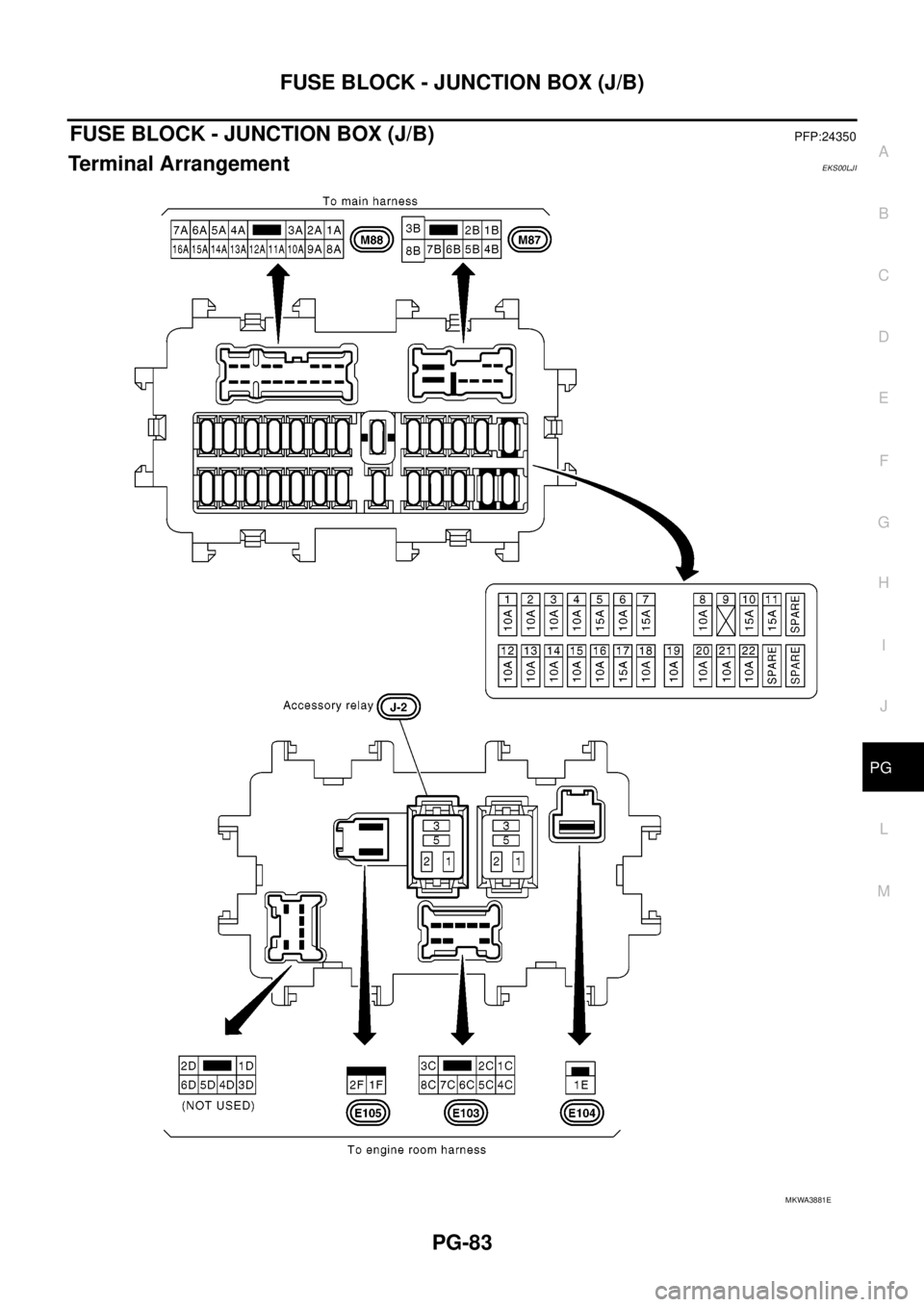

FUSE BLOCK - JUNCTION BOX (J/B)

PG-83

C

D

E

F

G

H

I

J

L

MA

B

PG

FUSE BLOCK - JUNCTION BOX (J/B)PFP:24350

Terminal ArrangementEKS00LJI

MKWA3881E

Page 2613 of 3171

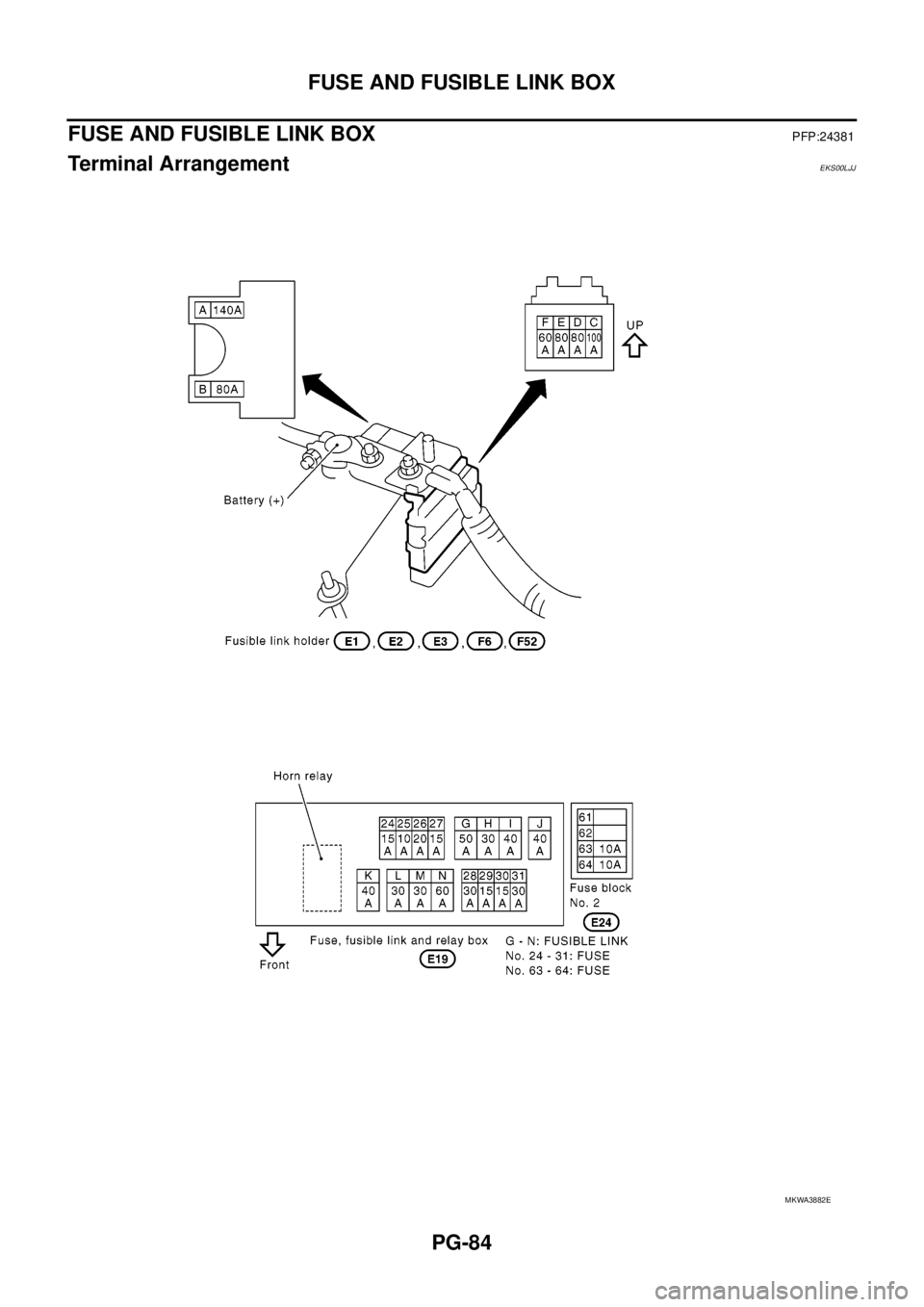

PG-84

FUSE AND FUSIBLE LINK BOX

FUSE AND FUSIBLE LINK BOX

PFP:24381

Terminal ArrangementEKS00LJJ

MKWA3882E

Page 2614 of 3171

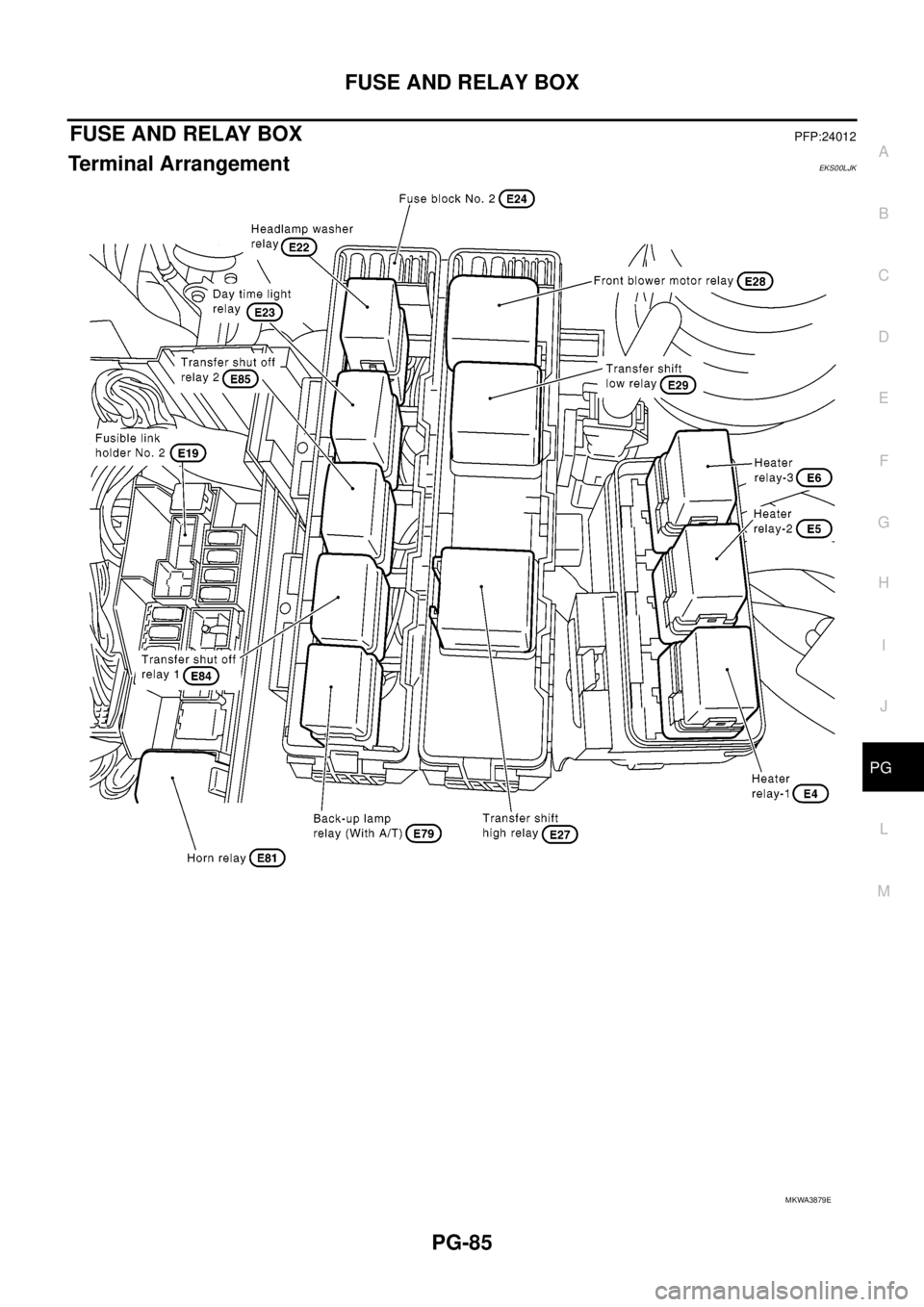

FUSE AND RELAY BOX

PG-85

C

D

E

F

G

H

I

J

L

MA

B

PG

FUSE AND RELAY BOXPFP:24012

Terminal ArrangementEKS00LJK

MKWA3879E

Page 2615 of 3171

Page 2616 of 3171

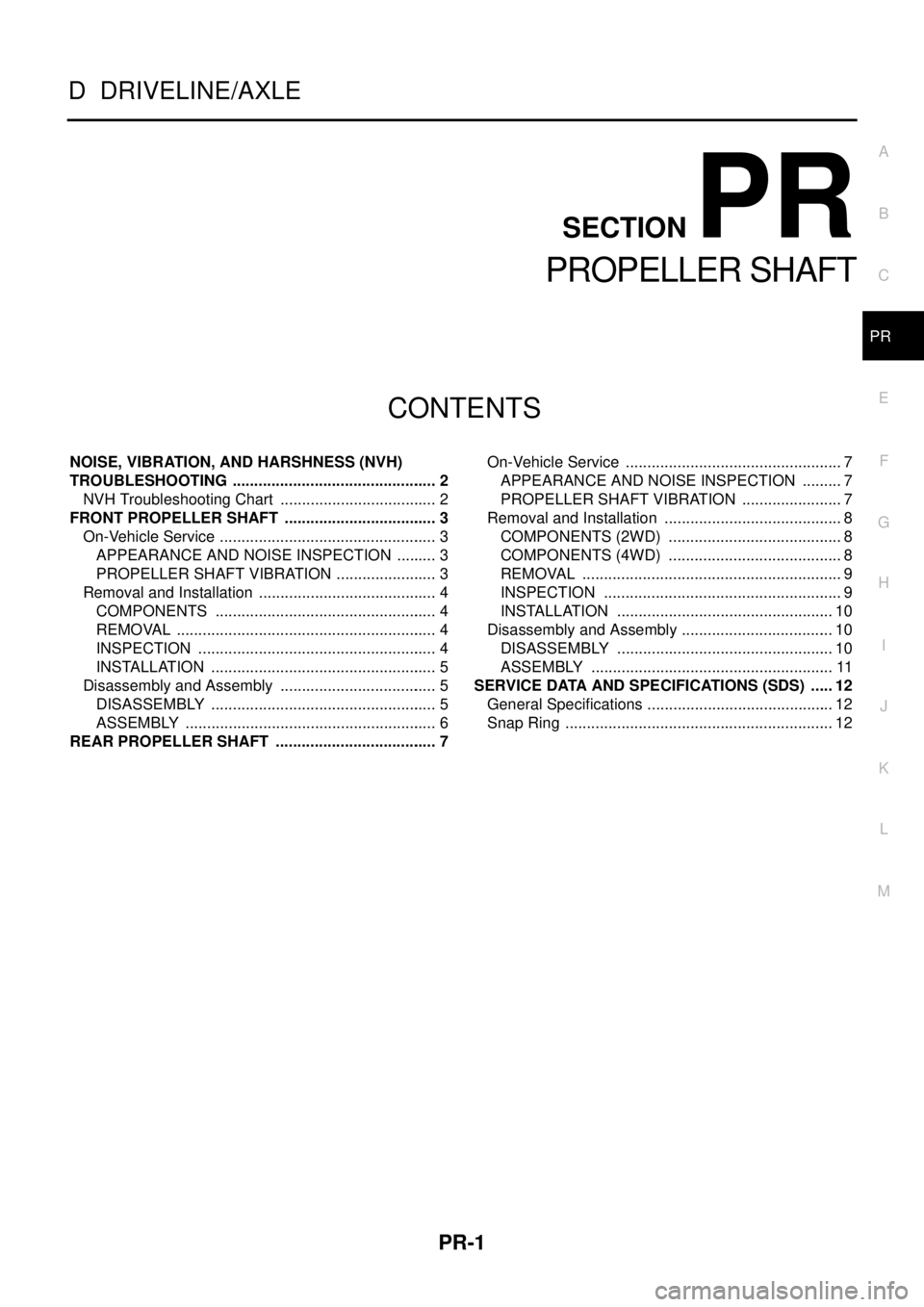

PR-1

PROPELLER SHAFT

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONPR

A

B

PR

PROPELLER SHAFT

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 2

NVH Troubleshooting Chart ..................................... 2

FRONT PROPELLER SHAFT .................................... 3

On-Vehicle Service ................................................... 3

APPEARANCE AND NOISE INSPECTION .......... 3

PROPELLER SHAFT VIBRATION ........................ 3

Removal and Installation .......................................... 4

COMPONENTS .................................................... 4

REMOVAL ............................................................. 4

INSPECTION ........................................................ 4

INSTALLATION ..................................................... 5

Disassembly and Assembly ..................................... 5

DISASSEMBLY ..................................................... 5

ASSEMBLY ........................................................... 6

REAR PROPELLER SHAFT ...................................... 7On-Vehicle Service ................................................... 7

APPEARANCE AND NOISE INSPECTION .......... 7

PROPELLER SHAFT VIBRATION ........................ 7

Removal and Installation .......................................... 8

COMPONENTS (2WD) ......................................... 8

COMPONENTS (4WD) ......................................... 8

REMOVAL ............................................................. 9

INSPECTION ........................................................ 9

INSTALLATION ................................................... 10

Disassembly and Assembly .................................... 10

DISASSEMBLY ................................................... 10

ASSEMBLY ......................................................... 11

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 12

General Specifications ............................................ 12

Snap Ring ............................................................... 12

Page 2617 of 3171

PR-2

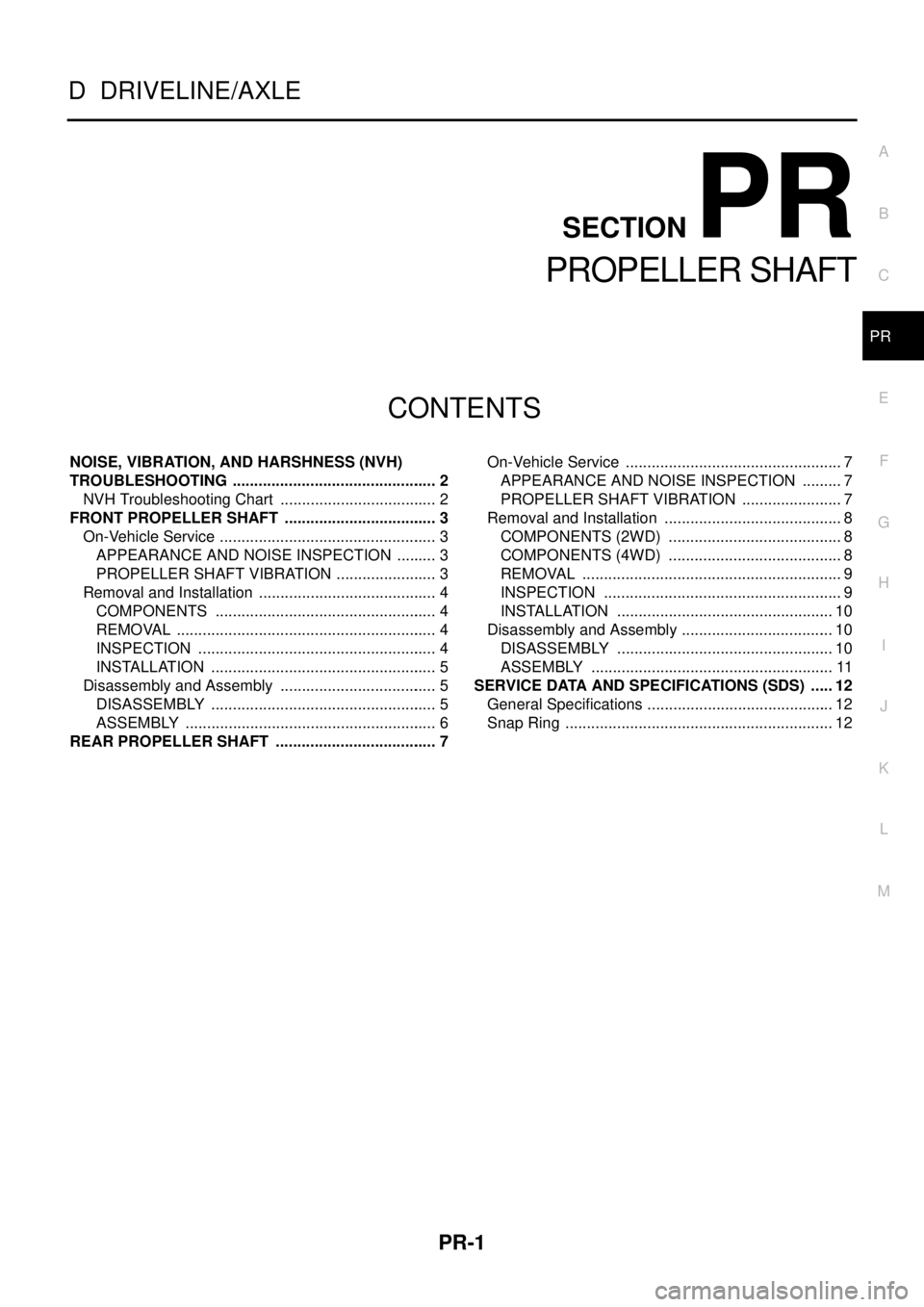

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

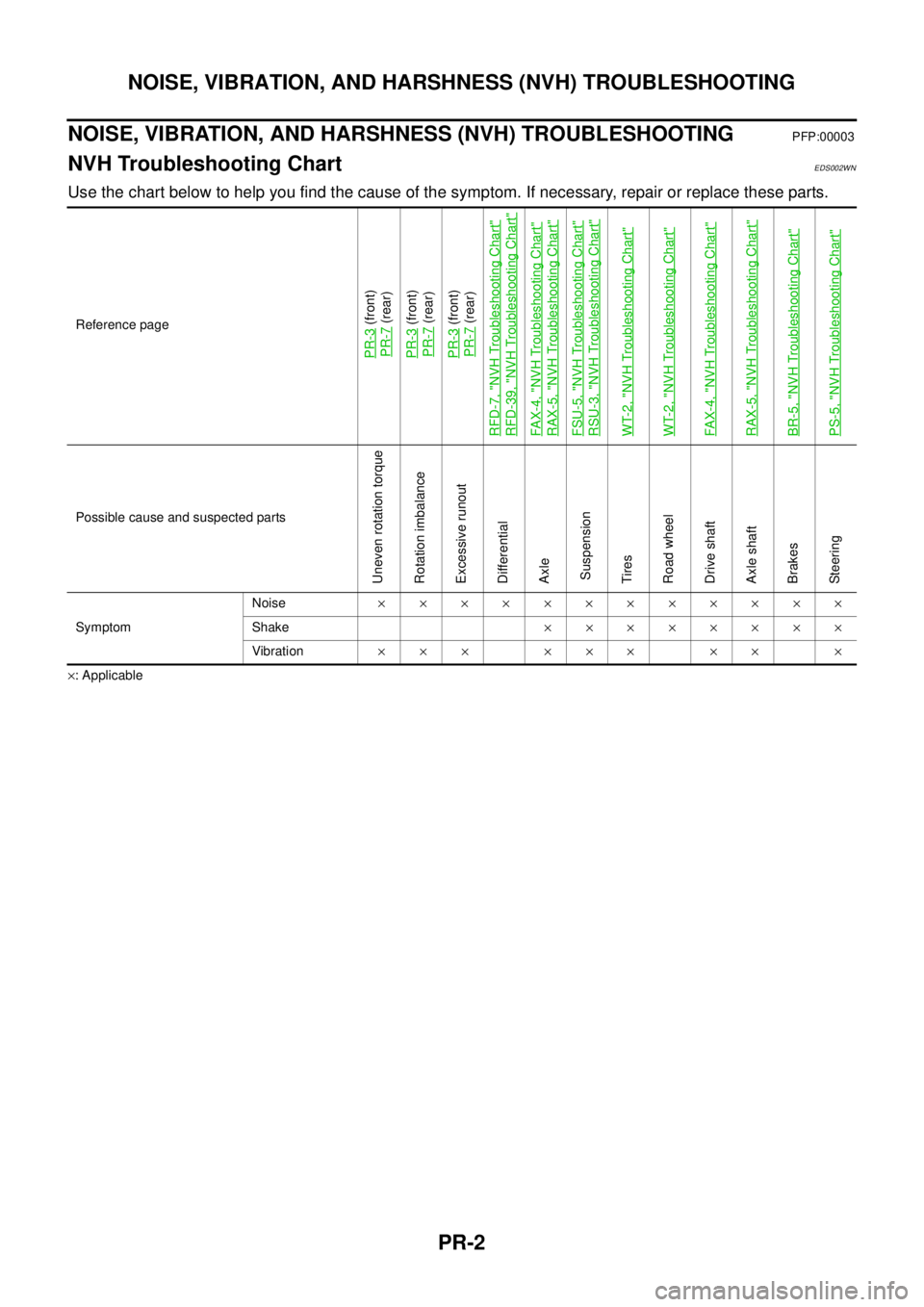

NVH Troubleshooting ChartEDS002WN

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

PR-3

(front)

PR-7(rear)

PR-3(front)

PR-7(rear)

PR-3(front)

PR-7(rear)

RFD-7, "

NVH Troubleshooting Chart

"

RFD-39, "

NVH Troubleshooting Chart

"

FA X -4 , "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

FSU-5, "

NVH Troubleshooting Chart

"

RSU-3, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

FA X -4 , "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and suspected parts

Uneven rotation torque

Rotation imbalance

Excessive runout

Differential

Axle

Suspension

Tires

Road wheel

Drive shaft

Axle shaft

Brakes

Steering

SymptomNoise´´´´´´´´´´´´

Shake´´´´´´´´

Vibration´´´ ´´´ ´´ ´

Page 2618 of 3171

FRONT PROPELLER SHAFT

PR-3

C

E

F

G

H

I

J

K

L

MA

B

PR

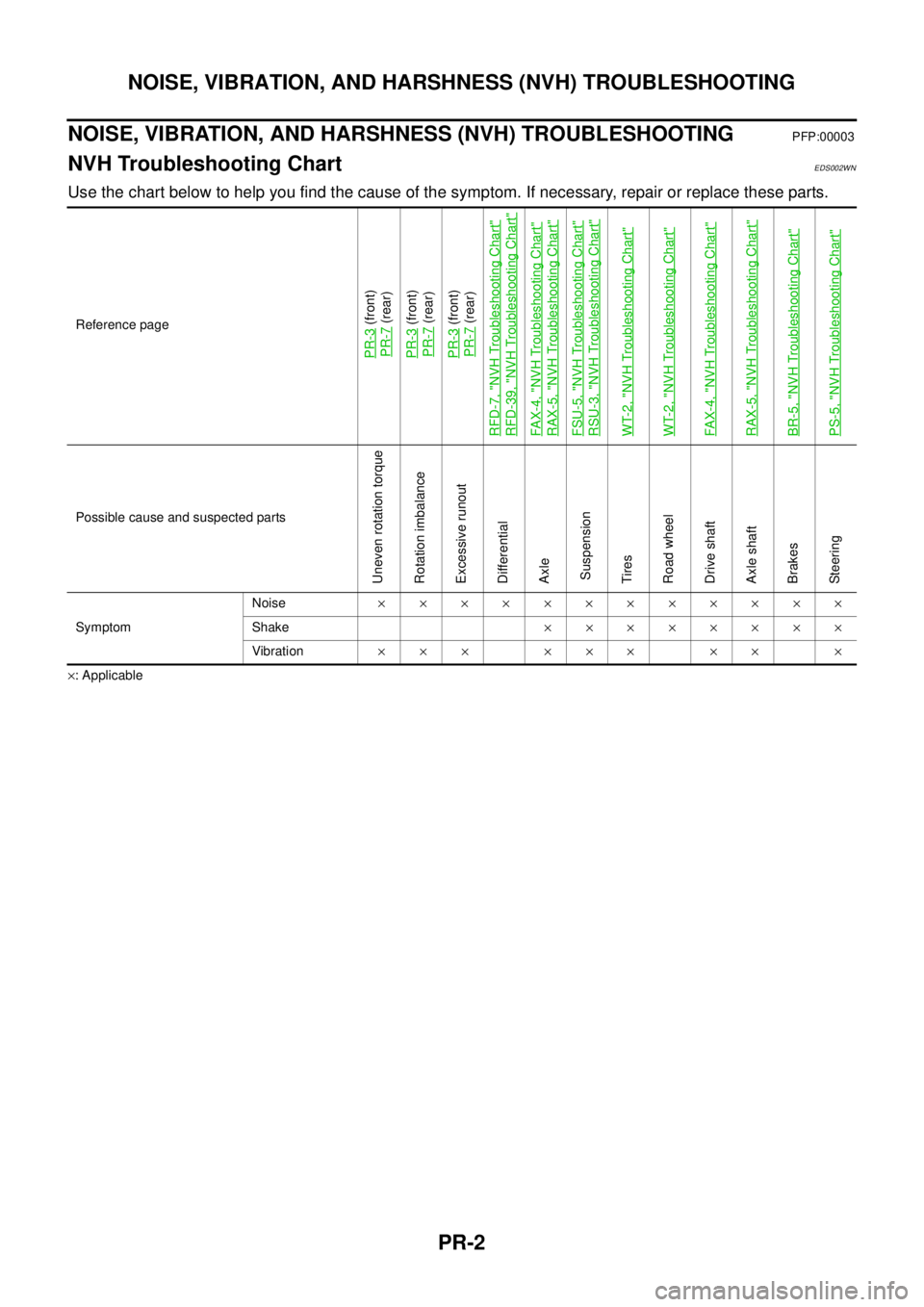

FRONT PROPELLER SHAFTPFP:37200

On-Vehicle ServiceEDS002WO

APPEARANCE AND NOISE INSPECTION

lCheck the propeller shaft tube surface for dents or cracks. If damaged, replace the propeller shaft assem-

bly.

lCheck the bearings for noise and damage. Repair or replace the bearings as necessary.

PROPELLER SHAFT VIBRATION

If a vibration is present at high speed, inspect the propeller shaft runout first.

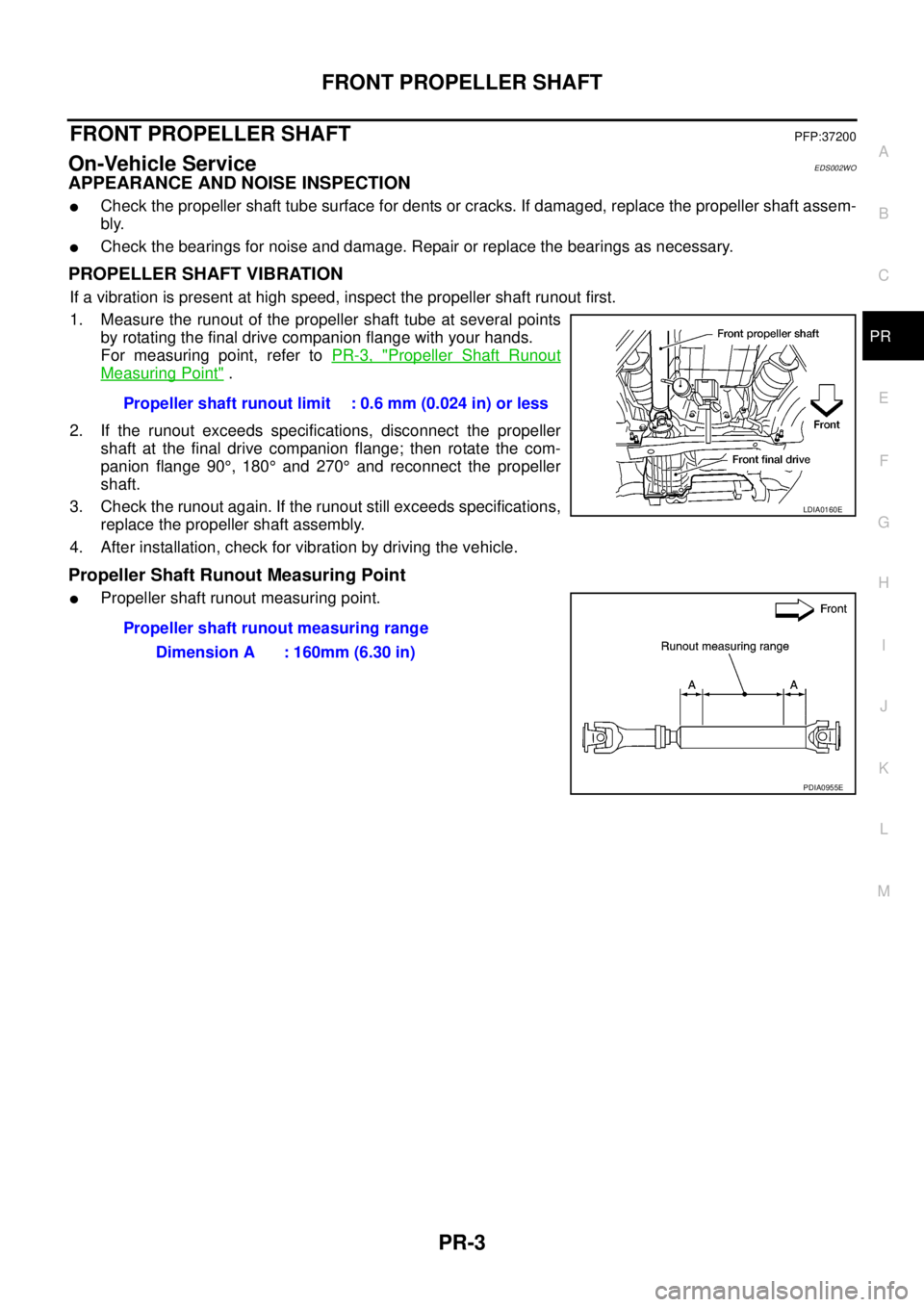

1. Measure the runout of the propeller shaft tube at several points

by rotating the final drive companion flange with your hands.

For measuring point, refer toPR-3, "

Propeller Shaft Runout

Measuring Point".

2. If the runout exceeds specifications, disconnect the propeller

shaft at the final drive companion flange; then rotate the com-

panion flange 90°,180°and 270°and reconnect the propeller

shaft.

3. Check the runout again. If the runout still exceeds specifications,

replace the propeller shaft assembly.

4. After installation, check for vibration by driving the vehicle.

Propeller Shaft Runout Measuring Point

lPropeller shaft runout measuring point.Propeller shaft runout limit : 0.6 mm (0.024 in) or less

LDIA0160E

Propeller shaft runout measuring range

Dimension A : 160mm (6.30 in)

PDIA0955E

Page 2619 of 3171

PR-4

FRONT PROPELLER SHAFT

Removal and Installation

EDS002WP

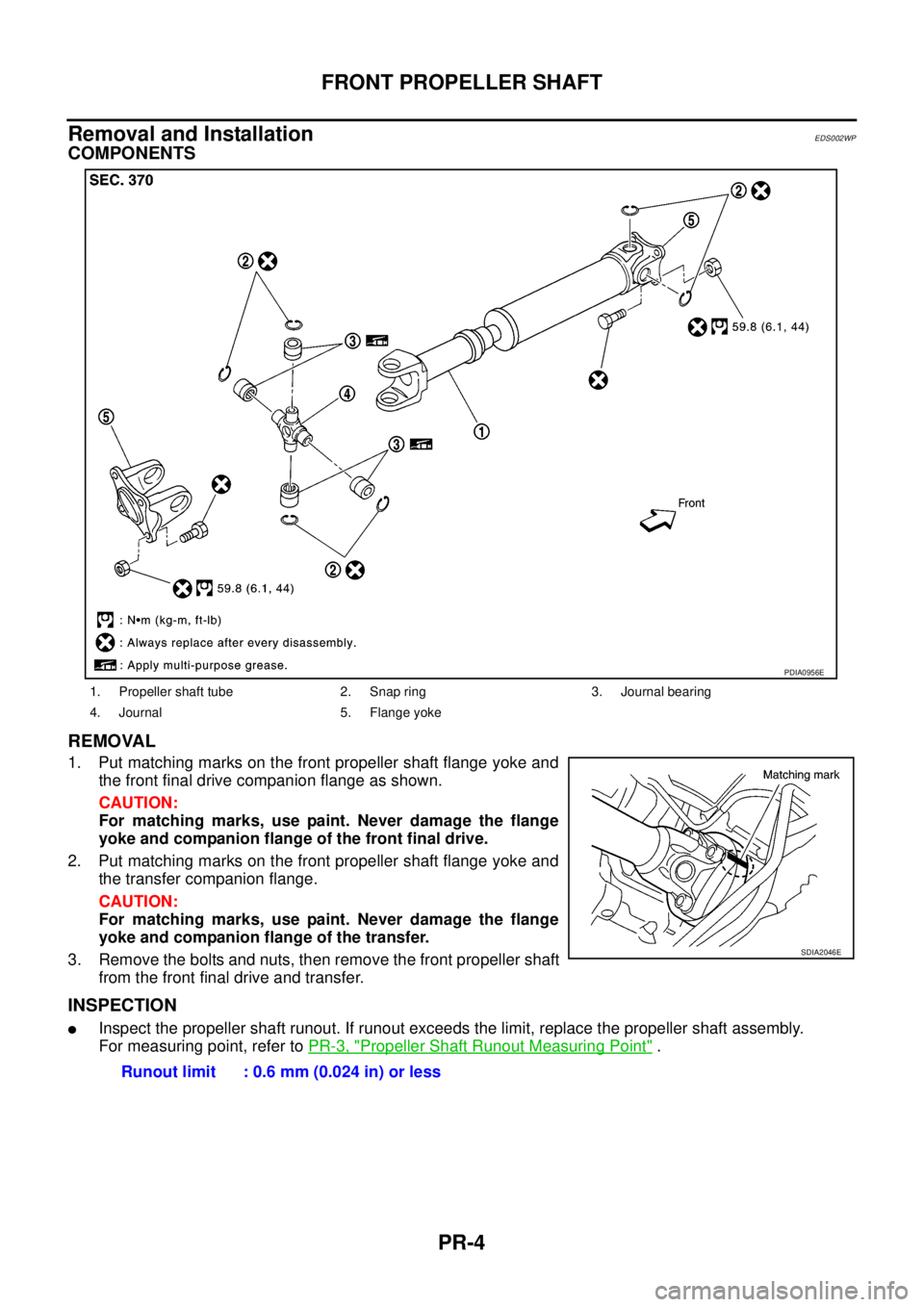

COMPONENTS

REMOVAL

1. Put matching marks on the front propeller shaft flange yoke and

the front final drive companion flange as shown.

CAUTION:

For matching marks, use paint. Never damage the flange

yoke and companion flange of the front final drive.

2. Put matching marks on the front propeller shaft flange yoke and

the transfer companion flange.

CAUTION:

For matching marks, use paint. Never damage the flange

yoke and companion flange of the transfer.

3. Remove the bolts and nuts, then remove the front propeller shaft

from the front final drive and transfer.

INSPECTION

lInspect the propeller shaft runout. If runout exceeds the limit, replace the propeller shaft assembly.

For measuring point, refer toPR-3, "

Propeller Shaft Runout Measuring Point".

1. Propeller shaft tube 2. Snap ring 3. Journal bearing

4. Journal 5. Flange yoke

PDIA0956E

SDIA2046E

Runout limit : 0.6 mm (0.024 in) or less

Page 2620 of 3171

FRONT PROPELLER SHAFT

PR-5

C

E

F

G

H

I

J

K

L

MA

B

PR

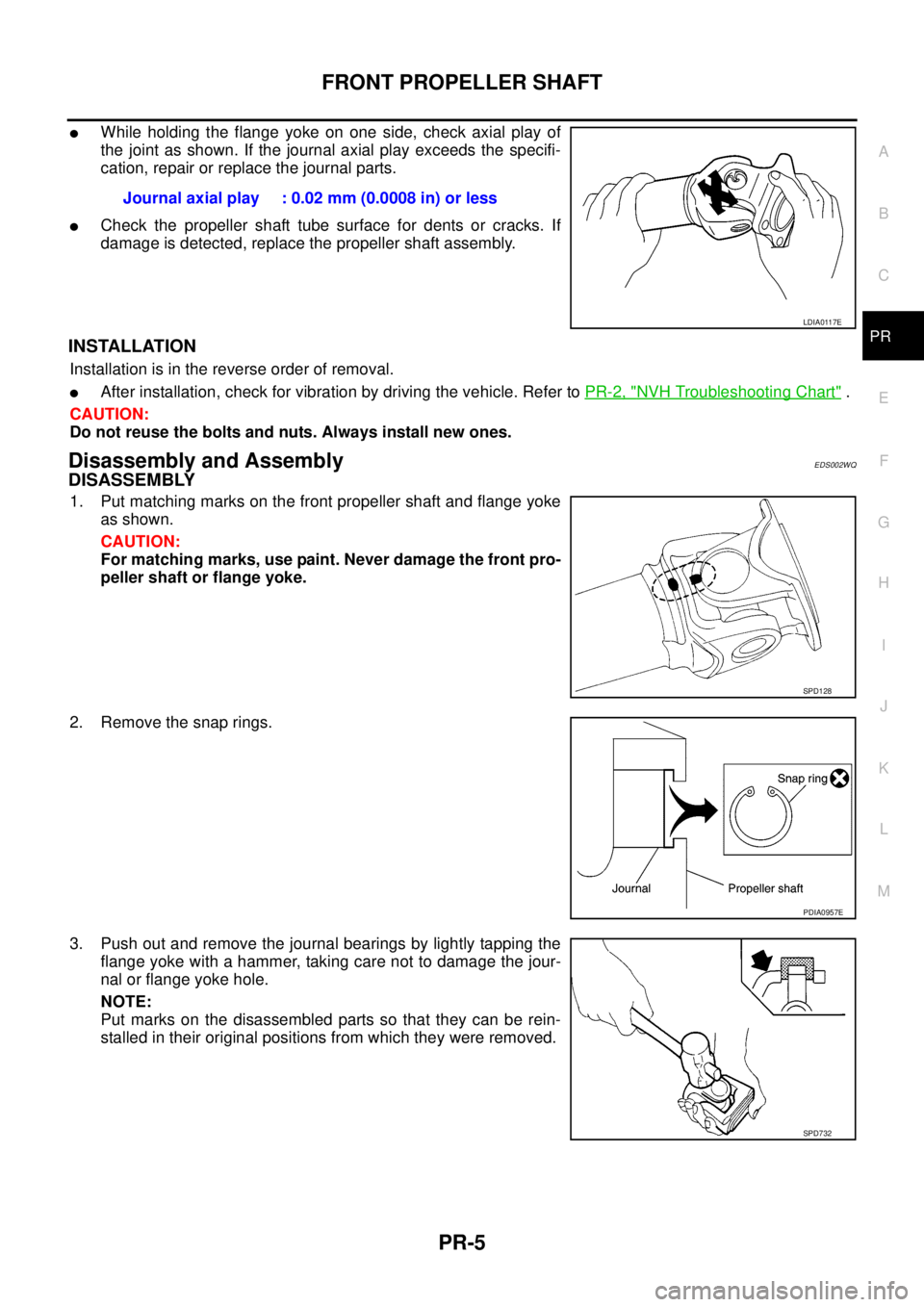

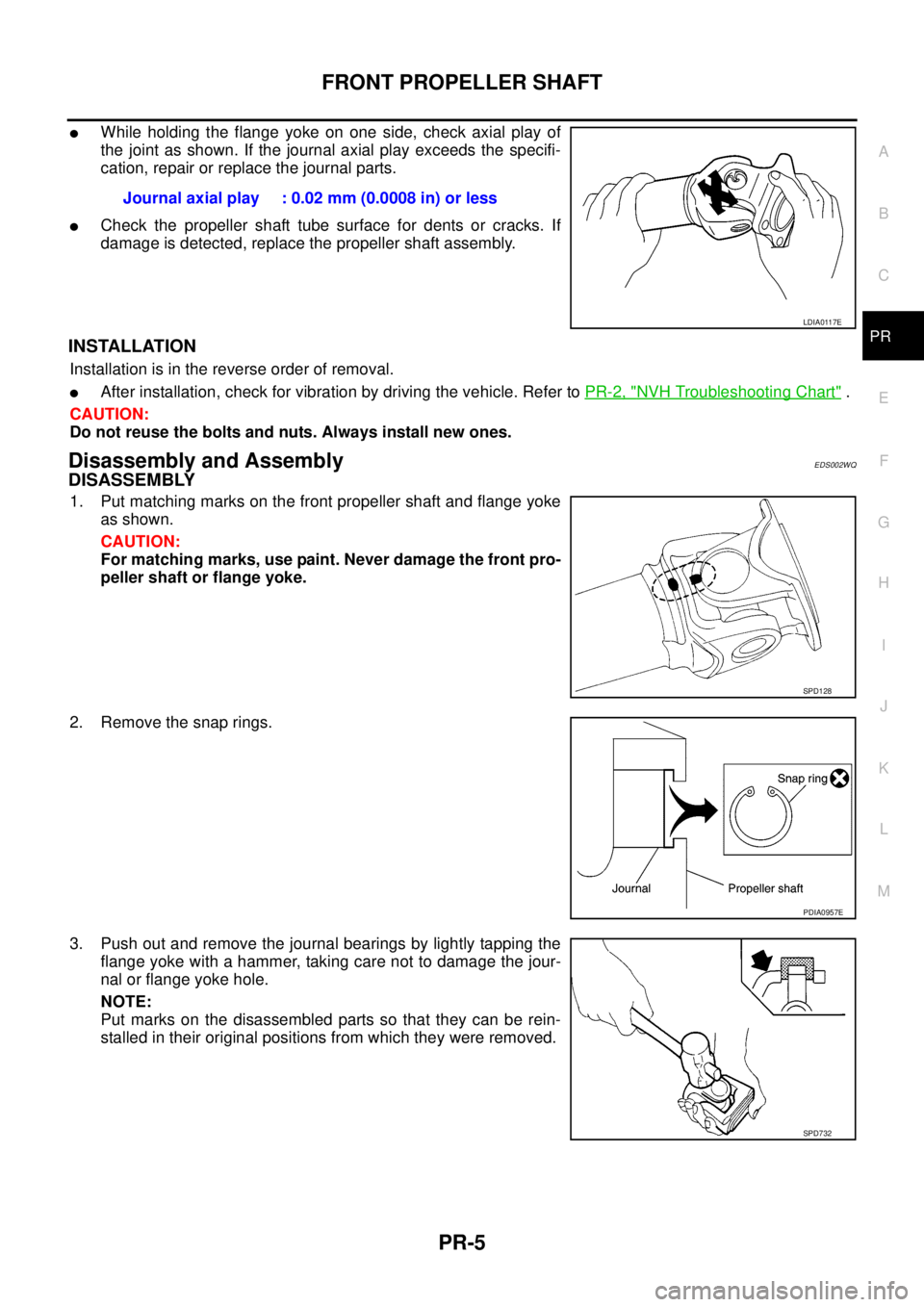

lWhile holding the flange yoke on one side, check axial play of

the joint as shown. If the journal axial play exceeds the specifi-

cation, repair or replace the journal parts.

lCheck the propeller shaft tube surface for dents or cracks. If

damage is detected, replace the propeller shaft assembly.

INSTALLATION

Installation is in the reverse order of removal.

lAfter installation, check for vibration by driving the vehicle. Refer toPR-2, "NVH Troubleshooting Chart".

CAUTION:

Do not reuse the bolts and nuts. Always install new ones.

Disassembly and AssemblyEDS002WQ

DISASSEMBLY

1. Put matching marks on the front propeller shaft and flange yoke

as shown.

CAUTION:

For matching marks, use paint. Never damage the front pro-

peller shaft or flange yoke.

2. Remove the snap rings.

3. Push out and remove the journal bearings by lightly tapping the

flange yoke with a hammer, taking care not to damage the jour-

nal or flange yoke hole.

NOTE:

Put marks on the disassembled parts so that they can be rein-

stalled in their original positions from which they were removed.Journal axial play : 0.02 mm (0.0008 in) or less

LDIA0117E

SPD128

PDIA0957E

SPD732

Trending: trunk, navigation, fuel pump, brake pads, oil filter, sun sensor, towing