NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2981 of 3171

TF-14

4WD SYSTEM

Power Transfer

EDS0031K

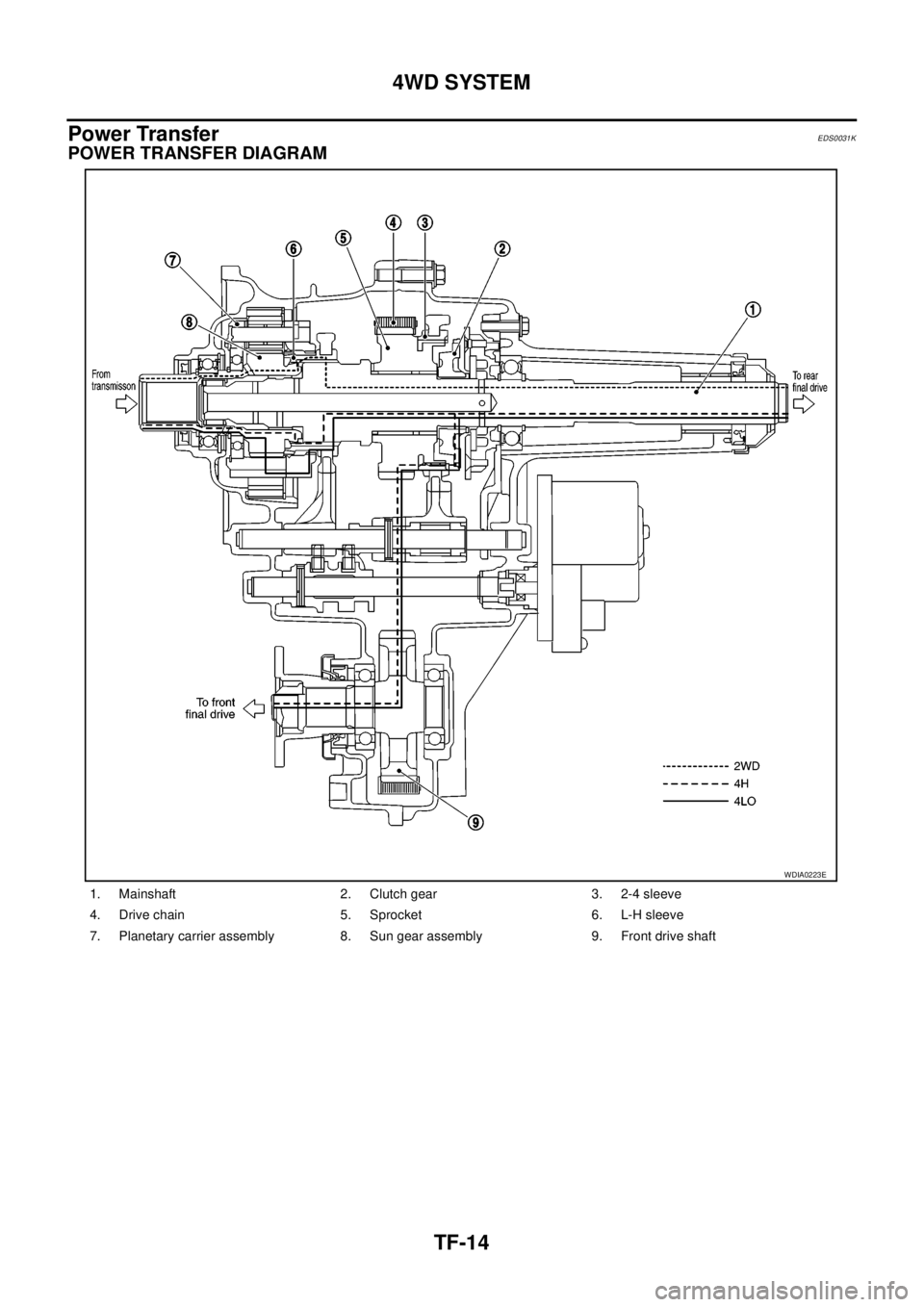

POWER TRANSFER DIAGRAM

1. Mainshaft 2. Clutch gear 3. 2-4 sleeve

4. Drive chain 5. Sprocket 6. L-H sleeve

7. Planetary carrier assembly 8. Sun gear assembly 9. Front drive shaft

WDIA0223E

Page 2982 of 3171

4WD SYSTEM

TF-15

C

E

F

G

H

I

J

K

L

MA

B

TF

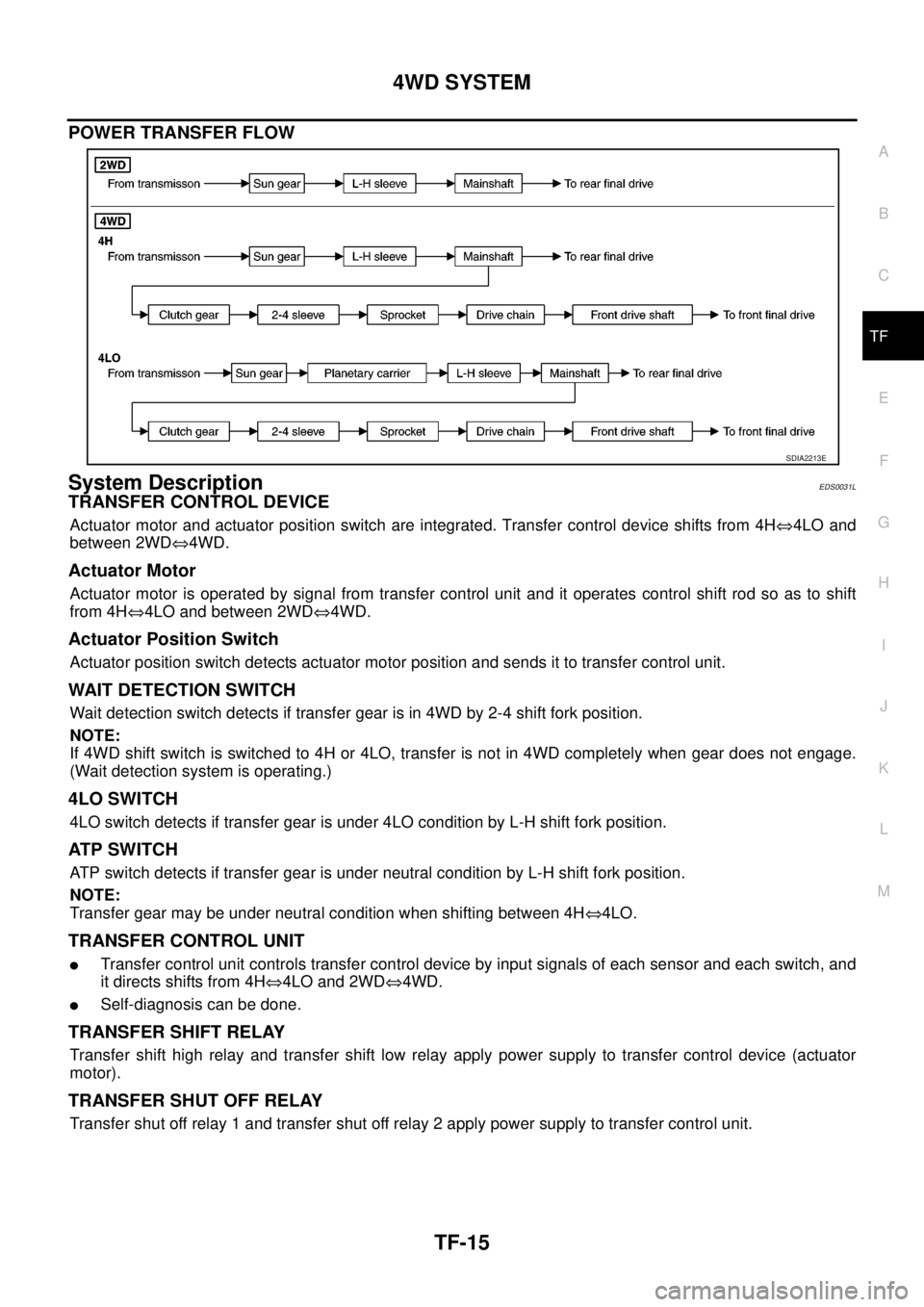

POWER TRANSFER FLOW

System DescriptionEDS0031L

TRANSFER CONTROL DEVICE

Actuator motor and actuator position switch are integrated. Transfer control device shifts from 4HÛ4LO and

between 2WDÛ4WD.

Actuator Motor

Actuator motor is operated by signal from transfer control unit and it operates control shift rod so as to shift

from 4HÛ4LO and between 2WDÛ4WD.

Actuator Position Switch

Actuator position switch detects actuator motor position and sends it to transfer control unit.

WAIT DETECTION SWITCH

Wait detection switch detects if transfer gear is in 4WD by 2-4 shift fork position.

NOTE:

If 4WD shift switch is switched to 4H or 4LO, transfer is not in 4WD completely when gear does not engage.

(Wait detection system is operating.)

4LO SWITCH

4LO switch detects if transfer gear is under 4LO condition by L-H shift fork position.

AT P S W I T C H

ATP switch detects if transfer gear is under neutral condition by L-H shift fork position.

NOTE:

Transfer gear may be under neutral condition when shifting between 4HÛ4LO.

TRANSFER CONTROL UNIT

lTransfer control unit controls transfer control device by input signals of each sensor and each switch, and

itdirectsshiftsfrom4HÛ4LO and 2WDÛ4WD.

lSelf-diagnosis can be done.

TRANSFER SHIFT RELAY

Transfer shift high relay and transfer shift low relay apply power supply to transfer control device (actuator

motor).

TRANSFER SHUT OFF RELAY

Transfer shut off relay 1 and transfer shut off relay 2 apply power supply to transfer control unit.

SDIA2213E

Page 2983 of 3171

TF-16

4WD SYSTEM

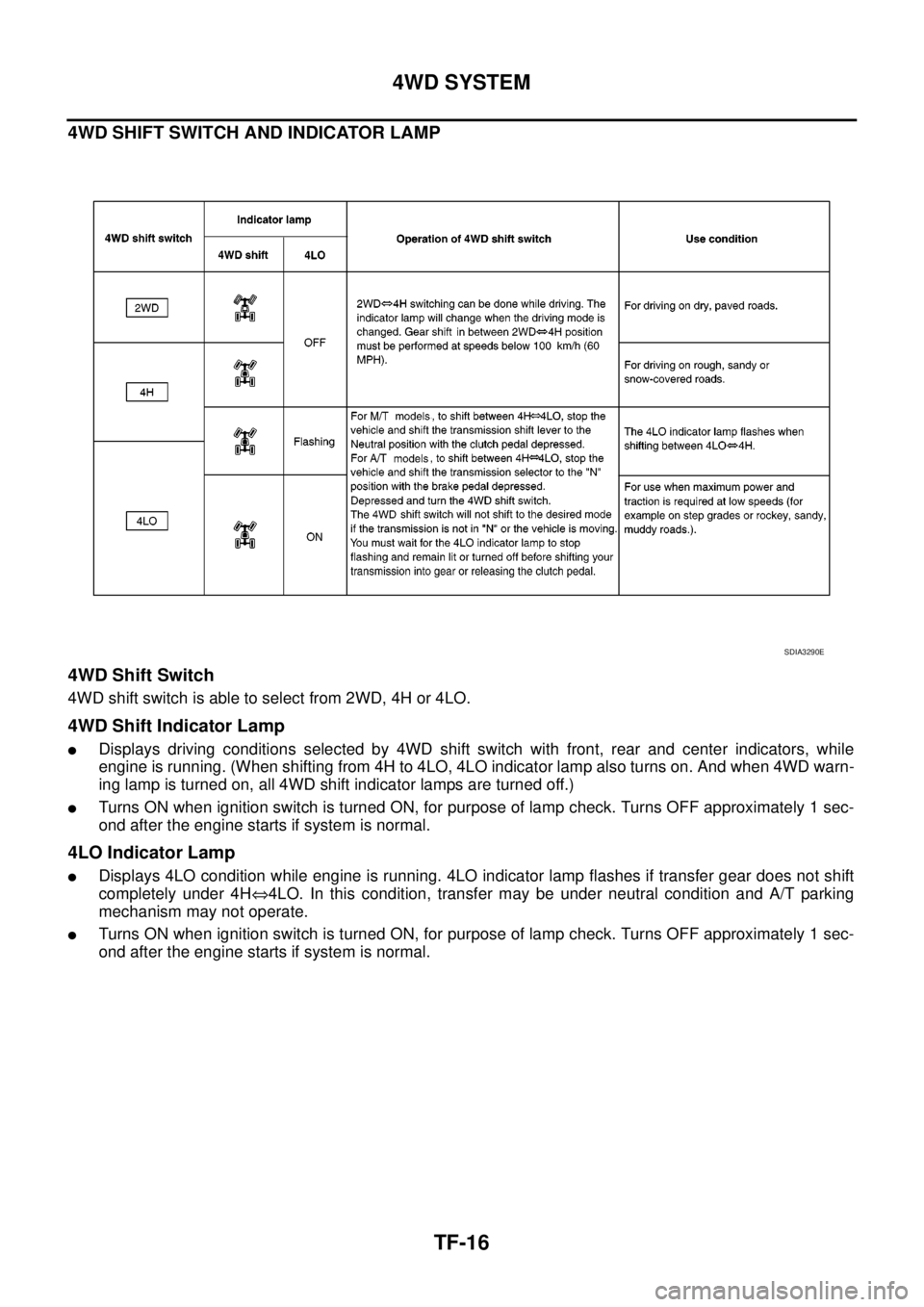

4WD SHIFT SWITCH AND INDICATOR LAMP

4WD Shift Switch

4WD shift switch is able to select from 2WD, 4H or 4LO.

4WD Shift Indicator Lamp

lDisplays driving conditions selected by 4WD shift switch with front, rear and center indicators, while

engine is running. (When shifting from 4H to 4LO, 4LO indicator lamp also turns on. And when 4WD warn-

ing lamp is turned on, all 4WD shift indicator lamps are turned off.)

lTurns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF approximately 1 sec-

ondaftertheenginestartsifsystemisnormal.

4LO Indicator Lamp

lDisplays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 4HÛ4LO. In this condition, transfer may be under neutral condition and A/T parking

mechanism may not operate.

lTurns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF approximately 1 sec-

ondaftertheenginestartsifsystemisnormal.

SDIA3290E

Page 2984 of 3171

4WD SYSTEM

TF-17

C

E

F

G

H

I

J

K

L

MA

B

TF

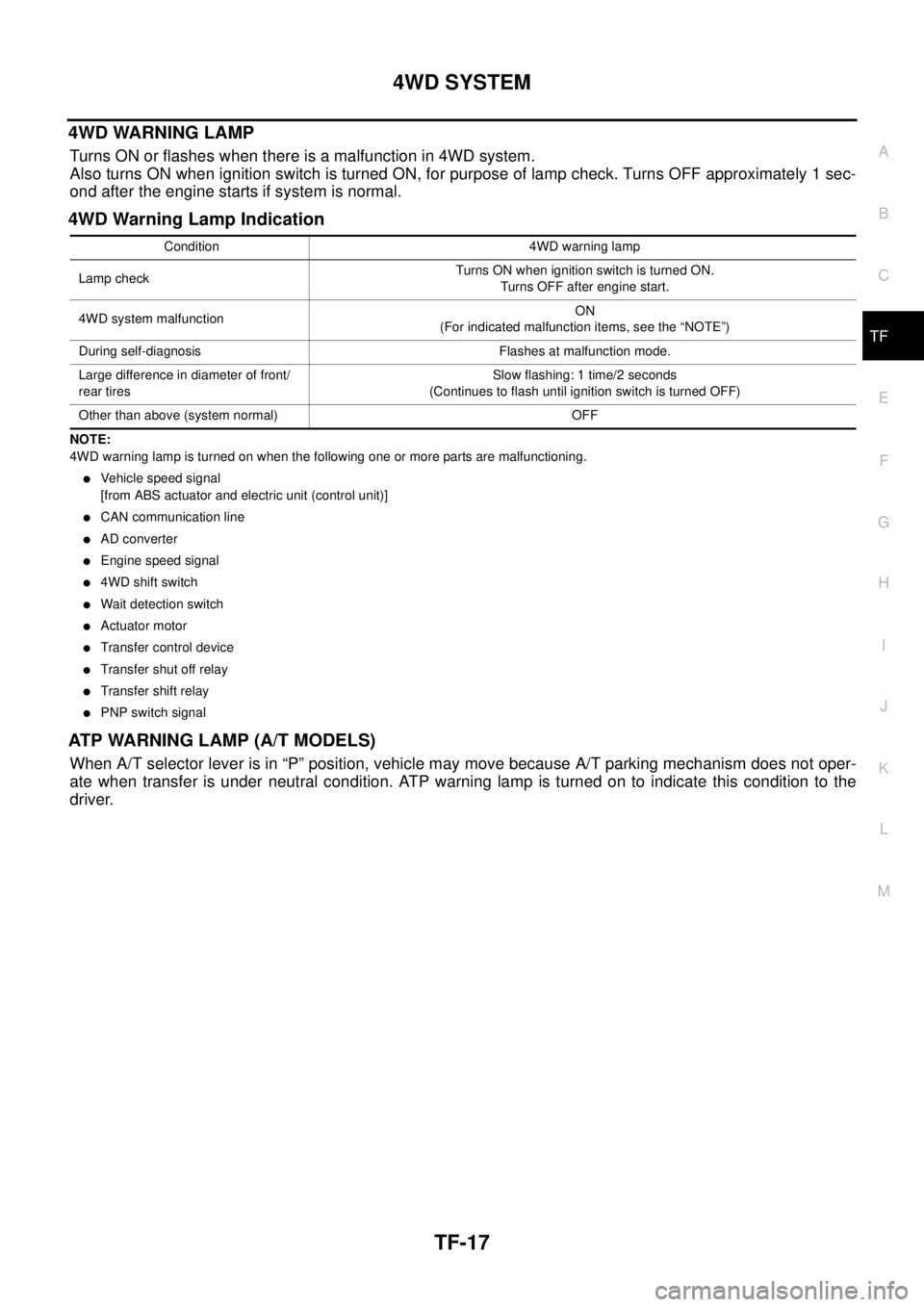

4WD WARNING LAMP

Turns ON or flashes when there is a malfunction in 4WD system.

Also turns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF approximately 1 sec-

ond after the engine starts if system is normal.

4WD Warning Lamp Indication

NOTE:

4WD warning lamp is turned on when the following one or more parts are malfunctioning.

lVehicle speed signal

[from ABS actuator and electric unit (control unit)]

lCAN communication line

lAD converter

lEngine speed signal

l4WD shift switch

lWait detection switch

lActuator motor

lTransfer control device

lTransfer shut off relay

lTransfer shift relay

lPNP switch signal

ATP WARNING LAMP (A/T MODELS)

When A/T selector lever is in “P” position, vehicle may move because A/T parking mechanism does not oper-

ate when transfer is under neutral condition. ATP warning lamp is turned on to indicate this condition to the

driver.

Condition 4WD warning lamp

Lamp checkTurns ON when ignition switch is turned ON.

Turns OFF after engine start.

4WD system malfunctionON

(For indicated malfunction items, see the “NOTE”)

During self-diagnosis Flashes at malfunction mode.

Large difference in diameter of front/

rear tiresSlow flashing: 1 time/2 seconds

(Continues to flash until ignition switch is turned OFF)

Other than above (system normal) OFF

Page 2985 of 3171

TF-18

4WD SYSTEM

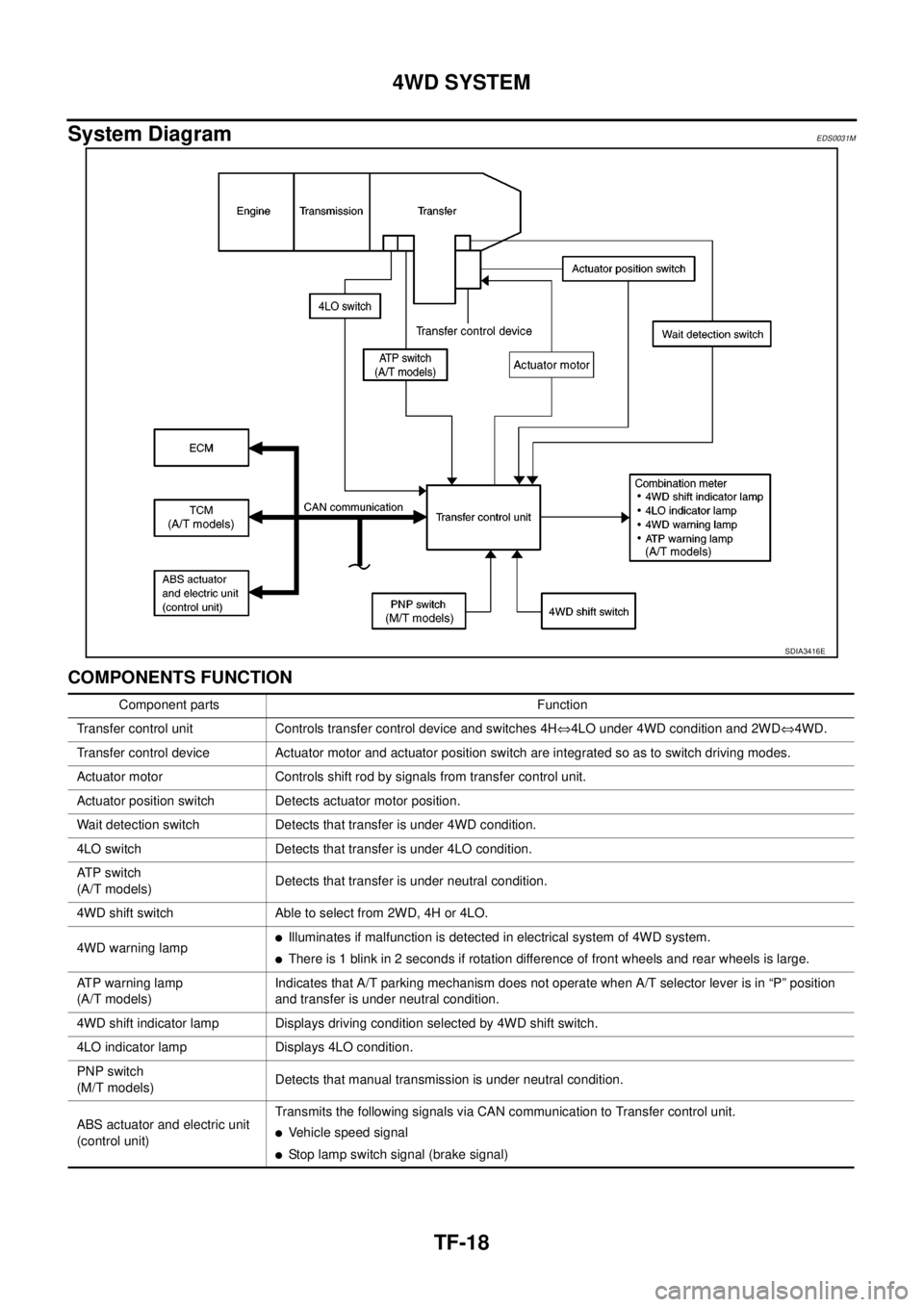

System Diagram

EDS0031M

COMPONENTS FUNCTION

SDIA3416E

Component parts Function

Transfer control unit Controls transfer control device and switches 4HÛ4LO under 4WD condition and 2WDÛ4WD.

Transfer control device Actuator motor and actuator position switch are integrated so as to switch driving modes.

Actuator motor Controls shift rod by signals from transfer control unit.

Actuator position switch Detects actuator motor position.

Wait detection switch Detects that transfer is under 4WD condition.

4LO switch Detects that transfer is under 4LO condition.

AT P s w i t c h

(A/T models)Detects that transfer is under neutral condition.

4WD shift switch Able to select from 2WD, 4H or 4LO.

4WD warning lamp

lIlluminates if malfunction is detected in electrical system of 4WD system.

lThere is 1 blink in 2 seconds if rotation difference of front wheels and rear wheels is large.

ATP warning lamp

(A/T models)Indicates that A/T parking mechanism does not operate when A/T selector lever is in “P” position

and transfer is under neutral condition.

4WD shift indicator lamp Displays driving condition selected by 4WD shift switch.

4LO indicator lamp Displays 4LO condition.

PNP switch

(M/T models)Detects that manual transmission is under neutral condition.

ABS actuator and electric unit

(control unit)Transmits the following signals via CAN communication to Transfer control unit.

lVehicle speed signal

lStop lamp switch signal (brake signal)

Page 2986 of 3171

4WD SYSTEM

TF-19

C

E

F

G

H

I

J

K

L

MA

B

TF

CAN CommunicationEDS0031N

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

For details, refer toLAN-23, "

CAN COMMUNICATION".

TCM

(A/T models)Transmits the following signal via CAN communication to Transfer control unit.lOutput shaft revolution signal

lA/T position indicator signal (PNP switch signal)

ECMTransmits engine speed signal via CAN communication to Transfer control unit.

lEngine speed signal Component parts Function

Page 2987 of 3171

TF-20

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

PFP:00004

How to Perform Trouble DiagnosisEDS0031O

BASIC CONCEPT

lTo perform trouble diagnosis, it is important to have understanding about vehicle systems (control and

mechanism).

lIt is also important to clarify customer complaints before inspec-

tion.

First of all, reproduce symptoms, and understand them fully.

Ask customer about his/her complaints carefully. In some cases,

it will be necessary to check symptoms by driving vehicle with

customer.

CAUTION:

Customers are not professional. It is dangerous to make an

easy guess like "maybe the customer means that...," or

"maybe the customer mentions this symptom".

lIt is essential to check symptoms right from the beginning in

order to repair malfunctions completely.

For intermittent malfunctions, reproduce symptoms based on

interview with customer and past examples. Do not perform

inspection on ad hoc basis. Most intermittent malfunctions are

caused by poor contacts. In this case, it will be effective to shake

suspected harness or connector by hand. When repairing with-

out any symptom diagnosis, you cannot judge if malfunctions

have actually been eliminated.

lAfter completing diagnosis, always erase diagnostic memory.

Refer toTF-51, "

ERASE SELF-DIAGNOSIS".

lFor intermittent malfunctions, move harness or harness connec-

tor by hand. Then check for poor contact or reproduced open circuit.

SEF233G

SEF234G

Page 2988 of 3171

TROUBLE DIAGNOSIS

TF-21

C

E

F

G

H

I

J

K

L

MA

B

TF

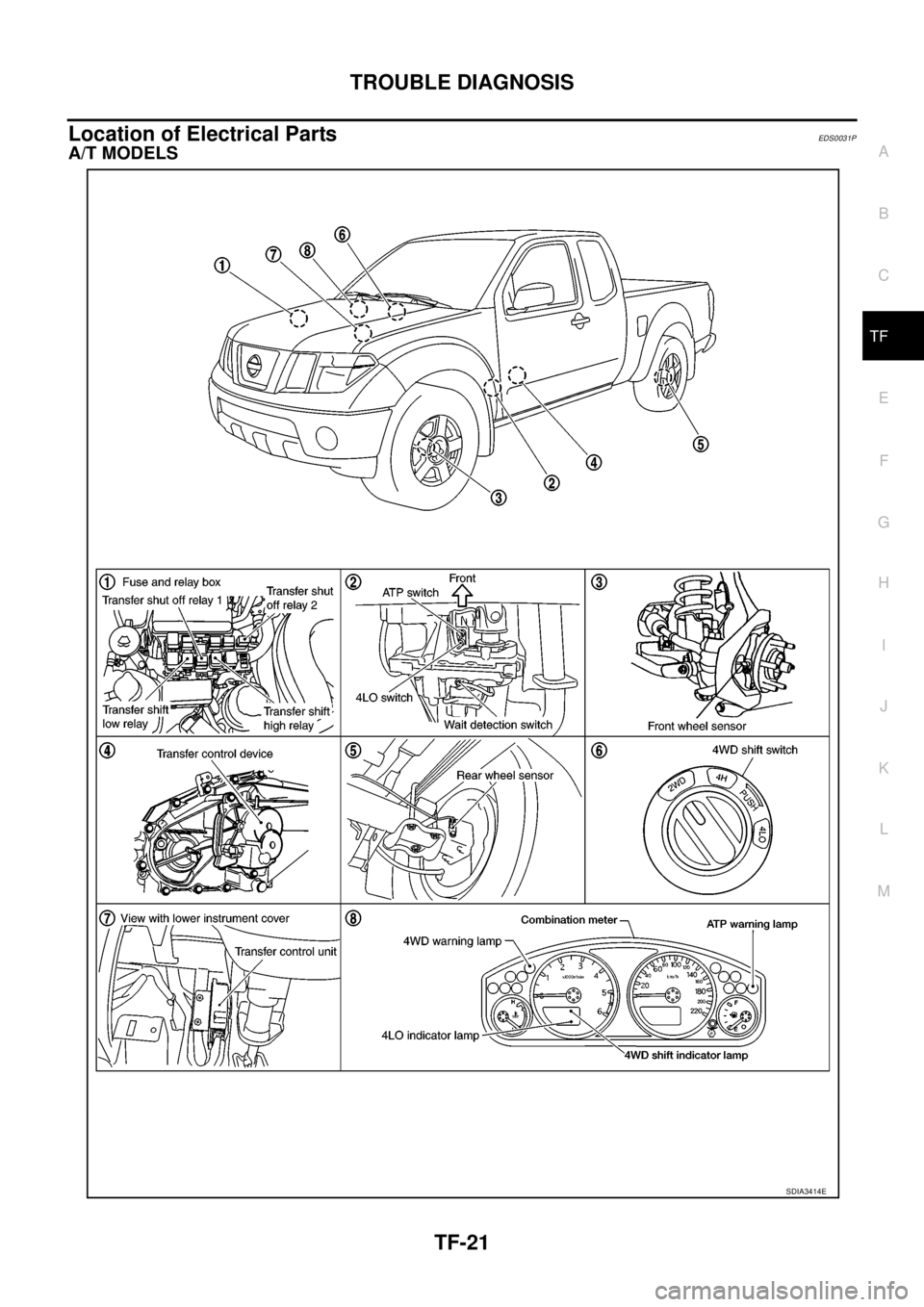

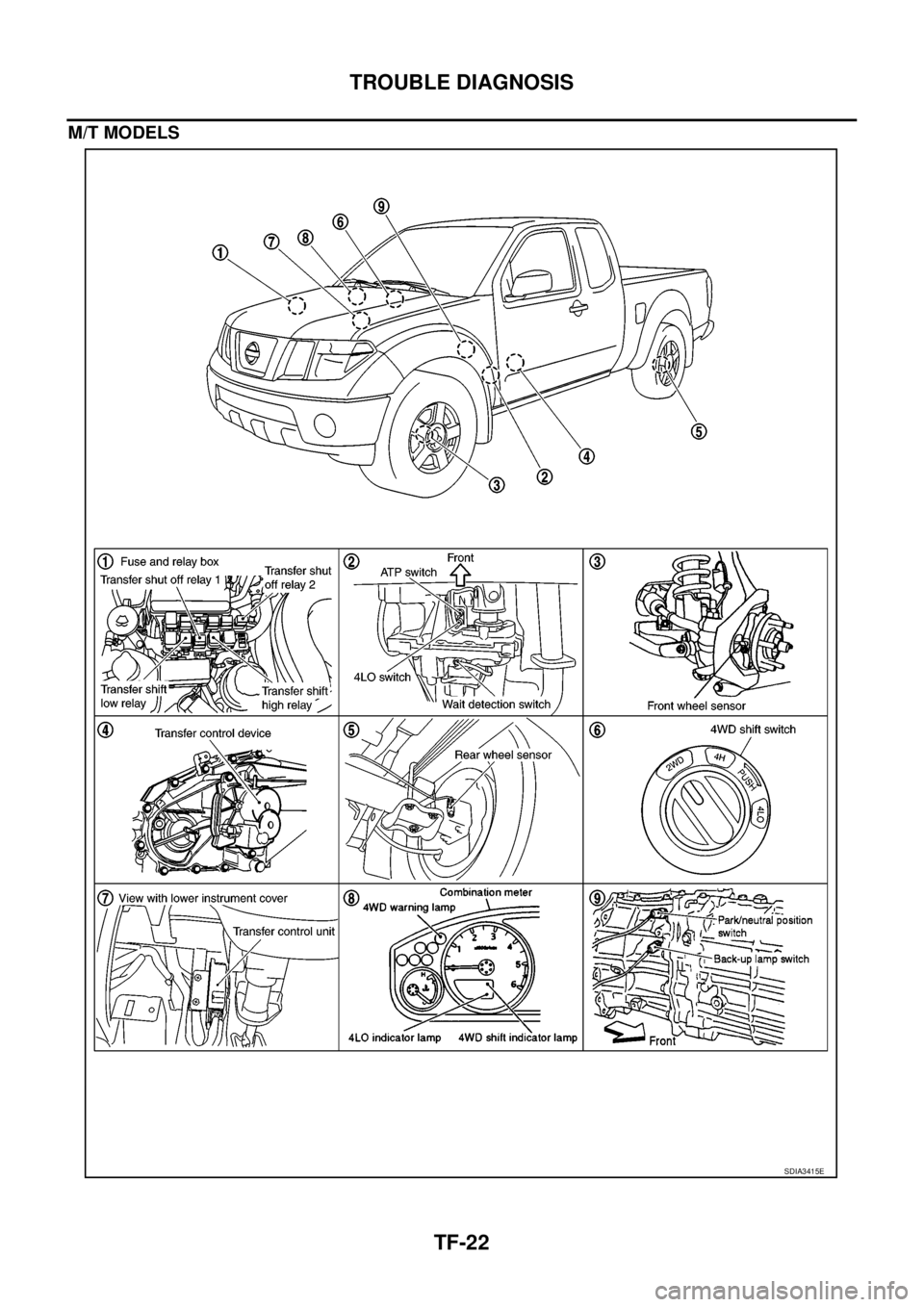

Location of Electrical PartsEDS0031P

A/T MODELS

SDIA3414E

Page 2989 of 3171

TF-22

TROUBLE DIAGNOSIS

M/T MODELS

SDIA3415E

Page 2990 of 3171

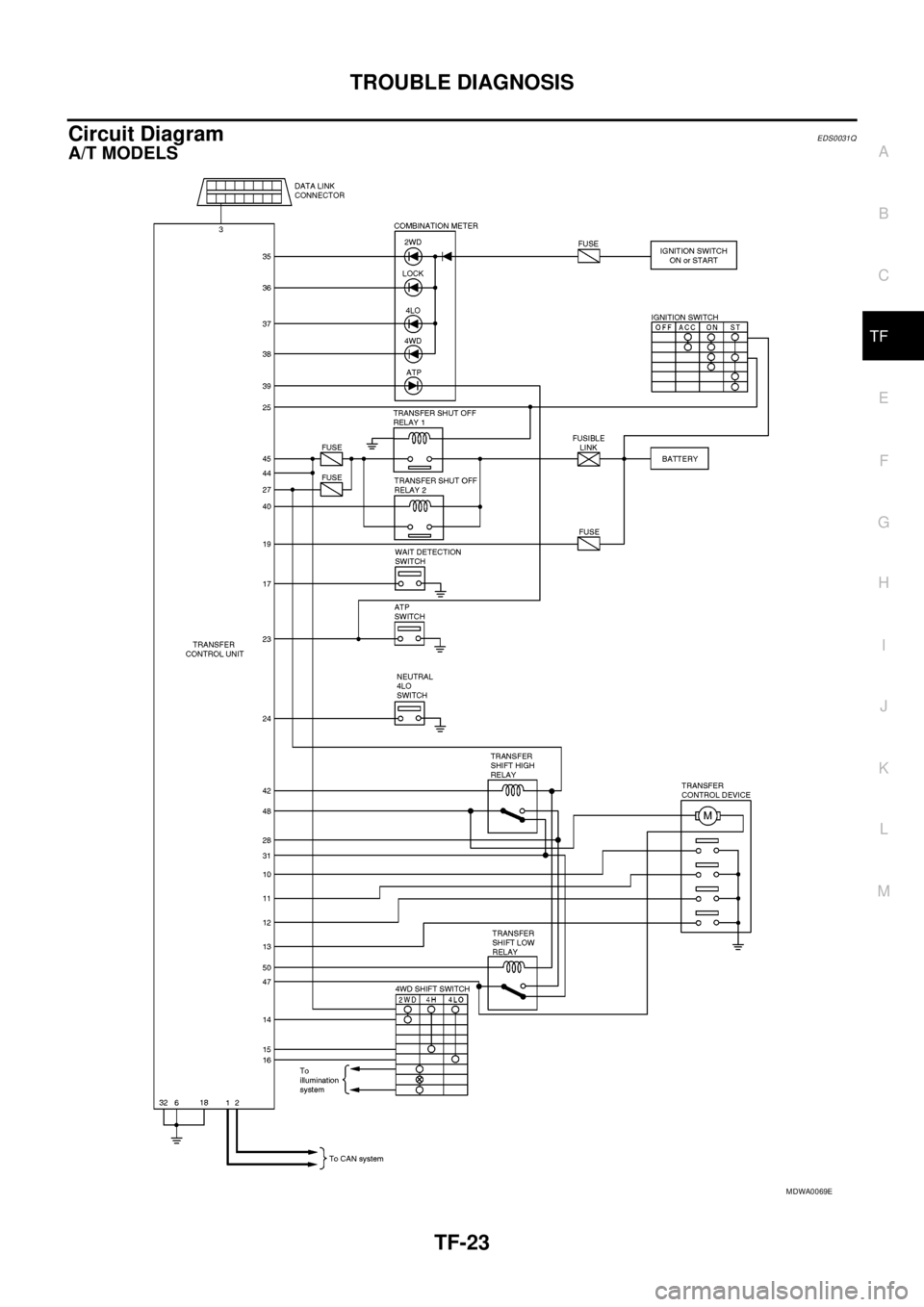

TROUBLE DIAGNOSIS

TF-23

C

E

F

G

H

I

J

K

L

MA

B

TF

Circuit DiagramEDS0031Q

A/T MODELS

MDWA0069E